1. Introduction

Current market trends, the variety of consumer demand, the short life cycle of the product, and competitive pressure have pushed companies to tackle the problem of reduction of production costs through better management of available resources. One fundamental tool is represented by the scheduling algorithms for the optimization of production [

1]. Scheduling problems are decision-making problems in which the factor of time is of fundamental importance, understood as a (scarce) resource to be allocated in an optimal way [

2]. In the context of industrial manufacturing, scheduling consists in determining the sequential allocation of jobs to the machines, which optimizes a certain objective function and respects at the same time the constraints imposed [

3]. More specifically, a scheduling problem is uniquely described by three factors: architecture of the production system, process parameters, and any constraints of the function to be optimized. The scheduling problem has been analyzed in numerous studies, which have allowed the development of different models that represent it and different methods to solve it [

4]. Several applications can be traced back to scheduling problems: the regulation of user access to a service, the assignment of operations at workstations during the transformation process of a product, the timing of activities to be carried out within a project complex, the assignment of classrooms to a set of classes, regulation of vehicle accesses at an intersection through traffic light control, the assignment of tracks to railway trains, and the use of tracks and/or gates by planes arriving or departing from an airport. Scheduling problems can be represented through appropriate models [

5,

6,

7,

8,

9,

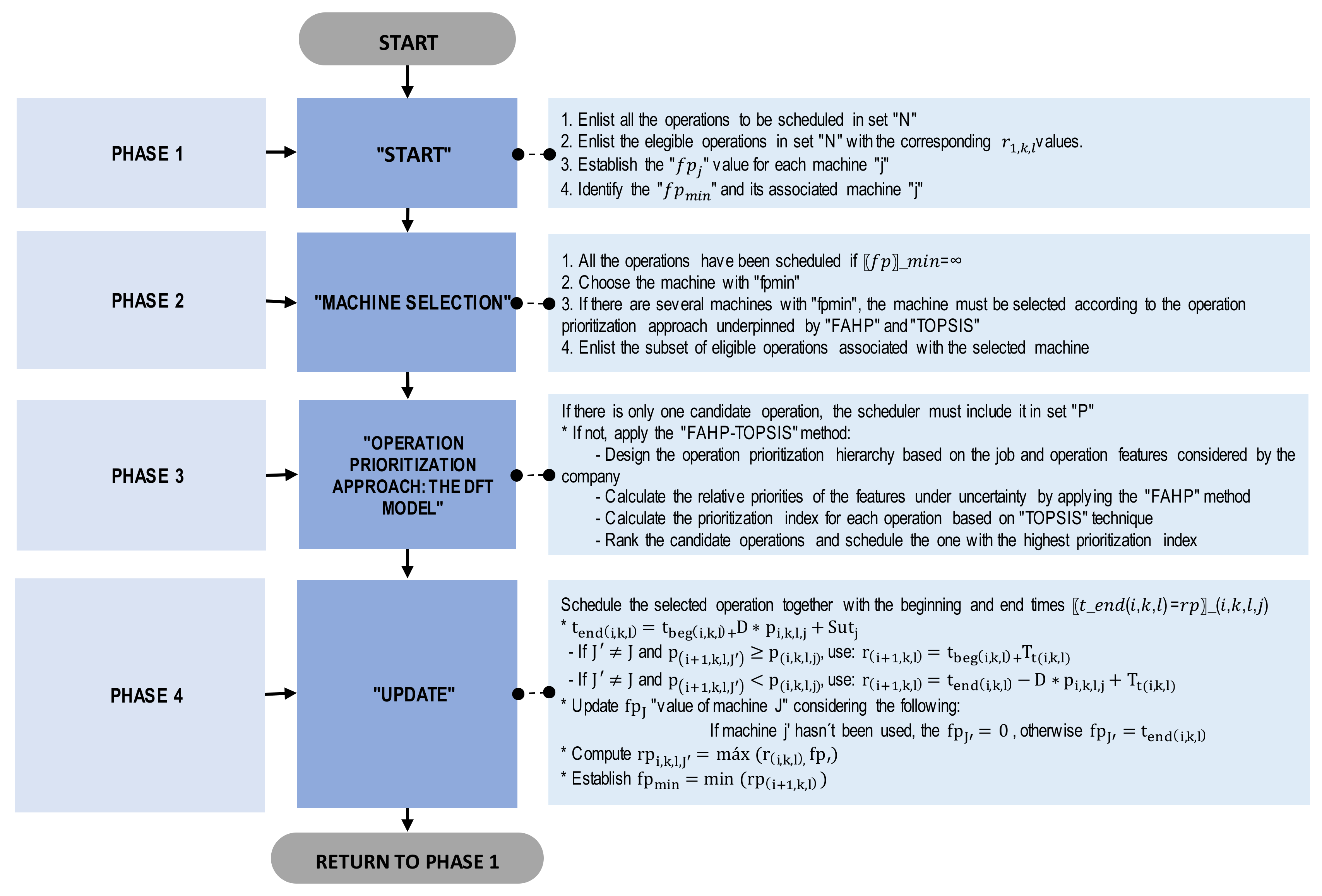

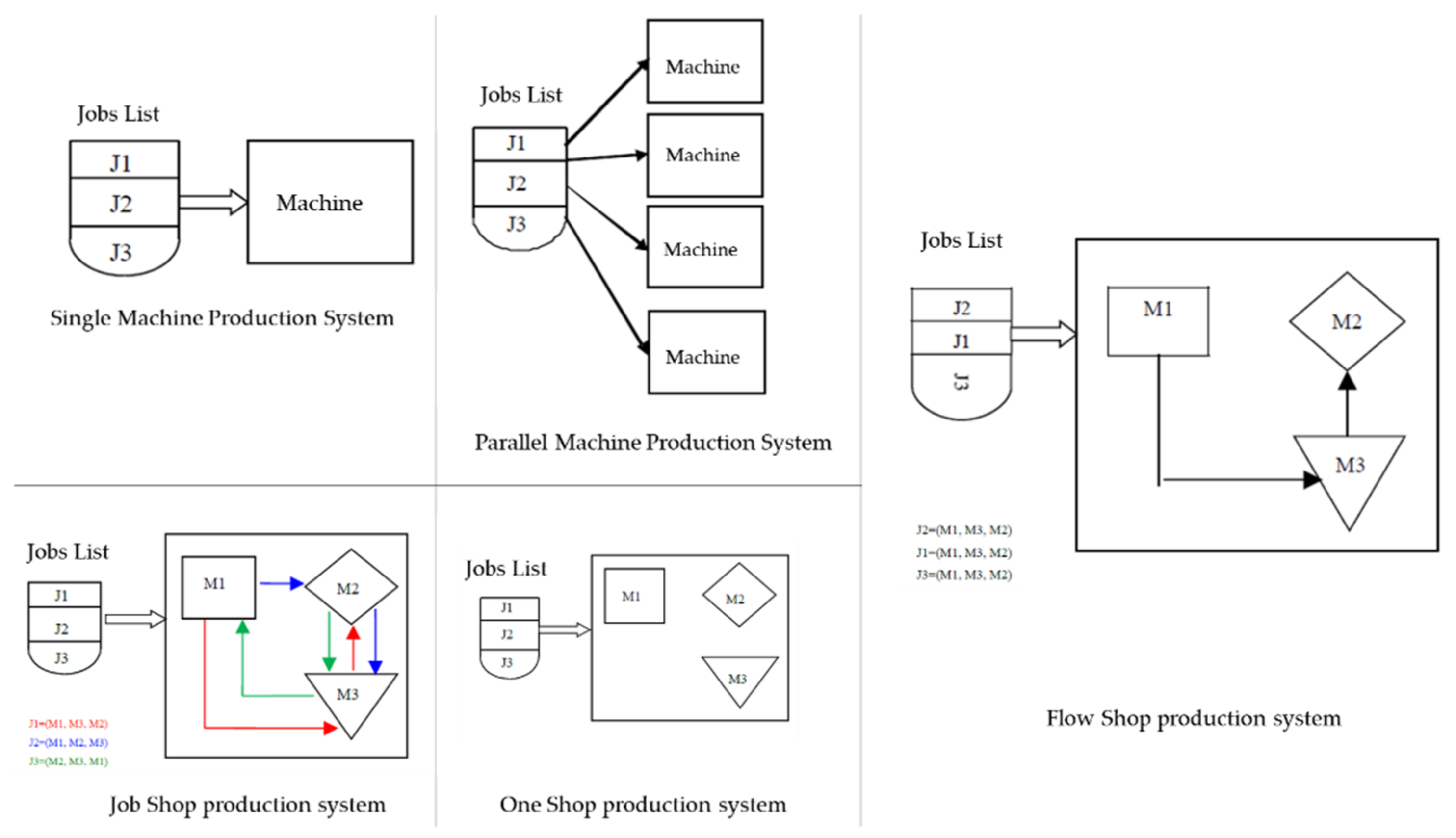

10]. The main scheduling models are (1) single machine, (2) parallel machines, (3) job shop, (4) flexible job shop, (5) flow shop, (6) flexible flow shop, and (7) open shop. The complexity of the models depends on the resources available, the type of constraints present, and the choice of objectives. In

Figure 1, the main models used for the scheduling problems are illustrated.

An extension of the classical job shop scheduling problem is the flexible job-shop system (FJSS). It is a very important topic in the field of production management and smart manufacturing [

11]. FJSS algorithms should be adapted to effectively support the response of available operational technology (OT) within the day-to-day operations of smart companies. However, classical scheduling methods are generally incapable of solving complex problems characterized by a continuous upgrading of the production mode of the manufacturing system [

12]. A key aspect to be addressed in this aim is the adoption of a multi-criteria operation selection approach, incorporating the current dynamics of smart FJSS [

13]. To face this challenge, this paper proposes a hybrid and innovative model of a dispatching algorithm based on fuzzy AHP (FAHP) and TOPSIS. In particular, FAHP was used to calculate the criteria weights under uncertainty, and TOPSIS was later applied to rank the eligible operations. A case study from the smart apparel industry was employed to validate the effectiveness of the proposed approach. In this case, a FJSS with two objectives (minimize the average lateness and maximize throughput), seven sub-processes, 13 products, and 29 orders was considered. The results evidenced that our approach outperformed the current company’s scheduling method by a median lateness of 3.86 days while prioritizing high-throughput products for earlier delivery. Our approach differs from previous work published in the literature that tended to focus solely on the classical approach. Our aim is to propose an integrated approach for the flexible job-shop scheduling problem for smart manufacturing that combines the benefits of each method.

The rest of the paper is structured as follows:

Section 2 presents a literature review on FJSS and smart manufacturing. The aim of

Section 2 is to briefly outline the trends in the topic analyzed.

Section 3 explains materials and methods. Thereafter,

Section 4 presents an illustrative example from the smart apparel industry. Results and discussion of the main findings of the research are analyzed in

Section 5. Finally,

Section 6 provides implications for research and future development.

2. Literature Review on FJSS and Smart Manufacturing

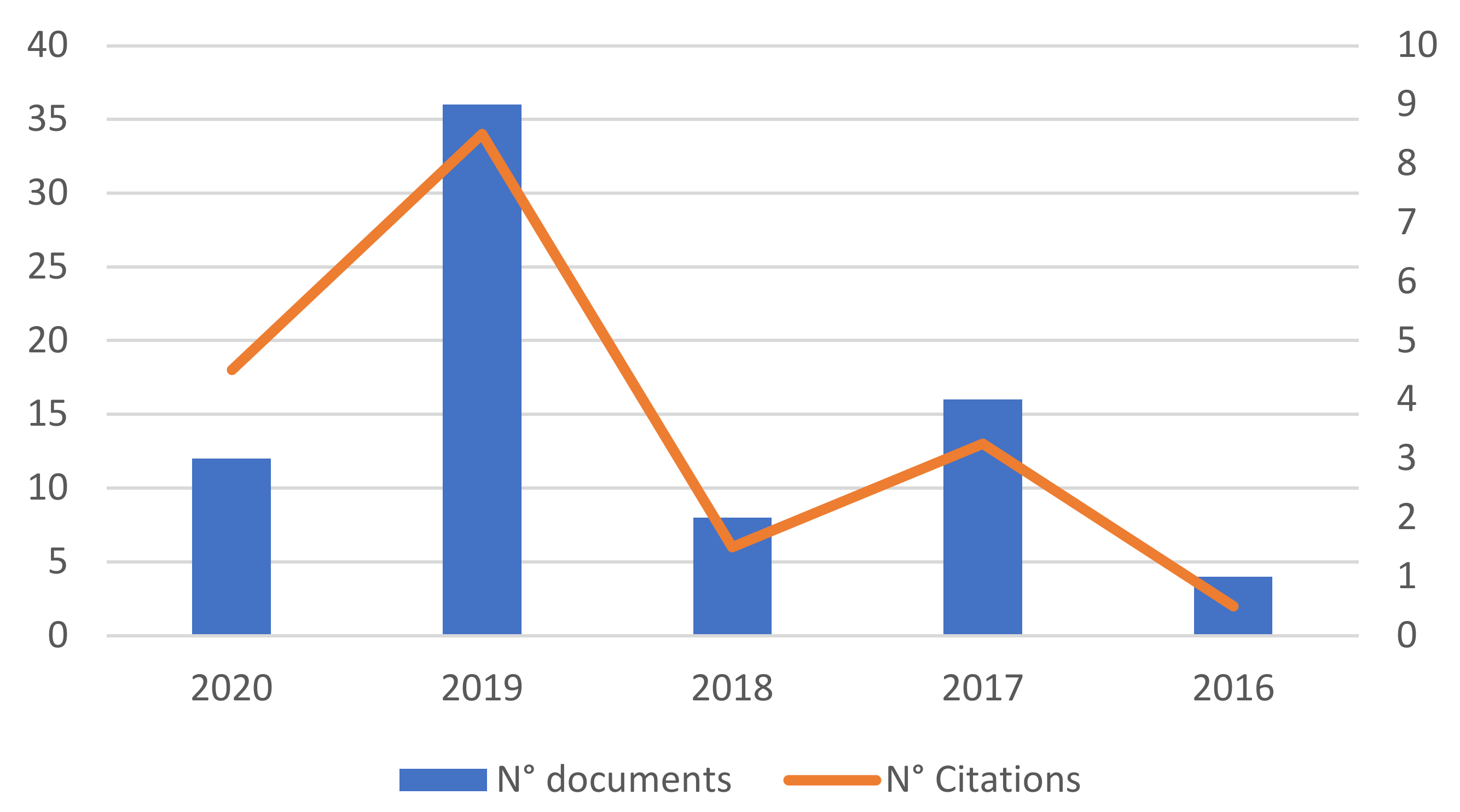

The topic of scheduling flexible job-shop systems (FJSS) is a theme analyzed in the scientific literature as early as the 1980s, as demonstrated by a survey carried out on Elsevier’s Scopus, the largest abstract and citation database of peer-reviewed literature. In order to identify publications on FJSS, an investigation using the string “Scheduling flexible job-shop systems” has been used. Only articles in which the string was found in the (1) article title, (2) abstract, or (3) keywords were analyzed (TITLE-ABS-KEY (scheduling AND flexible AND job-shop AND systems). The analysis on Scopus found 961 documents resulting from 1980 to 2021 (May 2021, period of investigation). The research highlighted a growth in the number of publications. Most of them have been published in 2020 (86 documents).

Figure 2 shows the trend of publications over the years.

The investigation on Scopus highlighted that the three most productive countries are China (287; 30%), the United States (123; 13%), and France (67; 7%). The result is not a surprise, because it only confirms that “big” countries in terms of population are obviously the most productive ones. Interestingly, other countries like Japan are also making great advances now in plant scheduling. A worthy study was proposed in 2019 by Sun et al. [

14] in which a hybrid cooperative coevolution algorithm (hCEA) for the minimization of fuzzy makespan was proposed. Furthermore, in 2015, Gen et al. [

15] developed hybrid genetic algorithms (HGA) and multiobjective HGA (Mo-HGA) to solve manufacturing scheduling problems.

We have also investigated other parameters, as explained below. In particular, the analysis of documents by type pointed out the following distribution: articles (548; 57%), conference papers (346; 36%), conference reviews (44; 5%), books and chapters (8; 1%), reviews (8; 1%), and other (Letter. Editorial. Note 5; 1%). The analysis of documents by subject area highlighted that most of the publications (92%) belong to the following area: engineering (34%); computer science (29%); mathematics (10%); decision sciences (10%); business, management, and accounting (8%); and other (9%).

The literature on the subject is certainly very extensive. Thus, we investigated a very precise aspect related to smart manufacturing. In the context of “smart manufacturing”, we have selected 19 documents in line with our research goal. We selected the documents by examining the keywords and the field of application by analyzing all the documents resulting from the investigation.

Table 1 summarizes the number of documents by year and by type.

Figure 3 depicts the time distribution of the papers and the number of citations.

According to the literature analysis, we have analyzed in detail the 19 documents as shown below. In particular, the following considerations emerged.

Recently, Li et al. [

16] developed an optimization algorithm to solve the FJSP in the context of a smart production plant. Ghaleb et al. [

17] proposed a real-time scheduling model for the FJSP. Mihoubi et al. [

18] proposed a genetic algorithm to solve the FJSP problem. In 2019, Lim et al. [

19] proposed a reusable scheduling problem decomposition framework for Industry 4.0 that facilitates agent-embedded optimization. In 2019, Vazan et al. [

20] defined a simulation model of the smart flexible manufacturing system with interchangeable workplaces. A different point of view was introduced by Ma et al. in 2019 [

21]. They introduced an anarchic manufacturing model to evaluate the relative flexibility of a representative hierarchical system against an anarchic system in a job shop scenario. A survey on the scheduling in production in the context of Industry 4.0 systems was proposed by Dolgui et al., 2019 [

22]. Heger and Voß [

23] presented a scheduling and dispatching approach for a flexible job shop incorporating travel times of autonomous guided vehicles. Some studies propose functional architecture for flexible manufacturing systems [

24,

25]. Other studies develop a heuristics model and algorithm to optimize and support scheduling flexible job-shop systems [

26,

27,

28,

29,

30]. In 2017, a heterarchical approach based on intelligent products was analyzed by Bouazza et al. [

31]. Dolgui with Ivanov and Sokolov [

32] developed a model of job shop scheduling in a customized manufacturing process. A simulation approach was proposed in some studies such as by Son et al. [

33] that simulate a flexible manufacturing system for producing aircraft. A novel approach based on Machine to Machine (M2M) was well argued by Yuan et al. [

34]. From our point of view, it was also important to analyze the keywords in common with the selected documents and the most used ones. In this regard,

Table 2 shows a classification of documents by keywords.

The analysis of the literature review pointed out that the selected documents are very heterogeneous with each other. Most of them propose traditional methods for solving scheduling problems. Some of them highlight the importance of communication technologies as the key tool that enables the interconnection among a priori isolated business processes. Among them, Jacob et al. [

35] analyzed the use of 5G and Tian et al. [

36] investigated the use of the Internet of Things, as they enabled manufacturing enterprise information systems to solve scheduling problems. Already in 2010, Zhao et al. [

37] proposed a hybrid algorithm for production scheduling integration in holonic manufacturing systems. It is also clear that in modern competitive companies, the scheduling problem is also associated with correct maintenance, as pointed out by some authors [

38,

39]. In addition, it is important to note that, although several studies on FJSS have been published, the integration of a decision tool based on MCDA is not treated to solve the flexible job shop scheduling problem. However, it is clear that in a dynamic and complex environment such as the modern smart factories, the use of multi-criteria decision-making methods could represent an opportunity from a practical and problem-solving point of view, as stated by several authors [

40,

41,

42]. In this way, more perspectives can be considered. It is a fundamental management strategy from a smart manufacturing perspective in which many factors must be taken into consideration. In fact, scheduling is a “form” of decision-making, which consists in allocating finite resources in such a way that a given goal is optimized. A scheduling problem contains the following information: (1) the decision variable and (2) the criterion by which the decision variables are evaluated (performance measure). In other words, a solution to a scheduling problem consists in identifying the optimal decision in the sense specified by the particular criterion adopted. As -making methods definitely represent a very effective tool in modern factories from a managerial point of view, our research aims to cover the literature gap.

4. Numerical Experiment for a Smart Apparel Industry

The DFT algorithm here proposed was implemented in the production system of a South American textile firm (13/13/G/Tmed) whose demand schedule is comprised of 29 jobs. The process steps and sequence of operations are outlined in

Figure 6.

Six main processes compose this system: WEAVING, DYEING, PRINTING, CUTTING, WHIPSTITCHING, and CLEANING. In particular, WEAVING has a set of three worker-machines (T1, T2, and T3), while DYEING can be performed by four machines (C1, C2, C3, and C4). On the other hand, there is only one PRINTING machine (E), supported by a manufacturing cell. In addition, two machines (CL1 and CL2) can carry out the WHIPSTITCHING sub-process. Finally, two worker cells (LP1 and LP2) are available for underpinning the CLEANING stage. In this case, the reference scheduling date is 31 January. On a different tack, as observed in

Figure 5, each product type follows a specific processing route with m machines capable of performing the operations at different production rhythms and thereby configuring the FJSS. Additionally, the regular working period is 24 h per day. The arduous task then lies in scheduling a system with a variety of product references, orders, transfer times, and machines with different production speeds and setup times while minimizing the average lateness, a characteristic scenario of an NP-hard problem [

58].

Table A1 (

Appendix A) enlists the processing times (in min) of each sub-process in each machine

j. In this table, “-“ denotes that a particular machine is not technically available for processing the reference or the sub-process is not part of the reference operation route. For instance, PRINTING is not a sub-process within the production path of SINGLE COLOR BEDCOVER and SINGLE FRINGE COLORED BEDCOVER, whereas the DYEING department does not process WHITE MULERA units. A different scenario is observed in references such as STAMPED SINGLE BEDCOVER and STAMPED DOUBLE BEDCOVER that go through all the sub-processes integrating the FJSS.

The company currently employs the earliest delivery date (EDD) approach, where the orders are processed considering the earliest due date first.

The demand schedule containing the delivery dates of these jobs is shown in

Table A2. This table also reveals the presence of tardy jobs (31.03%; n = 9 jobs), whose days of tardiness are specified in the DOT column. The order quantity, average monthly demand (MD) throughput, and % of tardiness are also outlined in this table.

Table A2 (

Appendix A) presents the customer type and quantity related to the orders integrating the demand schedule. This information is useful for the deployment of the DFT approach (operation selection policy) proposed in this paper. The significant proportion of tardy jobs, the great percentage of tardiness in some high-priority references, and the need for reducing lateness as a competitive strategy have motivated the company schedulers to implement the proposed framework. If not addressed, these inefficiencies may result in possible financial sanctions and loss of customer loyalty to the firm.

On a different note,

Table A3 (

Appendix A) depicts the setup times and available machines for each operation. In this case, the setup times include all the activities related to the machine preparation and work-in-process (WIP) mounting/disassembly. These times vary according to the operation to be performed. For example, the setup time in PRINTING includes (i) putting the fabric roll on the printing machine, (ii) installing the printing frames, and (iii) spraying the ink onto the surface of the bedcover.

Table A3 (

Appendix A) also pinpoints that not all the machines are available for processing a particular product reference. For instance, T1 and T2 can be used for weaving the SINGLE COLORED BEDCOVER fabric, which is not possible in the SINGLE FRINGE COLORED BEDCOVER due to technical restrictions.

Before implementing the proposed method, it was necessary to create the MCDM model supporting the operation prioritization phase. In reply, seven job criteria or features (F1: job quantity; F2: customer type; F3: throughput; F4: monthly demand; F5: number of tardy jobs per product; F6: tardiness; and F7: number of remaining process steps) were identified.

This set of criteria (

Figure 7) was pointed out considering the pertinent scientific literature and the experts’ opinion (5 production managers, 2 sales staff, the general manager, and the administrative director of the company). The experts have wide experience in production and demand management (>20 years); in addition, they have been related to the textile sector for more than 15 years and hold a professional degree in Business Administration/Industrial Engineering fields. The design of the hierarchy was led by two coauthors of this paper (MO and NJ) who have significant expertise and background in MCDM methods.

The next step was to elicit the relative priorities of each job criterion in the global decision of selecting the highest priority operation. FAHP was implemented to deal with this task considering its advantage of calculating the importance of each decision element under uncertainty. The ambiguity was incorporated in this application to obtain more realistic results given the nature of human thought and reasoning; in this case, represented by paired judgments or comparisons. In particular, the experts used the five-point scale depicted in

Table A4 (

Appendix A) to establish how important criterion

i is with respect to criterion

j when choosing the highest priority operation in FJSP. The comparisons were collected through a survey designed in a Microsoft Excel spreadsheet. The matrixes of fuzzy judgments

were derived for each expert using Equation (1). After this, the matrixes were aggregated by employing Equations (2) and (3). The resulting matrix

is presented in

Table A5 (

Appendix A). Following this, the geometric means of the fuzzy comparisons (

) were calculated for each decision element (job criterion or feature) by implementing Equation (4) (

Table A6).

Table A6 (

Appendix A) also presents the fuzzy relative priorities of criteria (

), which were achieved by using Equation (5). The fuzzy weights were then converted into crisp values using the center of area method (Equation (6)) (

Table A6). These weights were normalized via applying Equation (7). The results revealed that tardiness (F6) was found to be the most important feature (GW = 0.414) when selecting the highest priority operation. This is supported by the fact that clients are more aware of being supplied in a timely manner, as previously agreed. Therefore, non-compliance with this critical factor of satisfaction may represent a potential loss of loyalty and future incomes. In fact, various competitors can take advantage of this weakness and subsequently increase their market share. This is also greatly related to the second aspect of importance in this application (number of tardy jobs per product—F5; GW= 0.203), which aims to reduce the dissatisfaction proportion of products with high expectations and background in the market. Another aspect of relevance is the throughput—F3 (GW = 0.200) of the references offered by the company. The throughput is defined as the amount of money earned by the company per time unit in the bottleneck resource; in other words, the speed at which the FJSS generates money for the firm [

32,

33]. In this respect, the company is interested in prioritizing those products with high throughput, which would ensure better utilization of their resources. The rest of the criteria (monthly demand, number of remaining steps, and customer type) were not found to be highly significant (GW < 0.10) on the operation selection model. On the other hand, as the CR (0.09082) was found to be less than 0.10, the matrix is concluded to be consistent, and the resulting weights are considered reliable for implementation in the practical scenario. This outcome also supports the use of a shorter version of Saaty’s scale as well as the importance of deeply understanding the hierarchy before making the comparisons. These weights (W) were later incorporated into the initial matrix

X (Equation (8)) of TOPSIS application, as evidenced in

Table A7 (

Appendix A). This table enlists all the eligible operations in iteration 1 in conjunction with their criteria values to show an example of this procedure. In addition, the ideal (

) and anti-ideal (

) scenarios are presented in this table according to Equations (12) and (13), correspondingly. The norm of each column was then calculated via implementing Equation (10) (

Table A7). Following this, the normalized decision matrix R was achieved by using Equation (9) (

Table A8 in

Appendix A). Afterward, the weighted normalized decision matrix

V was computed by implementing Equation (11) (

Table A9, in

Appendix A). The next step was to derive the Euclidean distance of each criterion to the ideal (

) (Equation (14)) and anti-ideal (

) (Equation (15)) scenarios in each eligible operation, as observed in

Table A10 and

Table A11 (

Appendix A), respectively.

Finally, the closeness coefficient or “priority index” of each eligible operation was computed via employing Equation (16) (

Table A12 in

Appendix A). In this iteration, the operation (1, 1, 9) was found to have the highest priority and had to be then chosen as the first operation to be scheduled. It is important to note that the first 6 ranked operations—

CCi* > 0.5 (1,1,8; 1,1,10; 1,1,3; 1,2,8; 1,2,2; 1,1,2)—correspond to orders with the highest tardiness at the beginning of the scheduling process. This is explained by the fact that the two most relevant job features are associated with tardiness. On a different tack, the resulting schedule using the proposed DFT algorithm is shown in

Table A13 (

Appendix A). When contrasting the methods, we found that DFT (Test 1: −2.03 days) provides lower average lateness compared to EDD (Test 1: −0.41 days). This represents a reduction of 395.12%, which would increase the competitiveness of the smart textile company in both national and international markets. A more detailed analysis of iteration 1 is depicted in

Figure 6, where we can observe that the overall DFT performance is mainly related to the orders (1,6), (3,2), (2,6), (2,1), (2,3), (1,1), and (1,7).

6. Conclusions

Scheduling flexible job-shop systems is a complex challenge in the context of smart manufacturing due to the dynamic and changing nature of the productive environment often characterized by a wide product portfolio, different production paths, technical restrictions, the availability of distinct technology types for the same operation, and the constant need for high customer satisfaction. In this regard, the use of integrated approaches to select operations considering different multi-criteria prioritization rules, especially in uncertain environments, can support decision-makers in the continuous improvement of the production scheduling process in FJS systems, which also contributes to bridging the existing knowledge gap referring to these applications in the smart factory industry.

In particular, this study proposed a new framework based on the integration between the dispatching algorithm and a hybrid MCDM model composed of fuzzy AHP and TOPSIS methods to reduce the average lateness while simultaneously considering different job features of common interest for the stakeholders. The proposed DFT approach was deployed via an innovative four-phase methodology, allowing the companies to underpin the scheduling process, consider the advantages of the dispatching algorithm for addressing the FJSP and the strengths of the fuzzy multi-criteria approach to prioritize eligible operations under conditions of uncertainty, and demand changes and high product differentiation. For the development of this approach, seven criteria from market, financial, and technical domains were regarded for prioritizing the operations. Specifically, the case study here presented revealed that DFT outperformed the company’s method (EDD) by an average of 3.86 days (p-value = 0.005), while prioritizing high-throughput products for earlier delivery. The managerial and research-level implications of these outcomes extend previous studies incorporating the use of MCDM as techniques supporting the implementation of a decision support system (DSS) that facilitates the FJS scheduling operation in smart manufacturing. Future studies can consider the application of the DFT model in other FJS environments and other smart manufacturing sectors. On the other hand, maintenance restrictions and transfer batches can be incorporated to increase the robustness and applicability in the real manufacturing scenario. Additionally, there are opportunities to expand the research field upon comparing the DFT model proposed with other FJS algorithms including recent MCDM techniques like complex proportional assessment (COPRAS), best–worst method (BWM), and intuitionistic fuzzy AHP (IF-AHP) so that improvements on average lateness and other key performance measures can be achieved.