Modeling and Analysis of a Generic Internal Cargo Airdrop System for a Tandem Helicopter

Abstract

1. Introduction

2. Internal Cargo Airdrop System

2.1. Linear Dynamics Descriptions

2.2. Rotational Dynamics Descriptions

2.3. Cargo Kinematics Descriptions

2.4. Forces and Moments Acting on the Helicopter

- In the first type of the flight operation, the cargo is stationary relative to the helicopter. Thus, we can let in this circumstance. The gravity of the ith discrete section of the cargo acting on the helicopter in the helicopter body axis system () can be written as follows:

- In the second type of the flight operation, the cargo is moving backward and airdropping. Thus, the forces of the ith discrete section of the cargo acting on the helicopter in the helicopter body axis system () can be written as follows:

3. Flight Dynamics Model

3.1. Basic Model Descriptions

3.2. Trim Algorithm

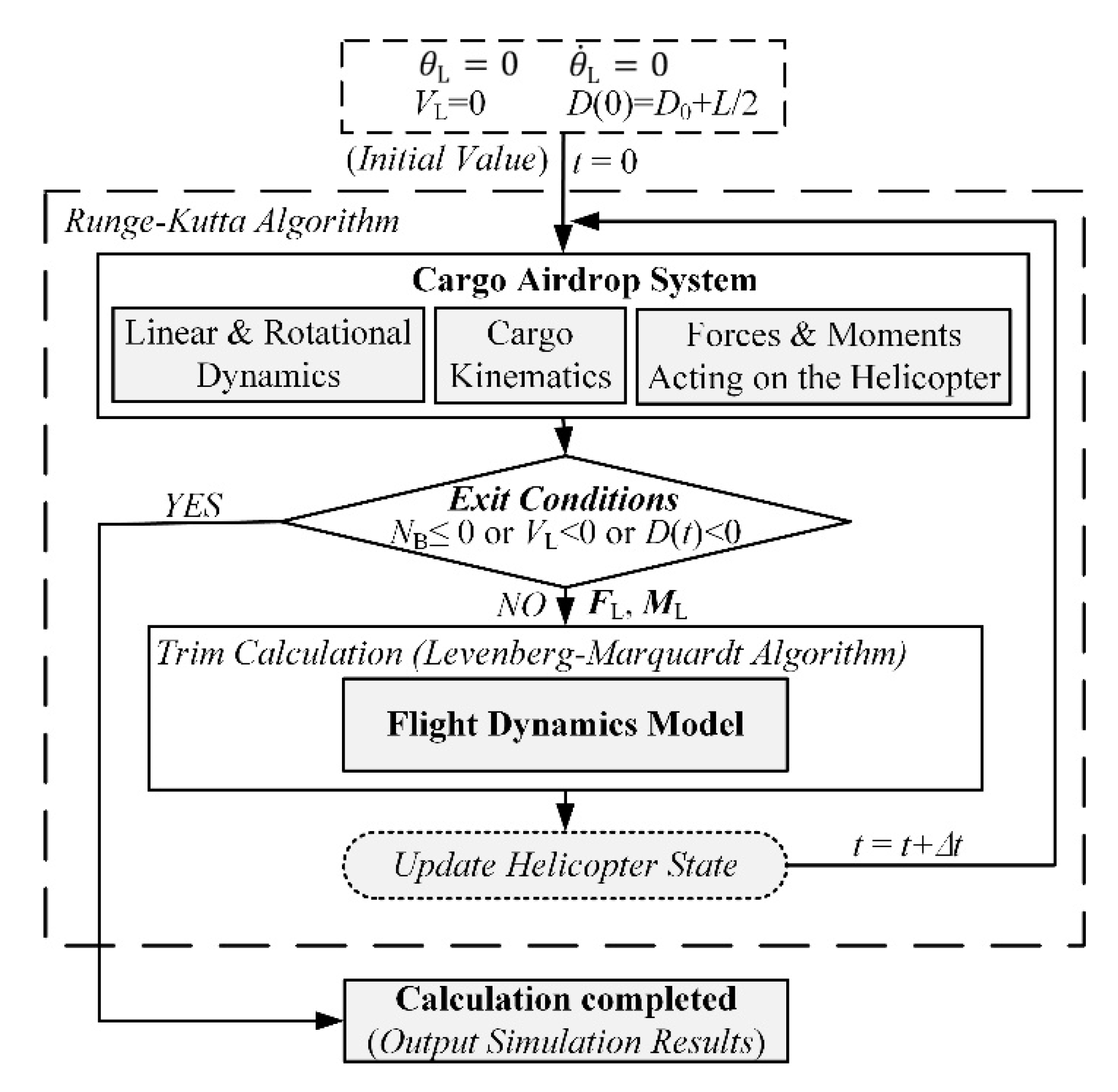

3.3. Simulation Method

4. Trim Analysis

4.1. Case of Helicopter Flight Operation Loading an Internal Cargo

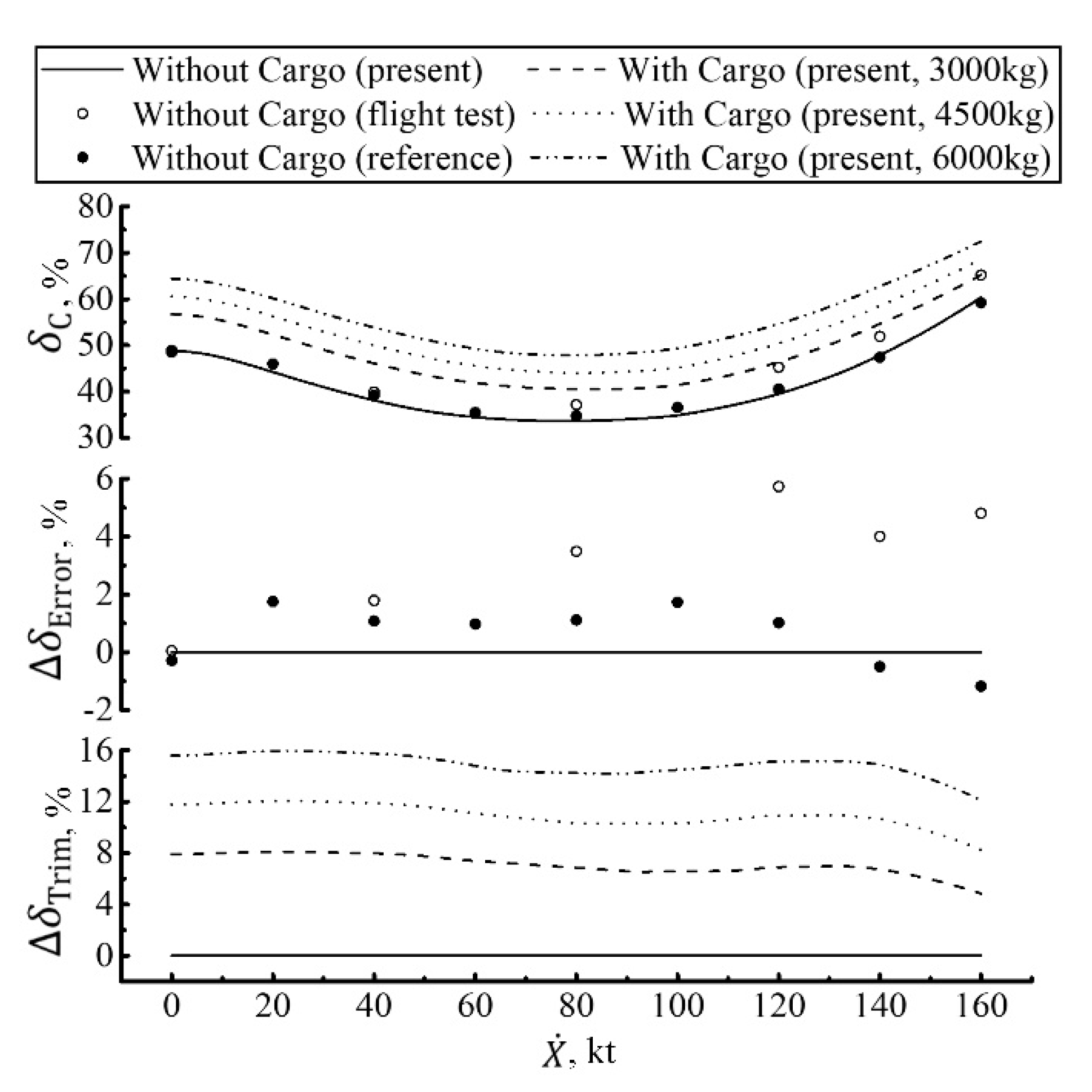

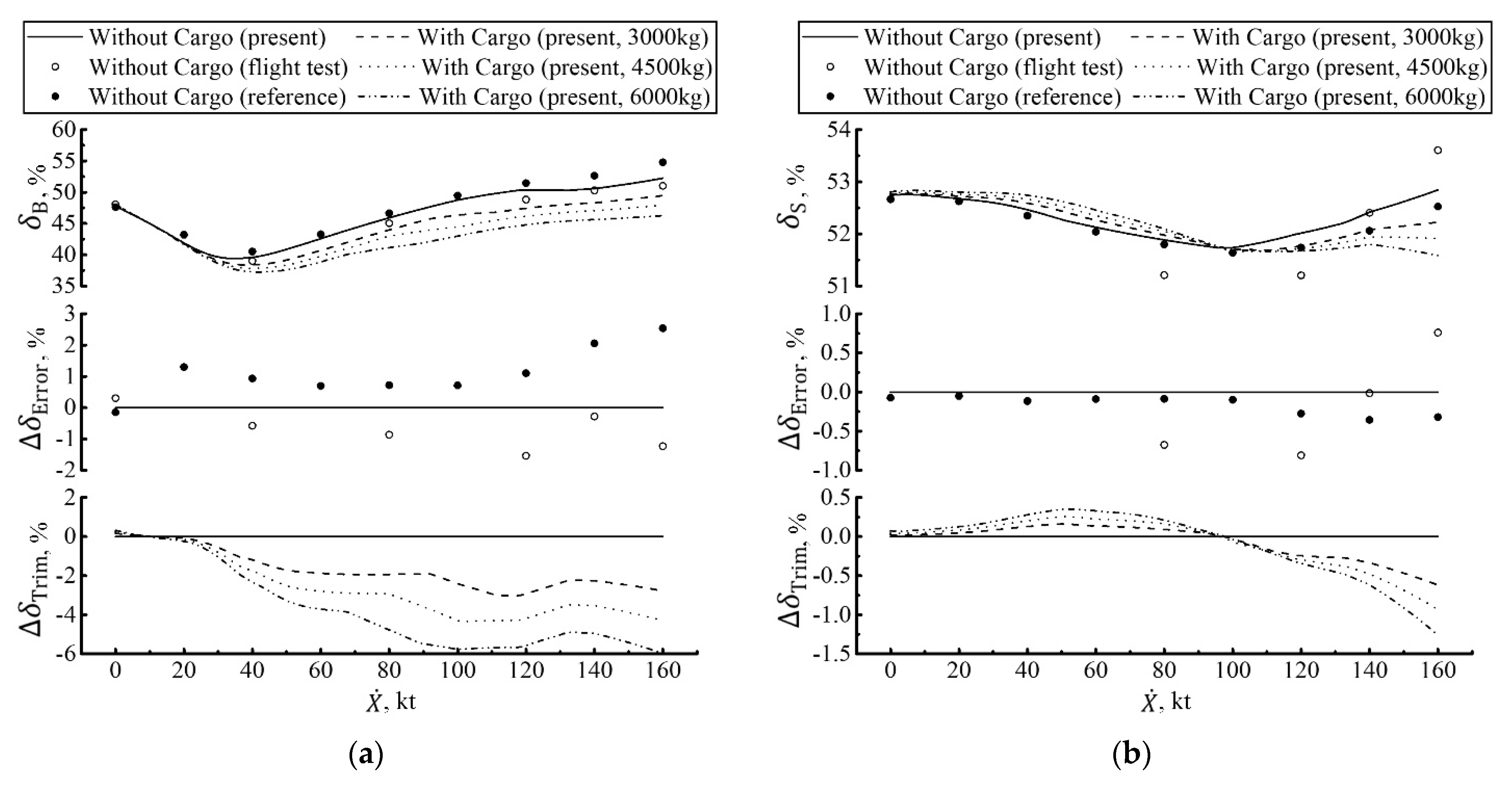

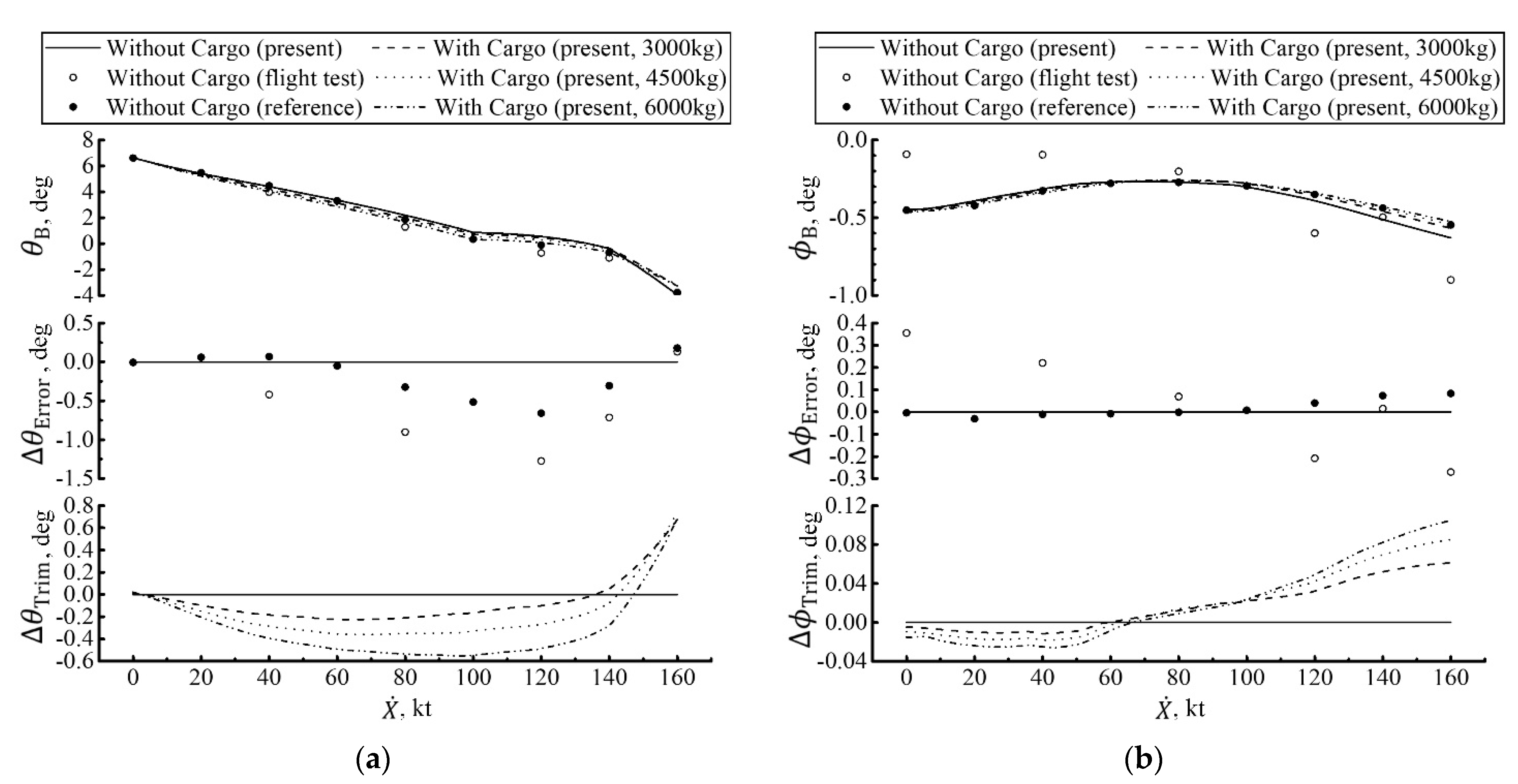

- Flight operation loading an internal cargo mainly evidently affects the trim positions of the thrust and longitudinal cyclic controls, especially flying at a large flight velocity, as shown in Figure 3 and Figure 4a. In detail, it decreases the trim position of the longitudinal cyclic control, except for hovering and flying at a low flight velocity less than 10 knots. It also increases the trim position of the thrust control due to the mass of the cargo. In addition, the increase in the mass of the cargo would decrease the trim position of the longitudinal cyclic control and further increase the trim position of the thrust control. Taking the trim results of the helicopter that flies with a cargo of 6000 kg as an example, the maximum negative trim deviation of the longitudinal cyclic control reaches by −6% of the travel and the maximum positive trim deviation of the thrust control by +16% of the travel.

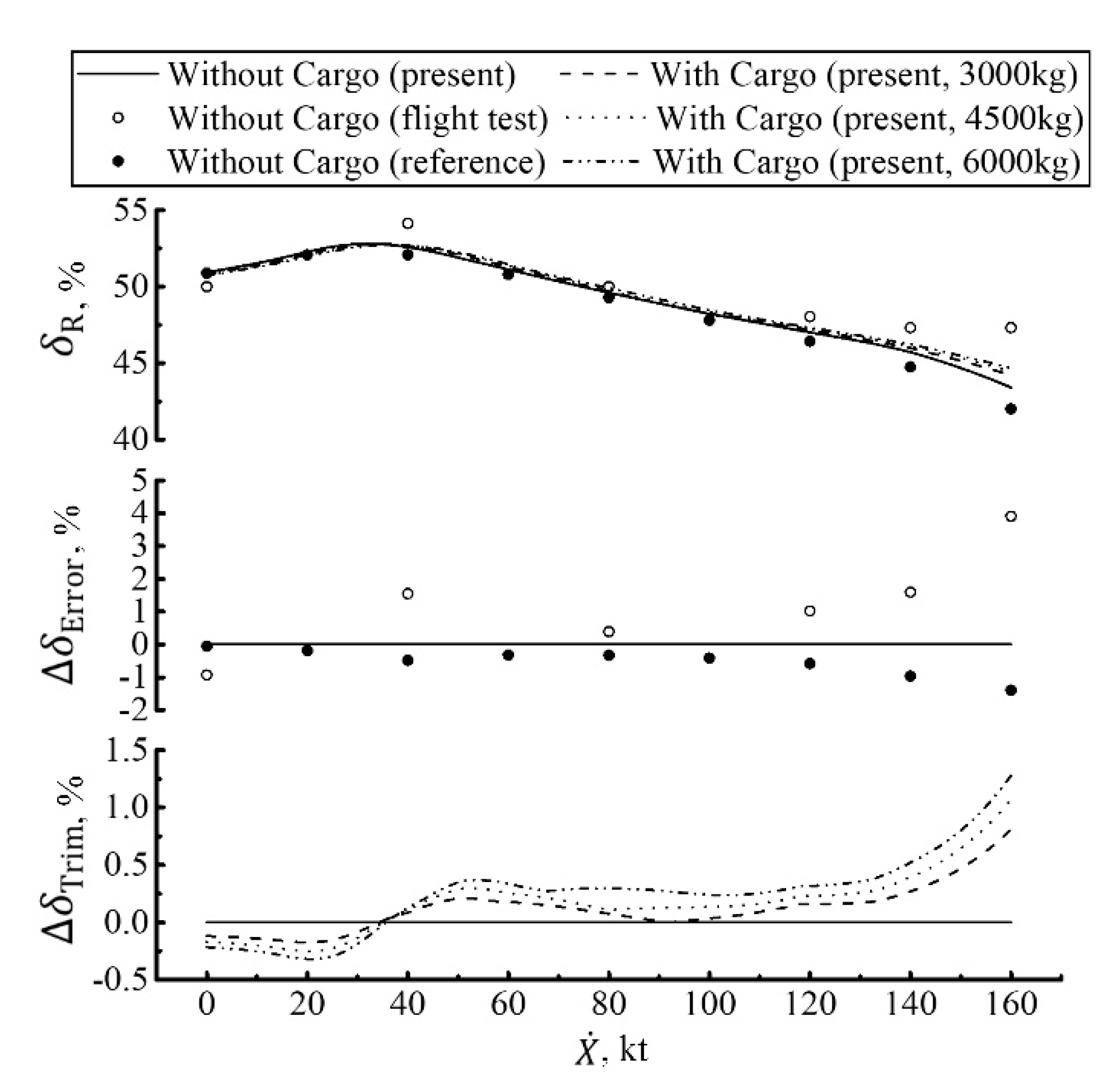

- In most practical applications, the internal cargo is generally set in the longitudinal symmetry plane of the helicopter with no lateral movement; thus, there is a small effect on the trim positions of the lateral cyclic and pedal controls, as shown in Figure 4 and Figure 5. In detail, compared with the trim results of helicopter flying without internal cargo, the maximum change in the trim positions of the lateral cyclic and pedal controls with internal cargo (maximum mass of 6000 kg) is less than 1.5%. However, there are some interesting changes in the trim position of the lateral cyclic control. It is that flight operation loading an internal cargo increases the trim position of the lateral cyclic control at a flight velocity less than 100 knots, and decreases the trim position of the lateral cyclic control at a flight velocity higher than 100 knots. These might be related to the changes in trim position of the rolling attitude angles at different flight velocities.

- In Figure 6, within the helicopter flight velocity envelope, flight operation loading an internal cargo has a slight effect on the trim positions of the pitching and rolling attitude angles. It indicates that the tandem rotor helicopter has a good attitude maintaining ability in the whole flight velocity envelope when the helicopter conducts airdrops. Maybe this is the right reason for which the tandem rotor helicopter is more suitable for conducting internal cargo transport compared with the conventional single rotor helicopter.

4.2. Case of Helicopter Flight Operation in the Process of Internal Cargo Airdrops

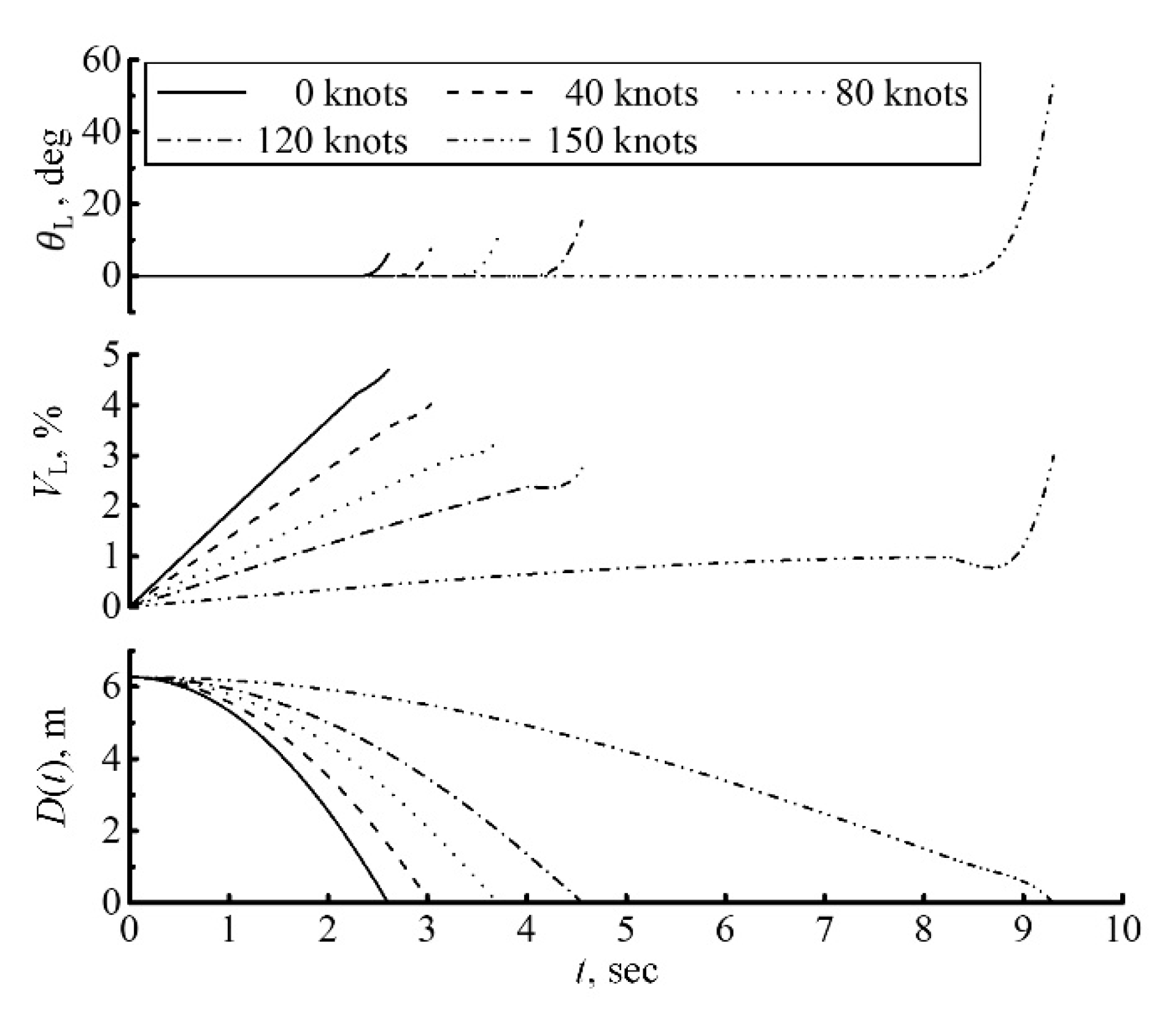

- The longitudinal cyclic control should be continuously decreased when the helicopter flies at the velocity of less than 120 knots, and be decreased firstly and then increased when the helicopter flies at the velocity of 150 knots.

- The lateral cyclic control should be continuously increased when the helicopter flies at the velocity of less than 40 knots, and be decreased when the helicopter flies at the velocity between 80 and 120 knots, and be decreased firstly and then increased when the helicopter flies at the velocity of 150 knots.

- A slight adjustment of the pedal control should be made in order to trim the helicopter.

- The airdrop operation significantly decreases the trim position of the longitudinal cyclic control within the helicopter flight velocity envelope flight operation, and significantly decreases the thrust control when the helicopter flies at the velocity of 150 knots. In detail, the negative maximum of the trim deviations from the initial trim state of the longitudinal cyclic and thrust controls reach by about 15% and 25%, respectively. These are because the pitching moment acting on the helicopter would increase gradually when the cargo is moving backward. Furthermore, when the cargo starts to rotate around the tipoff, because the pitching moment acting on the helicopter decreases quickly, the trim positions of the longitudinal cyclic and thrust controls have an obvious trend of returning to the trim state of flight operation without cargo.

- The increase in flight velocity will evidently increase the influence of the airdrop operation on the thrust control and the pitching attitude when the helicopter flies at a velocity between 0 and 150 knots, and evidently decrease the influence of the airdrop operation on the lateral cyclic and pedal controls when the helicopter flies at a velocity of less than 120 knots.

- The airdrop has a little effect on the rolling attitude. In detail, the maximum of the deviation from the initial trim position of the rolling attitude angle is less than 0.1 deg.

5. Stability Analysis

- The airdrop operation will not reduce the stability of the heave-pitch mode; on the contrary, it will make the stability root of the mode increase negatively evidently when the helicopter flies at a high velocity of greater than 120 knots. This might be attributed to the little effect of the airdrop operation on the vertical channel and the large minus pitching attitude angle at the high flight velocity. For the same reason, the airdrop operation will reduce the stabilities of the longitudinal velocity and pitch mode, especially when the helicopter flies at a high velocity of greater than 120 knots.

- The airdrop operation will evidently reduce the stabilities of both the roll mode and the spiral mode, especially as the flight velocity increases, except the spiral mode at a helicopter velocity of 0 knots. This might be contributed to the changing lateral force and the changing rolling and yawing moment of the cargo acting on the helicopter during the airdrop.

- The stabilities of both the longitudinal and lateral periodic modes (the phugoid mode and the dutch-roll mode) are continuously decreased during the backward movement of the cargo. In particular, when the airdrop is conducted at hovering, the stability of the dutch-roll mode will continue to decrease in the process of the rotation of the cargo around the point of tipoff.

6. Conclusions

- Flight operation loading an internal cargo mainly evidently affects the trim positions of the thrust and longitudinal cyclic controls, especially flying at a large flight velocity. It has a small effect on the trim positions of the lateral cyclic and pedal controls. It also has a slight effect on the trim positions of the pitching and rolling attitude angles. Thus, the tandem rotor helicopter has a good attitude maintaining ability in the whole flight velocity envelope when the helicopter conducts airdrops.

- The increase in flight velocity will constantly decrease the helicopter pitching attitude angle, thus increases the total airdrop time and decreases the backward moving velocity of the cargo. Overall, considering the actual influence of the high speed of the moving cargo on the worker’s safety tandem rotor helicopter flying at a velocity between 80 and 120 knots might be acceptable in the practical application.

- The airdrop operation will also significantly affect the trim positions of the thrust and longitudinal cyclic controls. The increase in flight velocity will evidently increase the influence of the airdrop operation on the thrust control and the pitching attitude, and evidently decrease the influence of the airdrop operation on the lateral cyclic and pedal controls. In addition, the airdrop affects the rolling attitude a little.

- The airdrop operation will not reduce the stability of the heave-pitch mode, but reduce the stabilities of the longitudinal velocity and pitch mode. It will also evidently reduce the stabilities of both the roll mode and the spiral mode, especially as the flight velocity increases. The stabilities of both the longitudinal and lateral periodic modes are continuously decreased during the backward movement of the cargo.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lucassen, L.R.; Sterk, F.J. Dynamic Stability Analysis of a Hovering Helicopter with a Sling Load. J. Am. Helicopter Soc. 1965, 10, 6–12. [Google Scholar] [CrossRef]

- Feaster, L.; Poli, C.; Kirchhoff, R. Dynamics of a Slung Load. J. Aircr. 1975, 14, 115–121. [Google Scholar] [CrossRef]

- Fusato, D.; Guglieri, G.; Celi, R. Flight Dynamics of an Articulated Rotor Helicopter with an External Slung Load. J. Am. Helicopter Soc. 2001, 46, 3–13. [Google Scholar] [CrossRef]

- Morten, B.; Jan, D.B.; Ander, I.C.H. Modeling of Generic Slung Load System. J. Guid. Control. Dyn. 2009, 32, 573–585. [Google Scholar]

- Cao, Y.; Wang, Z. Equilibrium characteristics and stability analysis of helicopter slung-load system. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2016, 231, 1056–1064. [Google Scholar] [CrossRef]

- Cao, Y.; Qi, Q.; Zhang, N. Flight Dynamic Characteristics of Tiltrotor Aircraft Slung-Load System. J. Aircr. 2017, 54, 1–8. [Google Scholar] [CrossRef]

- Cao, Y.H.; Nie, W.S.; Wang, Z.R. Dynamic Modeling of Helicopter-Slung Load System under the Flexible Sling Hy-pothesis. Aerosp. Sci. Technol. 2020, 99, 1–9. [Google Scholar] [CrossRef]

- Gupta, N.K.; Bryson, A.E.; Ryson, A.E. Near-hover control of a helicopter with a hanging load. J. Aircr. 1976, 13, 217–222. [Google Scholar] [CrossRef]

- Raz, R.; Rosen, A.; Ronen, T. Active aerodynamic stabilization of a helicopter/sling-load system. J. Aircr. 1989, 26, 822–828. [Google Scholar] [CrossRef]

- Adams, C.; Potter, J.; Singhose, W. Input-Shaping and Model-Following Control of a Helicopter Carrying a Suspended Load. J. Guid. Control. Dyn. 2015, 38, 94–105. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Soltani, A. Modeling and control for cooperative transport of a slung fluid container using quadrotors. Chin. J. Aeronaut. 2018, 31, 262–272. [Google Scholar] [CrossRef]

- Cicolani, L.S.; Cone, A.; Theron, J.N.; Robinson, D.; Lusardi, J.; Tischler, M.B.; Rosen, A.; Raz, R. Flight Test and Sim-ulation of a Cargo Container Slung Load in Forward Flight. J. Am. Helicopter Soc. 2009, 54, 032006. [Google Scholar] [CrossRef]

- Hoh, R.H.; Heffley, R.K.; Mitchell, D.G. Development of Handling Qualities Criteria for Rotorcraft with Externally Slung Loads. NASA.CR-2006-213488; 2006. Available online: https://ntrs.nasa.gov/citations/20070009837 (accessed on 24 August 2013).

- Xu, B.; Chen, J. Review of modeling and control during transport airdrop process. Int. J. Adv. Robot. Syst. 2016, 13, 1–8. [Google Scholar] [CrossRef]

- Usbaldo, F., Jr. Airdrop Technology Multi-Operational Simulation (ATMOS); AIAA Aviation 2019 Forum: Dallas, TX, USA, 2019; pp. 1–15. [Google Scholar]

- Lopez, M.; Wuest, M. C-17A cargo airdrop testing. In Proceedings of the 13th Aerodynamic Decelerator Systems Technology Conference, Clearwater, FL, USA, 15–18 May 1995. AIAA-1995-1578. [Google Scholar]

- Bergeron, K.; Ghoreyshi, M.; Jirasek, A. Dynamic Maneuver and 6DOF Exit Simulations for C-130 H/J Airdrop Con-figurations. In Proceedings of the 2018 Applied Aerodynamics Conference, Atlanta, GA, USA, 25–29 June 2018. AIAA 2018-3008. [Google Scholar]

- Stein, J.; Machin, R.; Wolf, D.; Hillebrandt, F. Low Velocity Airdrop Tests of an X-38 Backup Parachute Design. In Proceedings of the 18th AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Munich, Germany, 23–26 May 2005. AIAA 2005-1649. [Google Scholar]

- Usbaldo, F., Jr. Dynamic Modeling-Simulation of Advanced Low Velocity Airdrop Systems (ALVADS): First Edition. In Proceedings of the 24th AIAA Aerodynamic Decelerator Systems Technology Conference, Denver, CO, USA, 5–9 June 2017. AIAA-2017-3537. [Google Scholar]

- Chakoian, G.; Michal, J.L. A parachute Retrorocket System for Low Altitude Airdrop of Cargo and Other Special Applications. In Proceedings of the 2nd Aerodynamic Deceleration Systems Conference, El Centro, CA, USA, 23–25 September 1968. AIAA 1968-956. [Google Scholar]

- Han, Y. Modeling and control for ultra-low altitude cargo airdrop. Aircr. Eng. Aerosp. Technol. 2018, 90, 219–228. [Google Scholar] [CrossRef]

- Leonard, A.; Rogers, J.; Gerlach, A. Probabilistic Release Point Optimization for Airdrop with Variable Transition Altitude. J. Guid. Control. Dyn. 2020, 43, 1487–1497. [Google Scholar] [CrossRef]

- Bonaceto, B.; Stalker, P. Design and Development of a New Cargo Parachute and Container Delivery System. In Proceedings of the 18th AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Munich, Germany, 23–26 May 2005. AIAA 1968-1647. [Google Scholar]

- Henry, M.R.; Patel, S. High Speed Container Delivery System Joint Capability Technology Demonstration. In Proceedings of the 23rd AIAA Aerodynamic Decelerator Systems Technology Conference, Daytona, FL, USA, 30 March–2 April 2015. AIAA 2015-2141. [Google Scholar]

- Wright, R.; Benney, R.; McHugh, J. Precision Airdrop System. In Proceedings of the 18th AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Munich, Germany, 23–26 May 2005. AIAA 2005-1644. [Google Scholar]

- Martin, R.C.; Mark, C. Adaptive Control of Precision Guided Airdrop Systems with Highly Uncertain Dynamics. J. Guid. Control. Dyn. 2018, 41, 1025–1035. [Google Scholar]

- Yang, S.; Jeon, S. Recursive Path Planning and Wind Field Estimation for Precision Airdrop. J. Guid. Control. Dyn. 2019, 42, 1429–1437. [Google Scholar] [CrossRef]

- Lang, C.J. Engineering Design Handbook: Design for Air Transport and Airdrop of Materiel; Headquarters, United States Army Materiel Command: Washington, DC, USA, 1967. [Google Scholar]

- Lee, C.-T.; Tsai, C.-C. Adaptive backstepping integral control of a small-scale helicopter for airdrop missions. Asian J. Control. 2010, 12, 531–541. [Google Scholar] [CrossRef]

- Cui, Z.X.; Cao, Y.H. Dynamics Characteristics of Helicopter under Heavy Cargo Airdrop Condition. J. Aerosp. Power 2019, 34, 451–459. (In Chinese) [Google Scholar]

- Papastavridis, J.; Yagasaki, K. Analytical Mechanics: A Comprehensive Treatise on the Dynamics of Constrained Systems; for Engineers, Physicists, and Mathematicians. Appl. Mech. Rev. 2003, 56, B22. [Google Scholar] [CrossRef]

- Beer, F.; Johnston, E.; Mazurek, D. Vector Mechanics for Engineers: Statics and Dynamics, 12th ed.; McGraw-Hill Education: New York, NY, USA, 2013; Chapters 3–5, 15. [Google Scholar]

- Chen, J.; Shi, Z. Aircraft Modeling and Simulation with Cargo Moving Inside. Chin. J. Aeronaut. 2009, 22, 191–197. [Google Scholar] [CrossRef][Green Version]

- Zhang, H.M.; Wang, D.; Zhang, Y.J. Cargo Movement Influences Analysis on the Airplane during Low Altitude Heavy Equipment Airdrop. Aeronaut. Sci. Technol. 2014, 12, 39–43. (In Chinese) [Google Scholar]

- Ouyang, S.X.; Ding, C.S. The Study on the Dynamic Characteristics of Aircraft with Cargos Moving in its Cargo Cabin. Flight Dyn. 1992, 10, 77–86. (In Chinese) [Google Scholar]

- Ke, P.; Yang, C.-X.; Yang, X.-S. Extraction Phase Simulation of Cargo Airdrop System. Chin. J. Aeronaut. 2006, 19, 315–321. [Google Scholar] [CrossRef]

- Li, D.D.; Sun, X.X.; Dong, W.H. Improved heavy weight airdrop model considering many influence factors. Syst. Eng. Electron. 2013, 35, 447–451. [Google Scholar]

- Chapman, A.E. Biomechanical Analysis of Fundamental Human Movements; Human Kinetics: Champaign, IL, USA, 2008; pp. 160–161. [Google Scholar]

- Leishman, J.G. Principles of Helicopter Aerodynamics, 2nd ed.; Cambridge University Press: Cambridge, UK, 2006; pp. 59–68. [Google Scholar]

- Ostroff, A.J.; Downing, D.R.; Rood, W.J. A Technique Using a Nonlinear Helicopter Model for Determine Trims and Derivatives. NASA TN D 8159. 1976. Available online: https://www.researchgate.net/publication/24332049 (accessed on 24 August 2013).

- Weber, J.M.; Liu, T.Y.; Chung, W. A Mathematical Simulation Model of a CH-47B Helicopter. NASA TM 84351; 1984. Available online: https://ntrs.nasa.gov/citations/19850001726 (accessed on 5 September 2013).

- Transtrum, M.K.; Sethna, J.P. Improvements to the Levenberg-Marquardt Algorithm for Nonlinear Least-Squares Minimization. Available online: https://arxiv.org/abs/1201.5885 (accessed on 27 January 2012).

- Dormand, J.R.; Prince, P.J. A family of embedded Runge-Kutta formulae. J. Comput. Appl. Math. 1980, 6, 19–26. [Google Scholar] [CrossRef]

- Cao, Y.; Li, G.; Yang, Q. Studies of trims, stability, controllability, and some flying qualities of a tandem rotor helicopter. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2008, 223, 171–177. [Google Scholar] [CrossRef]

- Davis, J.M. Stability and Control Analysis. No. 114-AD-603 (Contract DA23-204-AMC-04366 (Y)). In NASA Technical Paper; University of Michigan Library: Ann Arbor, MI, USA, 28 November 1966. [Google Scholar]

- Townsend, B.K. The Application of Quadratic Optimal Cooperative Control Synthesis to a CH-47 Helicopter. J. Am. Helicopter Soc. 1987, 32, 33–44. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Cao, Y.; Wang, M. Modeling and Analysis of a Generic Internal Cargo Airdrop System for a Tandem Helicopter. Appl. Sci. 2021, 11, 5109. https://doi.org/10.3390/app11115109

Li G, Cao Y, Wang M. Modeling and Analysis of a Generic Internal Cargo Airdrop System for a Tandem Helicopter. Applied Sciences. 2021; 11(11):5109. https://doi.org/10.3390/app11115109

Chicago/Turabian StyleLi, Guozhi, Yihua Cao, and Maosheng Wang. 2021. "Modeling and Analysis of a Generic Internal Cargo Airdrop System for a Tandem Helicopter" Applied Sciences 11, no. 11: 5109. https://doi.org/10.3390/app11115109

APA StyleLi, G., Cao, Y., & Wang, M. (2021). Modeling and Analysis of a Generic Internal Cargo Airdrop System for a Tandem Helicopter. Applied Sciences, 11(11), 5109. https://doi.org/10.3390/app11115109