Systematic Analysis of Micro-Fiber Thermal Insulations from a Thermal Properties Point of View

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. The Tested Material

2.2. Application Possibilities and Experiences of Micro-Fiber Based Insulations

2.3. Thermal Conductivity Measurements and Specific Heat Capacity Measurements

2.4. Combustion Heat Measurements of the Samples with Cal2 ECO Bomb Calorimeter

2.5. Experiments Executed by Scanning Electron Microscope

2.6. Raman Spectroscopy

2.7. Differential Scanning Calorimetry Measurements

2.8. Sorption Isotherms

2.9. Hydrophobic Tests

3. Results and Discussion

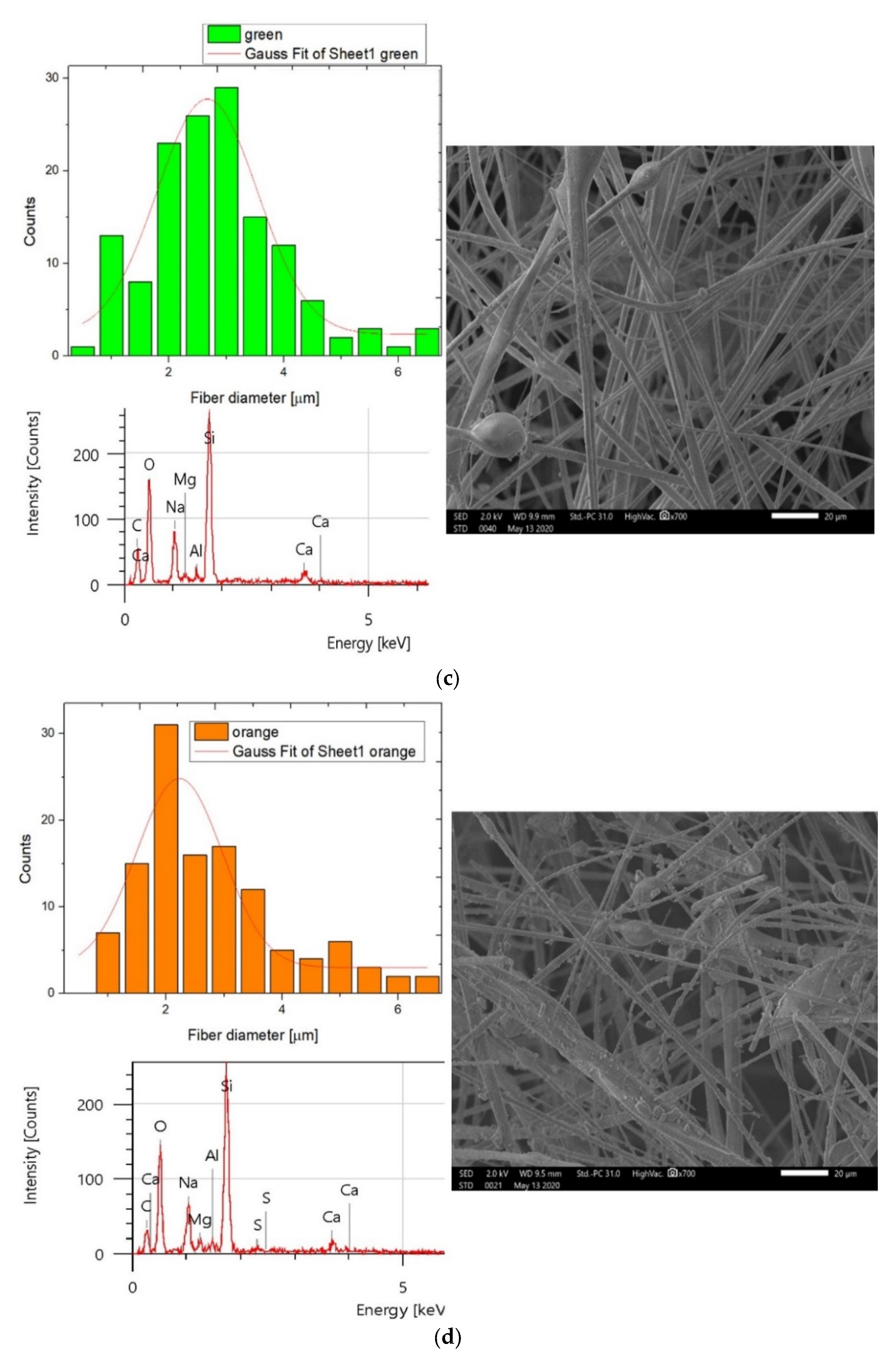

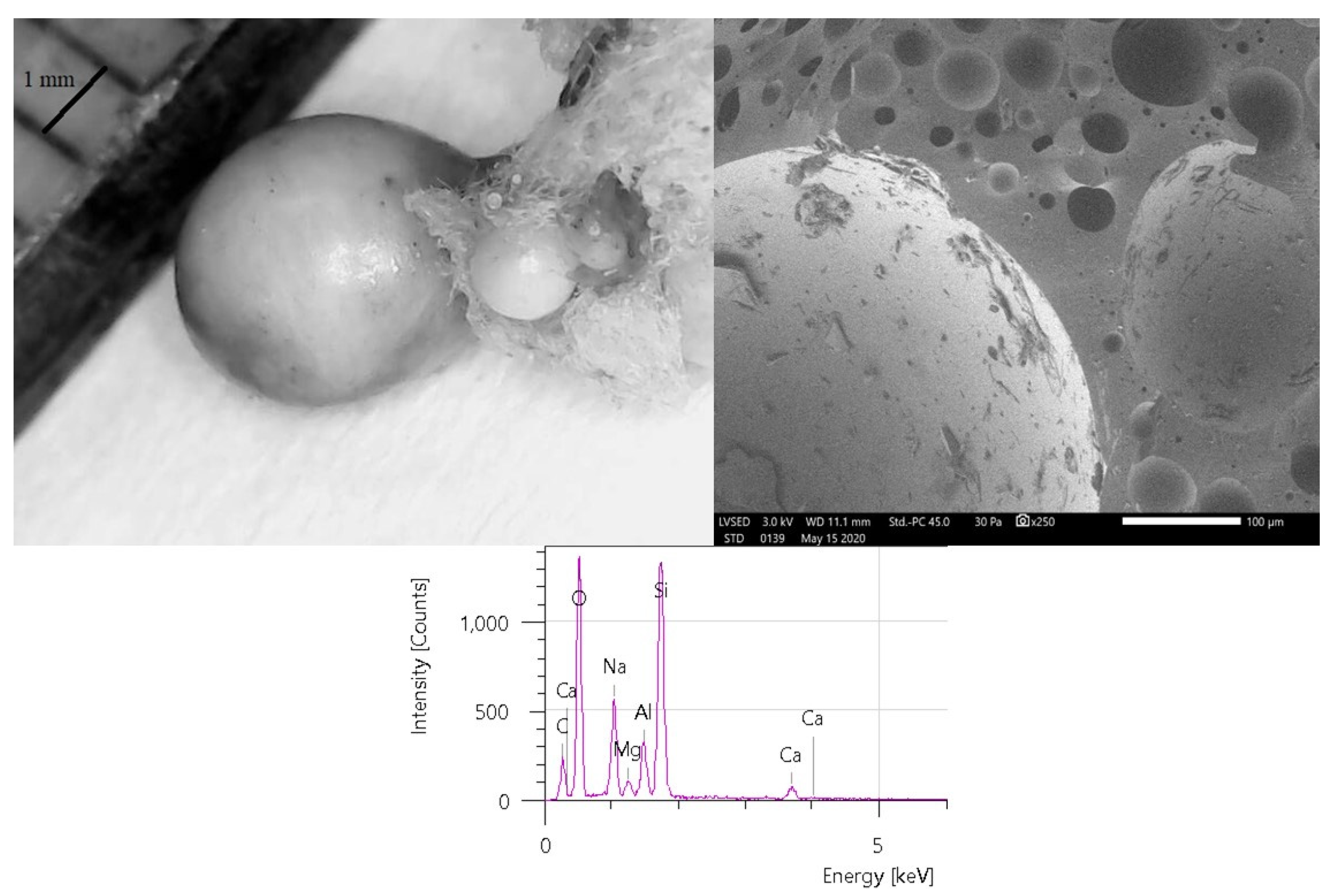

3.1. Surface Morphology and Fiber Distribution Investigations by Scanning Electron Microscopy

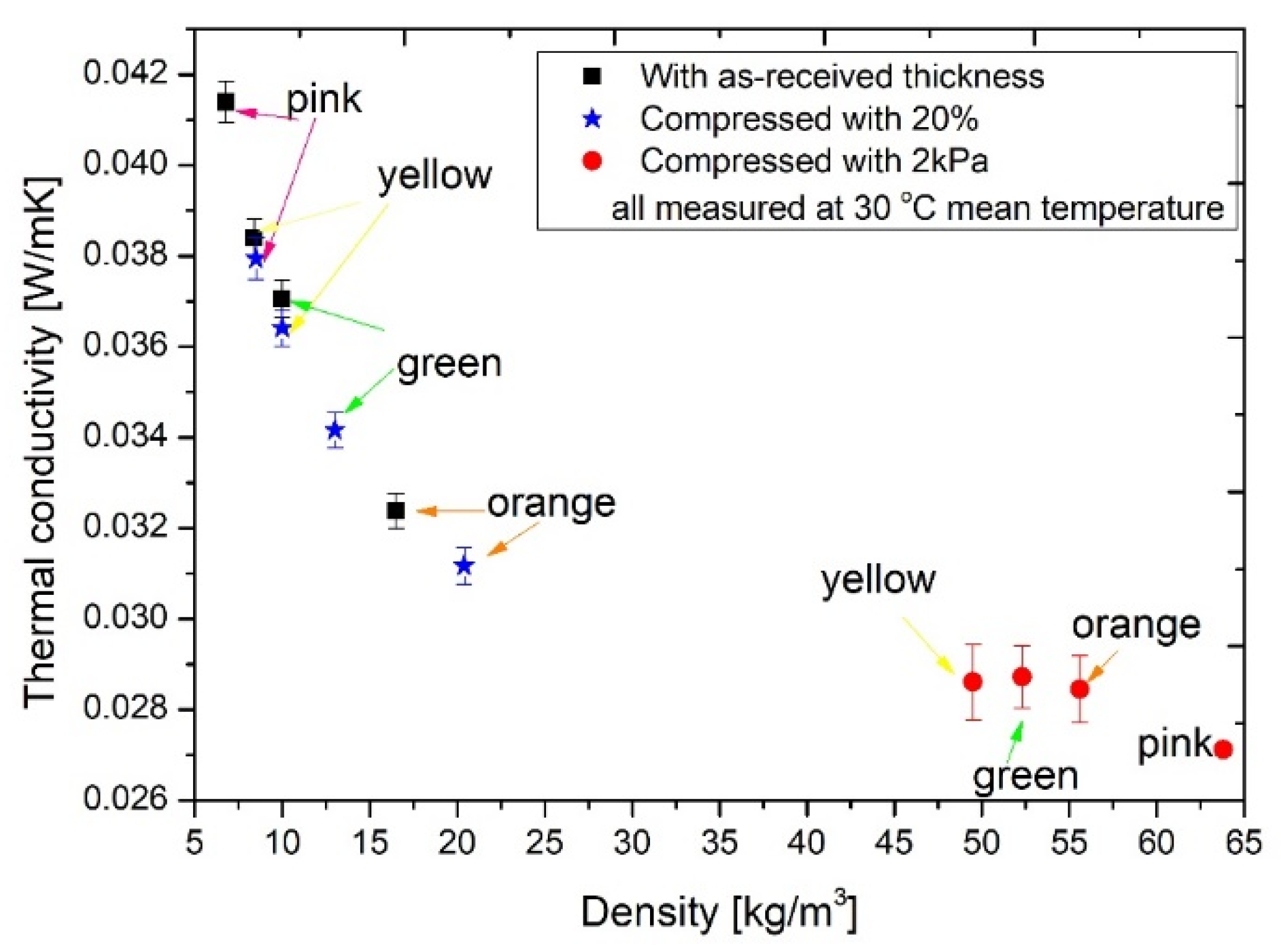

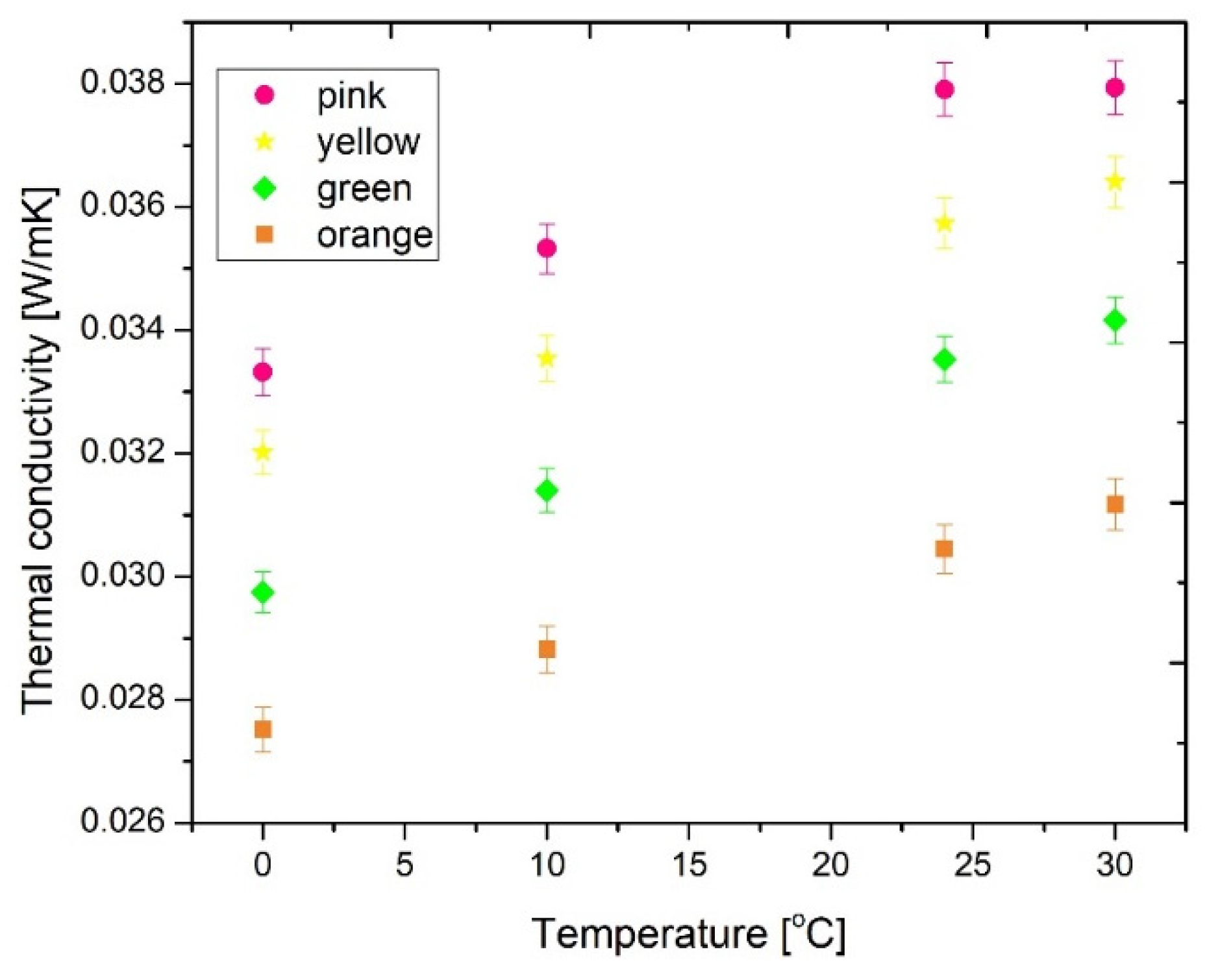

3.2. Thermal Conductivity Measurement Results

3.3. Wetting Tests

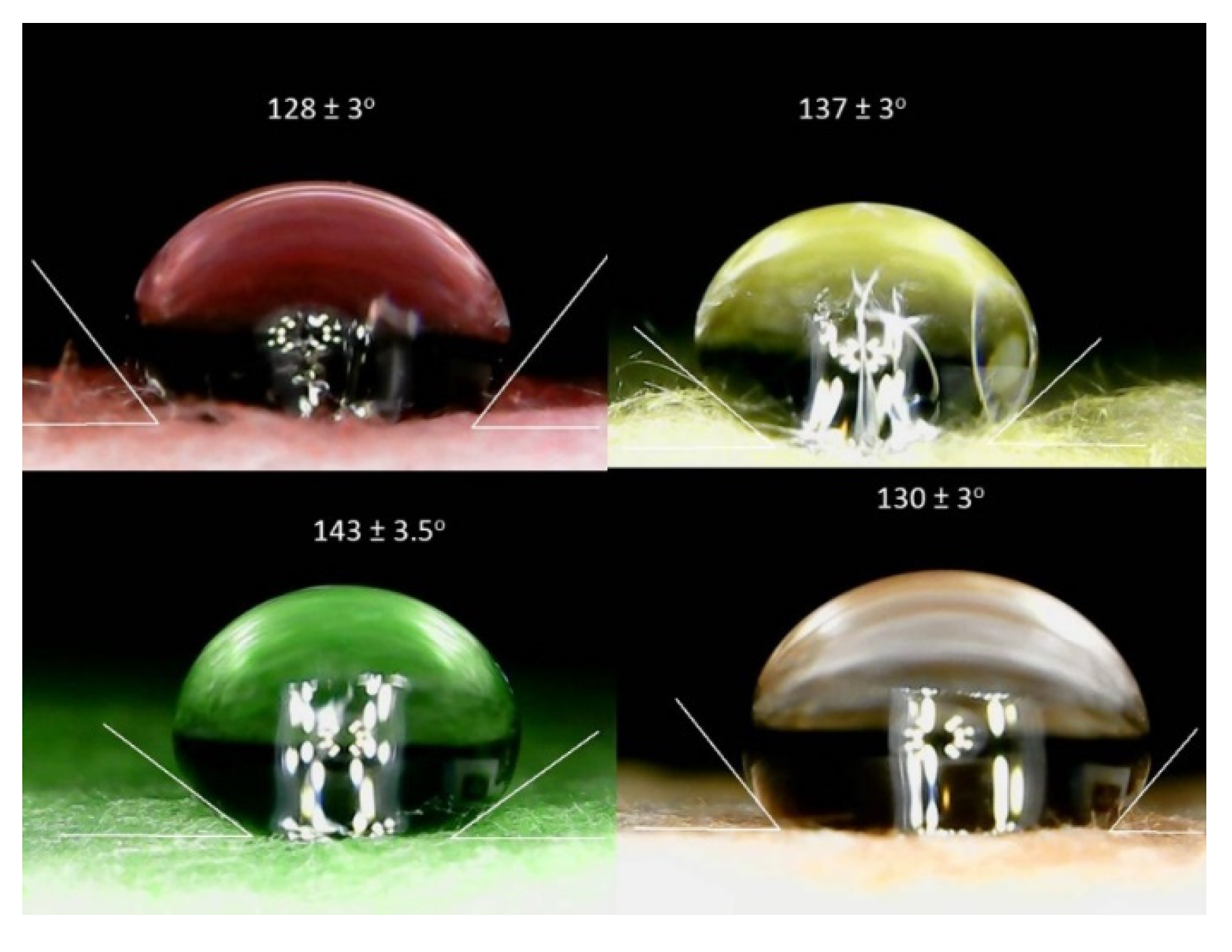

3.3.1. Hydrophobic Tests

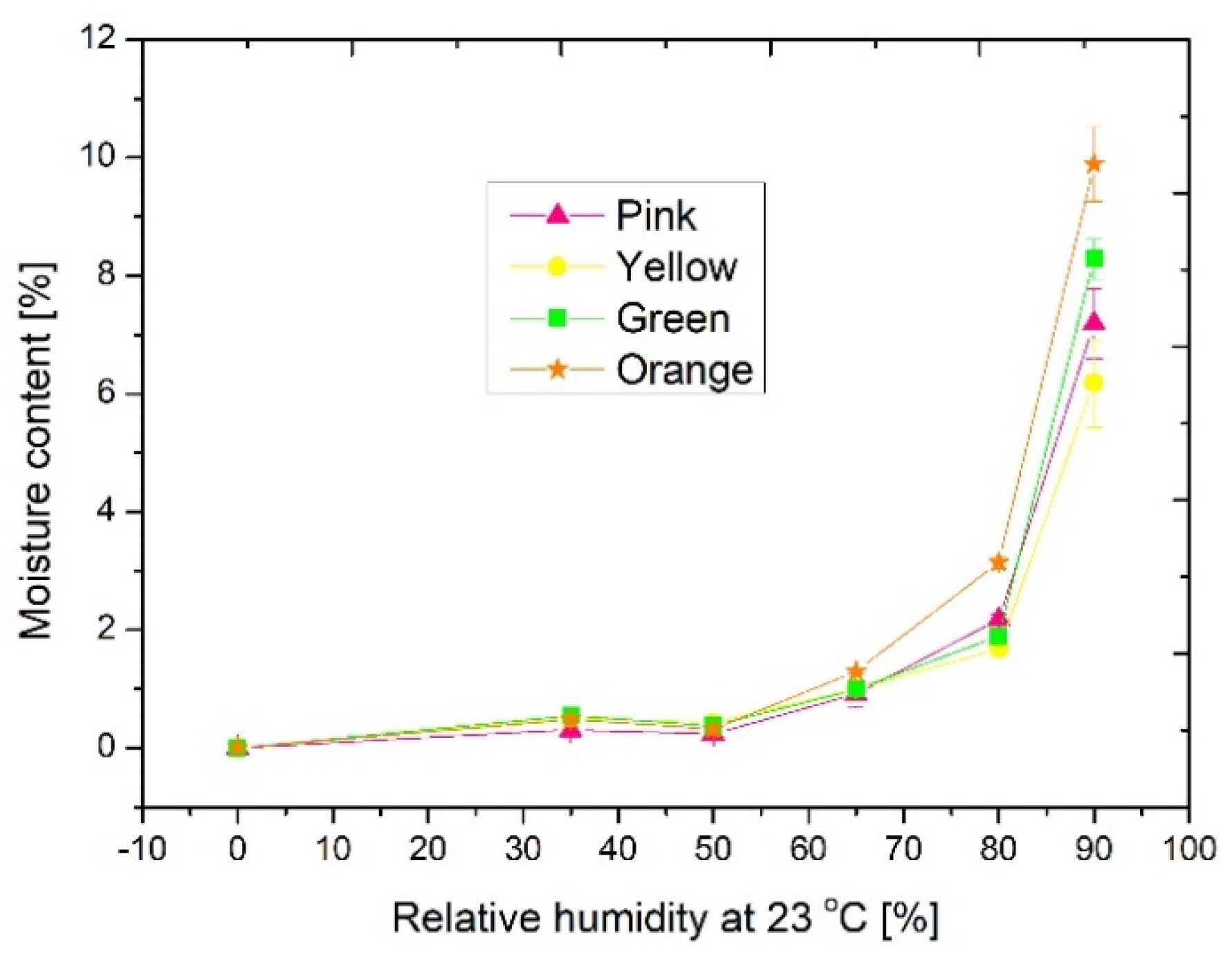

3.3.2. Sorption Isotherm Measurement Results

3.4. Investigations of the Thermal Degradation

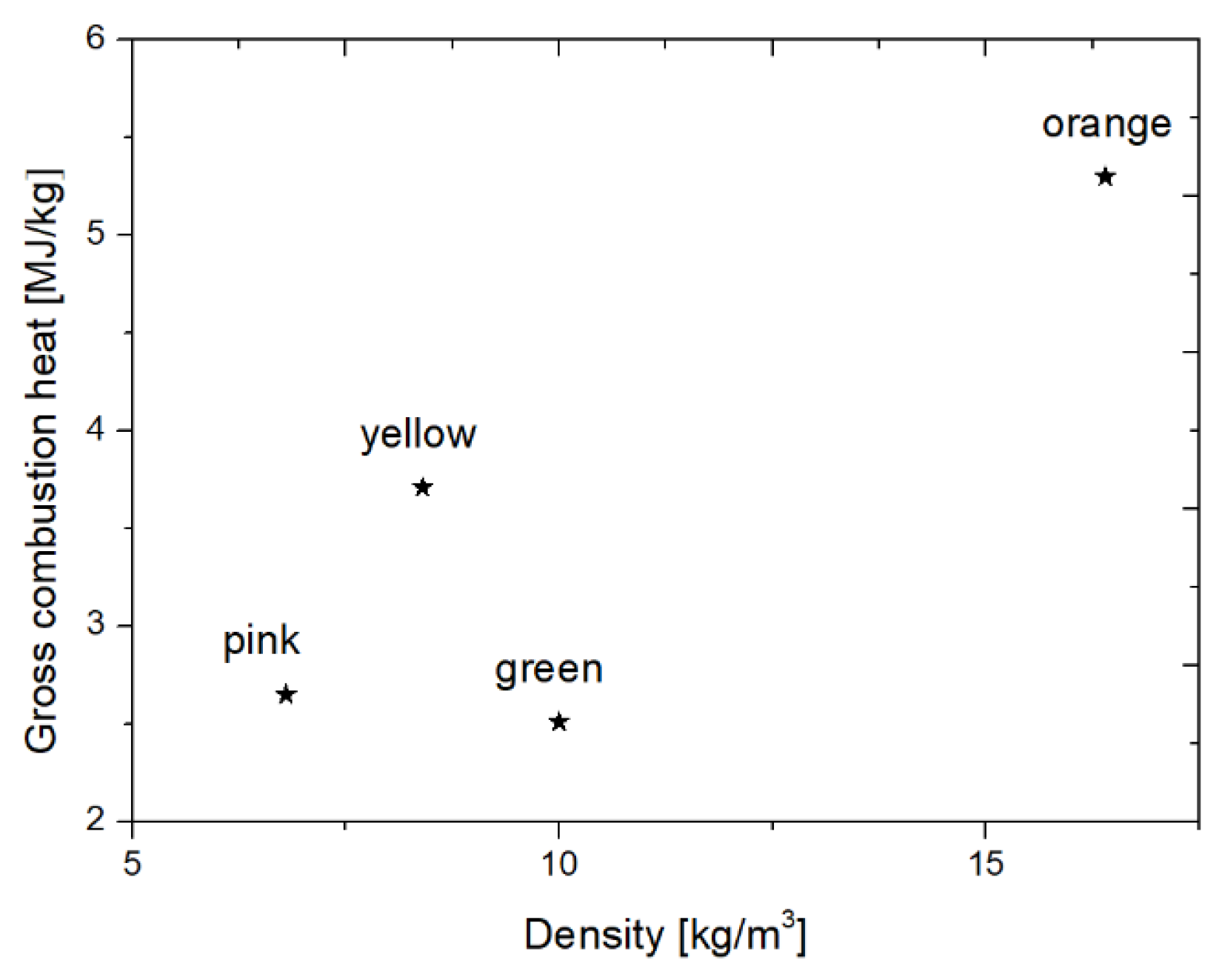

3.4.1. Measurements of the Gross Combustion Heat

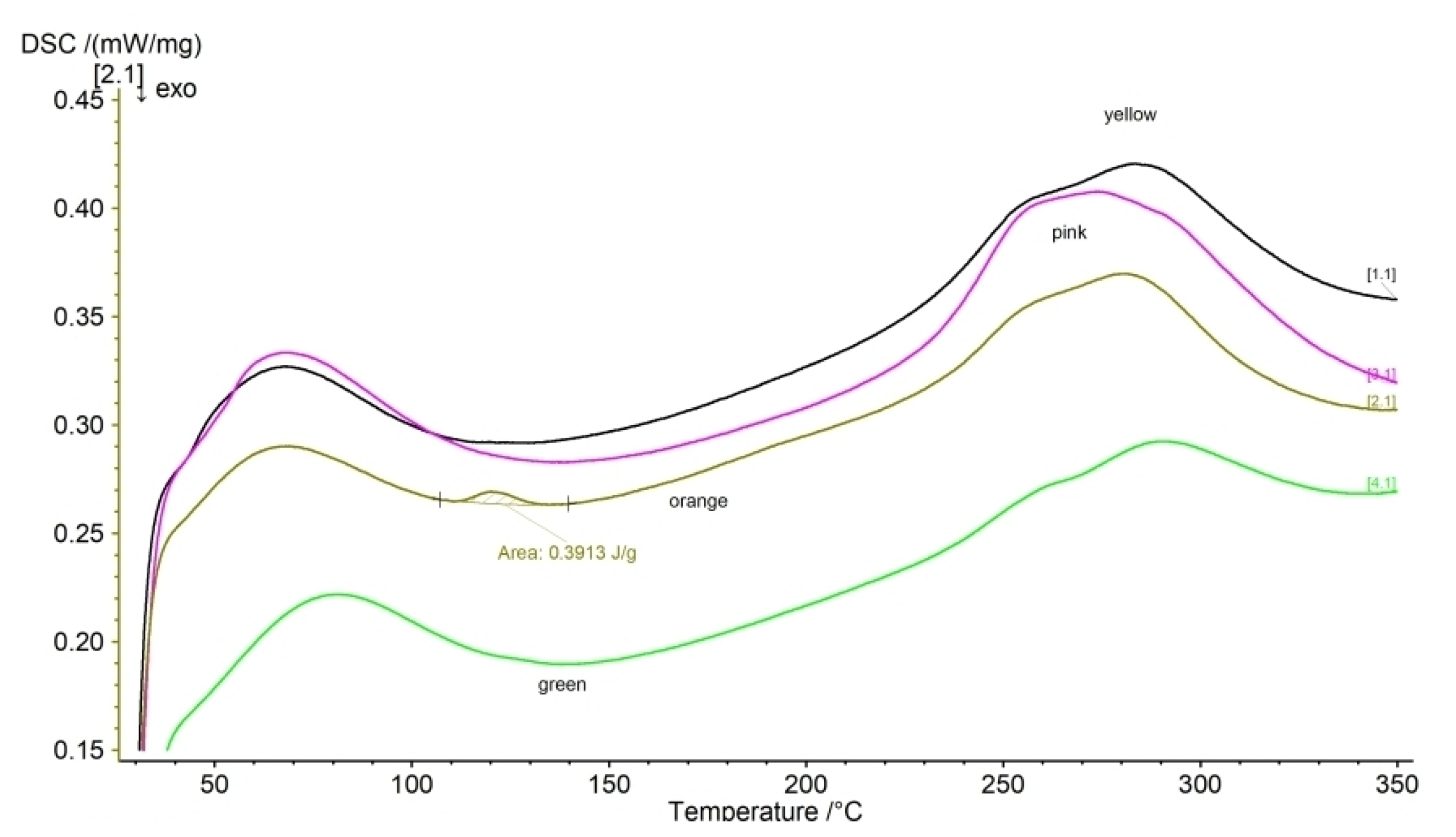

3.4.2. Differential Scanning Calorimetry Measurement Results

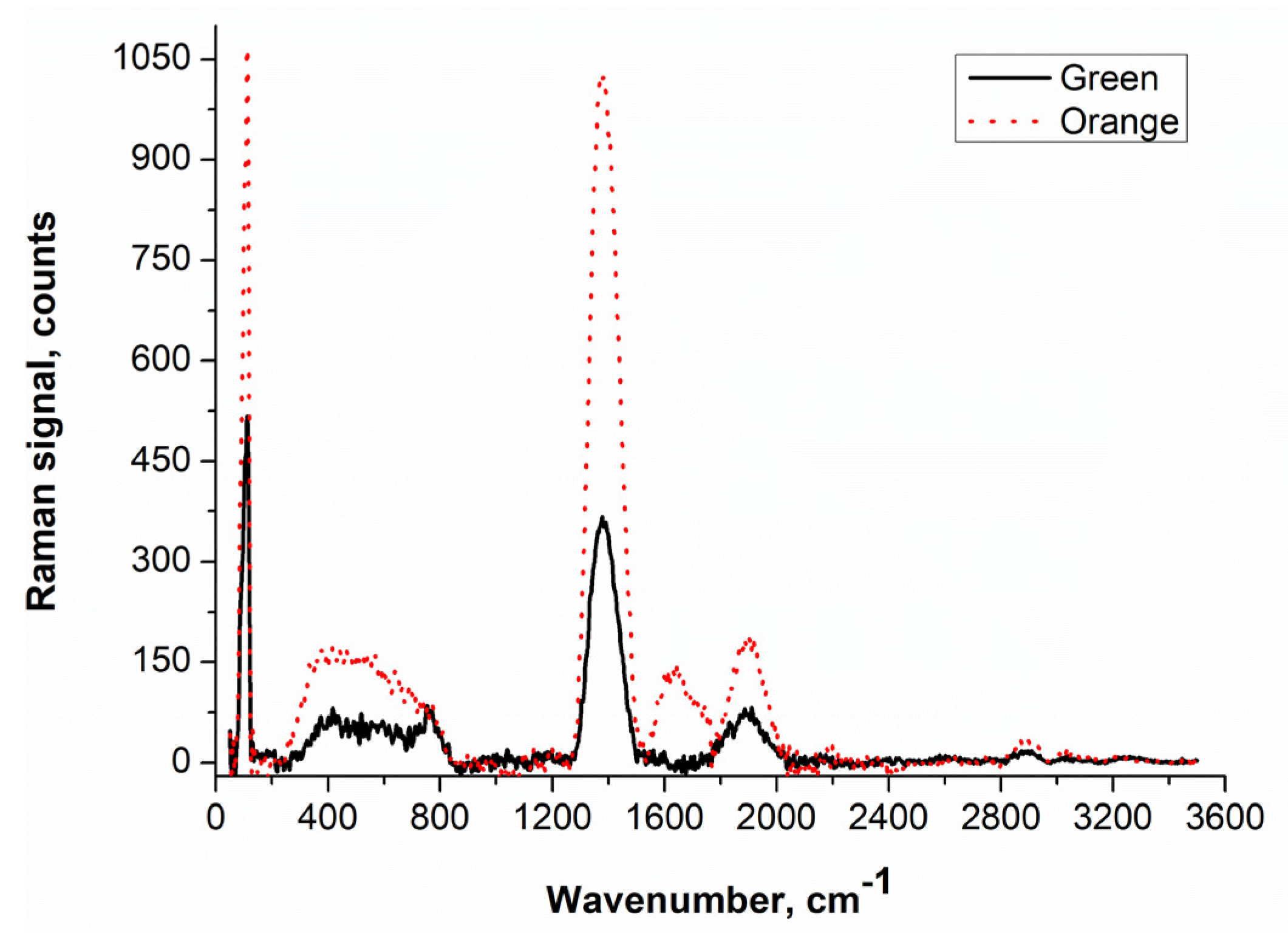

3.5. Raman Spectroscopy Measurement Results

4. Conclusions

- After examining the samples with scanning electron microscopy, it was revealed that the bases of the materials were mainly silicon, calcium, magnesium, sodium, alumina, and carbon, and possibly their oxides. Moreover, some also contained traces of sulfur. The results showed that the mean pore diameter of the cylindrical fibers varied between 0.5 and 7 µm at random locations. The presence of colorized binders was also depicted. The increase in the fiber diameter increased the density and resulted in a better thermal insulation capability;

- Through thermal conductivity measurements, it was revealed that thermal conductivity decreased with increasing density independently from the mean temperature of the samples, but due to their loose-filled structure, unfortunately, they cannot be used in situations where they would be exposed to significant mechanical effects. By only applying a 2 kPa load on the sample, their material thickness decreased. This assay determined the applicability limit of the samples;

- From the specific heat capacity measurements, it was shown that Cp values of the samples fitted in the normal range of insulation materials (~1000 J/kgK);

- From microscopic tests, we found all the samples to be hydrophobic;

- We have characterized sorption isotherm profiles as showing type III isotherms from the BET theory, which defines weak adsorption under low-relative humidity. It must be mentioned that the materials could be used in cases where the relative humidity of the environment is under 70%. It is also notable that the orange sample had the highest amount of adsorbed water, caused mainly by its declared acrylic content;

- From bomb calorimetry measurements, it was clearly shown that the materials were fire retardant and the heat released during combustion was low (2–4 MJ/kg), except for the orange material with about GHC = 5.5 MJ/kg—possibly due to its slightly different components. All the samples took on a spherical shape after their combustion;

- Differential scanning calorimetry measurements were performed on the samples between 30 and 350 °C in order to determine their thermal stability. The shapes of the curves were the same, with a broad peak up to 100 °C; over this temperature, a continuous increase in the DSC indicated that a crystallization process might have taken place. It is also notable that the orange sample had a slight peak near 120 °C, possibly showing melting of one of the components;

- Raman spectroscopy results collated our findings and made them complex. It was revealed through the Raman experiments that the samples had an amorphous glassy bond structure; moreover, the orange sample had additional acrylic acid content.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, Z.; Li, X.; Li, Z.; Si, J.; Xu, S.; Nie, R. Optimal Scheduling Strategy of Building Integrated Photovoltaic Microgrid Considering Virtual Energy Storage. Appl. Sci. 2020, 10, 6176. [Google Scholar] [CrossRef]

- Huang, B.; Lu, W. Experimental Investigation of the Multi-Physical Properties of an Energy Efficient Translucent Concrete Panel for a Building Envelope. Appl. Sci. 2020, 10, 6863. [Google Scholar] [CrossRef]

- Pereira, M.C.; Soares, A.; Flores-Colen, I.; Correiaj, R. Influence of Exposure to Elevated Temperatures on the Physical and Mechanical Properties of Cementitious Thermal Mortars. Appl. Sci. 2020, 10, 2200. [Google Scholar] [CrossRef] [Green Version]

- Capozzoli, A.; Fantucci, S.; Favoino, F.; Perino, M. Vacuum Insulation Panels: Analysis of the Thermal Performance of Both Single Panel and Multilayer Boards. Energies 2015, 8, 2528–2547. [Google Scholar] [CrossRef] [Green Version]

- Moga, L.M.; Bucur, A.; Iancu, I. Current Practices in Energy Retrofit of Buildings. In Environmental and Human Impact of Buildings: An Energetics Perspective; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–41. [Google Scholar]

- Fort, J.; Koci, J.; Pokorny, J.; Podolka, L.; Kraus, M.; Cerny, R. Characterization of Responsive Plasters for Passive Moisture and Temperature Control. Appl. Sci. 2020, 10, 9116. [Google Scholar] [CrossRef]

- Lakatos, Á. Stability investigations of the thermal insulating performance of aerogel blanket. Energy Build. 2019, 139, 506–516. [Google Scholar] [CrossRef] [Green Version]

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.D.; Gomes, M.G. Nanomaterials’ Influence on the Performance of Thermal Insulating Mortars—A Statistical Analysis. Appl. Sci. 2020, 10, 2219. [Google Scholar] [CrossRef] [Green Version]

- Lakatos, Á. Exceeding the Applicability Limit of Aerogel Super Insulation Materials in Different Environmental Conditions. Appl. Sci. 2020, 10, 7824. [Google Scholar] [CrossRef]

- Berardi, U. The impact of aging and environmental conditions on the effective thermal conductivity of several foam materials. Energy 2019, 182, 777–794. [Google Scholar] [CrossRef]

- Koru, M. Determination of Thermal Conductivity of Closed-Cell Insulation Materials That Depend on Temperature and Density. Arab. J. Sci. Eng. 2016, 41, 4337–4346. [Google Scholar] [CrossRef]

- Miros, A. Thermal Aging Effect on Thermal Conductivity Properties of Mineral Wool Pipe Samples at High Temperature. In Proceedings of the 3rd World Congress on Mechanical, Chemical, and Material Engineering (MCM’17), Rome, Italy, 8–10 June 2017. [Google Scholar]

- Miros, A.; Psiuk, B.; Szpikowska-Sroka, B. Aerogel insulation materials for industrial installation: Properties, and structure of new factory-made products. J. Sol Gel Sci. Technol. 2017, 84, 496–506. [Google Scholar] [CrossRef] [Green Version]

- Semeniuk, B.P.; Göransson, P.; Dazel, O. Dynamic equations of a transversely isotropic, highly porous, fibrous material including oscillatory heat transfer effects. J. Acoust. Soc. Am. 2019, 146, 2540–2551. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fangrat, J. On non-combustibility of commercial building materials. Fire Mater. 2017, 41, 99–110. [Google Scholar] [CrossRef]

- Lakatos, Á.; Csík, A.; Csarnovics, I. Experimental verification of thermal properties of the aerogel blanket. Case Stud. Therm. Eng. 2021, 25, 100966. [Google Scholar] [CrossRef]

- Zhu, J.; Zhao, F.; Xiong, R.; Peng, T.; Ma, Y.; Hu, J.; Xie, L.; Jiamg, C. Thermal insulation and flame retardancy of attapulgite reinforced gelatin-based composite aerogel with enhanced strength properties. Comp. Part A Appl. Sci. Manuf. 2020, 138, 106040. [Google Scholar] [CrossRef]

- Wakili, K.G.; Remhof, A. Reaction of aerogel containing ceramic fibre insulation to fire exposure. Fire Mater. 2017, 41, 29–39. [Google Scholar] [CrossRef]

- Boulaoued, I.; Amara, I.; Mhimid, A. Experimental determination of thermal conductivity and diffusivity of new building insulating materials. Int. J. Heat Technol. 2016, 34, 325–331. [Google Scholar] [CrossRef]

- Jelle, B.P. Accelerated climate ageing of building materials, components and structures in the laboratory. J. Mater. Sci. 2012, 47, 6475–6496. [Google Scholar] [CrossRef] [Green Version]

- Berardi, U.; Nosrati, R.H. Long-term thermal conductivity of aerogel-enhanced insulating materials under different laboratory aging conditions. Energy 2018, 147, 1188–1202. [Google Scholar] [CrossRef]

- Semeniuk, B.P.; Göransson, P. Microstructure based estimation of the dynamic drag impedance of lightweight fibrous materials. J. Acoust. Soc. Am. 2017, 141, 1360–1370. [Google Scholar] [CrossRef] [Green Version]

- Jeon, C.K.; Lee, J.S.; Chung, H.; Kim, J.H.; Park, J.P. A Study on Insulation Characteristics of Glass Wool and Mineral Wool Coated with a Polysiloxane Agent. Adv. Mater. Sci. Eng. 2017, 2017, 3938965. [Google Scholar] [CrossRef] [Green Version]

- Hung, W.C.; Horng, R.S.; Shia, R.E. Investigation of thermal insulation performance of glass/carbon fiber-reinforced silica aerogel composites. J. Sol Gel Sci. Technol. 2021, 97, 414–421. [Google Scholar] [CrossRef]

- Chyu, M.C.; Zeng, X.; Ye, L. Performance of fibrous glass pipe insulation subjected to underground water attack. In Proceedings of the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Winter Meeting, Philadelphia, PA, USA, 24–28 February 1997. [Google Scholar]

- Kodur, V.K.R.; Sultan, M.A.; Latour, J.C.; Leroux, P.; Monette, R.C. Fire Resistance Tests on Cellulose and Glass Fiber Insulated Wood Stud Shear Walls; IRC-IR-806, NRC-CNRC Report; National Research Council of Canada: Ottawa, ON, Canada, 2000. [Google Scholar]

- Vinh, T.L.; Ngoc, S.H.; Nam, S.G.; Jae, Y.K. Insulation System Using High-Temperature Fibrous Insulation Materials. Heat Trans. Eng. 2019, 40, 1523–1538. [Google Scholar]

- Mao, S.; Kan, A.; Huang, Z.; Zhu, W. Prediction of thermal performance of vacuum insulation panels (VIPs) withmicro-fiber core materials. Mater. Today Commun. 2020, 22, 100786. [Google Scholar] [CrossRef]

- Alam, M.; Singh, H.; Limbachiya, M.C. Vacuum Insulation Panels (VIPs) for building construction industry—A review of the contemporary developments and future directions. Appl. Energy 2011, 88, 3592–3602. [Google Scholar] [CrossRef] [Green Version]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Unic, R. Carbon footprint of thermal insulation materials in building envelopes. Energy Effic. 2017, 10, 1511–1528. [Google Scholar]

- Asdrubali, F. The role of Life Cycle Assessment (LCA) in the design of sustainable buildings: Thermal and sound insulating materials. In Proceedings of the Euronoise 2009, Edinburg, UK, 26–28 October 2009. [Google Scholar]

- Ayadi, A.; Stiti, N.; Boumchedda, K.; Rennai, H.; Lerari, Y. Elaboration and characterization of porous granules based on waste glass. Powder Technol. 2011, 208, 423–426. [Google Scholar] [CrossRef]

- ISO. EN ISO 10456: 277 Standard: Building Materials and Products. Hygrothermal Properties. Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; ISO: Geneve, Switzerland, 2007. [Google Scholar]

- ISO. EN ISO 8301:1991, Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus; ISO: Geneve, Switzerland, 1991. [Google Scholar]

- Lakatos, Á.; Csarnovics, I. Influence of thermal annealing on structural properties of silica aerogel super insulation material. J. Therm. Anal. Calorim. 2020, 142, 321–329. [Google Scholar] [CrossRef] [Green Version]

- Kočí, V.; Maděra, J.; Trník, A.; Černý, R. Heat transport and storage processes in differential scanning calorimeter: Computational analysis and model validation. Int. J. Heat Mass. Transf. 2019, 136, 355–364. [Google Scholar] [CrossRef]

- ISO. ISO 12571:2013 Hygrothermal Performance of Building Materials and Products—Determination of Hygroscopic Sorption Properties; ISO: Geneve, Switzerland, 2013. [Google Scholar]

- Novak, V.; Zach, J. Study of the efficiency and durability of hydrophobization modifications of building elements. IOP Conf. Ser. Mater. Sci. Eng. 2019, 583, 012032. [Google Scholar] [CrossRef]

- Nagy, B.; Simon, K.T.; Nemes, R. Effect of built-in mineral wool insulations durability on its thermal and mechanical performance. J. Therm. Anal. Calorim. 2020, 139, 169–181. [Google Scholar] [CrossRef] [Green Version]

- Silligardi, C.; Miselli, P.; Francia, E.; Lassinantti, G. Temperature-induced microstructural changes of fiber-reinforced silica aerogel (FRAB) and rock wool thermal insulation materials: A comparative study. Energy Build. 2017, 138, 80–87. [Google Scholar] [CrossRef]

- Dieckmann, E.; Onsiong, R.; Nagy, B.; Sheldrick, L.L.; Cheeseman, C. Valorization of Waste Feathers in the Production of New Thermal Insulation Materials. Waste Biomass. Valorization 2021, 12, 1119–1131. [Google Scholar] [CrossRef] [Green Version]

- Wakili, K.G.; Binder, B.; Vonbank, R. A simple method to determine the specific heat capacity of thermal insulations used in building construction. Energy Build. 2003, 35, 413–415. [Google Scholar] [CrossRef]

- Brunauer, S.; Deming, L.S.; Teller, E. On a theory of Van der Waals adsorption of gases. J. Am. Chem. Soc. 1940, 62, 1723–1732. [Google Scholar] [CrossRef]

- Avadhesh, K.Y.; Prabhakar, S. A Review on Structure of Glasses by Raman Spectroscopy. RSC Advs. 2015, 5, 67583–67609. [Google Scholar] [CrossRef]

- Hussin, R.; Salim, M.; Alias, N.; Abdullah, M.; Abdullah, S.; Ahmad, F.; Hamdan, S.; Hamdan, S.; Nor, M.; Yusuf, M. Vibrational Studies of Calcium Magnesium Ultraphosphate Glasses. Malays. J. Fund. Appl. Sci. 2014, 5, 41–53. [Google Scholar] [CrossRef] [Green Version]

- Todica, M.; Rázvan, S.; Pop, C.; Loredana, O. IR and Raman Investigation of Some Poly(acrylic) Acid Gels in Aqueous and Neutralized State. Acta Phys. Pol. A 2015, 128, 128–135. [Google Scholar] [CrossRef]

- Available online: https://spectrabase.com/spectrum/2Ntd4smFCEW (accessed on 25 October 2020).

- Ferreira, G.B.; Comerlato, M.N.; Wardell, J.L.; Hollauer, E. Vibrational spectra of bis(dmit) complexes of main group metals: IR, Raman and ab initio calculations. J. Braz. Chem. Soc. 2004, 15, 951–963. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez, U.A. Fundamentals and Characterization of Fungally Modified Polysaccharides for the Production of Bio-Plastics. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2010. [Google Scholar]

| Insulation Material | As-Received Density [kg/m3] st. dev. ±3% | As-Received Thickness [cm] st. dev. ±2% |

|---|---|---|

| Pink | 6.8 | 4.08 |

| Yellow | 8.4 | 4.35 |

| Green | 10 | 4.7 |

| Orange | 16.5 | 3 |

| Gaussian Model | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pink | st. Err. | Yellow | st. Err. | Green | st. Err. | Orange | st. Err. | |

| Adj. R-squared | 0.986 | 0.88 | 0.879 | 0.765 | ||||

| xc | 2.37 | 0.025 | 2.25 | 0.093 | 2.66 | 0.0944 | 2.23 | 0.125 |

| sigma | 0.66 | 0.029 | 0.86 | 0.11 | 0.87 | 0.123 | 0.742 | 0.15 |

| Calculated mean | 2.36 | 0.725 | 2.47 | 1.02 | 2.87 | 1.18 | 2.8 | 1.27 |

| Density [kg/m3] | |||

|---|---|---|---|

| Temperature [°C] | 6.70 | 9.60 | 19.00 |

| Thermal Conductivity [W/mK] | |||

| 10 | 0.036 | 0.035 | |

| 24 | 0.04 | 0.036 | 0.029 |

| 38 | 0.043 | 0.039 | 0.03 |

| 93 | 0.055 | 0.051 | 0.036 |

| 149 | 0.068 | 0.061 | |

| 204 | 0.092 | 0.079 | |

| Insulation Material | Thickness at 20% Compression [cm] | Thickness at 2 kPa [cm] |

|---|---|---|

| Pink | 3.30 | 0.44 |

| Yellow | 3.65 | 0.74 |

| Green | 3.66 | 0.91 |

| Orange | 2.25 | 0.82 |

| Specific Heat Capacity [J/kgK] | ||||

|---|---|---|---|---|

| Temperature [°C] | Pink | Yellow | Green | Orange |

| 10 | 740 | 1170 | 955 | 976 |

| Peak Position, [cm−1] | Vibration Mode | Comparison |

|---|---|---|

| 100, 110 | Boson peak and glass network [45] | Appeared in both samples, larger intensity for the orange sample |

| 480 | Mg–O, Ca–O, and Si–O [45,46] | Appeared in both samples, larger intensity for the orange sample |

| 1378 | Basic bonds of the glassy network [45] | Appeared in both samples, larger intensity for the orange sample |

| 1637 | Bonds of acrylic acid [47,48] | Appeared only for the orange sample |

| 1894 | Metal complex bond [49] | Appeared in both samples, larger intensity for the orange sample |

| 2892 and 3045 | Symmetric and anti-symmetric stretching vibrations of CH, CH2, or CH3 groups [50] | Appeared in both samples, larger intensity for the orange sample |

| 3230 | Stretching modes of OH [50] | Appeared in both samples, with the same intensity |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lakatos, Á.; Csarnovics, I.; Csík, A. Systematic Analysis of Micro-Fiber Thermal Insulations from a Thermal Properties Point of View. Appl. Sci. 2021, 11, 4943. https://doi.org/10.3390/app11114943

Lakatos Á, Csarnovics I, Csík A. Systematic Analysis of Micro-Fiber Thermal Insulations from a Thermal Properties Point of View. Applied Sciences. 2021; 11(11):4943. https://doi.org/10.3390/app11114943

Chicago/Turabian StyleLakatos, Ákos, István Csarnovics, and Attila Csík. 2021. "Systematic Analysis of Micro-Fiber Thermal Insulations from a Thermal Properties Point of View" Applied Sciences 11, no. 11: 4943. https://doi.org/10.3390/app11114943

APA StyleLakatos, Á., Csarnovics, I., & Csík, A. (2021). Systematic Analysis of Micro-Fiber Thermal Insulations from a Thermal Properties Point of View. Applied Sciences, 11(11), 4943. https://doi.org/10.3390/app11114943