The Interdisciplinary Approach of Some Middle Bronze Age Pottery from Eastern Romania

Abstract

:1. Introduction

2. Materials and Methods

2.1. Site Information

2.2. Methodology

2.2.1. Macroscopic Analyses

2.2.2. OM Analyses

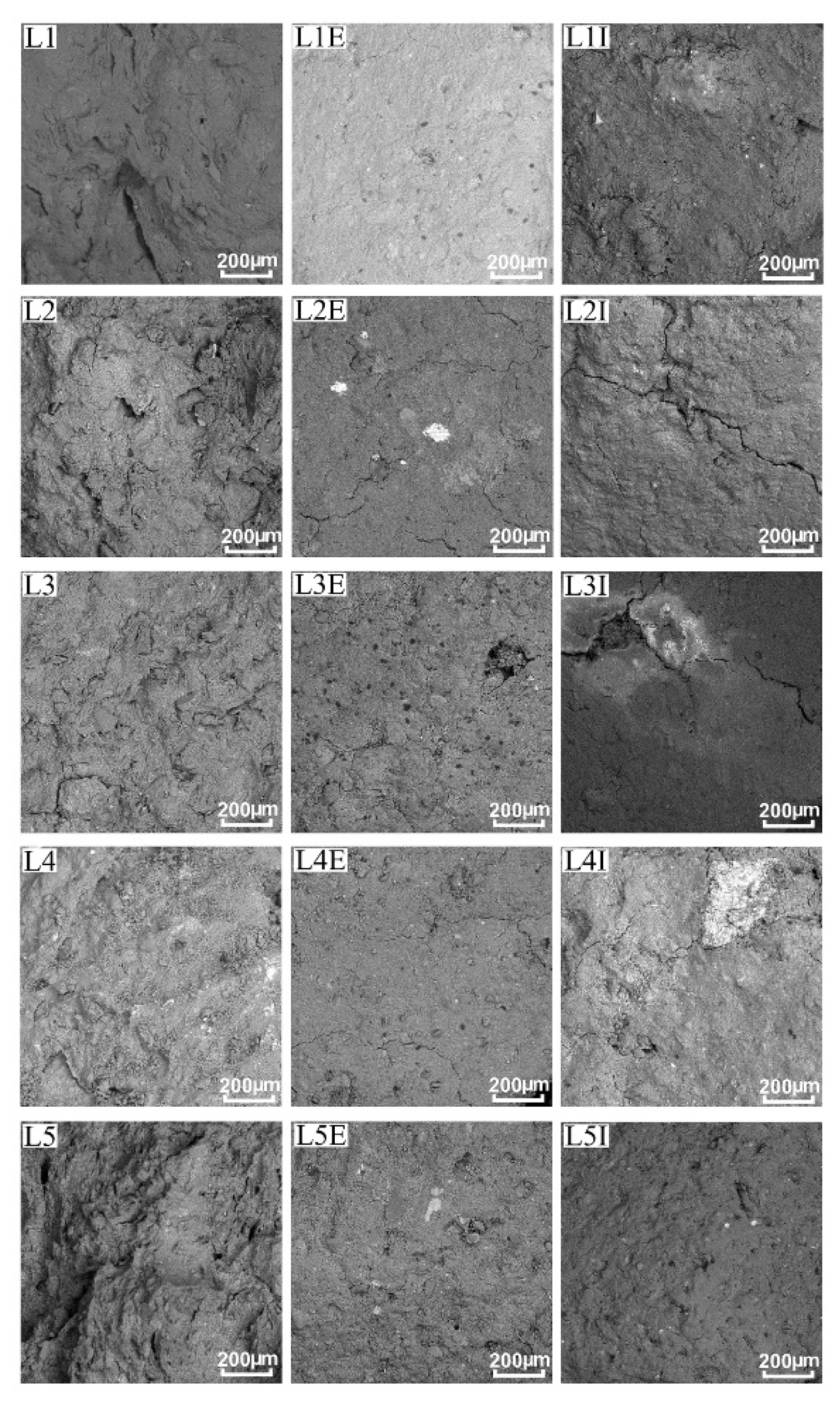

2.2.3. SEM-EDX Analyses

2.2.4. µFTIR Analyses

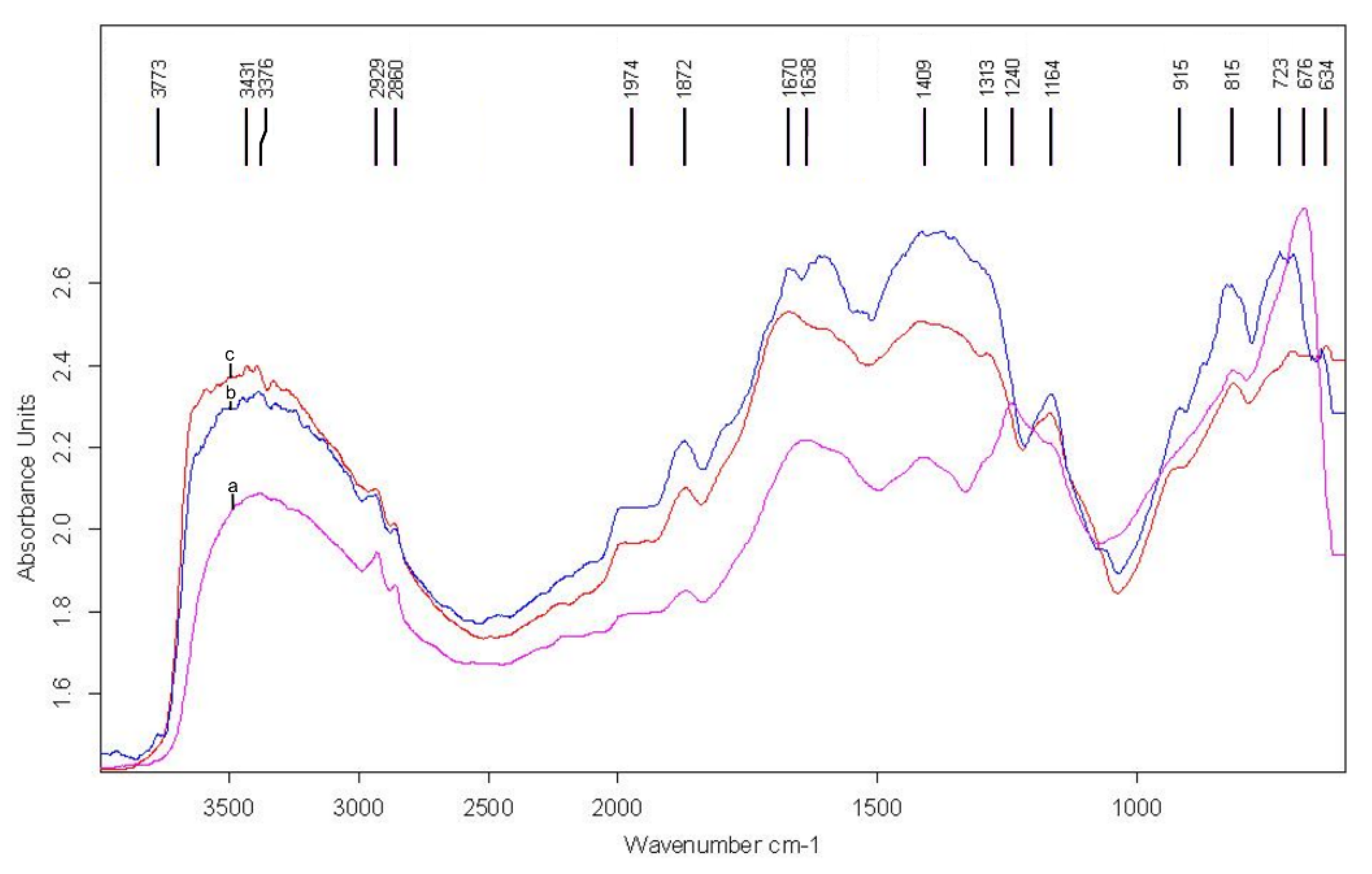

3. Results and Discussions

3.1. Macroscopic Results

3.2. Interdisciplinary Analyses

3.2.1. OM Analyses

3.2.2. SEM-EDX Analyses

3.2.3. µFTIR Analyses

3.3. L11 and the Presence of Organic Residues

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bolohan, N. “All in one”. Issues of Methodology, Paradigms and Radiocarbon Datings Concerning the Outer Eastern Carpathian Are. In Signa Praehistorica. Studia in Honorem Magistri Attila László Septuagesimo Anno. Honoraria, 9; Bolohan, N., Mățău, F., Tencariu, A.F., Eds.; Editura Universității „Alexandru Ioan Cuza” din Iași: Iași, Romania, 2010; pp. 229–244. [Google Scholar]

- Popescu, A.; Băjenaru, R. From the Middle Danube to Anatolia: Contacts During the Second Millennium BC. A Case Study. In SOMA 2011, Proceedings of the 15th Symposium on Mediterranean Archaeology, University of Catania, Catania, Italy, 3–5 March 2011; Militello, P.M., Öniz, H., Eds.; BAR IS 2695 (I): Oxford, UK, 2015; pp. 35–43. [Google Scholar]

- Bolohan, N.; Gafincu, A.; Stoleriu, I. Middle Bronze Age Chronology East of the Carpathian Area. A Bayesian Model. In Bronze Age Chronology in the Carpathian Basin, Proceedings of the International Colloquium from Târgu Mureș, Romania, 2–4 October 2014; Németh, R.E., Rezi, B., Eds.; Editura Mega: Târgu Mureș, Romania, 2015; pp. 131–146. [Google Scholar]

- Vulpe, A. Voice Costișa. In Enciclopedia Arheologiei și Istoriei Vechi a României 1 (A–C); Preda, C., Ed.; Editura Enciclopedică: București, Romania, 1994; p. 362. [Google Scholar]

- Vulpe, A. Perioada Mijlocie a Epocii Bronzului. In Istoria Românilor I, Moștenirea Timpurilor Îndepărtate, 2nd ed.; revised; Petrescu-Dîmbovița, M., Vulpe, A., Eds.; Editura Enciclopedică: București, Romania, 2010; pp. 244–265. [Google Scholar]

- Bolohan, N. Recent Discoveries Belonging to Early/Middle Bronze Age in Central Moldavia. Arh. Mold. 2003, 26, 195–206. [Google Scholar]

- Bolohan, N.; Crețu, C. Recent Discoveries Belonging to Early/Middle Bronze Age in Central Moldova. In Thracians and Circumpontic World; Niculiță, I., Zanoci, A., Băț, M., Eds.; Cartdidact: Chișinău, Moldavia, 2004; pp. 55–76. [Google Scholar]

- Popescu, A.-D.; Băjenaru, R. Rivalries and conflicts in the bronze age: Two contemporary communities in the same space. Dacia NS 2009, 52, 5–22. [Google Scholar]

- Nițu, A.; Zamoșteanu, I.; Zamoșteanu, M. Sondajele de la Piatra-Neamț. MCA 1959, 6, 359–374. [Google Scholar]

- Diaconu, V. Repertoriul Descoperirilor Atribuite Epocii Bronzului din Județul Neamț; Editura „Constantin Matasă”: Piatra-Neamț, Romania, 2016. [Google Scholar]

- Geological Map of Romania, Scale 1:200000; Editura Institutului Geologic al României: București, Romania, 1968.

- Soil Map of Romania, Scale 1:1000000; Institutul de Geodezie, Fotogrammetrie, Cartografie și Organizarea Teritoriului: București, Romania, 1978.

- Prehistoric Ceramics Research Group. The Study of Prehistoric Pottery: General Policies and Guidelines for Analysis and Publication, 3rd ed.; Wessex Archaeology Ltd.: Salisbury, UK, 2010. [Google Scholar]

- Rice, P.M. Pottery Analysis: A Sourcebook; University of Chicago Press: Chicago, IL, USA, 1987. [Google Scholar]

- Vuković, J. Archaeological Evidence of Pottery Forming Sequence: Traces of Manufacture in Late Neolithic Vinća Assemblage. In Archaeotechnology: Studying Technology from Prehistory to the Middle Ages; Vitezović, S., Antonović, D., Eds.; DC Grafički Centar: Belgrade, Serbia, 2014; pp. 177–199. [Google Scholar]

- Roux, V. La Technique du Tournage: Définition et Reconnaissance par les Macrotraces. In Terre Cuite et Société. La Céramique, Document Technique, Économique et Culturel. XIVe Rencontres Internationales d’Archéologie et d’Histoire d’Antibes; Audouze, F., Binder, D., Eds.; Editions APDCA: Juan-les-Pins, France, 1994; pp. 45–58. [Google Scholar]

- Joukowsky, M. A Complete Manual of Field Archaeology, Tools and Techniques of Field Work for Archaeologists; Prentice-Hall INC: New Jersey, NJ, USA, 1980. [Google Scholar]

- Henrickson, E.; McDonald, M.M.A. Ceramic form and Function: An Ethnographic Search and an archaeological Application. Am. Anthropol. 1983, 85, 630–643. [Google Scholar] [CrossRef]

- Bodi, G.; Solcan, L. Considerații asupra unei posibile tipologii funcționale a formelor ceramice cucuteniene specifice fazei A. Arh. Mold. 2010, 33, 315–323. [Google Scholar]

- Forte, V.; Cesaro, S.N.; Medeghini, L. Cooking traces on Copper Age pottery from central Italy: An integrated approach comparising use wear analysis, spectroscopic analysis and experimental archaeology. JAS Rep. 2018, 18, 121–138. [Google Scholar] [CrossRef]

- Vitelli, K.D. Were pots first made for foods? Doubts from Franchthi. World Archaeol. 1989, 21, 17–29. [Google Scholar] [CrossRef]

- Orton, C.; Tyres, P.; Vince, A. Pottery in Archaeology; Cambridge University Press: London, UK, 1993. [Google Scholar]

- Rye, O.S. Pottery Technology, Principles and Reconstruction (Manuals on Archaeology); Taraxacum: Washington, WA, USA, 1981. [Google Scholar]

- Ionescu, C.; Hoeck, V. Ceramic technology. How to investigate surface finishing. Archaeol. Anthrop. Sci. 2020, 12, 204–220. [Google Scholar] [CrossRef]

- Tite, M.S. Ceramic production, provenance and use–a review. Archaeometry 2008, 50, 216–231. [Google Scholar] [CrossRef]

- Ionescu, C.; Ghergari, L. Mic glosar de termeni geologici utilizați în studiul ceramicii arheologice. CA 2006, 33, 451–460. [Google Scholar] [CrossRef]

- Kreiter, A. Technological Choices and Material Meanings in Early and Middle Bronze Age Hungary: Understanding the Active Role of Material Culture through Ceramic Analysis; BAR IS 1604, Archaeopress: Oxford, UK, 2007. [Google Scholar]

- Skibo, J.M.; Schiffer, M.B.; Reid, K.C. Organic-tempered pottery: An experimental study. Am. Antiq. 1989, 54, 122–146. [Google Scholar] [CrossRef]

- Palanivel, R.; Meyvel, S. Microstructural and microanalytical study–(SEM) of archaeological pottery artifacts. Rom. J. Phys. 2010, 55, 333–341. [Google Scholar]

- Łaciaka, D.; Borowskib, M.P.; Łydżba-Kopczyńskac, B.; Barona, J.; Furmaneka, M. Archaeometric characterization and origin of black coatings on prehistoric pottery. Geochem. Int. 2019, 79, 453–466. [Google Scholar] [CrossRef]

- Maniatis, Y.; Tite, M.S. Technological Examination of Neolithic–Bronze Age Pottery from Central and Southeast Europe and from the Near East. J. Archaeol. Sci. 1981, 8, 59–76. [Google Scholar] [CrossRef]

- Karapukaitytė, A.; Pakutinskienė, I.; Tautkus, S.; Kareiva, A. SEM and EDX characterization of ancient pottery. Lith. J. Phys. 2006, 46, 383–388. [Google Scholar] [CrossRef]

- Amicone, S.; Radivojević, M.; Quinn, P.S.; Berthold, C.; Rehren, T. Pyrotechnological connections? Re-investigating the link between pottery firing technology and the origins of metallurgy in the Vinča Culture, Serbia. J. Archaeol. Sci. 2020, 11, 1–19. [Google Scholar] [CrossRef]

- Sandu, I.; Vasilache, V.; Tencariu, F.A.; Cotiugă, V. Conservarea Științifică a Artefactelor din Ceramică; Editura Universității „Alexandru Ioan Cuza”: Iași, România, 2010. [Google Scholar]

- Sandu, I.; Cotiugă, V.; Sandu, A.V.; Ciocan, A.C.; Olteanu, G.I.; Vasilache, V. New archaeometric characteristics for ancient pottery identification. Int. J. Conserv. Sci. 2010, 1, 75–82. [Google Scholar]

- Vasilache, V.; Sandu, I.; Enea, S.C.; Sandu, I.G. Determinări ceramografice pe loturi din siturile Costești și Giurgești. In Comunitățile Cucuteniene din Zona Târgului Frumos: Cercetări Interdisciplinare în Siturile de la Costești și Giurgești; Boghian, D., Enea, S.C., Ignătescu, S., Stanc, S.M., Eds.; Editura Universității „Alexandru Ioan Cuza”: Iași, Romania, 2014; pp. 138–147. [Google Scholar]

- Crupi, V.; Kasztovszky, Z.; Khalilli, F.; La Russa, M.F.; Macchia, A.; Majolino, D.; Rossi, B.; Rovella, N.; Ruffolo, S.A.; Venuti, V. Evaluation of complementary methodologies applied to a preliminary archaeometric study of glazed pottery from Agsu (Azerbaijan). Int. J. Conserv. Sci. 2016, 7, 901–912. [Google Scholar]

- Sharmin, D. Technological Interpretation of Traditional Ceramic Materials on Thin-Section Petrography. Int. J. Conserv. Sci. 2020, 11, 539–556. [Google Scholar]

- Sandu, I.G.; Vasilache, V.; Cotiugă, V. Revaluation of archaeological ceramics assets under generally accepted principles of integrated scientific conservation. Int. J. Conserv. Sci. 2010, 1, 241–247. [Google Scholar]

- Ravisankar, R.; Kiruba, S.; Shamira, C.; Naseerutheen, A.; Balaji, P.D.; Seran, M. Spectroscopic techniques applied to characterization of recently excavated ancient potteries from Thruverkadu Tamilandu, India. Microchem. J. 2011, 99, 370–375. [Google Scholar] [CrossRef]

- Duma, G. Phosphate Content of Ancient Pots as Indication of Use. Curr. Anthropol. 1972, 13, 127–130. [Google Scholar] [CrossRef]

- Béarat, H.; Dufournier, D. Quelques expériences sur la fixation du phosphore par les céramiques. Revue d’Archéométrie 1972, 18, 65–73. [Google Scholar] [CrossRef]

- Santos Rodrigues, S.F.; Lima da Costa, M. Phosphorus in archaeological ceramics as evidence of the use of pots for cooking food. Appl. Clay Sci. 2016, 123, 224–231. [Google Scholar] [CrossRef]

- Bong, W.S.K.; Matsumura, K.; Nakai, I. Firing Technologies and Raw Materials of Typical Early and Middle Bronze Age Pottery from Kaman-Kalehöyük: A Statistical and Chemical Analysis. Anatol. Stud. 2008, 17, 295–311. [Google Scholar]

- Aroke, U.O.; Abdulkarim, A.; Ogubunka, R.O. Fourier-transform Infrared Characterization of Kaolin, Granite, Bentonite and Barite. ATBU J. Environ. Technol. 2013, 6, 42–53. [Google Scholar]

- Frost, R.L.; Vassallo, A.M. The dehydroxylation of the kaolinite clay minerals using infrared emission spectroscopy. Clays Clay Miner. 1996, 44, 635–651. [Google Scholar] [CrossRef]

- Damjanović, L.; Holclajtner-Antunović, I.; Mioć, U.B.; Bikić, V.; Milovanović, D.; Radosavlkević Evans, I. Archaeometric study of medieval pottery excavated at Stari (old) Ras, Serbia. J. Archaeol. Sci. 2011, 38, 818–828. [Google Scholar] [CrossRef]

- Chen, Y.; Zou, C.; Mastalerz, M.; Hu, S.; Gasaway, C.; Tao, X. Applications of Micro-Fourier Transform Infrared Spectroscopy (FTIR) in the Geological Sciences—A Review. Int. J. Mol. Sci. 2015, 16, 30223–30250. [Google Scholar] [CrossRef]

- Oancea, A.V.; Bodi, G.; Nica, V.; Ursu, L.E.; Drobota, M.; Cotofana, C.; Vasiliu, A.L.; Simionescu, B.C.; Olaru, M. Multi-analytical characterization of Cucuteni pottery. J. Eur. Ceram. 2017, 37, 5079–5098. [Google Scholar] [CrossRef]

- Velraj, G.; Janaki, K.; Mustafa, A.M.; Palanivel, R. Estimation of firing temperatures of some archaeological pottery sherds excavated recently in Tamilandu, India. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2009, 72, 730–733. [Google Scholar] [CrossRef]

- Ravisankar, R.; Kiruba, S.; Eswaran, P.; Senthilkumar, G.; Chandrasekaran, A. Mineralogical Characterization Studies of Ancient Potteries of Tamilnadu, India by FT-IR Spectroscopic Technique. E-J. Chem. 2010, 7, S185–S190. [Google Scholar] [CrossRef]

- Nodari, L.; Marcuz, E.; Maritan, L.; Mazzoli, C.; Russo, U. Hematite nucleation and growth in the firing of carbonate-rich clay for pottery production. J. Eur. Ceram. 2007, 27, 4665–4673. [Google Scholar] [CrossRef]

- Gasaway, C.; Mastalerz, M.; Krause, F.; Clarkson, C.; Debuhr, C. Applicability of Micro-FTIR in Detecting Shale Heterogenity. Microscopy 2017, 265, 60–72. [Google Scholar] [CrossRef] [PubMed]

- Palanivel, R.; Kumar, U.R. Thermal and spectroscopic analysis of ancient potteries. Rom. J. Phys. 2011, 56, 195–208. [Google Scholar]

- Kumar, R.S.; Rajkumar, P. Characterization of minerals in air dust particles in the state of Tamilandu, India through FTIR Spectroscopy. Infrared Phys. Tchenol. 2014, 67, 30–41. [Google Scholar] [CrossRef]

- Barilaro, D.; Barone, G.; Crupi, V.; Majolino, D.; Mazzoleni, P.; Tigano, G.; Venuti, V. FT-IR absorbance spectroscopy to study Sicilian ‘‘proto-majolica’’ pottery. Vib. Spectrosc. 2008, 48, 269–275. [Google Scholar] [CrossRef]

- Vasilache, V.; Kavruk, V.; Tencariu, F.A. OM, SEM-EDX, and micro-FTIR analysis of the Bronze Age pottery from the Băile Figa salt production site (Transylvania, Romania). Microsc. Res. Tech. 2020, 83, 604–617. [Google Scholar] [CrossRef]

- Akyuza, S.; Guliyev, F.; Celik, S.; Ozel, A.E.; Alakbarov, V. Investigations of the Neolithic potteries of 6th millennium BC from Goytepe-Azerbaijan by vibrational spectroscopy and chemometric techniques. Vib. Spectrosc. 2019, 105, 102980. [Google Scholar] [CrossRef]

- Columbini, M.P.; Giachi, G.; Modugno, F.; Ribechini, E. Characterization of organic residues in pottery vessels of Roman age from Antinoe (Egypt). Microchem. J. 2005, 79, 83–90. [Google Scholar] [CrossRef]

- Maritan, L.; Mazzoli, C.; Nodari, L.; Russo, U. Second Iron Age grey pottery from Este (northeastern Italy): Study of provenance and technology. Appl. Clay Sci. 2005, 29, 31–44. [Google Scholar] [CrossRef]

- Costa, T.G.; de Correia, M.D.M.; Reis, L.B.; dos Santos, S.S.; Machado, J.S.; Bueno, L.; da Silva Müller, I. Spectroscopic characterization of recently excavated archaeological potsherds of Taquaea/Itararé tradition from Tobias Wagner site (Santa Catarina-Brazil). J. Archaeol. Sci. Rep. 2017, 12, 561–568. [Google Scholar]

- Torrisi, L.; Venuti, V.; Crupi, V.; Silipigni, L.; Cutroneo, M.; Paladini, G.; Torrisi, A.; Havránek, V.; Macková, A.; La Russa, M.F.; et al. RBS, PIXE, Ion-Microbeam and SR-FTIR Analyses of Pottery Fragments from Azerbaijan. Heritage 2019, 2, 1852–1873. [Google Scholar] [CrossRef] [Green Version]

- Sotiropoulou, S.; Papliaka, Z.E.; Vaccari, L. Micro FTIR imaging for the investigation of deteriorated organic binders in wall painting stratigraphies of diferent techniques and periods. Microchem. J. 2016, 124, 559–567. [Google Scholar] [CrossRef]

- Bolohan, N. On Clay and Pots in the Middle Bronze Age. A case Study from Siliștea-Pe Cetățuie, Neamț County. In Bronze Age Crafts and Craftsmen in the Carpathian Basin, Proceedings of the International Colloquium from Târgu Mureș, Romania, 5–7 October 2012; Rezi, B., Németh, R.E., Berecki, S., Eds.; Editura Mega: Târgu Mureș, Romania, 2013; pp. 33–56. [Google Scholar]

| Sample | Elemental Composition in Weight Percent (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Si | Al | P | Mg | Ca | K | Na | Fe | Ti | C | O | |

| L1 | 24.65 | 9.42 | 1.30 | 0.84 | 1.83 | 3.76 | 0.34 | 4.63 | 1.43 | - | 51.80 |

| L2 | 22.30 | 9.96 | 2.10 | 1.46 | 1.86 | 2.50 | 0.60 | 3.42 | 0.72 | 0.64 | 54.44 |

| L3 | 26.22 | 9.94 | 2.44 | 1.14 | 1.47 | 2.68 | 0.37 | 4.96 | 0.56 | 0.55 | 49.67 |

| L4 | 26.24 | 9.81 | 2.55 | 1.25 | 1.46 | 2.41 | 0.72 | 5.47 | 0.71 | - | 49.38 |

| L5 | 23.44 | 9.10 | 1.37 | 1.21 | 2.70 | 3.07 | 0.70 | 4.27 | 0.85 | - | 53.29 |

| L6 | 22.76 | 8.26 | 2.51 | 0.80 | 2.43 | 3.17 | 0.64 | 4.45 | 0.92 | 0.27 | 53.79 |

| L7 | 22.18 | 9.94 | 2.30 | 1.33 | 2.13 | 2.97 | 0.53 | 5.11 | 0.82 | 0.23 | 52.46 |

| L8 | 23.95 | 10.80 | 3.04 | 1.17 | 1.43 | 2.23 | 0.78 | 4.91 | 0.66 | - | 51.03 |

| L9 | 18.27 | 7.14 | 2.10 | 0.70 | 2.60 | 2.15 | 0.52 | 3.79 | 0.40 | 1.19 | 61.14 |

| L10 | 22.57 | 10.10 | 4.75 | 0.95 | 2.37 | 2.17 | 0.90 | 5.15 | 0.84 | 0.22 | 49.98 |

| Sample | Elemental Composition in Weight Percent (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Si | Al | C | P | Mg | Ca | K | Na | Fe | Ti | O | |

| L11 | 12.14 | 7.95 | 7.07 | 5.23 | 1.14 | 4.13 | 1.68 | 0.80 | 5.97 | 0.49 | 53.40 |

| L11 E | 7.55 | 2.83 | 16.96 | 0.37 | 0.26 | 3.18 | 1.55 | 0.10 | 3.96 | 0.47 | 62.77 |

| L11 I | 7.85 | 2.95 | 22.21 | 1.47 | 0.35 | 5.32 | 1.56 | 0.12 | 4.49 | 0.40 | 53.28 |

| L11 I 2 | 5.68 | 2.53 | 22.91 | 1.43 | 0.40 | 6.63 | 1.77 | 0.28 | 2.77 | 0.54 | 55.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drob, A.; Vasilache, V.; Bolohan, N. The Interdisciplinary Approach of Some Middle Bronze Age Pottery from Eastern Romania. Appl. Sci. 2021, 11, 4885. https://doi.org/10.3390/app11114885

Drob A, Vasilache V, Bolohan N. The Interdisciplinary Approach of Some Middle Bronze Age Pottery from Eastern Romania. Applied Sciences. 2021; 11(11):4885. https://doi.org/10.3390/app11114885

Chicago/Turabian StyleDrob, Ana, Viorica Vasilache, and Neculai Bolohan. 2021. "The Interdisciplinary Approach of Some Middle Bronze Age Pottery from Eastern Romania" Applied Sciences 11, no. 11: 4885. https://doi.org/10.3390/app11114885

APA StyleDrob, A., Vasilache, V., & Bolohan, N. (2021). The Interdisciplinary Approach of Some Middle Bronze Age Pottery from Eastern Romania. Applied Sciences, 11(11), 4885. https://doi.org/10.3390/app11114885