The Influence of Quality Management System on the Operation of Periodical Technical Inspection Stations

Abstract

:1. Introduction

2. Minimum Requirements for Quality Management at the PTI in the Slovak Republic

- (a)

- Documented procedure (internal regulation), which:

- Includes the checking of the correctness of the issuing documents on roadworthiness testing, stamping, signing and confirmation of acquaintance of the vehicle operator or driver of the vehicle with the result of the roadworthiness test.

- Determines the responsibilities of individual employees.

- Determines voluntary training of individual employees with the aim to increase quality.

- Determines the procedure for the handling of complaints.

- Determines the regular periods of internal control, determines the form of output from the performed internal control.

- Determines the procedure for ensuring the security of the use of the national information system.

- (b)

- (c)

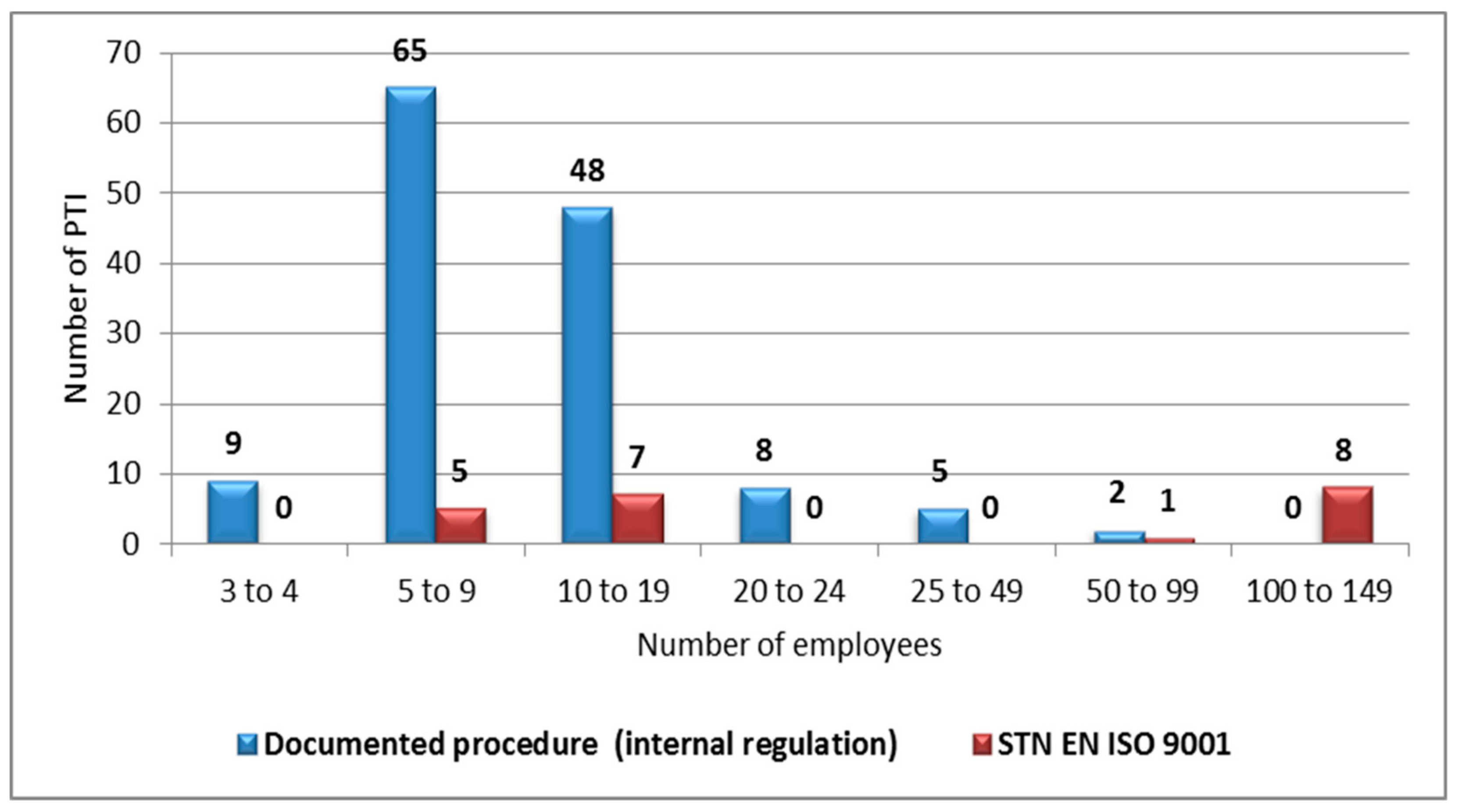

3. Survey on the Implemented Quality Management System at the PTI in the Slovak Republic

4. Evaluation of Technical Condition of Vehicles at the PTI

- 0.

- Vehicle identification;

- 1.

- Breaking equipment;

- 2.

- Steering control;

- 3.

- Clarity of view from the inside;

- 4.

- Lights equipment and parts of the electrical system;

- 5.

- Vehicle axles, wheels, tires, suspension;

- 6.

- Chassis and its accessories;

- 7.

- Other equipment;

- 8.

- Environmental impact;

- 9.

- (a)

- Minor defects, which do not affect the safety of the vehicle or the environment, as well as other minor non-conformities; the vehicle is “roadworthy for operation in road traffic”;

- (b)

- Major defects, which may affect the safety of the vehicle or the environment or pose a threat to other road traffic users, as well as other major cases of non-compliance; the vehicle is “temporarily roadworthy”;

- (c)

- Dangerous defects, which present a direct and immediate risk to road safety or have an impact on the environment and the use of the vehicle in road traffic must be prohibited; the vehicle is “not roadworthy for road traffic”.

5. The Influence of the Introduction of Quality Management System on the Results of PTI in Slovak Republic

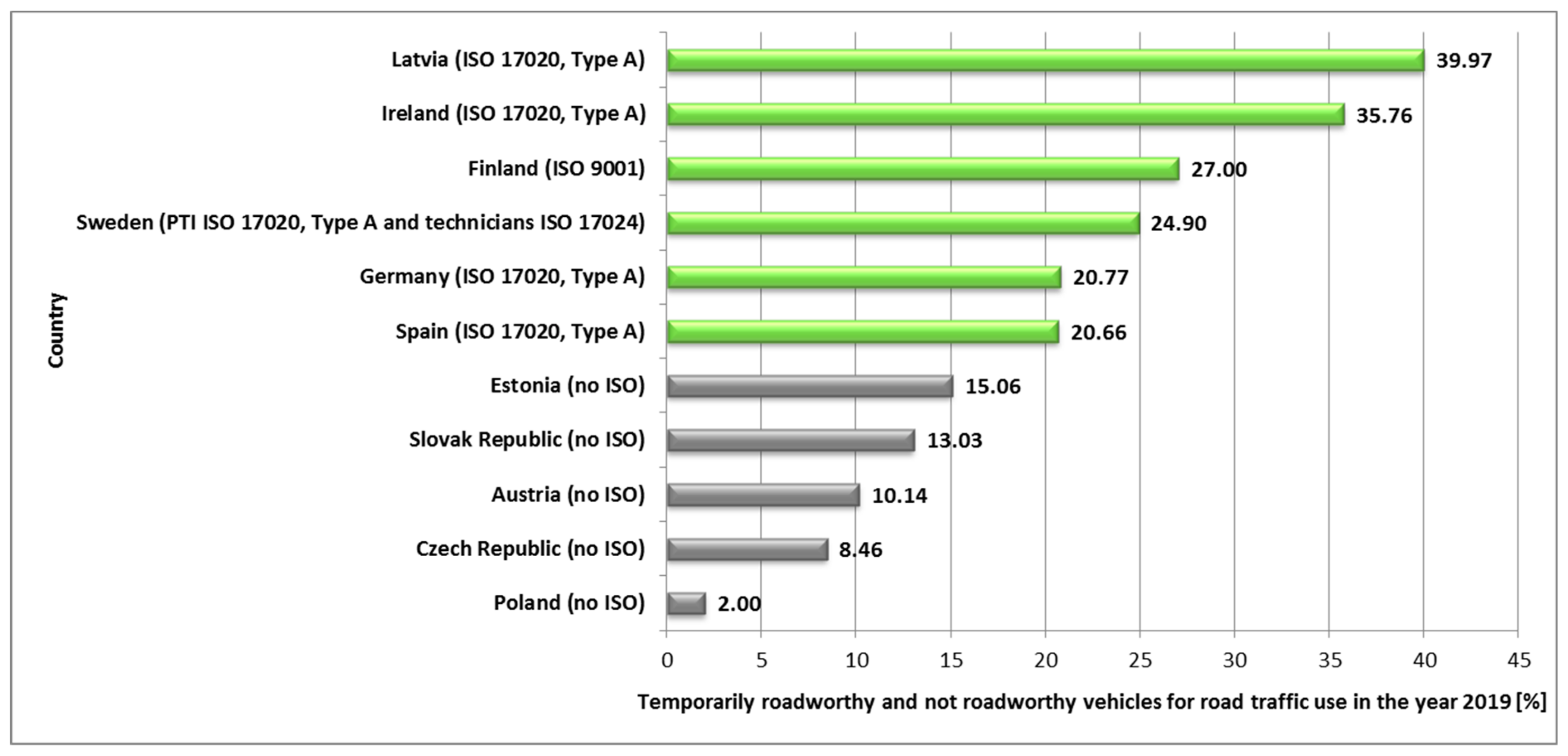

6. The Influence of the Introduction of Quality Management System on the Results of PTI in Selected Countries of the European Union

7. Discussion of the Results

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Konečný, V. Nástroje a metódy manažérstva kvality. In Návody na Cvičenia z Premetu Manažment Kvality, 1st ed.; Žilinská Univerzita: Žilina, Slovakia, 2012; ISBN 978-80-554-0601-5. [Google Scholar]

- Murphy, M.; Jiang, N.; Han, Z.; Hazlett, D.; Baumanis, C.; Ahsan, A.S.; Machemehl, R.; Zhang, Z. Economic and Safety Considerations: Motor Vehicle Safety Inspections for Passenger Vehicles in Texas; Texas Department of Public Safety, Center for Transportation Research at the University of Texas at Austin: Austin, TX, USA, 2018. [Google Scholar]

- Lejda, K.; Zielińska, E. Motor Vehicle Diagnosis in Terms of Technical Facilities Requirements. J. Pol. CIMAC 2013, 8, 61–70. [Google Scholar]

- Fazzalaro, J. Periodic Motor Vehicle Safety Inspections; Connecticut General Assembly Office of Legislative Research: Hartford, CT, USA, 2007; 2007-R-0591. Available online: https://www.cga.ct.gov/2007/rpt/2007-R-0591.htm (accessed on 30 November 2020).

- GAO; United States Government Accountability Office. Vehicle Safety Inspections: Improved DOT Communication Could Better Inform State Programs; Report to the Honorable Claire McCaskill; Report No. GAO-15-705l; U.S. Senate: Washington, DC, USA, 2015. [Google Scholar]

- Manitoba Infrastructure. The Official Website of Manitoba Province, Canada, Retrieved on 22 June 2018. Available online: http://www.gov.mb.ca/mit/mcd/mcs/index.html (accessed on 30 November 2020).

- Lukáč, S.; Marasová, D.; Mikušová, N.; Stopka, O. Quality management of information systems. Qual.-Access Success 2020, 21, 167–170. [Google Scholar]

- Zovak, G.; Cala, I.; Sisko, I. Application of standards in auditing of stations for technical inspections of vehicles. Promet-Traffic Transp. 2009, 21, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Bogucki, M.; Staçzek, P.; Płaska, S. Methods of improving quality product and process using experimental techniques. In Proceedings of the Second International CAMT Conference (Centre for Advanced Manufacturing Technologies), Modern Trends in Manufacturing, Wroclaw, Poland, 20–21 February 2003; pp. 15–20. [Google Scholar]

- Chovancova, M.; Klapita, V. Modeling the supply process using the application of selected methods of operational analysis. Open Eng. 2017, 7, 50–54. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, C.; Migliardi, A.; Tei, A. A bootstrap analysis to investigate the economic efficiency of the logistics industry in Italy. Int. J. Logist. Res. Appl. 2018, 21, 20–34. [Google Scholar] [CrossRef]

- Gola, A. Reliability analysis of reconfigurable manufacturing system structures using computer simulation methods. Eksploat. Niezawodn.-Maint. Reliab. 2019, 21, 90–102. [Google Scholar] [CrossRef]

- Swić, A.; Wołos, D.; Gola, A.; Šmidová, N. Accuracy control in the process of low-rigidity elastic deformable shafts turning. Teh. Vjesn. -Tech. Gaz. 2019, 26, 927–934. [Google Scholar]

- Stoma, M.; Dudziak, A.; Słowik, T.; Wasilewski, J.; Kuranc, A. Consumers’ perception of food quality and safety in terms of buying processes. In Proceedings of the Farm Machinery and Processes Management in Sustainable Agriculture, Lublin, Poland, 22–24 November 2017; Lorencowicz, E., Uziak, J., Huyghebaert, B., Eds.; Repozytorium CeON, University of Warsaw: Warsaw, Poland, 2017; pp. 354–358. [Google Scholar]

- Humić, R.; Abramović, B. Criteria for the quality of services of public interest organized by train operators. Transp. Res. Procedia 2019, 40, 259–264. [Google Scholar] [CrossRef]

- Stoma, M.; Dudziak, A.; Spalek, S. Strategic simulation games in management teaching. In Proceedings of the 13th International Technology, Education and Development Conference (INTED2019), INTED Proceedings, Valencia, Spain, 11–13 March 2019; pp. 4020–4028. [Google Scholar]

- Ngai, E.W.T.; Chau, D.C.K.; Poon, J.K.L.; To, C.K.M. Energy and utility management maturity model for sustainable manufacturing process. Int. J. Prod. Econ. 2013, 146, 453–464. [Google Scholar] [CrossRef]

- Vaughan, R.G. Safety maintenance of road vehicles. In Proceedings of the Institution of Mechanical Engineers, Braking of Road Vehicles, Birdcage Walk, London, UK, 23–24 March 1993. [Google Scholar]

- Droździel, P.; Winska, M.; Madlenak, R.; Szumski, P. Optimization of the position of the local distribution centre of the regional post logistics network. Transp. Probl. 2017, 12, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Simanová, Ľ.; Stasiak-Betlejewska, R. Selected approaches to change management and logistics in Slovak enterprises. LOGI-Sci. J. Transp. Logist. 2018, 9, 51–60. [Google Scholar] [CrossRef] [Green Version]

- Varhelyi, A. Road safety management—The need for a systematic approach. Open Transp. J. 2016, 10, 137–155. [Google Scholar] [CrossRef]

- Drozdziel, P.; Wrona, R. Legal and utility problems of accidents on express roads and motorways. In Proceedings of the 11th International Science and Technical Conference Automotive Safety 2018, Casta, Slovakia, 18–20 April 2018. [Google Scholar]

- Poliak, M.; Mrnikova, M.; Simurkova, P.; Medvid, P.; Poliakova, A.; Hernandez, S. Social law in road transport like tool safety road transport. In Proceedings of the 11th International Science and Technical Conference Automotive Safety 2018, Casta, Slovakia, 18–20 April 2018. [Google Scholar]

- Jurecki, R.S.; Poliak, M.; Jaskiewicz, M.J. Young adult drivers: Simulated behaviour in a car-following situation. Promet-Traffic Transp. 2017, 29, 381–390. [Google Scholar] [CrossRef]

- Ondrus, J.; Karoń, G. Video system as a psychological aspect of traffic safety increase. In Proceedings of the 17th International Conference on Transport Systems Telematics (TST), Katowice, Poland, 5–8 April 2017; Communications in Computer and Information Science. Volume 715, pp. 167–177. [Google Scholar] [CrossRef]

- Veternik, M.; Gogola, M. Examining of correlation between demographic development of population and their travel behaviour. Procedia Eng. 2017, 192, 929–934. [Google Scholar] [CrossRef]

- Bartuśka, L.; Stopka, O.; Lizbetin, J. Methodology for Determining the Traffic Volumes on Urban Roads in the Czech Republic. In Proceedings of 19th International Conference Transport Means 2015, Kaunas, Lithuania, 22–23 October 2015; pp. 215–218. [Google Scholar]

- Gnap, J.; Kupčuljaková, J.; Semanová, Š. Determination of time savings for passengers by applying the public passenger transport preference. Commun. Sci. Lett. Univ. Žilina 2018, 20, 3–8. [Google Scholar] [CrossRef]

- Lizbetin, J.; Bartuśka, L. The influence of human factor on congestion formation on urban roads. Procedia Eng. 2017, 187, 206–211. [Google Scholar] [CrossRef]

- Madleňak, R.; Hoštáková, D.; Madleňakova, L.; Drozdziel, P.; Török, A. The Analysis of the Traffic Signs Visibility During Night Driving. Adv. Sci. Technol. Res. J. 2018, 12, 71–76. [Google Scholar] [CrossRef]

- Matijosius, J.; Ciziuniene, K.; Petraska, A.; Sokolovskij, E. The comparison of the accident rates in heavy transport sectors of Europe and USA. In Proceedings of the Third International Conference on Traffic and Transport Engineering (ICTTE), Belgrade, Serbia, 24–25 November 2016; Cokorilo, O., Ed.; pp. 1097–1101. [Google Scholar]

- Tišljarić, L.; Carić, T.; Abramović, B.; Fratrović, T. Traffic state estimation and classification on citywide scale using speed transition matrices. Sustainability 2020, 12, 2547. [Google Scholar] [CrossRef]

- Abramović, B.; Lovrić, I.; Stupalo, V. Analysis of intermodal terminals service quality in the republic of Croatia. Promet-Traffic Transp. 2012, 24, 253–260. [Google Scholar] [CrossRef]

- Kilikevicius, A.; Kilikeviciene, K.; Matijosius, J. Investigation of drivers’ comfort factors influencing urban traffic safety. Lect. Notes Intell. Transp. Infrastruct. 2020, 159–165. [Google Scholar] [CrossRef]

- Kohút, P.; Macurová, Ľ.; Rédl, M.; Ballay, M. Application of rectification method for processing of documentation from the place of road accident. Arch. Automot. Eng. Arch. Motoryz. 2020, 88, 37–46. [Google Scholar]

- Makka, K.; Stachova, D.; Kampova, K. Assessment of the mobile risk source in road transport. Commun. Sci. Lett. Univ. Zilina 2019, 21, 68–73. [Google Scholar] [CrossRef]

- Samociuk, W.; Krzysiak, Z.; Bukova, B.; Brumercikova, E.; Bakowski, H.; Krzywonos, L. Analysis of international transport of chemical products in the countries of the Visegrad Group. Przem. Chem. 2018, 97, 829–833. [Google Scholar] [CrossRef]

- Zaranka, J.; Peceliunas, R.; Matijosius, J. Analysis of the influence of fatigue on passenger transport drivers’ performance capacity. Transport 2012, 27, 351–356. [Google Scholar] [CrossRef]

- Bańka, M.; Droździel, P.; Nieoczym, A. Lashing methods—Mathematical basis of the process of selecting the number of lashings. In Proceedings of the 23rd International Scientific Conference on Transport Means 2019, Palanga, Lithuania, 2–4 October 2019; pp. 99–103. [Google Scholar]

- Droździel, P.; Tarkowski, S.; Rybicka, I.; Wrona, R. Drivers’ reaction time research in the conditions in the real traffic. Open Eng. 2020, 10, 35–47. [Google Scholar] [CrossRef] [Green Version]

- Rievaj, V.; Vrábel, J.; Synak, F.; Bartuška, L. The effects of vehicle load on driving characteristics. Adv. Sci. Technol. Res. J. 2018, 12, 142–149. [Google Scholar] [CrossRef]

- Rodzeń, A.; Stoma, M.; Kuranc, A. Examination of vehicle exhaust gas analyzers in the context of the quality of periodic vehicle technical tests. Przem. Chem. 2018, 97, 762–766. [Google Scholar] [CrossRef]

- Sejkorová, M.; Verner, J.; Sejkora, F.; Hurtová, I.; Senkýř, J. Analysis of operation wear of brake fluid used in a Volvo car. In Proceedings of the International Conference 2018: Transport Means, Trakai, Lithuania, 3–5 October 2018; Kaunas University of Technology: Kaunas, Lithuania, 2018; pp. 592–596. [Google Scholar]

- Skrucany, T.; Kendra, M.; Kalina, T.; Jurkovič, M.; Vojtek, M.; Synák, F. Environmental comparison of different transport modes. Nase More 2018, 65, 192–196. [Google Scholar] [CrossRef]

- Tarkowski, S.; Rybicka, I. Distraction of the driver and its impact on road safety. Transp. Res. Procedia 2020, 44, 196–203. [Google Scholar] [CrossRef]

- Bartnik, G.; Krzysiak, Z.; Samociuk, W.; Łysiak, G.; Plizga, K.; Szmigielski, M.; Nieoczym, A.; Kaliniewicz, Z.; Brumerčik, F. Dokumentowanie spełniania wymagań w obszarze bezpieczeństwa technicznego na przykładzie dystrybucji paliw ciekłych. Przem. Chem. 2017, 96, 1039–1041. [Google Scholar] [CrossRef]

- Directive 2014/45/EU of the European Parliament and of the Council of 3 April 2014 on Periodic. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32014L0045&rid=5 (accessed on 20 November 2020).

- Roadworthiness Tests for Motor Vehicles and Their Trailers and of Repealing Directive 2009/40/ES. Available online: https://www.eumonitor.eu/9353000/1/j9vvik7m1c3gyxp/vi5uy1tr41z8 (accessed on 20 November 2020).

- STN EN ISO/IEC 17020 Conformity Assessments. Requirements for the operation of various types of bodies performing inspection. Available online: https://www.iso.org/obp/ui/#iso:std:52994:en (accessed on 25 November 2020).

- STN EN ISO 9001 Quality Management Systems. Available online: www.snas.sk (accessed on 25 October 2020).

- Law no. 106/2018 Z. z. On the Operation of Vehicles in Road Traffic and on the Change and Amendment of Certain Laws in View of Later Regulations. In Slovak. Available online: https://www.ssc.sk/en/legislation.ssc (accessed on 25 October 2020).

- Decree of the Ministry of Transport and Construction of the Slovak Republic no. 137/2018 Z. z. Laying Down the Details of the Periodical Technical Inspection. In Slovak. Available online: https://www.ssc.sk/en/legislation.ssc (accessed on 25 October 2020).

- STN EN ISO 9001 Quality Management Systems, Requirements (ISO 9001) (01 0320). Available online: https://www.iso.org/standard/62085.html (accessed on 25 November 2020).

- PTI in the Slovak Republic. Available online: www.mindop.sk (accessed on 25 October 2020).

- Skrúcaný, T.; Gnap, J. Energy intensity and greenhouse gases production of the road and rail Cargo transport using a software in simulate the energy consumption of a train, Telematics—Support of transport. In Proceedings of the 14th International Conference on Transport Systems Telematics, Katowice/Kraków and Ustroń, Poland, 22–25 October 2014. [Google Scholar]

- Number of Companies Operating PTIs by Number of Employees and Fulfilment of Quality Management Requirements. Available online: www.minv.sk (accessed on 25 October 2020).

- Additional Checks on Vehicles of Categories M2 and M3 Intended for Passenger Transport. Available online: www.finstat.sk (accessed on 25 October 2020).

- Methodological Instruction of the Ministry of Transport and Construction of the Slovak Republic No. 12/2018 on the License of the Inspector and Carrying Out the Expert Supervision of Compliance with Act No. 106/2018 Coll. on the Operation of Vehicles in Road Traffic as Amended. In Slovak. Available online: https://www.slov-lex.sk/static/vestniky/SK/RZ/MDVSR/V/2018/108/MP%2012-2018.pdf (accessed on 5 October 2020).

- Synák, F.; Kalašová, A.; Synák, J. Air filter and selected vehicle characteristics. Sustainability 2020, 12, 9326. [Google Scholar] [CrossRef]

- Hoagland, A.; Woolley, T. It’s No Accident: Evaluating the Effectiveness of Vehicle Safety Inspections. Contem. Econ. Policy 2018, 36, 607–628. [Google Scholar] [CrossRef] [Green Version]

- Czerwinski, J.; Comte, P.; Engelmann, D.; Mayer, A.; Lutz, T.; Hensel, V. Considerations of periodical technical inspection of vehicles with deNOx systems. SAE Tech. Paper 2019. [Google Scholar] [CrossRef]

- Tsybunov, E.; Shubenkova, K.; Buyvol, P.; Mukhametdinov, E. Interactive (Intelligent) Integrated System for the Road Vehicles’ Diagnostics. In Proceedings of the 1st International Conference on Intelligent Transport Systems INTSYS 2017, Hyvinkää, Finland, 29–30 November 2017; Volume 222, pp. 195–204. [Google Scholar] [CrossRef]

- Stopka, O.; Kampf, R.; Vrábel, J. Deploying the means of transport within the transport enterprises in the context of emission standards Transport means. In Proceedings of the 20th International Scientific Conference, Kaunas University of Technology, Juodkrante, Lithuania, 5–7 October 2016; pp. 185–190. [Google Scholar]

- Gajek, A. Directions for the development of periodic technical inspection for motor vehicles safety systems. Arch. Automot. Eng. Arch. Motoryz. 2018, 80, 37–51. [Google Scholar] [CrossRef]

- Results of the Evaluation of Vehicles at PTI Depending on the Method of Meeting the Requirements for Quality Management. Available online: www.testek.sk (accessed on 10 December 2020).

- Automated Information System for Technical Inspections. Available online: www.mindop.sk (accessed on 25 October 2020).

- Karpushko, M.O.; Bartolomei, I.L.; Karpushko, E.N. To a question of the setting of measures for culvert repair during technical inspection. In Proceedings of the International Scientific Conference on Construction and Architecture: Theory and Practice for the Innovation Development 2019, CATPID 2019, Kislovodsk, Russia, 1–5 October 2019; Volume 698, p. 077005. [Google Scholar] [CrossRef]

- Kravchenko, A.; Kravchenko, K. Monitoring of the technical condition of semi-trailer trucks. Arch. Automot. Eng. Arch. Motoryz. 2018, 81, 17–28. [Google Scholar] [CrossRef]

- Ondrus, J.; Kolla, E. Practical Use of the Braking Attributes Measurements Results. In Proceedings of the 18th International Scientific Conference on LOGI, MATEC Web Conference, Ceske Budejovice, Czech Republic, 19 October 2017; Volume 134, p. 00044. [Google Scholar] [CrossRef]

| Method of Meeting the Requirements for Quality Management at the PTI | Regions | All | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Bratislava | Trnava | Trenčín | Nitra | Žilina | Banská Bystrica | Prešov | Košice | ||

| documented procedure (internal regulation) | 17 | 20 | 13 | 15 | 14 | 21 | 18 | 19 | 137 |

| ISO/IEC 17020 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| STN EN ISO 9001 | 4 | 1 | 2 | 4 | 2 | 2 | 3 | 3 | 21 |

| All | 21 | 21 | 15 | 19 | 16 | 23 | 21 | 22 | 158 |

| Year | The Average Rate of Assessment of Temporary Roadworthiness and Not Roadworthiness of Vehicles for Road Traffic Use, Assessed by the PTI, Which Fulfil the Minimum Requirements for Quality Management by a Documented Procedure (Internal Regulation) | The Average Rate of Assessment of Temporary Roadworthiness and Not Roadworthiness of Vehicles for Road Traffic Use, Assessed by the PTI, Which Fulfil the Minimum Requirements for Quality Management According to STN EN ISO 9001 |

|---|---|---|

| 2019 | 12.52% | 14.17% |

| 2020 | 12.84% | 14.57% |

| F-Test Two-Sample for Variances | ||

|---|---|---|

| Variable 1 | Variable 2 | |

| Mean | 12.67635036 | 14.36952381 |

| Variance | 10.15508511 | 8.430314762 |

| Observations | 137 | 21 |

| df | 136 | 20 |

| F | 1.204591453 | |

| P(F ≤ f) one-tail | 0.32628342 | |

| F Critical one-tail | 1.890238594 | |

| F-Test Two-Sample for Variances | ||

|---|---|---|

| Variable 1 | Variable 2 | |

| Mean | 9.738 | 28.17666667 |

| Variance | 25.20812 | 64.01394667 |

| Observations | 5 | 6 |

| df | 4 | 5 |

| F | 0.393791061 | |

| P(F ≤ f) one-tail | 0.193727871 | |

| F Critical one-tail | 0.159845104 | |

| t-Test Two-Sample Assuming Equal Variances | ||

|---|---|---|

| Variable 1 | Variable 2 | |

| Mean | 12.67635036 | 14.36952381 |

| Variance | 10.15508511 | 8.430314762 |

| Observations | 137 | 21 |

| Pooled Variance | 9.933960708 | |

| Hypothesized Mean Difference | 0 | |

| df | 156 | |

| T Stat | −2.292353641 | |

| P(T ≤ t) one-tail | 0.011610975 | |

| t Critical one-tail | 1.654679996 | |

| P(T ≤ t) two-tail | 0.02322195 | |

| t Critical two-tail | 1.975287508 | |

| t-Test Two-Sample Assuming Equal Variances | ||

| Variable 1 | Variable 2 | |

| Mean | 9.738 | 28.17666667 |

| Variance | 25.20812 | 64.01394667 |

| Observations | 5 | 6 |

| Pooled Variance | 46.76691259 | |

| Hypothesized Mean Difference | 0 | |

| df | 9 | |

| t Stat | −4.45271038 | |

| P(T ≤ t) one-tail | 0.000796972 | |

| t Critical one-tail | 1.833112933 | |

| P(T ≤ t) two-tail | 0.001593944 | |

| t Critical two-tail | 2.262157163 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hudec, J.; Šarkan, B.; Czödörová, R.; Caban, J. The Influence of Quality Management System on the Operation of Periodical Technical Inspection Stations. Appl. Sci. 2021, 11, 4854. https://doi.org/10.3390/app11114854

Hudec J, Šarkan B, Czödörová R, Caban J. The Influence of Quality Management System on the Operation of Periodical Technical Inspection Stations. Applied Sciences. 2021; 11(11):4854. https://doi.org/10.3390/app11114854

Chicago/Turabian StyleHudec, Juraj, Branislav Šarkan, Renáta Czödörová, and Jacek Caban. 2021. "The Influence of Quality Management System on the Operation of Periodical Technical Inspection Stations" Applied Sciences 11, no. 11: 4854. https://doi.org/10.3390/app11114854

APA StyleHudec, J., Šarkan, B., Czödörová, R., & Caban, J. (2021). The Influence of Quality Management System on the Operation of Periodical Technical Inspection Stations. Applied Sciences, 11(11), 4854. https://doi.org/10.3390/app11114854