A Set Covering Model for a Green Ship Routing and Scheduling Problem with Berth Time-Window Constraints for Use in the Bulk Cargo Industry

Abstract

1. Introduction

2. Literature Review

2.1. Ship Routing and Scheduling Problems

2.2. Green Ship Routing and Scheduling Problem

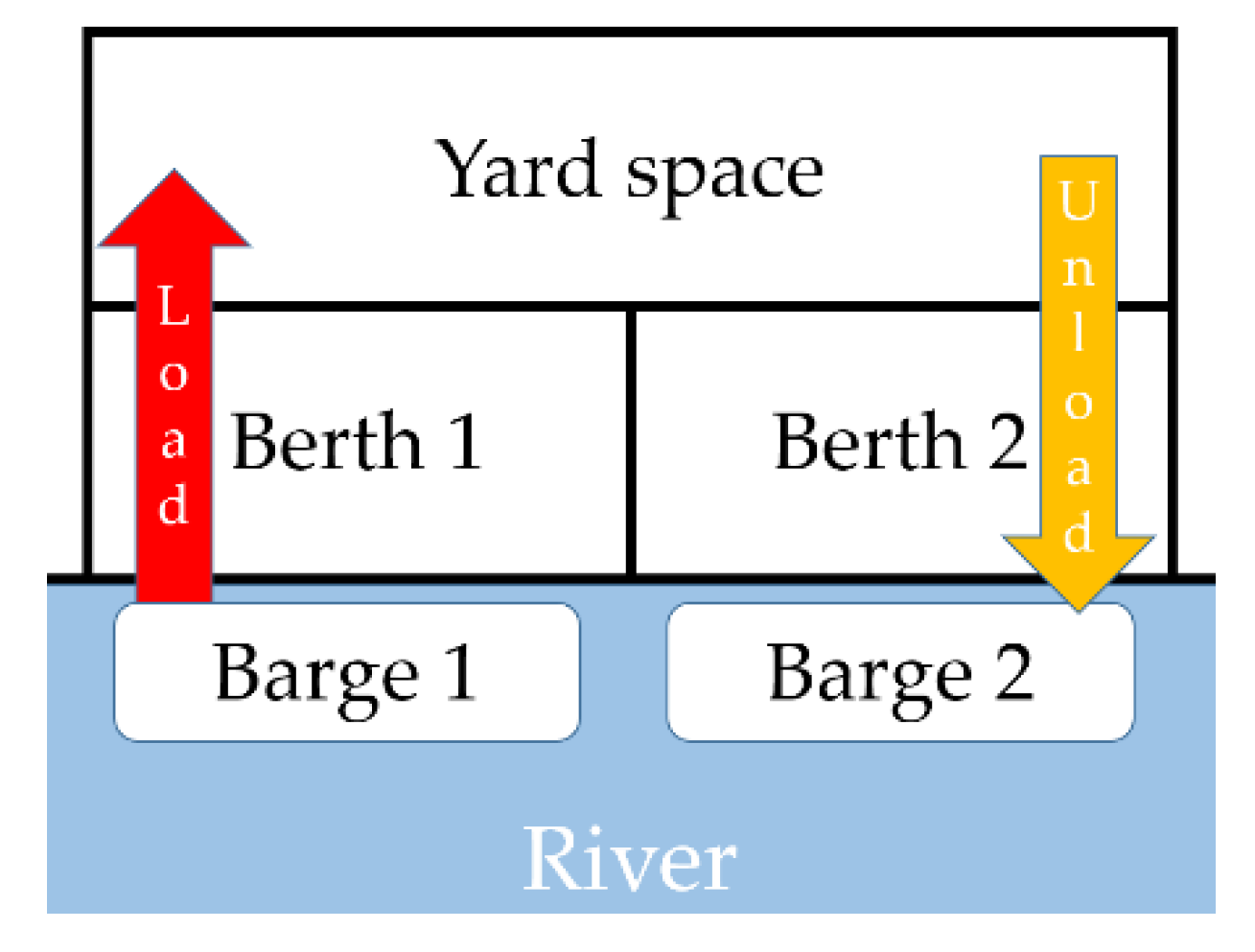

3. Problem Description

4. Proposed Method

| Set | |

| Set of feasible routes, | |

| Set of ports, | |

| Pv | Set of all ports used for job sequence numbers v in route r, pv ∈ Pv |

| Set of nodes, | |

| Vr | Set of job sequence numbers on route r, v ∈ Vr |

| S | Set of periods, |

| Svp | Set of periods for job sequence v operated from port p, svp∈Svp |

| G | Set of the number of Pareto solutions, g ∈ G |

| K | Set of the number of berths, k ∈ K |

| Kp | Set of the number of berths in port p, kp ∈ Kp |

| Parameters | |

| Emission factor—fuel consumption per liter. | |

| Emission factor for electricity consumption. | |

| Electricity consumed. | |

| Binary parameter that takes a value of 1 if job sequence v allows the loading or unloading of goods at berth k in period s and a value of 0 otherwise. | |

| Binary parameter that takes a value of 1 if job sequence v must load or unload of goods in port p within the specified time window and a value of 0 otherwise. | |

| Binary parameter that takes a value of 1 if the completion time of job sequence v in route r at port p is within the specified time window and a value of 0 otherwise. | |

| The number of trips required for transport job i using route r. | |

| Binary parameter that takes a value of 1 if the start time of job sequence v in route r is within the time windows of job sequence v and a value of 0 otherwise. | |

| Binary parameter that takes a value of 1 if the completion time of job sequence v in route r is within the time windows of job sequence v and a value of 0 otherwise. | |

| Earliest allowed arrival time for job sequence v operated in port p. | |

| Latest allowed arrival time for job sequence v operated in port p. | |

| Earliest allowed arrival time for job sequence v. | |

| Latest allowed arrival time for job sequence v. | |

| Start time for loading products from job sequence v in port p. | |

| Start time for unloading products from job sequence v in port p. | |

| Completion time for loading products from job sequence v in port p. | |

| Completion time for unloading products from job sequence v in port p. | |

| The amount of fuel used when traveling from node i to node j. | |

| The travel time taken when traveling from node i to node j. | |

| The service time at job i. Note that ti is dependent on the types of operation (either non-operation (job i is depot) or loading or unloading). where: | |

| Loading times at job i. | |

| Unloading times at job i. | |

| Binary parameter that takes a value of 1 if barge loading occurs at port p for transport job sequence v in route r in period s. | |

| Binary parameter that takes a value of 1 if barge unloading occurs at port p for transport job sequence v in route r in period s. | |

| The number of berths that are available in port p in period s. | |

| N | The carrier’s maximum number of barges |

| Time at which berth k in port p is ready. | |

| Latest allowed arrival time for berth k in port p. | |

| Variables | |

| The total CO2 equivalent emissions of route r. | |

| The total travel time for route r. | |

| Decision variables | |

| 1, if the barge traversed from job i to job j in route r. 0, otherwise. | |

| 1, if route r is selected. 0, otherwise. | |

4.1. Data Pre-Processing

4.2. Solving the Proposed Set Covering Model

4.2.1. Solving the Single Objective Set Covering Model

4.2.2. Setting the Number of Pareto Solutions

4.2.3. Plotting a Pareto Frontier

5. Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y. Application of New Technologies and Quality Standards System to Improve River Ship Officers’ Education and Training; World Maritime University: Malmö, Sweden, 1999. [Google Scholar]

- Beyer, A. Inland Waterways, Transport Corridors and Urban Waterfronts Discussion Paper; Organisation for Economic Co-operation and Development: Paris, France, 2018. [Google Scholar]

- NESDB. NESDB Economic Report; NESDB: Bangkok, Thailand, 2018. [Google Scholar]

- UNCTAD. Review of Maritime Transport; UNCTAD: New York, NY, USA, 2018. [Google Scholar]

- Kontovas, C.A. The Green Ship Routing and Scheduling Problem (GSRSP): A conceptual approach. Transp. Res. Part D Transp. Environ. 2014, 31, 61–69. [Google Scholar] [CrossRef]

- Buhaug, Ø.; Corbett, J.; Endresen, Ø.; Eyring, V.; Faber, J.; Hanayama, S.; Lee, D.; Lindstad, E.; Markowska, A.Z.; Mjelde, A.; et al. Second IMO GHG Study 2009; The International Maritime Organization: London, UK, 2009. [Google Scholar]

- Maneengam, A. A Bi-Objective Programming Model for Multimodal Transportation Routing Problem of Bulk Cargo Transportation. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–18 April 2020; pp. 890–894. [Google Scholar]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Ronen, D. Cargo ships routing and scheduling: Survey of models and problems. Eur. J. Oper. Res. 1983, 12, 119–126. [Google Scholar] [CrossRef]

- Ronen, D. Ship scheduling: The last decade. Eur. J. Oper. Res. 1993, 71, 325–333. [Google Scholar] [CrossRef]

- Christiansen, M.; Fagerholt, K.; Ronen, D. Ship Routing and Scheduling: Status and Perspectives. Transp. Sci. 2004, 38, 1–18. [Google Scholar] [CrossRef]

- Christiansen, M.; Fagerholt, K.; Nygreen, B.; Ronen, D. Ship routing and scheduling in the new millennium. Eur. J. Oper. Res. 2013, 228, 467–483. [Google Scholar] [CrossRef]

- Korsvik, J.E.; Fagerholt, K.; Laporte, G. A tabu search heuristic for ship routing and scheduling. J. Oper. Res. Soc. 2010, 61, 594–603. [Google Scholar] [CrossRef]

- Korsvik, J.E.; Fagerholt, K.; Laporte, G. A large neighbourhood search heuristic for ship routing and scheduling with split loads. Comput. Oper. Res. 2011, 38, 474–483. [Google Scholar] [CrossRef]

- Stålhane, M.; Andersson, H.; Christiansen, M.; Cordeau, J.F.; Desaulniers, G. A branch-price-and-cut method for a ship routing and scheduling problem with split loads. Comput. Oper. Res. 2012, 39, 3361–3375. [Google Scholar] [CrossRef]

- Kosmas, O.T.; Vlachos, D.S. Simulated annealing for optimal ship routing. Comput. Oper. Res. 2012, 39, 576–581. [Google Scholar] [CrossRef]

- Nishi, T.; Izuno, T. Column generation heuristics for ship routing and scheduling problems in crude oil transportation with split deliveries. Comput. Chem. Eng. 2014, 60, 329–338. [Google Scholar] [CrossRef]

- Lee, J.; Kim, B.I. Industrial ship routing problem with split delivery and two types of vessels. Expert Syst. Appl. 2015, 42, 9012–9023. [Google Scholar] [CrossRef]

- De, A.; Mamanduru, V.K.R.; Gunasekaran, A.; Subramanian, N.; Tiwari, M.K. Composite particle algorithm for sustainable integrated dynamic ship routing and scheduling optimization. Comput. Ind. Eng. 2016, 96, 201–215. [Google Scholar] [CrossRef]

- Guan, F.; Peng, Z.; Chen, C.; Guo, Z.; Yu, S. Fleet routing and scheduling problem based on constraints of chance. Adv. Mech. Eng. 2017, 9, 1–12. [Google Scholar] [CrossRef]

- Lin, D.Y.; Chang, Y.T. Ship routing and freight assignment problem for liner shipping: Application to the Northern Sea Route planning problem. Transp. Res. Part E: Logist. Transp. Rev. 2018, 110, 47–70. [Google Scholar] [CrossRef]

- Yamashita, D.; da Silva, B.J.V.; Morabito, R.; Ribas, P.C. A multi-start heuristic for the ship routing and scheduling of an oil company. Comput. Ind. Eng. 2019, 136, 464–476. [Google Scholar] [CrossRef]

- Li, F.; Yang, D.; Wang, S.; Weng, J. Ship routing and scheduling problem for steel plants cluster alongside the Yangtze River. Transp. Res. Part E: Logist. Transp. Rev. 2019, 122, 198–210. [Google Scholar] [CrossRef]

- Song, D.-P.; Li, D.; Drake, P. Multi-objective optimization for planning liner shipping service with uncertain port times. Transp. Res. Part E: Logist. Transp. Rev. 2015, 84, 1–22. [Google Scholar] [CrossRef]

- Dulebenets, M.A.; Golias, M.M.; Mishra, S. The green vessel schedule design problem: Consideration of emissions constraints. Energy Syst. 2017, 8, 761–783. [Google Scholar] [CrossRef]

- Dithmer, P.; Reinhardt, L.; Kontovas, C.A. The Liner Shipping Routing and Scheduling Problem Under Environmental Considerations: The Case of Emissions Control Areas BT—Computational Logistics. In Proceedings of the 8th International Conference (ICCL), Southampton, UK, 18–20 October 2017; pp. 336–350. [Google Scholar]

- Dulebenets, M.A. The green vessel scheduling problem with transit time requirements in a liner shipping route with Emission Control Areas. Alex. Eng. J. 2018, 57, 331–342. [Google Scholar] [CrossRef]

- Cheaitou, A.; Cariou, P. Greening of maritime transportation: A multi-objective optimization approach. Ann. Oper. Res. 2019, 273, 501–525. [Google Scholar] [CrossRef]

- Chen, G.; Wu, X.; Li, J.; Guo, H. Green vehicle routing and scheduling optimization of ship steel distribution center based on improved intelligent water drop algorithms. Math. Probl. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Zhen, L.; Hu, Z.; Yan, R.; Zhuge, D.; Wang, S. Route and speed optimization for liner ships under emission control policies. Transp. Res. Part C: Emerg. Technol. 2020, 110, 330–345. [Google Scholar] [CrossRef]

- Siahaan, J.J.A.; Pratiwi, E.; Setyorini, P.D. Study of Green-Ship Routing Problem (G-VRP) Optimization for Indonesia LNG Distribution. IOP Conf. Ser. Earth Environ. Sci. 2020, 557. [Google Scholar] [CrossRef]

- Baykasoğlu, A.; Subulan, K. A multi-objective sustainable load planning model for intermodal transportation networks with a real-life application. Transp. Res. Part E Logist. Transp. Rev. 2016, 95, 207–247. [Google Scholar] [CrossRef]

- Wibisono, E.; Jittamai, P. Multi-objective evolutionary algorithm for a ship routing problem in maritime logistics collaboration. Int. J. Logist. Syst. Manag. 2017, 28, 225. [Google Scholar] [CrossRef]

- Martínez-López, A.; Caamaño Sobrino, P.; Chica González, M.; Trujillo, L. Optimization of a container vessel fleet and its propulsion plant to articulate sustainable intermodal chains versus road transport. Transp. Res. Part D Transp. Environ. 2018, 59, 134–147. [Google Scholar] [CrossRef]

- Ma, W.; Ma, D.; Ma, Y.; Zhang, J.; Wang, D. Green maritime: A routing and speed multi-objective optimization strategy. J. Clean. Prod. 2021, 305, 127179. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, Y.; Zhang, Z.; Wang, H. Multicriteria ship route planning method based on improved particle swarm optimization–genetic algorithm. J. Mar. Sci. Eng. 2021, 9, 357. [Google Scholar] [CrossRef]

- De, A.; Choudhary, A.; Tiwari, M.K. Multiobjective Approach for Sustainable Ship Routing and Scheduling with Draft Restrictions. IEEE Trans. Eng. Manag. 2019, 66, 35–51. [Google Scholar] [CrossRef]

- Martínez-López, A. A multi-objective mathematical model to select fleets and maritime routes in short sea shipping: A case study in Chile. J. Mar. Sci. Technol. 2020, 1–20. [Google Scholar] [CrossRef]

- Maneengam, A.; Udomsakdigool, A. Solving the collaborative bidirectional multi-period vehicle routing problems under a profit-sharing agreement using a covering model. Int. J. Ind. Eng. Comput. 2020, 11, 185–200. [Google Scholar] [CrossRef]

- Maneengam, A.; Udomsakdigool, A. Solving the Bidirectional Multi-Period Full Truckload Vehicle Routing Problem with Time Windows and Split Delivery for Bulk Transportation Using a Covering Model. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 798–802. [Google Scholar]

- TGO (Thailand Greenhouse Gas Management Organization) Update Emission Factor CFP. Available online: http://thaicarbonlabel.tgo.or.th/admin/uploadfiles/emission/ts_822ebb1ed5.pdf (accessed on 20 January 2021).

- Chankong, V.; Haimes, Y.Y. Multiobjective Decision Making: Theory and Methodology; North-Holland/Elsevier Science Publishing Company, Inc.: New York, NY, USA, 1983; ISBN 0444007105. [Google Scholar]

- Friedrich, T.; Horoba, C.; Neumann, F. Multiplicative approximations and the hypervolume indicator. In Proceedings of the 11th Annual Genetic and Evolutionary Computation Conference (GECCO-2009), Montreal, QC, Canada, 8–12 July 2009; pp. 571–578. [Google Scholar] [CrossRef]

- Chiandussi, G.; Codegone, M.; Ferrero, S.; Varesio, F.E. Comparison of multi-objective optimization methodologies for engineering applications. Comput. Math. Appl. 2012, 63, 912–942. [Google Scholar] [CrossRef]

- Demir, E.; Hrušovský, M.; Jammernegg, W.; Van Woensel, T. Green intermodal freight transportation: Bi-objective modelling and analysis. Int. J. Prod. Res. 2019, 57, 6162–6180. [Google Scholar] [CrossRef]

- Zhao, Y.; Fan, Y.; Zhou, J.; Kuang, H. Bi-objective optimization of vessel speed and route for sustainable coastal shipping under the regulations of emission control areas. Sustainability 2019, 11, 6281. [Google Scholar] [CrossRef]

| Job (i) | Loading Operation (Oi,1) | Travel Operation (Oi,2) | Discharge Operation (Oi,2) |

|---|---|---|---|

| 1 | Port 2, Berth 1 | Port 2 > Port 1 | Port 1, Berth 1 |

| 2 | Port 1, Berth 1 | Port 1 > Port 2 | Port 2, Berth 2 |

| 3 | Port 1, Berth 2 | Port 1 > Port 2 | Port 2, Berth 1 |

| Location | Latitude, Longitude | Ready Time | Latest Allowed Arrival Time |

|---|---|---|---|

| 1 | (13.4735585, 100.98346600000002) | 1 | 17 |

| 2 | (13.6305239, 100.54398190000006) | 2 | 17 |

| 3 | (13.5234748, 100.26317930000005) | 3 | 18 |

| 4 | (14.0266045, 100.54322920000004) | 4 | 20 |

| 5 | (14.2508489, 100.58231790000002) | 2 | 19 |

| 6 | (14.3180176, 100.56809569999996) | 1 | 17 |

| 7 | (14.4157881, 100.59332919999997) | 2 | 18 |

| 8 | (14.4111553, 100.59306560000005) | 3 | 18 |

| 9 | (14.4772767, 100.6218513) | 3 | 18 |

| 10 | (13.140878, 100.823247) | 0 | 100 |

| Testing Instances | Number of Jobs (i) | Source > Destination | Ready Time of Job i–Latest Allowed Arrival Time of Job i |

|---|---|---|---|

| 1 | 6 | 8 > 10, 10 > 8, 10 > 5, 10 > 2, 9 > 10, 7 > 10 | 2–18 5–17, 1–20, 3–20, 1–20, 3–20 |

| 2 | 8 | 8 > 10, 10 > 6, 10 > 9, 7 > 10, 8 > 10, 10 > 2, 10 > 1, 5 > 10, | 1–17, 2–15, 3–16, 2–20, 3–17, 1–20, 4–15, 2–20 |

| 3 | 9 | 10 > 8, 7 > 10, 10 > 2, 10 > 3, 5 > 10, 10 > 8, 4 > 10, 10 > 6, 1 > 9, | 1–20, 4–17, 3–18, 5–17, 1–19, 4–18, 2–19, 3–18, 4–17 |

| Testing Instances | 1f1 | 2f2 |

|---|---|---|

| 1 | 64,427.55 | 55 |

| 2 | 74,107.45 | 55 |

| 3 | 83,244.64 | 68 |

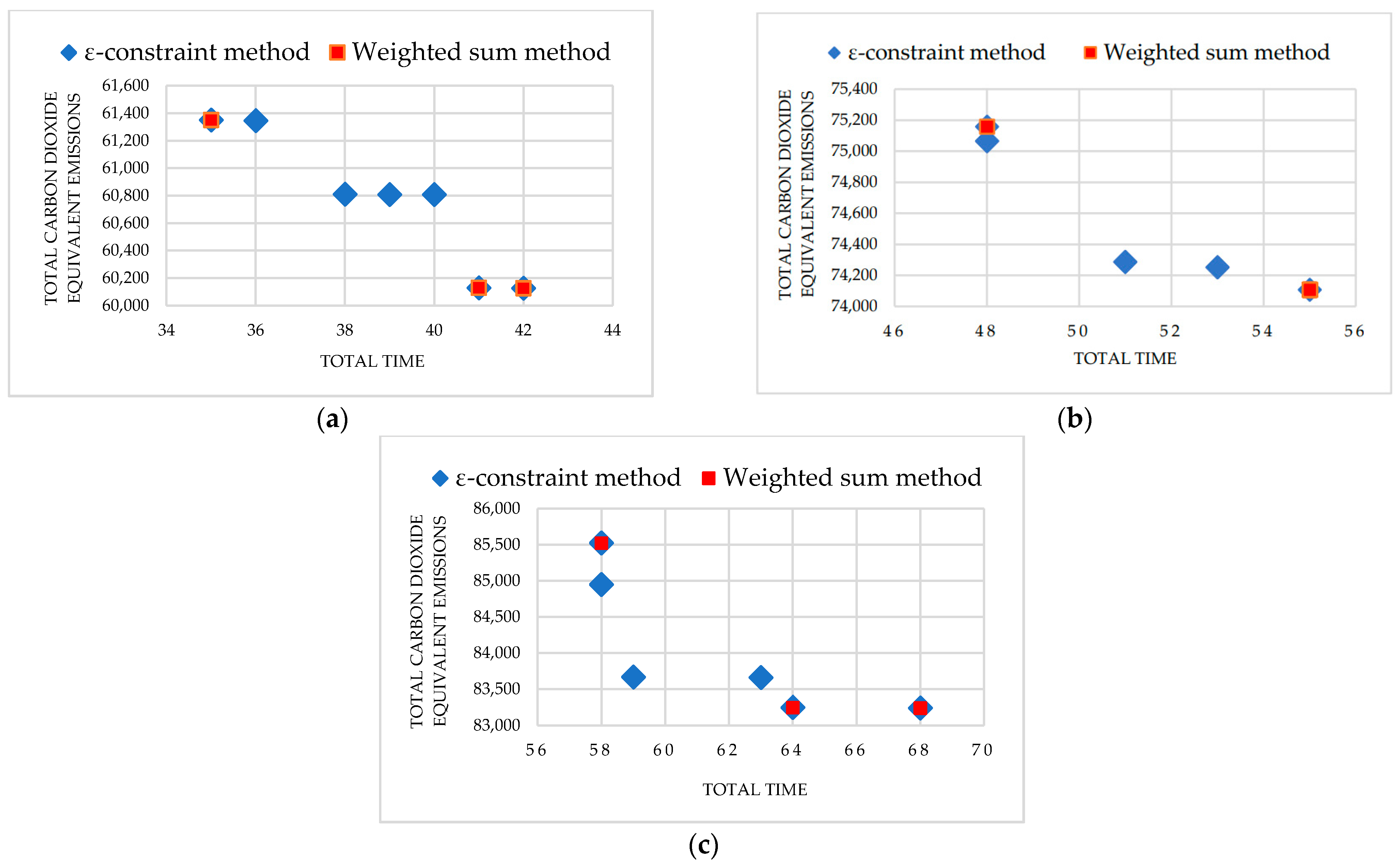

| Testing Instances | NO. | 2f2 | 1f1 Obtained from the ε-Constraint Method | 1f1 Obtained from the Weighted Sum Method |

|---|---|---|---|---|

| 1 | 35 | 61,350.20 | 61,350.20 | |

| 2 | 36 | 61,346.93 | - | |

| 3 | 38 | 60,811.46 | - | |

| 1 | 4 | 39 | 60,808.19 | - |

| 5 | 40 | 60,808.19 | - | |

| 6 | 41 | 60,129.29 | 60,129.29 | |

| 7 | 42 | 60,126.02 | 60,126.02 | |

| 1 | 48 | 75,159.00 | 75,159.00 | |

| 2 | 48 | 75,065.19 | - | |

| 2 | 3 | 51 | 74,287.01 | - |

| 4 | 53 | 74,251.77 | - | |

| 5 | 55 | 74,107.43 | 74,107.43 | |

| 1 | 58 | 85,523.51 | 85,523.51 | |

| 2 | 58 | 84,947.72 | - | |

| 3 | 59 | 83,668.38 | - | |

| 3 | 4 | 63 | 83,661.00 | - |

| 5 | 64 | 83,249.36 | 83,249.36 | |

| 6 | 68 | 83,241.98 | 83,241.98 |

| Testing Instances | 1 HVe | 2 HVw | HVe-HVw |

|---|---|---|---|

| 1 | 58.51% | 46.68% | 11.82% |

| 2 | 58.61% | 13.47% | 45.14% |

| 3 | 85.92% | 49.94% | 35.97% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maneengam, A.; Udomsakdigool, A. A Set Covering Model for a Green Ship Routing and Scheduling Problem with Berth Time-Window Constraints for Use in the Bulk Cargo Industry. Appl. Sci. 2021, 11, 4840. https://doi.org/10.3390/app11114840

Maneengam A, Udomsakdigool A. A Set Covering Model for a Green Ship Routing and Scheduling Problem with Berth Time-Window Constraints for Use in the Bulk Cargo Industry. Applied Sciences. 2021; 11(11):4840. https://doi.org/10.3390/app11114840

Chicago/Turabian StyleManeengam, Apichit, and Apinanthana Udomsakdigool. 2021. "A Set Covering Model for a Green Ship Routing and Scheduling Problem with Berth Time-Window Constraints for Use in the Bulk Cargo Industry" Applied Sciences 11, no. 11: 4840. https://doi.org/10.3390/app11114840

APA StyleManeengam, A., & Udomsakdigool, A. (2021). A Set Covering Model for a Green Ship Routing and Scheduling Problem with Berth Time-Window Constraints for Use in the Bulk Cargo Industry. Applied Sciences, 11(11), 4840. https://doi.org/10.3390/app11114840