Changes in Abrasive Wear Resistance during Miller Test of High-Manganese Cast Steel with Niobium Carbides Formed in the Alloy Matrix

Abstract

:1. Introduction

2. Materials and Methods

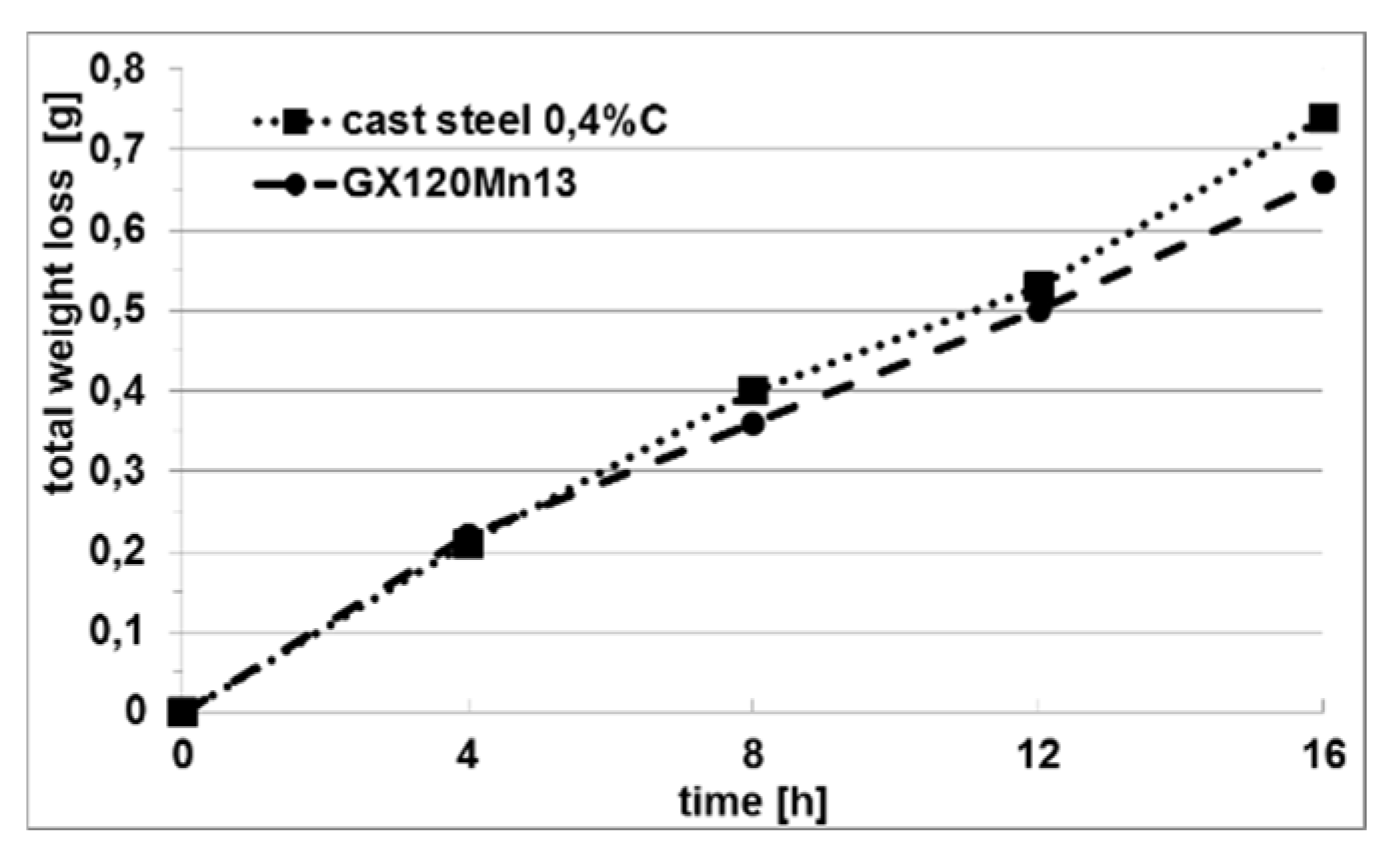

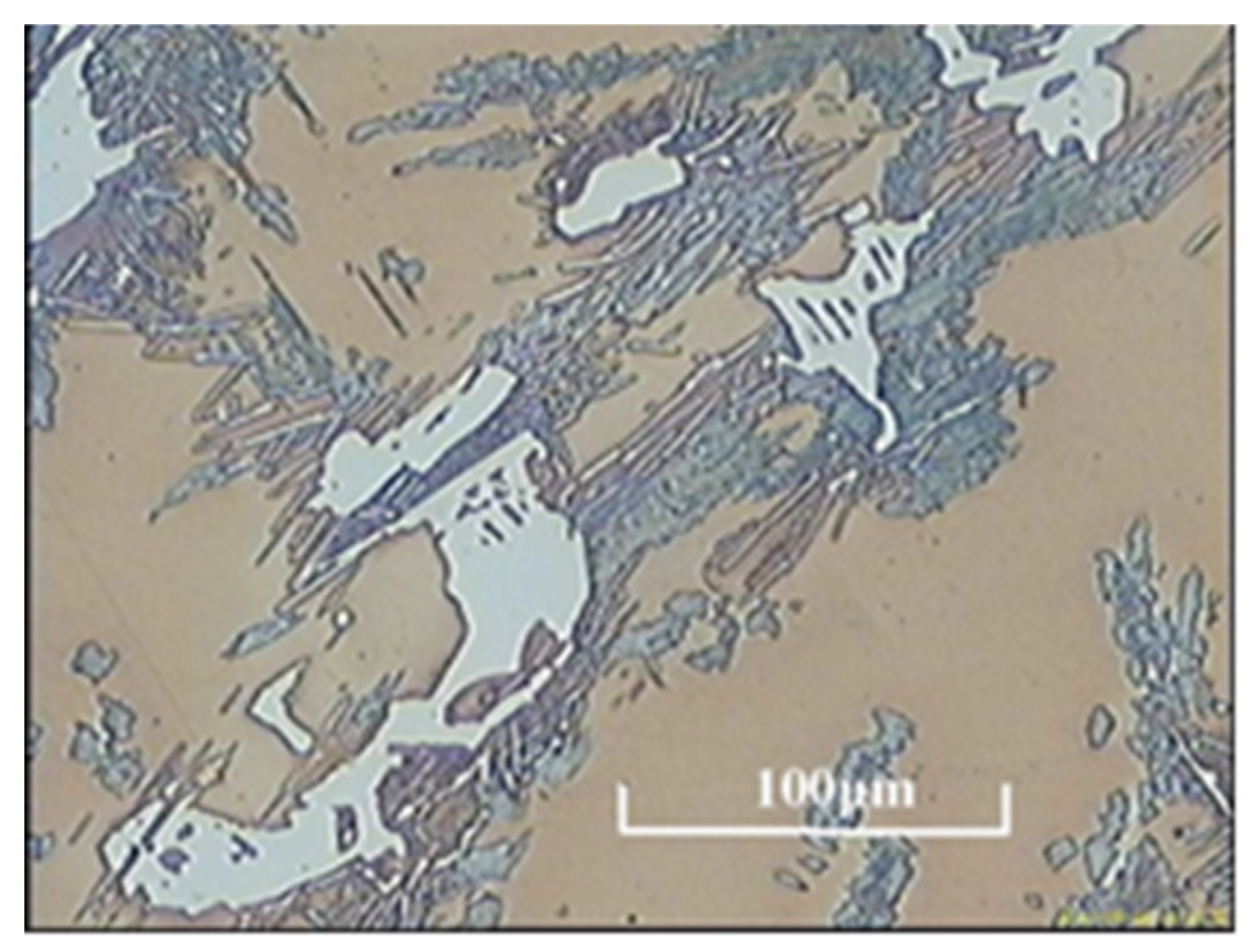

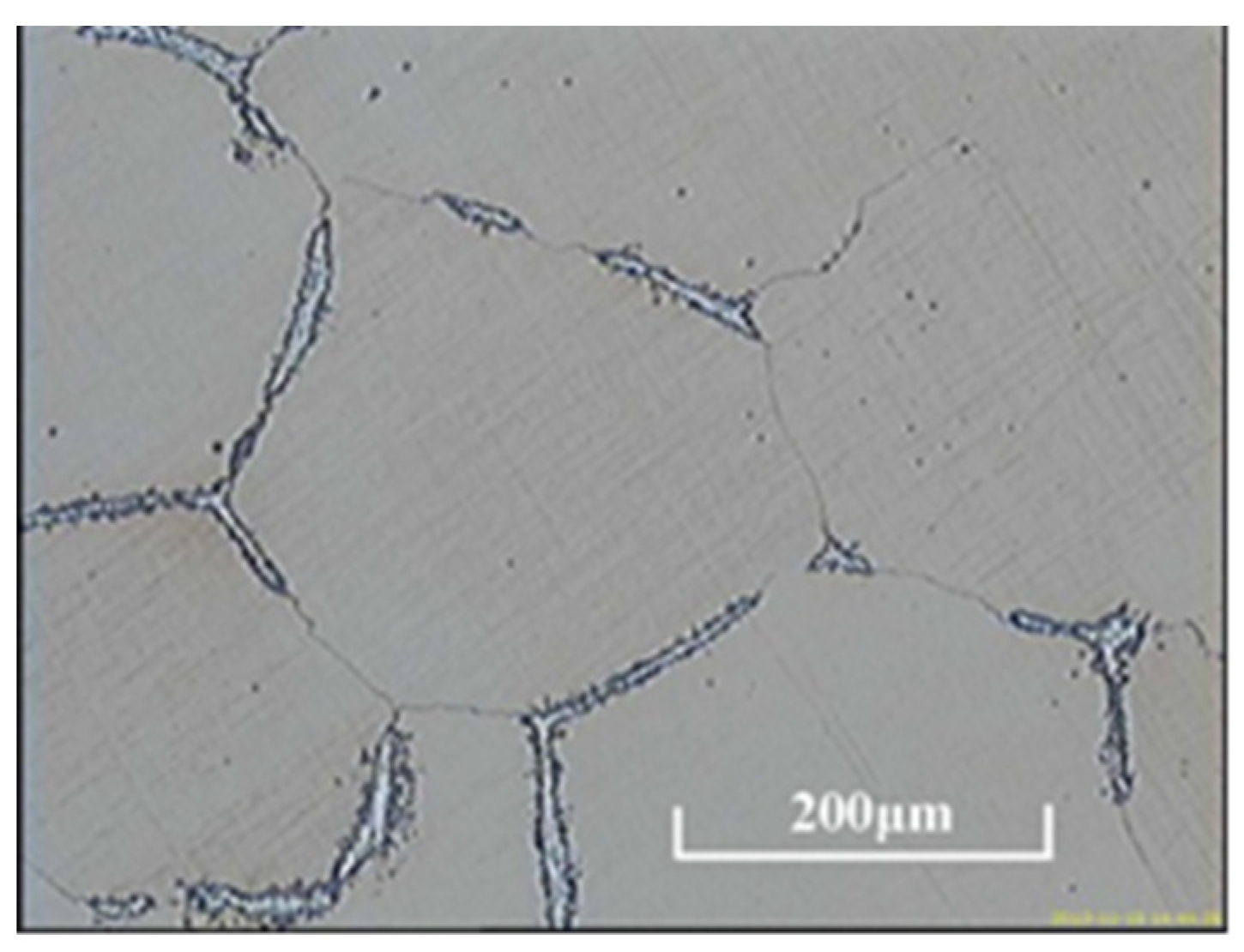

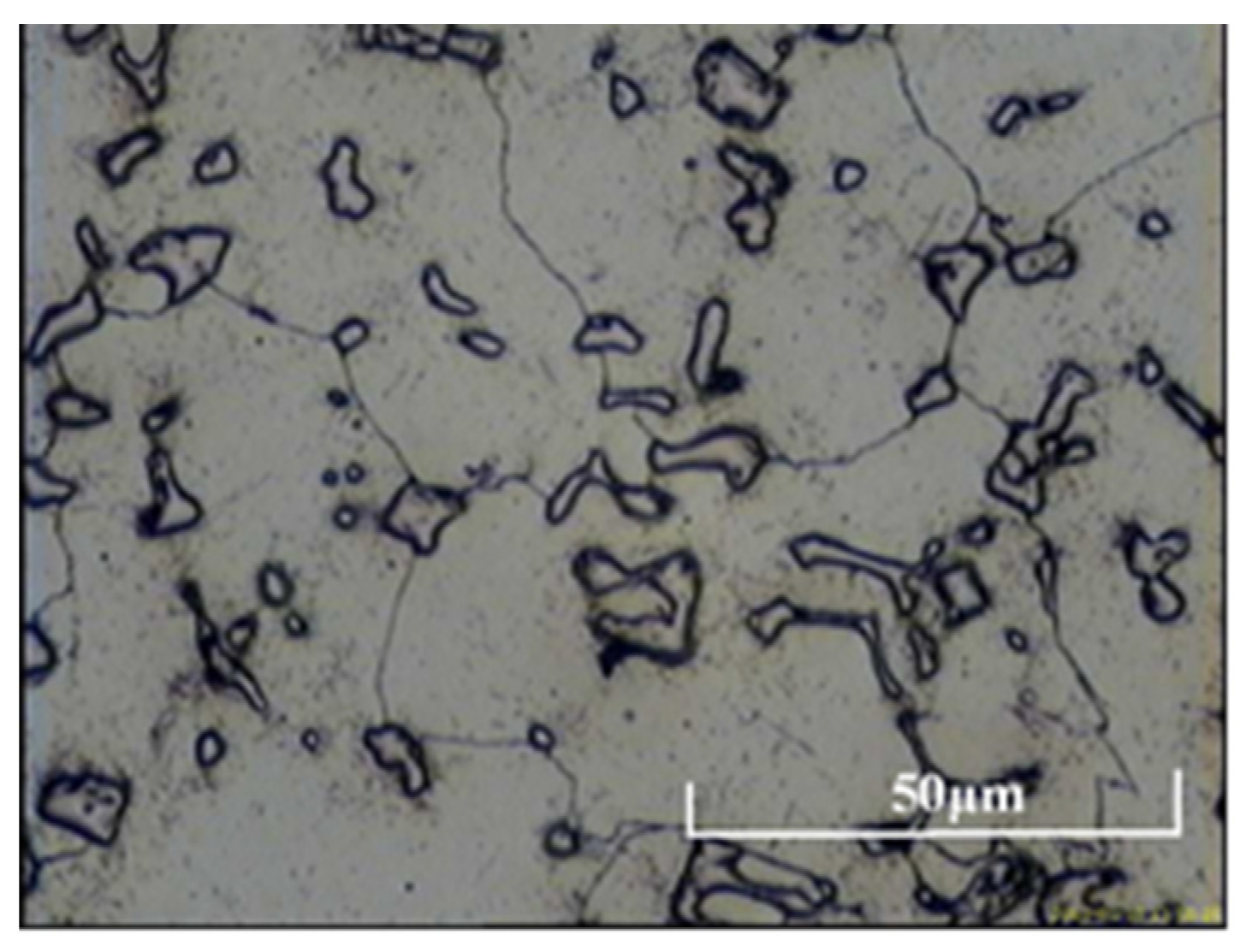

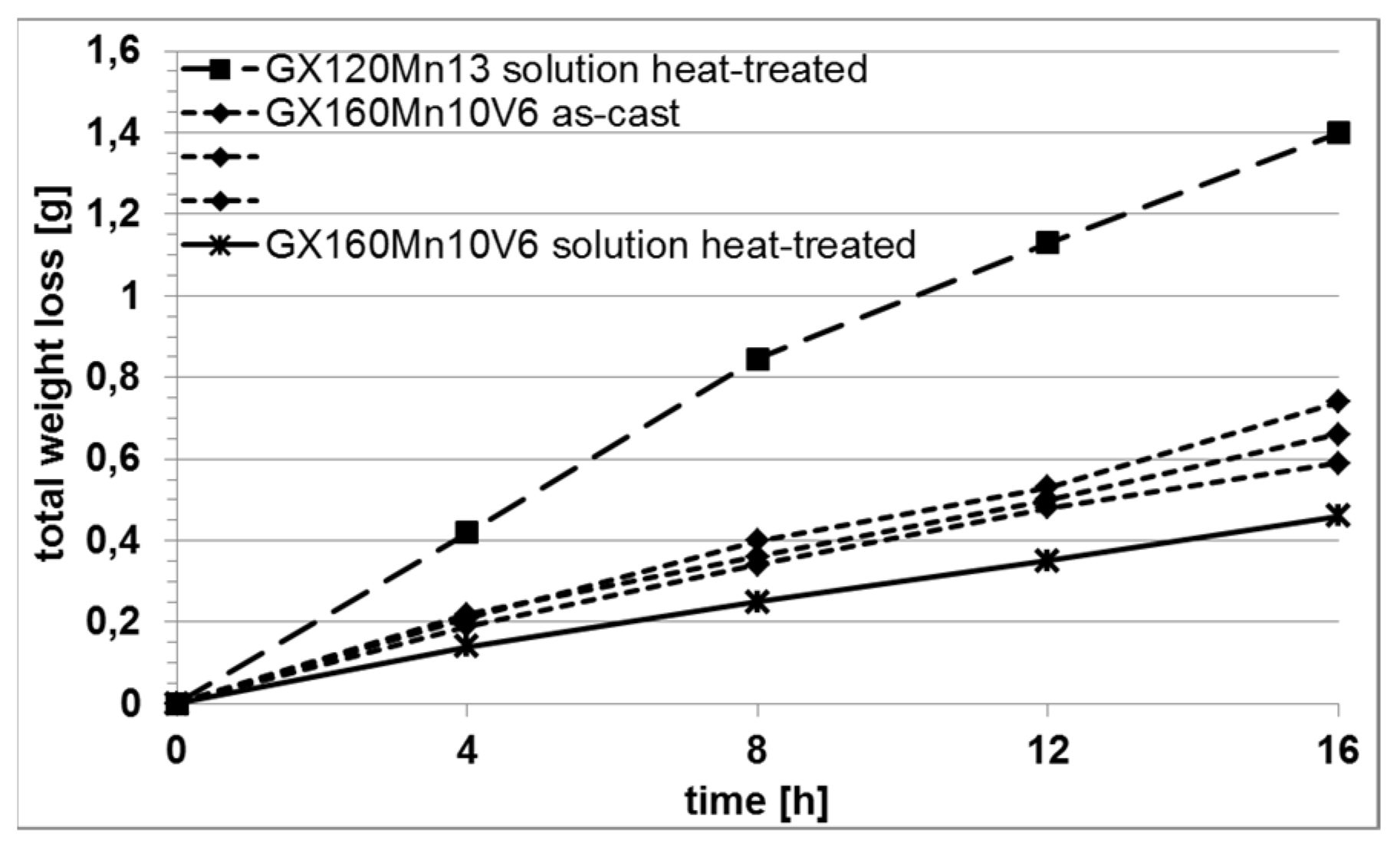

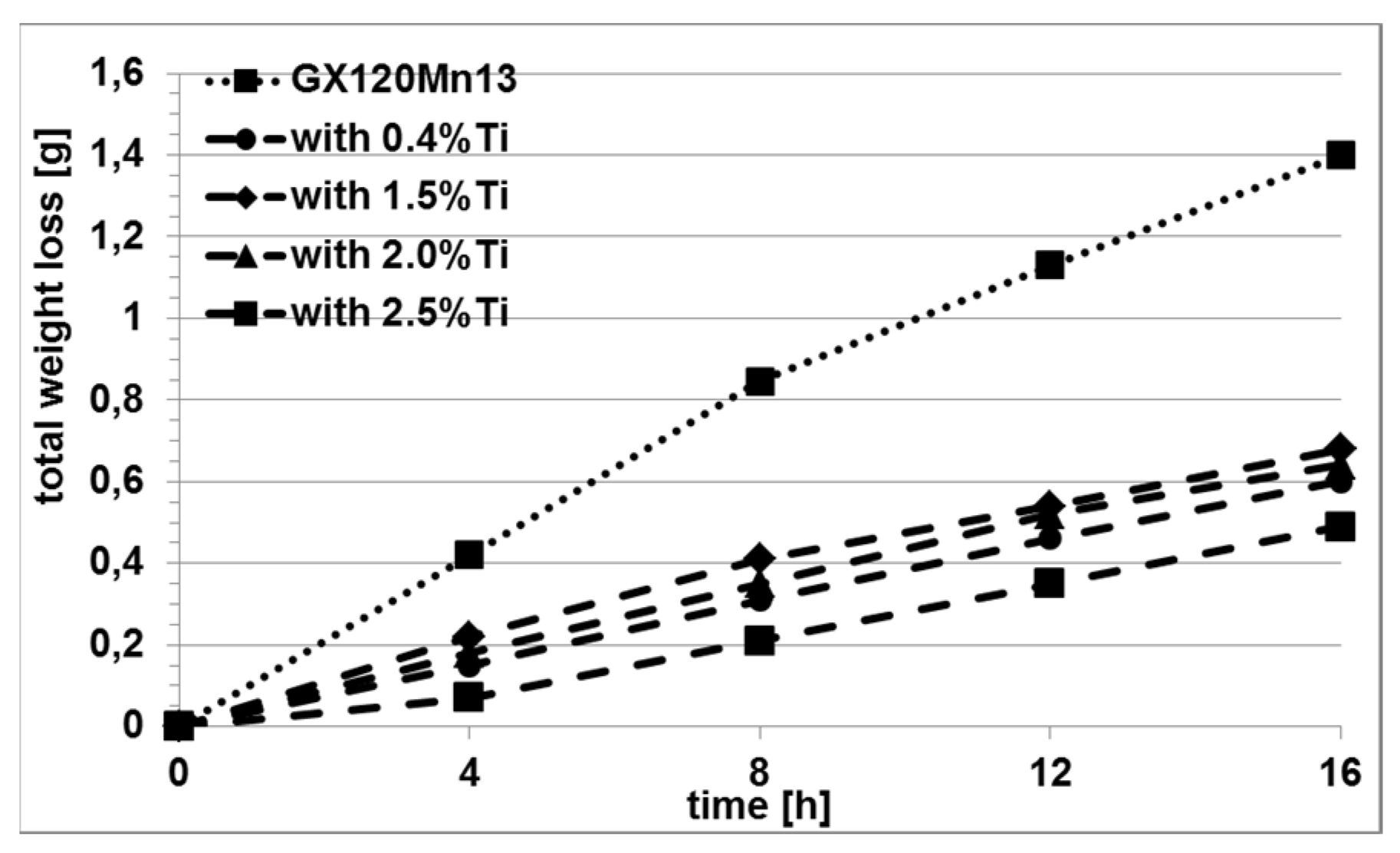

3. Test Results and Discussion

4. Conclusions

- The hardness of the tested samples in both as-cast condition and after solution heat treatment is about 260–290 HV which means that it is about 30–60 HV higher than the hardness of Hadfield cast steel.

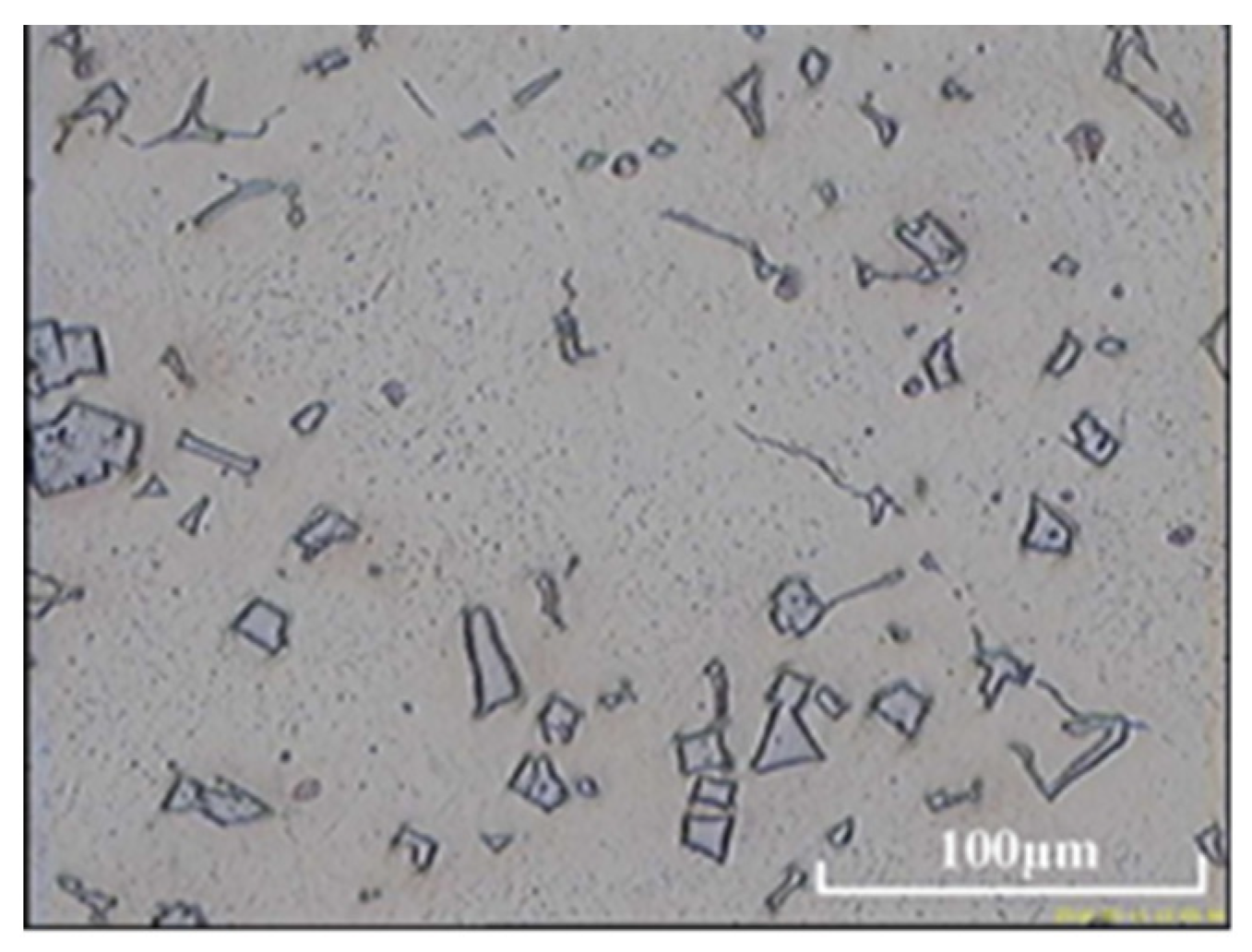

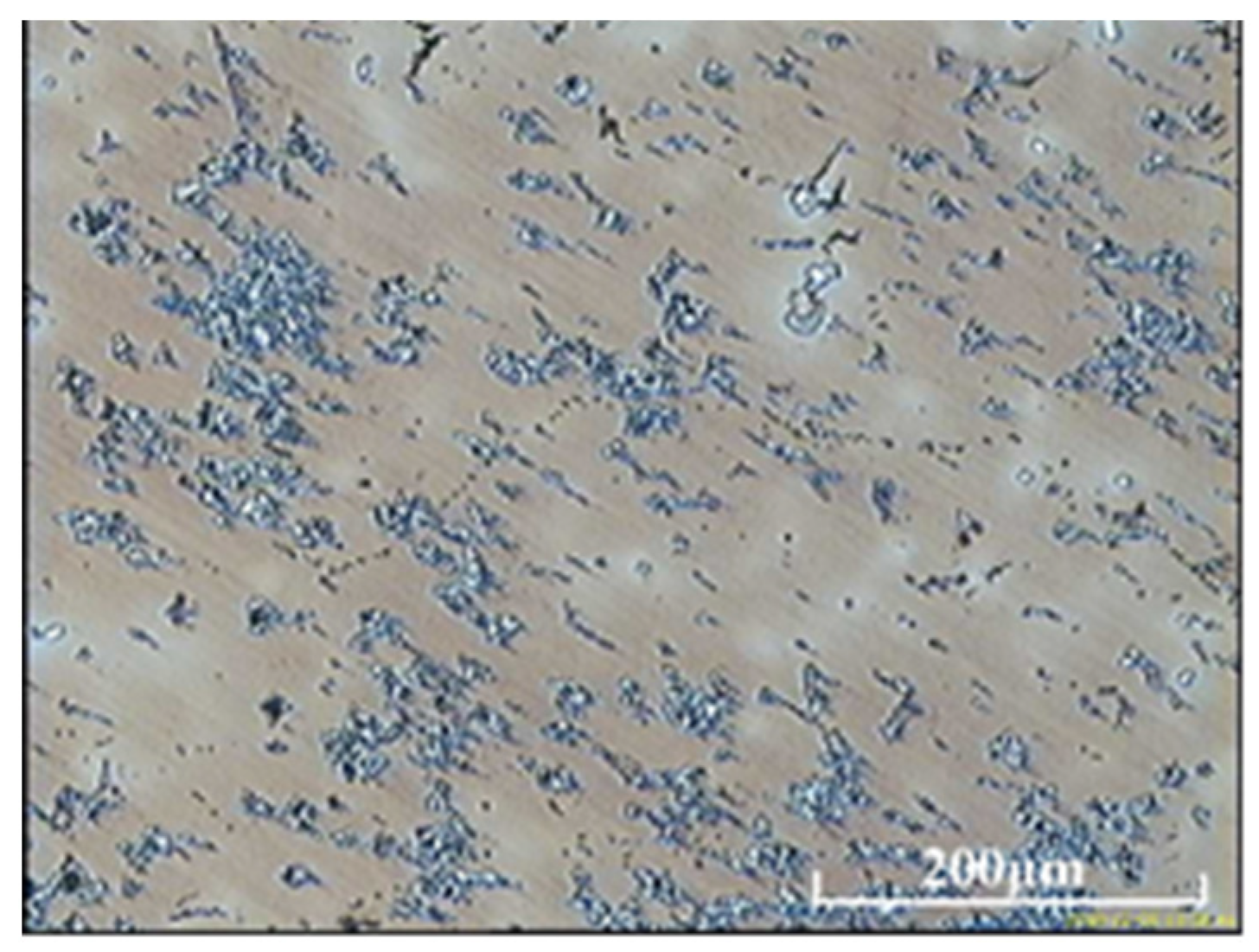

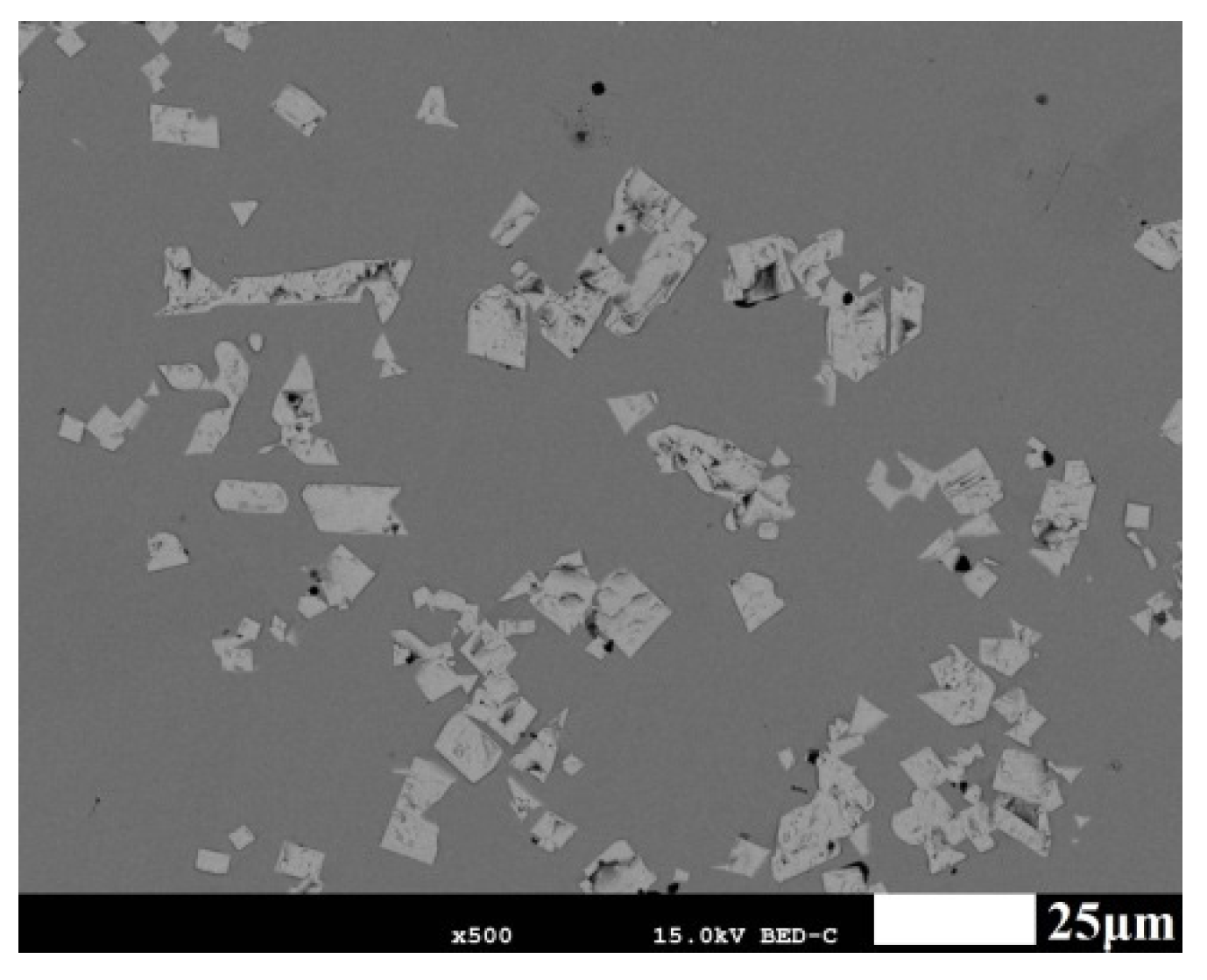

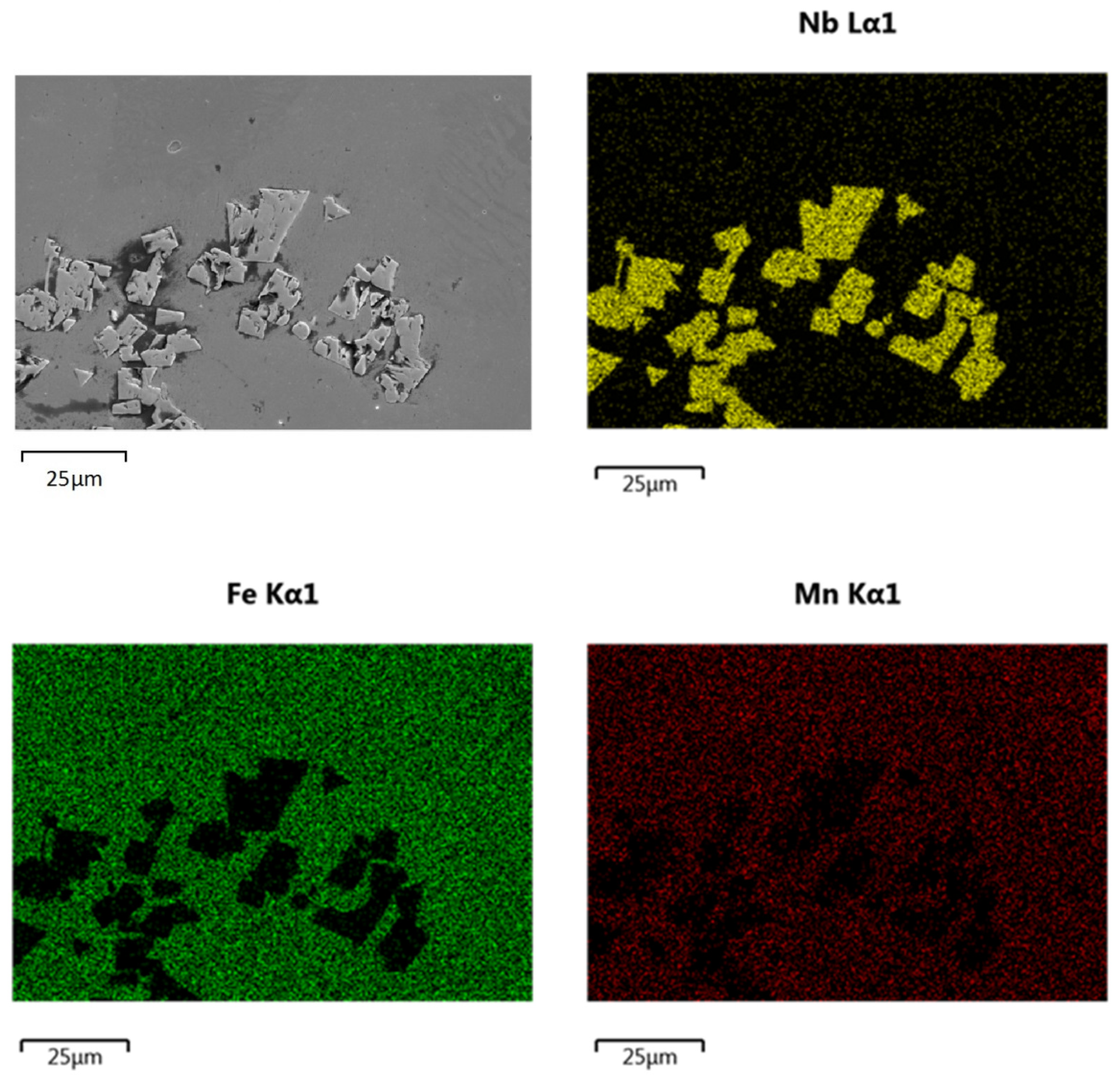

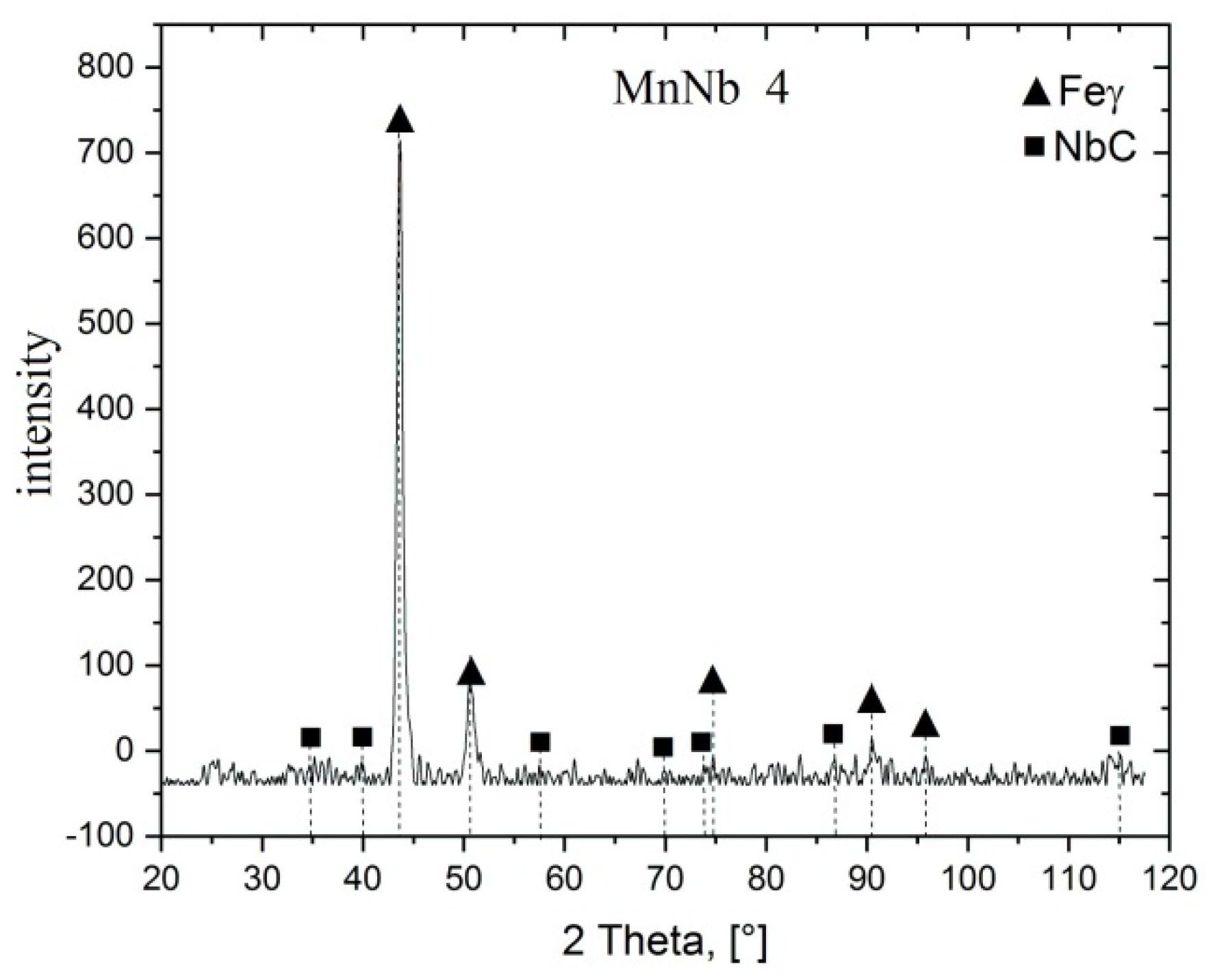

- The microstructure of the tested alloys after solution heat treatment consists of an austenitic matrix and primary niobium carbides evenly distributed in this matrix.

- The abrasive wear resistance of the tested high-manganese niobium-containing cast steel is at least 3 times higher than that of Hadfield cast steel.

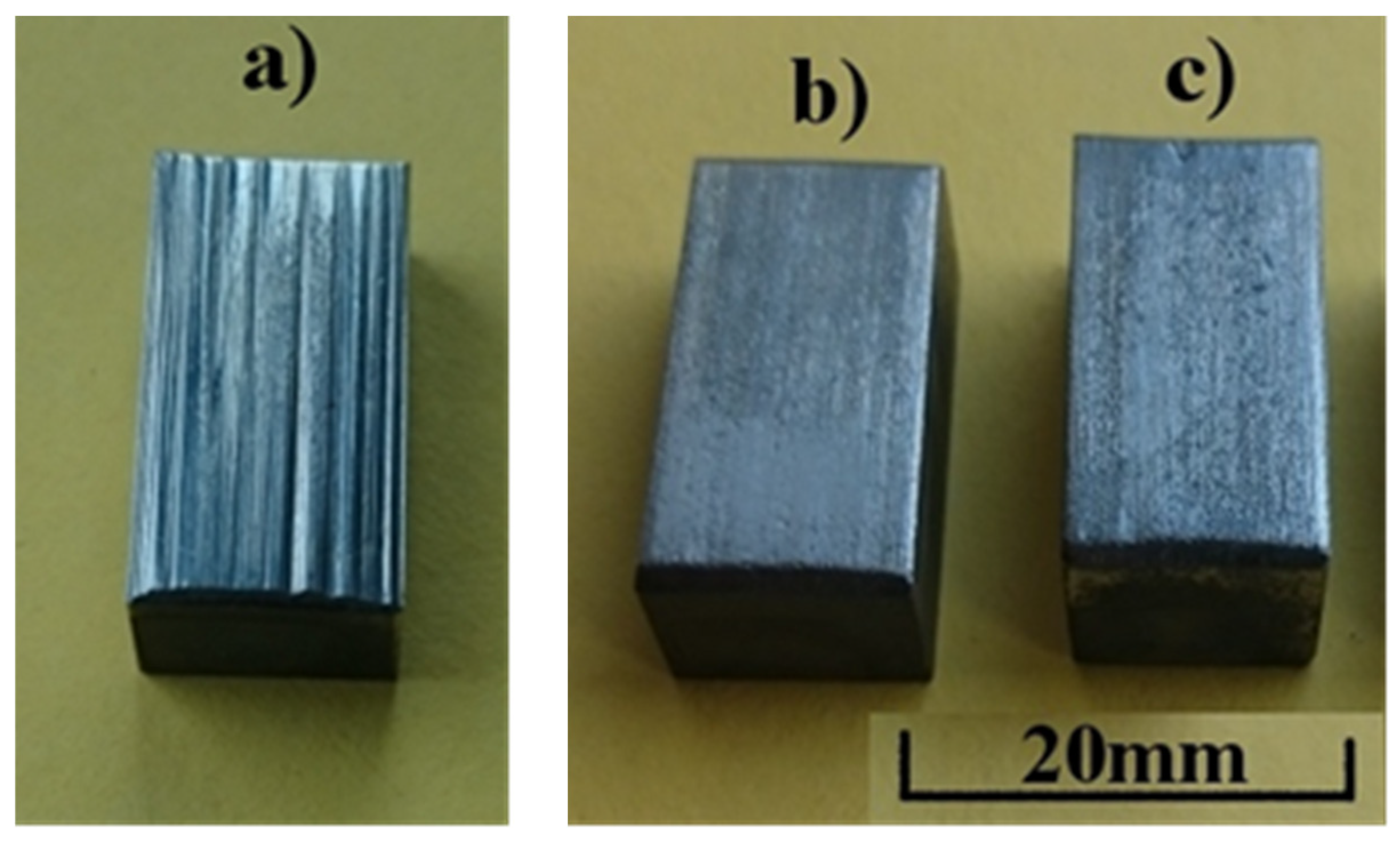

- The addition of Nb makes the sample wear uniform without any furrows and scratches.

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kniaginin, G. Austenityczne Staliwo Manganowe (Austenitic Manganese Cast Steel); PWN: Kraków, Poland, 1968. [Google Scholar]

- Smith, R.W.; DeMonte, A.; Mackay, W.B.F. Development of high-manganese steels for heavy duty cast-to-shape applications. J. Mater. Process. Technol. 2004, 153–154, 589–595. [Google Scholar] [CrossRef]

- Głownia, J. Odlewy ze Stali Stopowej–Zastosowanie (Castings from Alloy Steel–Applications); Fotobit: Kraków, Poland, 2002. [Google Scholar]

- Tęcza, G.; Sobula, S. Effect of heat treatment on change microstructure of cast high-manganese hadfield steel with elevated chromium content. Arch. Foundry Eng. 2014, 14, 67–70. [Google Scholar]

- Głownia, J.; Tęcza, G.; Asłanowicz, M.; Ościłowski, A. Tools cast from the steel of composite structure. Arch. Metall. Mater. 2013, 58, 803–808. [Google Scholar] [CrossRef] [Green Version]

- Tęcza, G.; Głownia, J. Resistance to abrasive wear and volume fraction of carbides in cast high-manganese austenitic steel with composite structure. Arch. Foundry Eng. 2015, 15, 129–133. [Google Scholar] [CrossRef]

- Tęcza, G.; Garbacz-Klempka, A. Microstructure of cast high-manganese steel containing titanium. Arch. Foundry Eng. 2016, 16, 163–168. [Google Scholar] [CrossRef] [Green Version]

- Tęcza, G.; Zapała, R. Changes in impact strength and abrasive wear resistance of cast high manganese steel due to the formation of primary titanium carbides. Arch. Foundry Eng. 2018, 18, 119–122. [Google Scholar]

- Głownia, J.; Kalandyk, B.; Camargo, M. Wear resistance of high Cr-Ni alloys in iron ore slurry conditions. Inżynieria Mater. 2002, 5, 694–697. [Google Scholar]

- Kalandyk, B.; Zapała, R. The abrasive wear behaviour of alloy cast steel in SiC-water slurry. Arch. Foundry Eng. 2009, 9, 91–94. [Google Scholar]

- Kalandyk, B.; Zapała, R. Effect of high-manganese cast steel strain hardening on the abrasion wear resistance in a mixture of SiC and water. Arch. Foundry Eng. 2013, 13, 63–66. [Google Scholar] [CrossRef]

- Kasinska, J.; Kalandyk, B. Effects of Rare Earth Metal Addition on Wear Resistance of Chromium-Molybdenum Cast Steel. Arch. Foundry Eng. 2017, 17, 63–68. [Google Scholar] [CrossRef] [Green Version]

- Kalandyk, B.; Tęcza, G.; Zapała, R.; Sobula, S. Cast High-Manganese Steel–the Effect of Microstructure on Abrasive Wear Behaviour in Miller Test. Arch. Foundry Eng. 2015, 15, 35–38. [Google Scholar] [CrossRef] [Green Version]

- Tęcza, G.; Nitkiewicz, Z.; Głownia, J. Porównanie odporności na ścieranie staliwa po obróbce cieplnej z przetopieniem powierzchni (Comparison of the abrasive wear resistance of cast steel after heat treatment with surface remelting). In Nowe Technologie i Osiągnięcia w Metalurgii i Inżynierii Materiałowej, Proceedings of the VI Międzynarodowa Konferencja Naukowa: Nowe Technologie i Osiągnięcia w Metalurgii i Inżynierii Materiałowej (VI International Scientific Conference on New Technologies and Achievements in Metallurgy and Materials Engineering), Częstochowa, Poland, 2 June 2005; Wydaw.WIPMiFS PC: Częstochowa, Poland, 2005; Volume 2, pp. 622–627. [Google Scholar]

| Alloy Designation | Chemical Composition [wt%] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | Mo | V | Ti | Nb | |

| MnNb_3 | 1.7 | 14.0 | 1.1 | 0.05 | 0.02 | 1.0 | 0.6 | 0.1 | 0.03 | 0.05 | 3.5 |

| MnNb_4 | 1.6 | 14.1 | 0.8 | 0.02 | 0.02 | 1.4 | 0.6 | 0.2 | 0.02 | 0.03 | 4.5 |

| Alloy Designation | Heat Treatment | Hardness [HV] |

|---|---|---|

| MnNb_3 | As cast | 291, 295, 289, 289, 295, 294, 290, 290, 293, 294 |

| 1050 °C/40 min/water quenching | 276, 283, 289, 276, 289, 285, 282, 287, 280, 277 | |

| MnNb_4 | As cast | 295, 291, 293, 291, 295, 294, 295, 293, 291, 293 |

| 1050 °C/40 min/water quenching | 262, 257, 262, 281, 265, 268, 275, 277, 271, 269, | |

| GX120Mn13 | 1050 °C/water quenching | 230, 227, 229, 230, 227, 228, 227, 229, 230, 230 |

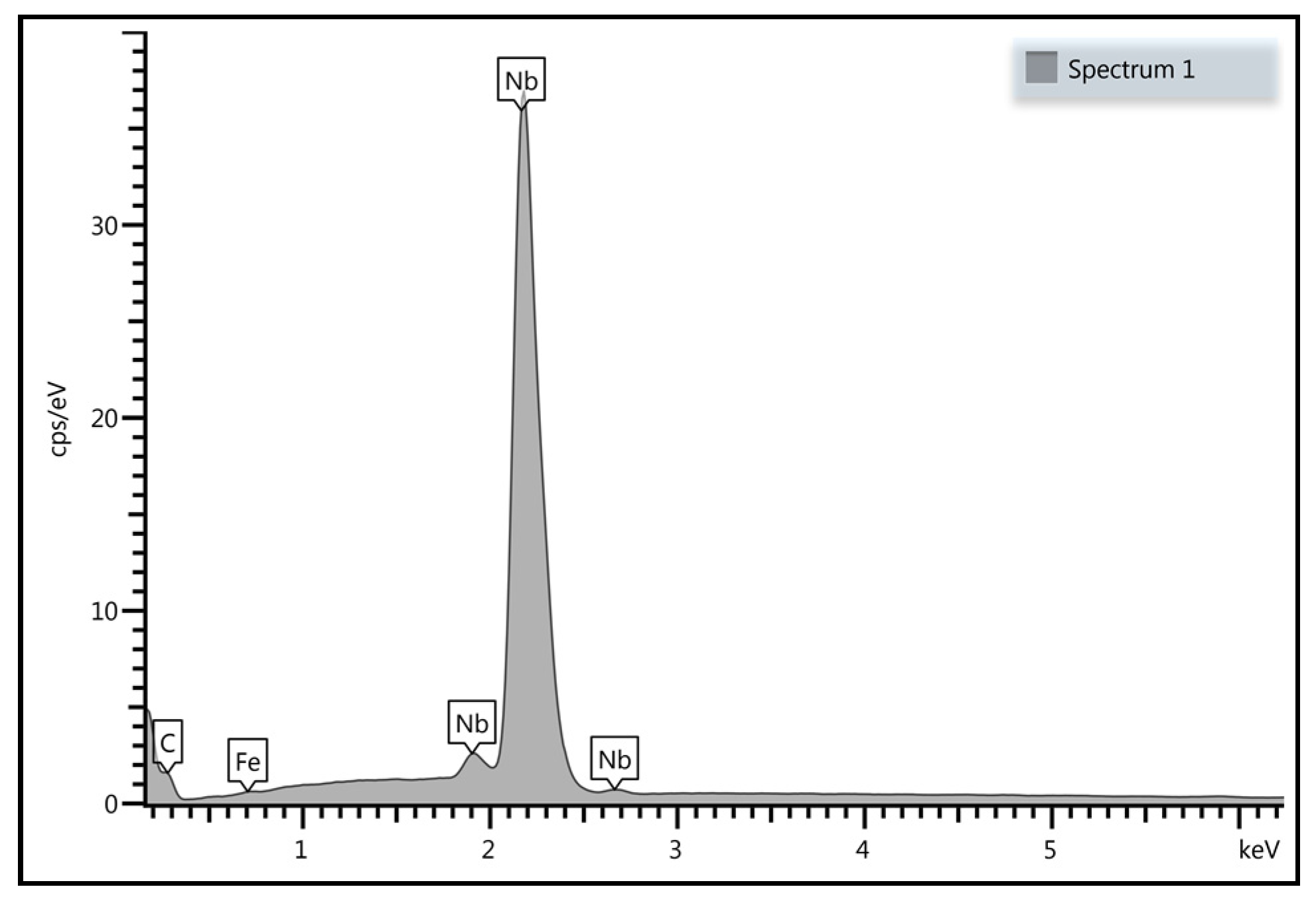

| Place of Analysis | [wt%] | ||||||

|---|---|---|---|---|---|---|---|

| Si | Ti | Cr | Mn | Fe | Nb | Other | |

| carbide | – | 0.6 | – | – | 2.6 | 94.9 | rest |

| – | 0.8 | – | – | 1.7 | 91.2 | rest | |

| – | – | – | – | 1.4 | 92.8 | rest | |

| matrix | 1.1 | – | 0.7 | 13.5 | 84.7 | – | rest |

| 1.2 | – | 1.0 | 16.4 | 8.4 | – | rest | |

| 1.3 | – | 0.5 | 15.4 | 81.4 | – | rest | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tęcza, G. Changes in Abrasive Wear Resistance during Miller Test of High-Manganese Cast Steel with Niobium Carbides Formed in the Alloy Matrix. Appl. Sci. 2021, 11, 4794. https://doi.org/10.3390/app11114794

Tęcza G. Changes in Abrasive Wear Resistance during Miller Test of High-Manganese Cast Steel with Niobium Carbides Formed in the Alloy Matrix. Applied Sciences. 2021; 11(11):4794. https://doi.org/10.3390/app11114794

Chicago/Turabian StyleTęcza, Grzegorz. 2021. "Changes in Abrasive Wear Resistance during Miller Test of High-Manganese Cast Steel with Niobium Carbides Formed in the Alloy Matrix" Applied Sciences 11, no. 11: 4794. https://doi.org/10.3390/app11114794

APA StyleTęcza, G. (2021). Changes in Abrasive Wear Resistance during Miller Test of High-Manganese Cast Steel with Niobium Carbides Formed in the Alloy Matrix. Applied Sciences, 11(11), 4794. https://doi.org/10.3390/app11114794