Transformative Use of Additive Technology in Design and Manufacture of Hydraulic Actuator for Fly-by-Wire System

Abstract

:1. Introduction

2. Mechanical Properties of Maraging Steels

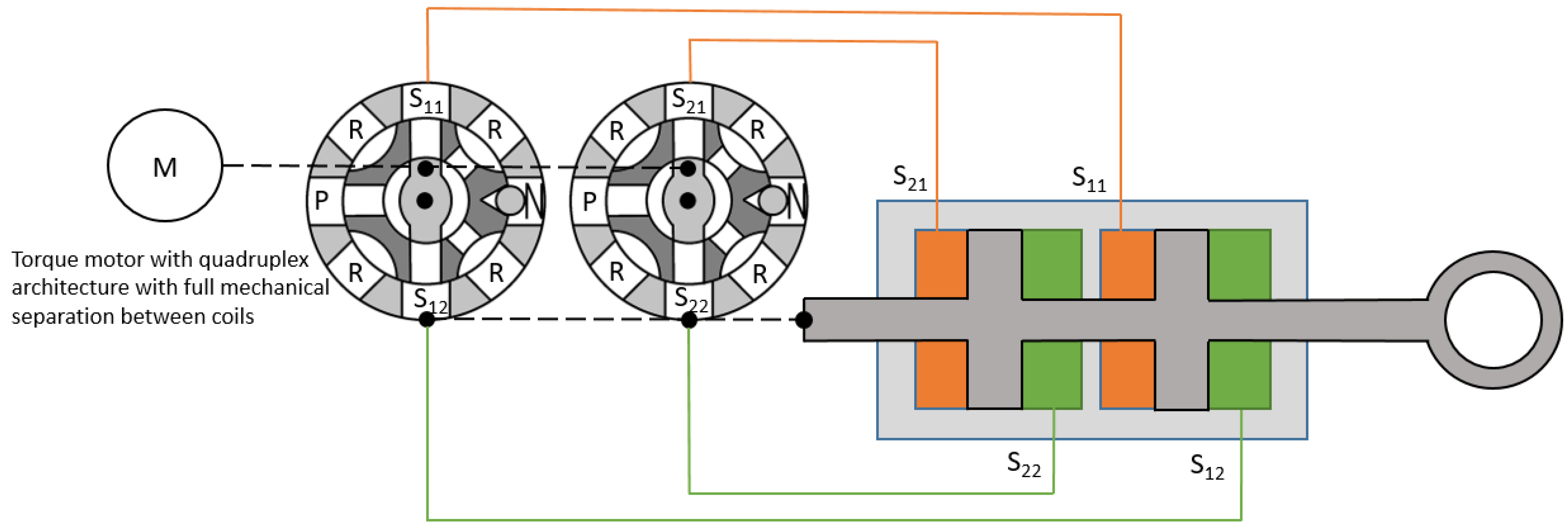

3. Verification of the Strength of Age-Hardened Maraging Steel Samples Produced with SLM Technology

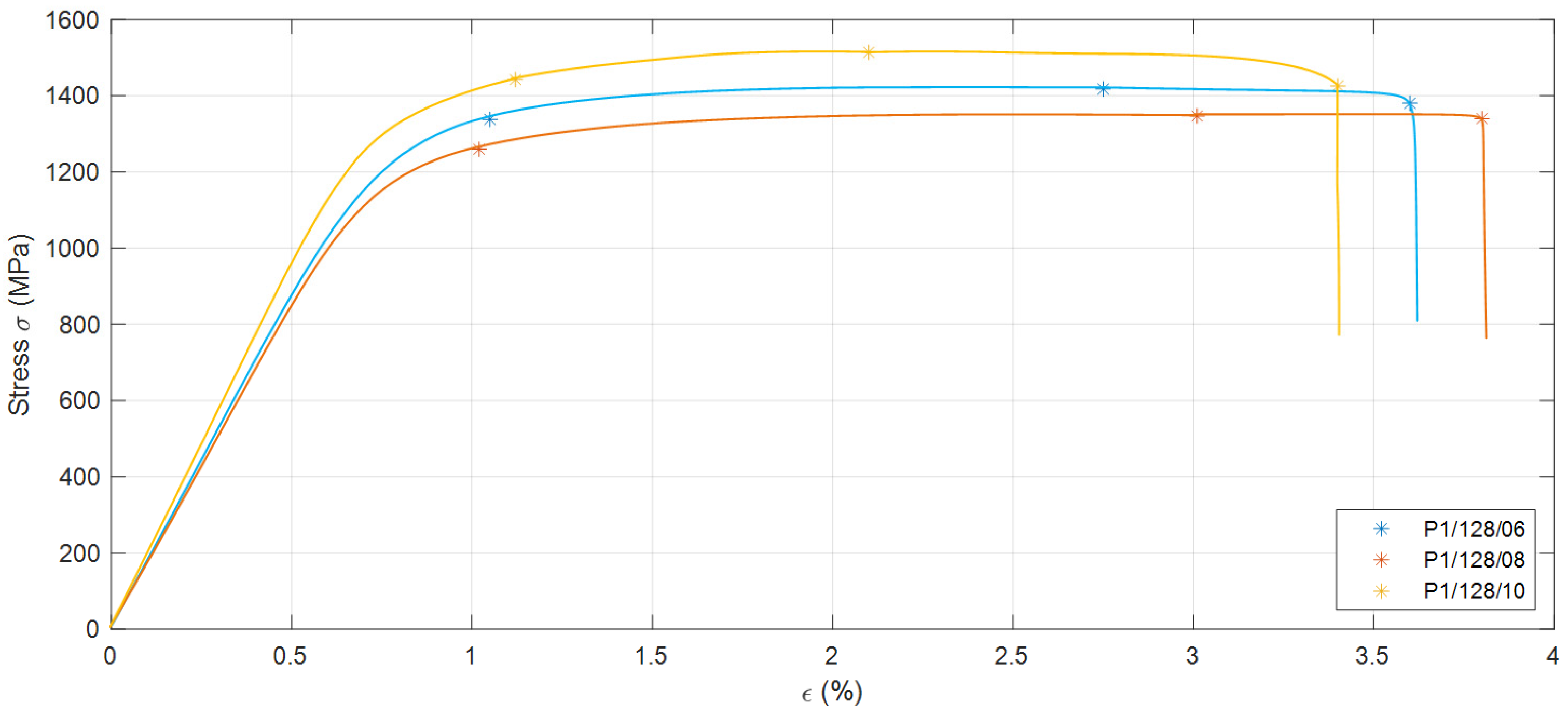

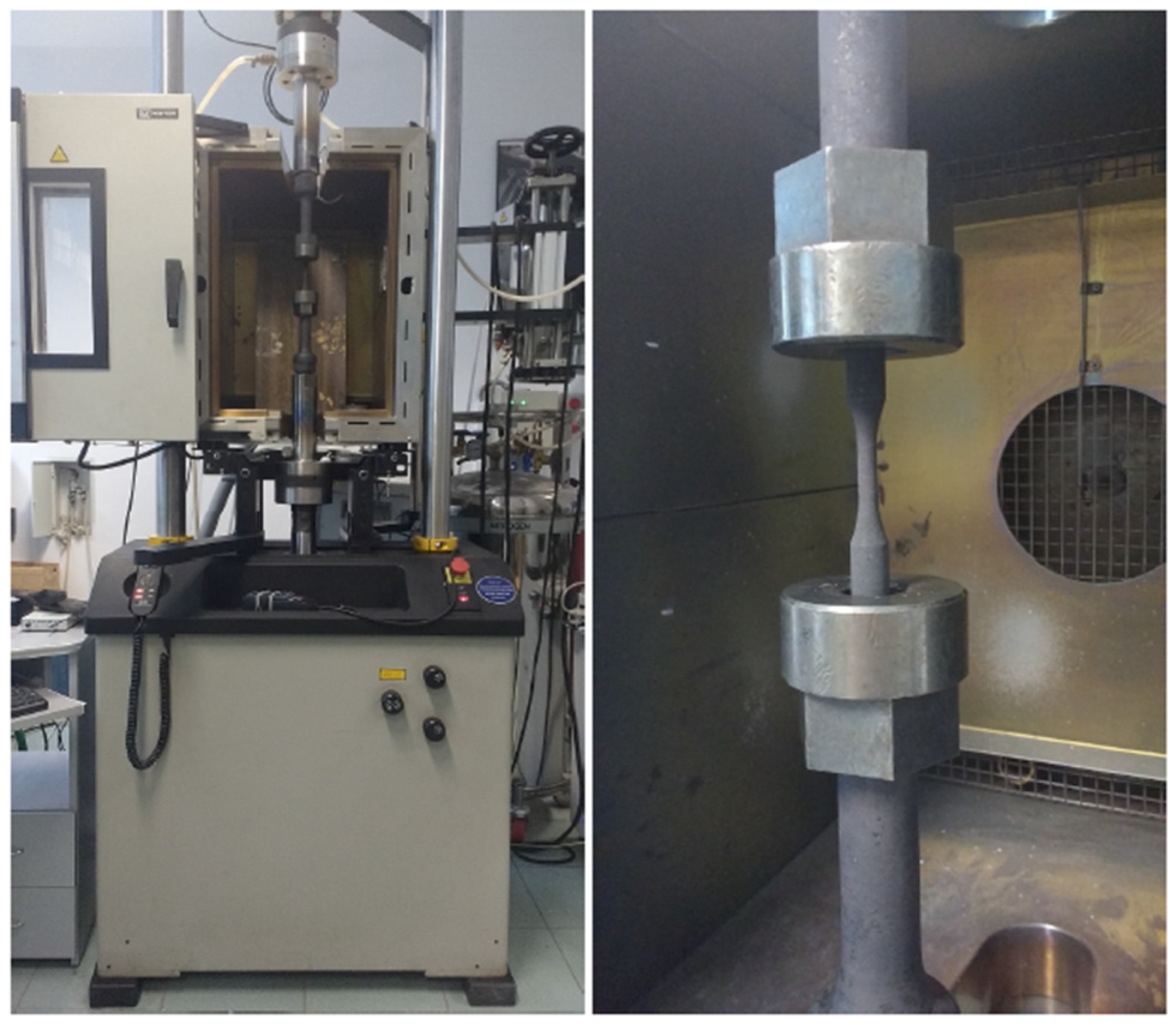

3.1. Tensile Testing

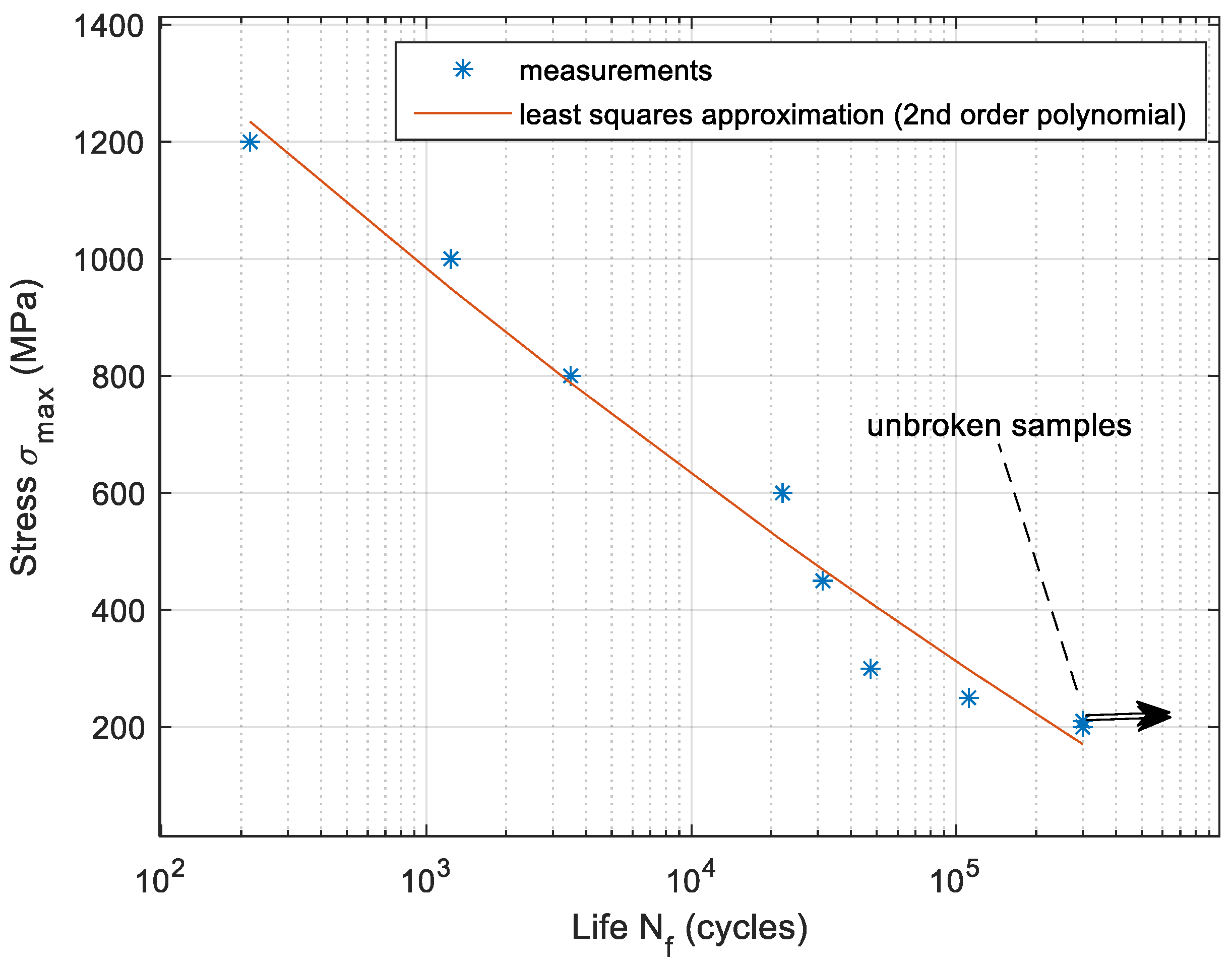

3.2. Tensile Fatigue Testing

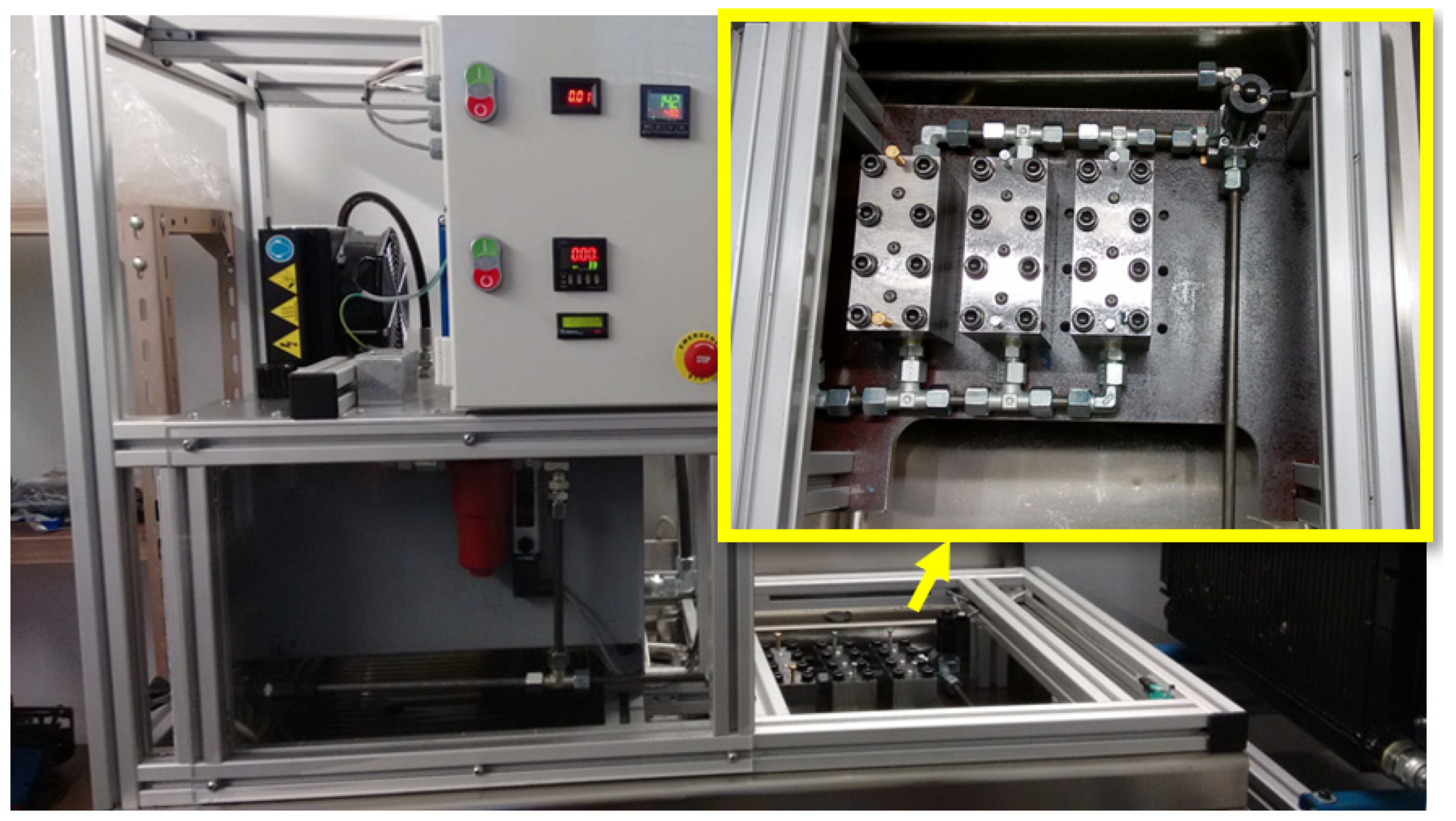

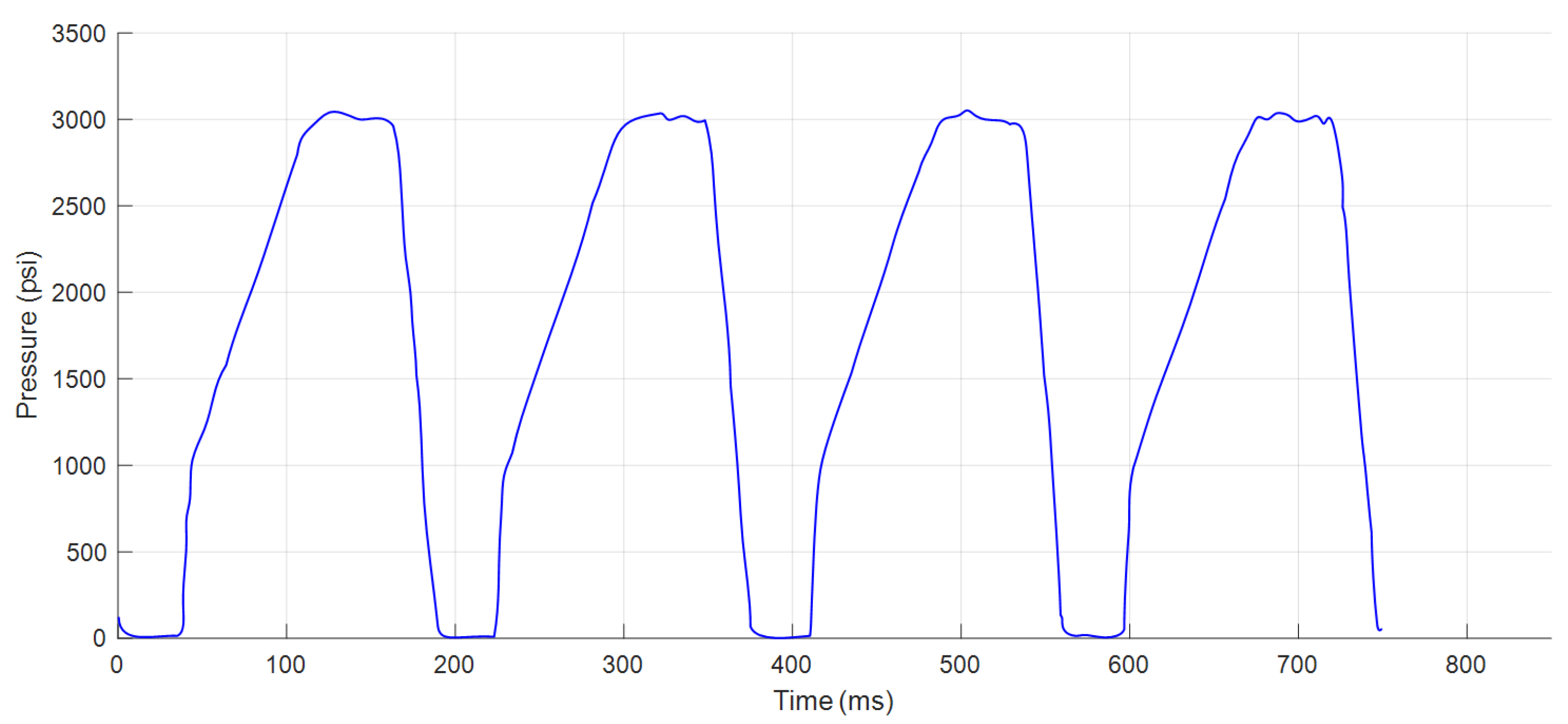

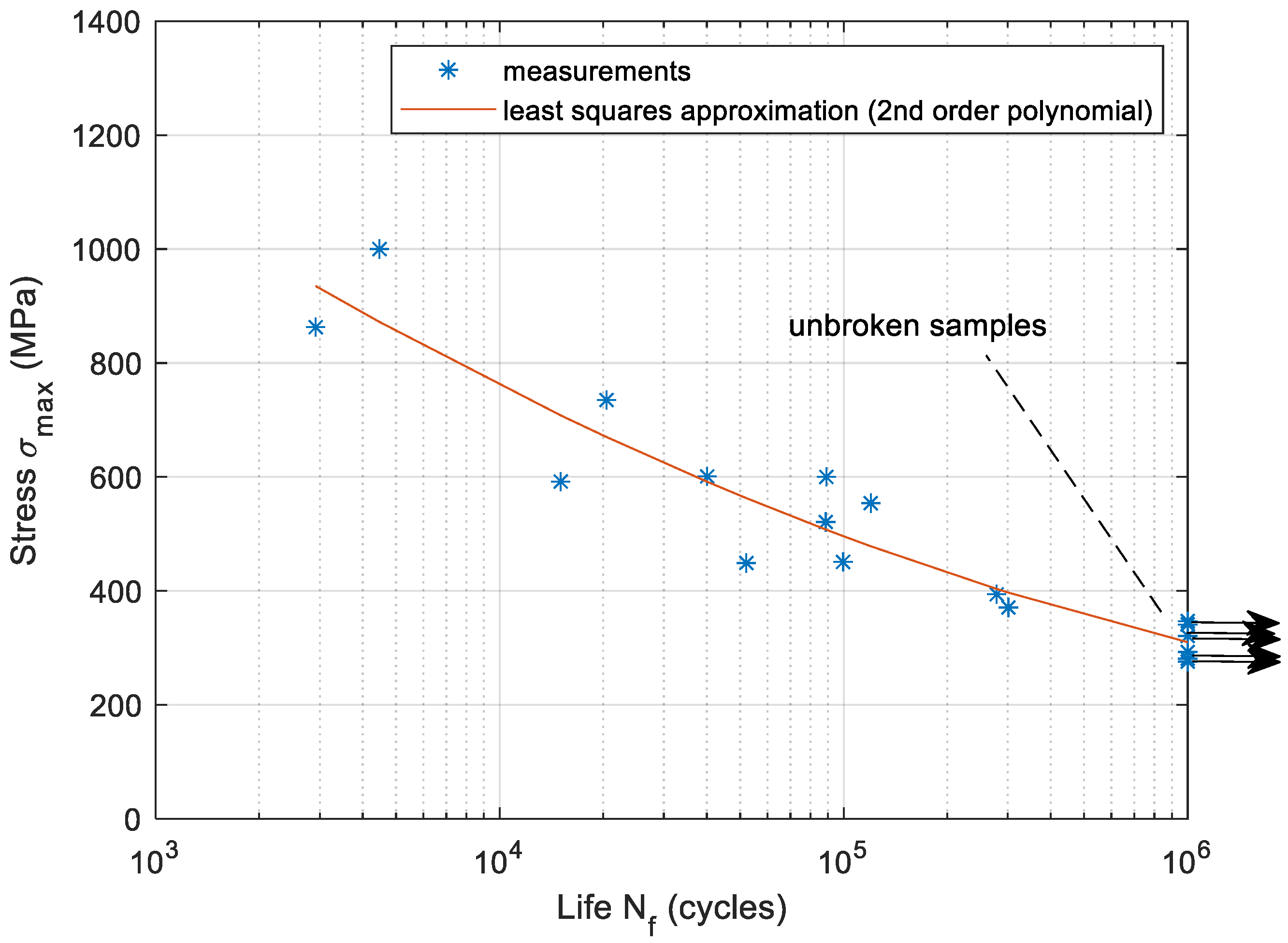

3.3. Pressure Fatigue Testing

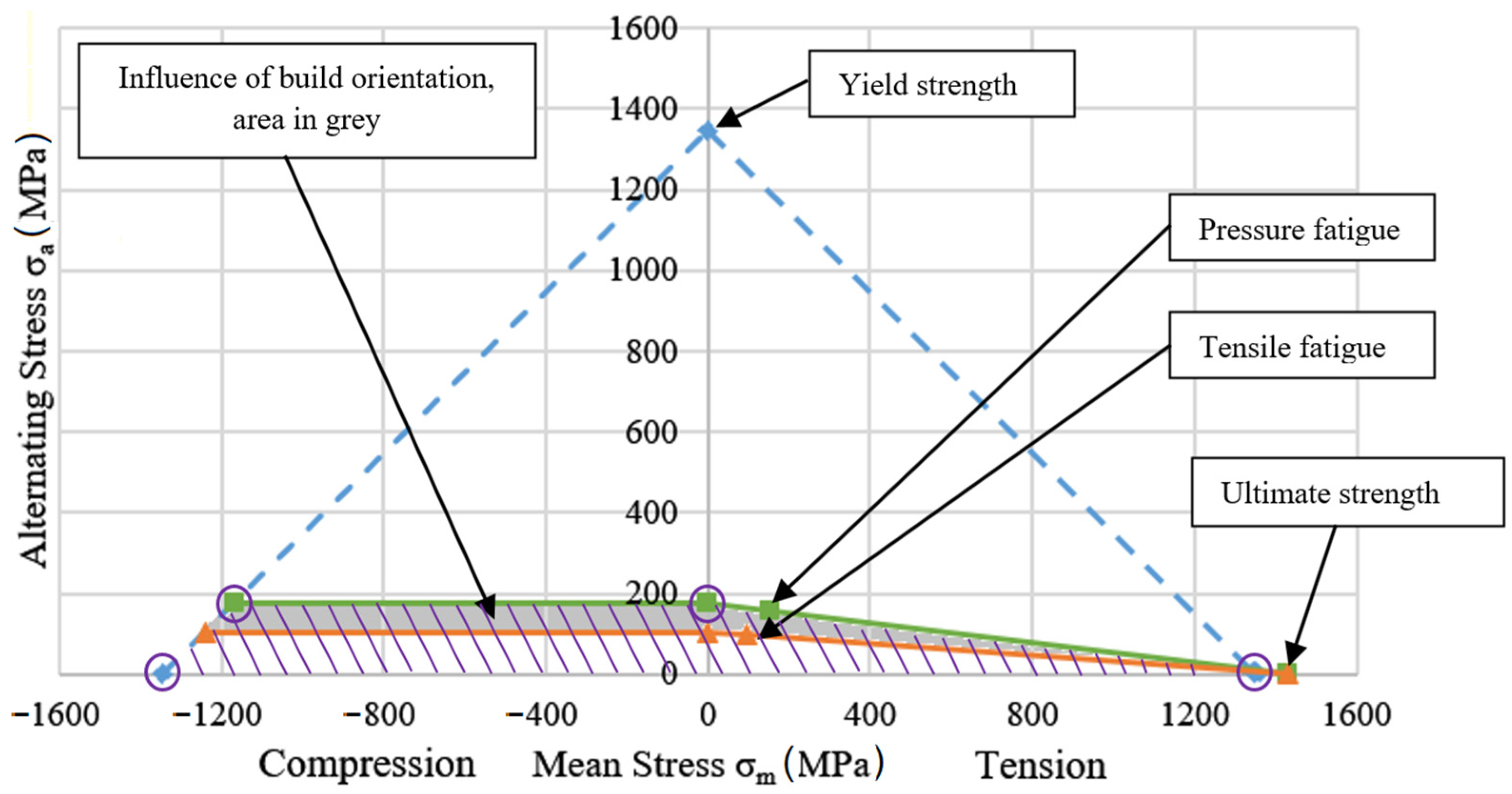

3.4. Goodman Diagram for Designing AM Maraging Steel Components for Fatigue

4. The Use of SLM Technology in the Production of Aviation Hydraulic Parts

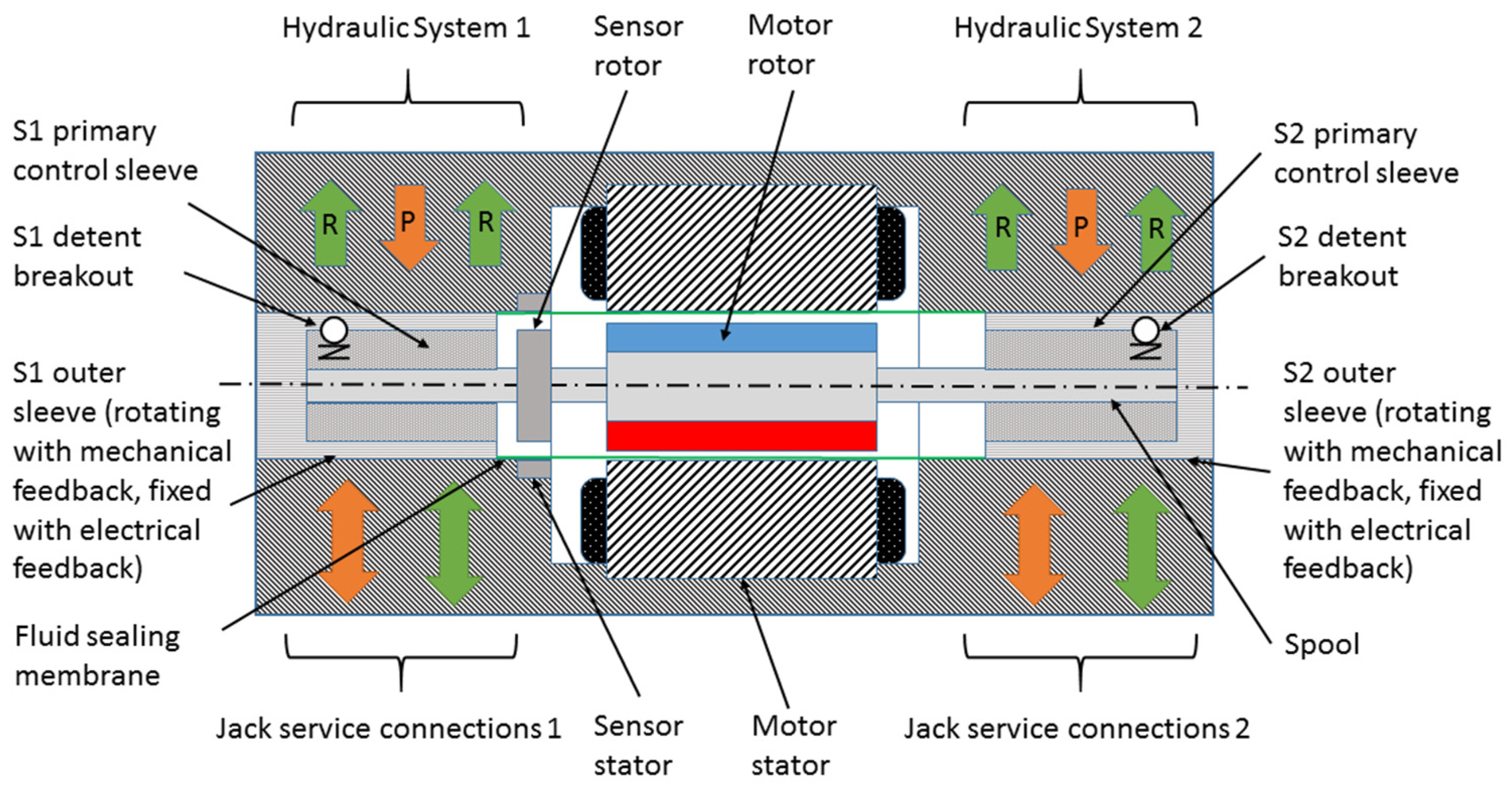

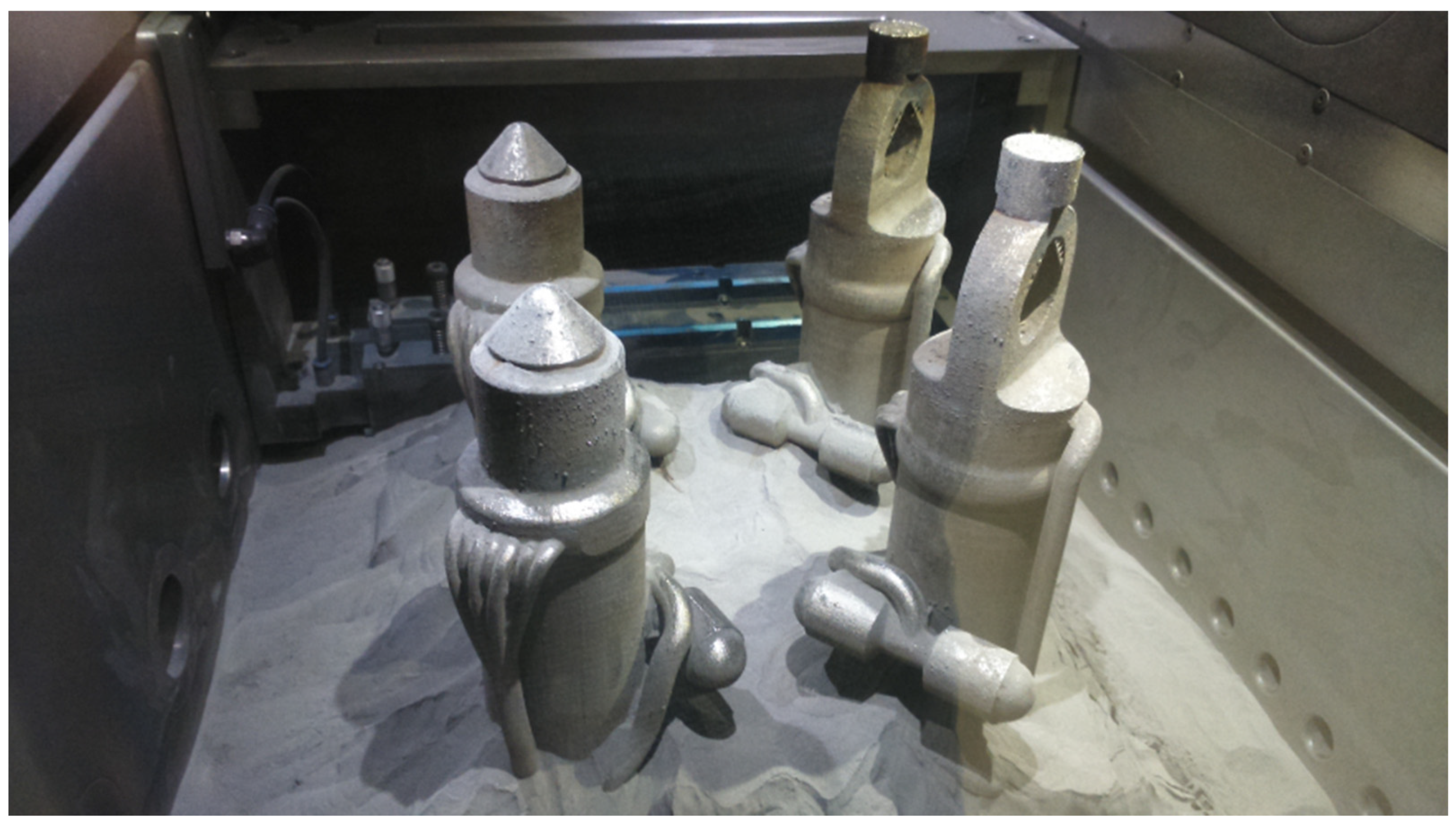

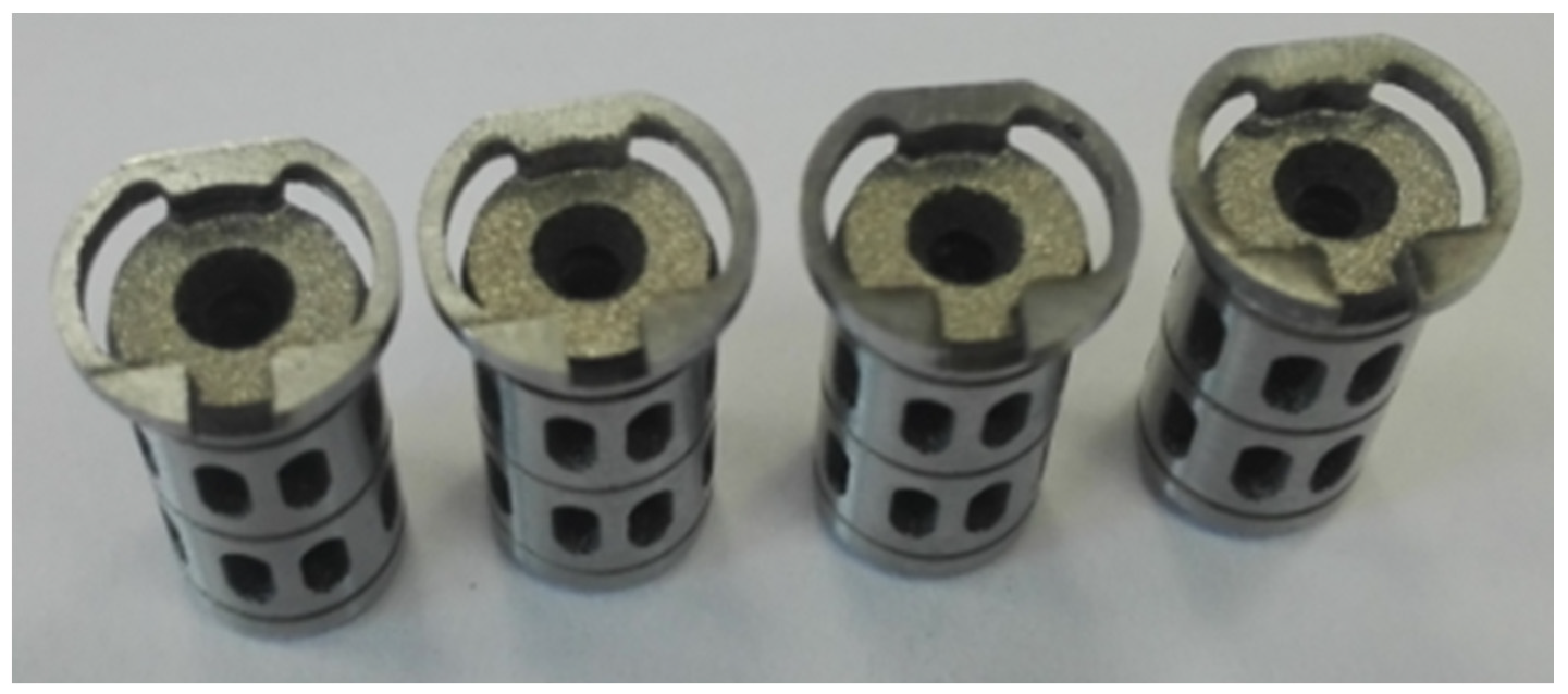

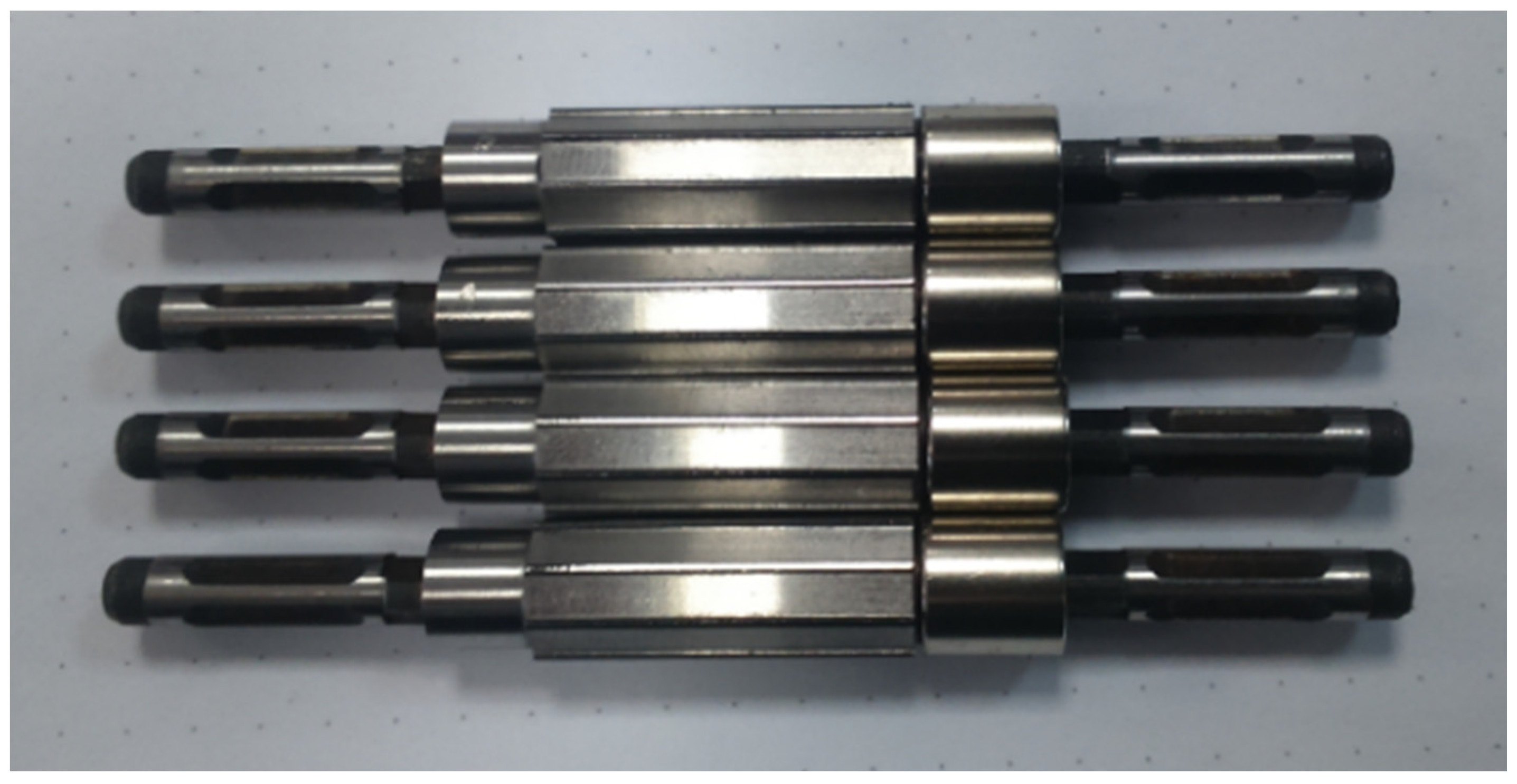

4.1. The Process of Manufacturing and Integrating the Hydraulic Actuator

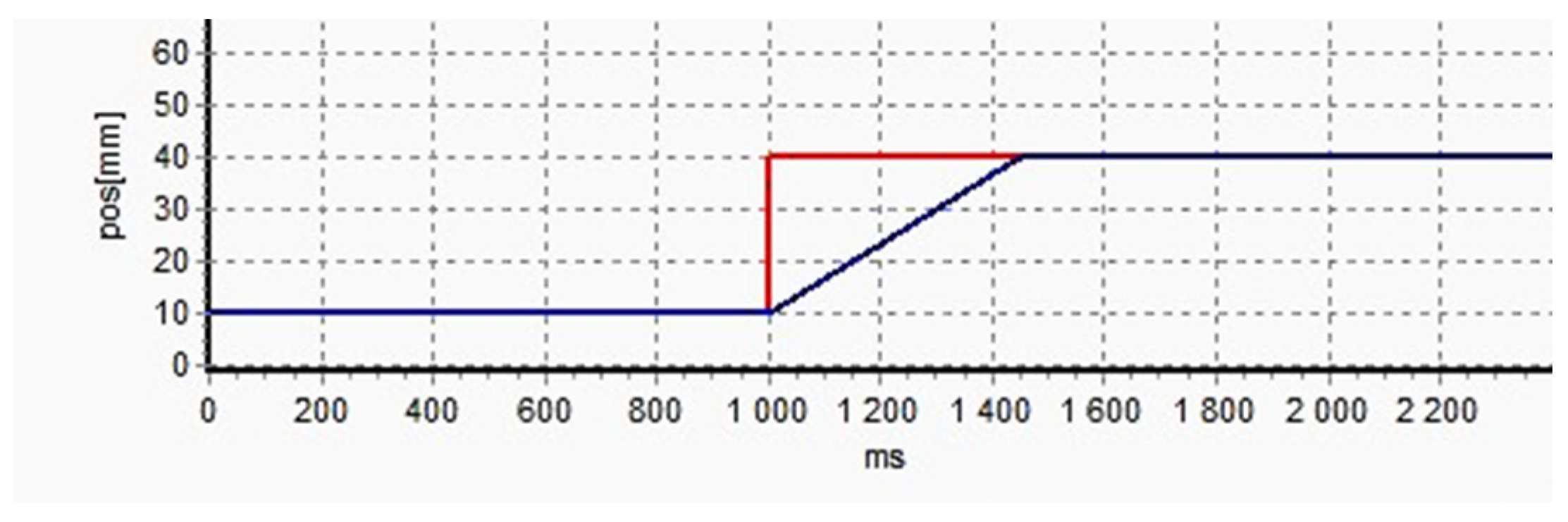

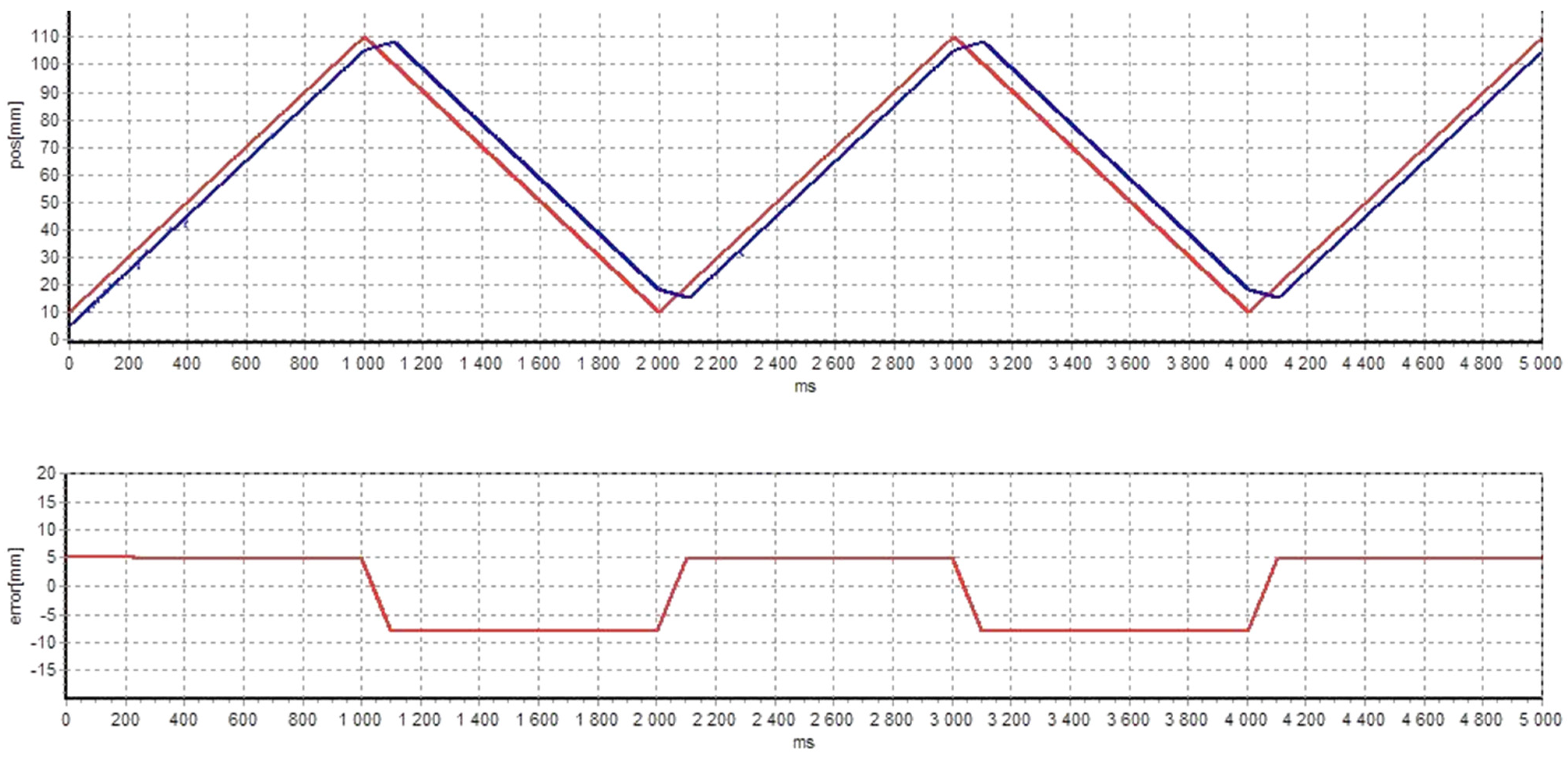

4.2. Results of the Preliminary Dynamic Tests

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Di Rito, G. Experiments and simulations for the study of temperature effects on the performances of a fly-by-wire hydraulic actuator. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2011, 225, 1195–1206. [Google Scholar] [CrossRef]

- Zhao, Z.; Yu, X.; Zhang, Z.; Shu, W.; Li, J. Attempting AG-Doped Diamond-Like Carbon Film to Improve Seal Performance of Hydraulic Servo-Actuator. Materials 2020, 13, 2618. [Google Scholar] [CrossRef] [PubMed]

- Di Rito, G.; Galatolo, R. Experimental assessment of the dynamic stiffness of a fault-tolerant fly-by-wire hydraulic actuator. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2012, 226, 679–690. [Google Scholar] [CrossRef]

- Garza, P.; Perinpanayagam, S.; Aslam, S.; Wileman, A. Qualitative Validation Approach Using Digital Model for the Health Management of Electromechanical Actuators. Appl. Sci. 2020, 10, 7809. [Google Scholar] [CrossRef]

- Huang, L.; Yu, T.; Jiao, Z.; Li, Y. Active Load-Sensitive Electro-Hydrostatic Actuator for More Electric Aircraft. Appl. Sci. 2020, 10, 6978. [Google Scholar] [CrossRef]

- Rahrovi, B.; Mehrdad, E. A review of the more electric aircraft power electronics. In Proceedings of the 2019 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 7–8 February 2019. [Google Scholar]

- Hospodka, J.; Bínová, H.; Pleninger, S. Assessment of All-Electric General Aviation Aircraft. Energies 2020, 13, 6206. [Google Scholar] [CrossRef]

- Thapa, N.; Ram, S.; Kumar, S.; Mehta, J. All electric aircraft: A reality on its way. Mater. Today Proc. 2021, 43, 175–182. [Google Scholar] [CrossRef]

- Vedova, M.D.L.D.; Germanà, A.; Berri, P.C.; Maggiore, P. Model-Based Fault Detection and Identification for Prognostics of Electromechanical Actuators Using Genetic Algorithms. Aerospace 2019, 6, 94. [Google Scholar] [CrossRef] [Green Version]

- Chudý, P.; Tomczyk, A.; Rzucidlo, P. Safety enhanced digital flight control system. Aircr. Eng. Aerosp. Technol. 2009, 81, 416–423. [Google Scholar] [CrossRef]

- Wang, X.; Liao, R.; Shi, C.; Wang, S. Linear Extended State Observer-Based Motion Synchronization Control for Hybrid Actuation System of More Electric Aircraft. Sensors 2017, 17, 2444. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, Y.-B.; Park, J.-W.; Lee, G.-C. A Study on Failure Analysis and High Performance of Hydraulic Servo Actuator. Appl. Sci. 2020, 10, 7451. [Google Scholar] [CrossRef]

- Jani, D.B.; Ashish, S.; Aditya, S.; Yash, S.; Bishambhar, S.; Nikhil, S.; Manmohan, S. An overview on aircraft hydraulic system. Renew. Sustain. Energy Rev. 2019, 6, 29–35. [Google Scholar]

- Han, C.; Kim, K. A Study on the Reliability and Maintainability Analysis Process for Aircraft Hydraulic System. J. Korea Soc. Syst. Eng. 2016, 12, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Wang, X.; Lin, S. Multi-Fault Diagnosis Approach Based on Updated Interacting Multiple Model for Aviation Hydraulic Actuator. Information 2020, 11, 410. [Google Scholar] [CrossRef]

- AF-9 Skydrol Overview, Eastman Chemical Company. Available online: https://www.eastman.com/Brands/EAS/Products/Pages/Skydrol.aspx (accessed on 15 March 2021).

- Helwig, A.; Müller, G.; Paul, S. Health Monitoring of Aviation Hydraulic Fluids Using Opto-Chemical Sensor Technologies. Chemosensors 2020, 8, 131. [Google Scholar] [CrossRef]

- Hueber, C.; Horejsi, K.; Schledjewski, R. Review of cost estimation: Methods and models for aerospace composite manufacturing. Adv. Manuf. Polym. Compos. Sci. 2016, 2, 1–13. [Google Scholar] [CrossRef]

- Aerospace: Liebherr—First Metal 3D Printed Primary Flight Control Hydraulic Component Flies on an AIRBUS A380. Available online: https://rmsiberia.com/aerospace-liebherr-first-metal-3d-printed-primary-flight-control-hydraulic-component-flies-on-an-airbus-a380/ (accessed on 15 March 2021).

- Antunes, F.; Santos, L.; Capela, C.; Ferreira, J.; Costa, J.; Jesus, J.; Prates, P. Fatigue Crack Growth in Maraging Steel Obtained by Selective Laser Melting. Appl. Sci. 2019, 9, 4412. [Google Scholar] [CrossRef] [Green Version]

- Cheng, C.-W.; Jian, W.-Y.J.; Makala, B.P.R. Selective Laser Melting of Maraging Steel Using Synchronized Three-Spot Scanning Strategies. Materials 2021, 14, 1905. [Google Scholar] [CrossRef] [PubMed]

- Saracyakupoglu, T. The Qualification of the Additively Manufactured Parts in the Aviation Industry. Am. J. Aerosp. Eng. 2019, 6, 1–10. [Google Scholar] [CrossRef]

- Kučerová, L.; Zetková, I.; Jeníček, Š.; Burdová, K. Production of Hybrid Joints by Selective Laser Melting of Maraging Tool Steel 1.2709 on Conventionally Produced Parts of the Same Steel. Materials 2021, 14, 2105. [Google Scholar] [CrossRef]

- Jarfors, A.E.W.; Shashidhar, A.C.G.H.; Yepur, H.K.; Steggo, J.; Andersson, N.-E.; Stolt, R. Build Strategy and Impact Strength of SLM Produced Maraging Steel (1.2709). Metals 2021, 11, 51. [Google Scholar] [CrossRef]

- Tyczyński, P.; Siemiątkowski, Z.; Bąk, P.; Warzocha, K.; Rucki, M.; Szumiata, T. Performance of Maraging Steel Sleeves Produced by SLM with Subsequent Age Hardening. Materials 2020, 13, 3408. [Google Scholar] [CrossRef] [PubMed]

- Kleemann, E.; Dey, D.; Recksiek, M.; DaimlerChrysler Aerospace. The development of a civilian fly by wire flight control system. Proceedings of ICAS Congress ICAS, Harrogate International Conference Centre, Harrogate, UK, 7 August–1 September 2000. [Google Scholar]

- Lu, Z.; Zhuang, L.; Dong, L.; Liang, X. Model-Based Safety Analysis for the Fly-by-Wire System by Using Monte Carlo Simulation. Processes 2020, 8, 90. [Google Scholar] [CrossRef] [Green Version]

- Jacazio, G.; Gastaldi, L. Robust pressure control improves the performance of redundant fly-by-wire hydraulic actuators. Int. J. Appl. Eng. Res. 2016, 11, 8590–8597. [Google Scholar]

- Dołęga, B. Some remarks about aircraft control and navigation system as reliable fault tolerant system. Pomiary Autom. Kontrola 2011, 57, 1024–1027. [Google Scholar]

- Dołęga, B.; Rzucidło, P. Controllers for fault tolerant actuators. Aviation 2007, 11, 23–27. [Google Scholar] [CrossRef]

- Sendeckyj, G.P. Constant life diagrams—A historical review. Int. J. Fatigue 2001, 23, 347–353. [Google Scholar] [CrossRef] [Green Version]

- Jimenez-Vicaria, J.D.; Gomez-Pulido, M.D.; Castro-Fresno, D. Numerical and Experimental Evaluation of a CFRP Fatigue Strengthening for Stringer-Floor Beam Connections in a 19th Century Riveted Railway Bridge. Metals 2021, 11, 603. [Google Scholar] [CrossRef]

- Dobrzański, L.A. Metal i ich Stopy; International OCSCO World Press: Gliwice, Poland, 2017. [Google Scholar]

- 18 Percent Nickel Maraging Steels, Engineering Properties; Publication No. 4419; Nickel Development Institute: Toronto, CA, USA, 1976.

- Vock, S.; Klöden, B.; Kirchner, A.; Weißgärber, T.; Kieback, B. Powders for powder bed fusion: A review. Prog. Addit. Manuf. 2019, 4, 383–397. [Google Scholar]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.-P.; Van Humbeeck, J. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Mooney, B.; Kourousis, K.I. A Review of Factors Affecting the Mechanical Properties of Maraging Steel 300 Fabricated via Laser Powder Bed Fusion. Metals 2020, 10, 1273. [Google Scholar] [CrossRef]

- Konieczny, B.; Szczesio-Wlodarczyk, A.; Sokolowski, J.; Bociong, K. Challenges of Co-Cr Alloy Additive Manufacturing Methods in Dentistry—The Current State of Knowledge (Systematic Review). Materials 2020, 13, 3524. [Google Scholar] [CrossRef]

- Collins, A. Servo Actuators. England Patent WO2016/075491 A1, 19 May 2016. [Google Scholar]

- Yasa Flight Control. Available online: http://yasa-motors.com/wp-content/uploads/2017/05/FBW-brochure.pdf (accessed on 15 March 2021).

- Warzocha, K.; Bąk, P. Method for Manufacturing the Aircraft Valve Block. Poland Patent PL227484, 23 June 2017. [Google Scholar]

- Nicolin, I.; Nicolin, B.A. The fly-by-wire system. INCAS Bull. 2019, 11, 217–222. [Google Scholar] [CrossRef]

- Meneghetti, G.; Rigon, D.; Cozzi, D.; Waldhauser, W.; Dabala, M. Influence of build orientation on static and axial fatigue properties of maraging steel specimens produced by additive manufacturing. In Proceedings of the 3rd International Symposium on Fatigue Design and Material Defects, FDMD 2017, Lecco, Italy, 19–22 September 2017. [Google Scholar]

| Grade | Wrought | Cast | AM Powder | |||

|---|---|---|---|---|---|---|

| 18Ni1400 | 18Ni1700 | 18Ni1900 | 18Ni2400 | 17Ni1600 | M300/1.2709 | |

| Nominal 0.2% Proof Stress (MPa) | 1400 | 1700 | 1900 | 2400 | 1600 | 1800 |

| Ni | 17–19 | 17–19 | 18–19 | 17–18 | 16–17.5 | 17–19 |

| Co | 8.0–9.0 | 7.0–8.5 | 8.0–9.5 | 12–13 | 9.5–11.0 | 8.5–9.5 |

| Mo | 3.0–3.5 | 4.6–5.1 | 4.6–5.2 | 3.5–4.0 | 4.4–4.8 | 4.5–5.2 |

| Ti | 0.15–0.25 | 0.3–0.5 | 0.5–0.8 | 1.6–2.0 | 0.15–0.45 | 0.6–0.8 |

| Al | 0.05–0.15 | 0.05–0.15 | 0.05–0.15 | 0.1–0.2 | 0.02–0.1 | 0.05–0.15 |

| Si max. | 0.12 | 0.12 | 0.12 | 0.1 | 0.1 | 0.1 |

| Mn max. | 012 | 0.12 | 0.12 | 0.1 | 0.1 | 0.1 |

| C max. | 0.03 | 0.03 | 0.03 | 0.01 | 0.03 | 0.03 |

| Fe | Balance | Balance | Balance | Balance | Balance | Balance |

| Sample No. | R0.2 (MPa) | Rm (MPa) | A (%) | Z (%) |

|---|---|---|---|---|

| P1/128/01 | 1317 | 1432 | 2.9 | 18 |

| P1/128/02 | 1359 | 1450 | 5.1 | 21 |

| P1/128/03 | 1445 | 1530 | 4.4 | 21 |

| P1/128/04 | 1309 | 1397 | 1.2 | 5 |

| P1/128/05 | 1530 | 1603 | 2.8 | 13 |

| P1/128/06 | 1338 | 1417 | 6.8 | 10 |

| P1/128/07 | 1268 | 1336 | 2.8 | 5 |

| P1/128/08 | 1259 | 1347 | 6.0 | 6 |

| P1/128/09 | 1204 | 1287 | 4.8 | 8 |

| P1/128/10 | 1442 | 1514 | 6.9 | 13 |

| Sample No. | σmax (MPa) | σmin (MPa) | Nf (Cycles) |

|---|---|---|---|

| R1/128/01 | 1200 | 60 | 216 |

| R1/128/02 | 1000 | 50 | 1237 |

| R1/128/03 | 800 | 40 | 3504 |

| R1/128/04 | 600 | 30 | 22,077 |

| R1/128/05 | 450 | 22.5 | 31,324 |

| R1/128/06 | 300 | 15 | 47,489 |

| R1/128/07 | 250 | 12.5 | 111,361 |

| R1/128/08 | 210 | 10.5 | 300,000 * |

| R1/128/09 | 200 | 10 | 300,000 * |

| Sample No. | t (mm) | P (psi) | σmax (MPa) | Nf (Cycles) |

|---|---|---|---|---|

| X0937 | 0.4 | 2900 | 592 | 15,052 |

| X0938 | 0.4 | 3600 | 735 | 20,452 |

| X0939 | 0.4 | 2200 | 449 | 52,125 |

| X0940 | 0.4 | 4895 | 1000 | 4474 |

| X0941 | 0.4 | 1375 | 281 | 1,000,000 * |

| X0942 | 0.4 | 1700 | 347 | 1,000,000 * |

| X0949 | 0.5 | 1375 | 276 | 1,000,000 * |

| X0950 | 0.5 | 1600 | 321 | 1,000,000 * |

| X0951 | 0.5 | 1850 | 371 | 301,249 |

| X0952 | 0.5 | 2600 | 521 | 88,639 |

| X0953 | 0.5 | 2250 | 451 | 99,572 |

| X0954 | 0.5 | 3000 | 601 | 40,106 |

| X0961 | 0.6 | 1375 | 293 | 1,000,000 * |

| X0962 | 0.6 | 1600 | 341 | 1,000,000 * |

| X0963 | 0.6 | 1850 | 394 | 278,403 |

| X0964 | 0.6 | 2600 | 554 | 119,877 |

| X0965 | 0.6 | 4050 | 863 | 2920 |

| X0966 | 0.6 | 2816 | 600 | 89,037 |

| Mechanical Data | Average Stress Values | Maximal Error |

|---|---|---|

| Yield strength | 1347 MPa | 13% |

| Ultimate strength | 1431 MPa | 12% |

| Tensile fatigue strength, mean, R = 0.05 | 97 MPa | 8% |

| Pressure fatigue strength, mean, R = 0 | 155 MPa | 11% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warzocha, K.; Szura, J.; Bąk, P.; Rzucidło, P.; Rogalski, T. Transformative Use of Additive Technology in Design and Manufacture of Hydraulic Actuator for Fly-by-Wire System. Appl. Sci. 2021, 11, 4772. https://doi.org/10.3390/app11114772

Warzocha K, Szura J, Bąk P, Rzucidło P, Rogalski T. Transformative Use of Additive Technology in Design and Manufacture of Hydraulic Actuator for Fly-by-Wire System. Applied Sciences. 2021; 11(11):4772. https://doi.org/10.3390/app11114772

Chicago/Turabian StyleWarzocha, Krzysztof, Jerzy Szura, Piotr Bąk, Paweł Rzucidło, and Tomasz Rogalski. 2021. "Transformative Use of Additive Technology in Design and Manufacture of Hydraulic Actuator for Fly-by-Wire System" Applied Sciences 11, no. 11: 4772. https://doi.org/10.3390/app11114772

APA StyleWarzocha, K., Szura, J., Bąk, P., Rzucidło, P., & Rogalski, T. (2021). Transformative Use of Additive Technology in Design and Manufacture of Hydraulic Actuator for Fly-by-Wire System. Applied Sciences, 11(11), 4772. https://doi.org/10.3390/app11114772