Influence of Laboratory Compaction Method on Compaction and Strength Characteristics of Unbound and Cement-Bound Mixtures

Abstract

:1. Introduction

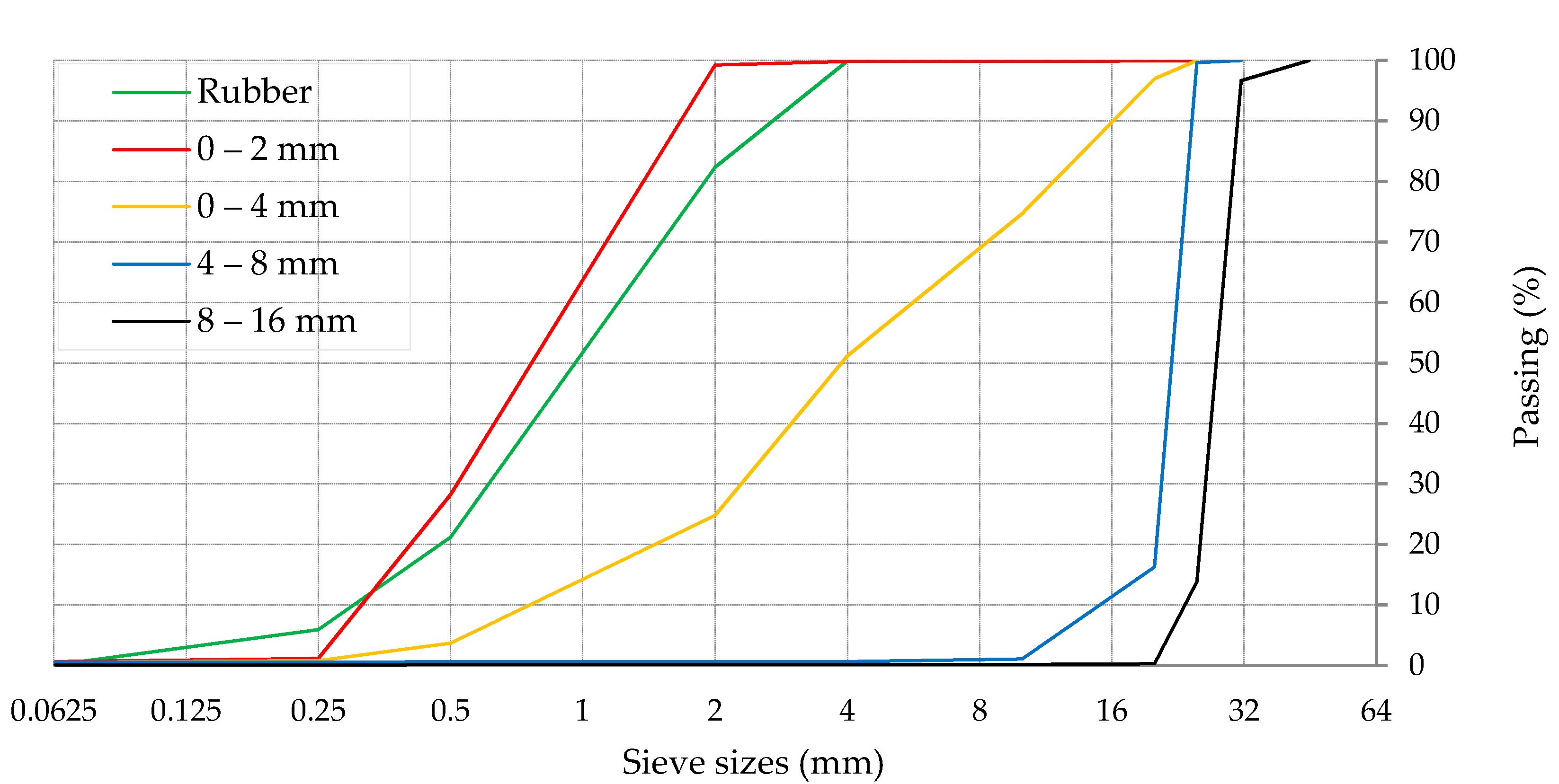

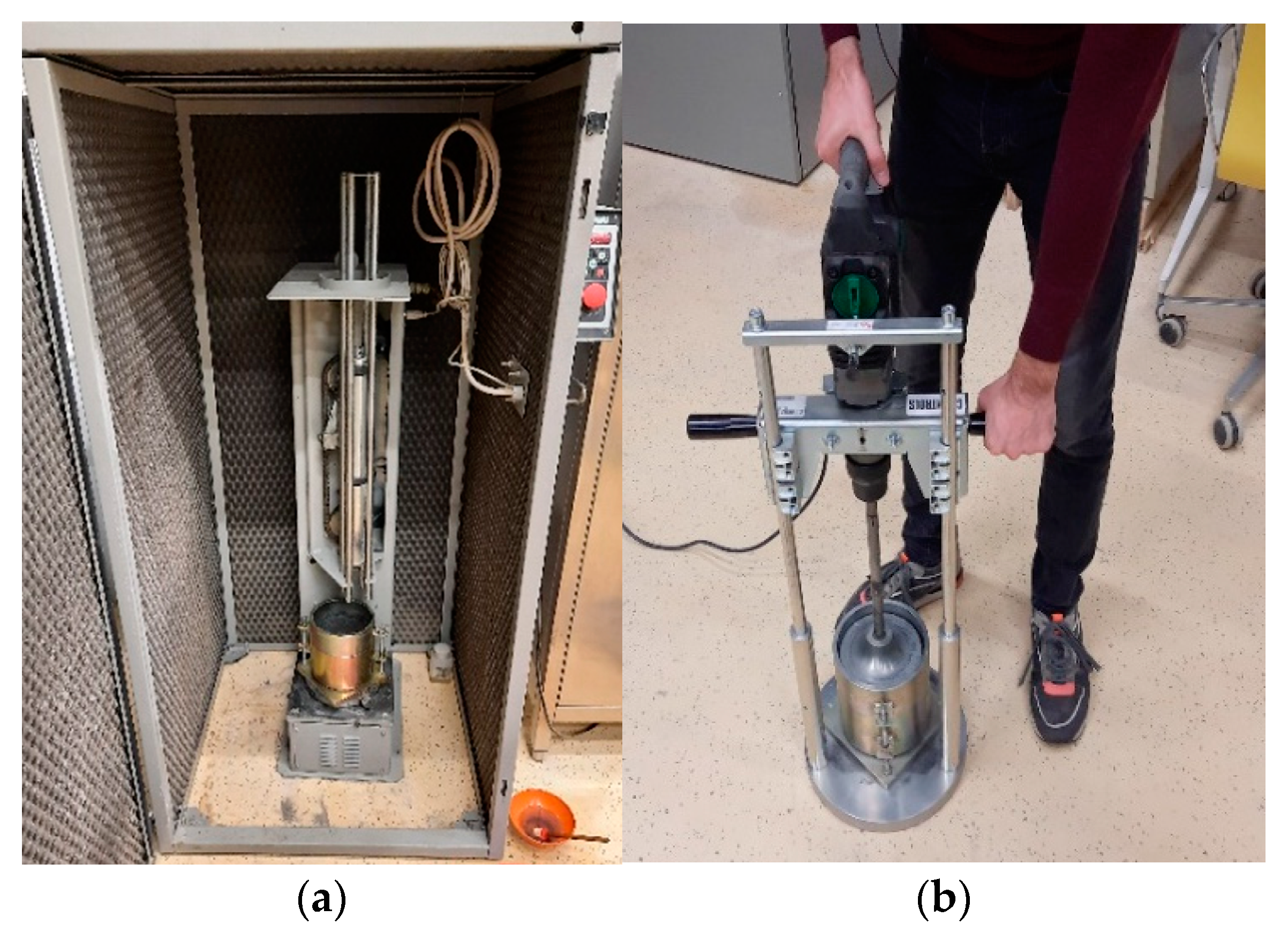

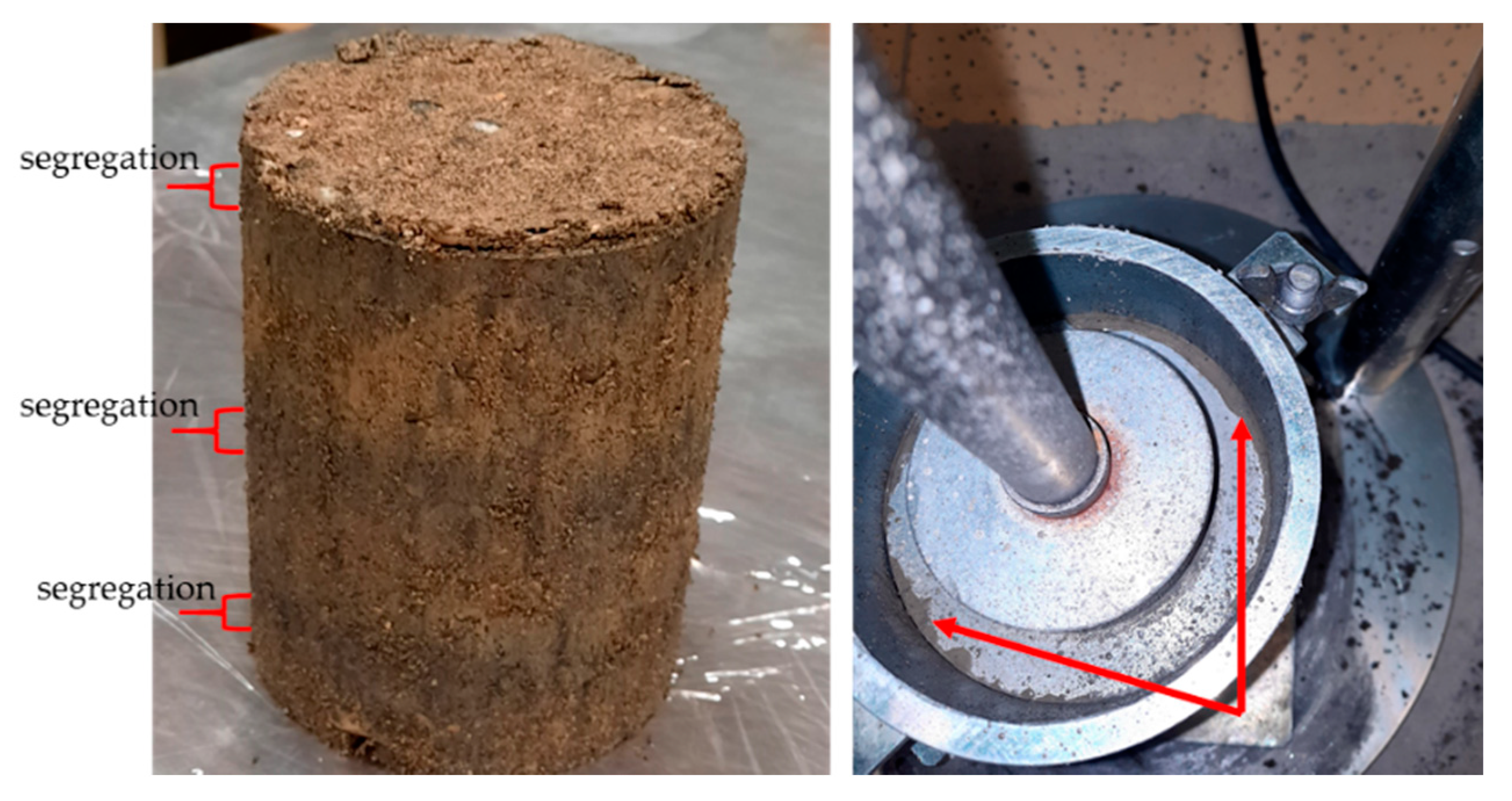

2. Materials and Methods

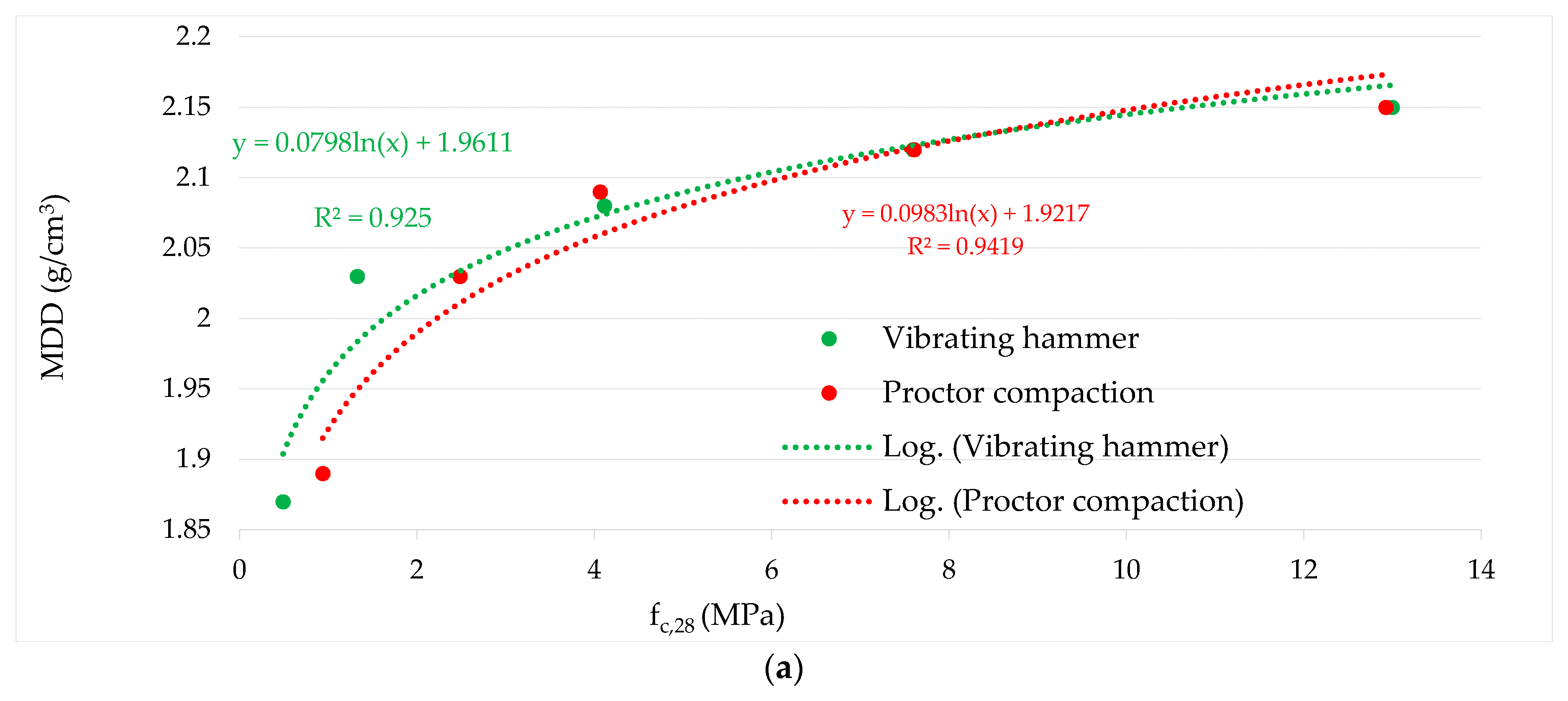

3. Results and Discussion

3.1. Compaction Characteristics

3.2. Strength Characteristics

4. Conclusions

- There is strong correlation between the compaction and strength characteristics obtained in laboratory conditions using the modified Proctor and vibrating hammer compaction methods for natural aggregate mixtures.

- A greater drop in the compaction characteristics for rubber mixtures and the use of the Proctor compaction method lead to the conclusion that the laboratory compaction method should be chosen carefully if alternative materials such as waste rubber are used.

- For higher cement content mixtures, a higher OMC difference depending on the laboratory compaction method used is observed and the laboratory compaction method should be chosen carefully, particularly if moisture-susceptible materials are used.

- Comparing the compaction effects (MDD, OMC and density), it can be observed that approximately the same compaction energy was applied using both compaction methods. However, calculation of the compaction energy using a vibrating hammer is more difficult than for the Proctor test, and it should be investigated in more detail. Further research should provide an additional insight into the comparability of the vibrating hammer and standard Proctor tests, applying less compaction energy than the modified Proctor test used in this research.

- The choice of laboratory compaction method should be made carefully depending on the specific behaviour of materials used and the expected field conditions.

Author Contributions

Funding

Institutional Review Boards Statement

Informed Consent Statement

Conflicts of Interest

References

- Zhu, X.; Bai, S.; Xue, G.; Yang, J.; Cai, Y.; Hu, W.; Jia, X.; Huang, B. Assessment of compaction quality of multi-layer pavement structure based on intelligent compaction technology. Constr. Build. Mater. 2018, 161, 316–329. [Google Scholar] [CrossRef]

- Bezak, S.; Bezak, S.; Ereš, M. (Eds.) General Technical Conditions for Road Works; Institut građevinarstva Hrvatske: Zagreb, Croatia, 2001. [Google Scholar]

- Xu, Q.; Chang, G.K. Adaptive quality control and acceptance of pavement material density for intelligent road construction. Autom. Constr. 2016, 62, 78–88. [Google Scholar] [CrossRef]

- Chen, L.; Qiao, L.; Li, Q. Study on dynamic compaction characteristics of gravelly soils with crushing effect. Soil Dyn. Earthq. Eng. 2019, 120, 158–169. [Google Scholar] [CrossRef]

- Triantafyllidis, T.; Kimmig, I. A simplified model for vibro compaction of granular soils. Soil Dyn. Earthq. Eng. 2019, 122, 261–273. [Google Scholar] [CrossRef]

- Chilukwa, N.N. Vibratory Hammer Compaction of Granular Materials; Stellenbosch University: Stellenbosch, South Africa, 2013. [Google Scholar]

- Kodikara, J.; Islam, T.; Sounthararajah, A. Review of soil compaction: History and recent developments. Transp. Geotech. 2018, 17, 24–34. [Google Scholar] [CrossRef]

- Fathi, A.; Tirado, C.; Rocha, S.; Mazari, M.; Nazarian, S. Assessing depth of influence of intelligent compaction rollers by integrating laboratory testing and field measurements. Transp. Geotech. 2021, 28, 100509. [Google Scholar] [CrossRef]

- Pistrol, J.; Adam, D. Fundamentals of roller integrated compaction control for oscillatory rollers and comparison with conventional testing methods. Transp. Geotech. 2018, 17, 75–84. [Google Scholar] [CrossRef]

- Pistrol, J.; Villwock, S.; Völkel, W.; Kopf, F.; Adam, D. Continuous Compaction Control (CCC) with Oscillating Rollers. Procedia Eng. 2016, 143, 514–521. [Google Scholar] [CrossRef] [Green Version]

- Paulmichl, I.; Adam, C.; Adam, D. Analytical modeling of the stick-slip motion of an oscillation drum. Acta Mech. 2019, 230, 3103–3126. [Google Scholar] [CrossRef] [Green Version]

- Hu, W.; Shu, X.; Huang, B.; Woods, M.E. An examination of compaction meter value for asphalt pavement compaction evaluation. Int. J. Pavement Eng. 2017, 19, 447–455. [Google Scholar] [CrossRef]

- Hu, W.; Huang, B.; Shu, X.; Woods, M. Utilising intelligent compaction meter values to evaluate construction quality of asphalt pavement layers. Road Mater. Pavement Des. 2016, 18, 980–991. [Google Scholar] [CrossRef]

- Hu, W.; Jia, X.; Zhu, X.; Gong, H.; Xue, G.; Huang, B. Investigating key factors of intelligent compaction for asphalt paving: A comparative case study. Constr. Build. Mater. 2019, 229, 116876. [Google Scholar] [CrossRef]

- Ling, J.; Lin, S.; Qian, J.; Zhang, J.; Han, B.; Liu, M. Continuous Compaction Control Technology for Granite Residual Subgrade Compaction. J. Mater. Civ. Eng. 2018, 30, 04018316. [Google Scholar] [CrossRef]

- Hu, W.; Shu, X.; Jia, X.; Huang, B. Geostatistical analysis of intelligent compaction measurements for asphalt pavement compaction. Autom. Constr. 2018, 89, 162–169. [Google Scholar] [CrossRef]

- Leonard, L.; Ekwue, E.I.; Taylor, A.; Birch, R. Evaluation of a machine to determine maximum bulk density of soils using the vibratory method. Biosyst. Eng. 2019, 178, 109–117. [Google Scholar] [CrossRef]

- Sengun, E.; Alam, B.; Shabani, R.; Yaman, I. The effects of compaction methods and mix parameters on the properties of roller compacted concrete mixtures. Constr. Build. Mater. 2019, 228, 116807. [Google Scholar] [CrossRef]

- Izquierdo, M.; Querol, X.; Vazquez, E. Procedural uncertainties of Proctor compaction tests applied on MSWI bottom ash. J. Hazard. Mater. 2011, 186, 1639–1644. [Google Scholar] [CrossRef]

- Drnevich, V.; Evans, A.; Prochaska, A. A Study of Effective Soil Compaction Control of Granular Soils. Jt. Transp. Res. Program 2007. [Google Scholar] [CrossRef] [Green Version]

- Hoff, I.; Bakløkk, L.J.; Aurstad, J. Influence of Laboratory Compaction Method on Unbound Granular Materials. In International Symposium on Pavements Unbound, 6th ed.; Dawson, A., Ed.; CRC Press: Nottingham, England, 2004. [Google Scholar]

- McLachlan, R.; Bagshaw, S. Standardisation of Laboratory Compaction Energies; NZ Transport Agency: Wellington, New Zeland, 2017. [Google Scholar]

- Wu, P.; Houben, L.J.M. Investigation of the Effects of Different Laboratory Compacting Methods on the Properties of Cement Stabilized Materials. In Proceedings of the Ninth International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 25–27 June 2013; Hoff, I., Mork, H., Garba Saba, R., Eds.; CRC Press: Boca Raton, FL, USA, 2018; Volume 2. [Google Scholar]

- Scott, B.T.; Jaksa, M.B.; Mitchell, P. Influence of towing speed on effectiveness of rolling dynamic compaction. J. Rock Mech. Geotech. Eng. 2020, 12, 126–134. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Characterization of rubberized cement bound aggregate mixtures using indirect tensile testing and fractal analysis. Constr. Build. Mater. 2016, 105, 94–102. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Effect of cementation level on performance of rubberized cement-stabilized aggregate mixtures. Mater. Des. 2016, 97, 98–107. [Google Scholar] [CrossRef]

- Huang, W.; Huang, X.; Xing, Q.; Zhou, Z. Strength reduction factor of crumb rubber as fine aggregate replacement in concrete. J. Build. Eng. 2020, 32, 101346. [Google Scholar] [CrossRef]

- Habib, A.; Yildirim, U.; Eren, O. Mechanical and dynamic properties of high strength concrete with well graded coarse and fine tire rubber. Constr. Build. Mater. 2020, 246, 118502. [Google Scholar] [CrossRef]

- Gou, Y.; Zhang, L.; Liu, C.; Zhang, H.; Wei, C.; Cai, X.; Yang, H.; Guan, Q.; Zhai, S.; Liu, L. Investigation of freeze-thaw mechanism for crumb rubber concrete by the online strain sensor. Measurement 2021, 174, 109080. [Google Scholar] [CrossRef]

- European Commitee for Standardization. HRN EN 933-1: 2012 Test for Geometrical Properties of Aggregates—Part 1: Determination of Particle size Distribution—Sievin Method; CEN: Brussels, Belgium, 2012. [Google Scholar]

- European Commitee for Standardization. HRN EN 13285:2018 Unbound Mixtures—Specifications; CEN: Brussels, Belgium, 2018. [Google Scholar]

- European Commitee for Standardization. HRN EN 14227-1:2013 Hydraulically bound mixtures—Specifications—Part 1: Cement Bound Granular Mixtures; CEN: Brussels, Belgium, 2013. [Google Scholar]

- European Commitee for Standardization. HRN EN 1097-6:2013 Test for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption; CEN: Brussels, Belgium, 2013. [Google Scholar]

- European Commitee for Standardization. HRN EN 196-6:2018 Methods of Testing Cement—Part 6: Determination of Fineness; CEN: Brussels, Belgium, 2018. [Google Scholar]

- Barišić, I.; Dimter, S.; Rukavina, T. Characterization of cement stabilized pavement layers with ultrasound testing. Teh. Vjesn. Tech. Gaz. 2016, 23, 447–453. [Google Scholar] [CrossRef] [Green Version]

- European Commitee for Standardization. HRN EN 13286-51:2004 Unbound and Hydraulically Bound Mixtures—Part 51: Methods for the Manufacture of Test Specimens of Hydraulically Bound Mixtures Using Vibrating Hammer Compaction; CEN: Brussels, Belgium, 2004. [Google Scholar]

- European Commitee for Standardization. HRN EN 13286-2:2010 Unbound and Hydraulically Bound Mixtures—Part 2: Test Method for Laboratory Dry Density and Water Content—Proctor Compaction; CEN: Brussels, Belgium, 2010. [Google Scholar]

- European Commitee for Standardization. HRN EN 13286-4:2003 Unbound and Hydraulically Bound Mixtures—Part 4: Test Methods for Laboratory Reference Density and Water Content—Vibrating Hammer; CEN: Brussels, Belgium, 2003. [Google Scholar]

- European Commitee for Standardization. HRN EN 13286-47:2012 Unbound and Hydraullically Bound Mixtures—Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling; CEN: Brussels, Belgium, 2012. [Google Scholar]

- European Commitee for Standardization. HRN EN 13286-41:2003 Unbound and Hydraulically Bound Mixtures-Pari 41: Test Method for the Determination of the Compressive Strenght of Hydraulically Bound Mixtures; CEN: Brussels, Belgium, 2003. [Google Scholar]

- European Commitee for Standardization. EN 13286-50 Unbound and hydraulicylly Bound Mixtures—Part 50: Method for the Manufacture of Test Specimens of Hydraulically Bound Mixtures Using Proctor Equipment or Vibrating Table Compaction; CEN: Brussels, Belgium, 2004. [Google Scholar]

- Ovad, E.; Barišić, I.; Zagvozda, M. Comparison of Croatian and European standards for Determining the Frost Suspectibility of Hydraulically Bound Mixtures. e-GFOS 2014, 5, 41–48. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H.; Adam, S.; Smith, M.J. Flexural characteristics of rubberized cement-stabilized crushed aggregate for pavement structure. Mater. Des. 2015, 88, 897–905. [Google Scholar] [CrossRef]

- Sun, X.; Wu, S.; Yang, J.; Yang, R. Mechanical properties and crack resistance of crumb rubber modified cement-stabilized macadam. Constr. Build. Mater. 2020, 259, 119708. [Google Scholar] [CrossRef]

| Mix | 0%C | 3%C | 5%C | 7%C | 5%C + 20%R | 5%C + 30%R | 5%C + 60%R |

|---|---|---|---|---|---|---|---|

| Cement [vol.%] | 0 | 2.78 | 4.56 | 6.26 | 4.56 | 4.56 | 4.56 |

| 0–2 mm [vol.%] | 19.60 | 23.61 | 23.18 | 22.77 | 18.54 | 16.23 | 9.27 |

| 0–4 mm [vol.%] | 38.00 | 22.87 | 22.46 | 22.06 | 22.46 | 22.46 | 22.46 |

| 4–8 mm [vol.%] | 32.00 | 25.69 | 25.21 | 24.76 | 25.21 | 25.21 | 25.21 |

| 8–16 mm [vol.%] | 10.40 | 25.05 | 24.59 | 24.15 | 24.59 | 24.59 | 24.59 |

| Rubber [vol.%] | 0 | 0 | 0 | 0 | 4.64 | 6.95 | 13.91 |

| Mix volume [%] | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 0%C | 3%C | 5%C | 7%C | 5%C + 20%R | 5%C + 30%R | 5%C + 60%R | |

|---|---|---|---|---|---|---|---|

| OMC [%] | 4.79/4.72 | 4.91/5.15 | 5.35/5.87 | 5.53/6.10 | 5.32/5.53 | 5.21/5.13 | 4.94/4.94 |

| MDD [g/cm3] | 2.01/1.97 | 2.08/2.09 | 2.12/2.12 | 2.15/2.15 | 2.10/2.06 | 2.03/2.03 | 1.87/1.89 |

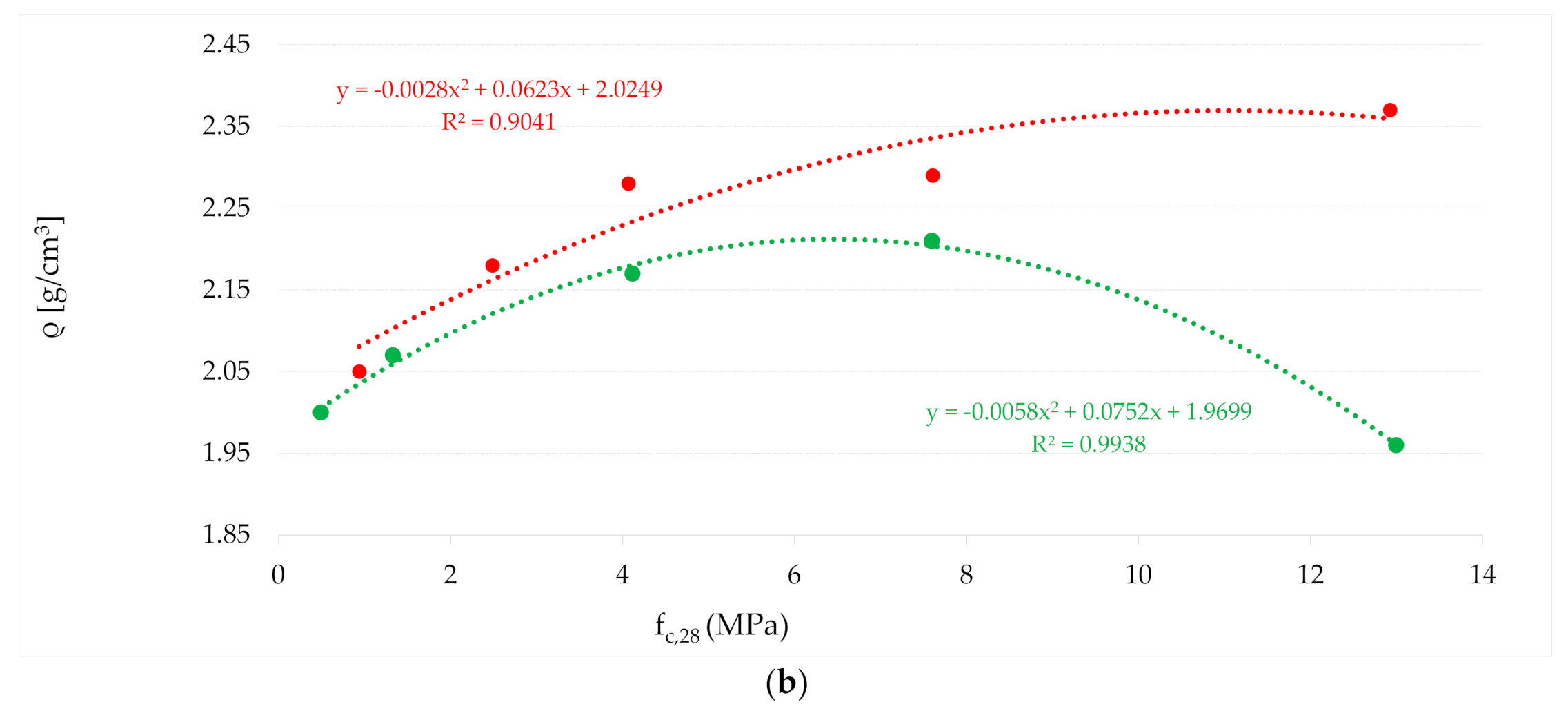

| ρ [g/cm3] | not applicable | 2.17/2.28 | 2.21/2.29 | 1.96/2.37 | 2.18/2.23 | 2.07/2.18 | 1.96/2.05 |

| CBR [%] | 101/98 | not applicable | not applicable | not applicable | not applicable | not applicable | not applicable |

| fc [MPa] | not applicable | 4.11/4.06 | 7.59/7.60 | 12.99/12.92 | 1.89/3.13 | 1.33/2.48 | 0.49/0.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zvonarić, M.; Barišić, I.; Galić, M.; Minažek, K. Influence of Laboratory Compaction Method on Compaction and Strength Characteristics of Unbound and Cement-Bound Mixtures. Appl. Sci. 2021, 11, 4750. https://doi.org/10.3390/app11114750

Zvonarić M, Barišić I, Galić M, Minažek K. Influence of Laboratory Compaction Method on Compaction and Strength Characteristics of Unbound and Cement-Bound Mixtures. Applied Sciences. 2021; 11(11):4750. https://doi.org/10.3390/app11114750

Chicago/Turabian StyleZvonarić, Matija, Ivana Barišić, Mario Galić, and Krunoslav Minažek. 2021. "Influence of Laboratory Compaction Method on Compaction and Strength Characteristics of Unbound and Cement-Bound Mixtures" Applied Sciences 11, no. 11: 4750. https://doi.org/10.3390/app11114750

APA StyleZvonarić, M., Barišić, I., Galić, M., & Minažek, K. (2021). Influence of Laboratory Compaction Method on Compaction and Strength Characteristics of Unbound and Cement-Bound Mixtures. Applied Sciences, 11(11), 4750. https://doi.org/10.3390/app11114750