Floor Heave Mechanism and Anti-Slide Piles Control Technology in Deep and Large-Span Chamber

Abstract

:1. Introduction

2. Discussion on the Floor Heave Mechanism in Deep Chambers

2.1. Plastic Flow Characteristics of the Floor in Deep Chambers

2.2. Ultimate Bearing Capacity of the Floor in Deep and Large-Span Chambers

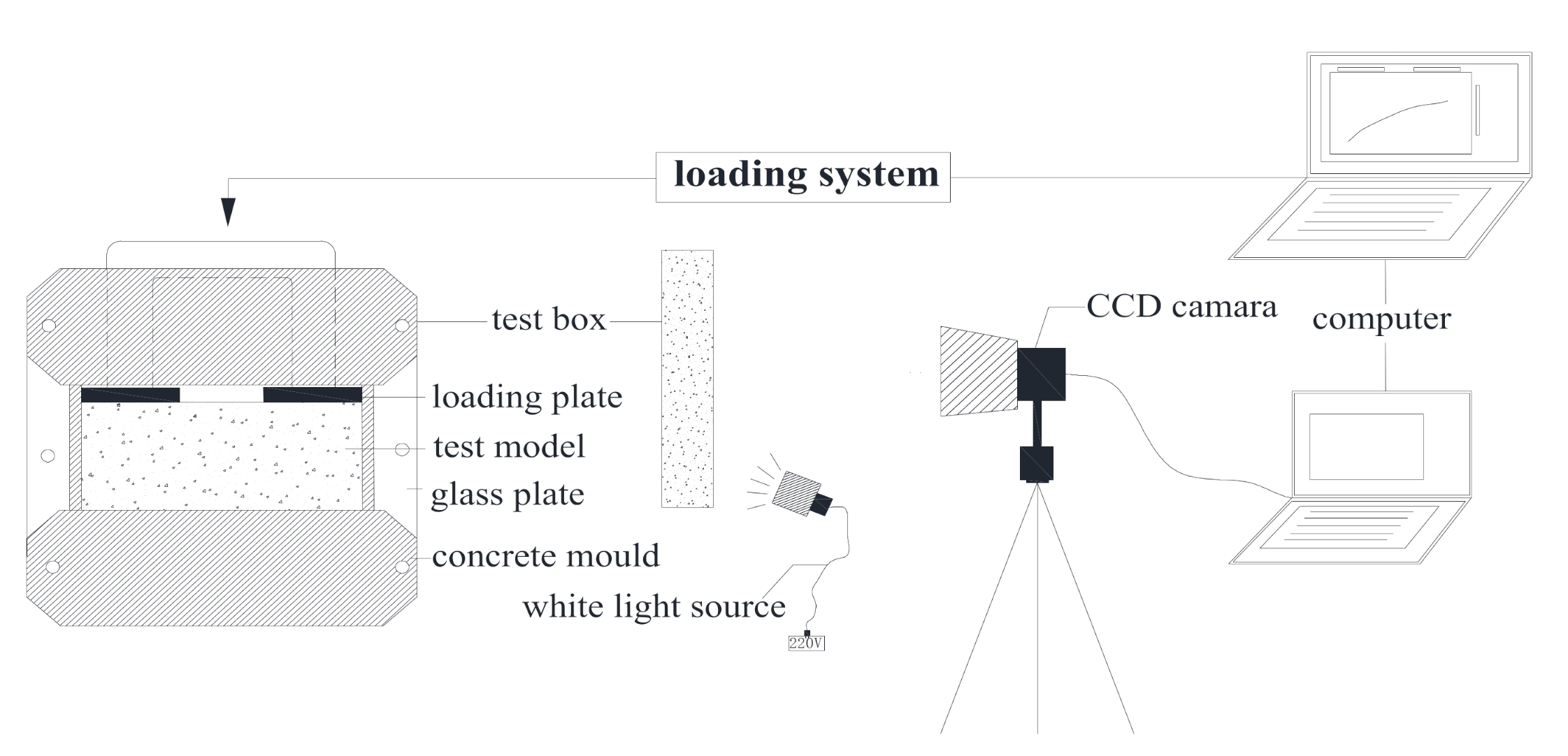

3. Model Test Based on Digital Speckle Correlation Method

3.1. Digital Speckle Correlation Method

3.2. Test Scheme

3.3. Analysis of Test Results

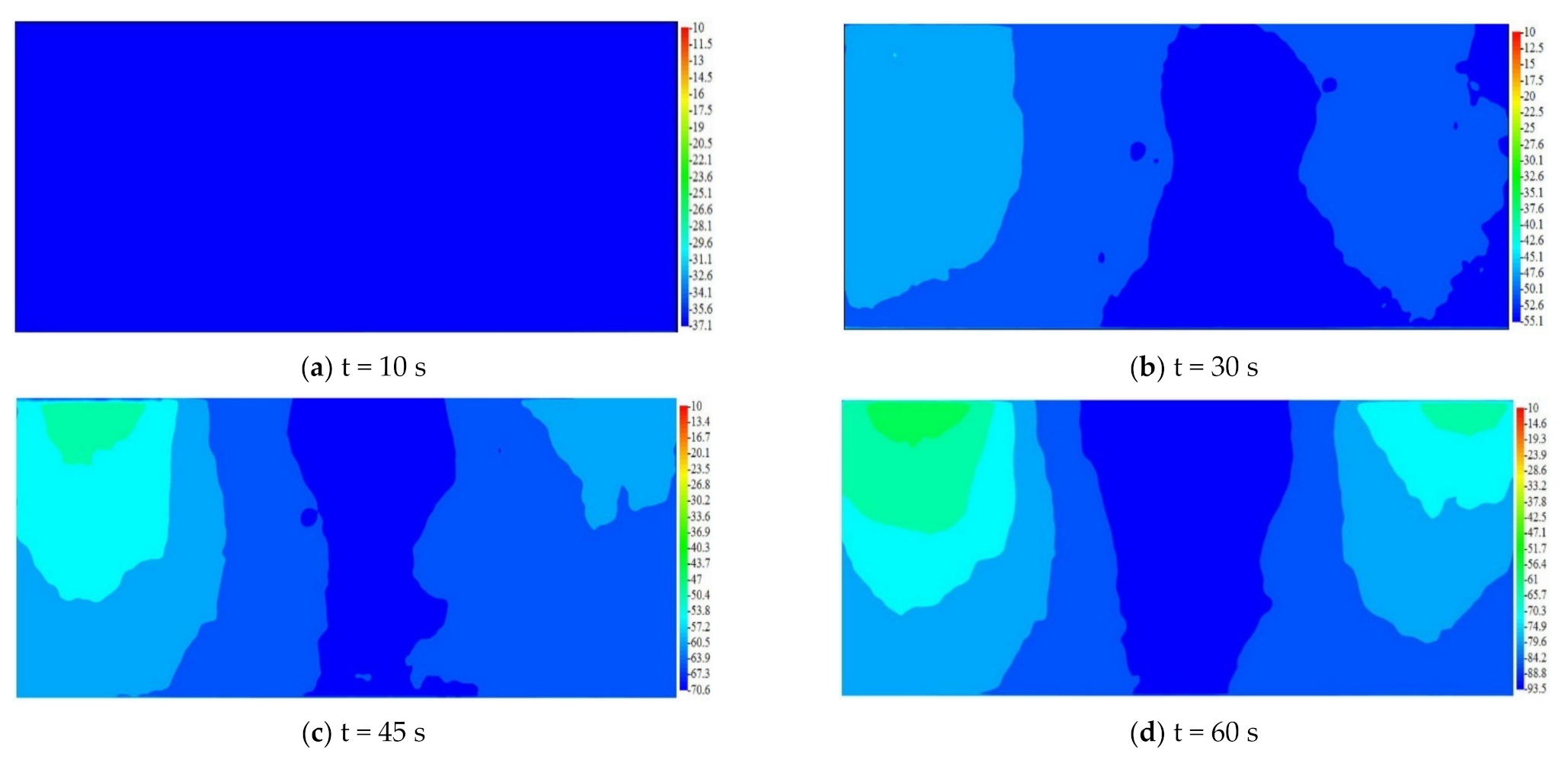

3.3.1. Analysis of Plastic Zone Range and Distribution Law

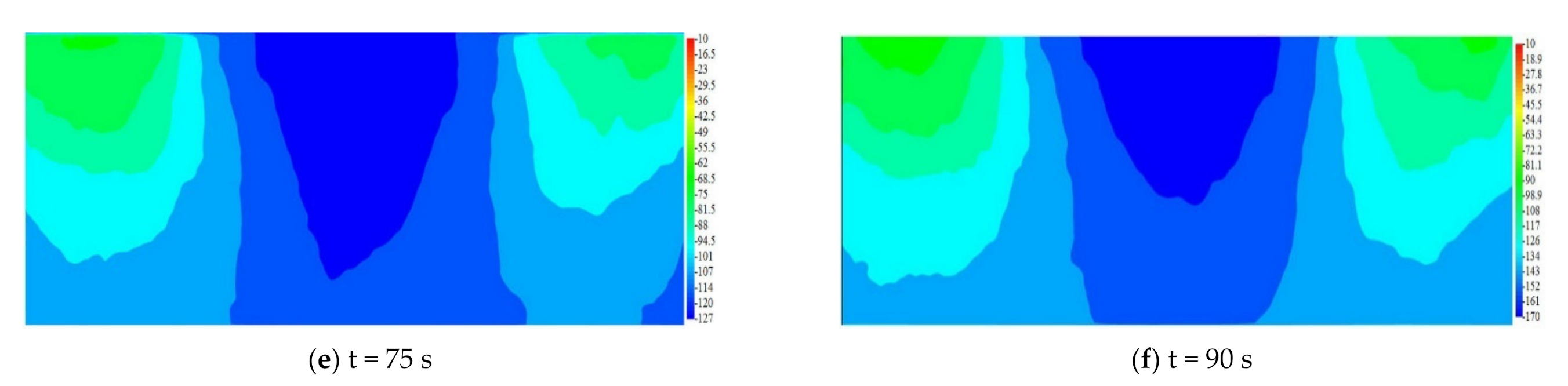

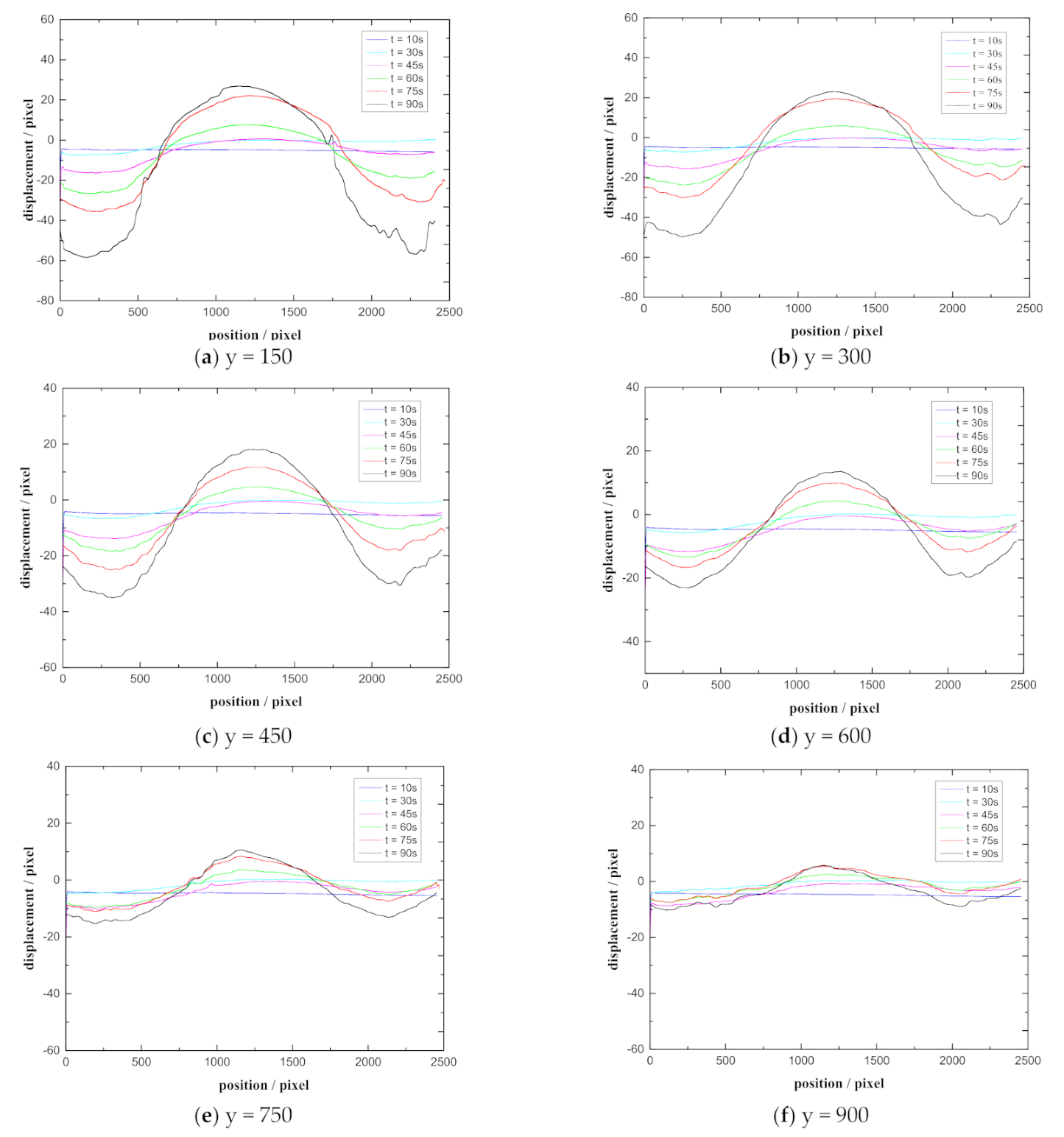

3.3.2. Analysis of Displacement Evolution Law

- At the initial stage of loading, the displacement of each section is approximately a straight line and the value of each point is negative, which indicates that the overall vertical compression deformation occurs when the load is small, which is elastic and recoverable;

- With the increase in load, the deformation of each section appears as a zoning phenomenon, that is, in the intervals of (0,750) and (1750,2500) in the X direction, the deformation continues to develop along the Y-axis in a negative direction, and the greater the load, the greater the deformation; whereas in interval (750,1750), the deformation continues to develop along the Y-axis in the positive direction, and the greater the load, the greater the deformation;

- The deformation of the midpoint in interval (750,1750) is the largest, whereas the deformation on both sides of the midpoint is relatively small, which is consistent with the Hill-like deformation mode of central uplift.

4. Anti-Slide Pile Control Technology and Supporting Parameter Determination

4.1. Length Determination of Anti-Slide Pile

4.2. Formatting of Mathematical Components

4.3. Bearing Capacity of Anti-Slide Pile

5. Engineering Application of Anti-Slide Pile to Controlling Floor Heave

5.1. General Engineering Situation

5.2. Support Scheme of Chamber Floor

5.3. Length Calculation of Anti-Slide Pile

5.4. Stability Check of Floor

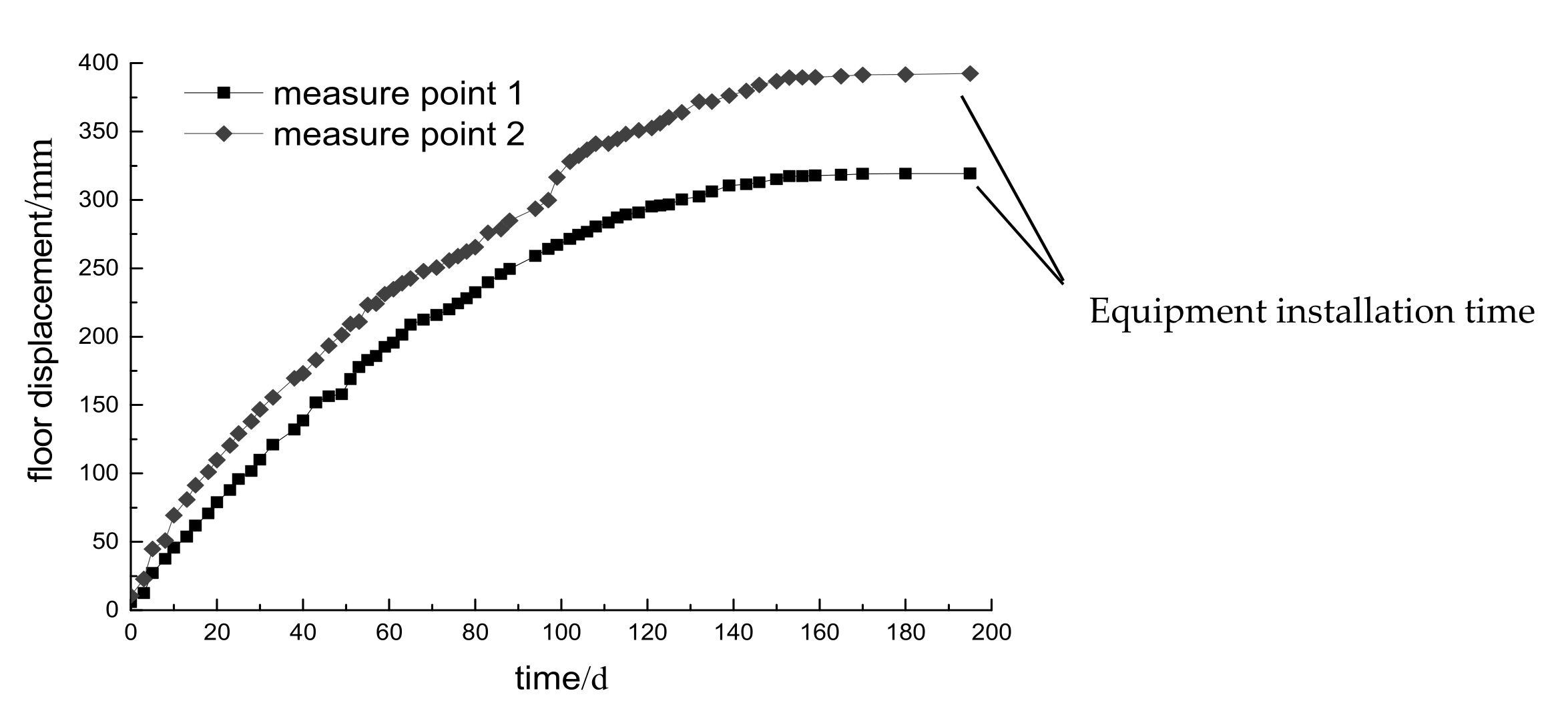

5.5. Support Effect

6. Conclusions

- (1)

- Under the action of the compression mold effect, the local shear failure first appears below the loading area and develops to the middle part gradually; when the load increases to a certain extent, the local shear failure develops to form a continuous sliding surface and continuous plastic flow deformation occurs.

- (2)

- The essential mechanism of the anti-slide pile controlling of floor heave is that the floor enters into plastic flow in the form of shear slip under stress from vertical load. Laying anti-slide piles perpendicular to the slip surface through the floor can resist shear deformation and realize the goal of stability.

- (3)

- For anti-slide piles, controlling floor heave was proposed according to plastic limit theory; the limit analysis of slip line theory provided a theoretical basis for the design and parameter determination of the anti-slide pile.

- (4)

- An example showed the scheme combining anti-slide piles with anchors has strong supporting capacity to control floor heave in deep chambers, which can meet the needs of using the floor under the limit equilibrium state. The combination is beneficial to ensuring the uniform stress of the floor in large-span chambers and maintaining the floor in good condition.

- (5)

- Practice proved that controlling floor heave by anti-slide piles provides the advantages of a simple process, fast construction, low cost, and significant effects, which have values for their popularization and application in similar conditions.

7. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Afrouz, A. Geotechnical assessment of the bearing capacity of coal mine floors. Int. J. Min. Geol. Eng. 1989, 6, 297–312. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Lu, S. Deformational behavior of roadway rocks in underground coal mines and principles for stability control. Int. J. Rock Mech. Min. Sci. 2000, 37, 937–946. [Google Scholar] [CrossRef]

- Meng, B.; Jing, H.W.; Chen, K.F.; Su, H.J. Failure mechanism and stability control of a large section of very soft roadway surrounding rock shear slip. Int. J. Min. Sci. Technol. 2013, 23, 127–134. [Google Scholar] [CrossRef]

- Wang, M.; Guo, G.L.; Wang, X.Y.; Guo, Y.; Dao, V. Floor heave characteristics and control technology of the roadway driven in deep inclined-strata. Int. J. Min. Sci. Technol. 2015, 25, 267–273. [Google Scholar] [CrossRef]

- Chang, J.C.; Xie, G.X. Floor heave mechanism and over-excavation & grouting-backfilling technology in rock roadway of deep mine. J. Min. Saf. Eng. 2011, 28, 361–364. [Google Scholar]

- Gao, M.Z. Mechanism of roadway floor heave by bending under pressure and its control. J. Anhui Univ. Sci. Technol. 2008, 28, 20–24. [Google Scholar]

- Liu, Q.S.; Liu, X.W.; Huang, X.; Liu, B. Research on the floor heave reasons and supporting measures of deep soft-fractured rock roadway. J. China Coal Soc. 2013, 38, 566–571. [Google Scholar]

- Zheng, X.G.; Liu, N.; Zhang, N.; Hua, J.B.; Feng, X.W. Floor heave mechanism and control technology of flexural and folded deep mine roadway. J. China Coal Soc. 2013, 39, 417–423. [Google Scholar]

- Liu, S.W.; Zhang, W.G.; Feng, Y.L. Study on migration mechanism of slipping floor heave rock mass in deep roadway and its control countermeasure. J. Min. Saf. Eng. 2013, 30, 706–711. [Google Scholar]

- Fu, J.J.; Liu, Q.S.; Zhao, H.B.; Qiu, S.M.; Shi, K. Mechanism and countern easure for floor heave of deep coal mine roadways. Min. Metall. Eng. 2010, 30, 21–26. [Google Scholar]

- Fang, X.Q.; Zhao, J.J.; Hong, M.Y. Failure mechanism and control measure of roadway deformation with fractured surrounding rock in deep mine. J. Min. Saf. Eng. 2012, 29, 1–7. [Google Scholar]

- Yue, Z.W.; Yang, R.S.; Yan, Z.D.; Zhang, Y.H.; Han, P.F. Experimental study on stability of surrounding rock of coal roadway with compound roof and large cross section. J. China Coal Soc. 2011, 36, 47–52. [Google Scholar]

- Zheng, P.Q.; Chen, W.Z.; Tan, X.J.; Dai, Y.H. Study of failure mechanism of floor heave and supporting technology in soft rock of large deformation roadway. Chin. J. Rock Mech. Eng. 2015, 34, 3143–3150. [Google Scholar]

- Li, S.C.; Wang, D.C.; Wang, Q.; Wang, F.Q.; Peng, P.; Li, W.T.; Jiang., B.; Wang, H.T. Development and application of large-scale geomechanical model test system for deep thick top coal roadway. J. China Coal Soc. 2013, 38, 1522–1530. [Google Scholar]

- Wang, H.P.; Li, S.C.; Xue, J.H.; Li, J.M.; Zhang, Q.H.; Ma, Q.Y. Control methods of stability of zonal disintegration surrounding rock in deep rock roadway and its application. Rock Soil Mech. 2014, 35, 1957–1964. [Google Scholar]

- Han, Q.Y.; Zhang, Z.; Yang, X.J.; Wang, F.Q.; Guo, Z.B.; Han, L.P. Mechanism and support measures of floor heave mainly caused by horizontal extrusion stress in soft rock roadway. In Proceedings of the Fifth International Symposium on In-Situ Rock Stress, Beijing, China, 25–28 August 2010. [Google Scholar]

- Wang, J.; Guo, Z.B.; Yan, Y.B.; Pang, J.W.; Zhao, S.J. Floor heave in the west wing track haulage roadway of the Tingnan coal mine: Mechanism and control. Int. J. Min. Sci. Technol. 2012, 22, 295–299. [Google Scholar] [CrossRef]

- Patrick, A.; John, H. The destressability index methodology for the assessment of the likelihood of success of a large-scale confined destress blast in an underground mine pillar. Int. J. Rock Mech. Min. Sci. 2008, 45, 407–421. [Google Scholar]

- Wang, C.; Chen, X.Y.; Zhang, J.D.; Wu, Y.P. Stability Mechanism and Repair Method of U-Shaped Steel Reverse Arch Support in Soft Floor Roadway. Adv. Civ. Eng. 2020, 2020, 8814365. [Google Scholar]

- Li, Z.J.; Li, S.B.; Zhao, X.L. Floor Heave Controlling Technology of Deep Soft Rock Roadway. Appl. Mech. Mater. 2012, 170, 68–71. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.G. Numerical simulation of grooving method for floor heave control in soft rock roadway. Min. Sci. Technol. 2011, 21, 49–56. [Google Scholar]

- Jiao, Y.Y.; Song, L.; Wang, X.Z.; Adoko, A.C. Improvement of the U-shaped steel sets for supporting the roadways in loose thick coal seam. Int. J. Rock Mech. Min. Sci. 2013, 60, 19–25. [Google Scholar] [CrossRef]

- Shi, J.; You, C.A.; Liu, Q.; Yang, L.; Bi, D.B.; Xuan, C. Determination of supporting parameters for floor anchor based on plastic limit analysis. Nonferrous Met. Eng. 2016, 6, 69–73. [Google Scholar]

- Xiao, F.K.; Zhang, C.J.; Gao, L.W.; Yue, Y.Y. Numerical Research on the Floor Heave Control of Deep Roadway in Coal Mining. Adv. Mater. Res. 2012, 1792, 446–449. [Google Scholar] [CrossRef]

- Wang, W.M.; Zhao, Z.H.; Wang, L. Safety analysis for soft rock tunnel floor destruction based on different yield criterions. Chin. J. Rock Mech. Eng. 2012, 31, 3920–3926. [Google Scholar]

- Shi, J.; You, C.A.; Xuan, C.; Yang, L.; Bi, D.B. Effect of the inverted arch manner props in mining roadway based on the maximum plastic limit analysis. J. Saf. Environ. 2016, 16, 139–143. [Google Scholar]

- Zheng, Y.R.; Kong, L. Geotechnical Plastic Mechanics; China Architecture & Building Press: Beijing, China, 2010. [Google Scholar]

- Chen, C.Y.; Martin, G.R. Soil-structure interaction for landslide stabilizing pile. Comput. Geotech. 2002, 29, 363–386. [Google Scholar] [CrossRef]

| Specification Name | Rail Type | Weight | Sectional Area | Steel Material | Tensile Strength |

|---|---|---|---|---|---|

| parameters | GB22 | 22.3 kg·m−1 | 28.39 cm2 | 55 Q | 780 MPa |

| Specification Name | Row × Line Space | Inside (Outside) Diameter | Tensile Strength | Supporting Force |

|---|---|---|---|---|

| parameters | 1000 mm × 1000 mm | 16 (32) mm | 280 kN | 0.28 MPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Kong, D. Floor Heave Mechanism and Anti-Slide Piles Control Technology in Deep and Large-Span Chamber. Appl. Sci. 2021, 11, 4576. https://doi.org/10.3390/app11104576

Shi J, Kong D. Floor Heave Mechanism and Anti-Slide Piles Control Technology in Deep and Large-Span Chamber. Applied Sciences. 2021; 11(10):4576. https://doi.org/10.3390/app11104576

Chicago/Turabian StyleShi, Jian, and Desen Kong. 2021. "Floor Heave Mechanism and Anti-Slide Piles Control Technology in Deep and Large-Span Chamber" Applied Sciences 11, no. 10: 4576. https://doi.org/10.3390/app11104576

APA StyleShi, J., & Kong, D. (2021). Floor Heave Mechanism and Anti-Slide Piles Control Technology in Deep and Large-Span Chamber. Applied Sciences, 11(10), 4576. https://doi.org/10.3390/app11104576