Generic Product Lifecycle Model: A Holistic and Adaptable Approach for Multi-Disciplinary Product–Service Systems

Abstract

Featured Application

Abstract

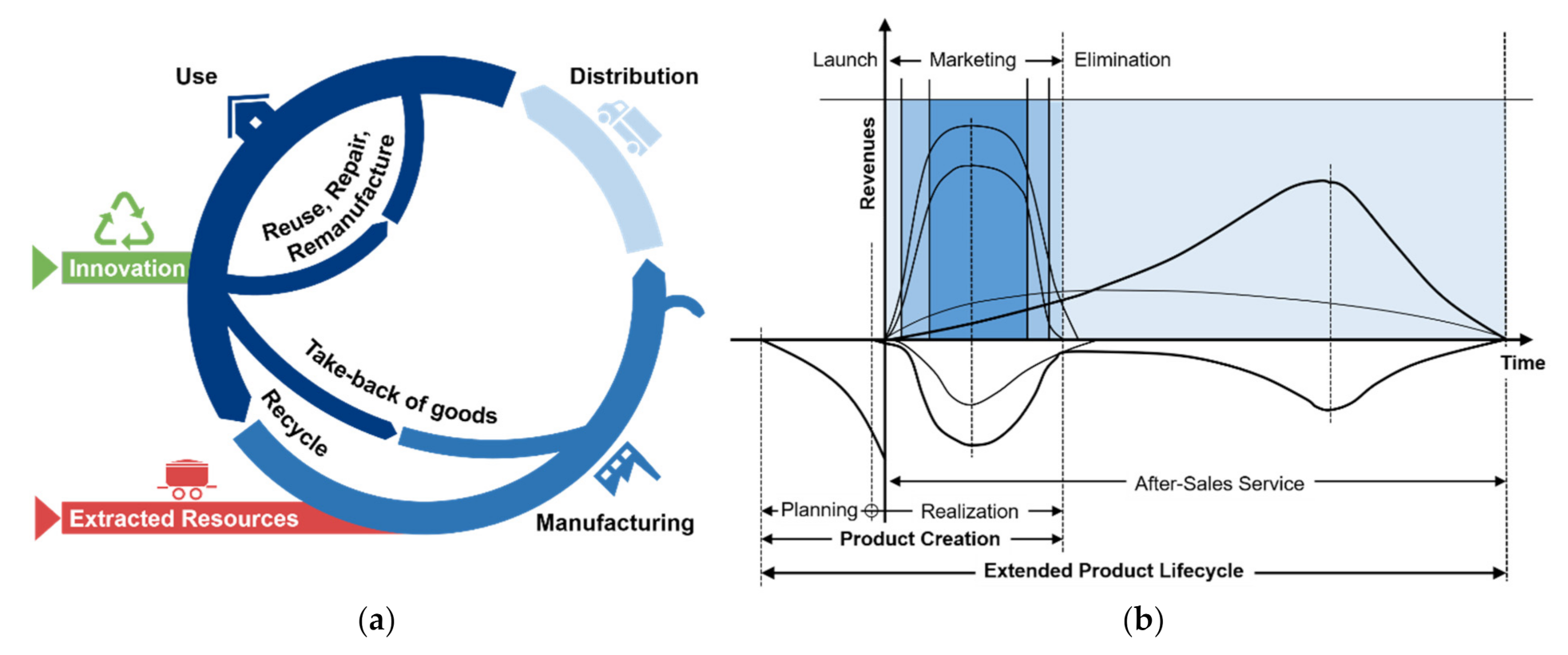

1. Introduction

2. Materials and Methods

- Search term vector TS 1.1 (cross-product):{lifecycle, life cycle} × {circular} × {engineering, planning, design};

- Search term vector TS 1.2: {product, system, plant, asset, software};

- Search term vector TS 1.3: {*, literature}.

- Search term vector TS 2.1: {lifecycle model, life cycle model}.

- Search term vector TS 2.2: {product, system}.

- Search term vector TS 2.3: {holistic, generic}.

- Integrating core elements of complementary models.

- Contextualizing lifecycle phases regarding different perspectives.

- Visualizing both sequential dependencies and circularity (focusing on data/knowledge and products/material).

- Providing means for adaptation/tailoring.

3. Results

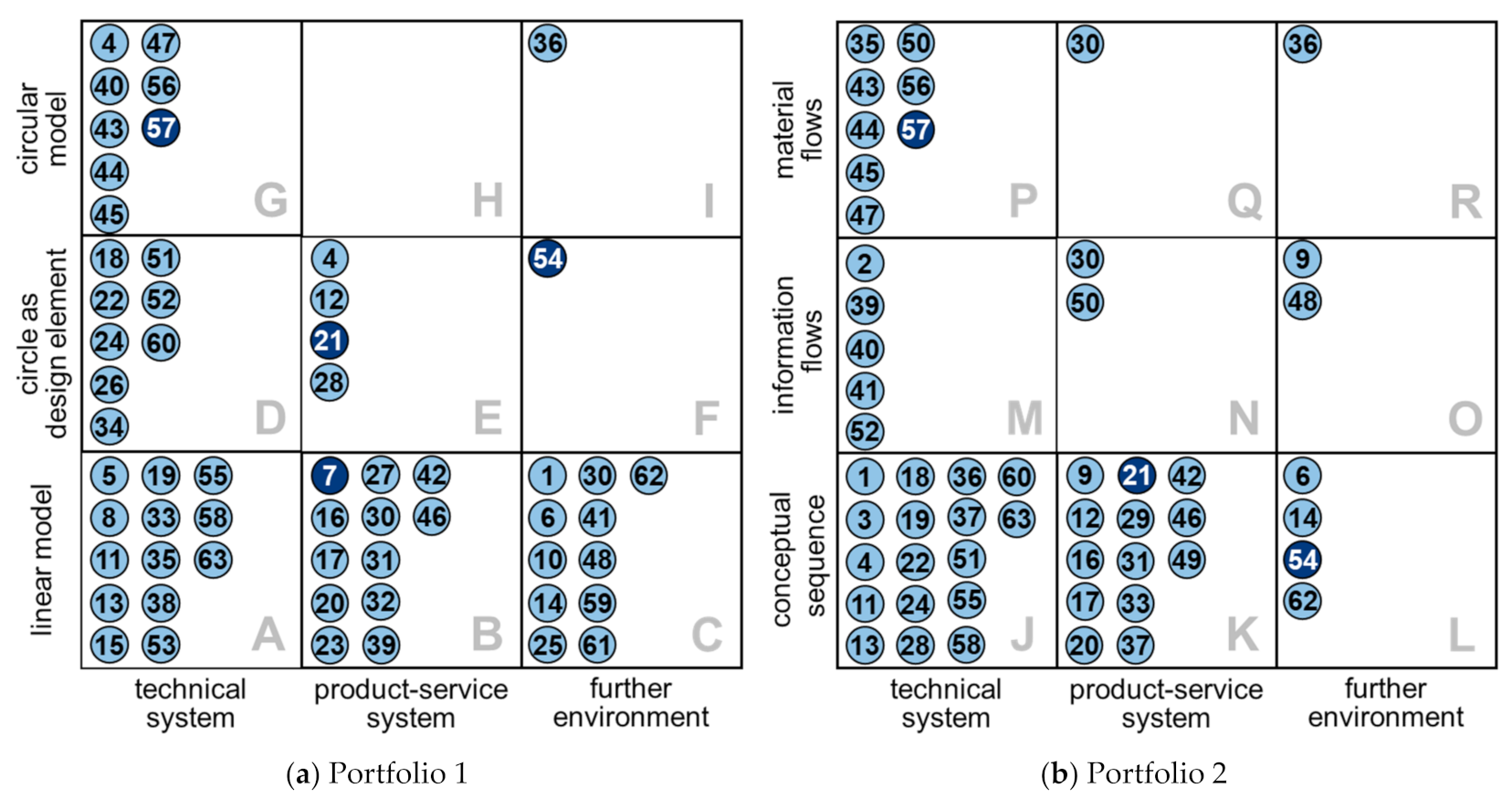

3.1. Literature Analysis

3.1.1. Specific Perspectives (Subjects)

3.1.2. Integrative Perspectives

3.1.3. Cross-Cutting Perspectives

3.2. Comparison and Correlation

| No. | Authors | Ref | No. | Authors | Ref | No. | Authors | Ref |

|---|---|---|---|---|---|---|---|---|

| 1 | Grant 1991 (2002) | [70] | 22 | Schatten et al., 2010 | [71] | 43 | Stahel 2016 | [58] |

| 2 | VDI 2243:1993 | [72] | 23 | Arnold et al., 2011 | [73] | 44 | VDI 4800:2016 | [74] |

| 3 | VDI 2221:1993 | [75] | 24 | Balzert and Liggesmeier 2011 | [38] | 45 | Bauer et al., 2017 | [61] |

| 4 | Hubka et al., 1996 | [29] | 25 | Diedrich et al., 2011 | [76] | 46 | Dang 2017 | [77] |

| 5 | Rajlich et al., 2000 | [41] | 26 | Goll 2011 | [39] | 47 | European Union 2017 | [37] |

| 6 | Wirth et al., 2000 | [78] | 27 | Meier et al., 2012 | [79] | 48 | Lin et al., 2017 | [51,80,81] |

| 7 | Schimmelpfeng 2002 | [35] | 28 | Meier et al., 2012/2017 | [82] | 49 | Meier et al., 2017 | [82] |

| 8 | VDI 2243:2002 | [83] | 29 | Freitag et al., 2012 | [84] | 50 | Nußholz 2017 | [85] |

| 9 | Meier 2004 | [86] | 30 | Hepperle 2013 | [43] | 51 | Bracht et al., 2018 | [31] |

| 10 | Schenk and Wirth 2004 | [34] | 31 | Laurischkat 2013 | [87] | 52 | Tao et al., 2018 | [55] |

| 11 | Abele et al., 2005 | [88] | 32 | Thomas and Nüttgens 2013 | [89] | 53 | VDI 4801:2018 | [90] |

| 12 | Tan et al., 2006 | [54] | 33 | Porter 2014 | [91] | 54 | Wiktorsson et al., 2018 | [46] |

| 13 | Zarnekow et al., 2005 | [69] | 34 | Vajna 2014 (2020) | [92] | 55 | Hastenteufel et al., 2019 | [40] |

| 14 | Westkämper 2008 | [93] | 35 | Vielhaber and Stoffels 2014 | [94] | 56 | Klenk et al., 2019 | [68] |

| 15 | Hulvej 2008 | [95] | 36 | E. MacArthur Fdt. 2015 | [59] | 57 | Raabe et al., 2019 | [36] |

| 16 | Becker et al., 2009 | [96] | 37 | Helu and Hedberg 2015 | [97] | 58 | Schleich et al., 2019 | [98] |

| 17 | Eigner et al., 2009 | [33] | 38 | Lehmhus et al., 2015 | [99] | 59 | Tao et al., 2019 | [100] |

| 18 | Robin et al., 2009 | [66] | 39 | Lu et al., 2015 | [101] | 60 | VDI 2221: 2019 | [28] |

| 19 | Ropohl 2009 | [57] | 40 | Wellsandt et al., 2015 | [30] | 61 | Güntner et al., 2020 | [102] |

| 20 | Aurich et al., 2010 | [103] | 41 | Lu et al., 2016 | [101] | 62 | Neuhäuser et al., 2020 | [104] |

| 21 | Blinn et al., 2010 | [64] | 42 | Mahut et al., 2016 | [42] | 63 | Yousefnezhad et al., 2020 | [105] |

- Business management-bound lifecycles for product–service systems do not address the specifics of technically demanding products, which is usually accompanied by multi-disciplinarity. As the model to be developed shall serve engineers as well as business economists, technical systems must not only be mentioned, but they need to be concretized in the way of their multidisciplinary interaction.

- No information- and material-flow-based view on Circular Economy of product–service systems incorporating multi-disciplinary material core products is concretized yet. However, this is needed to lay the foundation for a modern Circular Economy, minimizing resource consumption, waste production, emissions and energy waste. Further, the concretization of both information and material flows is a prerequisite for the development of new digital business models for CE.

- A full differentiation between product class and instance exists so far only in rudimentary form and has not yet been applied to the product life cycle of multi-disciplinary systems. This way, a sustainable design of material core products can be stimulated and a foundation for digital business models, Minimum Viable Products (MVPs) and DevOps for Circular Economy can be laid.

- Most existing approaches describe value creation from the manufacturer’s point of view. Only a few lifecycle models take the consumer or user into account, such as [59]. The manufacturer’s perspective is too narrow and needs to become expandable to further stakeholders, such as the user, consumer, recycler or society. This is due to the fact that different stakeholders have different views and interfaces to the same “thing” as outlined by Främling and Holmström against the backdrop of the Internet of Things [65].

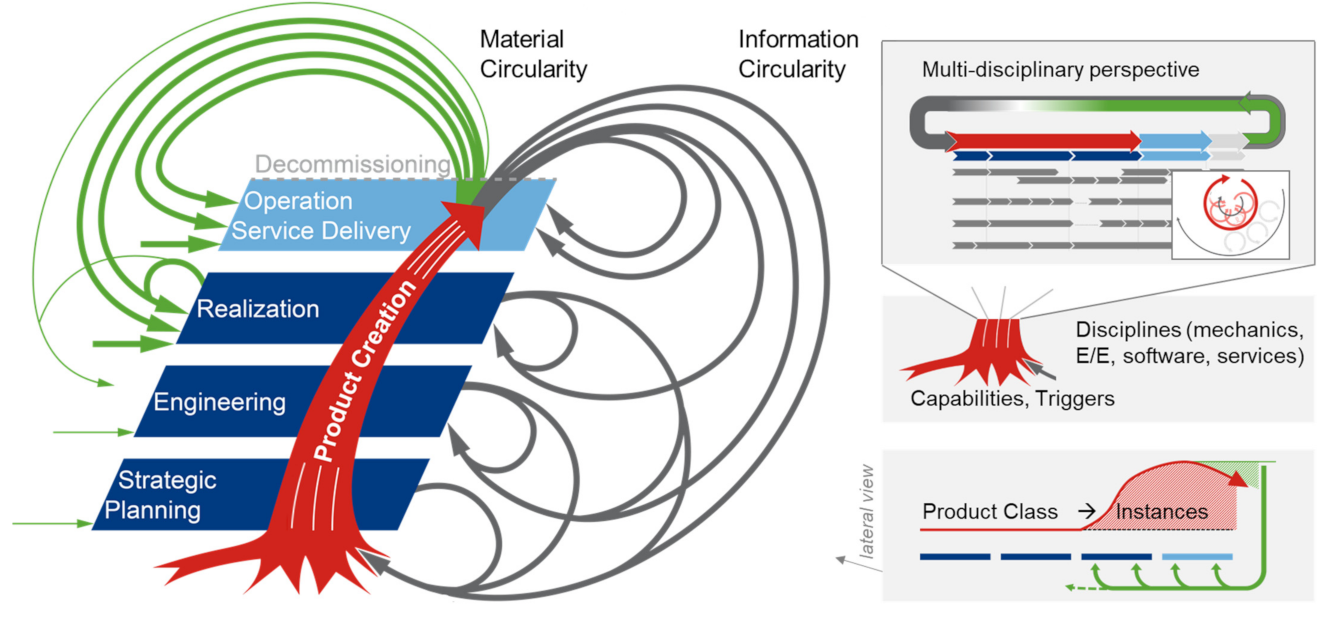

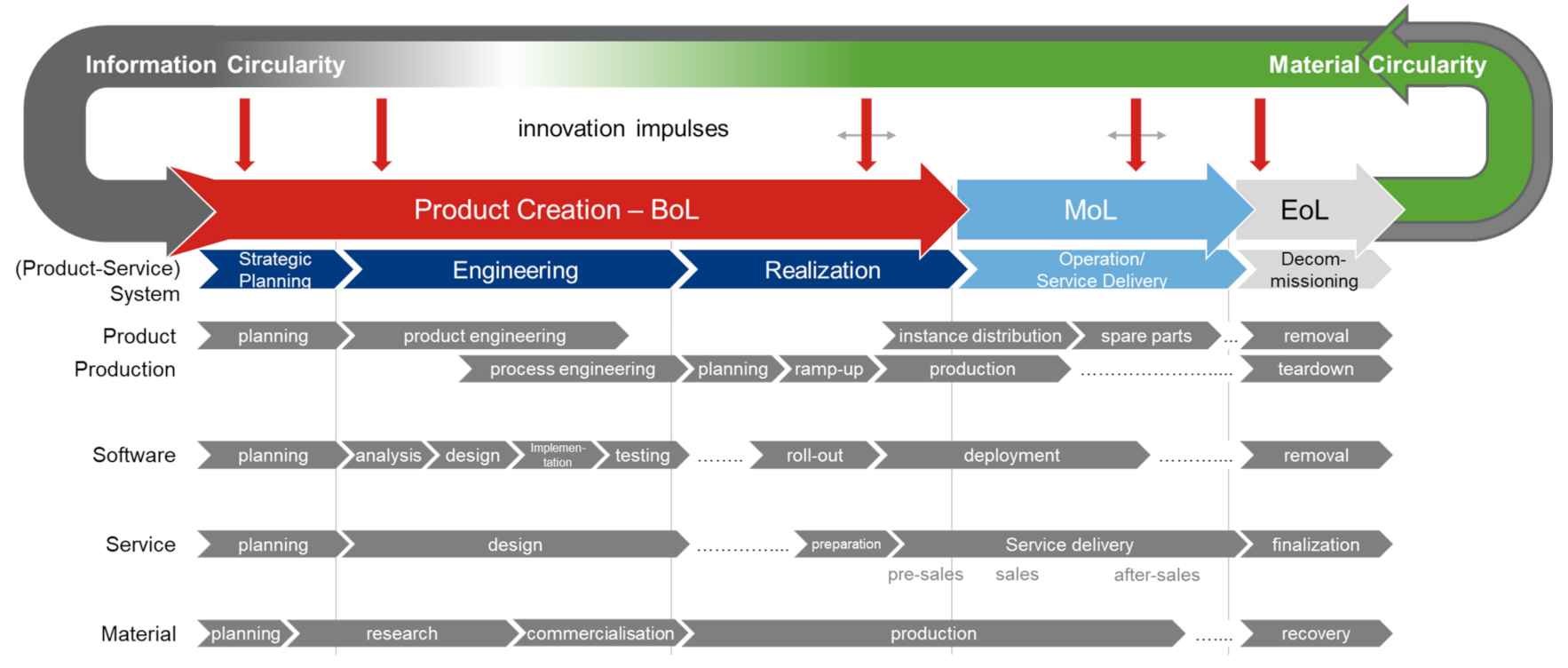

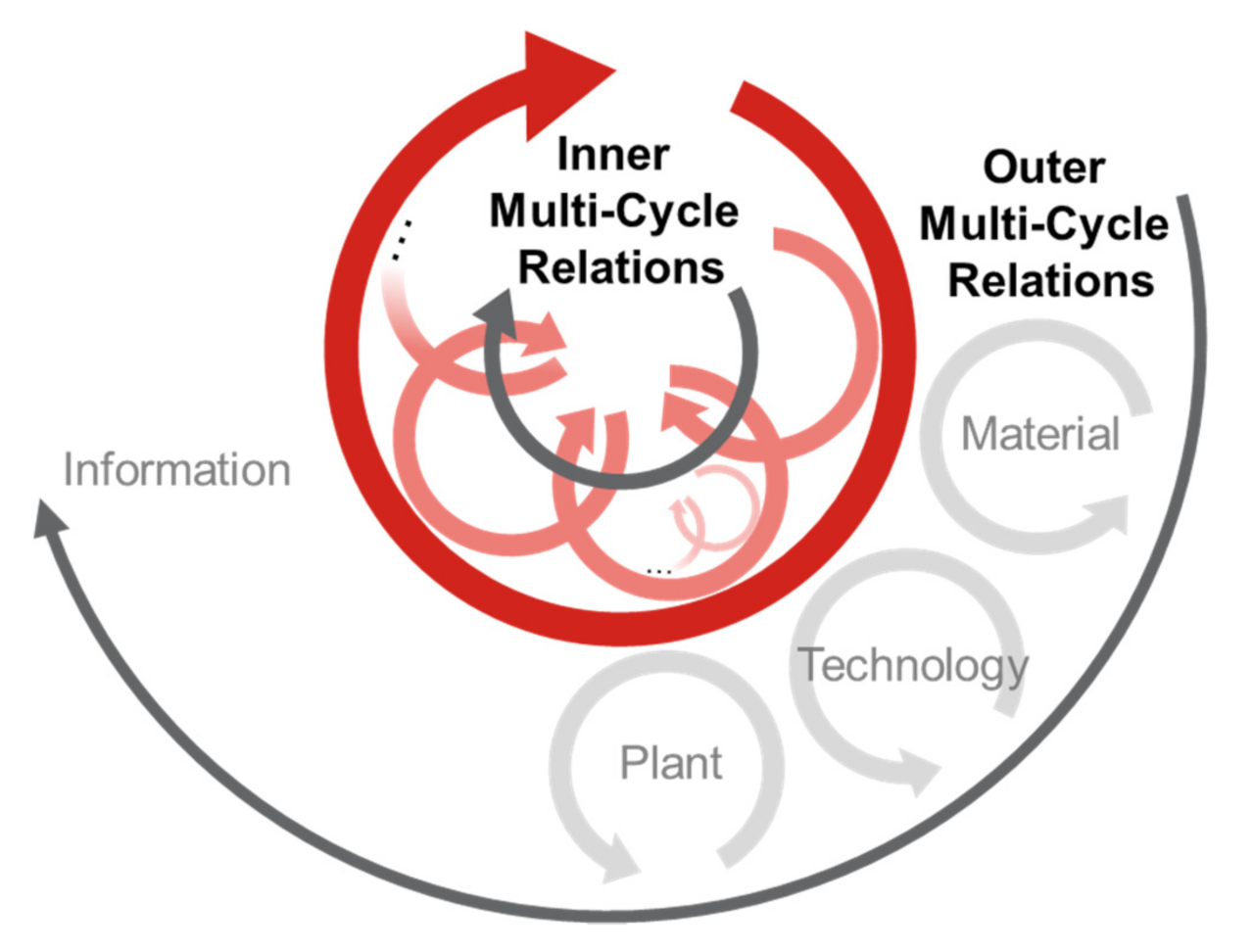

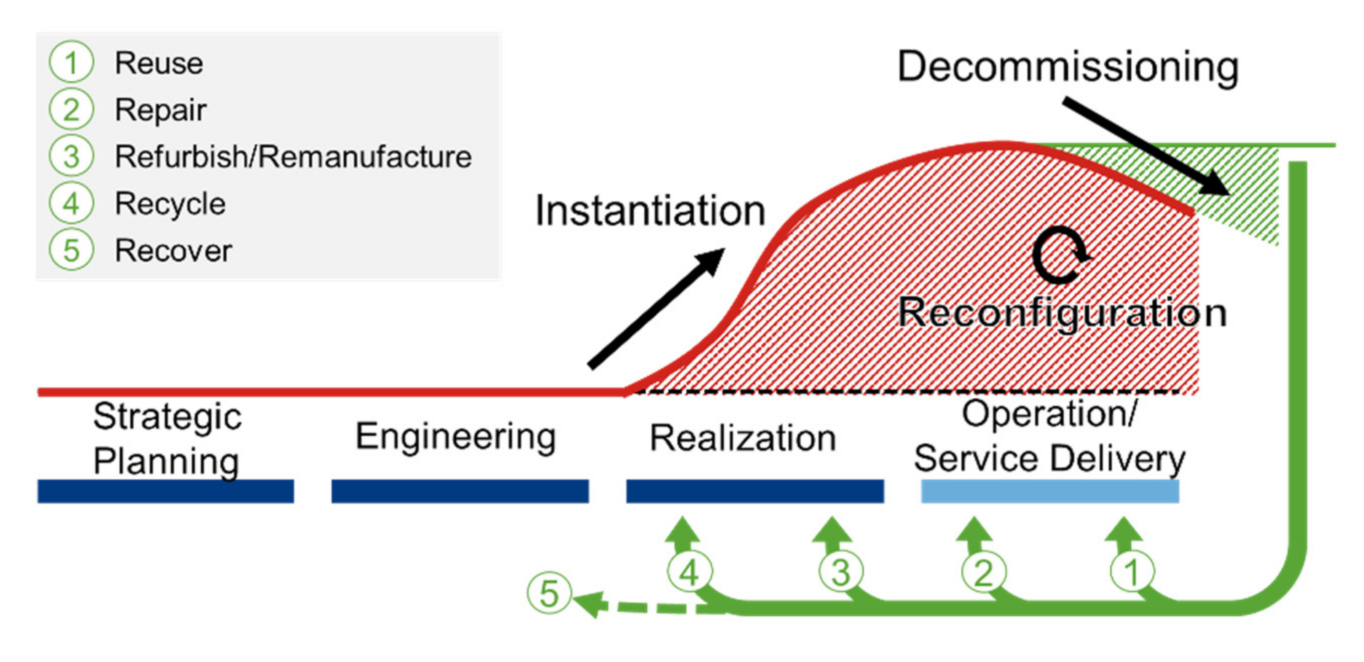

3.3. Synthesis: The generic Product Lifecycle Model (gPLC)

- intrinsic (based on the Product Creation process from classes to instances);

- circular (emphasizing material and information circularity);

- holistic (integrating single- and multi-disciplinary and cross-cutting perspectives);

- generic (applicable to a wide variety of specific industry branches);

- adaptable (providing handles to adapt inputs, phases and flows).

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; The Johns Hopkins University Press: Baltimore, MD, USA, 1990. [Google Scholar]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Lahane, S.; Prajapati, H.; Kant, R. Emergence of circular economy research: A systematic literature review. Manag. Environ. Qual. Int. J. 2021. [Google Scholar] [CrossRef]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.D.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Guan, G.; Jiang, Z.; Gong, Y.; Huang, Z.; Jamalnia, A. A Bibliometric Review of Two Decades’ Research on Closed-Loop Supply Chain: 2001–2020. IEEE Access 2021, 9, 3679–3695. [Google Scholar] [CrossRef]

- Lopes, J.; Farinha, L. Industrial Symbisosis in a Circular Economy: Towards Firms’ Sustainable Competitive Advantage. Int. J. Mechatron. Appl. Mech. 2019, 5, 27. [Google Scholar] [CrossRef]

- Núñez-Cacho, P.; Molina-Moreno, V.; Corpas-Iglesias, F.A.; Cortés-García, F.J. Family Businesses Transitioning to a Circular Economy Model: The Case of “Mercadona”. Sustainability 2018, 10, 538. [Google Scholar] [CrossRef]

- Isaksson, O.; Hallstedt, S.I.; Öhrwall, R.A. Digitalisation, sustainability and servitisation: Consequences on product development capabilities in manufacturing firms. In Proceedings of the NordDesign 2018—Design in the Era of Digitalization, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Kozma, D.; Varga, P.; Larrinaga, F. System of Systems Lifecycle Management—A New Concept Based on Process Engineering Methodologies. Appl. Sci. 2021, 11, 3386. [Google Scholar] [CrossRef]

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. What Gets Measured, Gets Done: Development of a Circular Economy Measurement Scale for Building Industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Implementing Circular Economy Strategies in Buildings—From Theory to Practice. Appl. Syst. Innov. 2021, 4, 26. [Google Scholar] [CrossRef]

- Bjørnbet, M.M.; Skaar, C.; Fet, A.M.; Schulte, K. Circular economy in manufacturing companies: A review of case study literature. J. Clean. Prod. 2021, 294, 126268. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef]

- Eigner, M. System Lifecycle Management: Engineering Digitalization (Engineering 4.0); Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Petticrew, M.; Roberts, H. Systematic Reviews in the Social Sciences; Blackwell Publishing Ltd.: Oxford, UK, 2006. [Google Scholar]

- Briner, R.B.; Denyer, D. Systematic review and evidence synthesis as a practice and scholarship tool. In The Oxford Handbook of Evidence-Based Management; Rousseau, D.M., Ed.; Oxford University Press: Oxford, UK; New York, NY, USA, 2014; pp. 112–129. [Google Scholar]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef]

- Bakker, C.; Wang, F.; Huisman, J.; Hollander, M.D. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- De los Rios, I.C.; Charnley, F.J. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Pottebaum, J.; Deppe, G.; Lindemann, C. Additive Manufacturing for Future Repair and Maintenance for the Aerospace Industry. In Aviation in Europe: Innovating for Growth, Proceedings of the Seventh European Aeronautics Days 2015, London, UK, 20–22 October 2015; Knörzer, D., Warsop, C., Diaconescu, C., Eds.; European Commission: Brussels, Belgium, 2017; pp. 547–557. [Google Scholar]

- Graessler, I.; Oleff, C.; Scholle, P. Method for Systematic Assessment of Requirement Change Risk in Industrial Practice. Appl. Sci. 2020, 10, 8697. [Google Scholar] [CrossRef]

- Graessler, I.; Poehler, A. Potentials of digitalization in the sugar industry. In Proceedings of the 6th ESST Conference, Pozna, Poland, 27–29 May2019; European Society for Sugar Technology: Poznan, Poland, 2019. [Google Scholar]

- VDI. VDI 2221 Design of Technical Products and Systems: Model of Product Design ICS 03.100.40 (VDI 2221, 2019); Beuth: Berlin, Germany, 2019. [Google Scholar]

- Hubka, V.; Eder, W.E. Design Science: Introduction to the Needs, Scope and Organization of Engineering Design; Springer: London, UK, 1996. [Google Scholar]

- Wellsandt, S.; Hribernik, K.; Thoben, K.-D. Sources and Characteristics of Information about Product Use. Procedia CIRP 2015, 36, 242–247. [Google Scholar] [CrossRef]

- Bracht, U.; Geckler, D.; Wenzel, S. Digitale Fabrik; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Vajna, S.; Weber, C.; Zeman, K. CAx für Ingenieure; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Eigner, M.; Stelzer, R. Product Lifecycle Management: Ein Leitfaden Für Product Development und Life Cycle Management; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Schenk, M.; Wirth, S. Fabrikplanung und Fabrikbetrieb: Methoden für die Wandlungsfähige und Vernetzte Fabrik; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Schimmelpfeng, K. Lebenszyklusorientiertes Produktionssystemcontrolling: Konzeption zur Verfügbarkeitssicherung Hochautomatisierter Produktionssysteme; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Raabe, D.; Tasan, C.C.; Olivetti, E.A. Strategies for improving the sustainability of structural metals. Nature 2019, 575, 64–74. [Google Scholar] [CrossRef] [PubMed]

- Publications Office of the European Union. Critical Raw Materials and the Circular Economy–Background Report; Publications Office of the European Union: Brussels, Belgium, 2017. [Google Scholar] [CrossRef]

- Balzert, H.; Liggesmeyer, P. Lehrbuch der Softwaretechnik: Entwurf, Implementierung, Installation und Betrieb, 3. Aufl. Lehrbücher der Informatik; Spektrum Akad. Verl: Heidelberg, Germany, 2011. [Google Scholar]

- Goll, J. Methoden und Architekturen der Softwaretechnik; Vieweg+Teubner Verlag: Wiesbaden, Germany, 2011. [Google Scholar]

- Hastenteufel, M.; Renaud, S. Software als Medizinprodukt; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019. [Google Scholar]

- Rajlich, V.T.; Bennett, K.H. A staged model for the software life cycle. Computer 2000, 33, 66–71. [Google Scholar] [CrossRef]

- Mahut, F.; Bricogne, M.; Daaboul, J. Servicization of Product Lifecycle Management: Towards Service Lifecycle Management. In Product Lifecycle Management in the Era of Internet of Things; Bouras, A., Eynard, B., Foufou, S., Eds.; Springer International Publishing: Cham, Switzerland, 2016; Volume 467, pp. 321–331. [Google Scholar]

- Hepperle, C. Planung Lebenszyklusgerechter Leistungsbündel. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2013. [Google Scholar]

- Ramaswamy, R. Design and management of service processes: Keeping customers for life, 1. printing. In Engineering Process Improvement Series; Addison-Wesley: Reading, MA, USA, 1996. [Google Scholar]

- Hayes, R.H.; Wheelwright, S.C. Link Manufacturing Process and Product Life Cycles. Harv. Bus. Rev. 1979, 133–140. [Google Scholar]

- Wiktorsson, M.; Andersson, C.; Turunen, V. Leading towards high-performance manufacturing–Enabling indicators in early R&D phases ensuring future KPI outcome. Procedia Manuf. 2018, 25, 223–230. [Google Scholar] [CrossRef]

- Westkämper, E.; Spath, D.; Constantinescu, C. Digitale Produktion; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Lu, Y.; Morris, K.C.; Frechette, S. Current Standards Landscape for Smart Manufacturing Systems; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016. [Google Scholar]

- Wang, B.; Tao, F.; Fang, X. Smart Manufacturing and Intelligent Manufacturing: A Comparative Review. Engineering 2020. [Google Scholar] [CrossRef]

- Stark, R.; Anderl, R.; Thoben, K.-D. WiGeP-Positionspapier: „Digitaler Zwilling“. Z. Wirtsch. Fabr. 2020, 115, 47–50. [Google Scholar] [CrossRef]

- Lin, S.-W. IIoT for Smart Manufacturing. 2017. Available online: https://www.arcweb.com/blog/iiot-smart-manufacturing (accessed on 19 March 2021).

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus Strat. Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Thomas, O.; Loos, P.; Nüttgens, M. Hybride Wertschöpfung: Mobile Anwendungssysteme Für Effiziente Dienstleistungsprozesse im Technischen Kundendienst; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Tan, A.; McAloone, T.; Andreasen, M. What Happens to Integrated Product Development Models with Product/Service-System Approaches? In Proceedings of the Integrated Product Development Workshop (IPD), Magdeburg, Germany, 18–20 September 2006; Available online: https://www.designsociety.org/publication/29267/IPD+2006%3A+Proceedings+of+the+6th+Workshop+on+Integrated+Product+Development%2C+Magdeburg%2C+Germany%2C+18.-20.09.2006 (accessed on 14 May 2021).

- Tao, F.; Cheng, J.; Qi, Q. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Schuh, G.; Uam, J.-Y. Product Lifecycle Management. In Innovationsmanagement; Schuh, G., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 351–410. [Google Scholar]

- Ropohl, G. Allgemeine Technologie: Eine Systemtheorie der Technik, 3., Überarbeitete Auflage; KIT Scientific Publishing: Karlsruhe, Germany, 2009. [Google Scholar]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation and McKinsey Center for Business and Environment: Brussels, Belgium, 2015. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Bauer, T.; Brissaud, D.; Zwolinski, P. Design for High Added-Value End-of-Life Strategies. In Sustainable Manufacturing: Challenges, Solutions and Implementation Perspectives; Stark, R., Seliger, G., Bonvoisin, J., Eds.; Springer Open: Cham, Switzerland, 2017; pp. 113–128. [Google Scholar]

- Vernon, R. International Investment and International Trade in the Product Cycle. Q. J. Econ. 1966, 80, 190. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Strategy: Techniques for Analyzing Industries and Competitors, First Free Press Export Edition; Free Press: New York, NY, USA; London, UK, 2004. [Google Scholar]

- Blinn, N.; Nüttgens, M.; Schlicker, M. Lebenszyklusmodelle hybrider Wertschöpfung: Modellimplikationen und Fallstudie. In Hybride Wertschöpfung: Mobile Anwendungssysteme für Effiziente Dienstleistungsprozesse im Technischen Kundendienst; Thomas, O., Loos, P., Nüttgens, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 130–143. [Google Scholar]

- Främling, K.; Holmström, J. How to create evolving information models by a layered information architecture. In Proceedings of the MITIP’2006: 8th International Conference on the Modern Information Technology in the Innovation the Industrial Enterprises, Budapest, Hungary, 11–12 September 2006; pp. 173–178. [Google Scholar]

- Robin, V.; Brunel, S.; Zolghadri, M. System Lifecycle Management: Preliminary concepts and tools. IFAC Proc. Vol. 2009, 42, 426–431. [Google Scholar] [CrossRef]

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Klenk, F.; Häfner, B.; Lanza, G. Kreislaufwirtschaft in globalen Wertschöpfungsnetzwerken. Ind. Manag. 2019, 2019, 29–32. [Google Scholar] [CrossRef]

- Zarnekow, R.; Brenner, W.; Pilgram, U. Integriertes Informationsmanagement: Strategien und Lösungen für das Management von IT-Dienstleistungen. In Business Engineering; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Grant, R.M. Contemporary Strategy Analysis: Concepts, Techniques, Applications, 4th ed.; Blackwell Publish: Malden, MA, USA, 2002. [Google Scholar]

- Schatten, A.; Demolsky, M.; Winkler, D. Best Practice Software-Engineering; Spektrum Akademischer: Heidelberg, Germany, 2010. [Google Scholar]

- VDI. VDI 2243 Designing Technical Products for Ease of Recycling (VDI 2243, 1991); Beuth: Berlin, Germany, 1991. [Google Scholar]

- Arnold, V.; Dettmering, H.; Engel, T. Product Lifecycle Management Beherrschen; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- VDI. VDI 4800-Resource Efficiency: Methodical Principles and Strategies (VDI 4800, 2016); Beuth: Berlin, Germany, 2016. [Google Scholar]

- VDI. VDI 2221 Systematic Approach to the Development and Design of Technical Systems and Products (VDI 2221, 1993); Beuth: Berlin, Germany, 1993. [Google Scholar]

- Diedrich, C.; Lüder, A.; Hundt, L. Bedeutung der Interoperabilität bei Entwurf und Nutzung von automatisierten Produktionssystemen. Automatisierungstechnik 2011, 59, 426–438. [Google Scholar] [CrossRef]

- Dang, H.B. Erweiterung des Product Lifecycle Managements für Produkt-Service Systeme: Lifecycle-begleitende Integrationsplattform für industrielle Produkt-Service Systeme (IPSS-LIP). In Maschinenbauinformatik; Shaker Verlag: Aachen, Germany, 2017. [Google Scholar]

- Wirth, S.; Enderlein, H.; Petermann, J. Kompetenznetze der Produktion. In Proceedings of the Technische Universität Chemnitz, Fakultät für Maschinenbau und Verfahrenstechnik, Institut für Betriebswissenschaften und Fabriksysteme Fachtagung mit internationaler Beteiligung und Ausstellung Vernetzt Planen und Produzieren, Chemnitz, Germany, 12–14 October 2020. [Google Scholar]

- Meier, H.; Uhlmann, E. Hybride Leistungsbündel–ein neues Produktverständnis. In Integrierte Industrielle Sach- und Dienstleistungen; Meier, H., Uhlmann, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–21. [Google Scholar]

- Lin, S.-W. IIoT for Smart Manufacturing Part 2: Digital Thread and Digital Twin. 2017. Available online: https://www.arcweb.com/blog/iiot-smart-manufacturing-part-2-digital-thread-and-digital-twin (accessed on 19 March 2021).

- Lin, S.-W. IIoT for Smart Manufacturing Part 3: A New Digitalization Architecture. 2017. Available online: https://www.arcweb.com/blog/iiot-smart-manufacturing-part-3-new-digitalization-architecture (accessed on 19 March 2021).

- Meier, H.; Uhlmann, E. Industrielle Produkt-Service Systeme; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- VDI. VDI 2243 Recycling-Oriented Product Development ICS 03.100.40; 21.020(VDI 2243, 2002); Beuth: Berlin, Germany, 2002. [Google Scholar]

- Freitag, M.; Münster, M. Anforderungen an ein Service Lifecycle Management: Kurzstudie bei Deutschen Unternehmen; Fraunhofer Verl: Stuttgart, Germany, 2013. [Google Scholar]

- Nußholz, J. Circular Business Models: Defining a Concept and Framing an Emerging Research Field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef]

- Meier, H. Embedded Online Service: Internetbasierte Dienstleistungsplattform für Produktionsbetriebe; Verbundprojekt im Rahmenkonzept Forschung für die Produktion von Morgen“ des Bundesministeriums für Bildung und Forschung (BMBF); Internetbasierte Referenz-Architektur für Fernerbrachte Dienstleistungen in der Produktionstechnik (EOS); VDMA-Verl: Frankfurt am Main, Germany, 2004. [Google Scholar]

- Laurischkat, K. Wandel des traditionellen Dienstleistungsverständnisses im Kontext von Product-Service Systems. In Dienstleistungsmodellierung 2012; Thomas, O., Nüttgens, M., Eds.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2013; pp. 74–95. [Google Scholar]

- Abele, E.; Anderl, R.; Birkhofer, H. Environmentally-Friendly Product Development; Springer: London, UK, 2005. [Google Scholar]

- Thomas, O.; Nüttgens, M. Dienstleistungsmodellierung 2012; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2013. [Google Scholar]

- VDI. VDI 4801 Resource Efficiency in Small and Medium-Sized Enterprises (SME): Strategies and Procedures for the Efficient Use of Natural Resources ICS 03.100.01, 13.020.01(VDI 4801); Beuth: Berlin, Germany, 2018. [Google Scholar]

- Porter, M.E. Wettbewerbsvorteile. Spitzenleistungen erreichen und behaupten. In Das Summa Summarum des Management; Boersch, C., Elschen, R., Eds.; Gabler: Wiesbaden, Germany, 2007; pp. 251–263. [Google Scholar]

- Vajna, S. Integrated Design Engineering; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Westkämper, E. Digital engineering of factories and processes. In Fertigungstechnisches Kolloquium (FTK): Stuttgarter Impulse-Fertigungstechnik Für Die Zukunft; Ges. für Fertigungstechnik: Stuttgart, Germany; pp. 427–452.

- Vielhaber, M.; Stoffels, P. Product Development vs. Production Development. Procedia CIRP 2014, 21, 252–257. [Google Scholar] [CrossRef]

- Hulvej, J. Integrierte Entwicklung von IT-Dienstleistungen. Ph.D. Thesis, University of St. Gallen, St. Gallen, Austria, 2008. [Google Scholar]

- Becker, J.; Beverungen, D.; Knackstedt, R. Ordnungsrahmen für die hybride Wertschöpfung. In Dienstleistungsmodellierung; Thomas, O., Nüttgens, M., Eds.; Physica-Verlag HD: Heidelberg, Germany, 2009; pp. 109–128. [Google Scholar]

- Helu, M.; Hedberg, T. Enabling Smart Manufacturing Research and Development using a Product Lifecycle Test Bed. Procedia Manuf. 2015, 1, 86–97. [Google Scholar] [CrossRef]

- Schleich, B.; Dittrich, M.-A.; Clausmeyer, T. Shifting value stream patterns along the product lifecycle with digital twins. Procedia CIRP 2019, 86, 3–11. [Google Scholar] [CrossRef]

- Lehmhus, D.; Wuest, T.; Wellsandt, S. Cloud-Based Automated Design and Additive Manufacturing: A Usage Data-Enabled Paradigm Shift. Sensors 2015, 15, 32079–32122. [Google Scholar] [CrossRef] [PubMed]

- Tao, F.; Zhang, M.; Nee, A.Y.C. Digital Twin Driven Smart Manufacturing; Elsevier Science Academic Press: San Diego, CA, USA, 2019. [Google Scholar]

- Lu, Y.; Morris, K.C.; Frechette, S. Standards landscape and directions for smart manufacturing systems. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 998–1005. [Google Scholar]

- Güntner, G.; Hoher, S. Digital Twins im Anlagen-Lebenszyklus; Salzburg Research: Salzburg, Austria, 2020; Available online: https://www.dtz-salzburg.at/2020/11/02/digital-twins-im-anlagen-lebenszyklus/ (accessed on 14 May 2021).

- Aurich, J.C.; Clement, M.H. Produkt-Service Systeme; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Neuhäuser, T.; Chen, Q.; Rösch, M. Building Information Modeling im Fabriklebenszyklus. Z. Wirtsch. Fabr. 2020, 115, 66–69. [Google Scholar] [CrossRef]

- Yousefnezhad, N.; Malhi, A.; Främling, K. Security in product lifecycle of IoT devices: A survey. J. Netw. Comput. Appl. 2020, 171, 102779. [Google Scholar] [CrossRef]

- Gräßler, I. Implementation-oriented synthesis of mechatronic reference models. In Proceedings of the VDI Mechatronik 2015, Dortmund, Germany, 12–13 March 2015; pp. 167–172. [Google Scholar]

- Albers, A.; Bursac, N.; Wintergerst, E. Product generation development–importance and challenges from a design research perspective. In New Developments in Mechanics and Mechanical Engineering, Proceedings of the International Conference on Mechanical Engineering (ME 2015) and the International Conference on Theoretical Mechanics and Applied Mechanics (TMAM 2015), Vienna, Austria, 15–17 March 2015; Mastorakis, N.E., Solomon, T.C.W., Eds.; World Scientific and Engineering Academy and Society (WSEAS): Athens, Greece, 2015; pp. 16–21. [Google Scholar]

- Gräßler, I.; Pottebaum, J. Szenarien für die Anwendung von Additive Manufacturing in der Instandhaltung. In Lean Smart Maintenance: Konzepte, Instrumente und Anwendungen für Eine Effiziente und Intelligente Instandhaltung, 30; Biedermann, H., Ed.; Instandhaltungs-Forum; TÜV Media: Köln, Germany, 2016; pp. 49–59. [Google Scholar]

- Sassanelli, C.; Urbinati, A.; Rosa, P. Addressing circular economy through design for X approaches: A systematic literature review. Comput. Ind. 2020, 120, 103245. [Google Scholar] [CrossRef]

- VDI. VDI 2206 Development of Cyber-Physical Mechatronic Systems (CPMS) (VDI 2206, 2020). 2020. Available online: https://www.vdi.de/richtlinien/details/vdi-2206-entwicklungsmethodik-fuer-mechatronische-systeme (accessed on 9 March 2021).

- Sinclair, M.; Sheldrick, L.; Moreno, M. Consumer Intervention Mapping—A Tool for Designing Future Product Strategies within Circular Product Service Systems. Sustainability 2018, 10, 2088. [Google Scholar] [CrossRef]

- Jensen, J.P.; Remmen, A. Enabling Circular Economy Through Product Stewardship. Procedia Manuf. 2017, 8, 377–384. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Russo-Garrido, S.; Merveille, N. Addressing the Social Aspects of a Circular Economy: A Systematic Literature Review. Sustainability 2020, 12, 7912. [Google Scholar] [CrossRef]

- Munten, P.; Vanhamme, J.; Swaen, V. Reducing obsolescence practices from a product-oriented PSS perspective: A research agenda. Rech. Appl. Mark. 2021, 205, 157. [Google Scholar] [CrossRef]

- Mark, P.; Lanza, G.; Lordick, D. Vom Handwerk zur individualisierten Serienfertigung. Bautechnik 2021, 98, 243–256. [Google Scholar] [CrossRef]

| Search Term | Web of Knowledge | ScienceDirect | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1945–2021 | Last 5 Years | Review Articles, Research Articles, Book Chapters | Review Articles | ||||||

| TS1.1 | TS1.2 | TS1.3 | Total | Total | Highly Cited | 1995–2021 | Last 5 Years | 1995–2021 | Last 5 Years |

| (lifecycle OR “life cycle”) AND (circular) AND (engineering OR planning OR design) | product | * | 371 | 324 | 8 | 14,662 | 8170 | 2204 | 1222 |

| literature | 77 | 72 | 4 | 8751 | 5695 | 1516 | 1104 | ||

| system | * | 321 | 276 | 8 | 18,273 | 9651 | 2604 | 1621 | |

| literature | 65 | 61 | 5 | 10,436 | 6476 | 1724 | 1215 | ||

| plant | * | 61 | 52 | 1 | 9015 | 5128 | 1566 | 1054 | |

| literature | 6 | 6 | 1 | 5601 | 3566 | 1124 | 821 | ||

| asset | * | 17 | 15 | 0 | 2121 | 1337 | 278 | 209 | |

| literature | 3 | 3 | 0 | 1530 | 1069 | 234 | 180 | ||

| software | * | 25 | 21 | 0 | 7752 | 4630 | 689 | 499 | |

| literature | 6 | 6 | 0 | 4531 | 3125 | 556 | 419 | ||

| TS2.1 | TS2.2 | TS2.3 | |||||||

| “lifecycle model” OR “life cycle model” | product | holistic | 5 | 1 | 0 | 571 | 230 | 51 | 34 |

| generic | 7 | 2 | 0 | 1140 | 77 | 305 | 31 | ||

| system | holistic | 10 | 4 | 0 | 1284 | 85 | 341 | 33 | |

| generic | 15 | 7 | 0 | 638 | 58 | 255 | 36 | ||

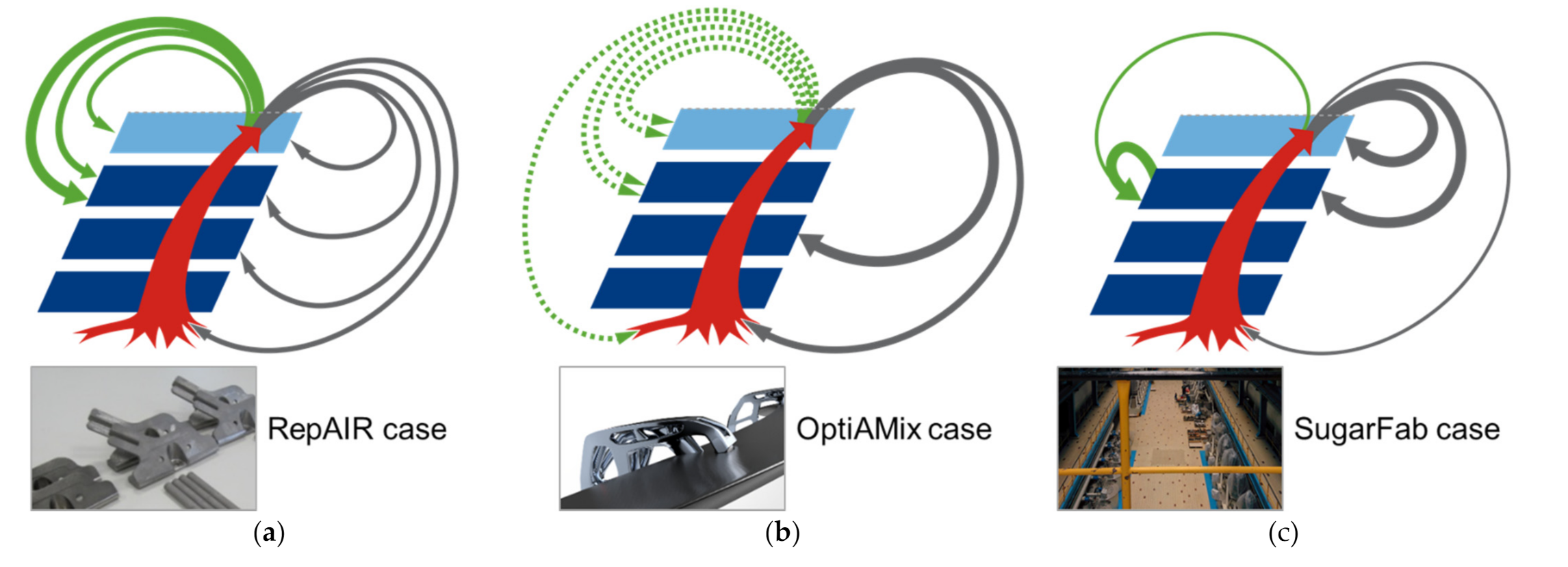

| Application Case | Dimensions | Characteristics |

|---|---|---|

| RepAIR case | Domain | aeronautics |

| Stakeholders | OEM 1, MRO 2 service provider, suppliers, machine manufacturers, IT service companies, QA 3 experts, predictive maintenance experts | |

| Product/Service | metal bracket of aircraft turbine: original part, repair process, spare part | |

| Material circularity | Repair | |

| Information circularity | RUL 4 estimation, predictive maintenance, decision support | |

| OptiAMix case | Domain | Automotive |

| Stakeholders | engineering services, third party manufacturer, IT service companies, decision support experts | |

| Product/Service | rear wing holder for luxury sports cars | |

| Material circularity | Anticipation of material flow | |

| Information circularity | Design guidelines based on aggregated digital twins, business model alternatives | |

| SugarFab case | Domain | food |

| Stakeholders | sugar fabrication company, farm cooperative | |

| Product/Service | sugar products for end consumers and for food industries | |

| Material circularity | Beets, energy from side-products in fabrication, package waste | |

| Information circularity | Supply chain from beet fields to warehousing and outbound logistics, intelligent process control |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gräßler, I.; Pottebaum, J. Generic Product Lifecycle Model: A Holistic and Adaptable Approach for Multi-Disciplinary Product–Service Systems. Appl. Sci. 2021, 11, 4516. https://doi.org/10.3390/app11104516

Gräßler I, Pottebaum J. Generic Product Lifecycle Model: A Holistic and Adaptable Approach for Multi-Disciplinary Product–Service Systems. Applied Sciences. 2021; 11(10):4516. https://doi.org/10.3390/app11104516

Chicago/Turabian StyleGräßler, Iris, and Jens Pottebaum. 2021. "Generic Product Lifecycle Model: A Holistic and Adaptable Approach for Multi-Disciplinary Product–Service Systems" Applied Sciences 11, no. 10: 4516. https://doi.org/10.3390/app11104516

APA StyleGräßler, I., & Pottebaum, J. (2021). Generic Product Lifecycle Model: A Holistic and Adaptable Approach for Multi-Disciplinary Product–Service Systems. Applied Sciences, 11(10), 4516. https://doi.org/10.3390/app11104516