Conflict Resolution in Mechatronic Collaborative Design Using Category Theory

Abstract

1. Introduction

2. Background

- Name inconsistency occurs between two independent elements with the same name. An example of this inconsistency would be two components named “sensor”, whereas the first one is an angle sensor and the second is a current sensor.

- Interface inconsistency concerns two elements having mismatching terminologies or values. For example, this inconsistency can be present when a distance “D” has two different values in two different models or when an “electrical connection” is named “electrical wiring” in another model.

- Behavioral inconsistency happens when the behavior of two elements does not match. This kind of inconsistency occurs when a distance is expressed in “meters” in a model and in “kilometers” in another one for example.

- Interaction inconsistency happens when an element does not respect certain interaction constraints.

- Refinement inconsistency happens when two models of different abstraction levels have different elements in order to fit the corresponding abstraction level. An example of refinement inconsistency would be if, in one model, a “control unit” is defined as a whole component, whereas it is defined as a combination of a controller, a signal voltage, and an angle sensor in a more detailed model.

3. State-of-the-Art

3.1. Conflict Resolution Approaches

3.1.1. Interoperability Approach

3.1.2. Ontology-Based Approach

3.1.3. Dependency Modeling Approach

3.1.4. Model Synchronization Approach

3.1.5. Inconsistency Pattern and Rule-Based Approach

3.1.6. Parameters and Constraints Approach

3.2. Synopsis

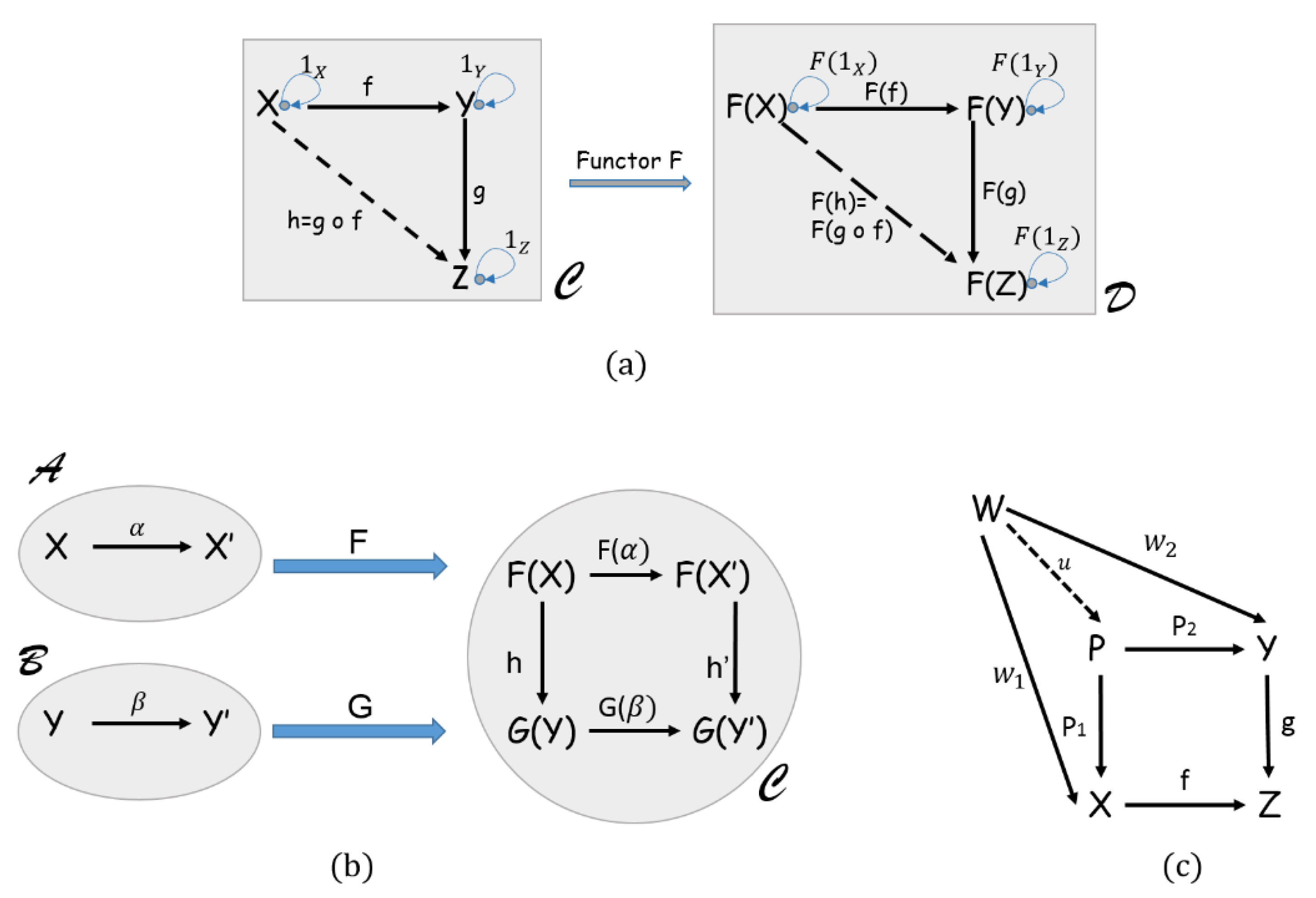

3.3. Category Theory (CT)

3.3.1. Category Theory Basic Concepts

3.3.2. Category Theory in Collaborative Design

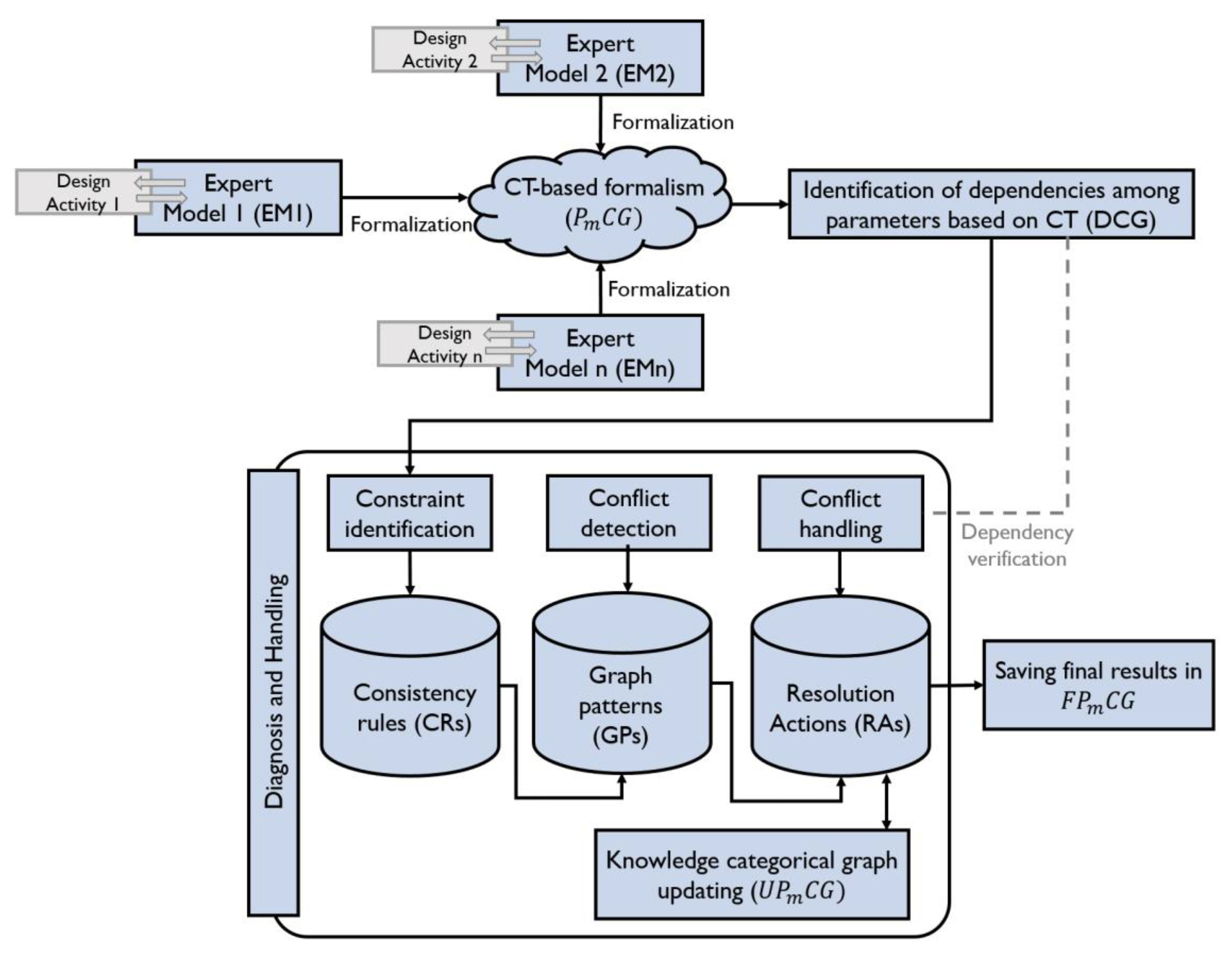

4. Conflict Resolution Approach Based on Category Theory

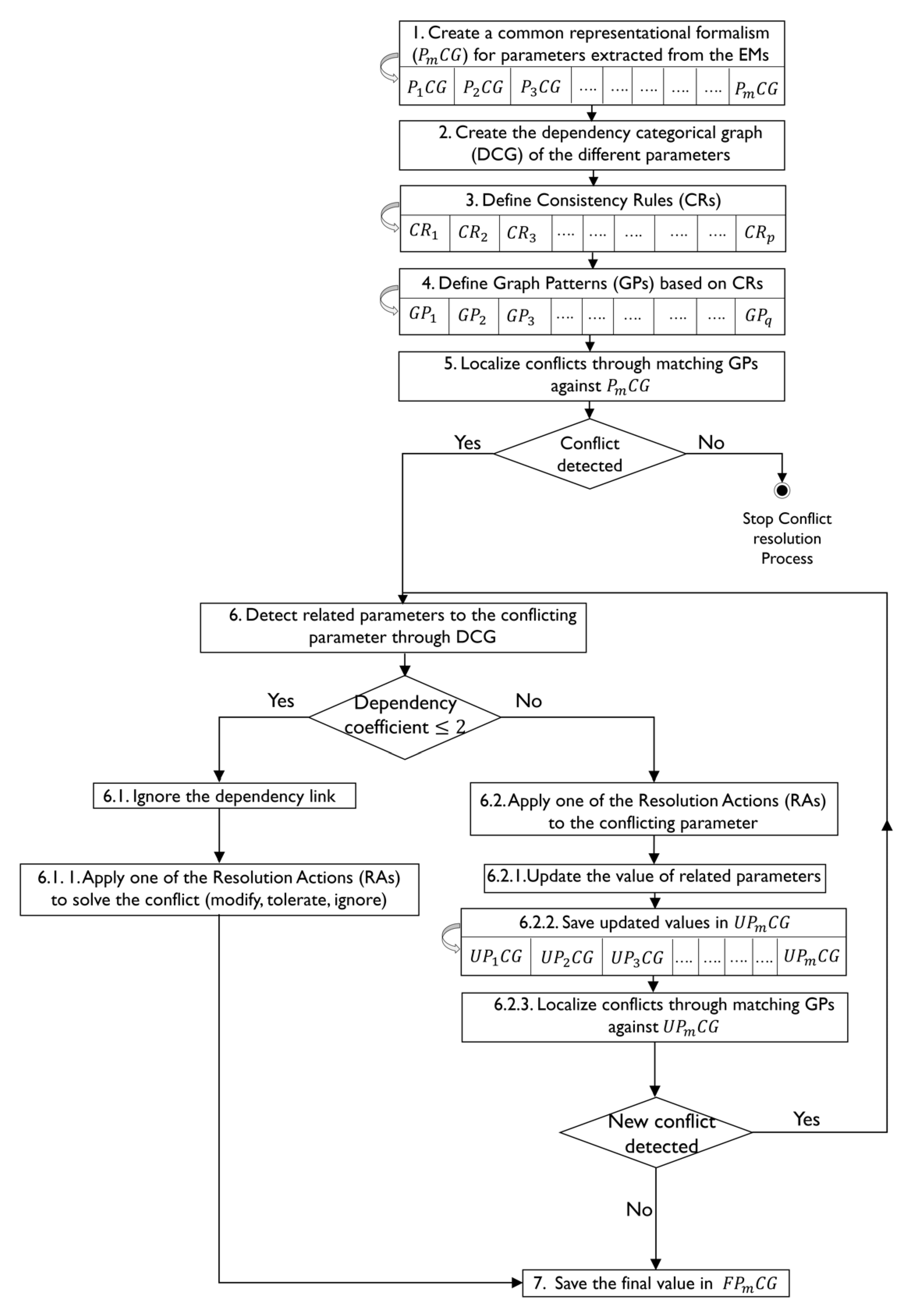

4.1. Main Concepts

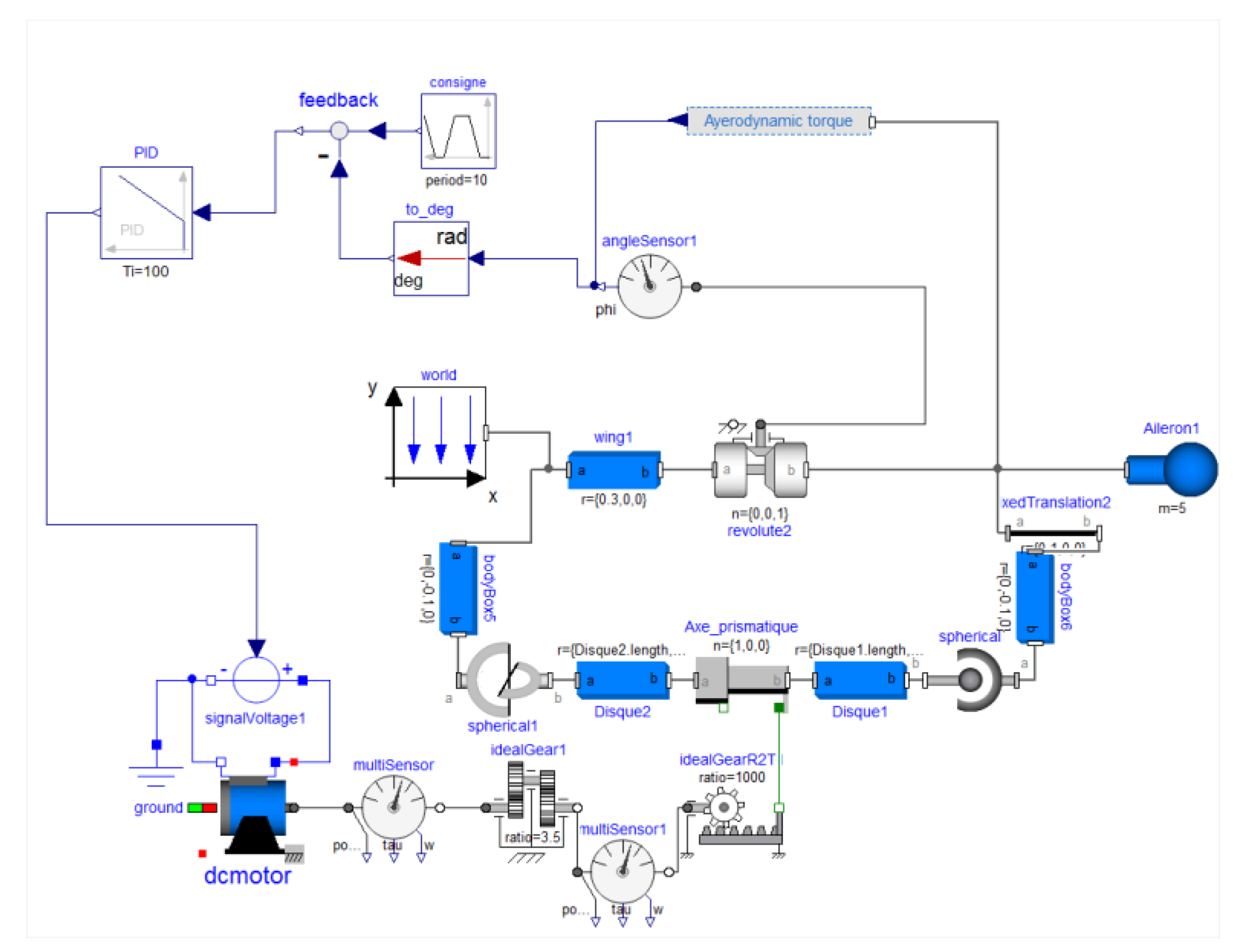

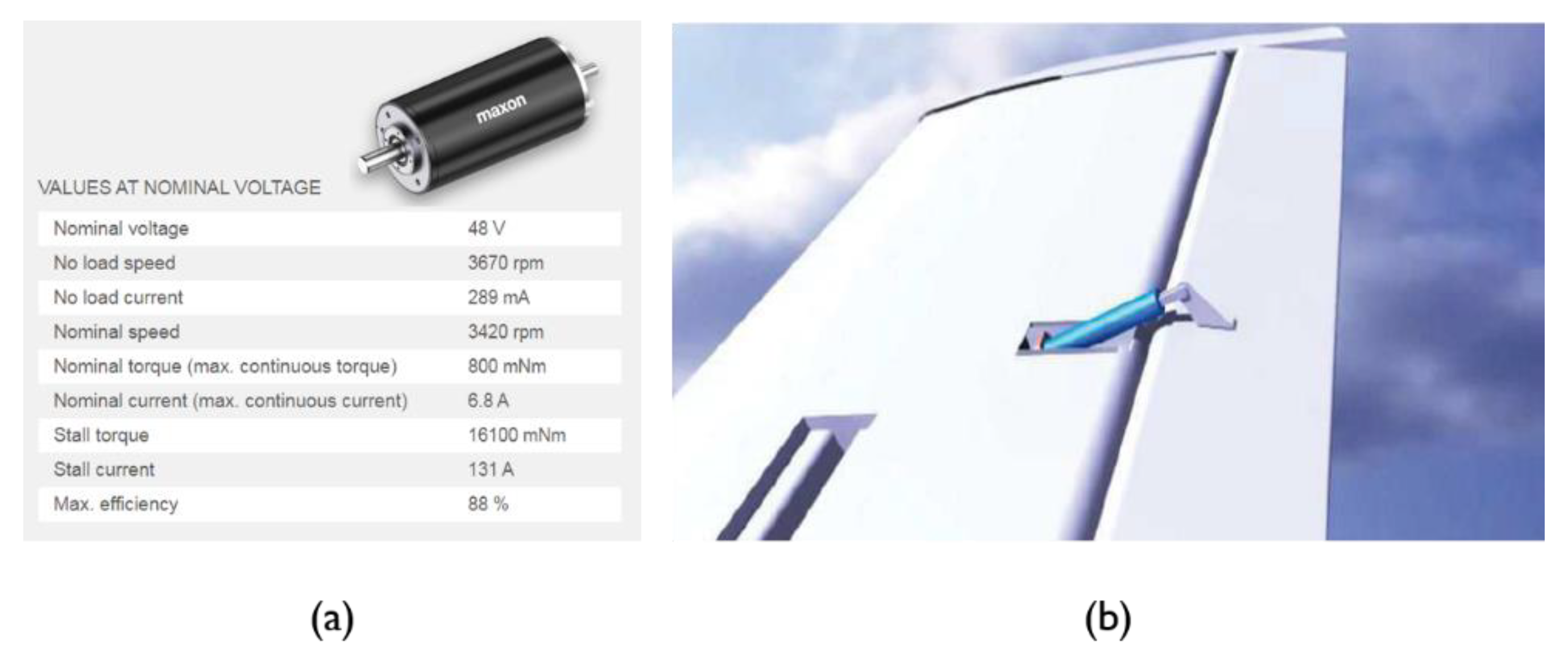

- Expert Model (EM) refers to a set of models, EM1, EM2, …, EMn, that are relative to different domains and involved in the collaborative process. Examples of expert models may be: a control model using for instance Simulink software [19], a multi-physical model using Modelica language within Dymola software [39], a 3D model with CATIA environment [40] in order to verify the integration of the whole mechanism, a Commercial off-the-shelf (COTS) model to select the appropriate components against the properties obtained from the simulation, etc.

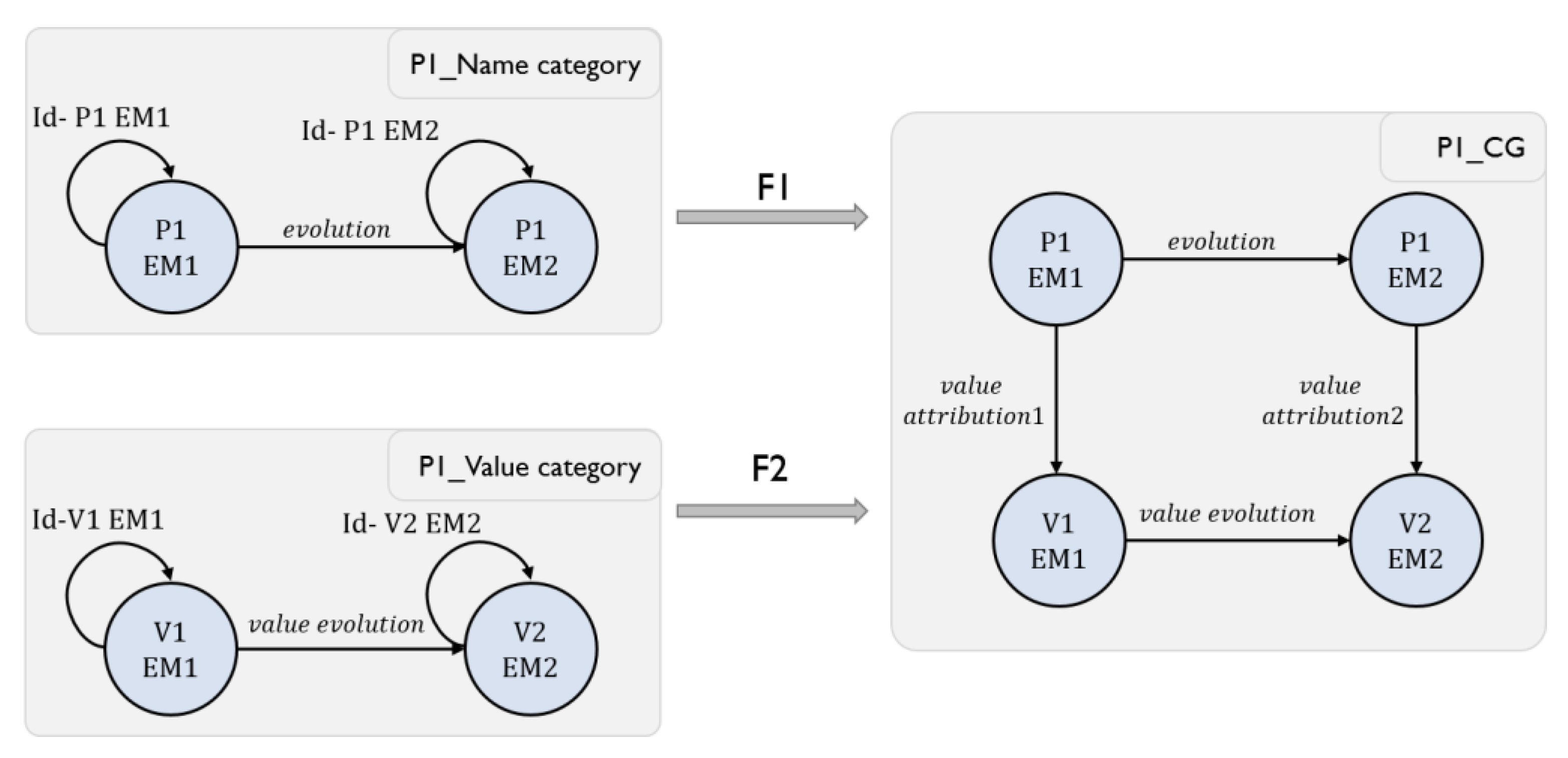

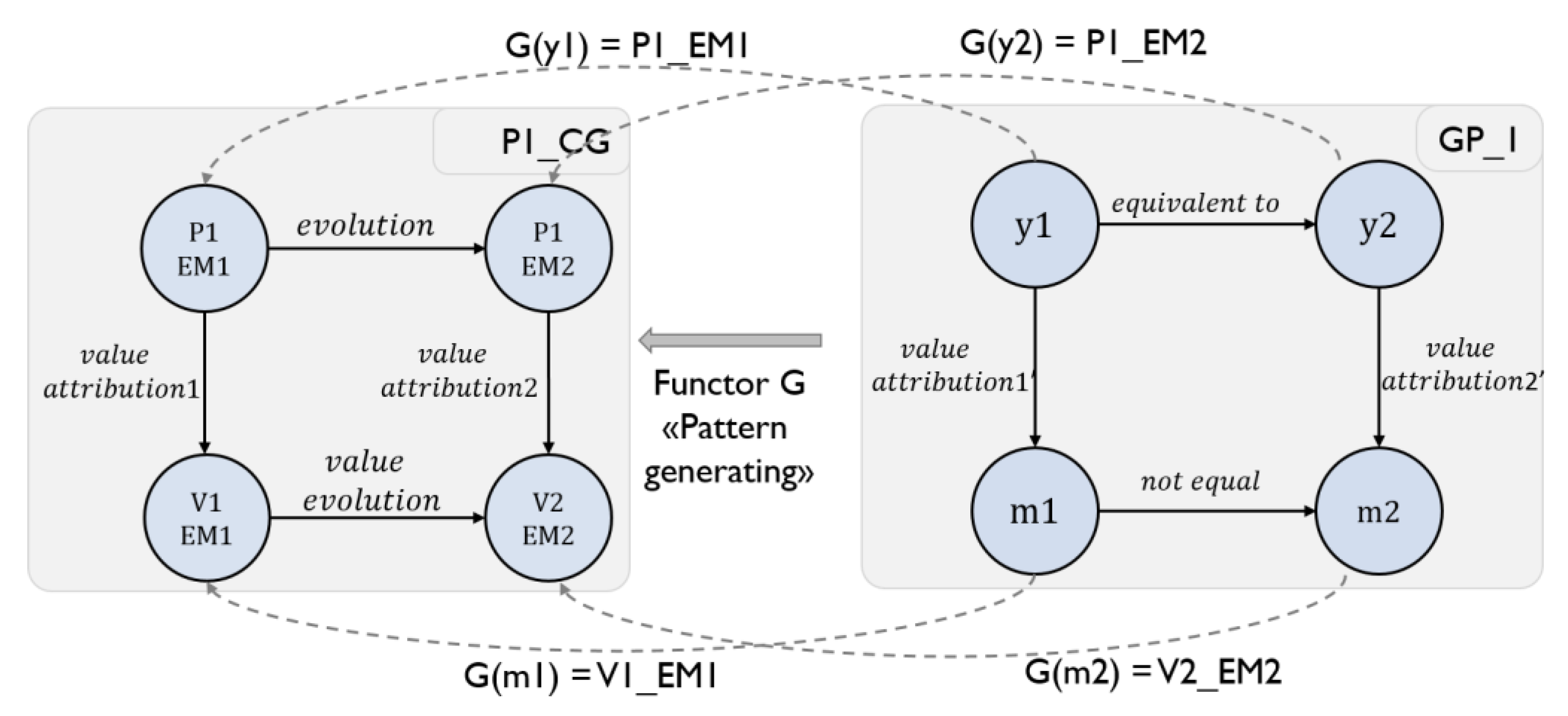

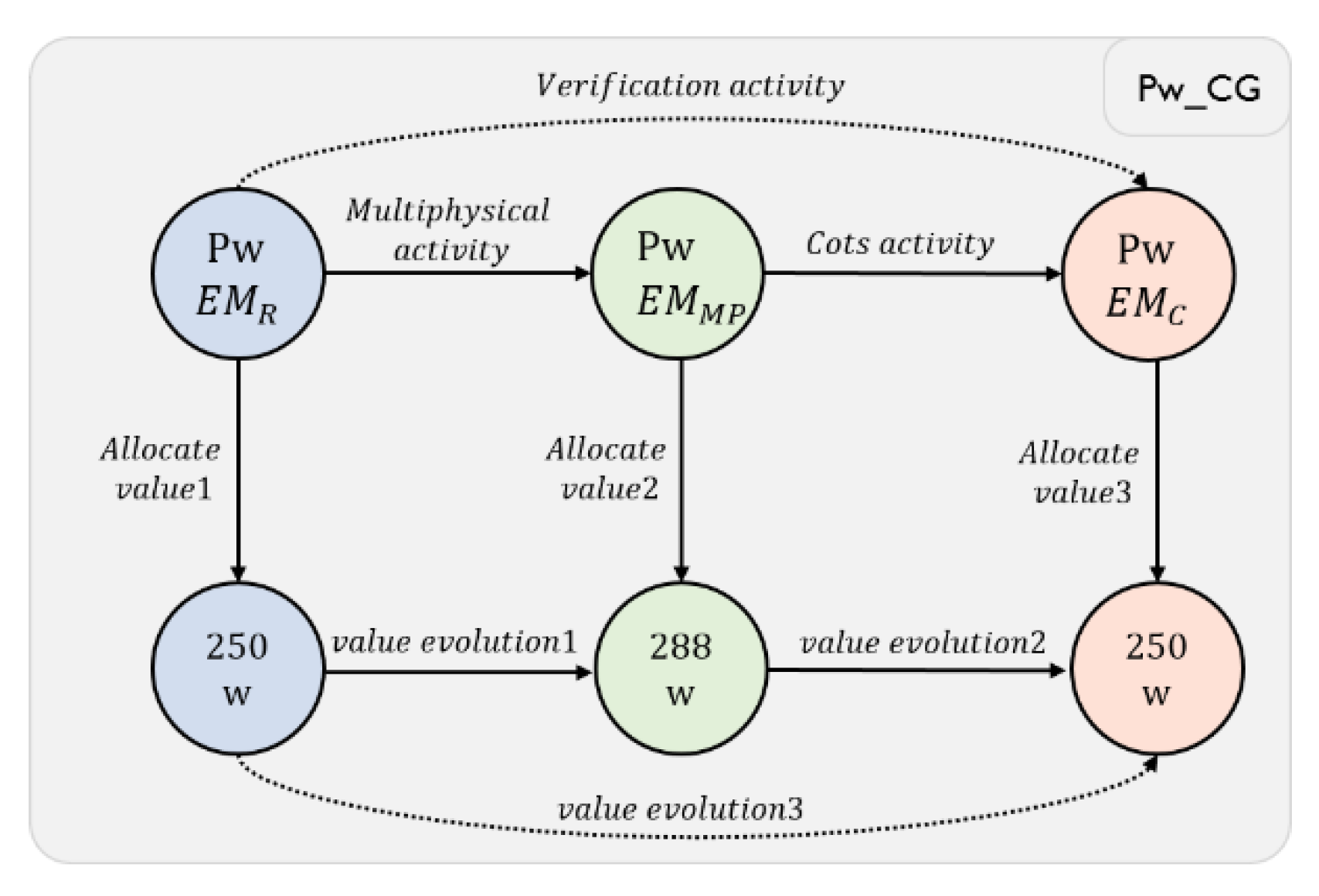

- Parameters Categorical Graph PCG represents the unified graphs based on category theory, P1CG, P2CG, …, PmCG, which contains crucial parameters extracted from the EMs and will help to capture conflicts between these models. A 5-tuple PmCG = <O, id, Ar, Lo, LAr> is an attributed, directed graph. In the context of CT, this graph represents a category where O = (O1,.., Oj) is a set of objects (i.e., vertices). Each object has its own identity id (i.e., the looped arrow). These objects are the different versions of parameters used by the involved experts as well as their values. Objects are related to each other through a set of arrows or morphisms Ar (i.e., edges). All the objects and arrows have labels (i.e., attributes) Lo and LAr respectively. A sample PmCG, created following the previous definition of comma category, is illustrated in Figure 3. The identity morphisms as well as the composition arrows are not represented in this category in order to avoid cluttering it with a large number of morphisms.

- Updated Parameters Categorical Graph UPmCG this category will contain the updated values obtained after each iteration of the conflict resolution process. Similar to the PmCG described beforehand, the UPmCG is considered as a category and inherits all the proprieties of the first PmCG. Through these updated categories, traceability can be ensured which will be useful in reuse perspectives.

- Final Parameter Categorical Graph FPmCG this category will contain the final results obtained after applying the appropriate RAs to the detected conflicts. Similarly, this categorical graph has the same form than the PmCG and UPmCG described previously.

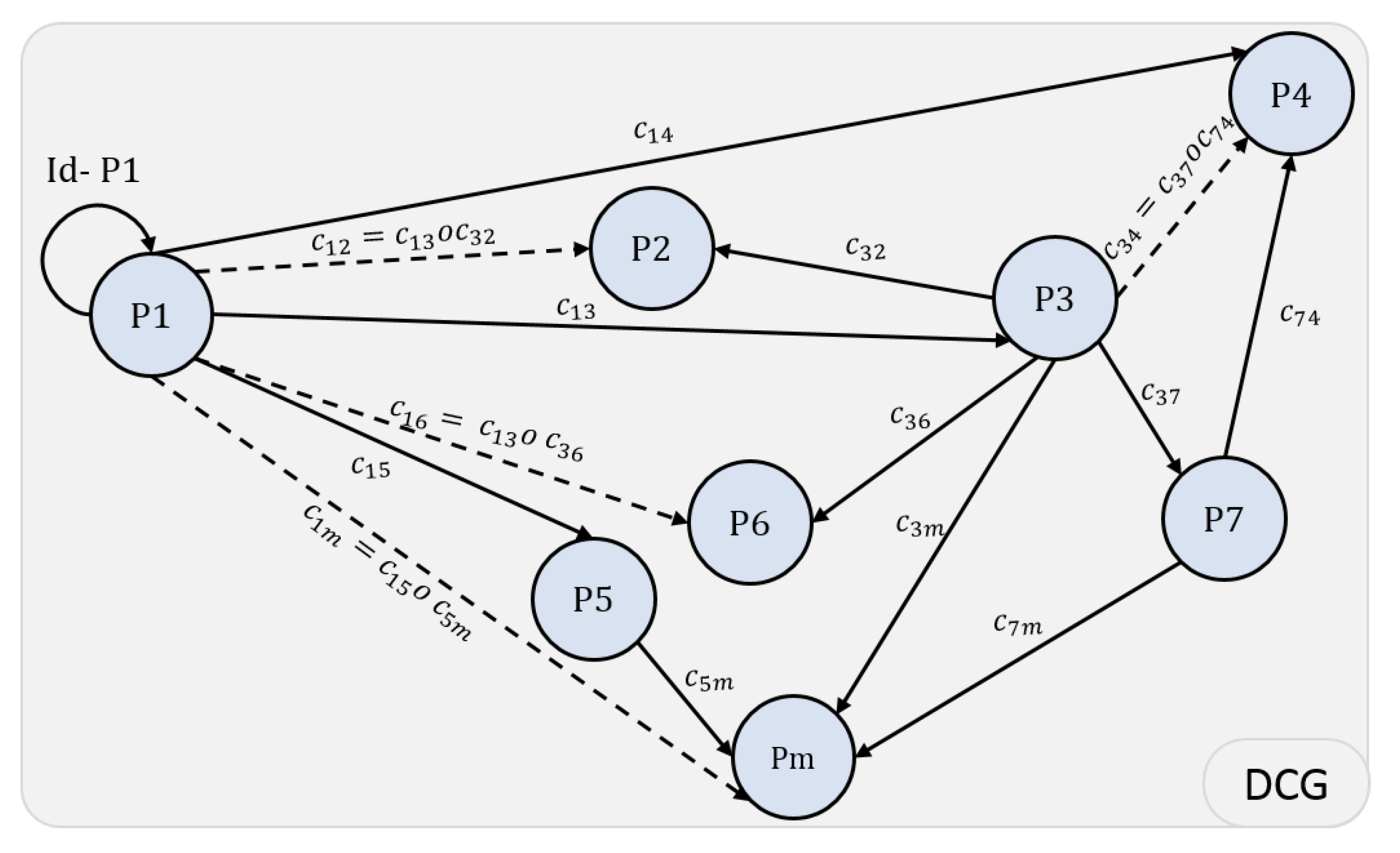

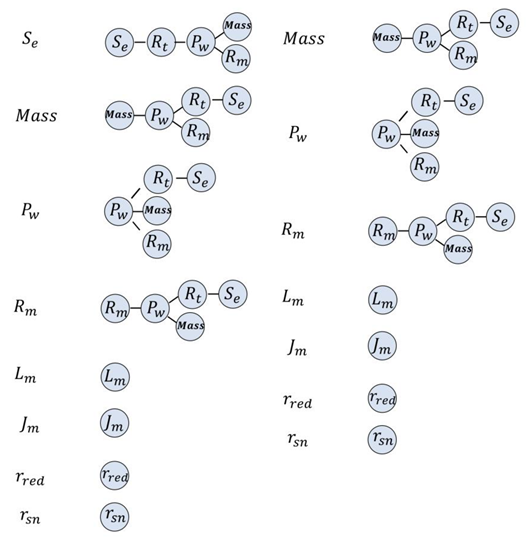

- Dependency Categorical Graph (DCG) illustrates the existing dependencies between the parameters presented in the PmCG based on category theory. A 5-tuple DCG = <Od, idd, Ard, Lod, LArd> is an attributed, directed graph and represents a category where O = O1, …, Om is a set of objects (i.e., vertices) where m refers to the number of parameters used in the collaborative process. Each object has its own identity idd. The identity morphism represents the internal evolution of each object. It is assumed to be present for the DCG. However, it is seldom shown in order to avoid cluttering the category with an identity morphism for each object. In this graph, the objects are the different parameters used by the involved experts. Objects (i.e., parameters) are related to each other through a set of arrows or morphisms Ard (i.e., edges). These morphisms highlight the dependency between the different parameters. All the objects and arrows have labels (or attributes) Lod and LArd respectively. The morphism labels represent the dependency coefficient of each relation between two objects. These coefficients will be used in conflict resolution process. A sample DCG is illustrated in Figure 4.

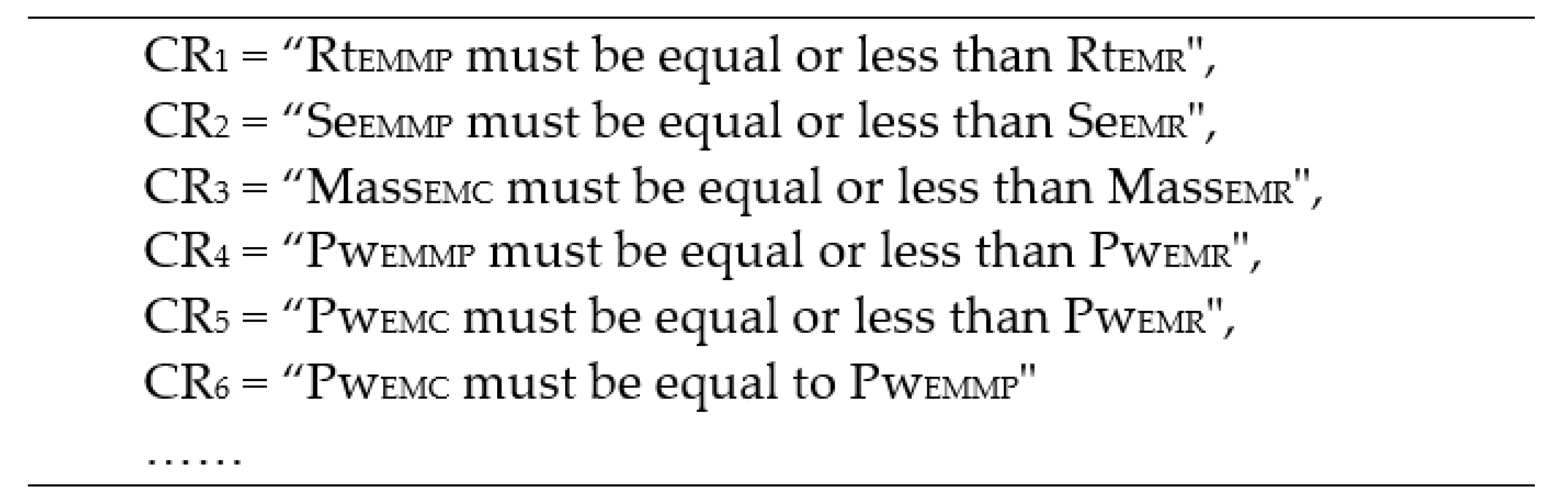

- Consistency rule (CR): A set of consistency rules, CR1, CR2, …, CRp, between elements of EMs. The EMs will be considered inconsistent if CRs are not respected.

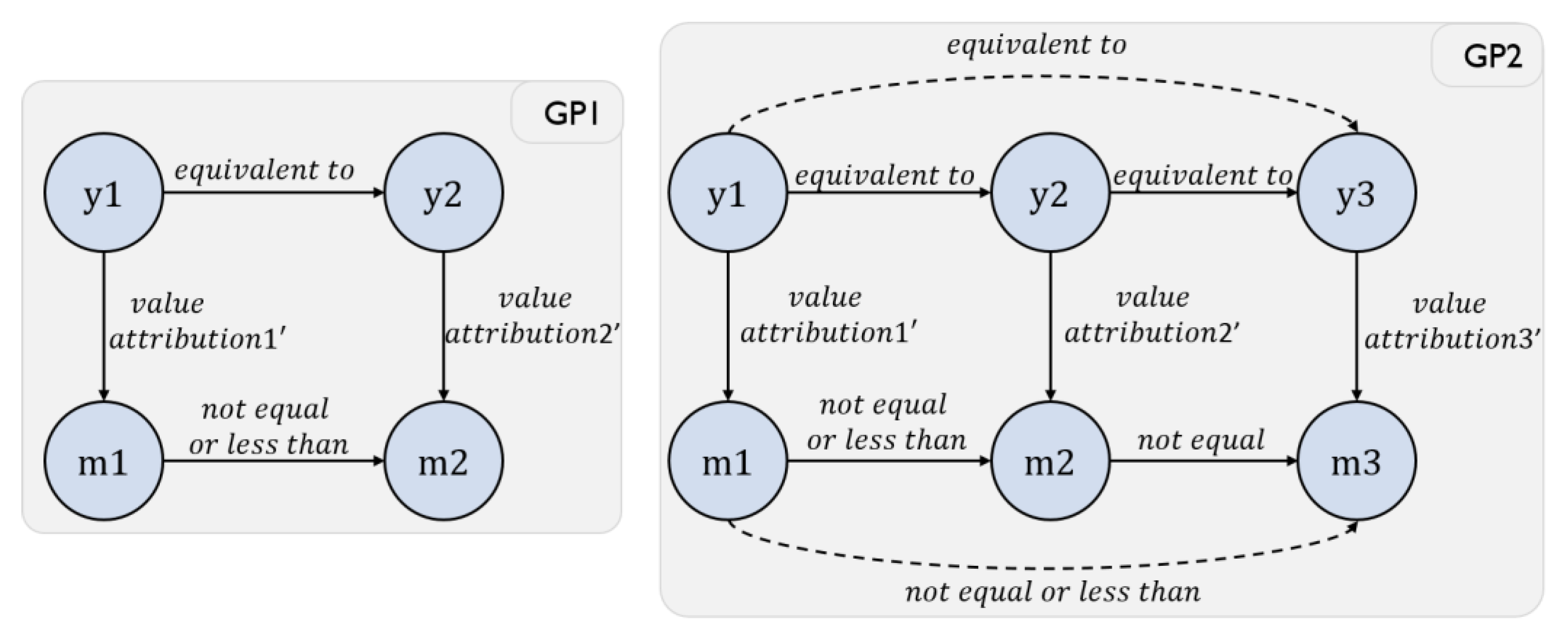

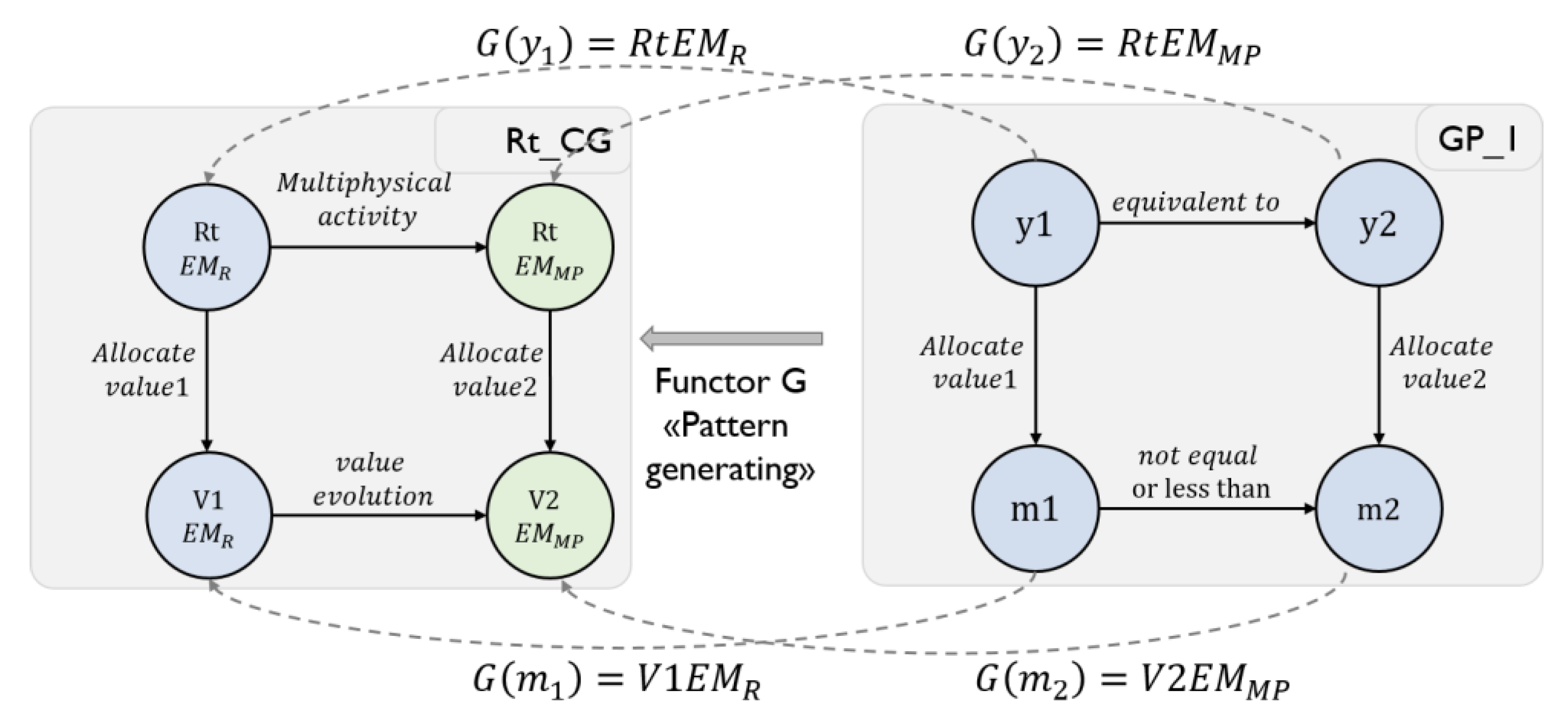

- Graph Pattern (GP), GP1, GP2, …, GPq, a set of categories aiming at describing the existence of a conflict. Querying the different PmCGs using these patterns can help in conflict detection. This graph is defined as a category containing a set of objects and morphisms. The objects of this category are either a string representing the parameter names and is unmodified through the different iterations or a variable for parameter values definition. The morphisms in the GP illustrate the value attribution for each parameter. The form of the GP can vary dependently to the PmCG to be queried. An example of GP is illustrated in Figure 5. The GP1 describes the existence of a conflict between two expert models where the value m1 is not equal or less than m2. The second GP2 represents a conflict among three expert models where m1 is not equal or less than m2 and m3. Moreover, a conflict can be detected when the values of m2 and m3 are not equal.

- Resolution action (RA): A set of actions, RA1, RA2, …, RAr, to resolve the conflicts detected by means of GPs. These actions cover modifying the value of the conflicting parameter, tolerating the conflict and ignoring it. The choice of these actions is ensured by the project manager and depends on the current context as well as the detected conflicts.

4.2. Proposed Methodology

4.2.1. Step 1: Creating a Common Representational Formalism (PmCG) Based on CT for Parameters Extracted from Expert Models (EMs)

4.2.2. Step 2: Creating the Parameters Dependency Categorical Graphs (DCG)

4.2.3. Step 3: Defining Consistency Rules (CRs)

4.2.4. Step 4: Defining Graph Patterns (GPs)

4.2.5. Step 5: Locating Conflicts through Matching GPs against PmCGs

4.2.6. Step 6: Detecting Related Parameters to the Conflicting Parameter through Checking DCG

4.2.7. Step 7: Saving the Final Values of Each Parameter in the Final Parameter Categorical Graph FPmCG

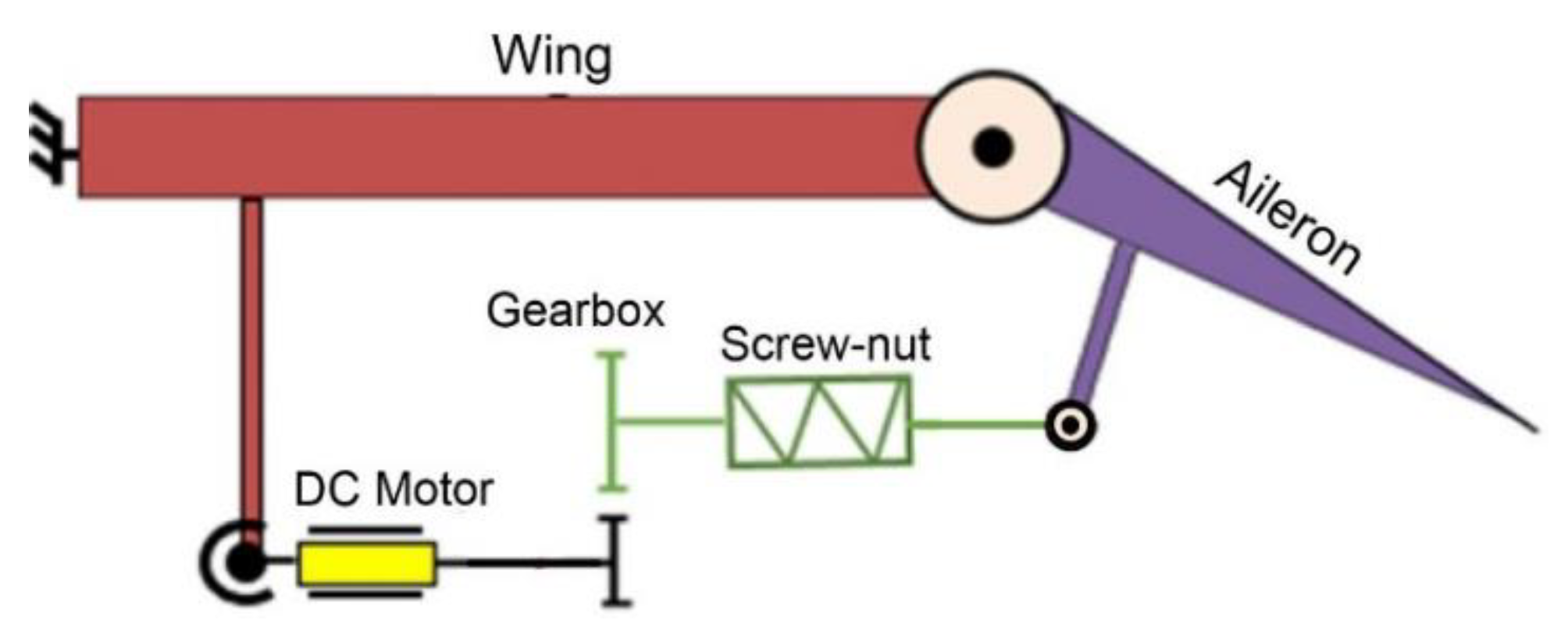

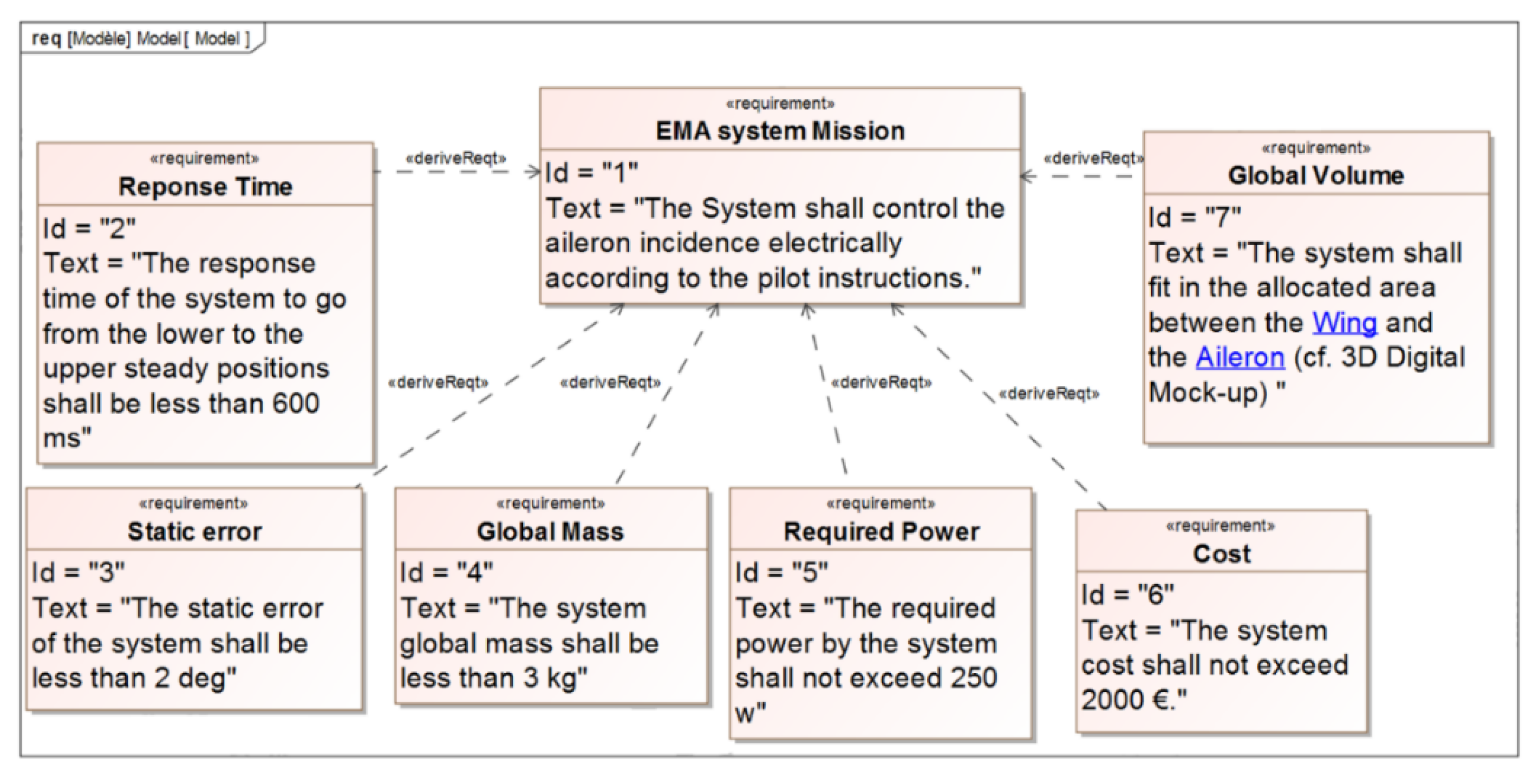

5. Case Study

5.1. Step 1: Creating a Common Representational Formalism (PmCG) Based on CT for Parameters Extracted from Expert Models (EMs)

5.2. Step 2: Creating the Parameters Dependency Categorical Graphs (DCG)

5.3. Step 3: Defining Consistency Rules (CRs)

5.4. Step 4: Defining Graph Patterns (GPs)

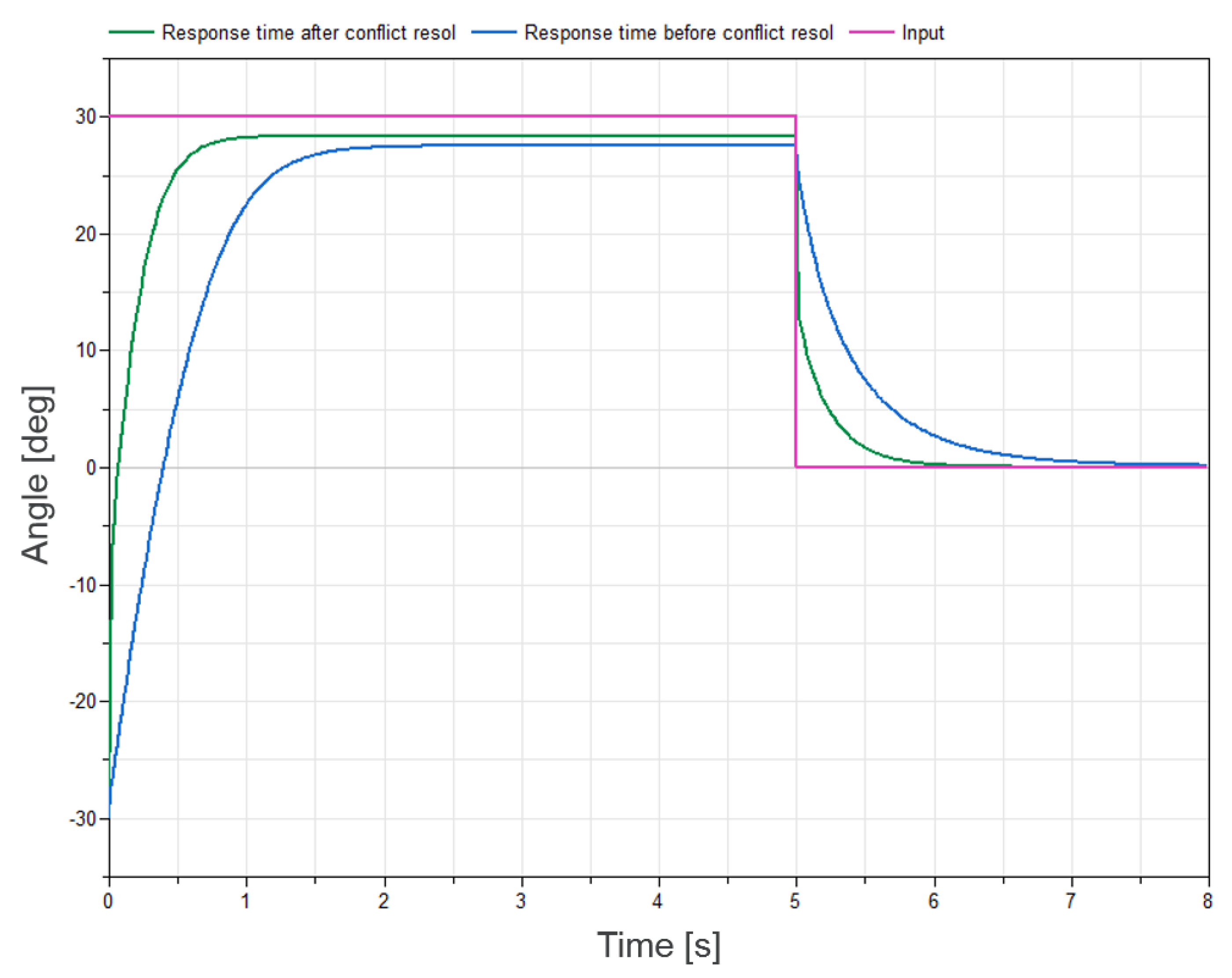

5.5. Step 5: Locating Conflicts through Matching GPs against PmCG

5.6. Step 6: Detecting Related Parameters to the Conflicting Parameter through Checking DCG

5.7. Step 7: Saving the Final Values of Each Parameter in the Final Parameter Categorical Graph (FPCG)

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Feldmann, S.; Kernschmidt, K.; Wimmer, M.; Vogel-Heuser, B. Managing inter-model inconsistencies in model-based systemsengineering: Application in automated production systems engineering. J. Syst. Softw. 2019, 153, 105–134. [Google Scholar] [CrossRef]

- Basirati, M.R.; Zou, M.; Bauer, H.; Kattner, N.; Reinhart, G.; Lindemann, U.; Vogel-Heuser, B. Towards systematic inconsistencyidentification for product service systems. In Proceedings of the DESIGN 2018 15th International Design Conference, DS 92, Dubrovnik, Croatia, 21–24 May 2018; pp. 2811–2820. [Google Scholar]

- Fradi, M.; Gaha, R.; Mlika, A.; Mhenni, F.; Choley, J.Y. Design of an Electronic Throttle Body Based on a New Knowledge Sharing Engineering Methodology. In Proceedings of the International Conference Design and Modeling of Mechanical Systems, Hammamet, Tunisia, 18–20 March 2019; pp. 55–63. [Google Scholar]

- Dávid, I.; Denil, J.; Gadeyne, K.; Vangheluwe, H. Engineering Process Transformation to Manage (In) consistency. In Proceedings of the 1st International Workshop on Collaborative Modelling in MDE (COMMitMDE 2016) Co-Located With ACM/IEEE 19th International Conference on Model Driven Engineering Languages and Systems (MoDELS 2016), St. Malo, France, 4 October 2016; pp. 7–16. [Google Scholar]

- Zhu, M.; Kuang, H.; Li, J. Representation of Categorical Specification of Self-Configurations in Reactive Autonomic Systems Framework. J. Comput. Commun. 2018, 6, 34–48. [Google Scholar] [CrossRef][Green Version]

- Fisher, A.; Nolan, M.; Friedenthal, S.; Loeffler, M.; Sampson, M.; Bajaj, M.; Hart, L. 3.1. 1 model lifecycle management for MBSE. In Proceedings of the INCOSE International Symposium, Las Vegas, NV, USA, 30 June–3 July 2014; Volume 24, pp. 207–229. [Google Scholar]

- Herzig, S.J. A Bayesian Learning Approach to Inconsistency Identification in Model-Based Systems Engineering. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2015. [Google Scholar]

- Mabrok, M.A.; Ryan, M.J. Category theory as a formal mathematical foundation for model-based systems engineering. Appl. Math. Inf. Sci. 2017, 11, 43–51. [Google Scholar]

- Spivak, D.I. Category theory for scientists (Old version). arXiv 2013, arXiv:1302.6946. [Google Scholar]

- Finkelstein, A.C.; Gabbay, D.; Hunter, A.; Kramer, J.; Nuseibeh, B. Inconsistency handling in multi-perspective specifications. IEEE Trans. Softw. Eng. 1994, 20, 569–578. [Google Scholar] [CrossRef]

- Medvidovic, N.; Taylor, R.N. Software architecture: Foundations, theory, and practice. In Proceedings of the 2010 ACM/IEEE 32nd International Conference on Software Engineering, Cape Town, South Africa, 2–8 May 2010; Volume 2, pp. 471–472. [Google Scholar]

- Torres, W.; Van den Brand, M.G.; Serebrenik, A. A systematic literature review of cross-domain model consistency checking bymodel management tools. Softw. Syst. Model. 2020. [Google Scholar] [CrossRef]

- Axelsson, J. Achieving System-of-Systems Interoperability Levels Using Linked Data and Ontologies. In Proceedings of the INCOSE International Symposium, Cape Town, South Africa, 18–23 July 2020; Volume 30, pp. 651–665. [Google Scholar]

- Guychard, C.; Guerin, S.; Koudri, A.; Beugnard, A.; Dagnat, F. Conceptual interoperability through models federation. In Proceedings of the Semantic Information Federation Community Workshop, Miami Beach, FL, USA, 29 September–4 October 2013; p. 23. [Google Scholar]

- Berriche, A.; Mhenni, F.; Mlika, A.; Choley, J.Y. Towards model synchronization for consistency management of mechatronicsystems. Appl. Sci. 2020, 10, 3577. [Google Scholar] [CrossRef]

- Qamar, A.; Meinhart, M.; Walley, G. Model based systems engineering to support failure mode avoidance for driver-assistancesystems. In Proceedings of the 2017 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2017; pp. 1–9. [Google Scholar]

- PLM Automation, Teamcenter. Available online: https://www.plm.automation.siemens.co-m/global/fr/products/teamcenter (accessed on 15 January 2021).

- Dassault Systèmes, MagicDraw. Available online: https://www.nomagic.com/products/ma-gicdraw (accessed on 23 October 2020).

- Mathworks, Simulink. Available online: https://www.mathworks.com/products/simulink (accessed on 15 January 2021).

- Bock, C.; Zha, X.; Suh, H.W.; Lee, J.H. Ontological product modeling for collaborative design. Adv. Eng. Inform. 2010, 24, 510–524. [Google Scholar]

- Penas, O.; Plateaux, R.; Patalano, S.; Hammadi, M. Multi-scale approach from mechatronic to Cyber-Physical Systems for thedesign of manufacturing systems. Comput. Ind. 2017, 86, 52–69. [Google Scholar]

- Qamar, A.; Paredis, C.J.; Wikander, J.; During, C. Dependency modeling and model management in mechatronic design. J. Comput. Inf. Sci. Eng. 2012, 12, 041009. [Google Scholar] [CrossRef]

- Törngren, M.; Qamar, A.; Biehl, M.; Loiret, F.; El-Khoury, J. Integrating viewpoints in the development of mechatronic products. Mechatronics 2014, 24, 745–762. [Google Scholar] [CrossRef]

- Legendre, A.; Lanusse, A.; Rauzy, A. Toward model synchronization between safety analysis and system architecture design inindustrial contexts. In Proceedings of the International Symposium on Model-Based Safety and Assessment, Trento, Italy, 14–16 September 2017; pp. 35–49. [Google Scholar]

- Herzig, S.J.; Qamar, A.; Paredis, C.J. An approach to identifying inconsistencies in model-based systems engineering. Procedia Comput. Sci. 2014, 28, 354–362. [Google Scholar] [CrossRef]

- Herzig, S.J.; Paredis, C.J. A conceptual basis for inconsistency management in model-based systems engineering. Procedia Cirp 2014, 21, 52–57. [Google Scholar] [CrossRef][Green Version]

- Kleiner, S.; Anderl, R.; Gräb, R. A collaborative design system for product data integration. J. Eng. Des. 2003, 14, 421–428. [Google Scholar] [CrossRef]

- Badin, J.; Chamoret, D.; Gomes, S.; Monticolo, D. Knowledge configuration management for product design and numericalsimulation. In Proceedings of the 18th International Conference on Engineering Design (ICED 11), Lyngby/Copenhagen, Denmark, 15–18 August 2011; Volume 6, pp. 161–172. [Google Scholar]

- Mcharek, M.; Azib, T.; Hammadi, M.; Choley, J.Y.; Larouci, C. Knowledge sharing for mechatronic systems design andoptimization. IFAC Pap. 2018, 51, 1365–1370. [Google Scholar] [CrossRef]

- Mcharek, M.; Hammadi, M.; Azib, T.; Larouci, C.; Choley, J.Y. Collaborative design process and product knowledge methodologyfor mechatronic systems. Comput. Ind. 2019, 105, 213–228. [Google Scholar] [CrossRef]

- Kuang, H. Towards a Formal Reactive Autonomic Systems Framework Using Category Theory. Ph.D. Thesis, Concordia University, Montreal, QC, Canada, 2013. [Google Scholar]

- Ormandjieva, O.; Bentahar, J.; Huang, J.; Kuang, H. Modelling multi-agent systems with category theory. Procedia Comput. Sci. 2015, 52, 538–545. [Google Scholar] [CrossRef]

- Roman, S. An Introduction to the Language of Category Theory; Birkhäuser: Cham, Switzerland, 2017. [Google Scholar]

- Phillips, S. A general (category theory) principle for general intelligence: Duality (adjointness). In Proceedings of the International Conference on Artificial General Intelligence, Melbourne, Australia, 15–18 August 2017; pp. 57–66. [Google Scholar]

- Guo, J. Using category theory to model software component dependencies. In Proceedings of the Ninth Annual IEEE International Conference and Workshop on the Engineering of Computer-Based Systems, Lund, Sweden, 8–11 April 2002; pp. 185–192. [Google Scholar]

- Suto, H.; Patitad, P. A representation model of collaboration in design process. In Proceedings of the 2015 10th Asian Control Conference (ASCC), Kota Kinabalu, Malaysia, 31 May–3 June 2015; pp. 1–5. [Google Scholar]

- Zhu, M.; Li, J. Towards a Categorical Framework for Verifying Design and Implementation of Concurrent Systems. J. Comput. Commun. 2018, 6, 227–246. [Google Scholar] [CrossRef][Green Version]

- Kibret, N.; Edmonson, W.; Gebreyohannes, S. Category theoretic based formalization of the verifiable design process. In Proceedings of the 2019 IEEE International Systems Conference (SysCon), Orlando, FL, USA, 8–11 April 2019; pp. 1–8. [Google Scholar]

- Dassault Systèmes. Available online: https://www.3ds.com/fr/produits-et-services/catia/produits/dymola/ (accessed on 10 July 2020).

- Dassault Systèmes. Available online: https://www.3ds.com/fr/produits-et-services/catia/ (accessed on 10 July 2020).

- Object Management Group. Model Driven Architecture (MDA)—MDA Guide 2.0. 2014. Available online: https://www.omg.org/mda/presentations.htm (accessed on 14 May 2021).

- Brigui-Chtioui, I.; Saad, I. A multiagent approach for collective decision making in knowledge management. Group Decis. Negot. 2011, 20, 19–37. [Google Scholar] [CrossRef]

- Saad, I.; Chakhar, S. A decision support for identifying crucial knowledge requiring capitalizing operation. Eur. J. Oper. Res. 2009, 195, 889–904. [Google Scholar] [CrossRef]

- Mhenni, F.; Choley, J.Y.; Caron, F.; Munck, A. Collaborative Mechatronic Design and Systems Engineering: An Educational Experiment with KARREN. In Proceedings of the 2018 IEEE International Systems Engineering Symposium (ISSE), Rome, Italy, 1–3 October 2018; pp. 1–7. [Google Scholar]

- Siala, H.; Mhenni, F.; Choley, J.Y.; Barkallah, M.; Louati, J.; Haddar, M. Toward a Robust Design of an Aileron Electromechanical Actuator: Sensitivity Analysis and Parametric Tolerancing Using a Variational Approach. IEEE Syst. J. 2020, 14, 3977–3986. [Google Scholar] [CrossRef]

- Shitahun, A.; Ruge, V.; Gebremedhin, M.; Bachmann, B.; Eriksson, L.; Andersson, J.; Fritzson, P. Model-based dynamicoptimization with openmodelica and casadi. IFAC Proc. Vol. 2013, 46, 446–451. [Google Scholar] [CrossRef]

| Dependency Coefficient | Description of Dependency Coefficient Levels |

|---|---|

| 1 | Low dependency |

| 2 | Moderated dependency |

| 3 | High dependency |

| Parameters | Unit | EMR | EMMP | EMC | EM3D |

|---|---|---|---|---|---|

| Response time (Rt) | ms | 600 | 535 | - | - |

| Static error (Se) | deg | 2 | 2.44 | - | - |

| Global Mass (Mass) | Kg | 3 | - | 3.143 | - |

| Maximal power (Pw) | W | 250 | 288 | 250 | - |

| Cost (Ct) | € | 2000 | - | 1555.65 | - |

| Motor diameter (Ømot) | mm | 70 | - | 65 | 70 |

| Motor Length (Lgthmot) | mm | 145 | - | 131.4 | 145 |

| Motor resistance (Rm) | Ohm | - | 0.5 | 0.356 | - |

| Motor Inductance (Lm) | mH | - | 0.0039 | 0.000161 | - |

| Motor Inertia (Jm) | Kg.m2 | - | 10 × 10−7 | 13.45 × 10−5 | - |

| Reducer diameter (Øred) | mm | 85 | - | 81 | 85 |

| Reducer Length (Lgthred) | mm | 95 | - | 91.9 | 95 |

| Reducer ratio (rred) | [] | - | 3.5 | 3.7 | - |

| Screw-nut diameter (Øsn) | mm | 25 | - | 22 | 25 |

| Screw-nut Length (Lgthsn) | mm | 60 | - | 58.4 | 60 |

| Screw-nut ratio (rsn) | [] | - | 330 | 333 | - |

| Iteration 1 | Iteration 2 |

|---|---|

| |

| Parameters | Unit | EMR | EMMP | EMC | EM3D |

|---|---|---|---|---|---|

| Response time (Rt) | ms | 600 | 140 | - | - |

| Static error (Se) | deg | 2 | 1.61 | - | - |

| Global Mass (Mass) | Kg | 3.500 | - | 3.143 | - |

| Maximal power (Pw) | W | 250 | 250 | 250 | - |

| Cost (Ct) | € | 2000 | - | 1555.65 | - |

| Motor diameter (Ømot) | mm | 70 | - | 65 | 70 |

| Motor Length (Lgthmot) | mm | 145 | - | 131.4 | 145 |

| Motor resistance (Rm) | Ohm | - | 0.356 | 0.356 | - |

| Motor Inductance (Lm) | mH | - | 0.000161 | 0.000161 | - |

| Motor Inertia (Jm) | Kg.m2 | - | 13.45 × 10−5 | 13.45 × 10−5 | - |

| Reducer diameter (Øred) | mm | 85 | - | 81 | 81 |

| Reducer Length (Lgthred) | mm | 95 | - | 91.9 | 92 |

| Reducer ratio (rred) | [] | - | 3.7 | 3.7 | - |

| Screw-nut diameter (Øsn) | mm | 25 | - | 22 | 22 |

| Screw-nut Length (Lgthsn) | mm | 60 | - | 58.4 | 60 |

| Screw-nut ratio (rsn) | [] | - | 333 | 333 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fradi, M.; Mhenni, F.; Gaha, R.; Mlika, A.; Choley, J.-Y. Conflict Resolution in Mechatronic Collaborative Design Using Category Theory. Appl. Sci. 2021, 11, 4486. https://doi.org/10.3390/app11104486

Fradi M, Mhenni F, Gaha R, Mlika A, Choley J-Y. Conflict Resolution in Mechatronic Collaborative Design Using Category Theory. Applied Sciences. 2021; 11(10):4486. https://doi.org/10.3390/app11104486

Chicago/Turabian StyleFradi, Mouna, Faïda Mhenni, Raoudha Gaha, Abdelfattah Mlika, and Jean-Yves Choley. 2021. "Conflict Resolution in Mechatronic Collaborative Design Using Category Theory" Applied Sciences 11, no. 10: 4486. https://doi.org/10.3390/app11104486

APA StyleFradi, M., Mhenni, F., Gaha, R., Mlika, A., & Choley, J.-Y. (2021). Conflict Resolution in Mechatronic Collaborative Design Using Category Theory. Applied Sciences, 11(10), 4486. https://doi.org/10.3390/app11104486