A Novel Method for Precise Guided Hole Fabrication of Dental Implant Surgical Guide Fabricated with 3D Printing Technology

Abstract

1. Introduction

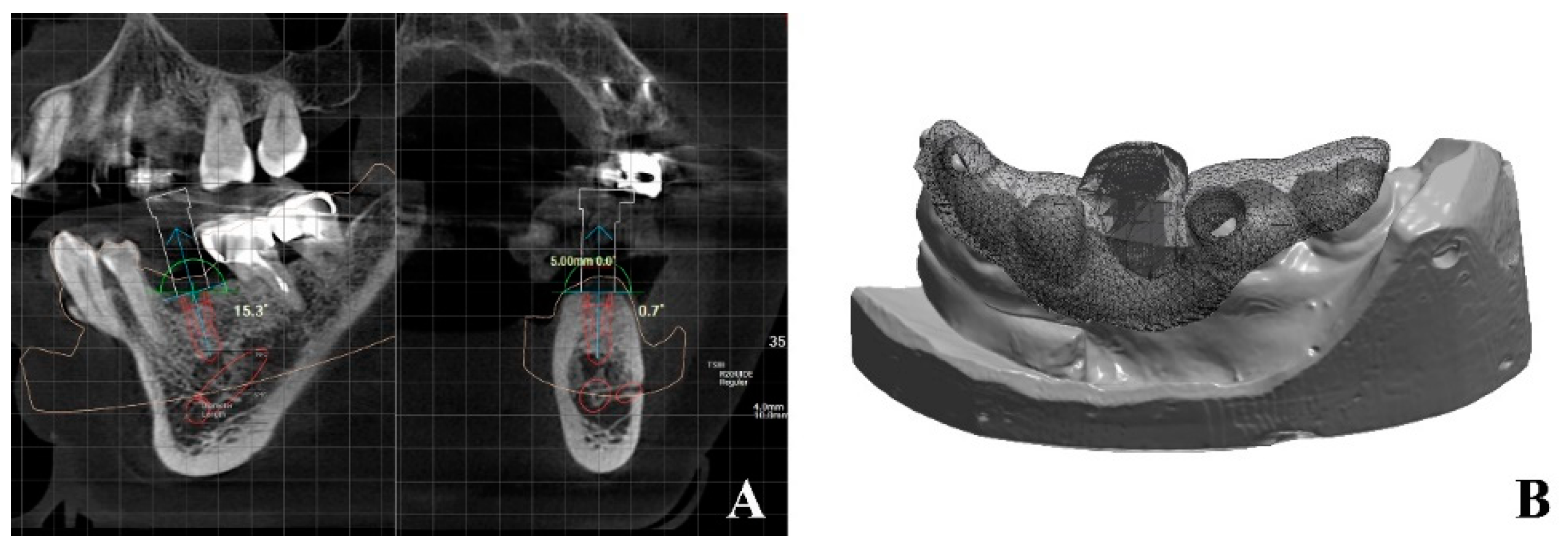

2. Materials and Methods

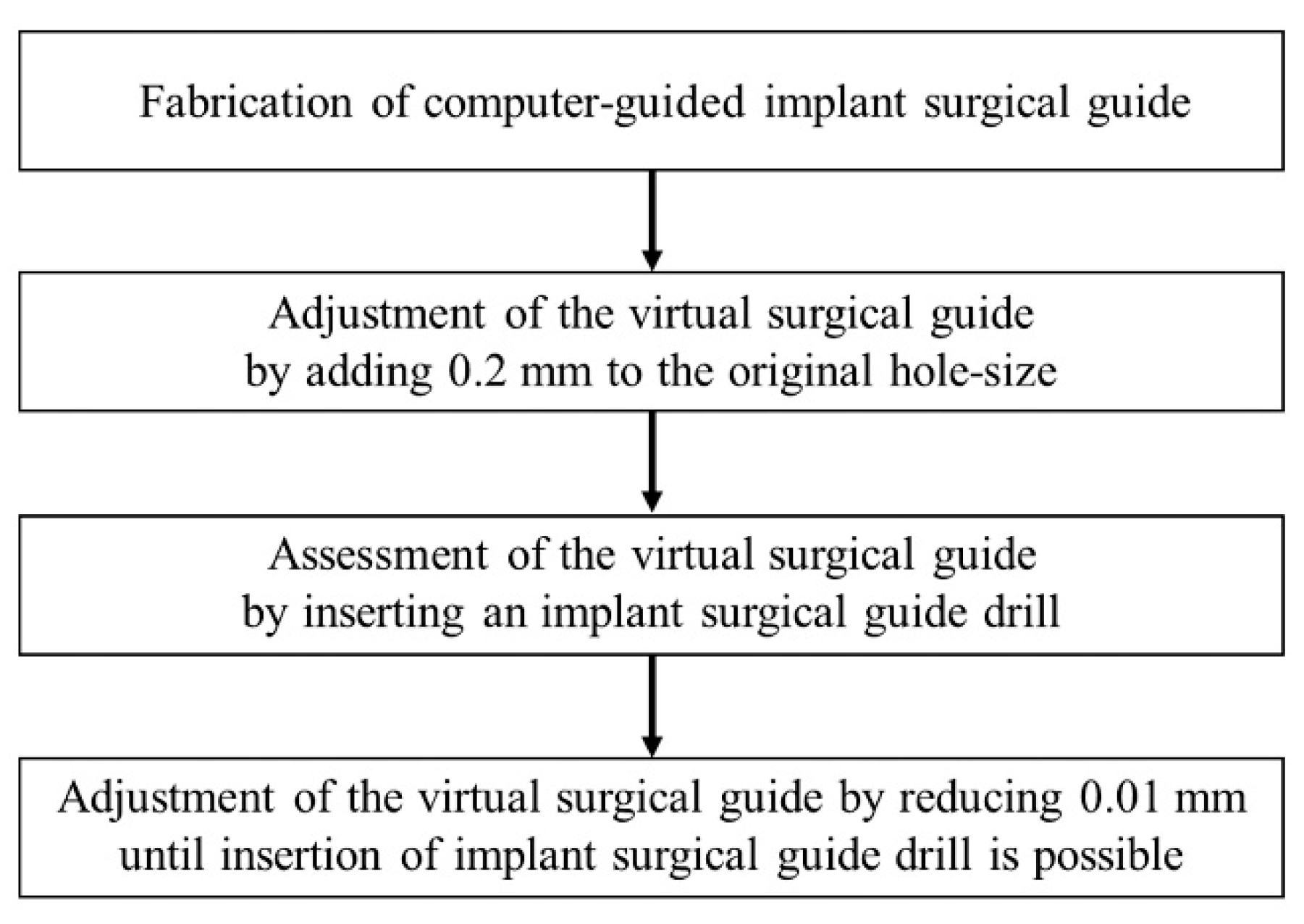

2.1. Technical Note: Adjustment of the Virtual Surgical Guide before Fabrication

- 2.

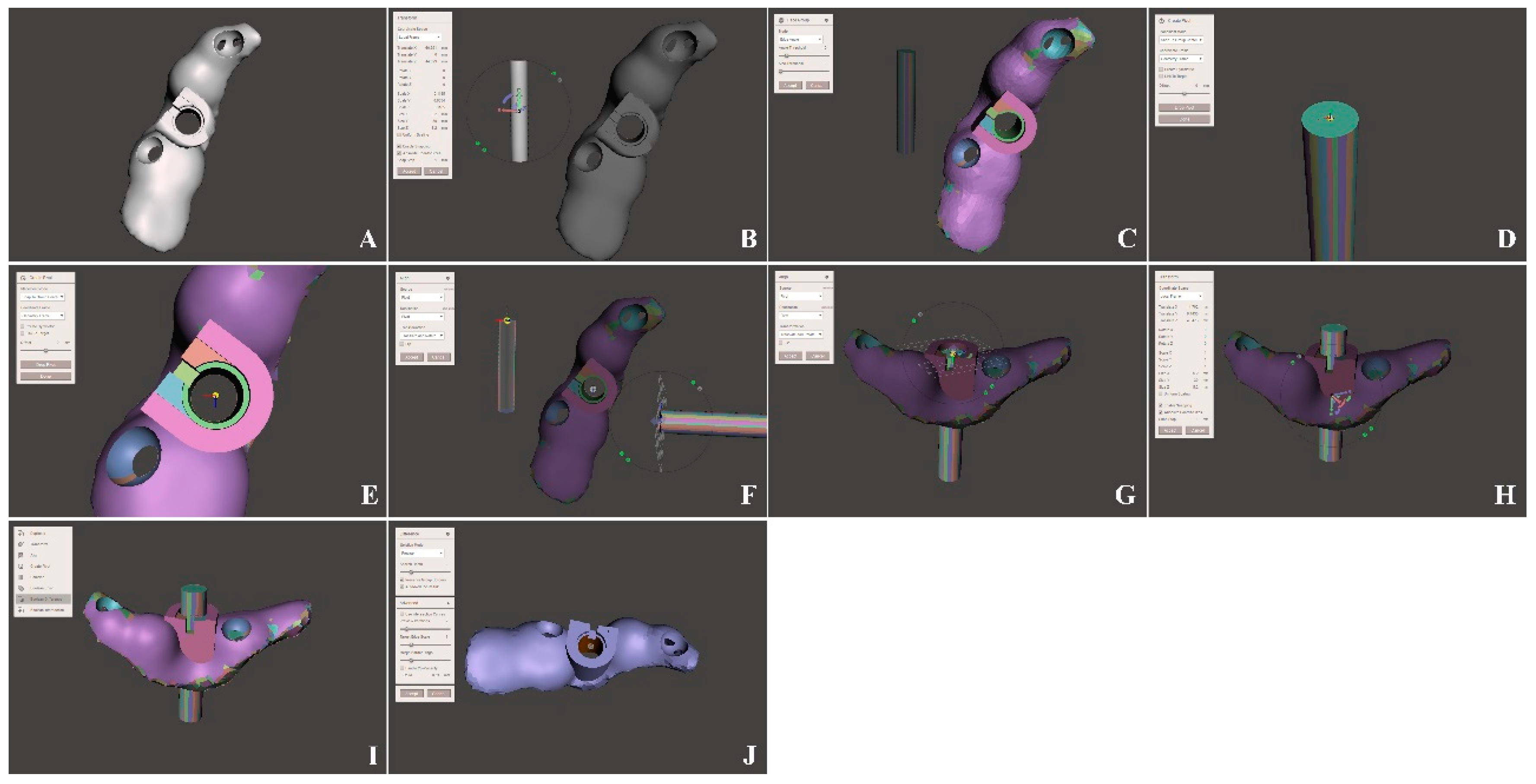

- Import the STL format file into a mesh editing software (Meshmixer; Autodesk Co, San Rafael, CA, USA) (Figure 3A).

- 3.

- Create the cylinder using a mesh editing software (Figure 3B). Then, adjust the size of the cylinder to a diameter of 5.2 mm by adding 0.2 mm to the original hole-size (5 mm) to compensate for the shrinkage of the resin material.

- 4.

- Use the “Face Group” function to separate the base of the cylinder and the guide hole in the surgical guide (Figure 3C).

- 5.

- Use the “Create Pivot” function to set up a reference point for alignment. Set the reference point at the base of the cylinder and the guide hole of the surgical guide (Figure 3D,E).

- 6.

- 7.

- Use the “Transform” function to move the cylinder so it can contact the entire guide hole (Figure 3H).

- 8.

- Use the “Boolean Difference” function to adjust the size of the guide hole. Select the surgical guide, hold down the Shift key while selecting the cylinder, and then select the “Boolean Difference” function (Figure 3I).

- 9.

- Check the adjusted guide hole (Figure 3J). Then, export the surgical guide with a guide hole of 5.2 mm diameter from the mesh editing software into a STL format file.

2.2. Technical Note: Identification of the Surgical Guide for the Optimized Guide Hole Size

- Fabricate the surgical guides with guide hole sizes of 5.0 mm (original size) and 5.2 mm (+0.2 mm) in diameter using a 3D printer (MegPrinter; Megagen, Daegu, Republic of Korea) with photosensitive liquid resins (RAYDENT SG; Ray, Seoul, Republic of Korea).

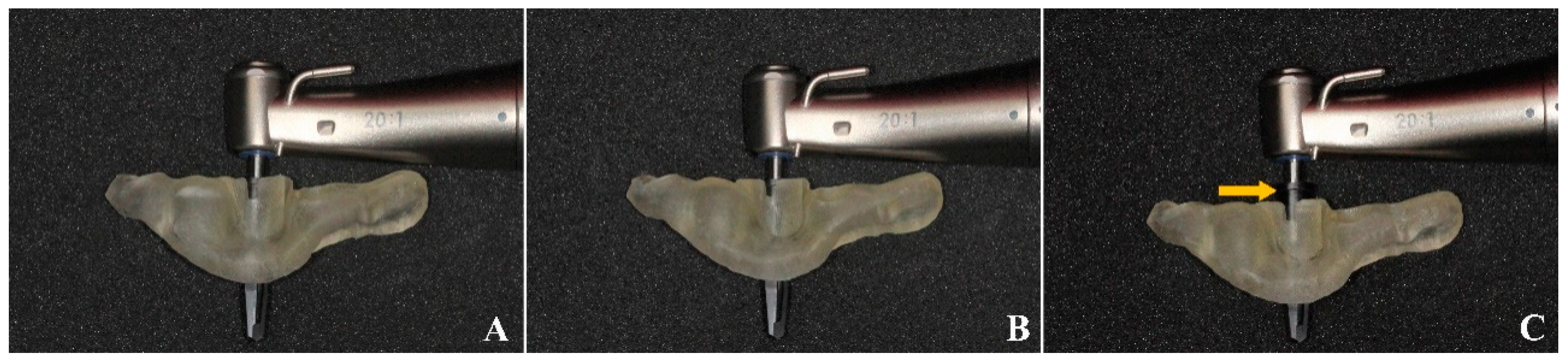

- Assess the size of the hole by inserting an implant surgical guide drill (R2GATE; Megagen, Daegu, Republic of Korea) into the hole of the surgical guides with guide hole sizes of 5.0 mm and 5.2 mm in diameter (Figure 4). The insertion of the drill was impossible at 5.0 mm (Figure 4A), while it was possible at 5.2 mm (Figure 4B).

- 3.

- Perform ‘Adjustment of the virtual surgical guide’ steps for the fabrication of surgical guides with guide hole sizes of 5.19 mm, 5.18 mm, and 5.17 mm in diameter. Using this process, it is possible to determine the minimum usable clearance between the hole and the drill.

- 4.

- Perform the 2 steps for assessment of the surgical guides with guide hole sizes of 5.19 mm, 5.18 mm, and 5.17 mm. The insertion of the drill was possible at 5.19 mm and 5.18 mm (Figure 5A,B), but was not possible at 5.17 mm (Figure 5C). Therefore, the value of 5.18 mm between 5.19 mm and 5.17 mm was determined as the minimum usable tolerance.

- 5.

- Fabricate 10 surgical guides with guide holes of 5.18 mm for repeatability. Then, assess the size of the hole by inserting an implant surgical guide drill.

- 6.

- Measure the size of the guide holes using a digital vernier caliper (500-197-20; Mitutoyo, Tokyo, Japan).

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bernard, L.; Vercruyssen, M.; Duyck, J.; Jacobs, R.; Teughels, W.; Quirynen, M. A randomized controlled clinical trial comparing guided with nonguided implant placement: A 3-year follow-up of implant-centered outcomes. J. Prosthet. Dent. 2019, 121, 904–910. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Lin, W.S.; Polido, W.D.; Eckert, G.J.; Morton, D. Accuracy, reproducibility, and dimensional stability of additively manufactured surgical templates. J. Prosthet. Dent. 2019, 122, 309–314. [Google Scholar] [CrossRef] [PubMed]

- Oh, K.C.; Park, J.M.; Shim, J.S.; Kim, J.H.; Kim, J.E.; Kim, J.H. Assessment of metal sleeve-free 3d-printed implant surgical guides. Dent. Mater. 2019, 35, 468–476. [Google Scholar] [CrossRef]

- Gjelvold, B.; Mahmood, D.J.H.; Wennerberg, A. Accuracy of surgical guides from 2 different desktop 3D printers for computed tomography-guided surgery. J. Prosthet. Dent. 2019, 121, 498–503. [Google Scholar] [CrossRef] [PubMed]

- Apostolakis, D.; Kourakis, G. CAD/CAM implant surgical guides: Maximum errors in implant positioning attributable to the properties of the metal sleeve/osteotomy drill combination. Int. J. Implant Dent. 2018, 4, 34. [Google Scholar] [CrossRef] [PubMed]

- Koop, R.; Vercruyssen, M.; Vermeulen, K.; Quirynen, M. Tolerance within the sleeve inserts of different surgical guides for guided implant surgery. Clin. Oral Implants Res. 2013, 24, 630–634. [Google Scholar] [CrossRef] [PubMed]

- Van Assche, N.; Quirynen, M. Tolerance within a surgical guide. Clin. Oral Implants Res. 2010, 21, 455–458. [Google Scholar] [CrossRef] [PubMed]

- Roe, P.; Rungcharassaeng, K.; Kan, J.Y.; Putra, A. Adhesive residue on the CAD-CAM surgical guide sleeve: A technical report. J. Prosthet. Dent. 2019, 121, 746–748. [Google Scholar] [CrossRef]

- Schneider, D.; Schober, F.; Grohmann, P.; Hammerle, C.H.; Jung, R.E. In-vitro evaluation of the tolerance of surgical instruments in templates for computer-assisted guided implantology produced by 3-D printing. Clin. Oral Implants Res. 2015, 26, 320–325. [Google Scholar] [CrossRef]

- Shim, J.S.; Kim, J.E.; Jeong, S.H.; Choi, Y.J.; Ryu, J.J. Printing accuracy, mechanical properties, surface characteristics, and microbial adhesion of 3D-printed resins with various printing orientations. J. Prosthet. Dent. 2020, 124, 468–475. [Google Scholar] [CrossRef]

- Kim, T.; Lee, S.; Kim, G.B.; Hong, D.; Kwon, J.; Park, J.W.; Kim, N. Accuracy of a simplified 3D-printed implant surgical guide. J. Prosthet. Dent. 2020, 124, 195–201. [Google Scholar] [CrossRef] [PubMed]

- Yeung, M.; Abdulmajeed, A.; Carrico, C.K.; Deeb, G.R.; Bencharit, S. Accuracy and precision of 3D-printed implant surgical guides with different implant systems: An in vitro study. J. Prosthet. Dent. 2020, 123, 821–828. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.Y.; Son, K.; Lee, K.B. Evaluation of intaglio surface trueness and margin quality of interim crowns in accordance with the build angle of stereolithography apparatus 3-dimensional printing. J. Prosthet. Dent. 2020, in press. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; An, X.; Jeong, S.M.; Choi, B.H. Accuracy of computer-guided implant placement in anterior regions. J. Prosthet. Dent. 2019, 121, 836–842. [Google Scholar] [CrossRef] [PubMed]

- Monaco, C.; Arena, A.; Corsaletti, L.; Santomauro, V.; Venezia, P.; Cavalcanti, R.; Zucchelli, G. 2D/3D accuracies of implant position after guided surgery using different surgical protocols: A retrospective study. J. Prosthodont. Res. 2020, 64, 424–430. [Google Scholar] [CrossRef]

- Tatakis, D.N.; Chien, H.H.; Parashis, A.O. Guided implant surgery risks and their prevention. Periodontol. 2000 2019, 81, 194–208. [Google Scholar] [CrossRef]

- Ackerman, S.; Aguilera, F.C.; Buie, J.M.; Glickman, G.N.; Umorin, M.; Wang, Q.; Jalali, P. Accuracy of 3-dimensional–printed Endodontic Surgical Guide: A Human Cadaver Study. J. Endod. 2019, 45, 615–618. [Google Scholar] [CrossRef]

- Son, K.; Huang, M.Y.; Lee, K.B. A method to evaluate the accuracy of dental implant placement without postoperative radiography after computer-guided implant surgery: A dental technique. J. Prosthet. Dent. 2020, 123, 661–666. [Google Scholar] [CrossRef]

- Kim, S.M.; Son, K.; Kim, D.Y.; Lee, K.B. Digital Evaluation of the Accuracy of Computer-Guided Dental Implant Placement: An In Vitro Study. Appl. Sci. 2019, 9, 3373. [Google Scholar] [CrossRef]

- Liu, Y.; Ye, H.; Wang, S.; Zhang, L.; Zhou, Y. An open protocol for evaluating the accuracy of guided implant surgery by using digital casts. J. Prosthet. Dent. 2020, in press. [Google Scholar] [CrossRef]

- Cheng, K.J.; Kan, T.S.; Liu, Y.F.; Zhu, W.D.; Zhu, F.D.; Wang, W.B.; Dong, X.T. Accuracy of dental implant surgery with robotic position feedback and registration algorithm: An in-vitro study. Comput. Biol. Med. 2020, 129, 104153. [Google Scholar] [CrossRef] [PubMed]

- Anunmana, C.; Ueawitthayasuporn, C.; Kiattavorncharoen, S.; Thanasrisuebwong, P. In Vitro Comparison of Surgical Implant Placement Accuracy Using Guides Fabricated by Three Different Additive Technologies. Appl. Sci. 2020, 10, 7791. [Google Scholar] [CrossRef]

- Schneider, D.; Marquardt, P.; Zwahlen, M.; Jung, R.E. A systematic review on the accuracy and the clinical outcome of computer-guided template-based implant dentistry. Clin. Oral Implants Res. 2009, 20, 73–86. [Google Scholar] [CrossRef] [PubMed]

- Tahmaseb, A.; Wu, V.; Wismeijer, D.; Coucke, W.; Evans, C. The accuracy of static computer-aided implant surgery: A systematic review and meta-analysis. Clin. Oral Implants Res. 2018, 29, 416–435. [Google Scholar] [CrossRef] [PubMed]

- Tahmaseb, A.; Wismeijer, D.; Coucke, W.; Derksen, W. Computer technology applications in surgical implant dentistry: A systematic review. Int. J. Oral Maxillofac. Implants 2014, 29, 25–42. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, K.; Lee, K.-B. A Novel Method for Precise Guided Hole Fabrication of Dental Implant Surgical Guide Fabricated with 3D Printing Technology. Appl. Sci. 2021, 11, 49. https://doi.org/10.3390/app11010049

Son K, Lee K-B. A Novel Method for Precise Guided Hole Fabrication of Dental Implant Surgical Guide Fabricated with 3D Printing Technology. Applied Sciences. 2021; 11(1):49. https://doi.org/10.3390/app11010049

Chicago/Turabian StyleSon, Keunbada, and Kyu-Bok Lee. 2021. "A Novel Method for Precise Guided Hole Fabrication of Dental Implant Surgical Guide Fabricated with 3D Printing Technology" Applied Sciences 11, no. 1: 49. https://doi.org/10.3390/app11010049

APA StyleSon, K., & Lee, K.-B. (2021). A Novel Method for Precise Guided Hole Fabrication of Dental Implant Surgical Guide Fabricated with 3D Printing Technology. Applied Sciences, 11(1), 49. https://doi.org/10.3390/app11010049