Development of a Throughflow-Based Simulation Tool for Preliminary Compressor Design Considering Blade Geometry in Gas Turbine Engine

Abstract

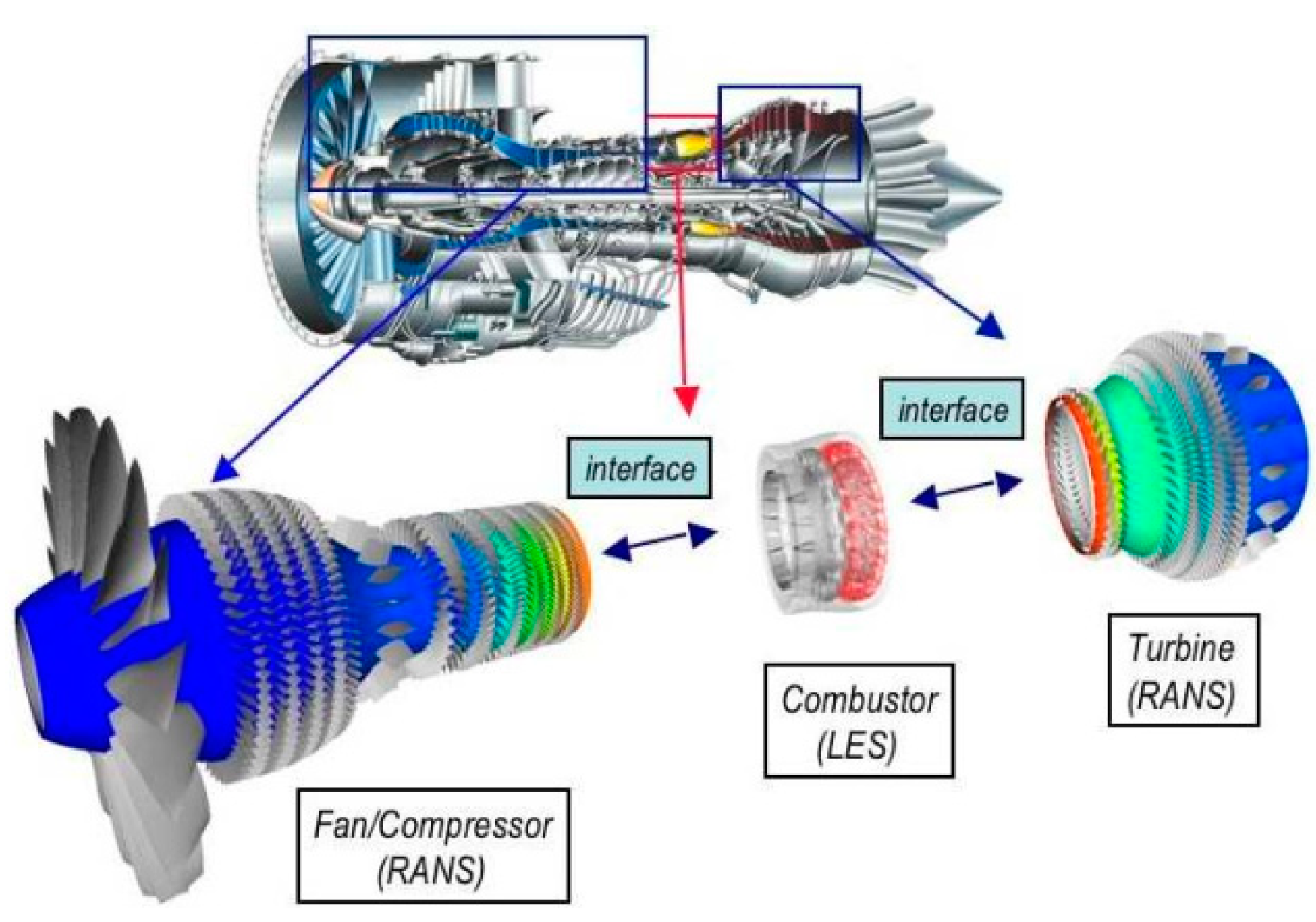

1. Introduction

2. Materials and Methodologies

2.1. Throughflow Analysis Tool

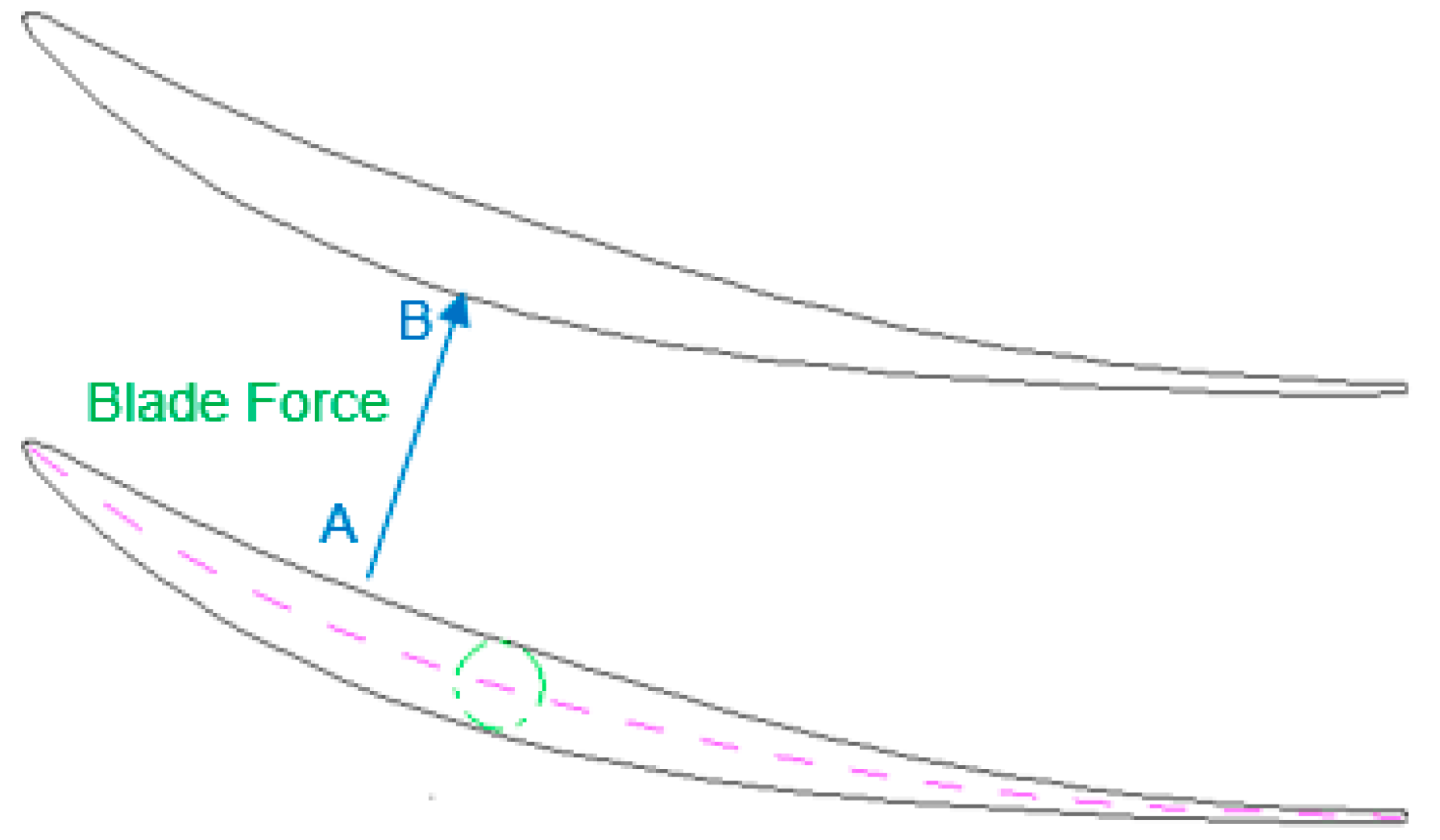

2.2. Development of the Inviscid Blade Force

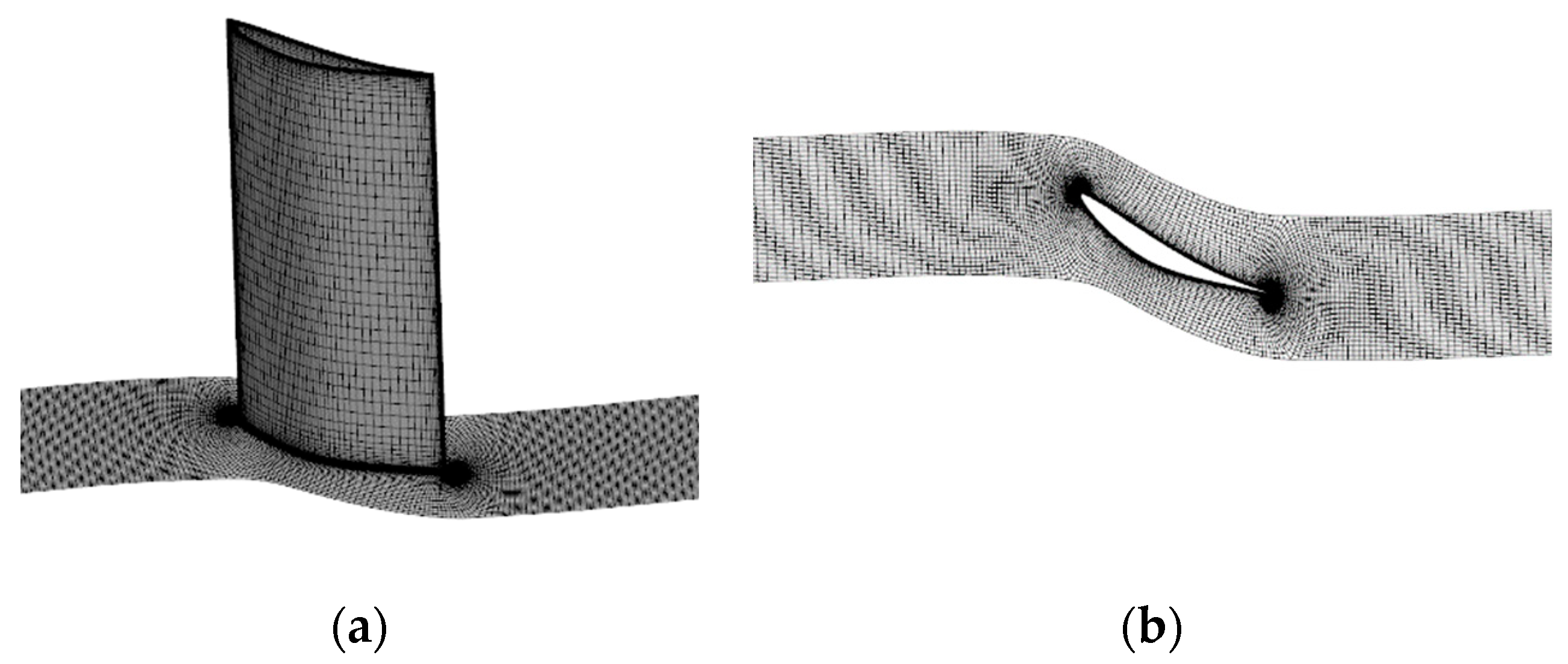

2.3. 3D CFD Method Verification

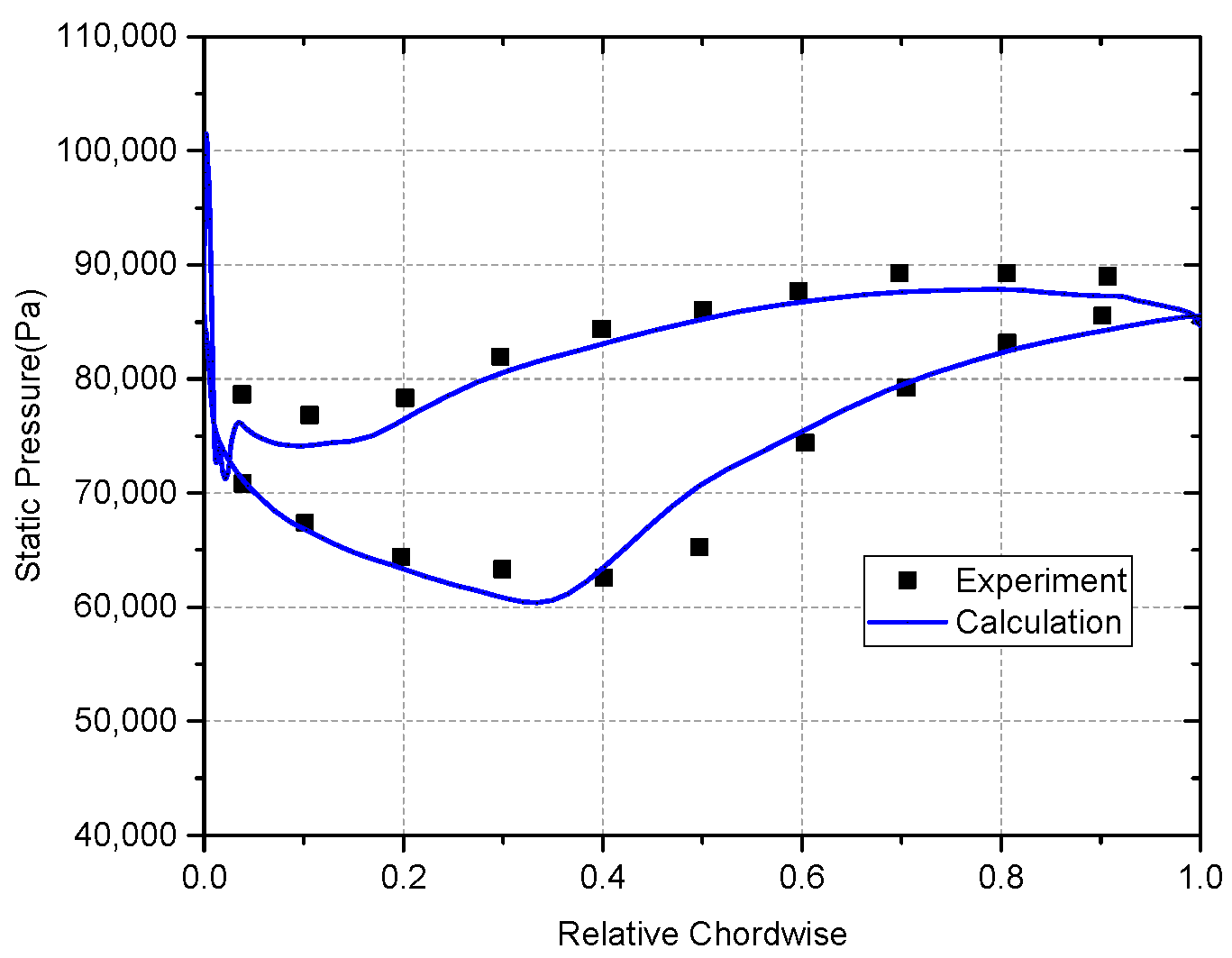

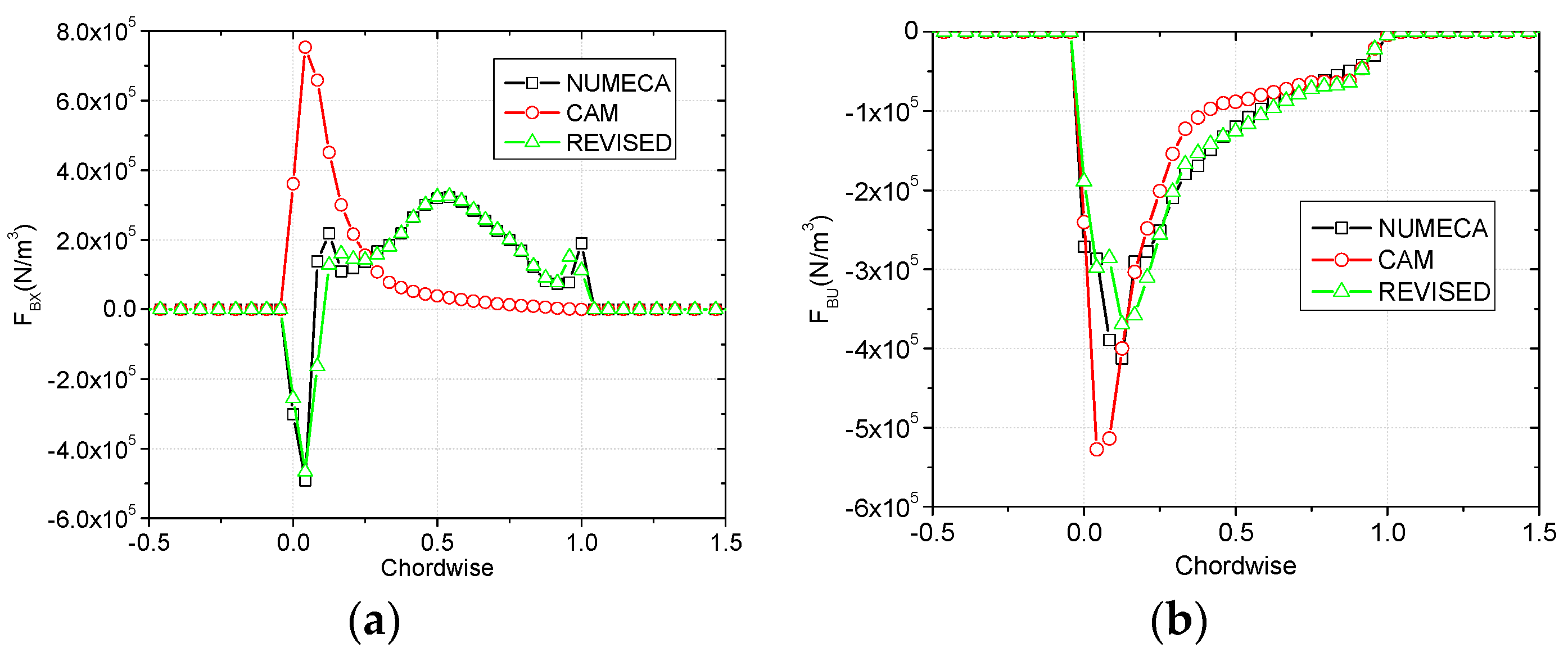

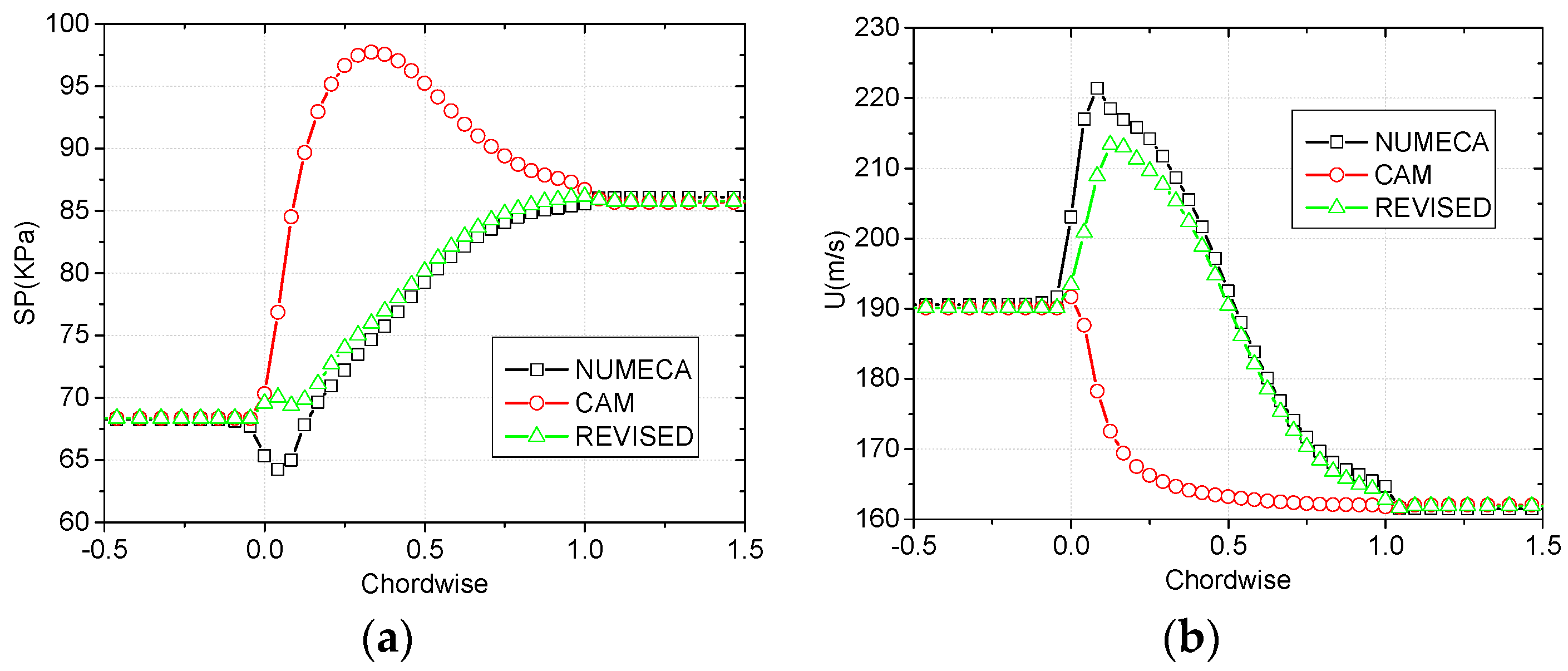

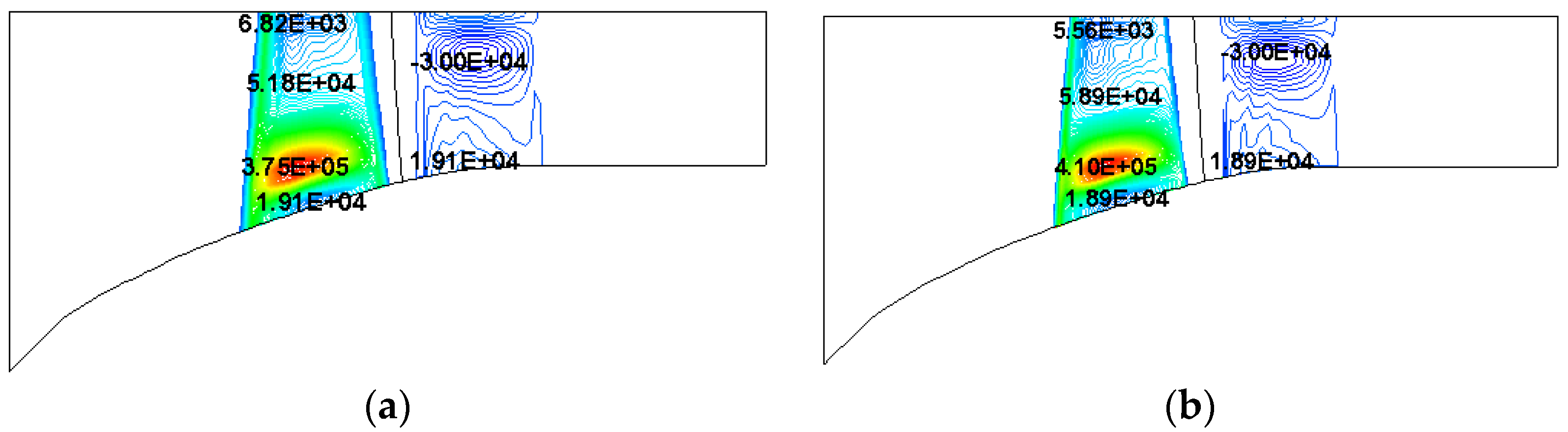

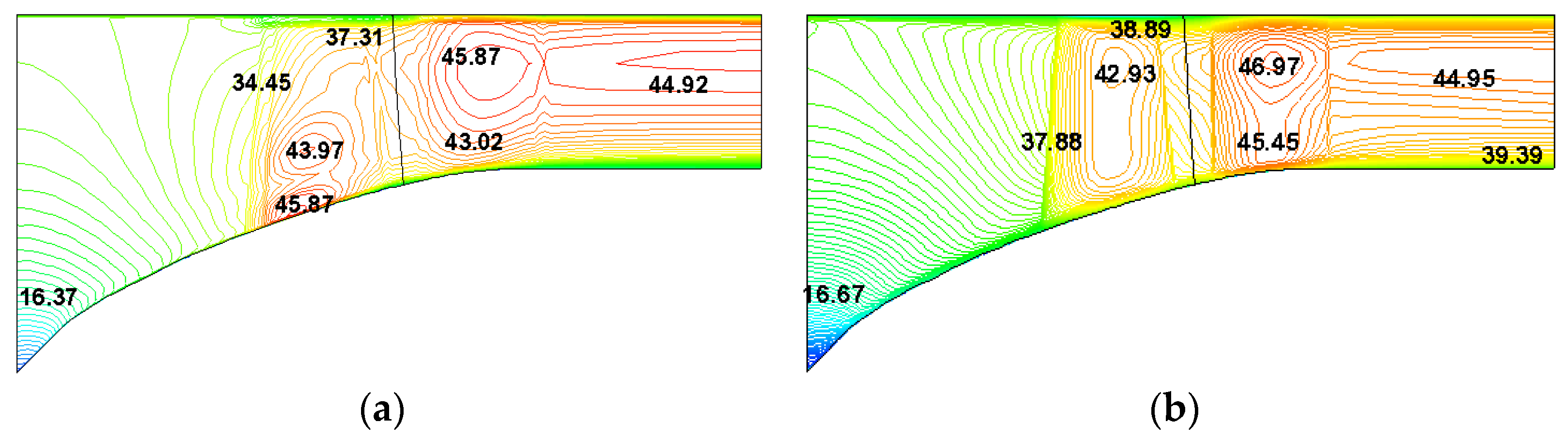

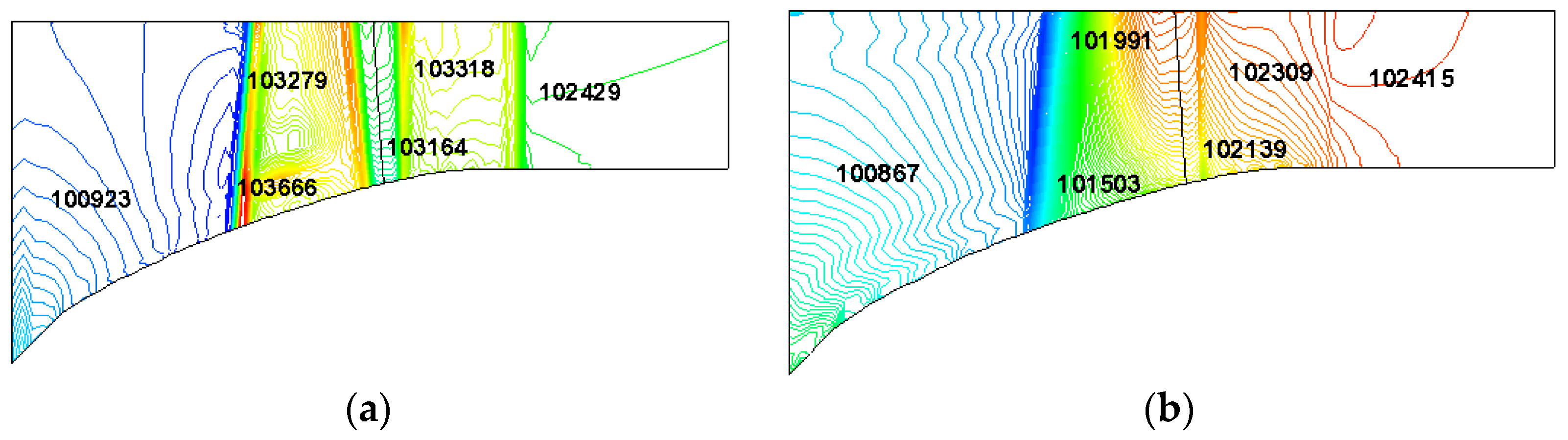

3. Modeling of the Inviscid Blade Force Based on a Linear Cascade

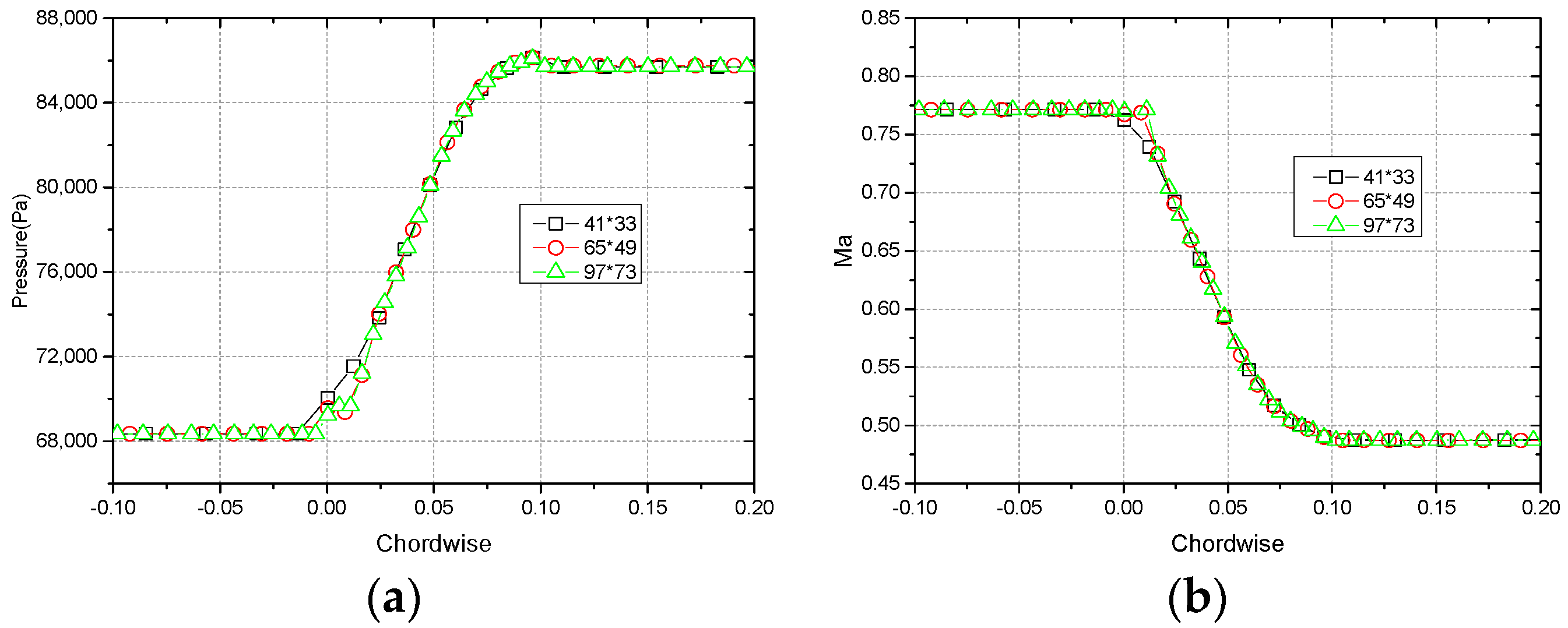

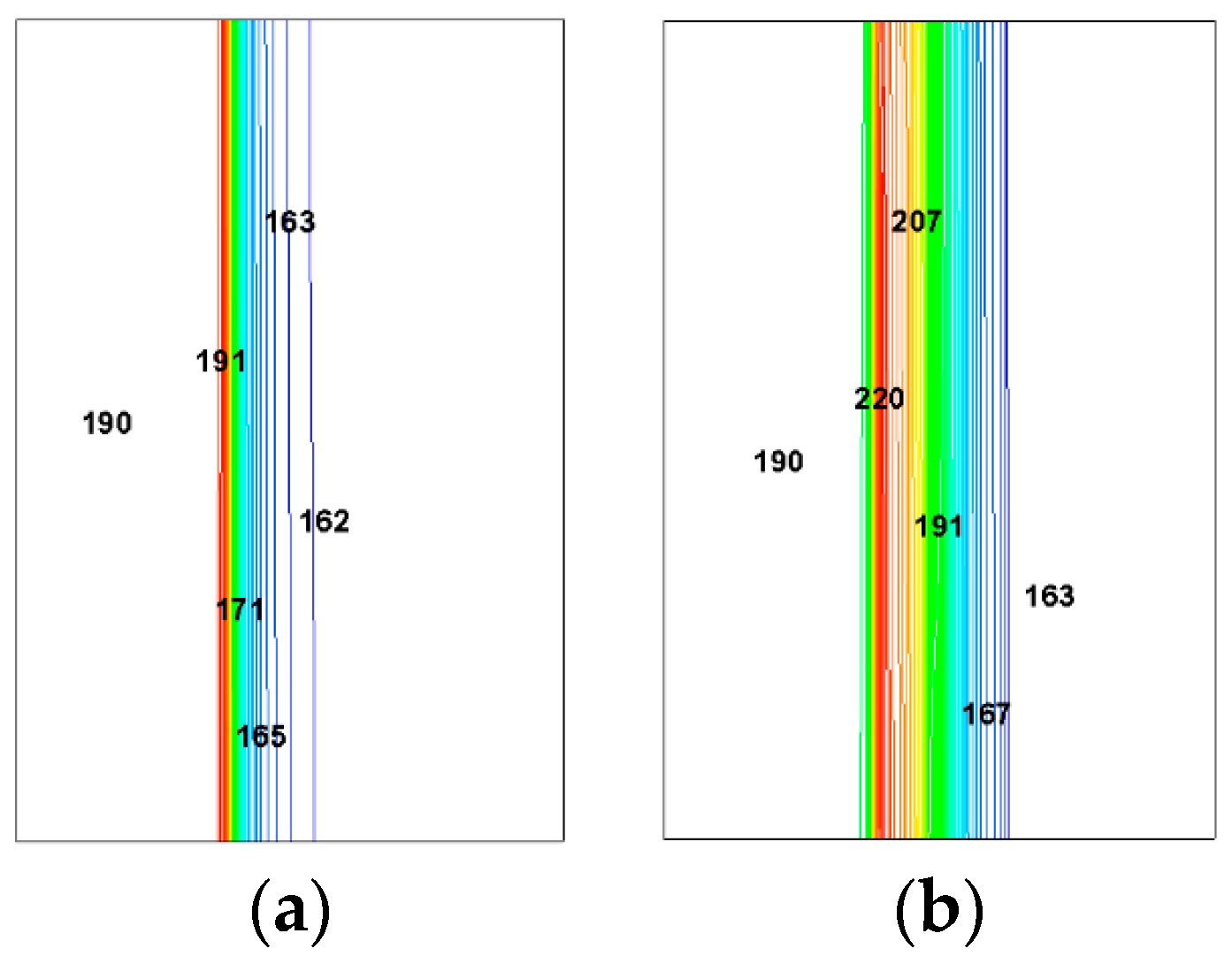

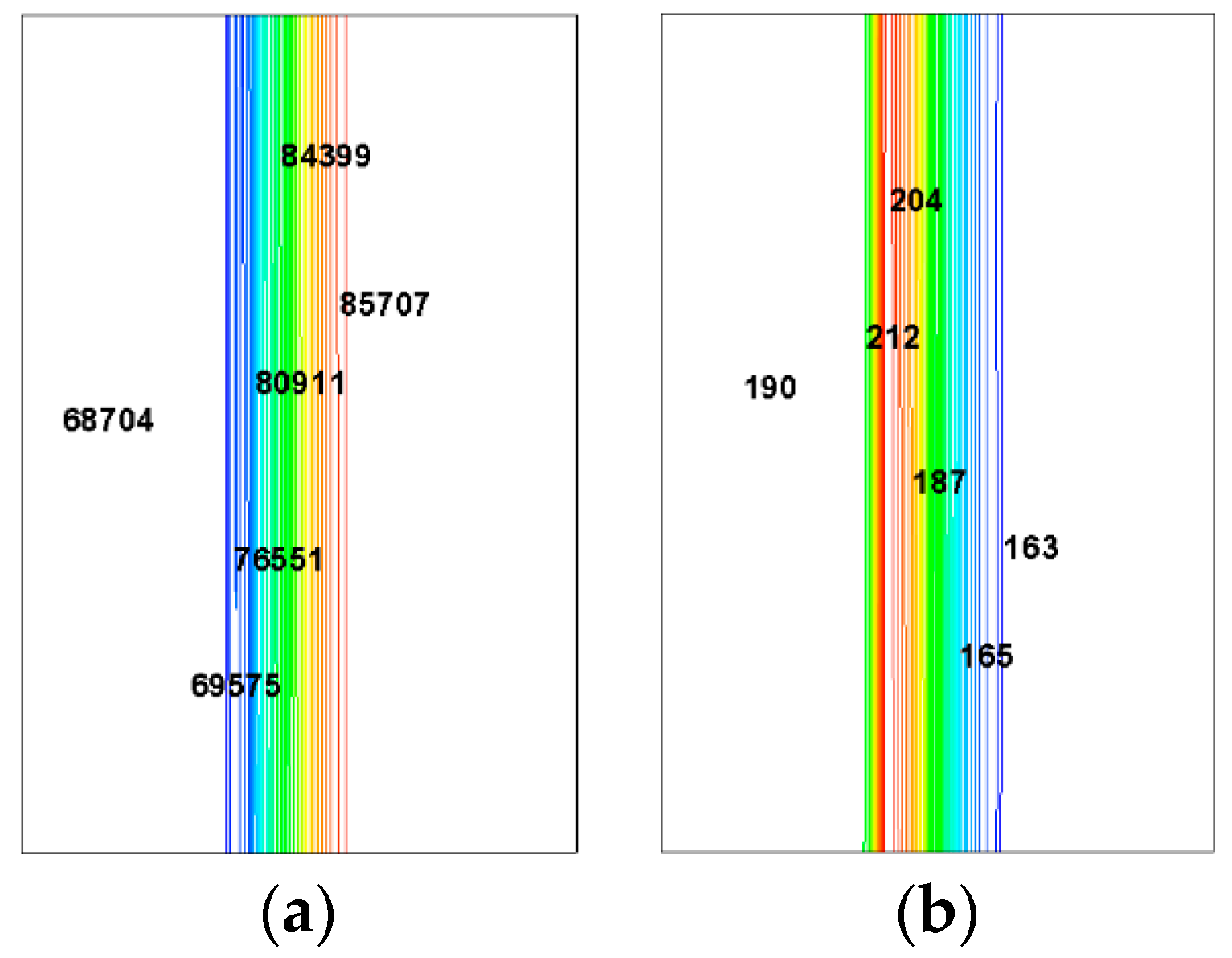

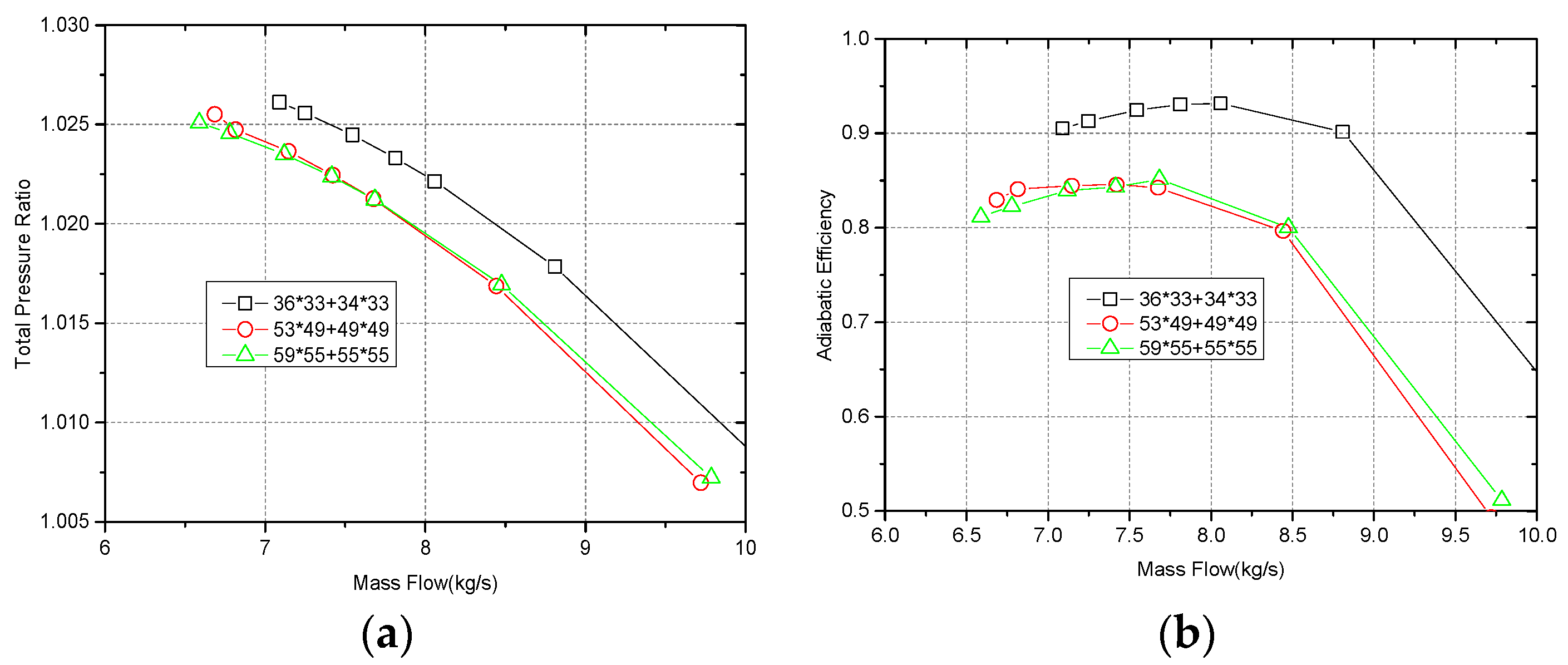

3.1. Grid Independence Verification

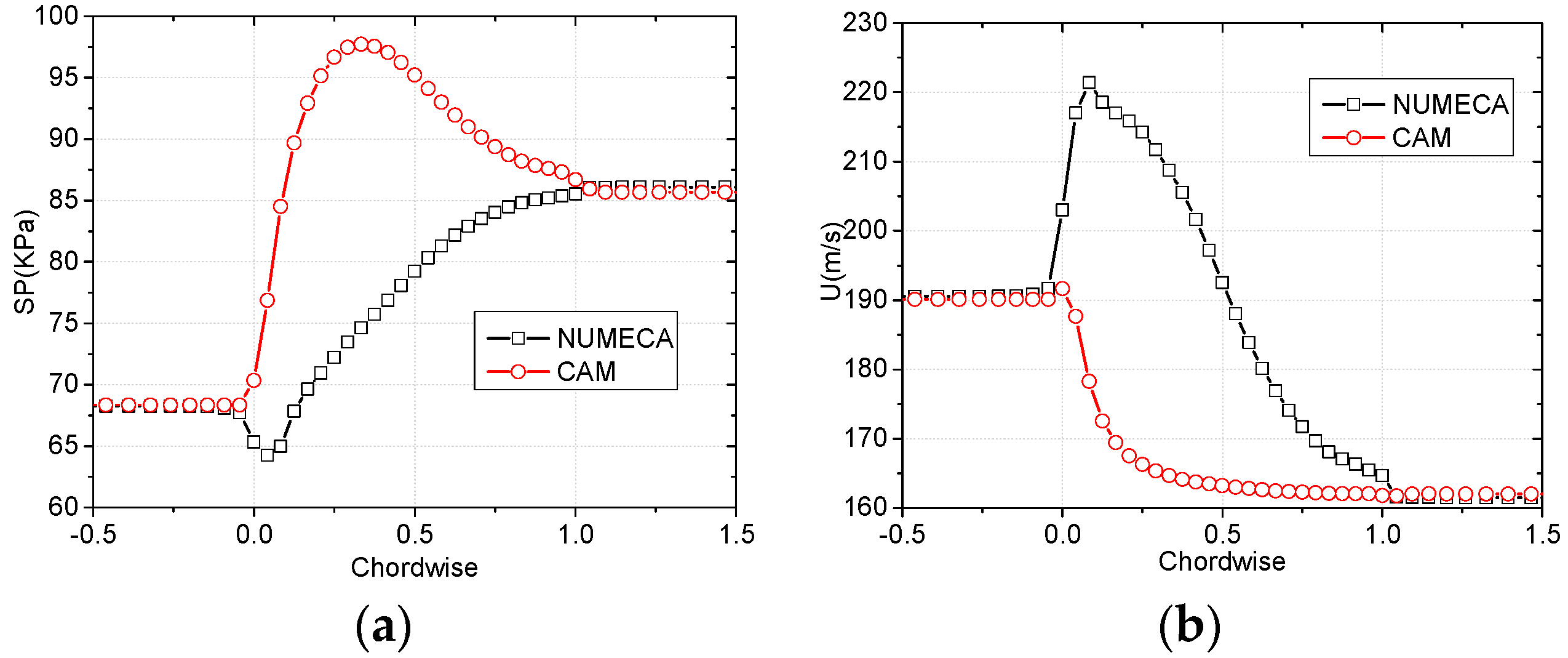

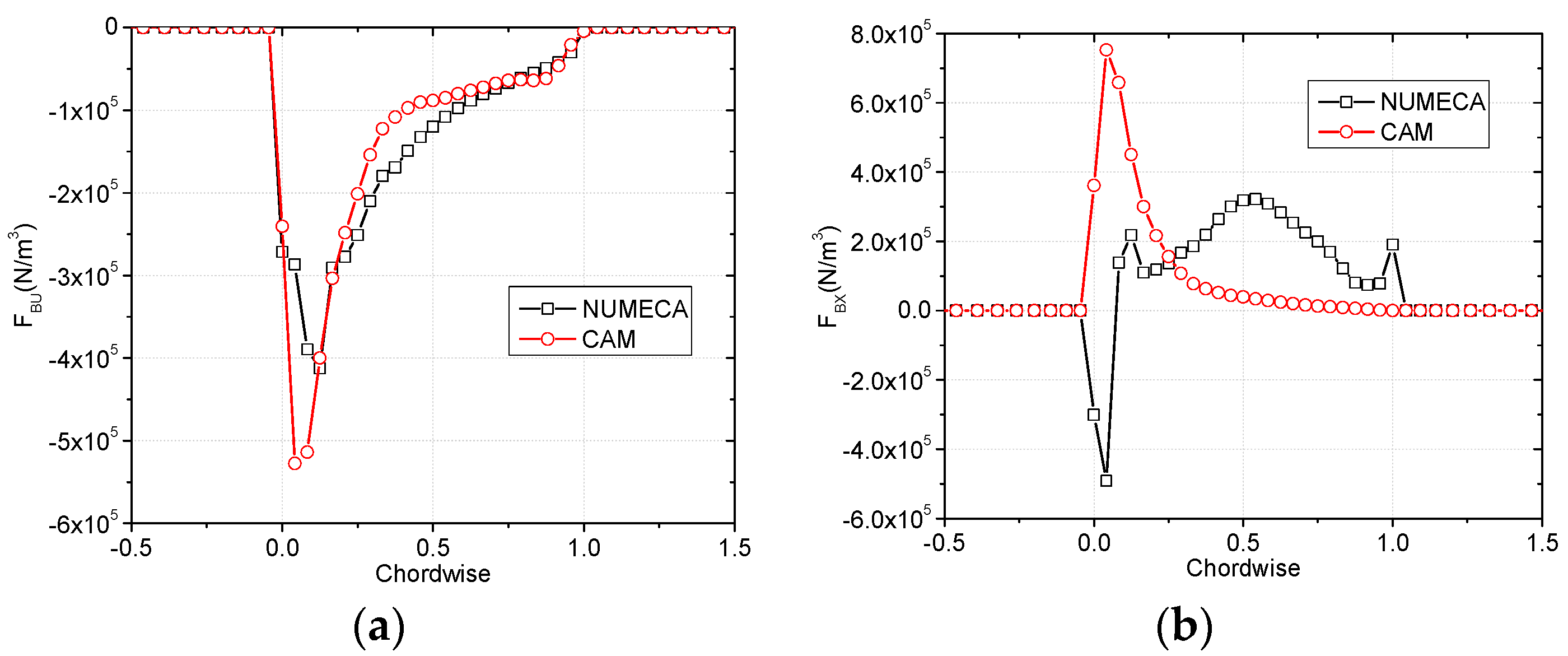

3.2. Model Analysis on the Subsonic Condition

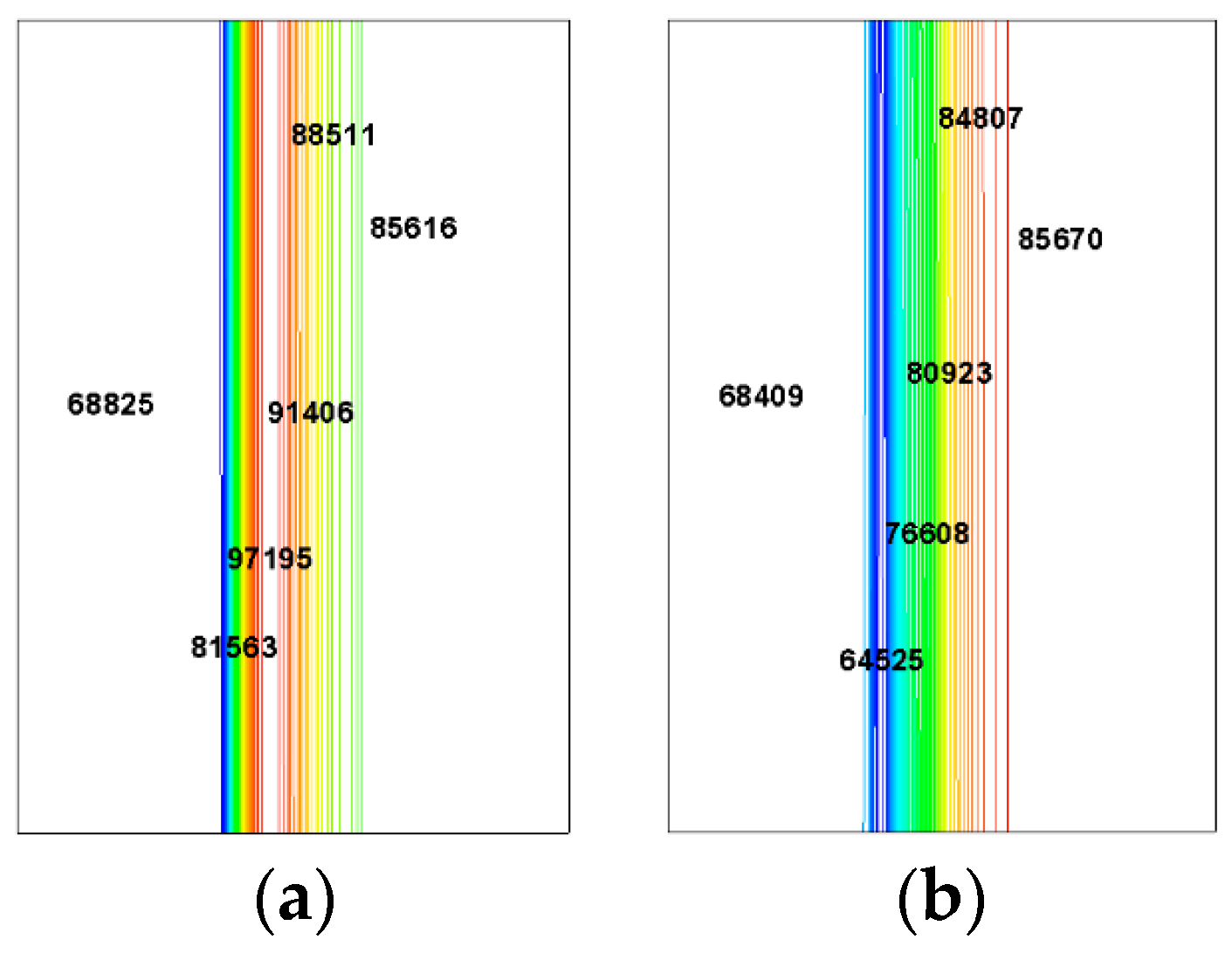

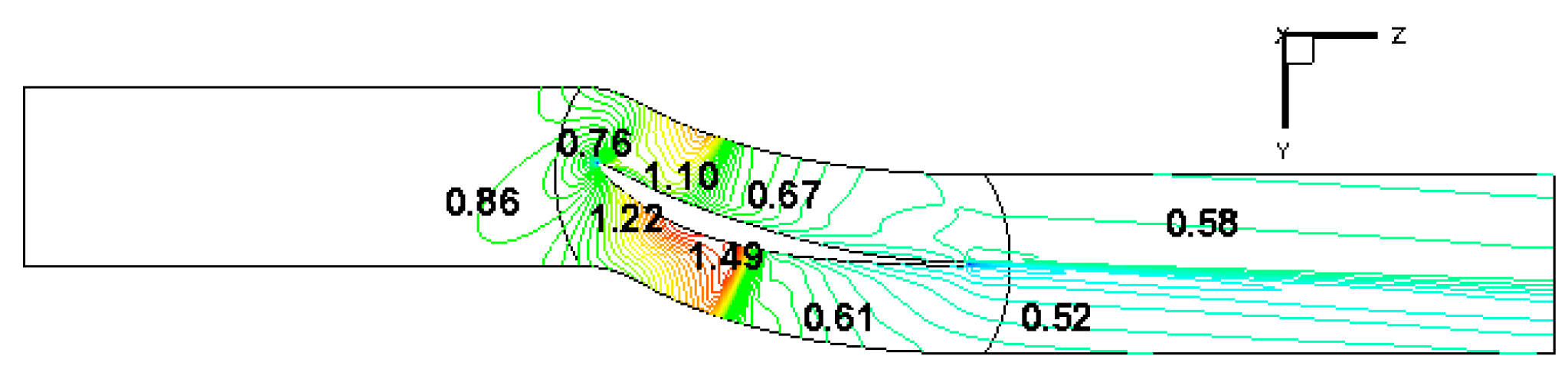

3.3. Model Analysis on the Transonic Condition

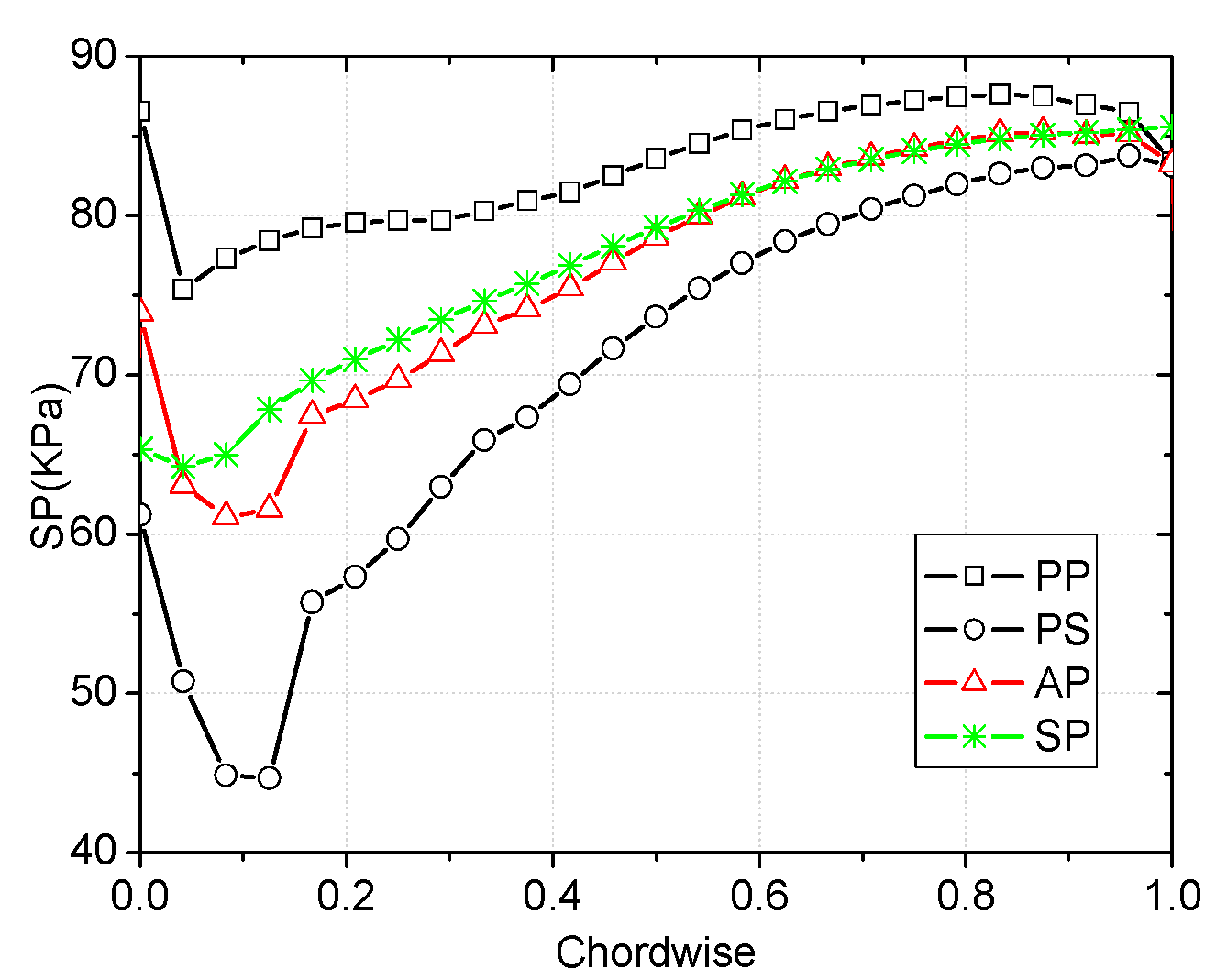

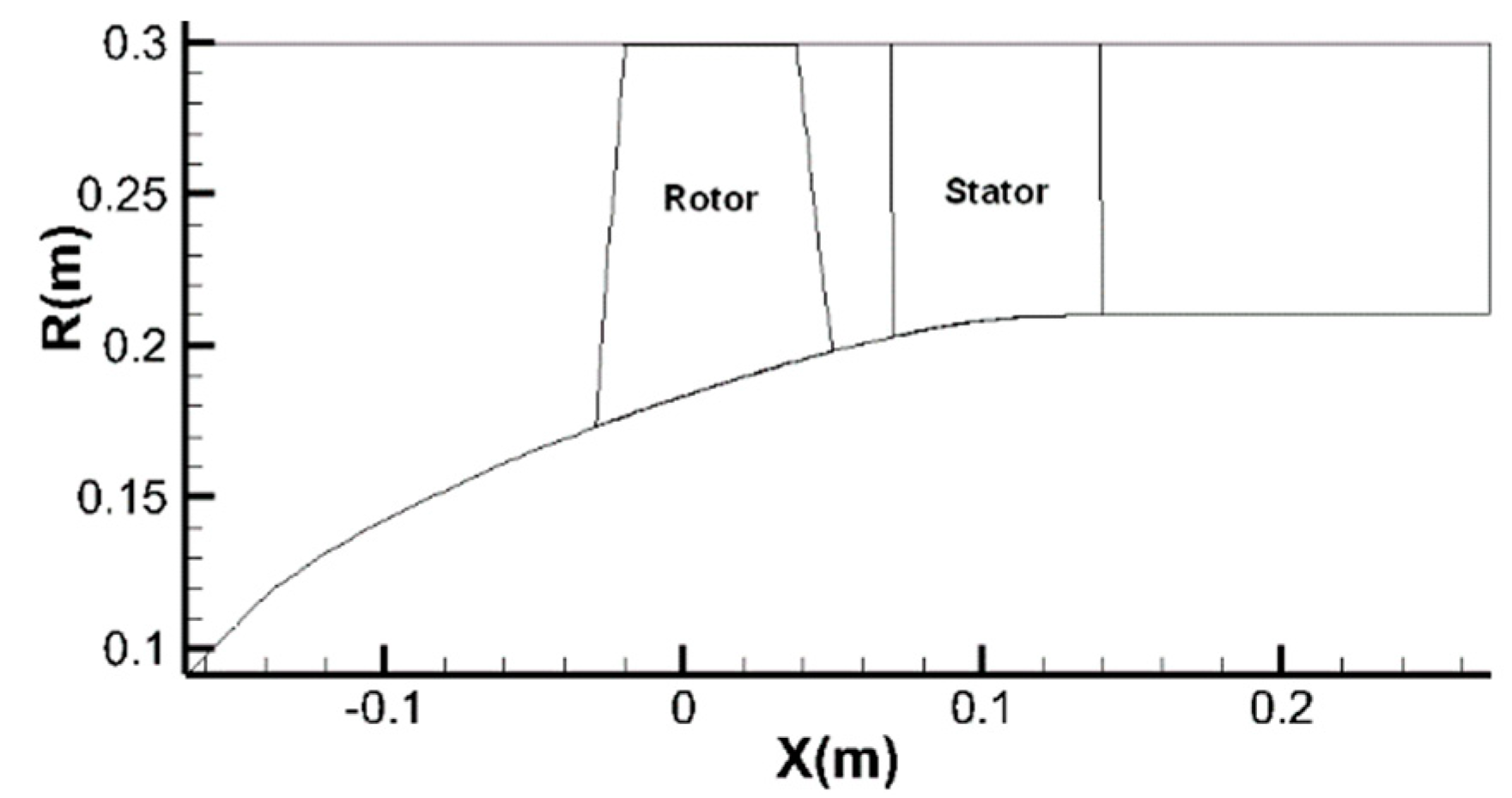

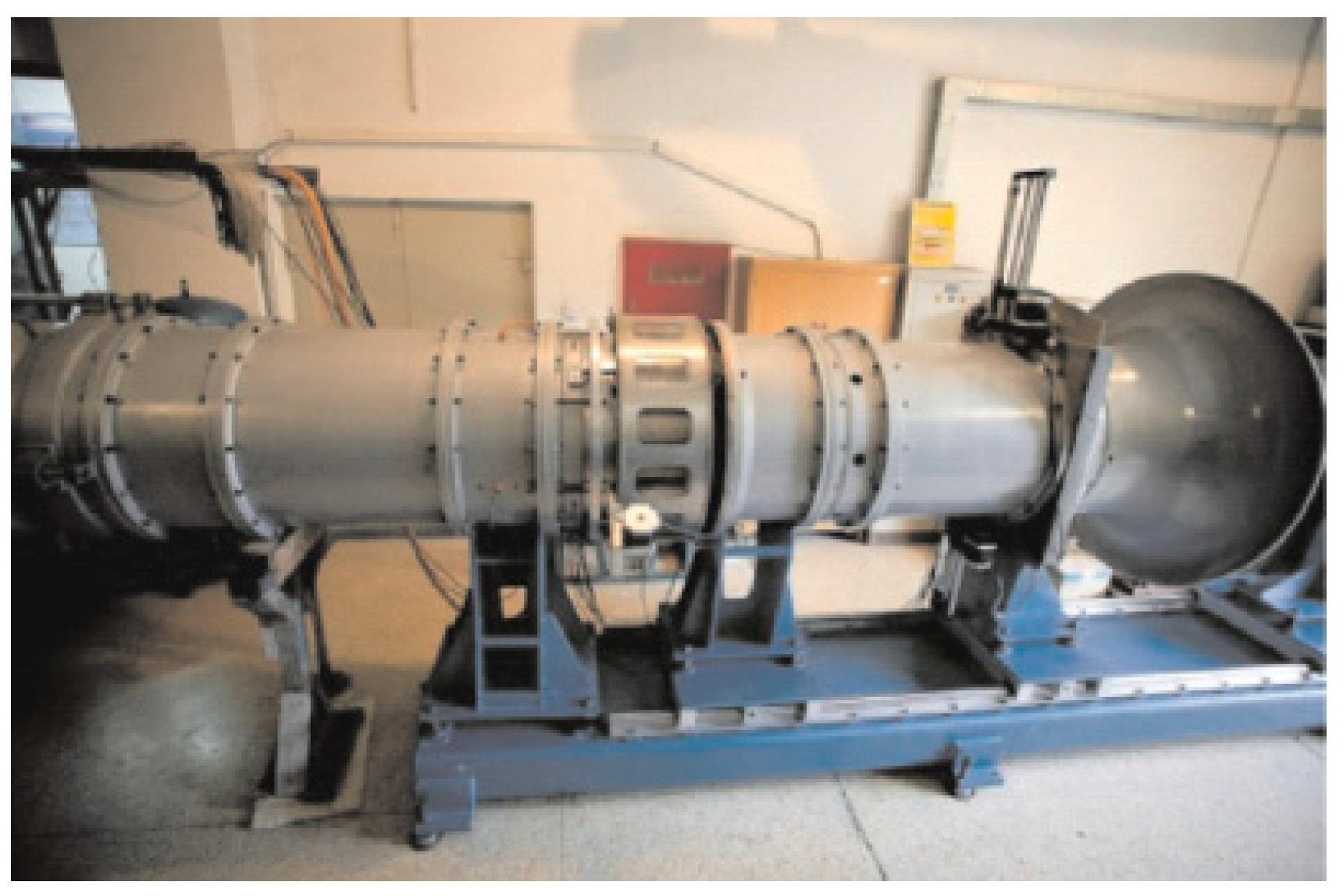

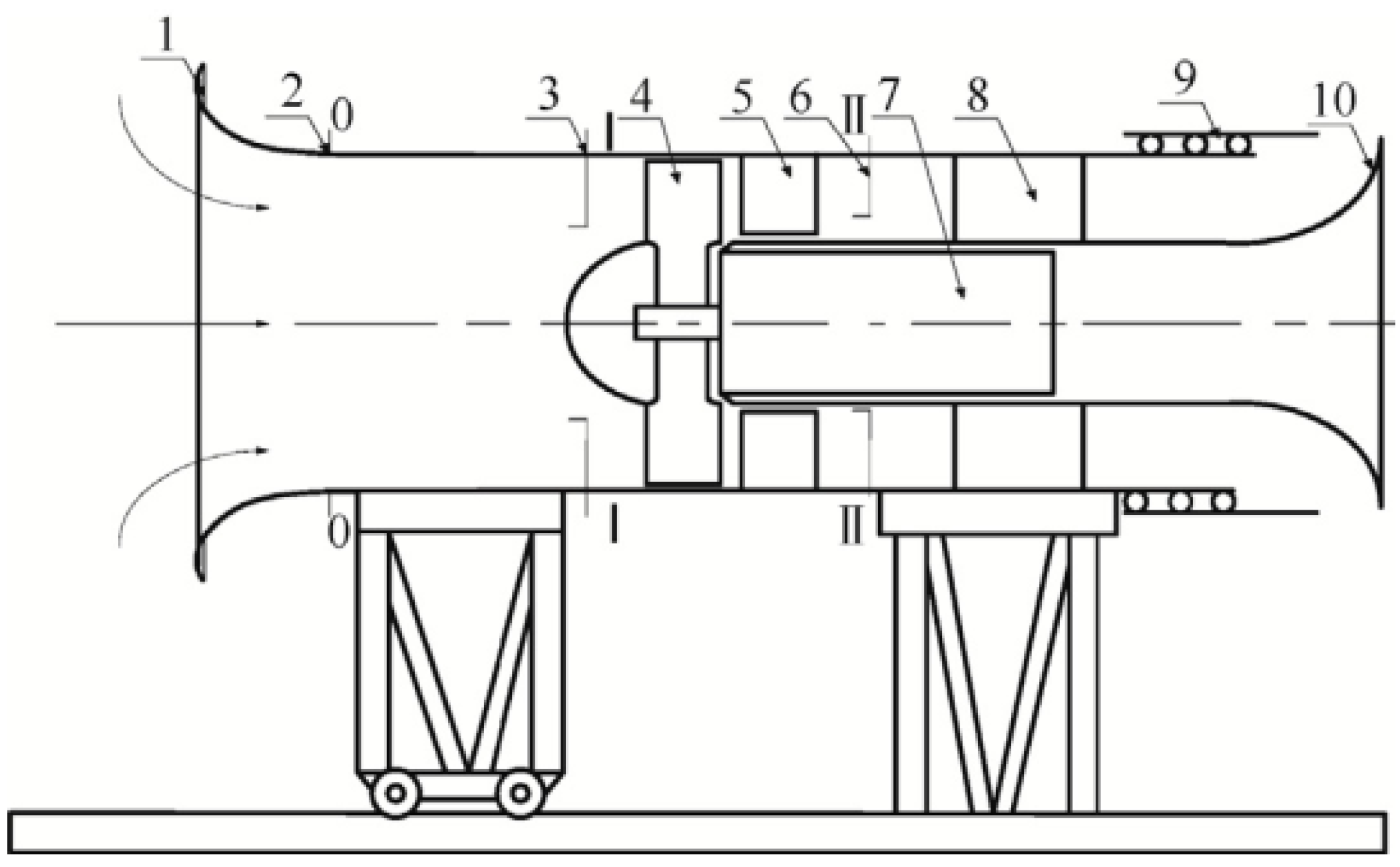

4. Application of the Improved Inviscid Blade Force Model in a Highly Loaded Low-Speed Fan

4.1. Experimental Facility

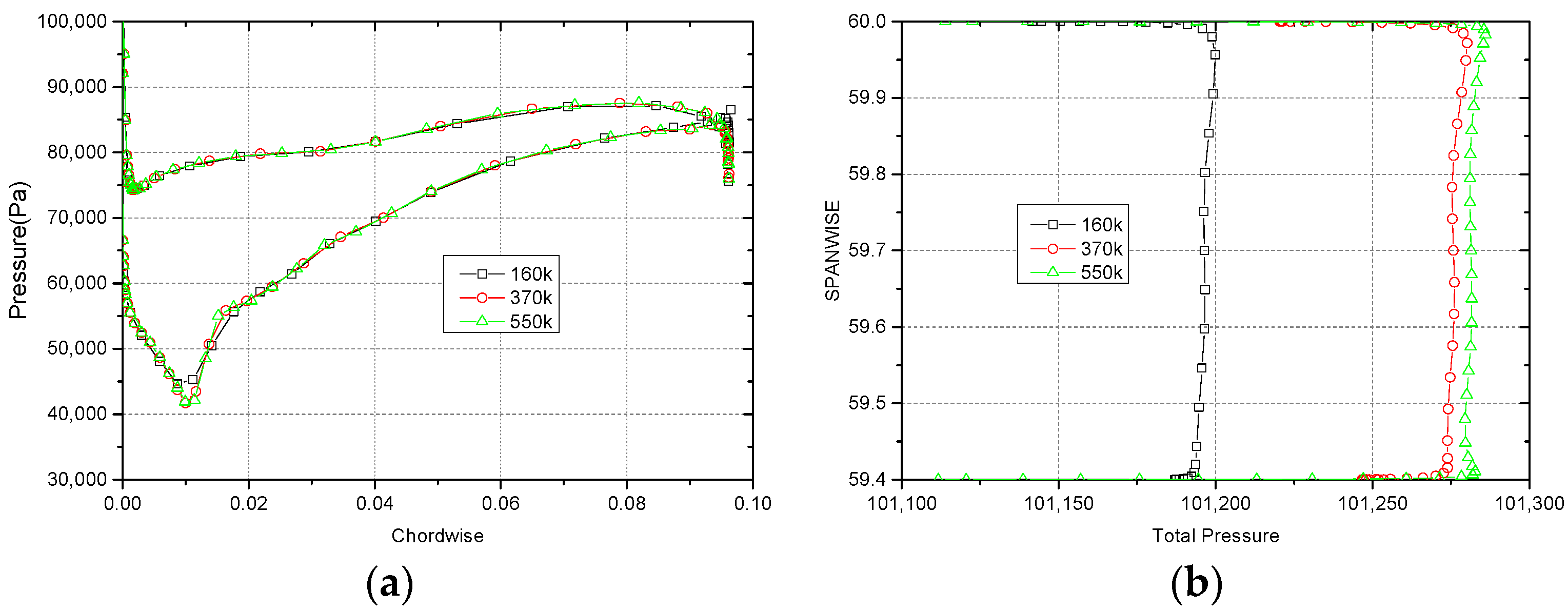

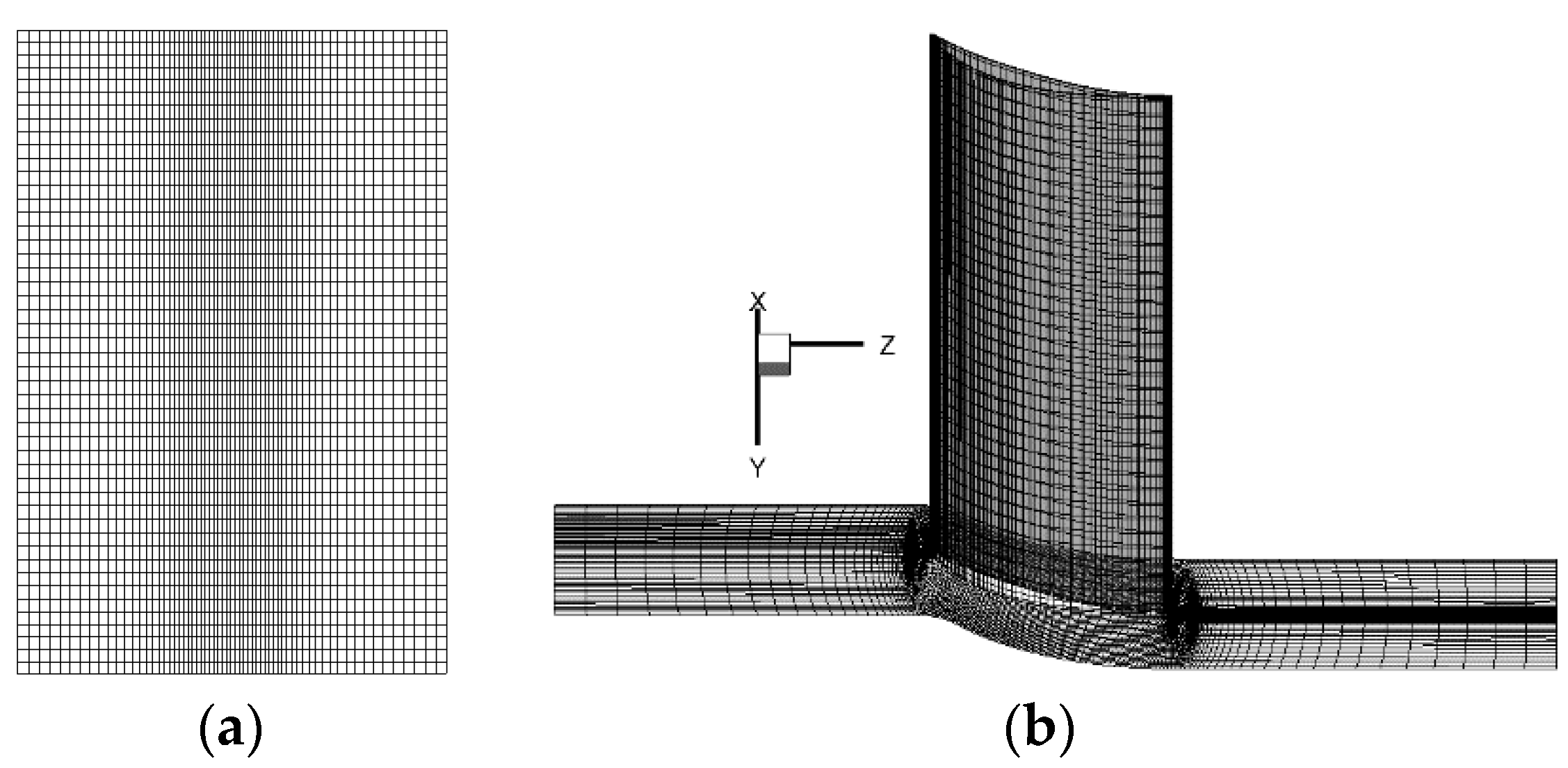

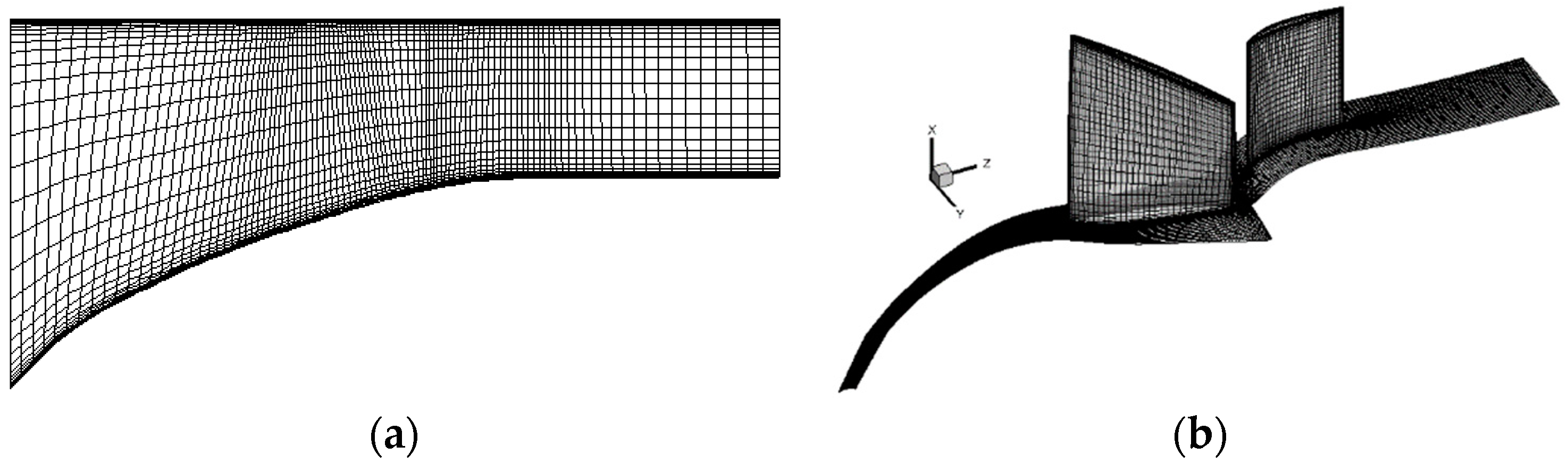

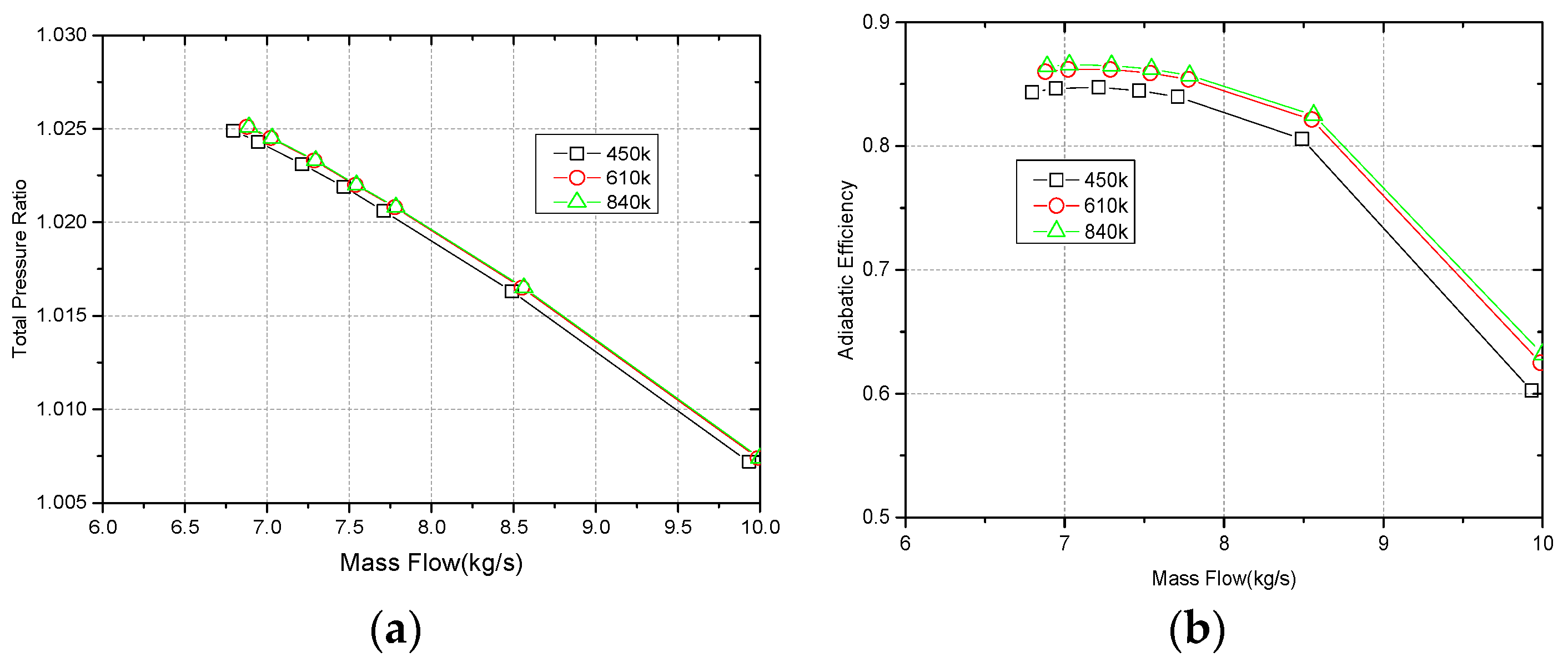

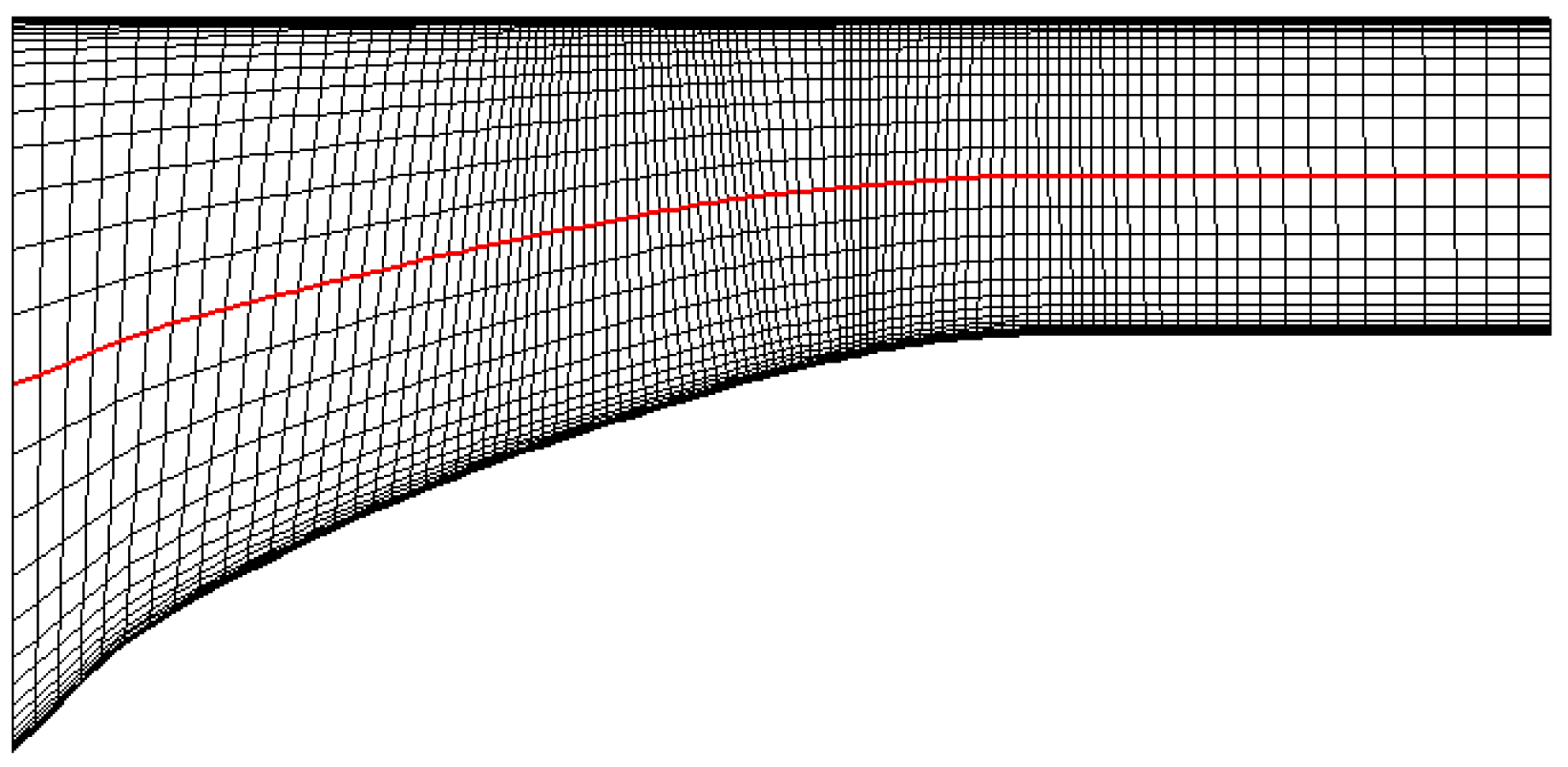

4.2. Grid Independence Verification

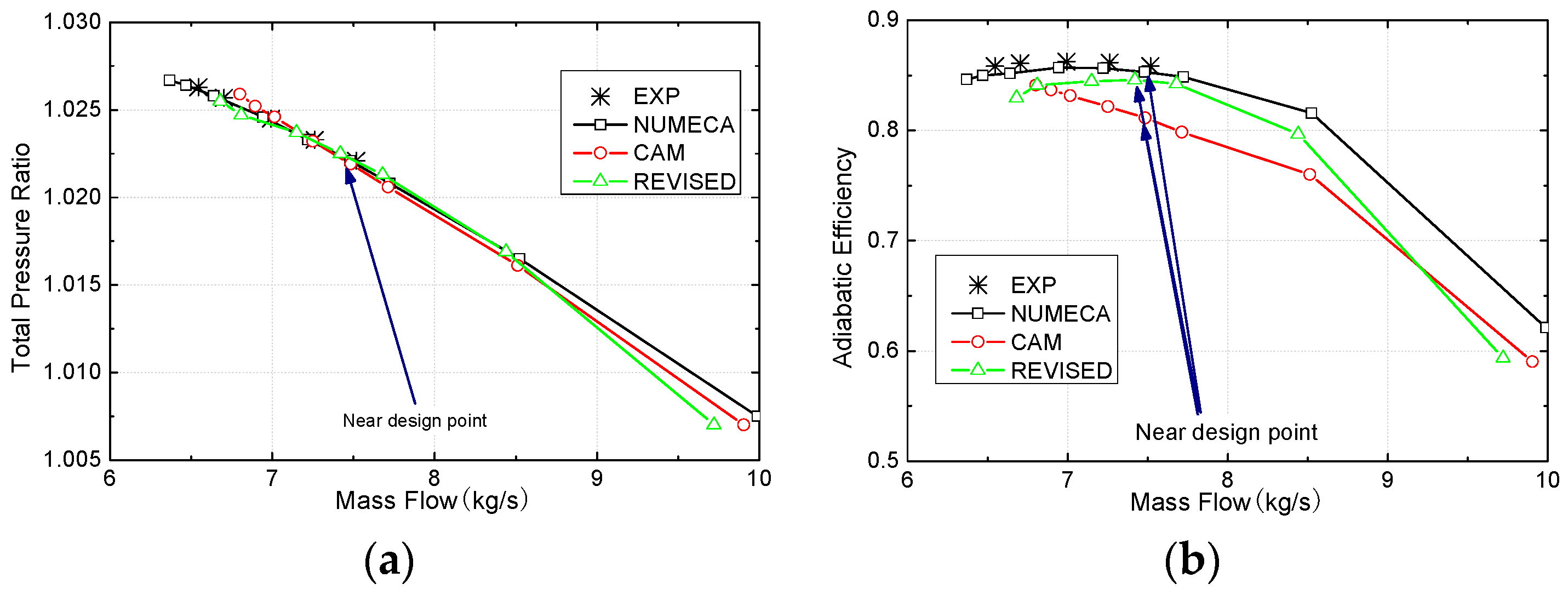

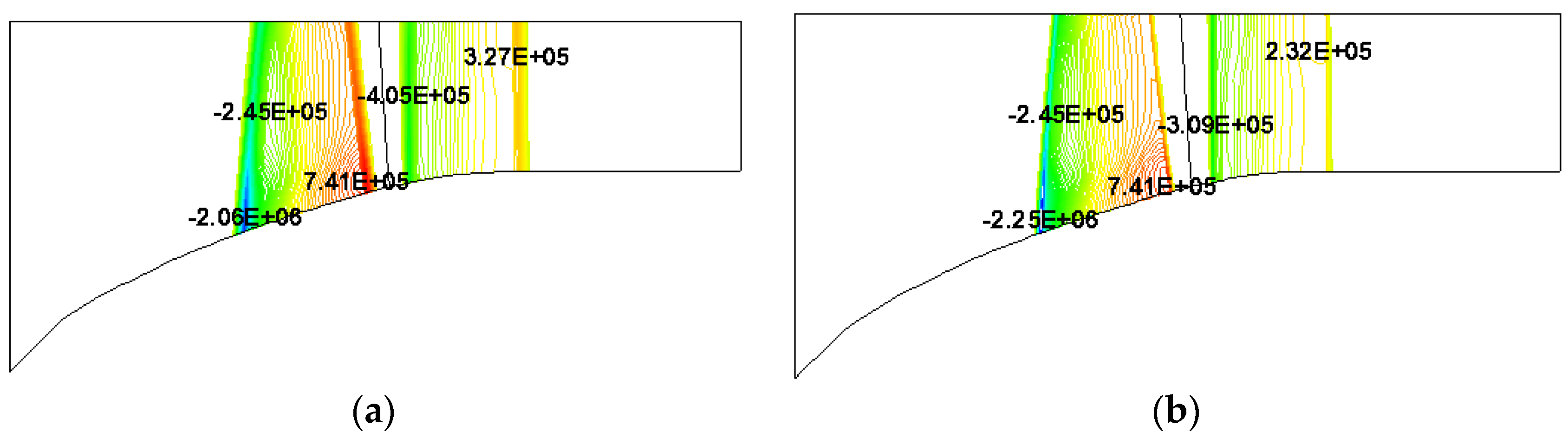

4.3. Numerical Analysis and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| blockage factor | radial coordinate (m) | ||

| specific heat at constant volume | vectors of source terms | ||

| total internal energy (J) | temperature | ||

| vectors of conservative variables | trailing edge | ||

| vectors of viscous fluxes | vectors of conservative variables | ||

| inviscid blade force | relative velocity (m/s) | ||

| viscous blade force | axial coordinate (m) | ||

| total enthalpy (J) | density (kg/m3) | ||

| leading edge | rotating speed (rad/s) | ||

| number of blades | viscous stress tensor | ||

| pressure (Pa) | circumferential coordinate (rad) angular coordinate on the blade | ||

| heat flux | |||

| some flow parameter | |||

| Subscripts | Superscripts | ||

| axial, radial and circumferential | ′ | non-axisymmetric terms | |

| components | ″ | non-axisymmetric terms | |

| suction surface | (density-weighted) | ||

| pressure surface | – | circumferential average parameter | |

| = | circumferential average parameter (density-weighted) | ||

References

- Feng, W. Whole Aero-Engine Meshing and CFD Simulation. Ph.D. Thesis, Imperial College, London, UK, 2013. [Google Scholar]

- Sajedin, A.; Shojaeefard, M.H.; Khalkhali, A. Radial Gradient Pressure Effects on Flow Behavior in a Dual Volute Turbocharger Turbine. Appl. Sci. 2018, 8, 1961. [Google Scholar] [CrossRef]

- Li, P.Y.; Gu, C.W.; Song, Y. A New Optimization Method for Centrifugal Compressors Based on 1D Calculations and Analyses. Energies 2015, 8, 4317–4334. [Google Scholar] [CrossRef]

- Medic, G.; You, D.; Kalitzin, G.; Marcus, H.; Frank, H.; Heinz, P.; van der Weide, E.; Alonso, J. Intergrated Computations of an Entire Jet Engine; ASME Paper No. GT2007-27094; American Society of Mechanical Engineers (ASME): Montreal, QC, Canada, 2007. [Google Scholar]

- Schlüter, J.U.; Pitsch, H.; Moin, P.; Shankaran, S.; Kim, S.; Alonso, J. Towards Multi-Component Analysis of Gas Turbines by CFD: Integration of RANS and LES Flow Solvers; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2003. [Google Scholar]

- Schlüter, J.U.; Pitsch, H.; Moin, P. Large-eddy Simulation Inflow Conditions for Coupling with Reynolds-averaged Flow Solvers. AIAA J. 2004, 42, 478–484. [Google Scholar] [CrossRef][Green Version]

- Medic, G.; Kalitzin, G.; You, D.; Herrmann, M.; Ham, F.; van der Weide, E.; Pitsch, H.; Alons, J. Integrated RANS/LES Computations of Turbulent Flow through a Turbofan Jet Engine. Annu. Res. Briefs 2006, 275–285. Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=d40f6dade92099fbba98506dd173abdf&site=xueshu_se (accessed on 5 November 2020).

- Schlüter, J.U.; Wu, X.; Kim, S.; Shankaran, S.; Alonso, J.J.; Pitsch, H. A Framework for Coupling Reynolds-Averaged with Large-Eddy Simulations for Gas Turbine Applications. ASME J. Fluids Eng. 2005, 127, 806–815. [Google Scholar] [CrossRef]

- Horlock, J.H.; Denton, J.D. A review of Some Early Design Practice Using Computational Fluid Dynamics and a Current Perspective. Trans. ASME J. Turbomach. 2005, 127, 5–13. [Google Scholar] [CrossRef]

- Smith, L.H., Jr. The radial-equilibrium equation of turbomachinery. J. Eng. Power Trans. ASME 1966, 88, 1–12. [Google Scholar] [CrossRef]

- Baralon, S.; Erikson, L.E.; Hall, U. Viscous Throughflow Modelling of Transonic Compressors Using a Time-Marching Finite-Volume Solver. In Proceedings of the 13th International Symposium on Airbreathing Engines (ISABE), Chattanooga, TN, USA, 7–12 September 1997. [Google Scholar]

- Simon, J.F.; Leonard, O. A Throughflow Analysis Tool Based on the Navier-Stokes Equations. In Proceedings of the 6th European Turbomachinery Conference, Lille, France, 7–11 March 2005. [Google Scholar]

- Sturmayr, A.; Hirsch, C. Shock Representation by Euler Throughflow Models and Comparison with Pitch-Averaged Navier-Stokes Solutions; ISABE 99-7281; PN Publications: Florence, Italy, 1999. [Google Scholar]

- Dawes, W.N. Toward Improved Throughflow Capability: The Use of Three Dimensional Viscous Flow Solvers in a Multistage Environment. Trans. ASME J. Turbomach. 1992, 114, 8–17. [Google Scholar] [CrossRef]

- Jin, H.L.; Jin, D.H.; Li, X.J.; Gui, X. A Time-Marching Throughflow Model and its Application in Transonic Axial Compressor. J. Therm. Sci. 2010, 19, 519–525. [Google Scholar] [CrossRef]

- Edwards, J.R. A Low-Diffusion Flux-Splitting Scheme for Navier-Stokes Calculations. Comput. Fluids 1997, 26, 635–659. [Google Scholar] [CrossRef]

- Sturmayr, A.; Hirsch, C. Throughflow Model for Design and Analysis Integrated in a Three-Dimensional Navier–Stokes Solver. J. Power Energy 1999, 213, 263–273. [Google Scholar] [CrossRef]

- Simon, J.F. Contribution to Throughflow Modelling for Axial Flow Turbomachines. Ph.D. Thesis, University of Liege, Liege, Belgium, 2007. [Google Scholar]

- Steinert, W.; Eisenberg, B.H. Design and Testing of a Controlled Diffusion Airfoil Cascade for Industrial Axial Flow Compressor Application. J. Turbomach. 1991, 113, 583–590. [Google Scholar] [CrossRef]

- Sturmayr, A. Evolution of a 3D Structured Navier-Stokes Solver towards Advanced Turbomachinery Applications. Ph.D. Thesis, Vrije Universiteit Brussel, Brussels, Belgium, 2004. [Google Scholar]

- Baralon, S.; Eriksson, L.-E.; Hall, U. Validation of a Throughflow TimeMarching Finite-Volume Solver for Transonic compressors. In Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, 98-GT-74, Stockholm, Sweden, 2–5 June 1998. [Google Scholar]

- Yao, Z.; Hirsch, C. Throughflow Model Using 3D Euler or Navier-Stokes Solver. In Proceedings of the 1st European Conference on Turbomachinery Fluid Dynamics and Thermodynamics, Eerlangen, Germany, 1–3 March 1995. [Google Scholar]

- Wan, K.; Jin, H.L.; Jin, D.H.; Gui, X.M. Influence of Non-Axisymmetric Terms on Circumferentially Averaged Method in Fan/Compressor. J. Therm. Sci. 2013, 22, 13–22. [Google Scholar] [CrossRef]

- Tang, M.Z.; Jin, D.H.; Gui, X.M. Modeling and numerical investigation of the inlet circumferential fluctuations of swept and bowed blades. J. Therm. Sci. 2017, 26, 1–10. [Google Scholar] [CrossRef]

- Xu, D.; Xiaohua, L.; Sun, D.; Sun, X. Experimental investigation on SPS casing treatment with bias flow. Chin. J. Aeronaut. 2014, 27, 1352–1362. [Google Scholar]

| Parameters | Values |

|---|---|

| Chord | 100 mm |

| Blade geometric inlet angle | |

| Stagger angle | |

| Aspect ratio of the cascade | 6.0 |

| Solidity | 2.15 |

| Geometrical Parameter | Value | |

|---|---|---|

| Rotor | Stator | |

| Number of blades | 20 | 27 |

| Tip diameter (mm) | 600 | 600 |

| Hub diameter (mm) | 346 | 401 |

| Stagger angle at the hub (°) | 45 | 0 |

| Aspect ratio | 1.18 | 1.40 |

| Mass Flow (kg/s) | Pressure Ratio | Adiabatic Efficiency | Power (kW) | Power Error (%) | |

|---|---|---|---|---|---|

| Experiment | 7.516 | 1.022 | 0.8583 | 15.81 | |

| NUMECA | 7.480 | 1.022 | 0.8531 | 15.83 | 0.128 |

| CAM | 7.485 | 1.022 | 0.8113 | 16.66 | 5.357 |

| Revised CAM | 7.421 | 1.022 | 0.8457 | 15.84 | 0.207 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wan, K.; Jin, D.; Gui, X. Development of a Throughflow-Based Simulation Tool for Preliminary Compressor Design Considering Blade Geometry in Gas Turbine Engine. Appl. Sci. 2021, 11, 422. https://doi.org/10.3390/app11010422

Liu X, Wan K, Jin D, Gui X. Development of a Throughflow-Based Simulation Tool for Preliminary Compressor Design Considering Blade Geometry in Gas Turbine Engine. Applied Sciences. 2021; 11(1):422. https://doi.org/10.3390/app11010422

Chicago/Turabian StyleLiu, Xiaoheng, Ke Wan, Donghai Jin, and Xingmin Gui. 2021. "Development of a Throughflow-Based Simulation Tool for Preliminary Compressor Design Considering Blade Geometry in Gas Turbine Engine" Applied Sciences 11, no. 1: 422. https://doi.org/10.3390/app11010422

APA StyleLiu, X., Wan, K., Jin, D., & Gui, X. (2021). Development of a Throughflow-Based Simulation Tool for Preliminary Compressor Design Considering Blade Geometry in Gas Turbine Engine. Applied Sciences, 11(1), 422. https://doi.org/10.3390/app11010422