Fatigue Cycles and Performance Evaluation of Accelerating Aging Heat Treated Aluminum Semi Solid Materials Designed for Automotive Dynamic Components

Abstract

1. Introduction

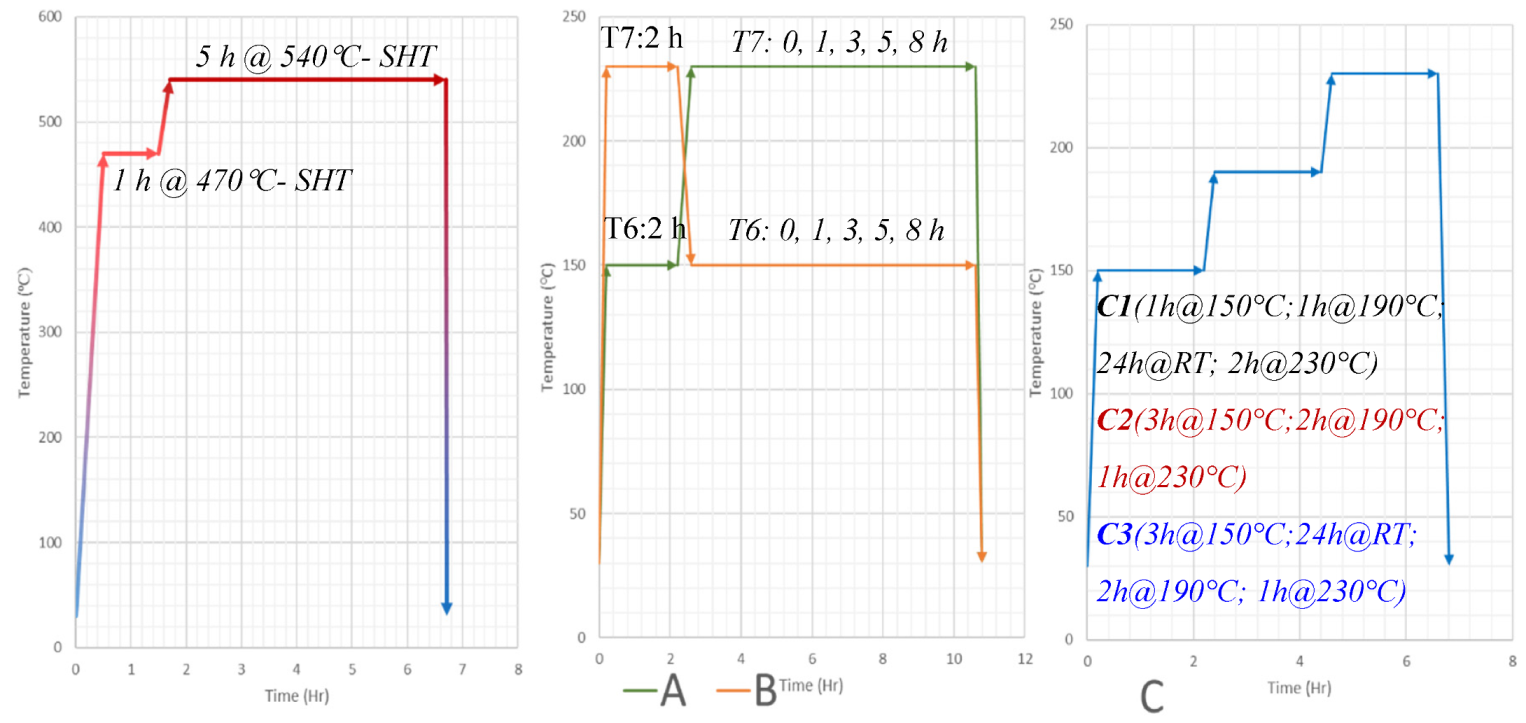

2. Materials Processing and Design Procedures

3. Results and Discussions

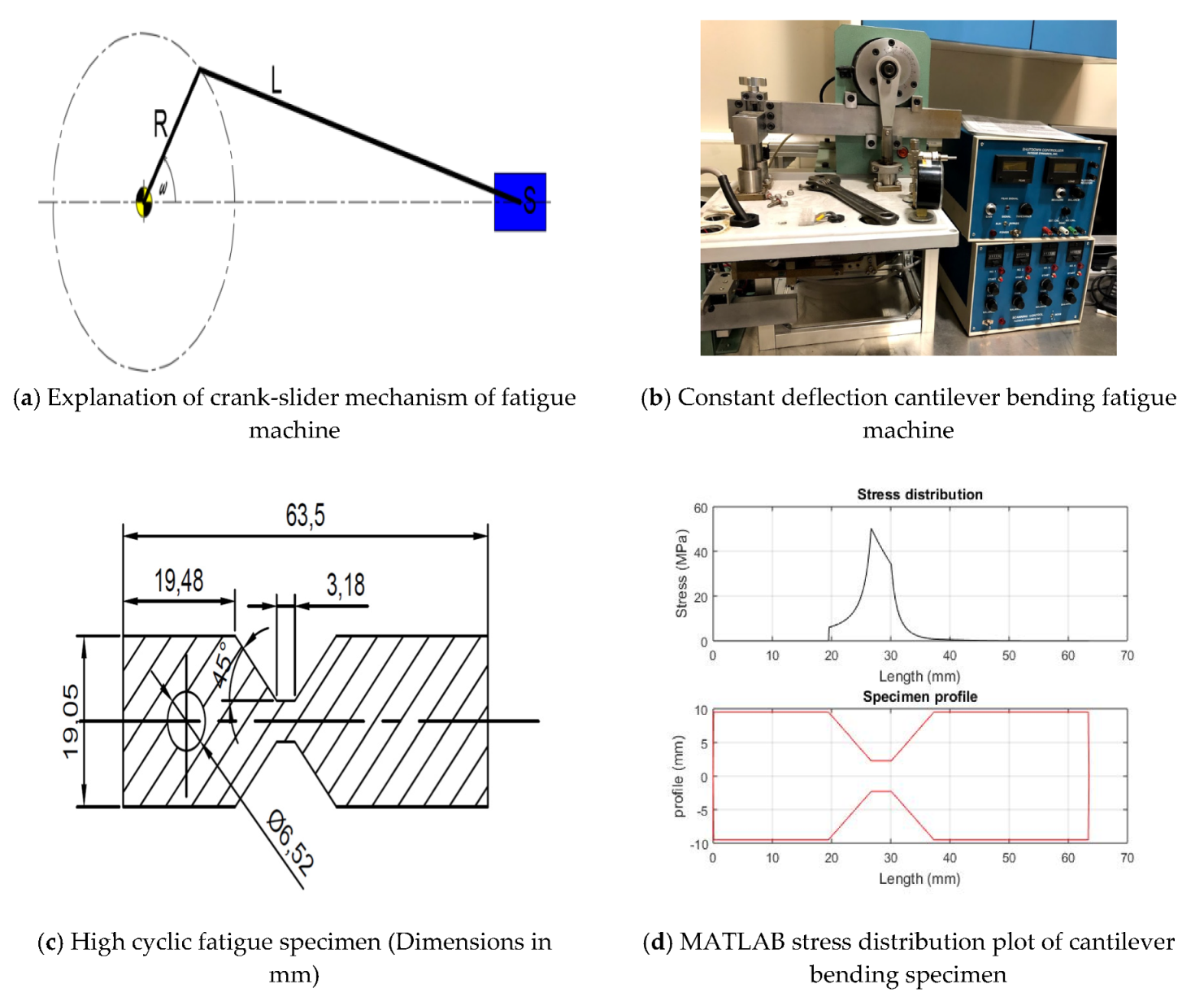

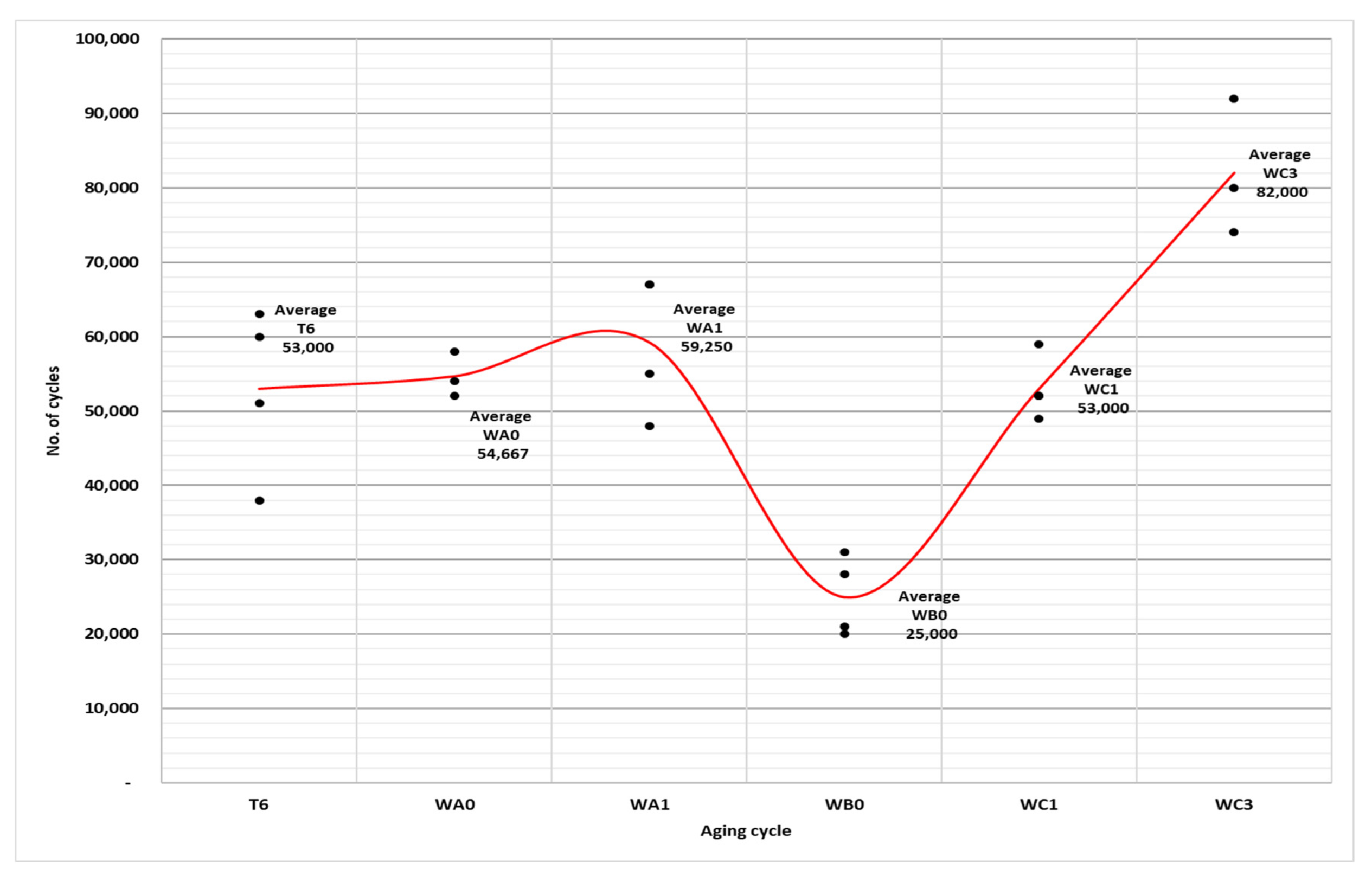

3.1. Fatigue Cycles and Performance

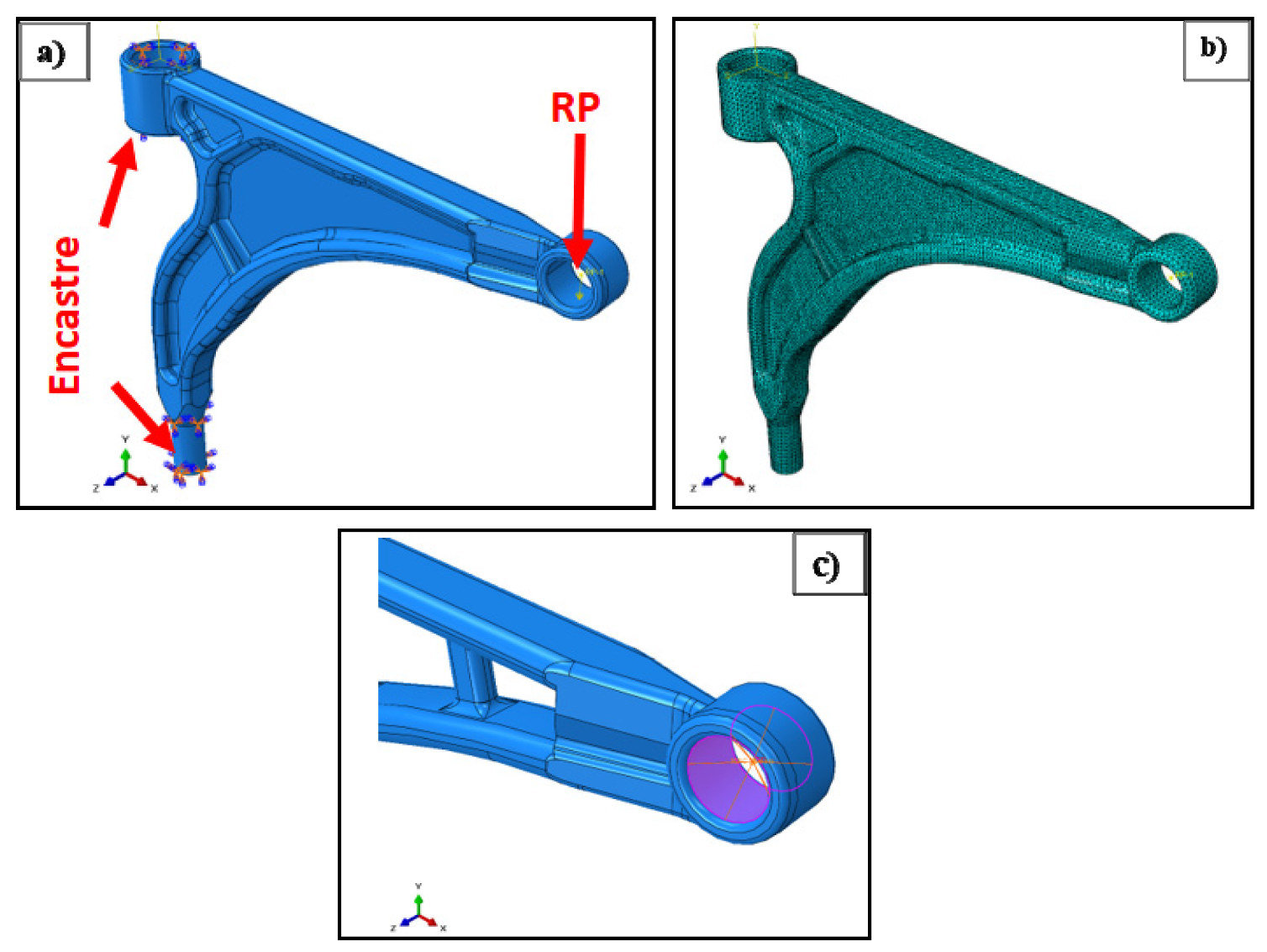

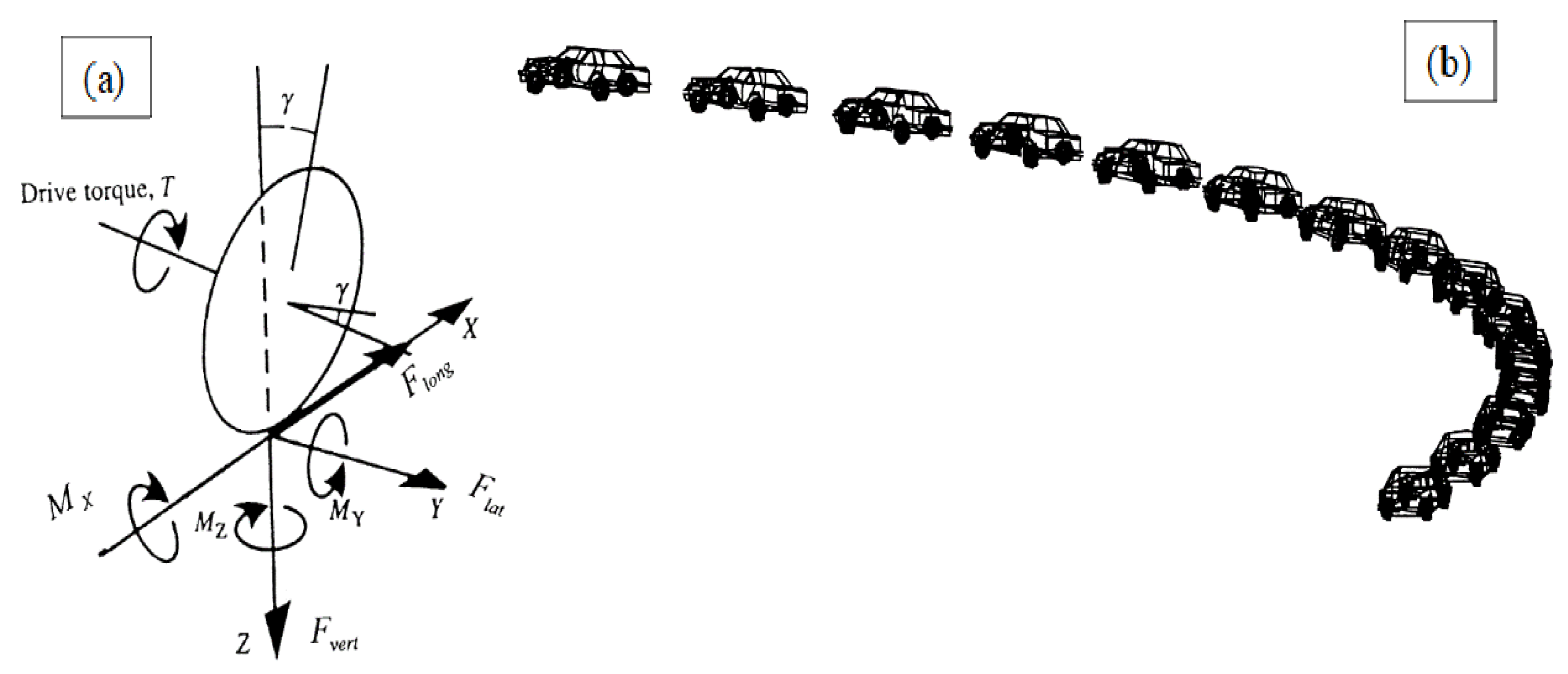

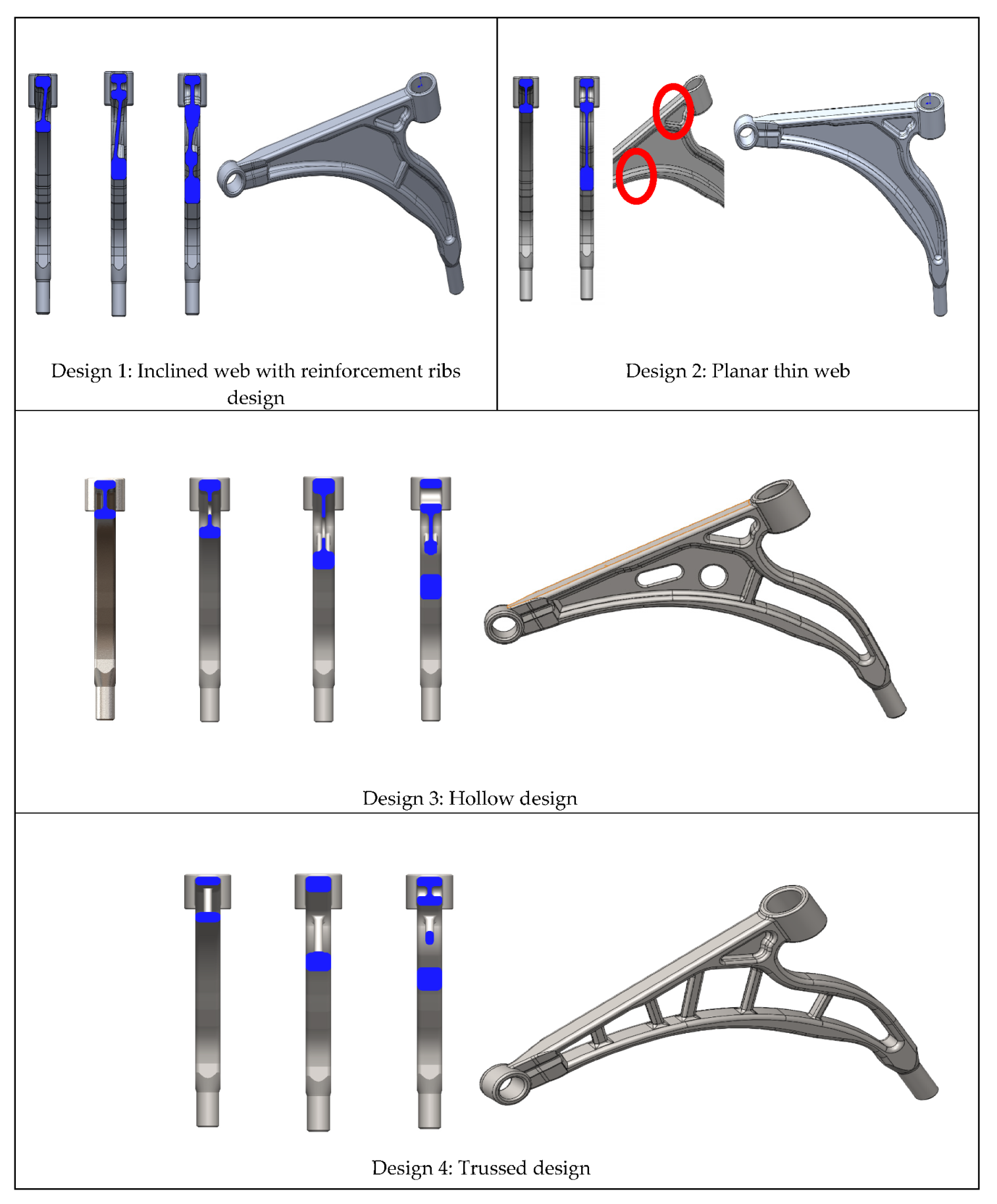

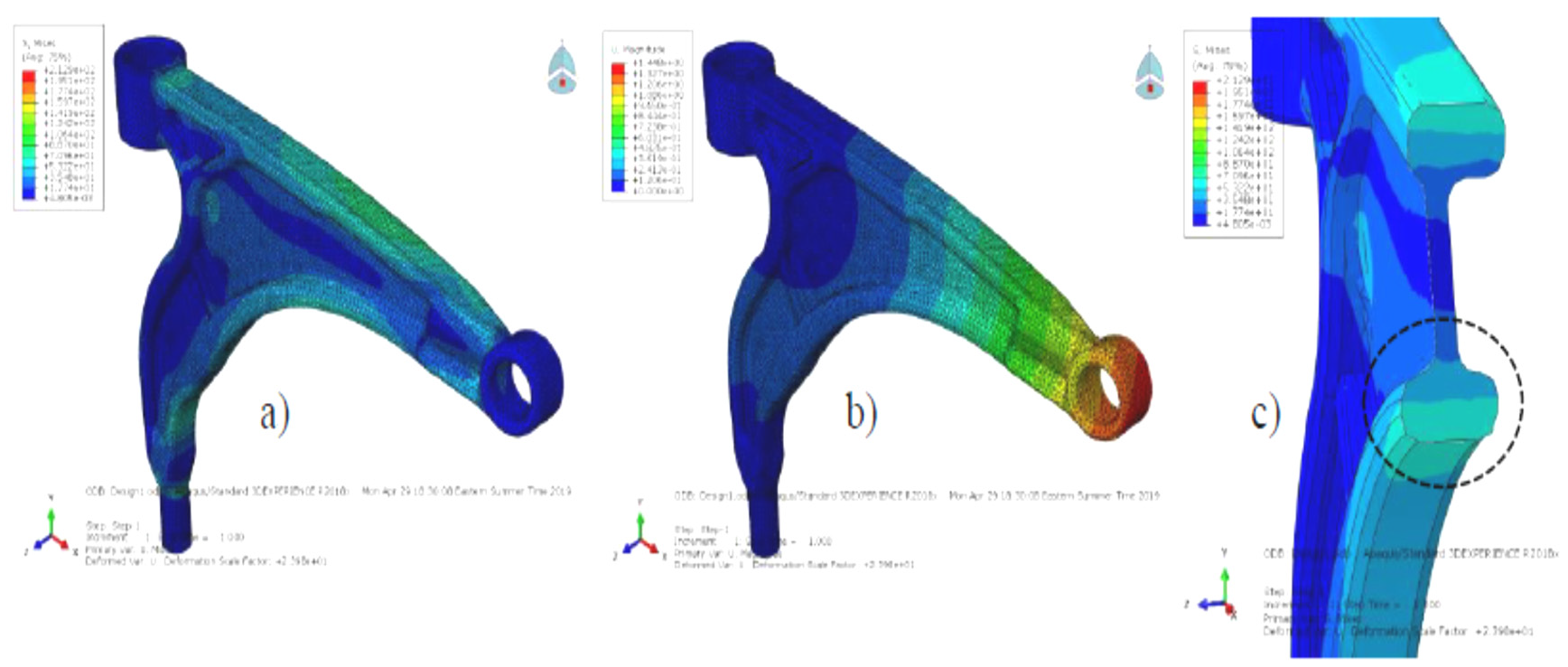

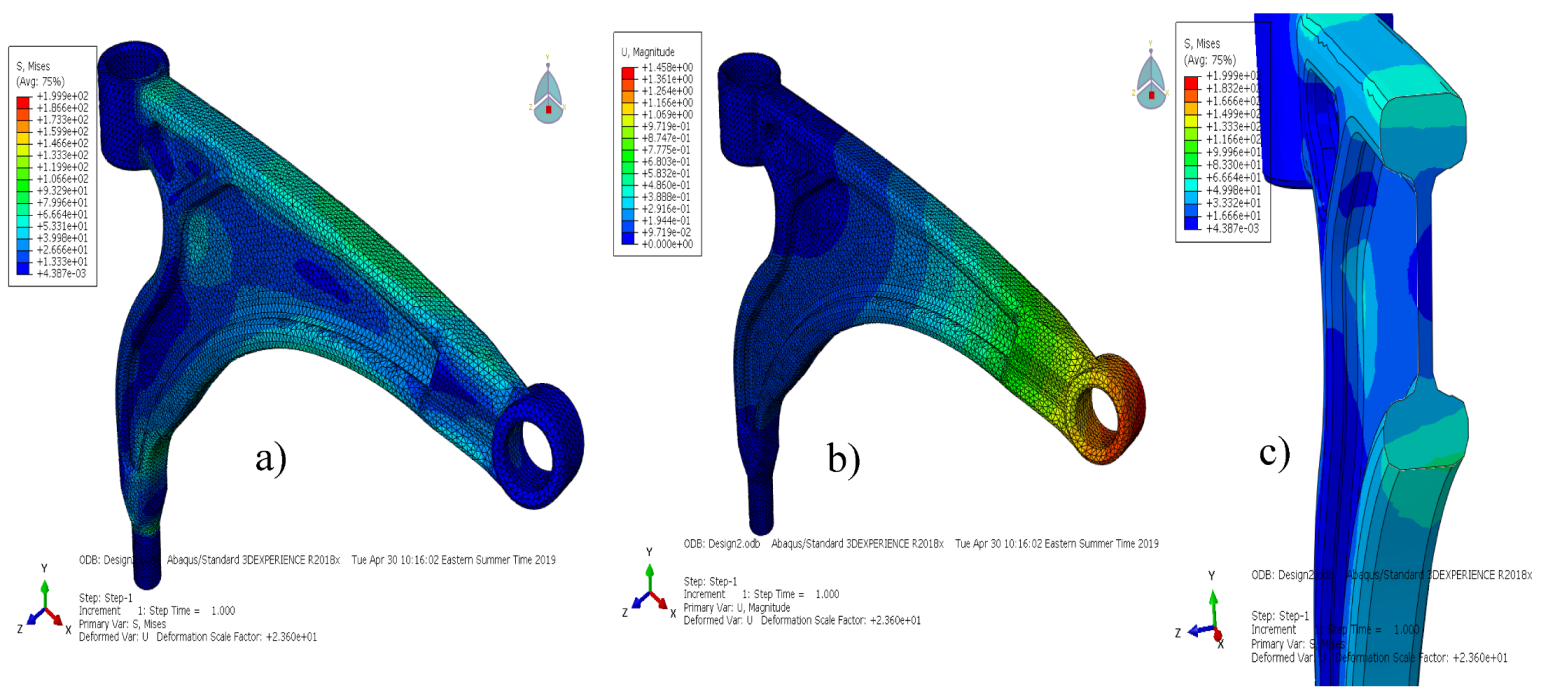

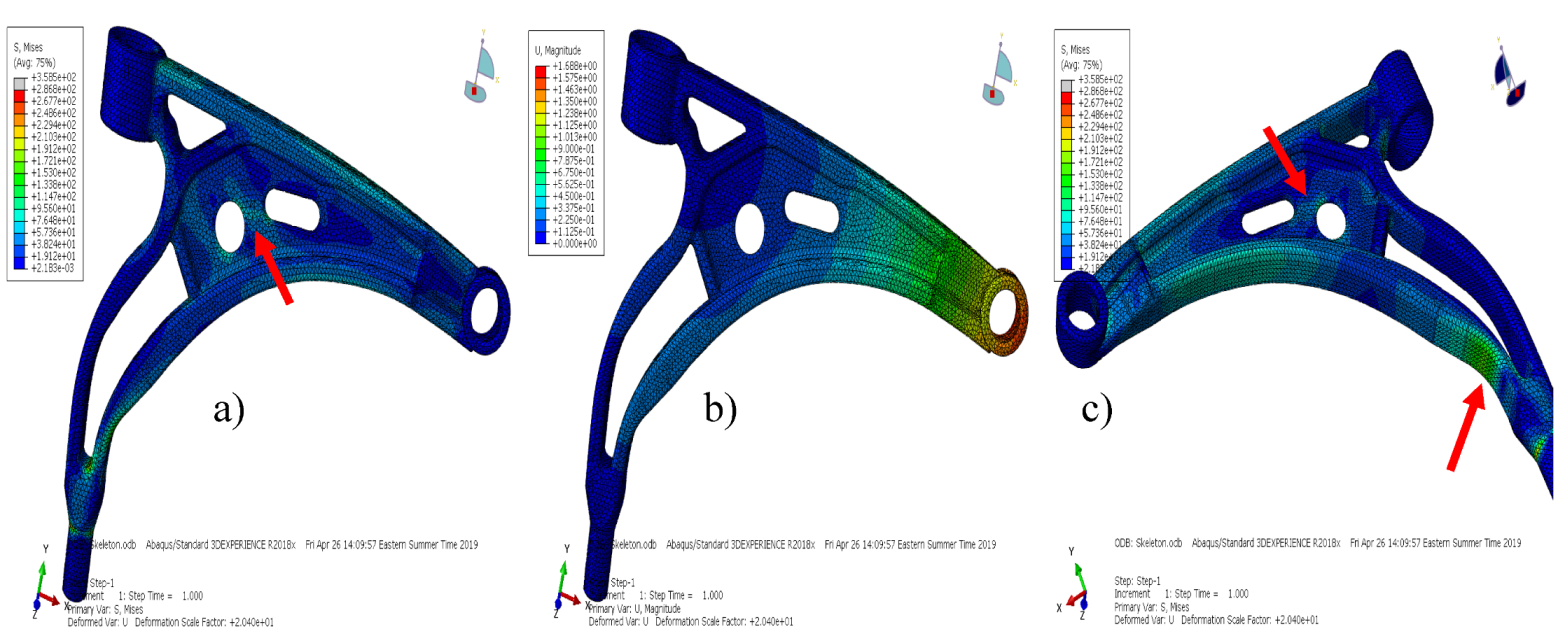

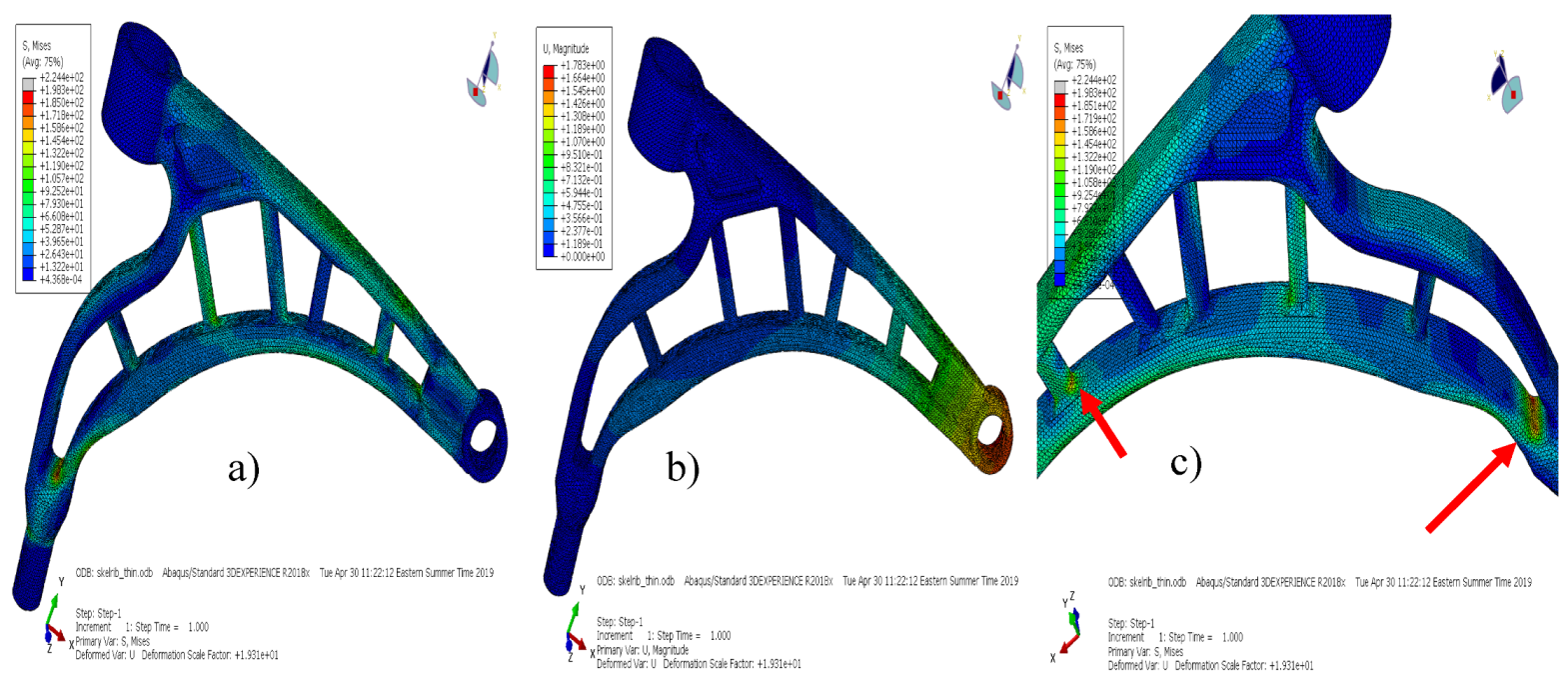

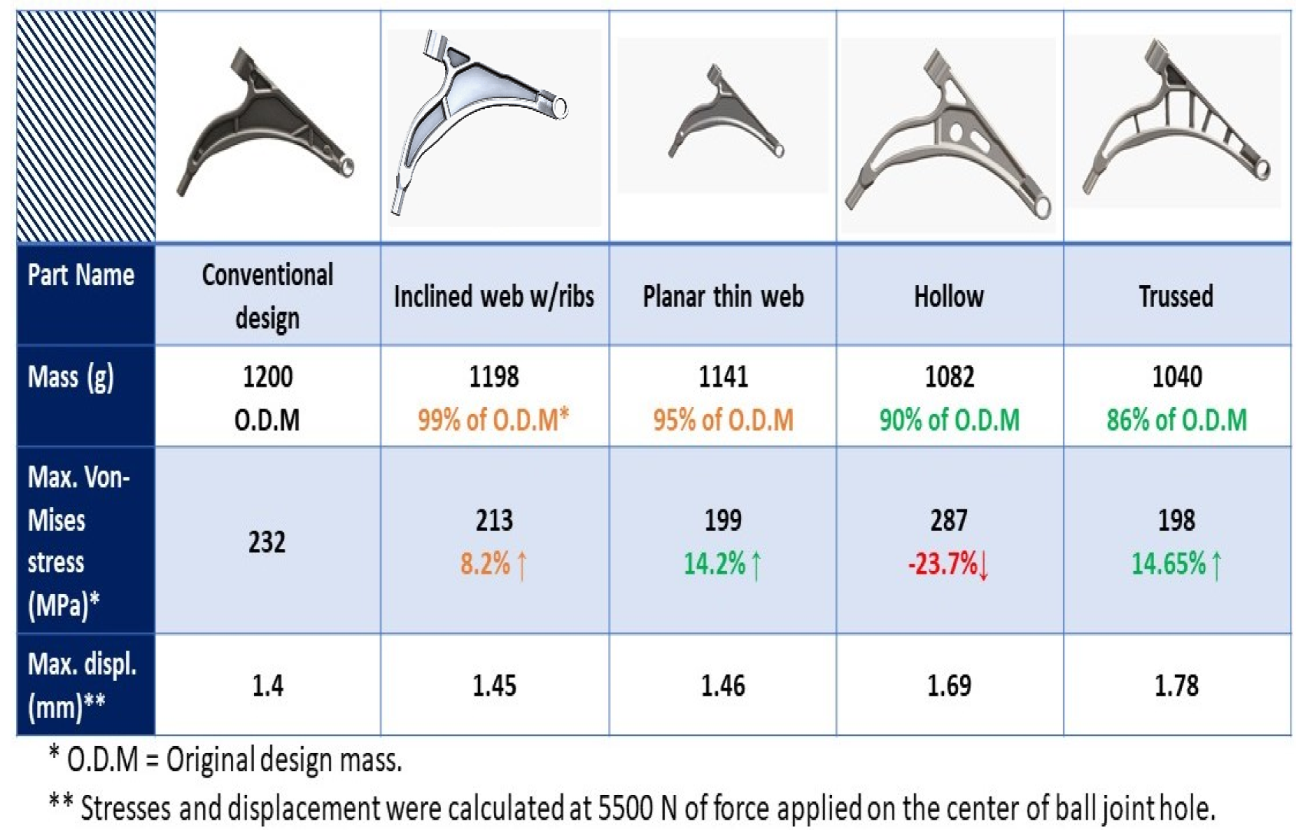

3.2. Design Analysis and Finite Elements

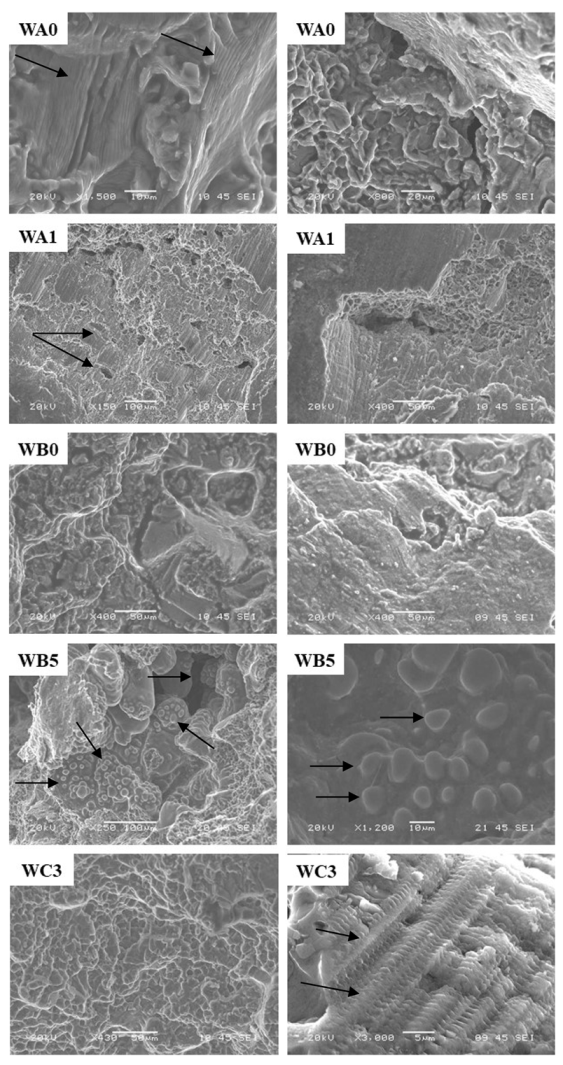

3.3. Fracture Surface Analysis

4. Conclusions

- The multiple accelerating thermal aging cycles of WC3 shows a superior enhancement of real part fatigue life than the standard T6 with 72,000 cycles for C3, compared to 36,000 cycles for T6. The thermal aging cycles of WA0 also shows enhanced low cyclic fatigue life of 40,000 cycles and is considered more economical than T6.

- The cantilever bending fatigue test reveals superior life cycles by applying the accelerating thermal aging treatment of WC3 with an average value of 82,000 cycles, compared to an average of 53,000 for T6. This proves the positive effect of multiple thermal aging treatments of WC3 on fatigue life. The aging cycle WA1 also shows enhancement over T6 with an average of 59,250 cycles; it is also considered more economical than T6.

- The trussed design (design 4) of the applicable component shows superior properties than all other proposed designs in this paper—with a 160 gm lighter than the original design and a maximum VM stress of 198 MPa compared to 232 MPa for the original design. Design 4 is also more flexible than the original design, which can improve damping and increase the life of the ball joint connected to the control arm significantly. This flexibility is believed to better cushion road impacts resulting in better suspension behavior and comfort.

- The application of selected WC3 multiple thermal aging treatments to the proposed design 4 (trussed design) is expected to withstand more than 84,300 cycles, which is 134% enhancement of the applicable part’s life. This is calculated by extrapolating the values of stresses of the original and new design with the values of T6, compared to WC3.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bouazara, M.; Bouaicha, A.; Ragab, K.A. Fatigue characteristics and quality index of A357 type semi-solid aluminum castings used for automotive application. J. Mater. Eng. Perform. 2015, 24, 3084–3092. [Google Scholar] [CrossRef]

- Rosso, M. The influence of casting process on quality and performances on Al based automotive components. In Proceedings of the 13th International scientific conference on Achievements in mechanical and materials engineering, Gliwice–Wista, Poland, 16–19 May 2005; pp. 547–550. [Google Scholar]

- Fridlyander, I.N.; Sister, V.G.; Grushko, O.E.; Berstenev, V.V.; Sheveleva, L.M.; Ivanova, L.A. Aluminum alloys: Promising materials in the automotive industry. Met. Sci. Heat Treat. 2002, 44, 365–370. [Google Scholar] [CrossRef]

- St John, D.; Caceres, C.; Zhang, D.; Edwards, G.; Taylor, J.; Schaffer, G. Aluminum alloys for cast automotive components. In Proceedings of the 2nd Conference and Exhibition on Materials in the Automotive Industry, IMMA, Melbourne, Victoria, Australia, 10–11 April 1996; pp. 140–143. [Google Scholar]

- Bouazara, M.; Banitalebi, H.; Ragab, K.A.; Mrad, H. On the characteristics of automotive low arm-suspension system parts made of aluminum casting alloys. Int. J. Cast Met. Res. 2016, 29, 129–136. [Google Scholar] [CrossRef]

- Bouazara, M.; Saoudi, A. Dynamic and Fatigue Study of the Automotive Upper Arm Suspension System. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 875, pp. 2269–2274. [Google Scholar]

- Uys, P.E.; Els, P.S.; Thoresson, M. Suspension settings for optimal ride comfort of off-road vehicles travelling on roads with different roughness and speeds. J. Terramech. 2007, 44, 163–175. [Google Scholar] [CrossRef]

- Doutre, D.; Langlais, J.; Roy, S. The seed process for semi-solid forming. In Proceedings of the 8th international conference on semi-solid processing of alloys and composites, Limassol, Cyprus, 21–23 September 2004; pp. 739–750. [Google Scholar]

- Ragab, K.A.; Bouazara, M.; Bouaicha, A.; Allaoui, O. Microstructural and mechanical features of aluminium semi-solid alloys made by rheocasting technique. Mater. Sci. Technol. 2017, 33, 646–655. [Google Scholar] [CrossRef]

- Langlais, J.; Lemieux, A. The SEED technology for semi-solid processing of aluminum alloys: A metallurgical and process overview. Solid State Phenom. 2006, 116, 472–477. [Google Scholar] [CrossRef]

- Birol, Y. A357 thixoforming feedstock produced by cooling slope casting. J. Mater. Process. Technol. 2007, 186, 94–101. [Google Scholar] [CrossRef]

- Flemings, M.C. Semi-solid forming: The process and the path forward. Metall. Sci. Technol. 2000, 18, 3–4. [Google Scholar]

- Zhu, H.; Guo, J.; Jia, J. Correlation of the aging characteristics and deformation behavior of A357 alloy. J. Mater. Eng. Perform. 2001, 10, 186–191. [Google Scholar] [CrossRef]

- Ragab, K.A.; Bouazara, M.; Chen, X.G. Influence of Thermal Aging Parameters on the Characteristics of Aluminum Semi-Solid Alloys. Metals 2018, 8, 746. [Google Scholar] [CrossRef]

- Ragab, K.A.; Bouazara, M.; Chen, X.G. Quality index charts of Al-Si-Mg semi solid alloys subjected to multiple temperatures aging treatments and different quenching media. Materials 2019, 12, 1834. [Google Scholar] [CrossRef] [PubMed]

- Avalle, M.; Belingardi, G.; Cavatorta, M.P.; Doglione, R. Casting defects and fatigue strength of a die cast aluminium alloy: A comparison between standard specimens and production components. Int. J. Fatigue 2002, 24, 1–9. [Google Scholar] [CrossRef]

- Gan, Y.X.; Overfelt, R.A. Fatigue property of semi-solid A357 aluminum alloy under different heat treatment conditions. J. Mater. Sci. 2006, 4, 7537–7544. [Google Scholar] [CrossRef]

- Hegazy, S.; Rahnejat, H.; Hussain, K. Multi-body dynamics in full-vehicle handling analysis. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2000, 213, 19–31. [Google Scholar] [CrossRef]

- Ning, X.; Zhao, C.; Shen, J. Dynamic analysis of car suspension using ADAMS/Car for development of a software interface for optimization. Procedia Eng. 2011, 16, 333–341. [Google Scholar] [CrossRef]

- Viqaruddin, M.; Ramana Reddy, D. Structural optimization of control arm for weight reduction and improved performance. Mater. Today Proc. 2017, 4, 9230–9236. [Google Scholar] [CrossRef]

- Ragab, K.A.; Bouaicha, A.; Bouazara, M. Optimization of Casting Design Parameters on Fabrication of Reliable Semi-Solid Aluminum Suspension Control Arm. J. Mater. Eng. Perform. 2017, 26, 4450–4461. [Google Scholar] [CrossRef]

- Nadot, Y.; Denier, V. Fatigue failure of suspension arm: Experimental analysis and multiaxial criterion. Eng. Fail. Anal. 2004, 11, 485–499. [Google Scholar] [CrossRef]

- Wang, Q.G.; Apelian, D.; Lados, D.A. Fatigue behavior of A356/357 aluminum cast alloys: Part II–Effect of microstructural constituents. J. Light Met. 2001, 1, 85–97. [Google Scholar] [CrossRef]

| Thermal Aging treatment | Fatigue Cycles |

|---|---|

| WA0 (T6/T7) Multiple thermal aging cycles | 40,000 cycles |

| WA8 (T6/T7) Multiple thermal aging cycles | 24,000 cycles |

| WB0 (T7/T6) Multiple thermal aging cycles | 30,000 cycles |

| WC1 (T4/T6/T7) Multiple thermal aging cycles | 33,000 cycles |

| WC3 (T4/T6/T7) Multiple thermal aging cycles | 72,000 cycles |

| T6 Standard thermal aging | 36,000 cycles |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Attia, M.; Ragab, K.A.; Bouazara, M.; Chen, X.-G. Fatigue Cycles and Performance Evaluation of Accelerating Aging Heat Treated Aluminum Semi Solid Materials Designed for Automotive Dynamic Components. Appl. Sci. 2020, 10, 3008. https://doi.org/10.3390/app10093008

Attia M, Ragab KA, Bouazara M, Chen X-G. Fatigue Cycles and Performance Evaluation of Accelerating Aging Heat Treated Aluminum Semi Solid Materials Designed for Automotive Dynamic Components. Applied Sciences. 2020; 10(9):3008. https://doi.org/10.3390/app10093008

Chicago/Turabian StyleAttia, Mohamed, Khaled Ahmed Ragab, Mohamed Bouazara, and X.-Grant Chen. 2020. "Fatigue Cycles and Performance Evaluation of Accelerating Aging Heat Treated Aluminum Semi Solid Materials Designed for Automotive Dynamic Components" Applied Sciences 10, no. 9: 3008. https://doi.org/10.3390/app10093008

APA StyleAttia, M., Ragab, K. A., Bouazara, M., & Chen, X.-G. (2020). Fatigue Cycles and Performance Evaluation of Accelerating Aging Heat Treated Aluminum Semi Solid Materials Designed for Automotive Dynamic Components. Applied Sciences, 10(9), 3008. https://doi.org/10.3390/app10093008