Optimal Scheduling of Large-Scale Wind-Hydro-Thermal Systems with Fixed-Head Short-Term Model

Abstract

1. Introduction

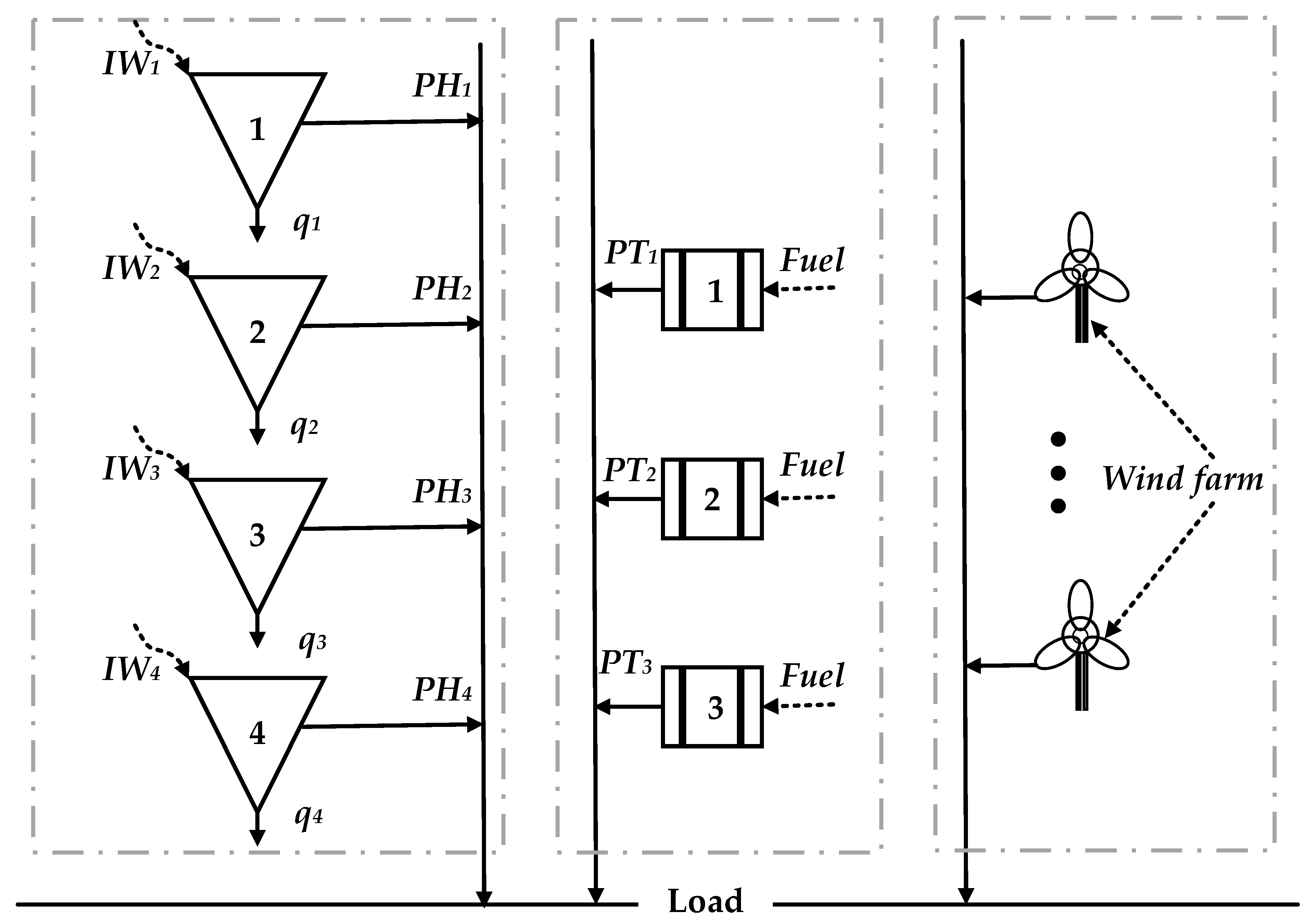

2. Formulation of Optimal Scheduling of Wind-Hydro-Thermal System

2.1. Total Electricity Generation Fuel Cost Reduction Objective

2.2. Set of Constraints and Wind Model

2.2.1. Constraints from Hydropower Plants

2.2.2. Constraint of Thermal Power Plant

2.2.3. Constraints of Power Systems

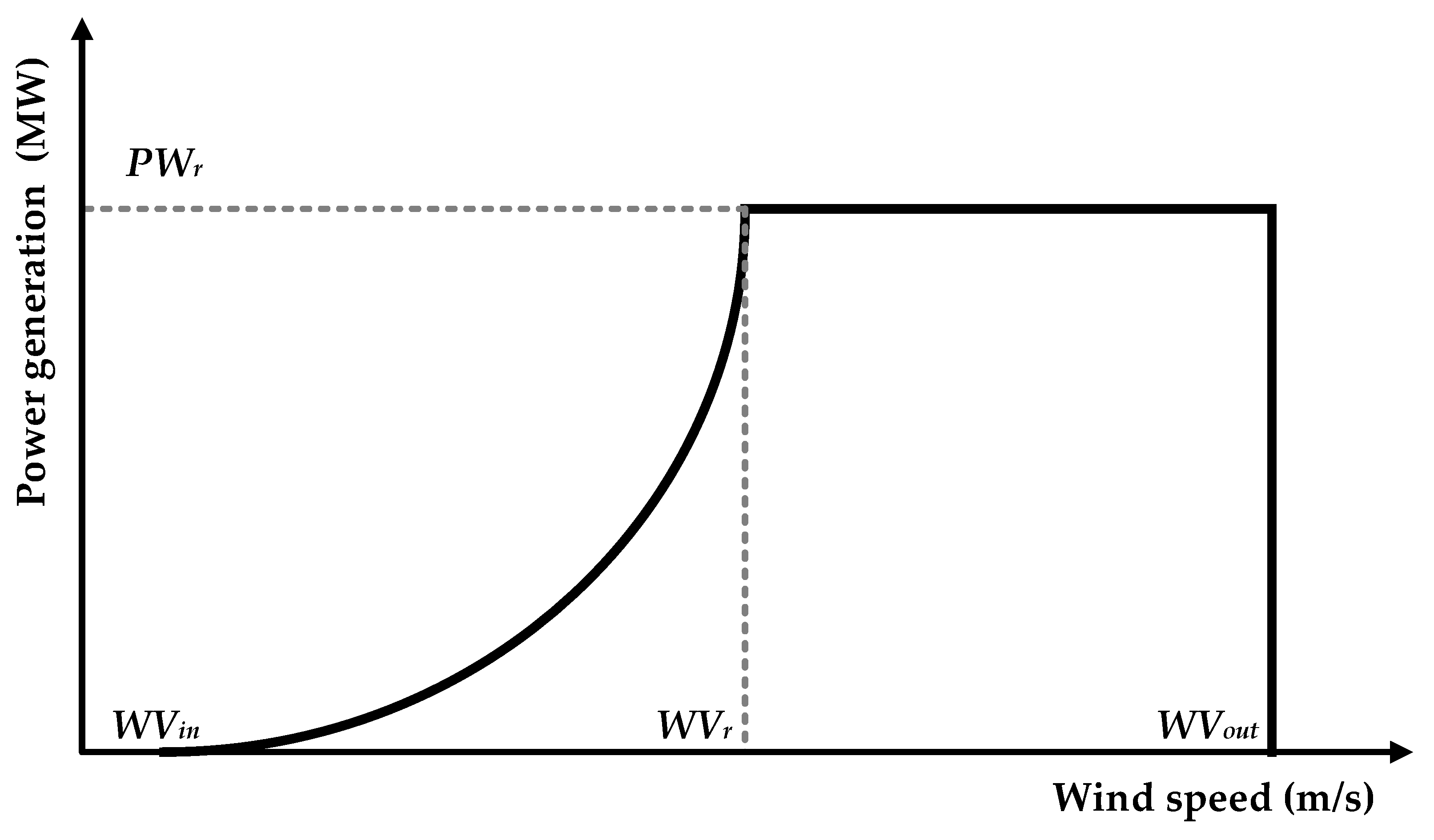

2.2.4. Modeling of Wind Uncertainty

3. The Proposed Method

3.1. Conventional Cuckoo Search Algorithm (CSA)

3.2. Modified Adaptive Selective Cuckoo Search Algorithm (MASCSA)

3.2.1. New Selection Mechanism (NSM)

3.2.2. Adaptive Mutation Mechanism (AMM)

3.2.3. The Modified Adaptive Mutation Mechanism (MAMM)

- Step 1: Set mutation factor MF to one

- Step 2: Calculate the fitness function of the sth solution, FFs and determine the lowest one, FFbest

- Step 3: Calculate the mean fitness function of all current solutions, FFa

- Step 4: Calculate EIs and EIa using Equations (17) and (18)

- Step 5: Compare EIs and EIa

- If EIs < EIa, apply Equation (15) for the sth solution.

- Otherwise, apply Equation (16) for the sth solution.

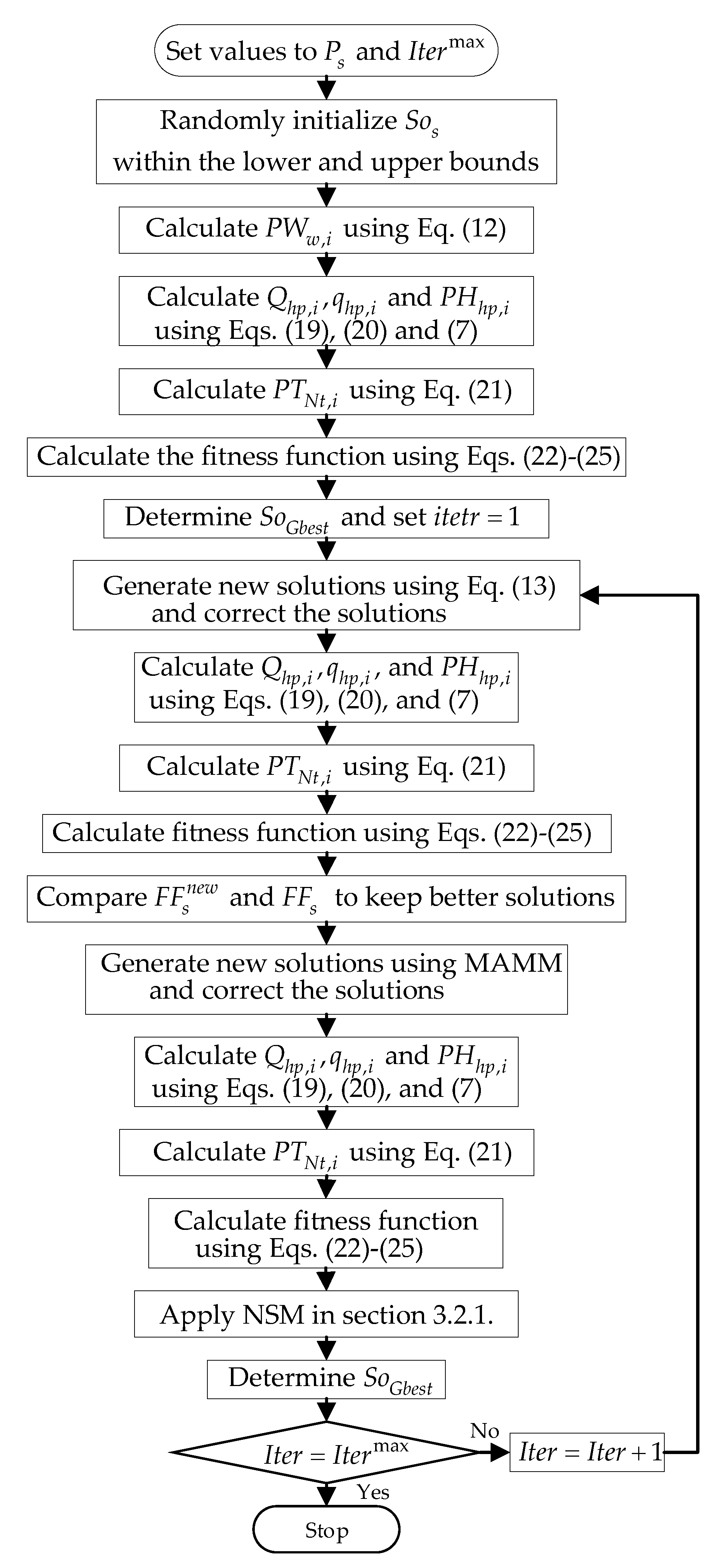

4. The Application of the Proposed MASCSA Method for OSWHT Problem

4.1. Decision Variables Selection

- Reservoir volume of all hydropower plants at the first subinterval to the (Ns − 1)th subinterval: Vhp,i, where hp = 1, …, Nh and i = 1, …, Ns.

- Power generation of the first (Nt − 1) thermal power plants for all subinterval: PTtp,i, where tp = 1, …, Nt − 1 and i = 1, …, Ns.

4.2. Handling Constraints of Hydropower Plants

4.3. Handling Power Balance Constraint

4.4. Fitness Function

4.5. The Whole Application Procedure of MASCSA for OSWHT Problem

- Step 1: Set values to Ps and Itermax

- Step 2: Randomly initialize Sos (s=1, …, Ps) within the lower and upper bounds

- Step 3: Calculate PWw,i using Equation (12)

- Step 4: Calculate Qhp,i, qhp,i and PHhp,i using Equations (19), (20), and (7).

- Step 5: Calculate PTNt,i using Equation (21)

- Step 6: Calculate the fitness function using Equations (22)–(25)

- Step 7: Determine SoGbest and set current iteration to 1 (Iter=1)

- Step 8: Generate new solutions using Equation (13) and correct the solutions

- Step 9: Calculate Qhp,i, qhp,i, and PHhp,i using Equation (19), (20), and (7).

- Step 10: Calculate PTNt,i using Equation (21)

- Step 11: Calculate fitness function using Equations (22)–(25)

- Step 12: Compare and to keep better solutions

- Step 13: Generate new solutions using MAMM and correct the solutions

- Step 14: Calculate Qhp,i, qhp,i, and PHhp,i using Equations (19), (20), and (7).

- Step 15: Calculate PTNt,i using Equation (21)

- Step 16: Calculate fitness function using Equations (22)–(25)

- Step 17: Apply NSM in Section 3.2.1.

- Step 18: Determine SoGbest

- Step 19: If Iter= Itermax, stop the solution searching algorithm. Otherwise, set Iter= Iter+1 and go back to Step 8

5. Numerical Results

- Test System 1: Four hydropower plants and four thermal power plants with valve effects are optimally scheduled over one day with twenty-four one-hour subintervals. The data of the system are modified from Test System 1 in [7] and also reported in Table A1, Table A2 and Table A3 in the Appendix A.

- Test System 2: Four hydropower plants, four thermal power plants, and two wind farms with the rated power of 120 MW and 80 MW are optimally scheduled over one day with twenty-four one-hour subintervals. The data of the hydrothermal system are taken from Test System 1 while wind data are taken from [45] and also reported in Table A3 in the Appendix A.

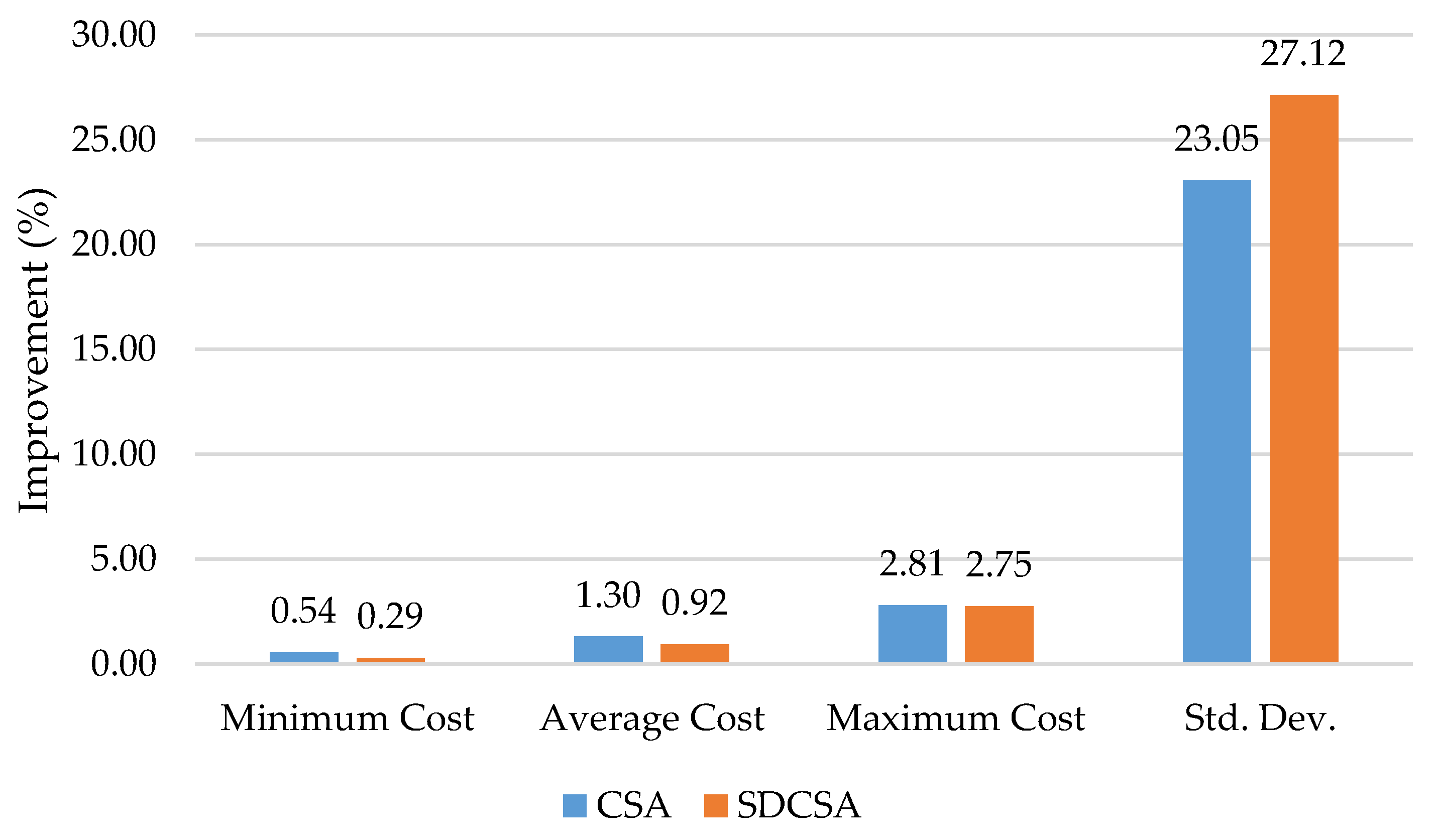

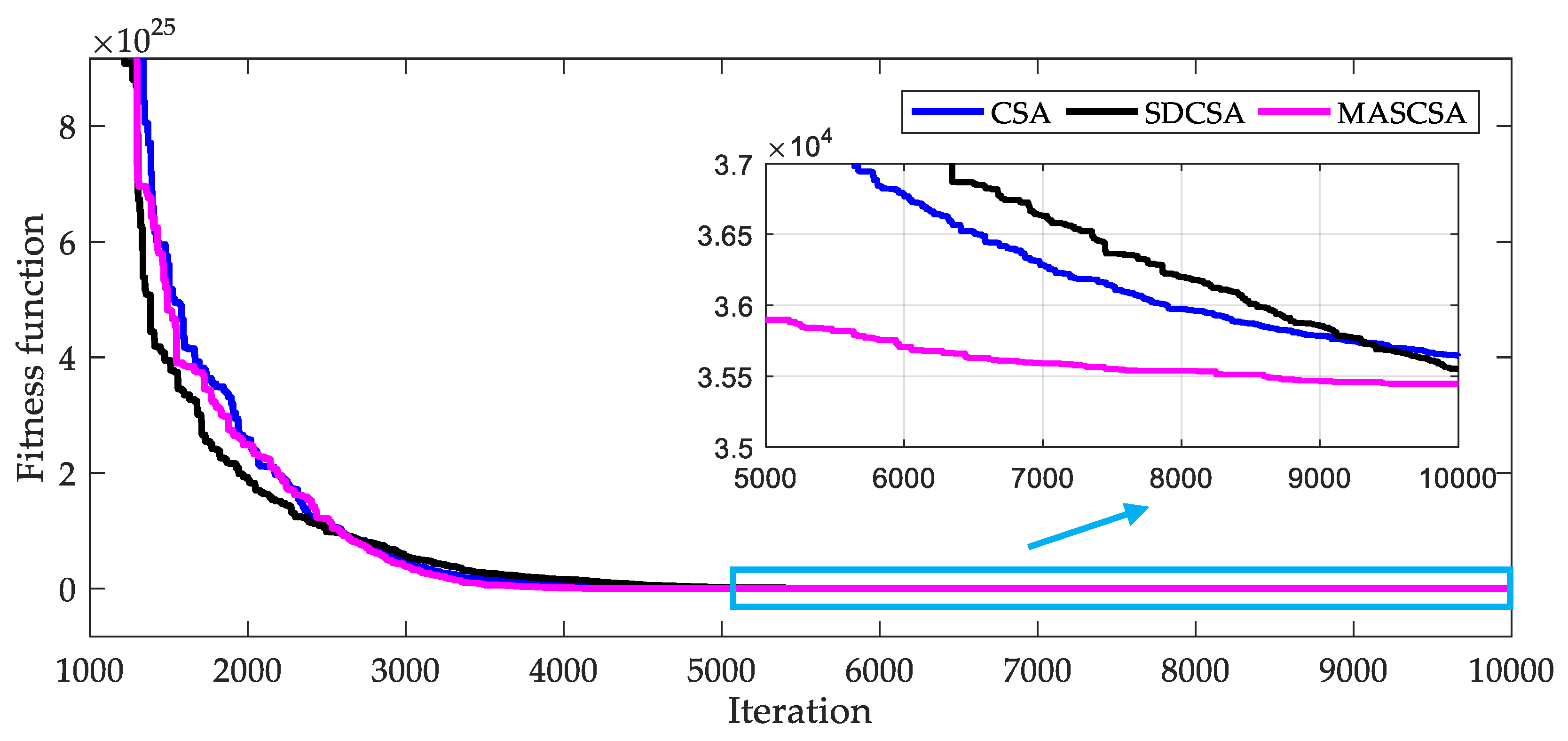

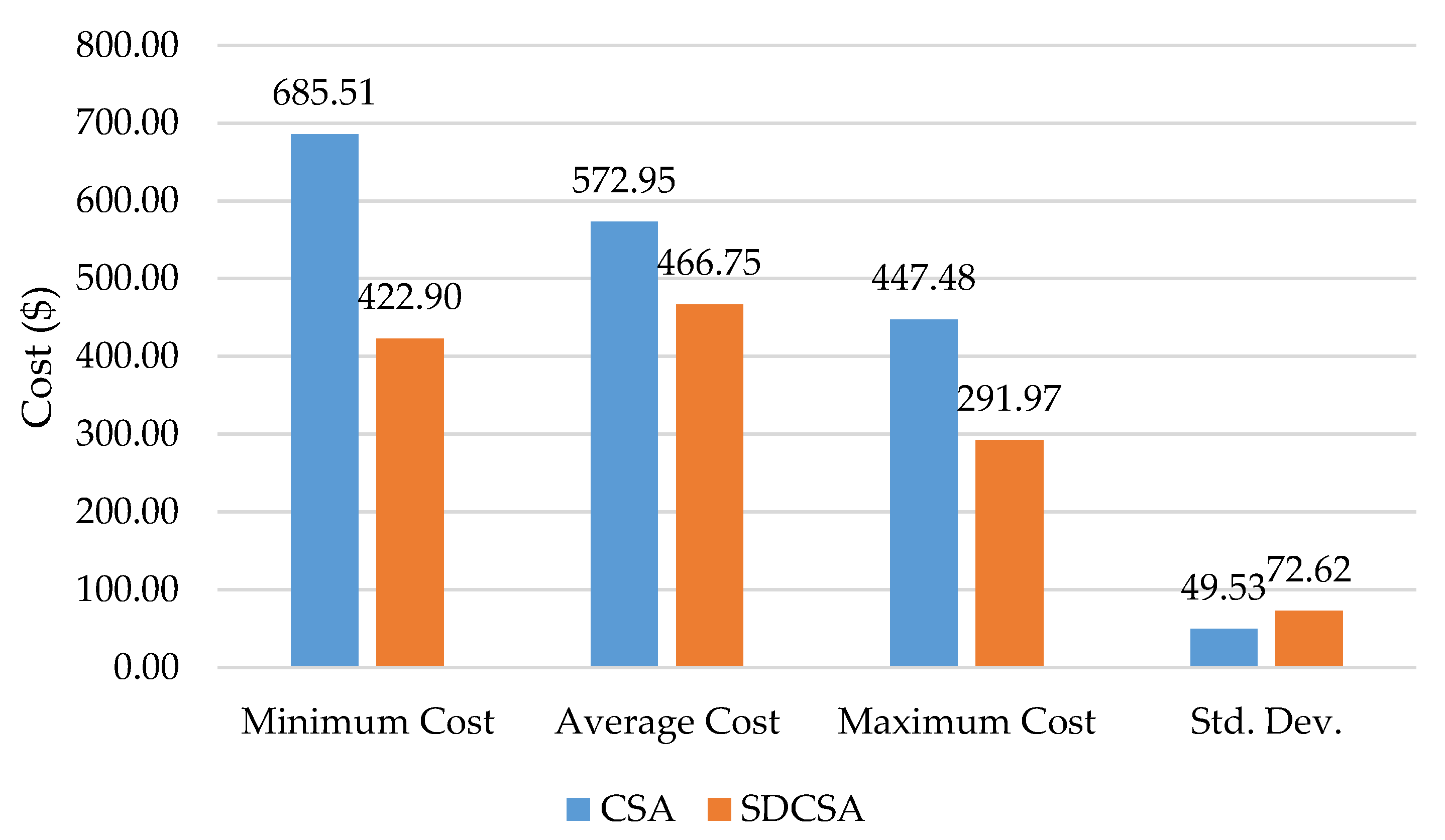

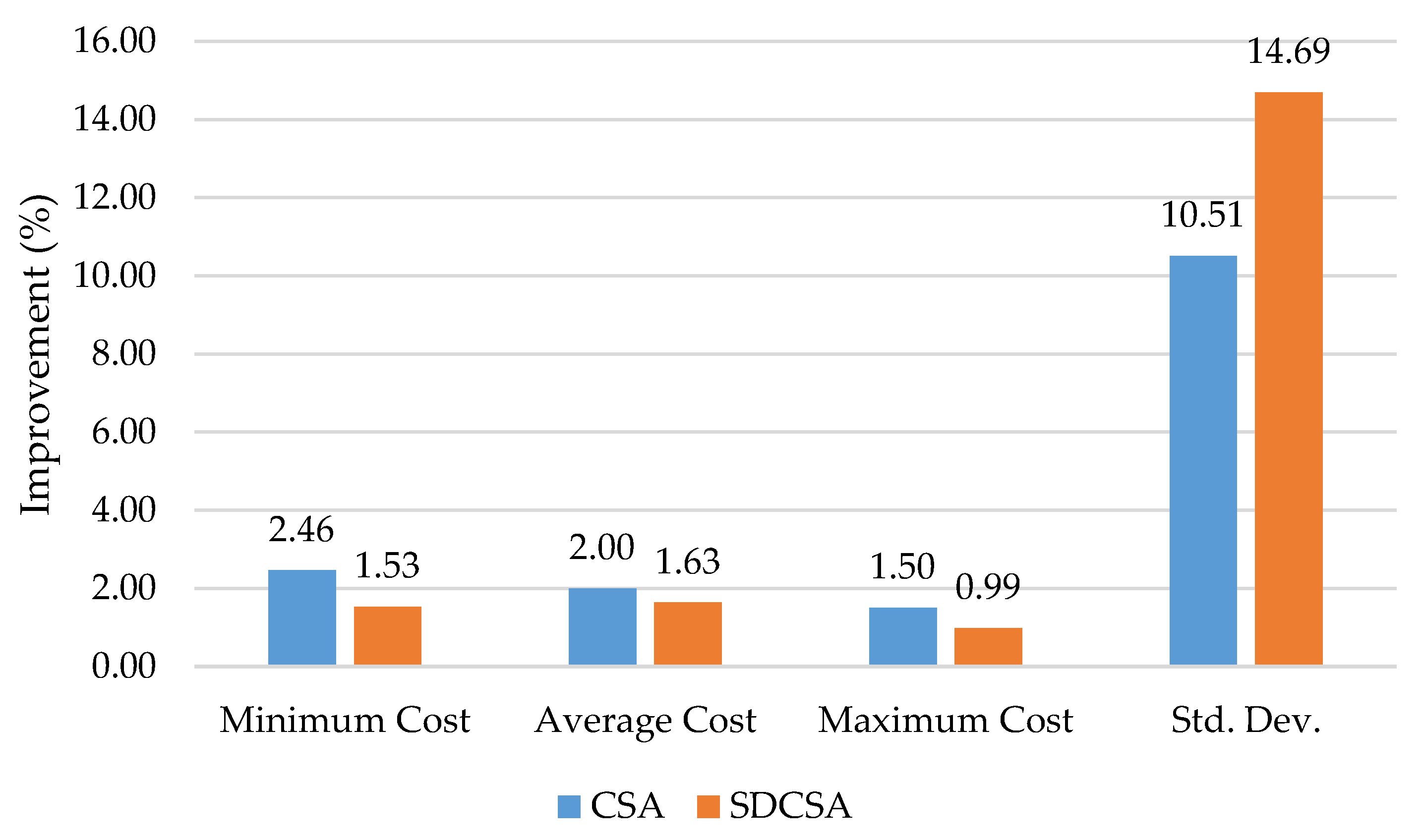

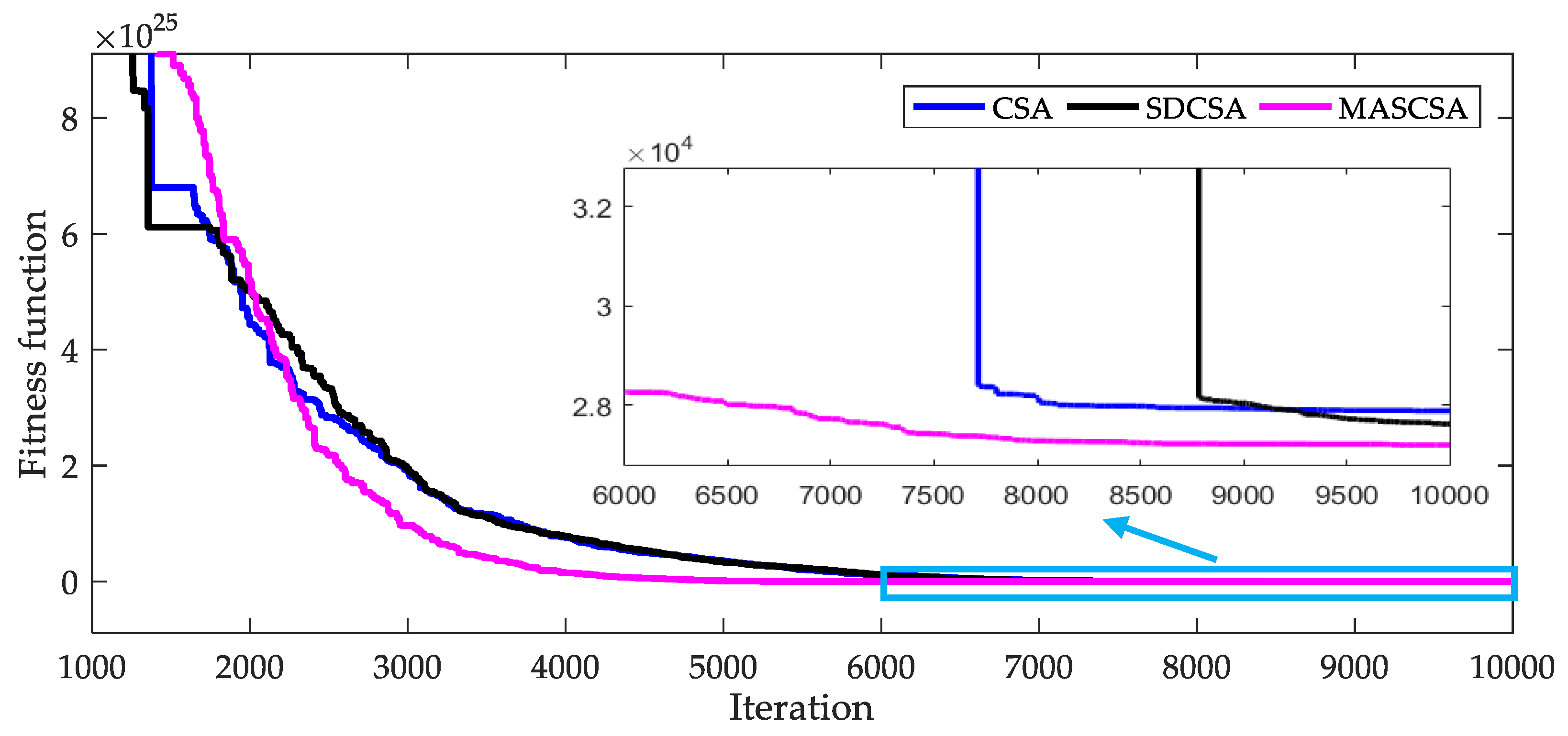

5.1. Comparison Results on Test System 1

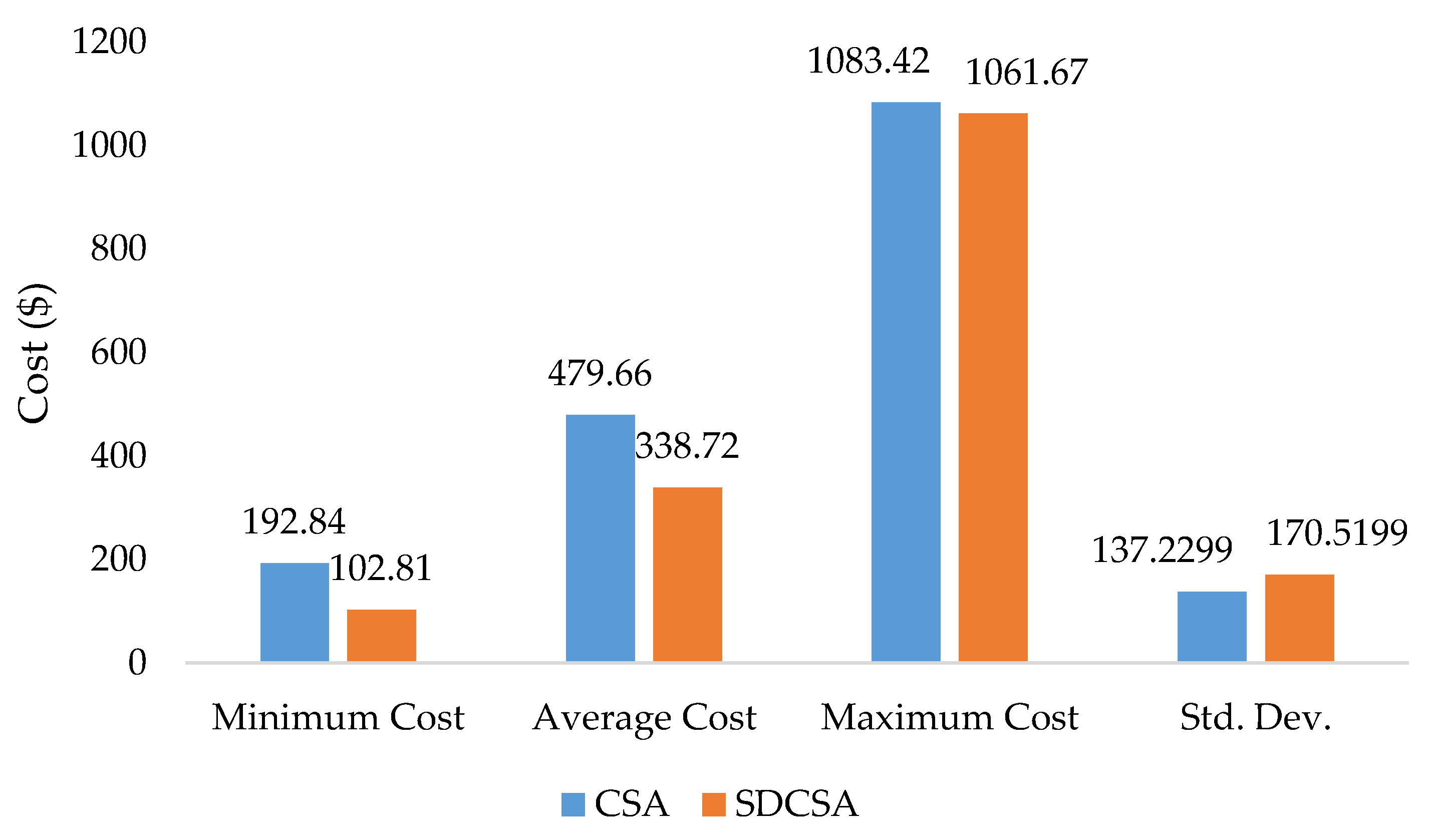

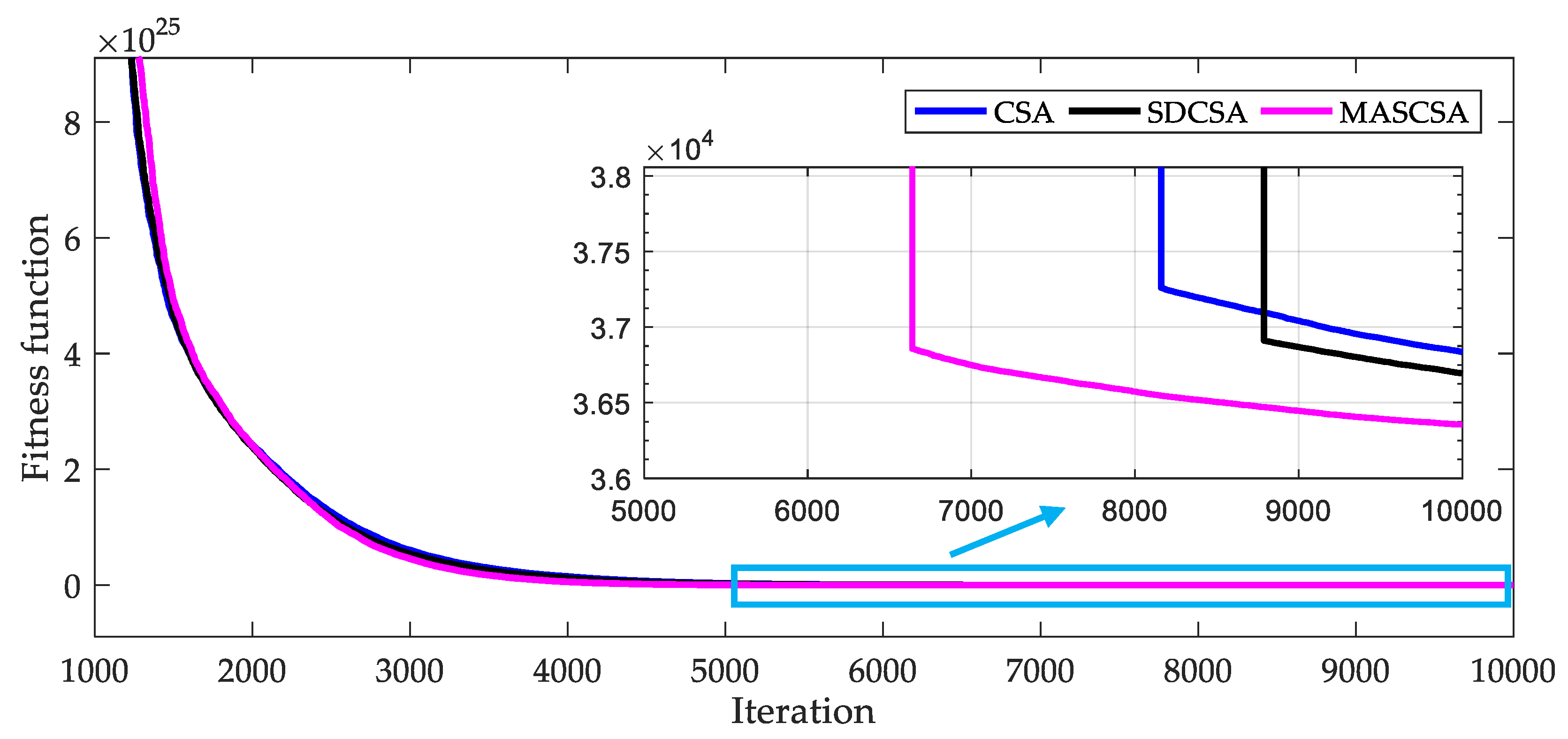

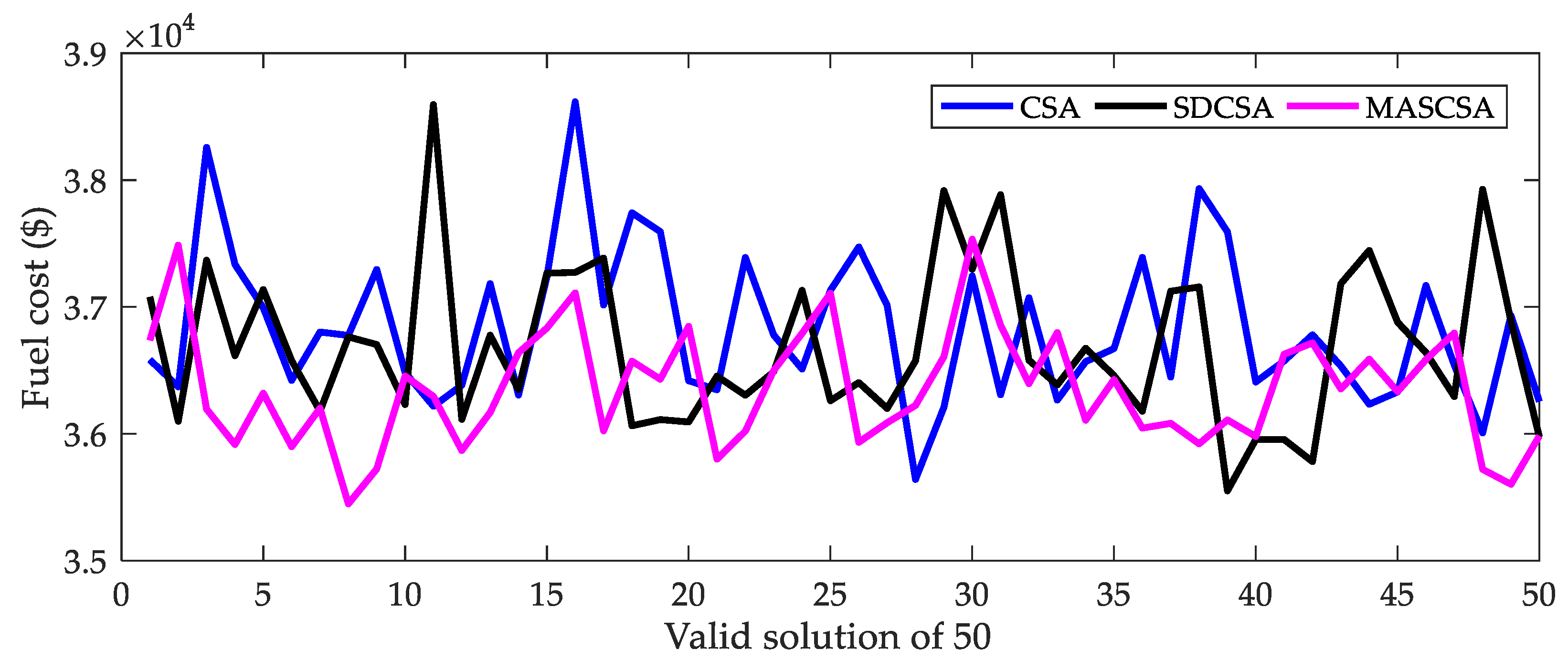

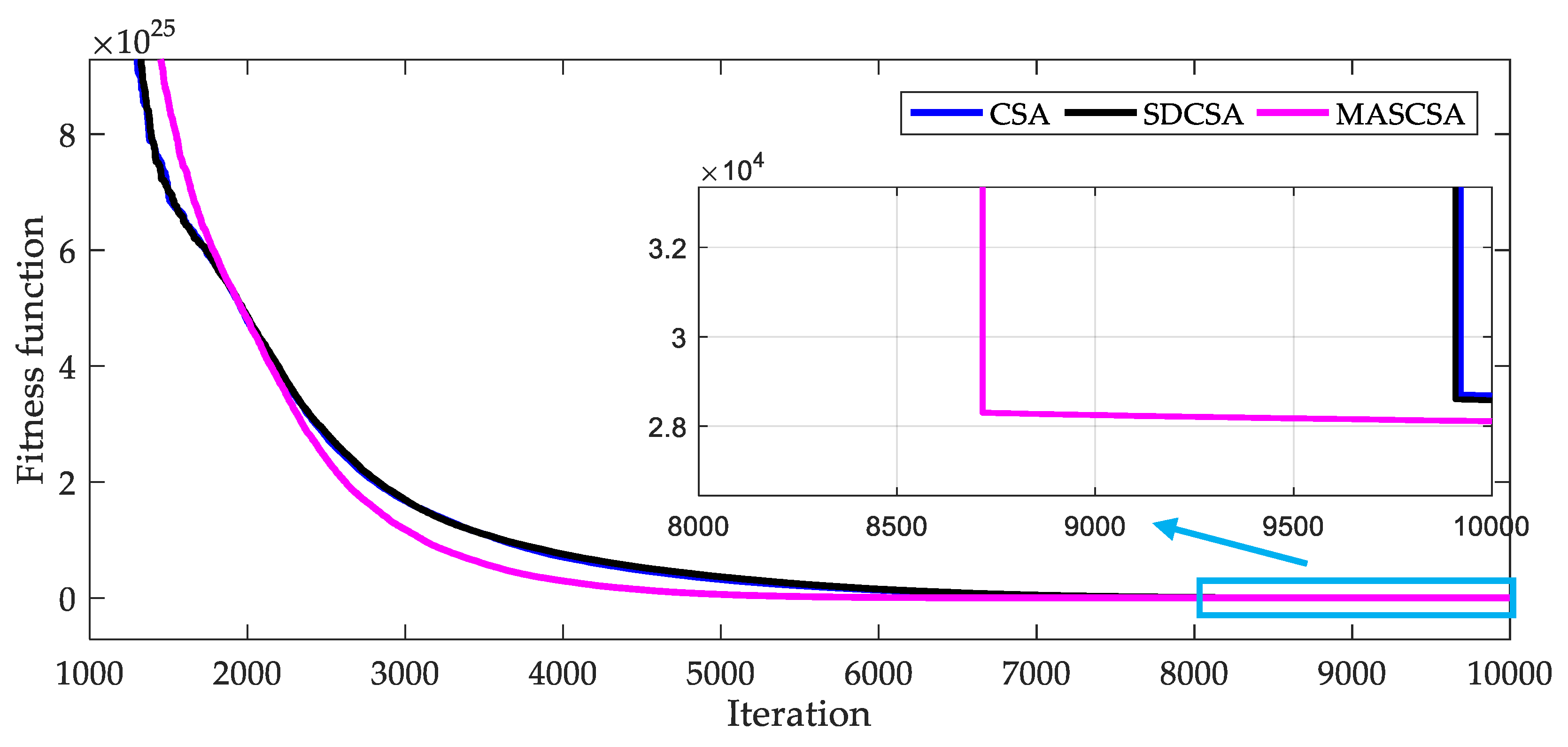

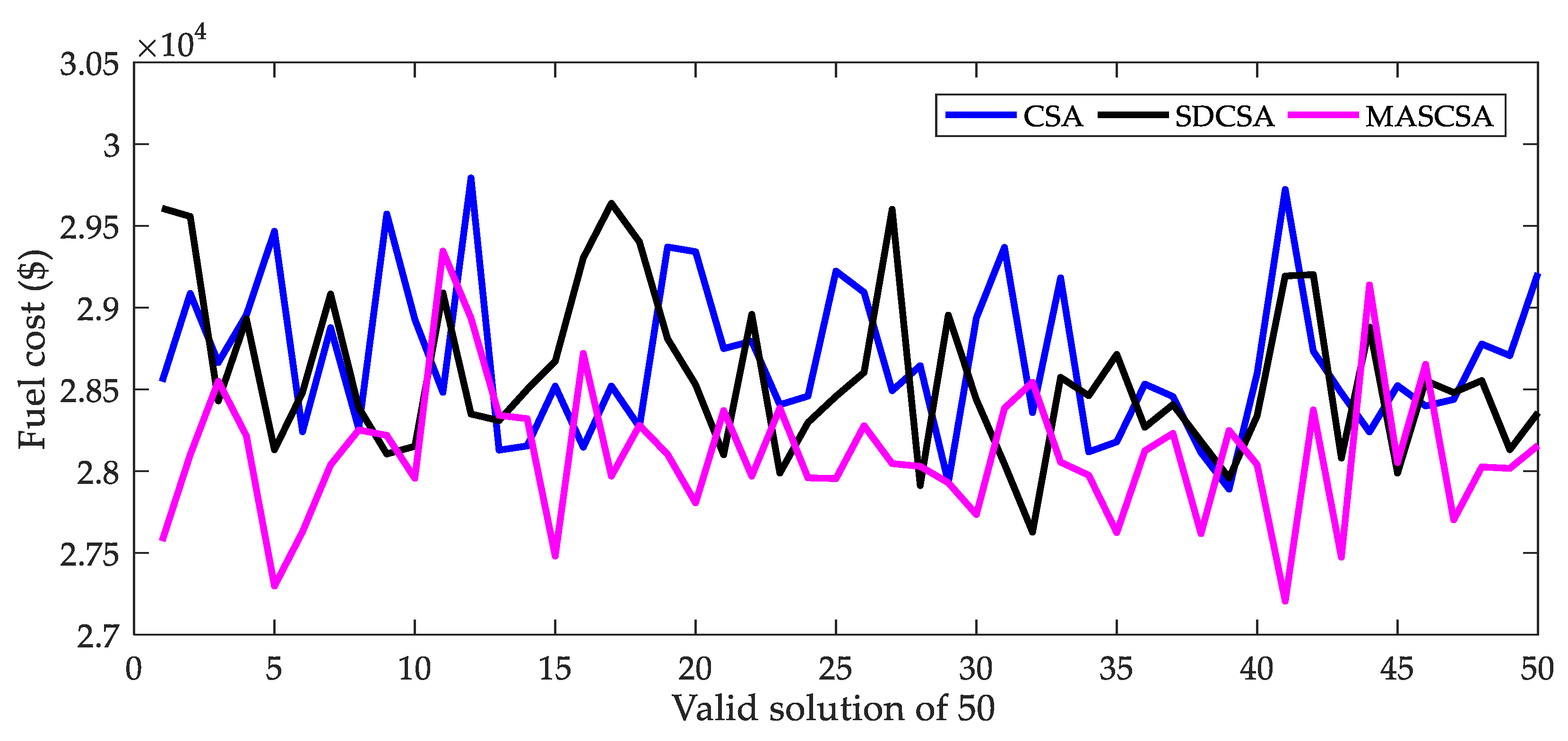

5.2. Comparison Results on Test System 2

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| TFC | Total fuel cost for generating electricity of all thermal power plants |

| ti | Number of hours for the ith subinterval |

| ktp, mtp, ntp, αtp, βtp | Coefficients of the fuel cost function of the tpth thermal power plant |

| PTtp,i | Power generation of the tpth thermal power plant at the ith subinterval |

| PTtp,min | Minimum power generation of the tpth thermal power plant |

| PTtp,max | Maximum power generation of the tpth thermal power plant |

| Nt | Number of thermal power plants |

| Ns | Number of subintervals |

| tp | Thermal power plant index |

| hp | Hydropower plant index |

| Nw | Number of wind turbines in a wind farm |

| Nh | Number of hydropower plants |

| RVhp,i | Reservoir volume of the hpth hydropower plant at the end of the ith subinterval |

| WIhp,i | Water inflow into the reservoir of the hpth hydropower plant at the ith subinterval |

| Qhp,i | Total water discharge through turbines of the hpth hydropower plant over the ith subinterval |

| RVhp,start | Available reservoir volume of the hpth hydropower plant before optimal scheduling |

| RVhp,end | Final reservoir volume of the hpth hydropower plant at the end of optimal scheduling |

| RVhp,Ns | Reservoir volume of the hpth hydropower plant at the end of the Nsth subinterval |

| RVhp,min | Minimum reservoir volume of the hpth hydropower plant |

| RVhp,max | Maximum reservoir volume of the hpth hydropower plant |

| qhp,min | Minimum discharge per hour through turbines of the hpth hydropower plant |

| qhp,max | Maximum discharge per hour through turbines of the hpth hydropower plant |

| qhp,i | Discharge per hour through turbines of the hpth hydropower plant over the ith subinterval |

| xhp, yhp, zhp | Discharge function coefficients of the hpth hydropower plant |

| PHhp,min | Minimum power generation of the hpth hydropower plant |

| PHhp,max | Maximum power generation of the hpth hydropower plant |

| PTtp,max | Maximum power generation of the tpth thermal power plant |

| w | Wind turbine index in the wind farm |

| PWw,i | Power output of the wth wind turbine at the ith subinterval |

| Nw | Number of wind turbines in a wind farm |

| PWw | Power generation of the wth wind turbine |

| PTL,i | Total power loss at the ith subinterval |

| PL,i | Power of load at the ith subinterval |

| PWw,r | Rated generation of the wth turbine |

| WVw | Wind speed flowing into the wind turbine |

| WVin | Cut-in wind speed |

| WVr | Rated wind speed |

| WVout | Cut-out wind speed |

| Sosnew | The sth new solution |

| Sos | The sth solution |

| δ | Randomly generated number within 0 and 1 |

| PS | Population size |

| Itermax | Maximum number of iterations |

| FFs | Fitness function of the sth solution |

| FFsnew | Fitness function of the sth new solution |

Appendix A

| Thermal Plant (tp) | ktp ($/h) | mtp ($/MWh) | ntp ($/MW2h) | αtp ($/h) | βtp (rad/MW) | PTtp,min (MW) | PTtp,max (MW) |

|---|---|---|---|---|---|---|---|

| 1 | 60 | 1.8 | 0.0011 | 14 | 0.04 | 10 | 500 |

| 2 | 100 | 2.1 | 0.0012 | 16 | 0.038 | 10 | 675 |

| 3 | 120 | 1.7 | 0.0013 | 18 | 0.037 | 10 | 550 |

| 4 | 40 | 1.5 | 0.0014 | 20 | 0.035 | 10 | 500 |

| Hydro Plant | xhp | yhp | zhp | PHhp,min (MW) | PHhp,max (MW) | RVhp,start (acre-ft) | RVhp,end (acre-ft) | RVhp,min (acre-ft) | RVhp,max (acre-ft) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 330 | 4.97 | 0.0001 | 0 | 1000 | 100,000 | 80,000 | 60,000 | 120,000 |

| 2 | 350 | 5.20 | 0.0001 | 0 | 1000 | 100,000 | 90,000 | 60,000 | 120,000 |

| 3 | 280 | 5.00 | 0.00011 | 0 | 1000 | 100,000 | 85,000 | 60,000 | 120,000 |

| 4 | 300 | 4.80 | 0.00011 | 0 | 1000 | 100,000 | 85,000 | 60,000 | 120,000 |

| i | PL,i (MW) | WI1,i (acre-ft/h) | WI2,i (acre-ft/h) | WI3,i (acre-ft/h) | WI4,i (acre-ft/h) | WV1,i (m/s) | WV2,i (m/s) |

|---|---|---|---|---|---|---|---|

| 1 | 1200 | 1000 | 800 | 800 | 600 | 13.2500 | 11.8000 |

| 2 | 1500 | 600 | 500 | 600 | 600 | 14.0000 | 12.0000 |

| 3 | 1100 | 700 | 500 | 700 | 700 | 12.7500 | 12.2000 |

| 4 | 1800 | 900 | 700 | 900 | 900 | 11.9000 | 12.4000 |

| 5 | 1200 | 900 | 700 | 900 | 900 | 12.5000 | 12.5000 |

| 6 | 1300 | 800 | 1000 | 800 | 800 | 13.9000 | 14.0000 |

| 7 | 1200 | 800 | 800 | 800 | 800 | 11.8000 | 15.0000 |

| 8 | 1500 | 700 | 800 | 700 | 700 | 12.7500 | 14.5000 |

| 9 | 1100 | 500 | 800 | 500 | 500 | 12.9000 | 13.0000 |

| 10 | 1800 | 500 | 800 | 500 | 500 | 12.2000 | 13.7500 |

| 11 | 1200 | 500 | 1000 | 500 | 500 | 15.0000 | 13.4000 |

| 12 | 1300 | 500 | 500 | 500 | 500 | 13.2500 | 13.4000 |

| 13 | 1200 | 800 | 500 | 700 | 800 | 14.3000 | 12.8000 |

| 14 | 1500 | 900 | 600 | 500 | 900 | 14.1000 | 12.2500 |

| 15 | 1100 | 600 | 600 | 600 | 600 | 14.2500 | 11.4000 |

| 16 | 1800 | 500 | 500 | 500 | 900 | 11.7500 | 11.5000 |

| 17 | 1200 | 950 | 950 | 950 | 900 | 13.7500 | 11.0000 |

| 18 | 1300 | 650 | 650 | 650 | 900 | 12.6000 | 11.2500 |

| 19 | 1200 | 550 | 550 | 550 | 700 | 11.5000 | 11.1000 |

| 20 | 1500 | 600 | 800 | 600 | 600 | 11.9000 | 11.0000 |

| 21 | 1100 | 600 | 800 | 600 | 600 | 14.5000 | 11.4500 |

| 22 | 1800 | 350 | 800 | 350 | 700 | 16.0000 | 11.8000 |

| 23 | 1200 | 600 | 1000 | 600 | 600 | 12.7000 | 11.7500 |

| 24 | 1300 | 400 | 400 | 800 | 800 | 13.0000 | 12.2500 |

| i | PH1,i (MW) | PH2,i (MW) | PH3,i (MW) | PH4,i (MW) | PT1,i (MW) | PT2,i (MW) | PT3,i (MW) | PT4,i (MW) |

|---|---|---|---|---|---|---|---|---|

| 1 | 44.80801 | 14.16502 | 490.1285 | 87.41643 | 89.3452 | 12.62116 | 88.98154 | 372.5341 |

| 2 | 609.7317 | 143.2493 | 12.82028 | 307.1734 | 23.53235 | 230.9884 | 137.2026 | 35.30191 |

| 3 | 109.6465 | 37.35409 | 2.452622 | 124.6044 | 28.81944 | 257.5346 | 262.3531 | 277.2352 |

| 4 | 118.6829 | 209.1928 | 666.0213 | 297.5565 | 12.51122 | 258.6675 | 166.9801 | 70.38769 |

| 5 | 56.98094 | 45.39613 | 206.5053 | 160.3263 | 78.1622 | 171.7098 | 110.8455 | 370.0738 |

| 6 | 503.2596 | 29.56263 | 129.0674 | 139.9014 | 22.80823 | 14.94842 | 269.5132 | 190.939 |

| 7 | 36.86074 | 25.08108 | 68.49895 | 347.292 | 94.01591 | 54.25231 | 265.6672 | 308.3319 |

| 8 | 354.087 | 119.3664 | 422.4064 | 22.18463 | 10.79384 | 40.37366 | 317.7927 | 212.9954 |

| 9 | 144.103 | 61.76661 | 44.56178 | 516.3614 | 25.04571 | 33.71163 | 15.01317 | 259.4367 |

| 10 | 655.2274 | 16.59057 | 91.88618 | 456.164 | 18.12036 | 176.5345 | 92.90249 | 292.5745 |

| 11 | 278.88 | 388.1928 | 55.58513 | 137.1538 | 91.58185 | 54.79326 | 122.1367 | 71.67637 |

| 12 | 139.7707 | 155.1218 | 691.5244 | 9.54121 | 32.3046 | 26.83425 | 147.7469 | 97.15622 |

| 13 | 303.2588 | 157.3504 | 313.9772 | 31.71765 | 83.83766 | 57.62889 | 109.2016 | 143.0277 |

| 14 | 10.34539 | 272.7907 | 410.6611 | 120.8436 | 18.08671 | 88.22264 | 305.0479 | 274.0019 |

| 15 | 88.28575 | 72.00485 | 91.75589 | 3.615984 | 125.1402 | 258.6483 | 264.4204 | 196.1286 |

| 16 | 202.7669 | 355.5148 | 124.7267 | 413.8378 | 21.4753 | 38.13277 | 185.3267 | 458.2191 |

| 17 | 405.6118 | 173.3598 | 65.81836 | 191.381 | 172.3582 | 81.61249 | 16.90782 | 92.95048 |

| 18 | 53.41923 | 578.2875 | 32.04454 | 36.24217 | 14.19755 | 206.3252 | 17.42234 | 362.0615 |

| 19 | 25.19439 | 55.43374 | 107.4736 | 606.1157 | 10.38145 | 17.65185 | 349.2747 | 28.47448 |

| 20 | 113.4698 | 387.7457 | 218.9941 | 476.7102 | 36.44216 | 61.98075 | 94.40057 | 110.2567 |

| 21 | 21.36867 | 45.56289 | 68.42235 | 0.01089 | 83.52566 | 176.4324 | 517.9546 | 186.7225 |

| 22 | 781.8121 | 182.5285 | 84.45162 | 206.7152 | 12.23156 | 10.00549 | 152.9166 | 369.3391 |

| 23 | 32.86834 | 39.96427 | 319.6729 | 24.81205 | 163.4837 | 28.45411 | 231.0542 | 359.6904 |

| 24 | 488.9518 | 0.799135 | 14.99782 | 405.5991 | 13.56384 | 100.0802 | 197.855 | 78.15313 |

| i | PH1,i (MW) | PH2,i (MW) | PH3,i (MW) | PH4,i (MW) | PT1,i (MW) | PT2,i (MW) | PT3,i (MW) | PT4,i (MW) | PW1,i (MW) | PW2,i (MW) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 16.85933 | 229.55 | 0.134587 | 148.8408 | 159.2501 | 36.35852 | 424.1347 | 31.472 | 99 | 54.4 |

| 2 | 109.9363 | 124.1835 | 450.167 | 129.3755 | 19.29588 | 30.2673 | 195.5862 | 277.1883 | 108 | 56 |

| 3 | 156.1532 | 89.33193 | 29.22211 | 424.3342 | 40.3847 | 18.70972 | 82.69941 | 108.5647 | 93 | 57.6 |

| 4 | 513.1342 | 271.1357 | 94.45502 | 420.9233 | 72.21183 | 249.6429 | 19.60898 | 16.88815 | 82.8 | 59.2 |

| 5 | 51.90915 | 130.3908 | 245.2019 | 379.6717 | 14.69276 | 115.6292 | 98.70234 | 13.80215 | 90 | 60 |

| 6 | 294.8739 | 11.9783 | 196.5268 | 34.98355 | 93.87338 | 35.32824 | 182.5234 | 271.1124 | 106.8 | 72 |

| 7 | 416.6924 | 85.92395 | 8.473279 | 179.9067 | 101.4721 | 22.10531 | 97.93109 | 125.8952 | 81.6 | 80 |

| 8 | 351.3595 | 155.4003 | 202.7161 | 240.5383 | 12.53609 | 48.06011 | 38.52946 | 281.8602 | 93 | 76 |

| 9 | 389.9609 | 30.64644 | 54.04259 | 10.0147 | 102.4636 | 86.01121 | 77.38582 | 190.6748 | 94.8 | 64 |

| 10 | 720.8998 | 144.4804 | 329.3808 | 181.5187 | 93.46645 | 33.37868 | 10.59862 | 129.8766 | 86.4 | 70 |

| 11 | 240.2481 | 189.7078 | 86.89813 | 349.9913 | 24.03108 | 13.15772 | 96.695 | 12.07097 | 120 | 67.2 |

| 12 | 244.4353 | 271.5002 | 395.8987 | 77.36695 | 41.96806 | 47.50929 | 45.08705 | 10.03442 | 99 | 67.2 |

| 13 | 168.0087 | 16.65194 | 56.36502 | 475.7266 | 11.10658 | 12.34142 | 73.02665 | 212.7731 | 111.6 | 62.4 |

| 14 | 388.4088 | 216.0905 | 196.185 | 6.14652 | 29.35371 | 72.20059 | 179.7867 | 244.6281 | 109.2 | 58 |

| 15 | 56.27707 | 87.74482 | 73.2046 | 34.60997 | 52.19771 | 161.4649 | 181.1577 | 291.1432 | 111 | 51.2 |

| 16 | 69.37554 | 645.5049 | 83.869 | 471.2085 | 10.57164 | 87.95043 | 180.7956 | 117.7243 | 81 | 52 |

| 17 | 24.40547 | 27.2146 | 408.8432 | 236.6929 | 27.55716 | 134.5309 | 146.7204 | 41.03535 | 105 | 48 |

| 18 | 402.7853 | 12.41216 | 333.9288 | 4.44101 | 33.34047 | 169.246 | 103.3128 | 99.33338 | 91.2 | 50 |

| 19 | 64.22907 | 202.1967 | 35.74582 | 90.85649 | 14.28666 | 246.1285 | 98.05939 | 321.6974 | 78 | 48.8 |

| 20 | 295.1399 | 75.00936 | 206.4338 | 254.5644 | 83.71423 | 100.8545 | 186.706 | 166.7778 | 82.8 | 48 |

| 21 | 36.08288 | 120.2875 | 402.702 | 24.58846 | 64.47947 | 139.7841 | 41.62437 | 104.8512 | 114 | 51.6 |

| 22 | 0.695207 | 18.65639 | 438.5363 | 708.044 | 58.3994 | 75.50154 | 141.1705 | 184.5967 | 120 | 54.4 |

| 23 | 178.9307 | 341.9207 | 198.9793 | 80.87282 | 22.25196 | 29.93504 | 10.96953 | 189.7399 | 92.4 | 54 |

| 24 | 396.5688 | 69.67454 | 216.289 | 157.7857 | 27.38508 | 154.2192 | 88.0156 | 36.06202 | 96 | 58 |

References

- Nguyen, T.T.; Vu Quynh, N.; Duong, M.Q.; Van Dai, L. Modified differential evolution algorithm: A novel approach to optimize the operation of hydrothermal power systems while considering the different constraints and valve point loading effects. Energies 2018, 11, 540. [Google Scholar] [CrossRef]

- Wood, A.; Wollenberg, B. Power Generation, Operation and Control; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Zaghlool, M.F.; Trutt, F.C. Efficient methods for optimal scheduling of fixed head hydrothermal power systems. IEEE Trans. Power Syst. 1988, 3, 24–30. [Google Scholar] [CrossRef]

- Basu, M. Hopfield neural networks for optimal scheduling of fixed head hydrothermal power systems. Electr. Power Syst. Res. 2003, 64, 11–15. [Google Scholar] [CrossRef]

- Wong, K.P.; Wong, Y.W. Short-term hydrothermal scheduling part. I. Simulated annealing approach. IEE Proc. Gener. Transm. Distrib. 1994, 141, 497–501. [Google Scholar] [CrossRef]

- Yang, P.C.; Yang, H.T.; Huang, C.L. Scheduling short-term hydrothermal generation using evolutionary programming techniques. IEE Proc. Gener. Transm. Distrib. 1996, 143, 371–376. [Google Scholar] [CrossRef]

- Hota, P.K.; Chakrabarti, R.; Chattopadhyay, P.K. Short-term hydrothermal scheduling through evolutionary programming technique. Electr. Power Syst. Res. 1999, 52, 189–196. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tyagi, R.; Singh, S.P. Short term hydrothermal scheduling using evolutionary programming. Int. J. Inv. Res., Eng. Sci. and Tech. 2014, 1, 19–23. [Google Scholar]

- Chang, H.C.; Chen, P.H. Hydrothermal generation scheduling package: A genetic based approach. IEE Proc. Gener. Transm. Distrib. 1998, 145, 451–457. [Google Scholar] [CrossRef][Green Version]

- Sinha, N.; Chakrabarti, R.; Chattopadhyay, P.K. Fast evolutionary programming techniques for short-term hydrothermal scheduling. IEEE Trans. Power Syst. 2003, 18, 214–220. [Google Scholar] [CrossRef]

- Nallasivan, C.; Suman, D.S.; Henry, J.; Ravichandran, S. A novel approach for short-term hydrothermal scheduling using hybrid technique. In Proceedings of the 2006 IEEE Power India Conference, New Delhi, India, 10–12 April 2006; p. 5. [Google Scholar]

- Samudi, C.; Das, G.P.; Ojha, P.C.; Sreeni, T.S.; Cherian, S. Hydro thermal scheduling using particle swarm optimization. In Proceedings of the 2008 IEEE/PES Transmission and Distribution Conference and Exposition, Chicago, IL, USA, 21–24 April 2008; pp. 1–5. [Google Scholar]

- Farhat, I.A.; El-Hawary, M.E. Short-term hydro-thermal scheduling using an improved bacterial foraging algorithm. In Proceedings of the 2009 IEEE Electrical Power & Energy Conference (EPEC), Montreal, QC, Canada, 22–23 October 2009; pp. 1–5. [Google Scholar]

- Thakur, S.; Boonchay, C.; Ongsakul, W. Optimal hydrothermal generation scheduling using self-organizing hierarchical PSO. In Proceedings of the IEEE PES General Meeting, Minneapolis, MN, USA, 26 July 2010; pp. 1–6. [Google Scholar]

- Türkay, B.; Mecitoğlu, F.; Baran, S. Application of a fast evolutionary algorithm to short-term hydro-thermal generation scheduling. Energy Sources Part B Econ. Plan. Policy 2011, 6, 395–405. [Google Scholar] [CrossRef]

- Padmini, S.; Rajan, C.C.A. Improved PSO for Short Term Hydrothermal Scheduling. In Proceedings of the International Conference on Sustainable Energy and Interlligent Systems, Chennai, India, 20–22 July 2011; pp. 332–334. [Google Scholar]

- Padmini, S.; Rajan, C.C.A.; Murthy, P. Application of improved PSO technique for short term hydrothermal generation scheduling of power system. In Proceedings of the International Conference on Swarm, Evolutionary, and Memetic Computing, Visakhapatnam, India, 19–21 December 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 176–182. [Google Scholar]

- Swain, R.K.; Barisal, A.K.; Hota, P.K.; Chakrabarti, R. Short-term hydrothermal scheduling using clonal selection algorithm. Int. J. Electr. Power Energy Syst. 2011, 33, 647–656. [Google Scholar] [CrossRef]

- Fakhar, M.S.; Kashif, S.A.R.; Saqib, M.A.; ul Hassan, T. Non cascaded short-term hydro-thermal scheduling using fully-informed particle swarm optimization. Int. J. Electr. Power Energy Syst. 2015, 73, 983–990. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Vo, D.N.; Ongsakul, W. One rank cuckoo search algorithm for short-term hydrothermal scheduling with reservoir constraint. In Proceedings of the 2015 IEEE Eindhoven PowerTech, Eindhoven, The Netherlands, 29 June–2 July 2015; pp. 1–6. [Google Scholar]

- Nguyen, T.T.; Vo, D.N.; Dinh, B.H. Cuckoo search algorithm using different distributions for short-term hydrothermal scheduling with reservoir volume constraint. Int. J. Electr. Eng. Inform. 2016, 8, 76. [Google Scholar] [CrossRef]

- Dinh, B.H.; Nguyen, T.T.; Vo, D.N. Adaptive cuckoo search algorithm for short-term fixed-head hydrothermal scheduling problem with reservoir volume constraints. Int. J. Grid Distrib. Comput. 2016, 9, 191–204. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Vo, D.N.; Deveikis, T.; Rozanskiene, A. Improved cuckoo search algorithm for nonconvex hydrothermal scheduling with volume constraint. Elektronika ir Elektrotechnika 2017, 23, 68–73. [Google Scholar]

- Nguyen, T.T.; Vo, D.N.; Dinh, B.H. An effectively adaptive selective cuckoo search algorithm for solving three complicated short-term hydrothermal scheduling problems. Energy 2018, 155, 930–956. [Google Scholar] [CrossRef]

- Jadhav, H.T.; Roy, R. Gbest guided artificial bee colony algorithm for environmental/economic dispatch considering wind power. Expert Syst. Appl. 2013, 40, 6385–6399. [Google Scholar] [CrossRef]

- Liu, X. Economic load dispatch constrained by wind power availability: A wait-and-see approach. IEEE Trans. Smart Grid 2010, 1, 347–355. [Google Scholar] [CrossRef]

- Yuan, X.; Tian, H.; Yuan, Y.; Huang, Y.; Ikram, R.M. An extended NSGA-III for solution multi-objective hydro-thermal-wind scheduling considering wind power cost. Energy Convers. Manag. 2015, 96, 568–578. [Google Scholar] [CrossRef]

- Zhou, J.; Lu, P.; Li, Y.; Wang, C.; Yuan, L.; Mo, L. Short-term hydro-thermal-wind complementary scheduling considering uncertainty of wind power using an enhanced multi-objective bee colony optimization algorithm. Energy Convers. Manag. 2016, 123, 116–129. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, W.; Liu, F.; Mei, S. Distributionally robust hydro-thermal-wind economic dispatch. Appl. Energy 2016, 173, 511–519. [Google Scholar] [CrossRef]

- de Moraes, R.A.; Fernandes, T.S.; Arantes, A.G.; Unsihuay-Vila, C. Short-term scheduling of integrated power and spinning reserve of a wind-hydrothermal generation system with ac network security constraints. J. Control. Autom. Electr. Syst. 2018, 29, 1–14. [Google Scholar] [CrossRef]

- Damodaran, S.K.; Sunil Kumar, T.K. Hydro-thermal-wind generation scheduling considering economic and environmental factors using heuristic algorithms. Energies 2018, 11, 353. [Google Scholar] [CrossRef]

- He, Z.; Zhou, J.; Sun, N.; Jia, B.; Qin, H. Integrated scheduling of hydro, thermal and wind power with spinning reserve. Energy Procedia 2019, 158, 6302–6308. [Google Scholar] [CrossRef]

- Cotia, B.P.; Borges, C.L.; Diniz, A.L. Optimization of wind power generation to minimize operation costs in the daily scheduling of hydrothermal systems. Int. J. Electr. Power Energy Syst. 2019, 113, 539–548. [Google Scholar] [CrossRef]

- Daneshvar, M.; Mohammadi-Ivatloo, B.; Zare, K.; Asadi, S. Two-stage stochastic programming model for optimal scheduling of the wind-thermal-hydropower-pumped storage system considering the flexibility assessment. Energy 2020, 193, 116657. [Google Scholar] [CrossRef]

- Dasgupta, K.; Roy, P.K.; Mukherjee, V. Power flow based hydro-thermal-wind scheduling of hybrid power system using sine cosine algorithm. Electr. Power Syst. Res. 2020, 178, 106018. [Google Scholar] [CrossRef]

- Yang, X.S.; Deb, S. Cuckoo search via Lévy flights. In Proceedings of the 2009 World Congress on Nature & Biologically Inspired Computing (NaBIC) IEEE, Coimbatore, India, 9–11 December 2009; pp. 210–214. [Google Scholar]

- Rakhshani, H.; Rahati, A. Snap-drift cuckoo search: A novel cuckoo search optimization algorithm. Appl. Soft Comput. 2017, 52, 771–794. [Google Scholar] [CrossRef]

- Mohammadi, F.; Zheng, C. Stability Analysis of Electric Power System. In Proceedings of the 4th National Conference on Technology in Electrical and Computer Engineering, Tehran, Iran, 27 December 2018. [Google Scholar]

- Mohammadi, F.; Nazri, G.-A.; Saif, M. A bidirectional power charging control strategy for plug-in hybrid electric vehicles. Sustainability 2019, 11, 4317. [Google Scholar] [CrossRef]

- Mohammadi, F.; Nazri, G.-A.; Saif, M. An improved droop-based control strategy for MT-HVDC systems. Electronics 2020, 9, 87. [Google Scholar] [CrossRef]

- Mohammadi, F.; Nazri, G.-A.; Saif, M. An improved mixed AC/DC power flow algorithm in hybrid AC/DC grids with MT-HVDC systems. Appl. Sci. 2020, 10, 297. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Mohammadi, F. Optimal placement of TCSC for congestion management and power loss reduction using multi-objective genetic algorithm. Sustainability 2020, 12, 2813. [Google Scholar] [CrossRef]

- Shojaei, A.H.; Ghadimi, A.A.; Miveh, M.R.; Mohammadi, F.; Jurado, F. Multi-Objective Optimal Reactive Power Planning under Load Demand and Wind Power Generation Uncertainties Using ε-Constraint Method. Appl. Sci. 2020, 10, 2859. [Google Scholar] [CrossRef]

- Yao, F.; Dong, Z.Y.; Meng, K.; Xu, Z.; Iu, H.H.C.; Wong, K.P. Quantum-inspired particle swarm optimization for power system operations considering wind power uncertainty and carbon tax in Australia. IEEE Trans. Ind. Inform. 2012, 8, 880–888. [Google Scholar] [CrossRef]

- Zhang, H.; Yue, D.; Xie, X.; Dou, C.; Sun, F. Gradient decent based multi-objective cultural differential evolution for short-term hydrothermal optimal scheduling of economic emission with integrating wind power and photovoltaic power. Energy 2017, 122, 748–766. [Google Scholar] [CrossRef]

| Method | CSA | SDCSA | MASCSA |

|---|---|---|---|

| Minimum Cost ($) | 35640.09 | 35550.06 | 35447.25 |

| Average Cost ($) | 36835.21 | 36694.27 | 36355.55 |

| Maximum Cost ($) | 38616.82 | 38595.07 | 37533.4 |

| Std. Dev. ($) | 595.36 | 628.65 | 458.1301 |

| Computation Time (s) | 437.30 | 498.71 | 457.92 |

| Success Rate | 50/70 | 50/50 | 50/50 |

| Method | CSA | SDCSA | MASCSA |

|---|---|---|---|

| Minimum Cost ($) | 27890.67 | 27628.06 | 27205.16 |

| Average Cost ($) | 28682.37 | 28576.17 | 28109.42 |

| Maximum Cost ($) | 29793.52 | 29638.01 | 29346.04 |

| Std. Dev. | 471.41 | 494.50 | 421.88 |

| Computation Time (s) | 440.5 | 499. 1 | 462.4 |

| Success Rate (%) | 50/72 | 50/65 | 50/50 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.T.; Pham, L.H.; Mohammadi, F.; Kien, L.C. Optimal Scheduling of Large-Scale Wind-Hydro-Thermal Systems with Fixed-Head Short-Term Model. Appl. Sci. 2020, 10, 2964. https://doi.org/10.3390/app10082964

Nguyen TT, Pham LH, Mohammadi F, Kien LC. Optimal Scheduling of Large-Scale Wind-Hydro-Thermal Systems with Fixed-Head Short-Term Model. Applied Sciences. 2020; 10(8):2964. https://doi.org/10.3390/app10082964

Chicago/Turabian StyleNguyen, Thang Trung, Ly Huu Pham, Fazel Mohammadi, and Le Chi Kien. 2020. "Optimal Scheduling of Large-Scale Wind-Hydro-Thermal Systems with Fixed-Head Short-Term Model" Applied Sciences 10, no. 8: 2964. https://doi.org/10.3390/app10082964

APA StyleNguyen, T. T., Pham, L. H., Mohammadi, F., & Kien, L. C. (2020). Optimal Scheduling of Large-Scale Wind-Hydro-Thermal Systems with Fixed-Head Short-Term Model. Applied Sciences, 10(8), 2964. https://doi.org/10.3390/app10082964