Development of Control System for Automated Manual Transmission of 45-kW Agricultural Tractor

Abstract

1. Introduction

2. Experimental Design

3. Materials and Methods

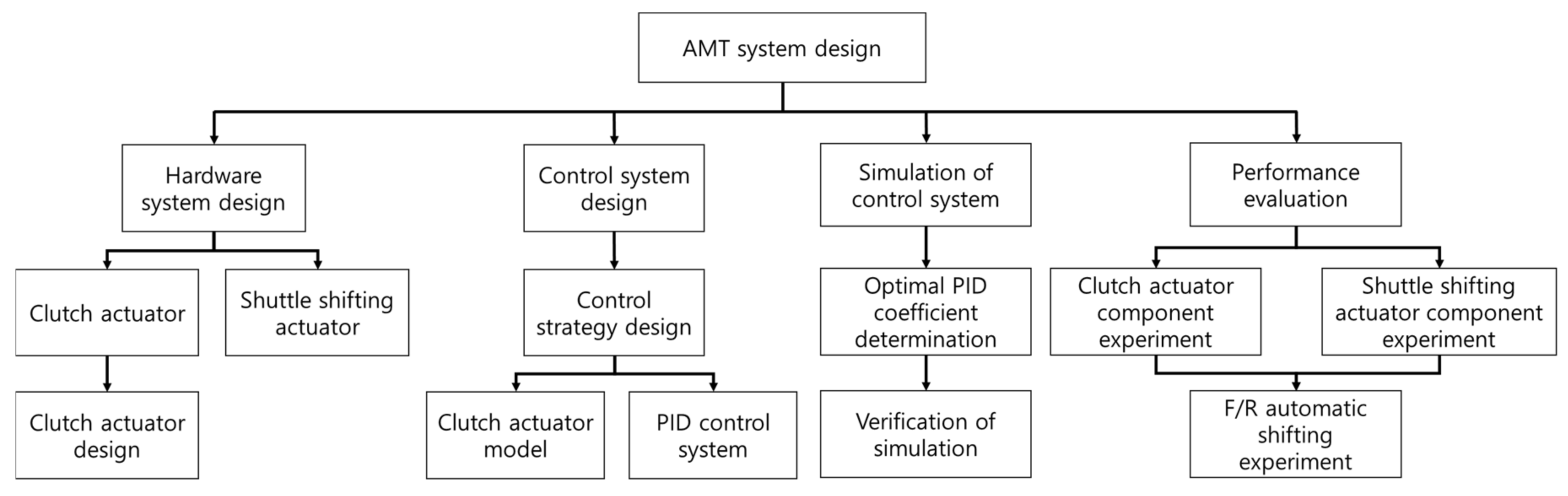

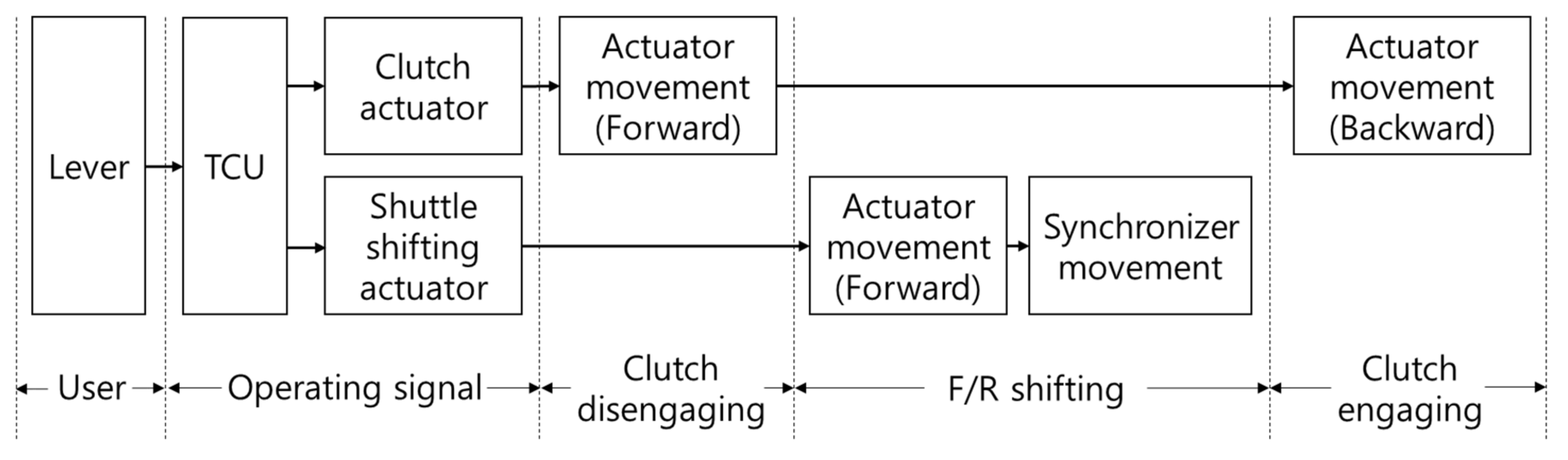

3.1. AMT System Design

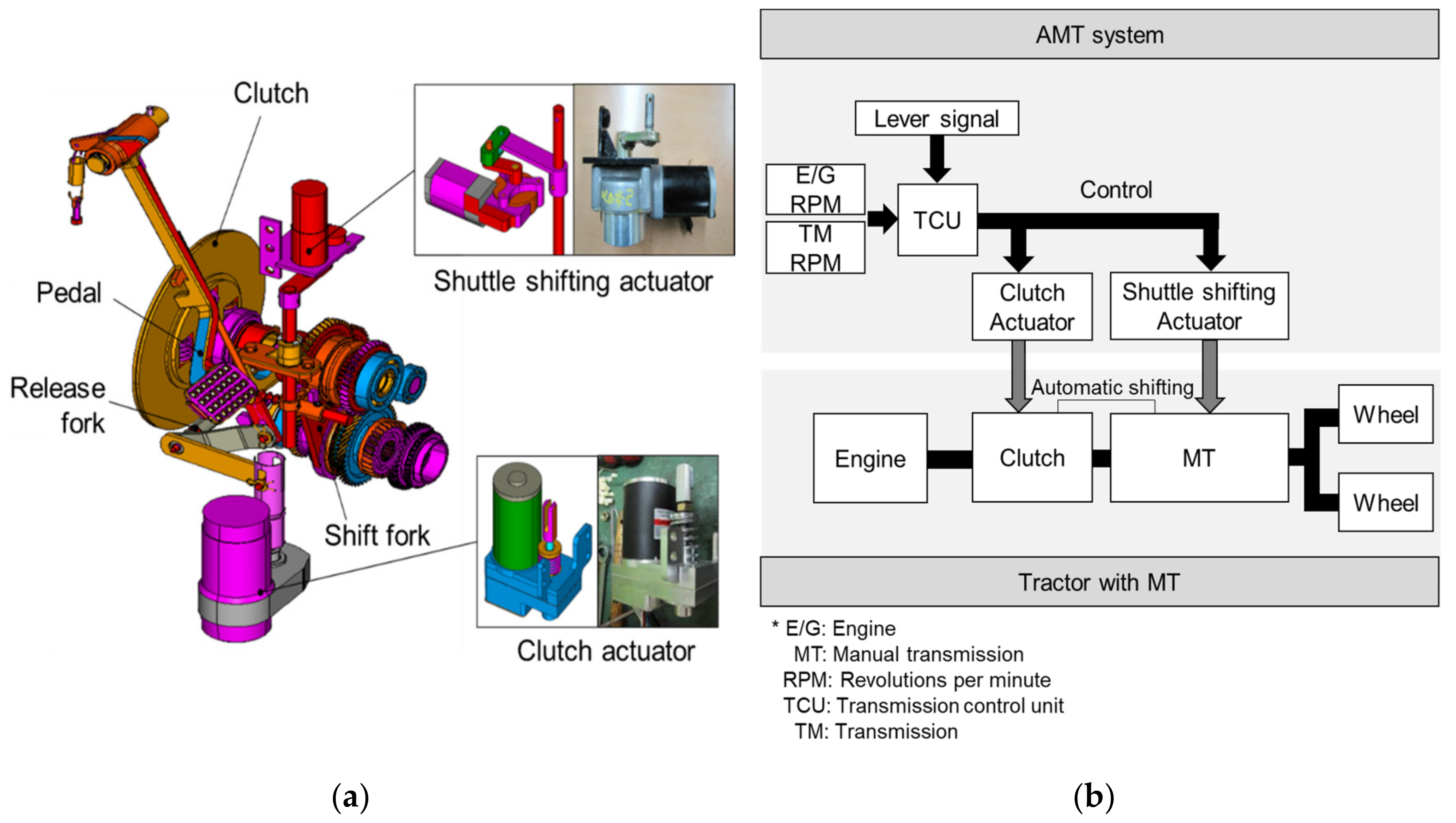

3.2. Hardware System Design

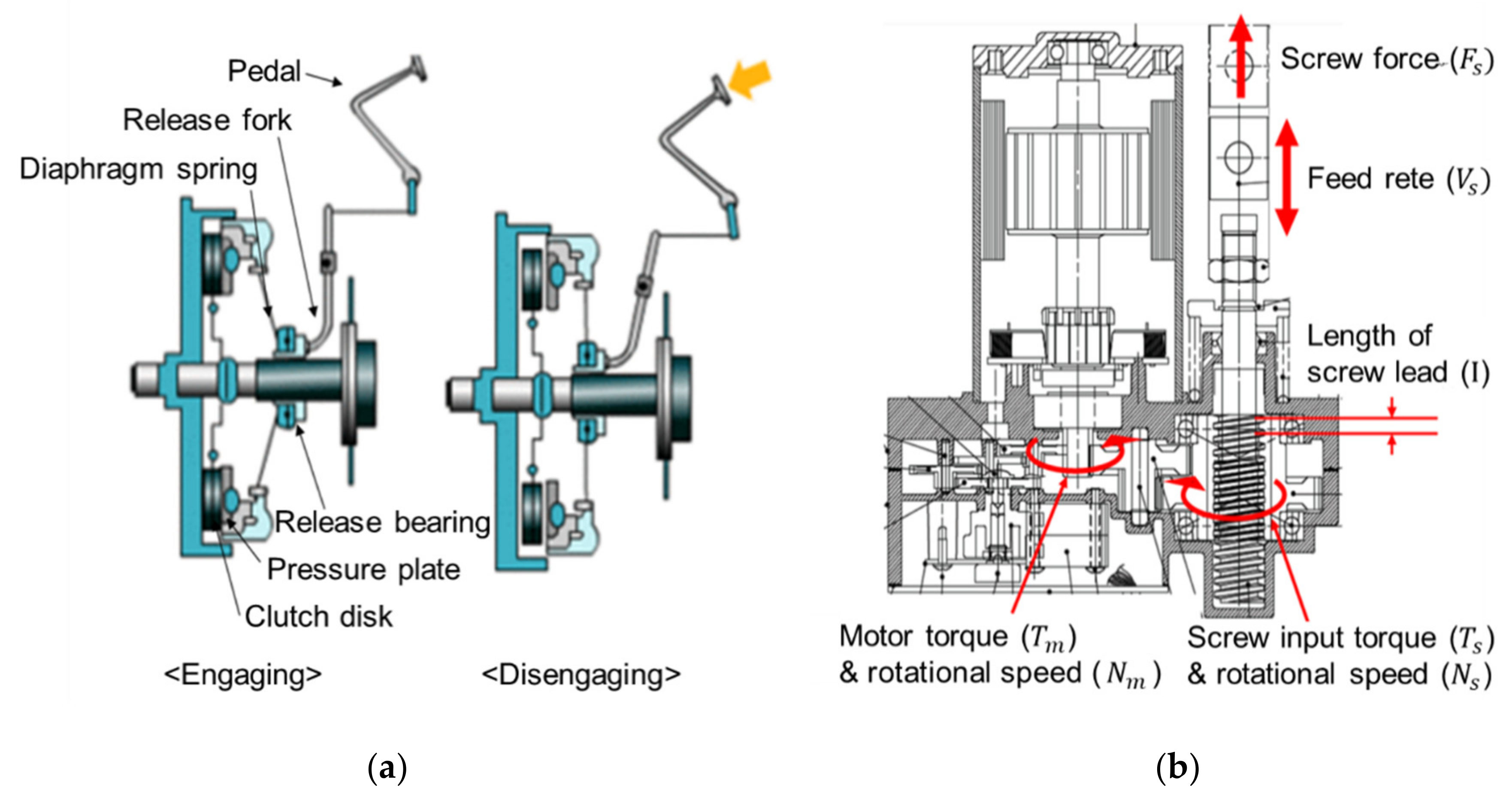

3.2.1. Clutch Actuator

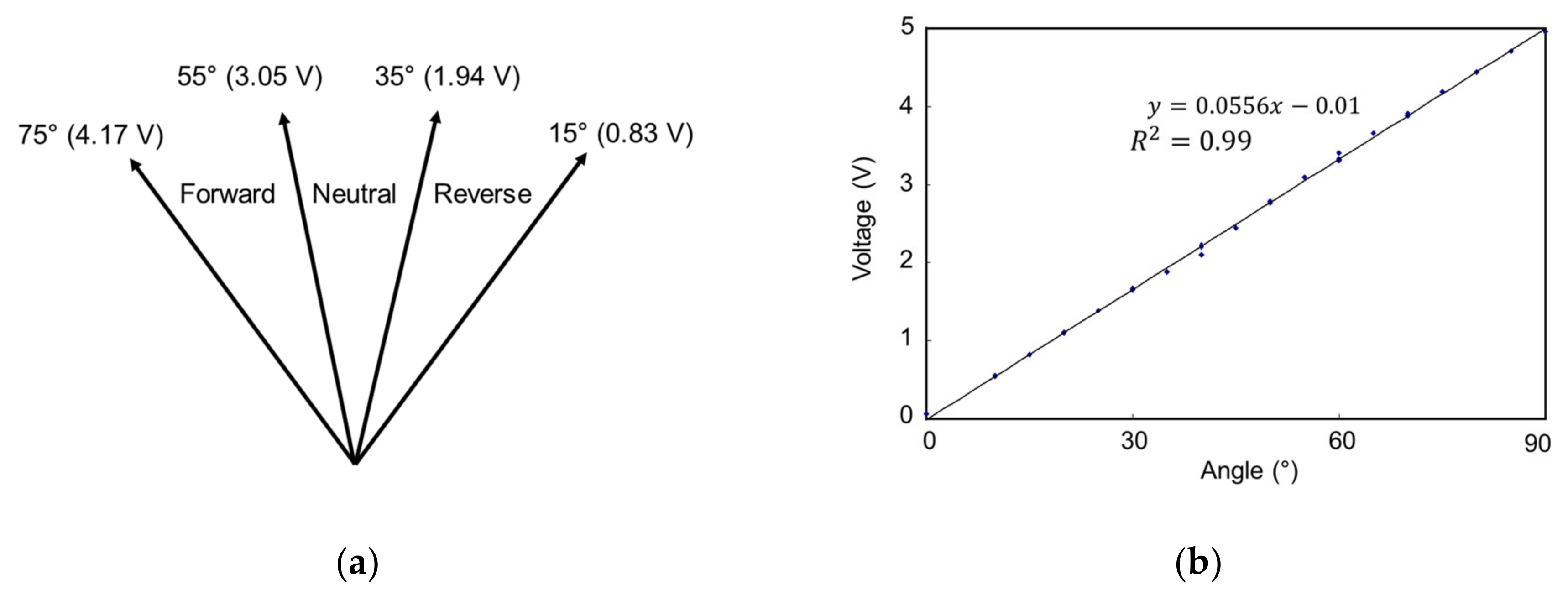

3.2.2. Shuttle Shifting Actuator

3.3. Control System Design

3.3.1. Control Strategy

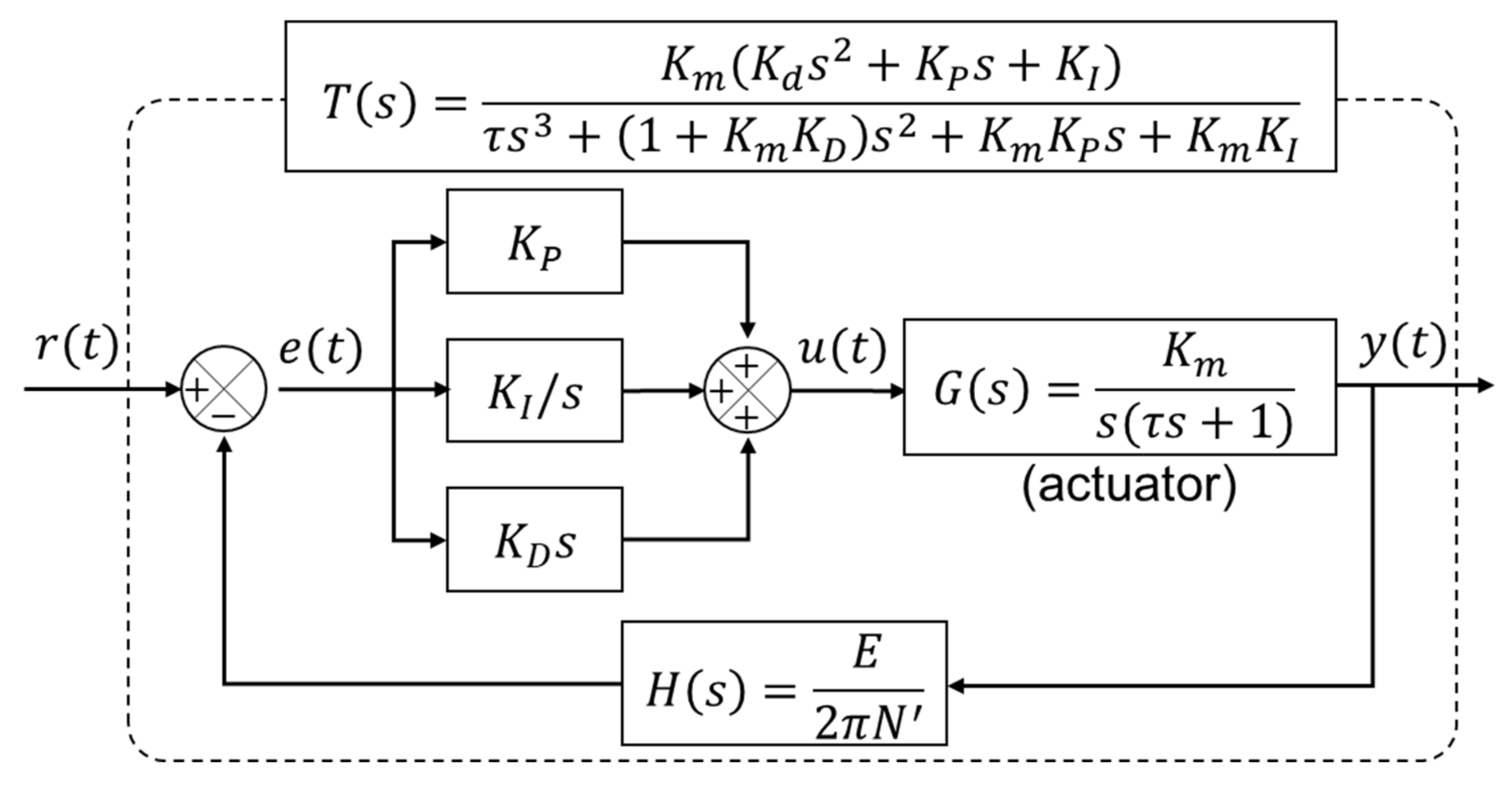

3.3.2. Clutch and Actuator Model

3.3.3. PID Control System

3.3.4. PID Coefficient Determination

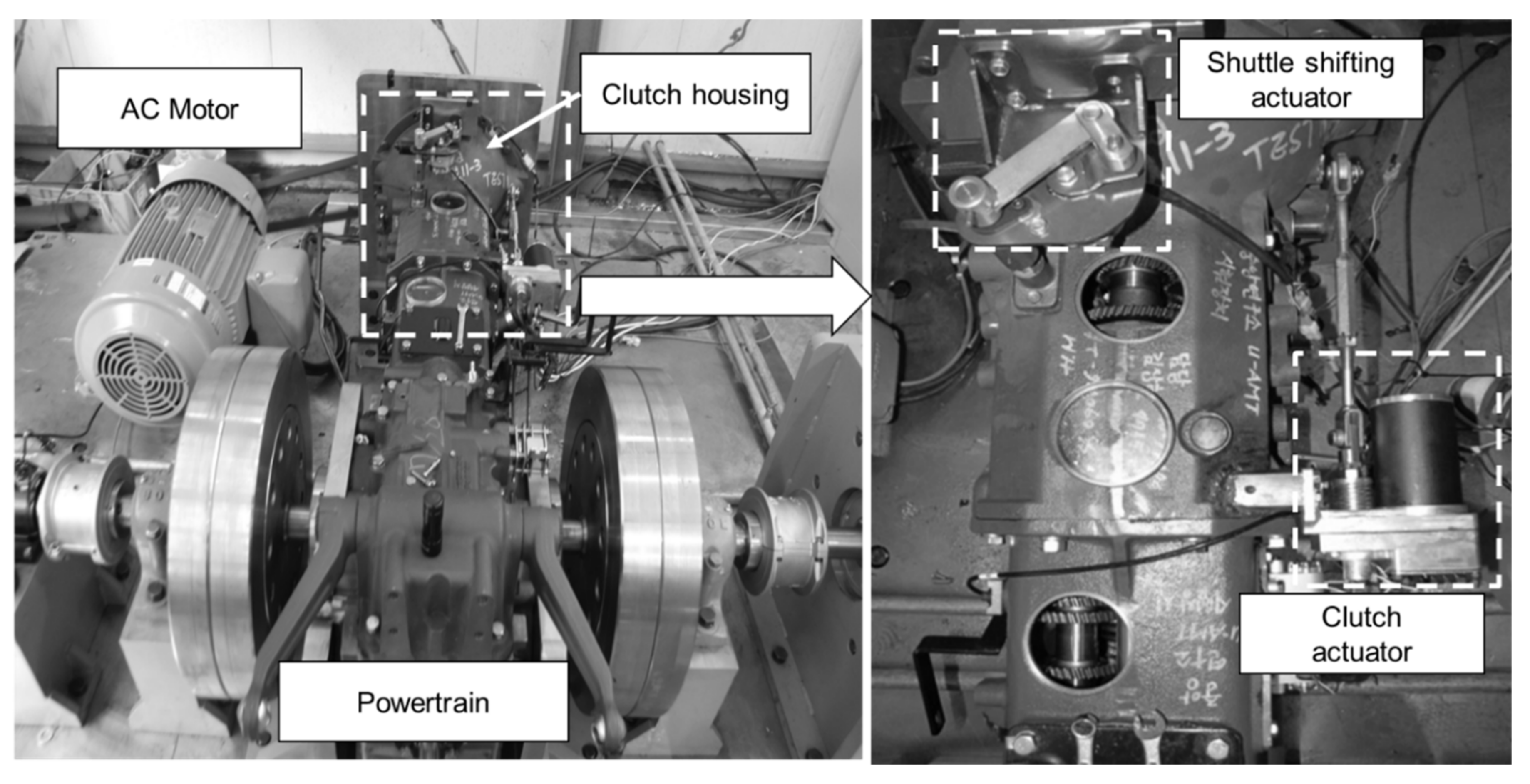

3.4. Experimental Test-Bed

3.5. Experiment Method

3.5.1. Simulation and Laboratory Experiment

3.5.2. Actuator Component Performance

3.5.3. F/R Automatic Shifting Performance

4. Results and Discussion

4.1. Simulation of Control System

4.1.1. Initial PID Coefficients

4.1.2. Determination of Optimal PID Coefficient

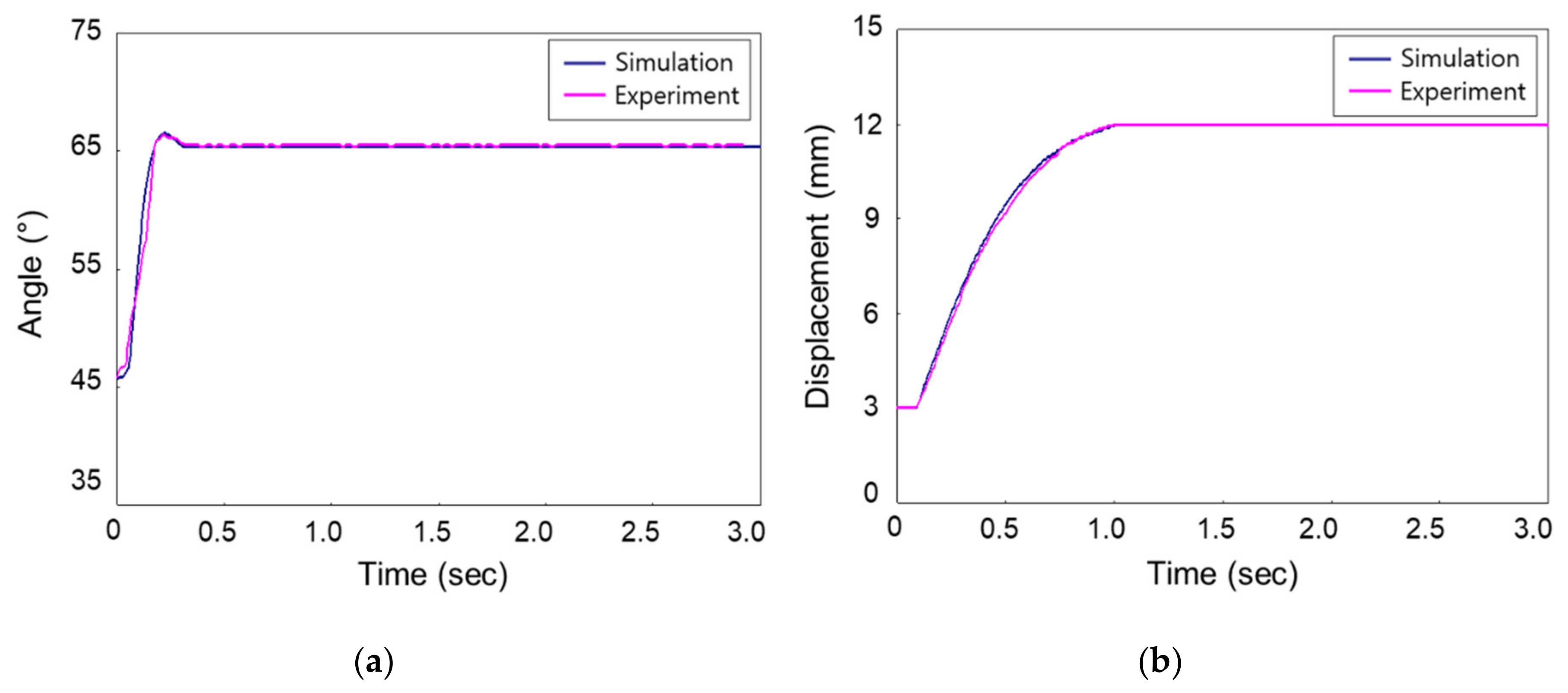

4.1.3. Verification of Simulation

4.2. Performance Evaluation of Actuator Component

4.2.1. Clutch Actuator

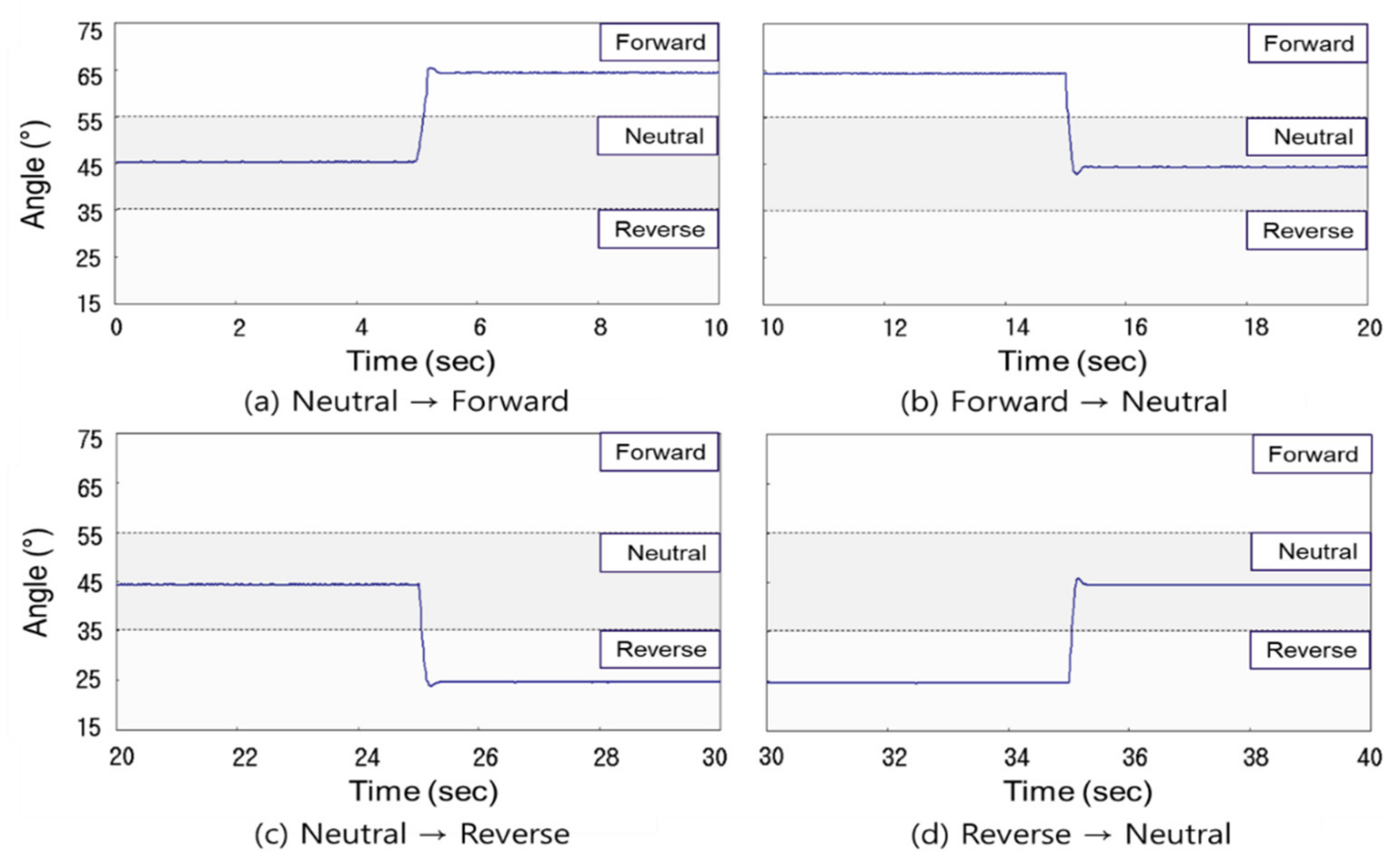

4.2.2. Shuttle Shifting Actuator

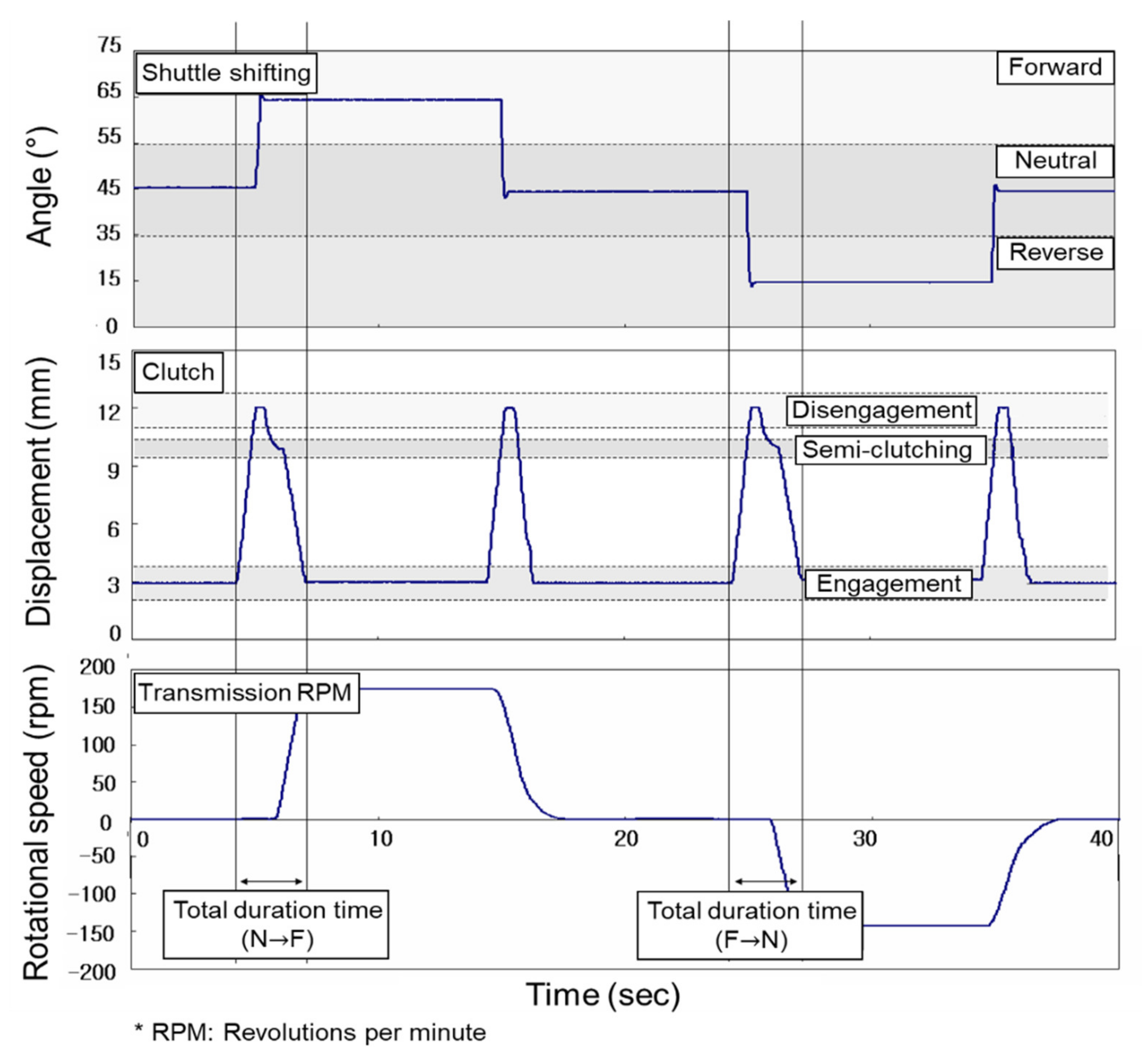

4.3. Performance Evaluation of F/R Automatic Shifting

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, W.S.; Kim, Y.J.; Park, S.U.; Hong, S.J.; Kim, Y.S. Evaluation of PTO severeness for 78 kW-class tractor according to disk plow tillage and rotary tillage. J. Drive Control 2019, 16, 23–31. [Google Scholar]

- Kim, W.S.; Baek, S.Y.; Kim, T.J.; Kim, Y.S.; Park, S.U.; Choi, C.H.; Hong, S.J.; Kim, Y.J. Work load analysis for determination of the reduction gear ratio for a 78 kW all wheel drive electric tractor design. Korean J. Agric. Sci. 2019, 46, 613–627. [Google Scholar]

- Islam, N.; Iqbal, Z.; Kabir, S.N.; Jung, K.Y.; Mun, D.H.; Chung, S.O. Performance evaluation of trenchless subsurface drainage piping machine. J. Biosyst. Eng. 2019, 44, 218–225. [Google Scholar] [CrossRef]

- Mordor Intelligence. Uility Tractors Market–Growth, Trends, and Forecast (2020-2025); Mordor Intelligence: Hyderabad, India, 2020; Available online: https://www.mordorintelligence.com/industry-reports/utility-tractor-markethttps://www.mordorintelligence.com/industry-reports/india-agricultural-tractor-machinery-market (accessed on 23 April 2020).

- Jang, J.H.; Kim, W.S.; Choi, C.H.; Park, S.U.; Kim, Y.J. Analysis of power requirement of the underground crop harvester attached on agricultural tractor during traction operation. Korea Inf. Electron. Commun. Technol. 2018, 11, 150–155. [Google Scholar]

- Rossetti, A.; Macor, A. Control strategies for a powertrain with hydromechanical transmission. Energy Procedia 2018, 148, 978–985. [Google Scholar] [CrossRef]

- Kim, W.S.; Kim, Y.S.; Kim, T.J.; Park, S.U.; Choi, Y.; Choi, I.S.; Kim, Y.K.; Kim, Y.J. Analysis of power requirement of 78 kW class agricultural tractor according to the major field operation. Trans. Korean Soc. Mech. Eng. A 2019, 43, 911–922. [Google Scholar] [CrossRef]

- Lee, N.G.; Kim, Y.J.; Kim, W.S.; Kim, Y.S.; Kim, T.J.; Baek, S.M.; Choi, Y.; Kim, Y.K.; Choi, I.S. Study on the improvement of transmission error and tooth load distribution using micro-geometry of compound planetary gear reducer for tractor final driving shaft. J. Drive Control 2020, 17, 1–12. [Google Scholar]

- Kim, T.J.; Kim, W.S.; Kim, Y.S.; Chung, S.O.; Park, S.U.; Hong, S.J.; Choi, C.H.; Kim, Y.J. Strength analysis of mechanical transmission using equivalent torque of plow tillage of an 82 kW-class tractor. Korean J. Agric. Sci. 2019, 46, 723–735. [Google Scholar]

- İnce, E.; Güler, M.A. On the advantages of the new power-split infinitely variable transmission over conventional mechanical transmissions based on fuel consumption analysis. J. Clean. Prod. 2020, 244, 118795. [Google Scholar] [CrossRef]

- Wang, G.; Song, Y.; Wang, J.; Chen, W.; Cao, Y.; Wang, J. Study on the shifting quality of the CVT tractor under hydraulic system failure. Appl. Sci. 2020, 10, 681. [Google Scholar] [CrossRef]

- Janulevičius, A.; Giedra, K. Analysis of main dynamic parameters of split power transmission. Transport 2008, 23, 112–118. [Google Scholar] [CrossRef]

- Xia, Y.; Sun, D.; Qin, D.; Zhou, X. Optimisation of the power-cycle hydro-mechanical parameters in a continuously variable transmission designed for agricultural tractors. Biosyst. Eng. 2020, 193, 12–24. [Google Scholar] [CrossRef]

- Kim, D.M.; Kim, S.C.; Noh, D.K.; Jang, J.S. Jerk phenomenon of the hydrostatic transmission through the experiment and analysis. Int. J. Automot. Technol. 2015, 16, 783–790. [Google Scholar] [CrossRef]

- Renius, K.T.; Resch, R. Continuously variable transmissions. In Proceedings of the 2005 Agricultural Equipment Technology Conference, Louisville, Kentucky, USA, 14–16 February 2005; Volume 29, pp. 1–37. [Google Scholar]

- Galvagno, E.; Velardocchia, M.; Vigliani, A. Analysis and simulation of a torque assist automated manual transmission. Mech. Syst. Signal Process. 2011, 25, 1877–1886. [Google Scholar] [CrossRef]

- Kim, Y.J.; Chung, S.O.; Choi, C.H. Effects of gear selection of an agricultural tractor on transmission and PTO load during rotary tillage. Soil Tillage Res. 2013, 134, 90–96. [Google Scholar] [CrossRef]

- Li, C.; Ke, M.; Wu, Y. Research and implementation of tractor power shift clutch control system. In Proceedings of the MATEC Web of Conferences, Kuala Lumpur, Malaysia, 28–30 February 2017; Volume 153, p. 04003. [Google Scholar]

- Xu, L.Y.; Zhang, Y.H.; Shi, J.Z.; Yan, X.H. Optimization of power shift tractor clutch based on ahp and improved genetic algorithm. Acta Tech. 2017, 62, 373–384. [Google Scholar]

- Raikwar, S.; Tewari, V.K.; Mukhopadhyay, S.; Verma, C.R.B.; Rao, M. Simulation of components of a power shuttle transmission system for an agricultural tractor. Comput. Electron. Agric. 2015, 114, 114–124. [Google Scholar] [CrossRef]

- Tanelli, M.; Panzani, G.; Savaresi, S.M.; Pirola, C. Transmission control for power-shift agricultural tractors: Design and end-of-line automatic tuning. Mechatronics 2011, 21, 285–297. [Google Scholar]

- Kim, D.C.; Kim, K.U.; Park, Y.J.; Huh, J.Y. Analysis of shifting performance of power shuttle transmission. J. Terramech. 2007, 44, 111–122. [Google Scholar] [CrossRef]

- Molari, G.; Sedoni, E. Experimental evaluation of power losses in a power-shift agricultural tractor transmission. Biosyst. Eng. 2008, 100, 177–183. [Google Scholar] [CrossRef]

- Li, B.; Sun, D.; Hu, M.; Zhou, X.; Liu, J.; Wang, D. Coordinated control of gear shifting process with multiple clutches for power-shift transmission. Mech. Mach. Theory 2019, 140, 274–291. [Google Scholar] [CrossRef]

- Li, B.; Sun, D.; Hu, M.; Liu, J. Research on economic comprehensive control strategies of tractor-planter combinations in planting, including gear-shift and cruise control. Energies 2018, 11. [Google Scholar] [CrossRef]

- Li, B.; Sun, D.; Hu, M.; Zhou, X.; Wang, D.; Xia, Y.; You, Y. Automatic gear-shifting strategy for fuel saving by tractors based on real-time identification of draught force characteristics. Biosyst. Eng. 2020, 193, 46–61. [Google Scholar] [CrossRef]

- Zhao, M.; Shi, J.; Lin, C.; Zhang, J. Application-oriented optimal shift schedule extraction for a dual-motor electric bus with automated manual transmission. Energies 2018, 11, 325. [Google Scholar] [CrossRef]

- Carbone, G.; Mangialardi, L.; Mantriota, G. Fuel consumption of a mid class vehicle with infinitely variable transmission. SAE Int. J. Engines 2001, 110, 2474–2483. [Google Scholar]

- Li, L.; He, K.; Wang, X.; Liu, Y. Sensor fault-tolerant control for gear-shifting engaging process of automated manual transmission. Mech. Syst. Signal Process. 2018, 99, 790–804. [Google Scholar] [CrossRef]

- Choi, C.H.; Woo, M.N.; Lee, D.H.; Kim, Y.J.; Jeong, J.H. Development of electric actuator position control system for automatic shuttle shifting of tractor. J. Biosyst. Eng. 2010, 35, 224–230. [Google Scholar] [CrossRef]

- Van Berkel, K.; Hofman, T.; Serrarens, A.; Steinbuch, M. Fast and smooth clutch engagement control for dual-clutch transmissions. Control Eng. Pract. 2014, 22, 57–68. [Google Scholar] [CrossRef]

- Sun, Z.; Gao, B.; Jin, J.; Sanada, K. Modelling, analysis and simulation of a novel automated manual transmission with gearshift assistant mechanism. Int. J. Automot. Technol. 2019, 20, 885–895. [Google Scholar] [CrossRef]

- Gao, B.Z.; Chen, H.; Sanada, K.; Hu, Y. Design of clutch-slip controller for automatic transmission using backstepping. IEEE/ASME Trans. Mechatron. 2011, 16, 498–508. [Google Scholar] [CrossRef]

- Hu, Y.; Tian, L.; Gao, B.; Chen, H. Nonlinear gearshifts control of dual-clutch transmissions during inertia phase. ISA Trans. 2014, 53, 1320–1331. [Google Scholar] [CrossRef] [PubMed]

- Glielmo, L.; Iannelli, L.; Vacca, V.; Vasca, F. Gear shift control for automated manual transmissions. IEEE/ASME Trans. Mechatron. 2006, 11, 17–26. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, D.; Jiang, H.; Zhang, Y. Shift control strategy and experimental validation for dry dual clutch transmissions. Mech. Mach. Theory 2014, 75, 41–53. [Google Scholar] [CrossRef]

- Zhang, J.; Ni, Q.; Xu, L.; Liu, J. Shifting control strategy of a tractor AMT system. Aust. J. Mech. Eng. 2018, 16, 9–15. [Google Scholar] [CrossRef]

- Xu, L.; Zhao, Y.; Zhou, Z.; Xi, Z.; Xing, M. Research on the law of AMT tractor clutch engagement at starting condition. Adv. Mater. Res. 2012, 482–484, 1418–1425. [Google Scholar] [CrossRef]

- Dogan, O.; Karpat, F.; Yuce, C.; Kaya, N.; Yavuz, N.; Sen, H. A novel design procedure for tractor clutch fingers by using optimization and response surface methods. J. Mech. Sci. Technol. 2016, 30, 2615–2625. [Google Scholar] [CrossRef]

- Zhong, Z.; Kong, G.; Yu, Z.; Chen, X.; Chen, X.; Xin, X. Concept evaluation of a novel gear selector for automated manual transmissions. Mech. Syst. Signal Process. 2012, 31, 316–331. [Google Scholar] [CrossRef]

- Oh, J.Y.; Song, C.S. Development of Automated Mechanical Transmission Model to Evaluate TCU Control Logic. J. Korean Soc. Precis. Eng. 2010, 27, 118–126. [Google Scholar]

- Horn, J.; Bamberger, J.; Michau, P.; Pindl, S. Flatness-based clutch control for automated manual transmissions. Control Eng. Pract. 2003, 11, 1353–1359. [Google Scholar] [CrossRef]

- Siddique, A.A.; Kim, W.S.; Baek, S.Y.; Kim, Y.S.; Choi, C.H.; Kim, Y.J.; Park, J.K. Determination of PID coefficients for the ascending and descending system using proportional valve of a rice transplanter. J. Biosyst. Eng. 2018, 43, 331–341. [Google Scholar]

- Sasane, A. An abstract Nyquist criterion containing old and new results. J. Math. Anal. Appl. 2010, 370, 703–715. [Google Scholar] [CrossRef]

| Range shift | 2nd | 3rd | |||||||

| Driving shift | 1st | 2nd | 3rd | 4th | 1st | 2nd | 3rd | 4th | |

| Rotational speed | Forward | 66 | 79 | 93 | 124 | 147 | 174 | 205 | 276 |

| Reverse | 55 | 65 | 76 | 102 | 121 | 143 | 168 | 225 | |

| Actuator | Parameters | Max. Overshoot (%) | Settling Time (s) | Steady-State Error (%) |

|---|---|---|---|---|

| Shuttle shifting | KP=6.30, KI=4.80, KD=0.155 | 8.50 | 1.18 | 0.00 |

| KP=6.50, KI=5.70, KD=0.240 | 3.00 | 0.44 | 0.00 | |

| KP=6.70, KI=6.05, KD=0.330 | 1.50 | 3.74 | 4.50 | |

| Clutch | KP=1.25, KI=2.85, KD=0.065 | 0.00 | 2.50 | 0.00 |

| KP=1.45, KI=3.45, KD=0.190 | 0.00 | 1.06 | 0.00 | |

| KP=1.65, KI=4.15, KD=0.325 | 0.00 | 1.68 | 0.00 |

| Actuator | Max. Overshoot (%) | Settling Time (s) | Steady-State Error (%) | |||

|---|---|---|---|---|---|---|

| Simulation | Experiment | Simulation | Experiment | Simulation | Experiment | |

| Shuttle shifting | 3.00 | 3.03 ± 0.02 | 0.44 | 0.42 ± 0.01 | 0.00 | 0.002 ± 0.001 |

| Clutch | 0.00 | 0.00 ± 0.00 | 1.06 | 1.04 ± 0.01 | 0.00 | 0.002 ± 0.001 |

| Range Shift | Driving Shift | Max. Overshoot (%) | Settling Time (s) | Steady-State Error (%) | ||

|---|---|---|---|---|---|---|

| Partially Engaging (a) | Fully Engaging (b) | Total (a + b) | ||||

| 2nd | 1st | 0.00 ± 0.00 | 0.49 ± 0.02 | 0.97 ± 0.02 | 1.46 ± 0.04 | 0.14 ± 0.028 |

| 2nd | 0.00 ± 0.00 | 0.51 ± 0.03 | 0.92 ± 0.02 | 1.43 ± 0.04 | 0.11 ± 0.022 | |

| 3rd | 0.00 ± 0.00 | 0.53 ± 0.03 | 0.93 ± 0.01 | 1.46 ± 0.03 | 0.19 ± 0.125 | |

| 4th | 0.00 ± 0.00 | 0.51 ± 0.02 | 0.92 ± 0.02 | 1.43 ± 0.04 | 0.12 ± 0.034 | |

| 3rd | 1st | 0.00 ± 0.00 | 0.49 ± 0.01 | 0.89 ± 0.01 | 1.37 ± 0.02 | 0.15 ± 0.064 |

| 2nd | 0.00 ± 0.00 | 0.50 ± 0.02 | 0.91 ± 0.01 | 1.41 ± 0.03 | 0.23 ± 0.189 | |

| 3rd | 0.00 ± 0.00 | 0.50 ± 0.02 | 0.91 ± 0.01 | 1.41 ± 0.02 | 0.36 ± 0.071 | |

| 4th | 0.00 ± 0.00 | 0.49 ± 0.03 | 1.00 ± 0.01 | 1.49 ± 0.05 | 0.26 ± 0.170 | |

| Control Direction | Max. Overshoot (%) | Settling Time (s) | Steady-State Error (%) |

|---|---|---|---|

| Neutral → Forward | 2.58 ± 0.035 | 0.43 ± 0.012 | 0.04 ± 0.003 |

| Forward → Neutral | 3.11 ± 0.085 | 0.37 ± 0.023 | 0.03 ± 0.005 |

| Neutral → Reverse | 3.36 ± 0.068 | 0.40 ± 0.020 | 0.02 ± 0.010 |

| Reverse → Neutral | 2.78 ± 0.040 | 0.31 ± 0.012 | 0.03 ± 0.005 |

| Shifting Condition | Range Shift | Driving Shift | Total Duration Time (s) | RPM Reaching Time (s) | Transmission RPM (rpm) |

|---|---|---|---|---|---|

| Neutral → Forward | 2nd | 1st | 2.40 ± 0.04 | 2.63 ± 0.05 | 66.3 ± 0.05 |

| 2nd | 2.35 ± 0.05 | 2.59 ± 0.04 | 79.1 ± 0.10 | ||

| 3rd | 2.40 ± 0.04 | 2.65 ± 0.03 | 93.1 ± 0.13 | ||

| 4th | 2.38 ± 0.07 | 2.65 ± 0.08 | 124.1 ± 0.15 | ||

| 3rd | 1st | 2.29 ± 0.03 | 2.62 ± 0.04 | 147.1 ± 0.03 | |

| 2nd | 2.36 ± 0.03 | 2.69 ± 0.03 | 174.0 ± 0.20 | ||

| 3rd | 2.37 ± 0.03 | 2.75 ± 0.03 | 204.8 ± 0.25 | ||

| 4th | 2.43 ± 0.06 | 2.88 ± 0.05 | 274.0 ± 0.22 | ||

| Neutral → Reverse | 2nd | 1st | 2.39 ± 0.05 | 2.61 ± 0.08 | 55.0 ± 0.15 |

| 2nd | 2.33 ± 0.06 | 2.55 ± 0.06 | 65.0 ± 0.10 | ||

| 3rd | 2.38 ± 0.04 | 2.60 ± 0.03 | 75.8 ± 0.65 | ||

| 4th | 2.37 ± 0.06 | 2.63 ± 0.08 | 102.0 ± 0.06 | ||

| 3rd | 1st | 2.29 ± 0.04 | 2.58 ± 0.03 | 121.6 ± 0.47 | |

| 2nd | 2.36 ± 0.03 | 2.63 ± 0.03 | 143.6 ± 0.32 | ||

| 3rd | 2.37 ± 0.04 | 2.73 ± 0.05 | 168.2 ± 0.36 | ||

| 4th | 2.41 ± 0.03 | 2.81 ± 0.05 | 225.1 ± 0.30 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, W.-S.; Kim, Y.-J.; Kim, Y.-S.; Baek, S.-Y.; Baek, S.-M.; Lee, D.-H.; Nam, K.-C.; Kim, T.-B.; Lee, H.-J. Development of Control System for Automated Manual Transmission of 45-kW Agricultural Tractor. Appl. Sci. 2020, 10, 2930. https://doi.org/10.3390/app10082930

Kim W-S, Kim Y-J, Kim Y-S, Baek S-Y, Baek S-M, Lee D-H, Nam K-C, Kim T-B, Lee H-J. Development of Control System for Automated Manual Transmission of 45-kW Agricultural Tractor. Applied Sciences. 2020; 10(8):2930. https://doi.org/10.3390/app10082930

Chicago/Turabian StyleKim, Wan-Soo, Yong-Joo Kim, Yeon-Soo Kim, Seung-Yun Baek, Seung-Min Baek, Dae-Hyun Lee, Kyu-Chul Nam, Tae-Bum Kim, and Hyo-Jai Lee. 2020. "Development of Control System for Automated Manual Transmission of 45-kW Agricultural Tractor" Applied Sciences 10, no. 8: 2930. https://doi.org/10.3390/app10082930

APA StyleKim, W.-S., Kim, Y.-J., Kim, Y.-S., Baek, S.-Y., Baek, S.-M., Lee, D.-H., Nam, K.-C., Kim, T.-B., & Lee, H.-J. (2020). Development of Control System for Automated Manual Transmission of 45-kW Agricultural Tractor. Applied Sciences, 10(8), 2930. https://doi.org/10.3390/app10082930