Development of Equipment and Application of Machine Learning Techniques Using Frequency Response Data for Cap Damage Detection of Porcelain Insulators

Abstract

1. Introduction

2. Materials and Methods

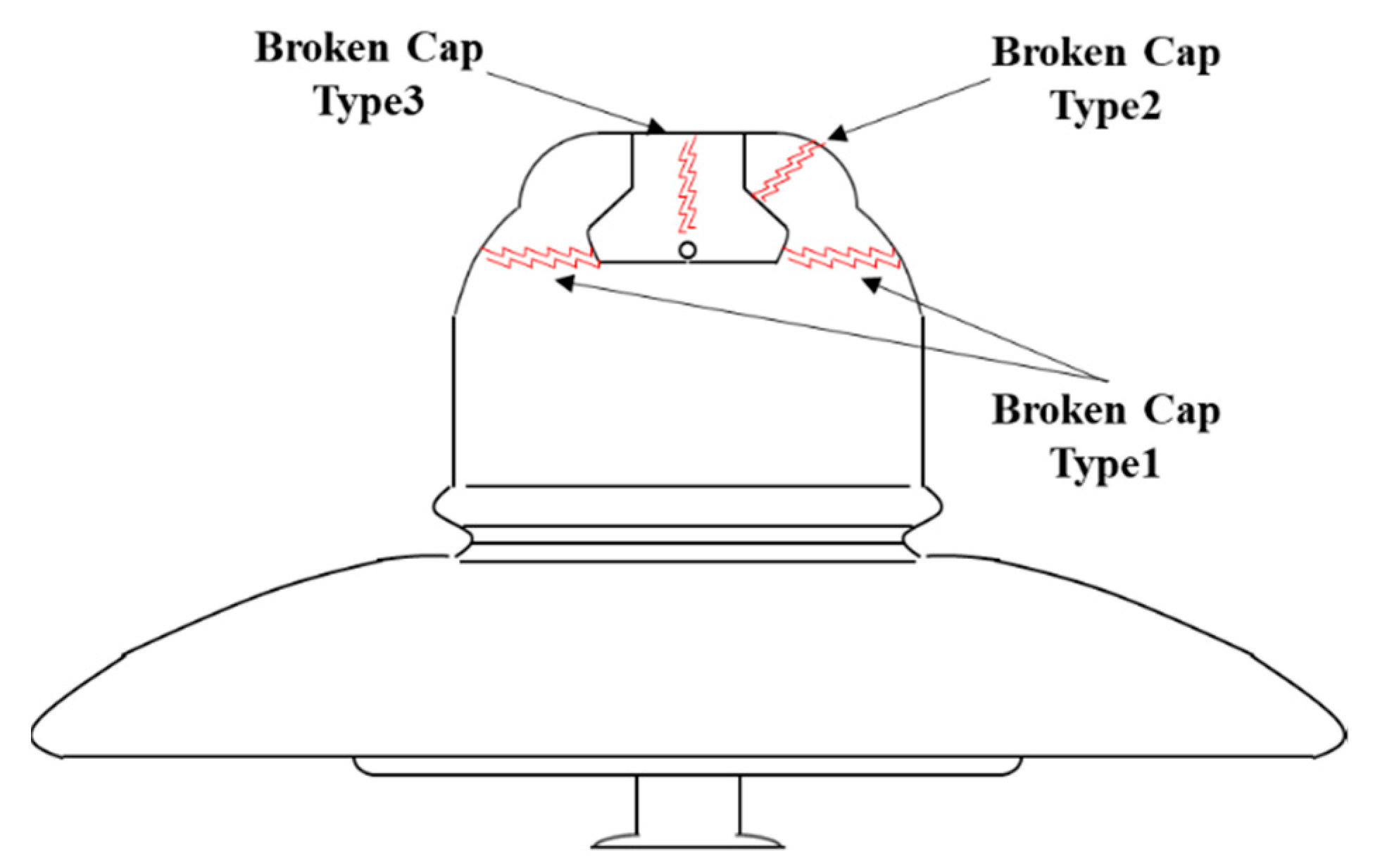

2.1. Types of Insulators

2.2. Frequency Response Function (FRF)

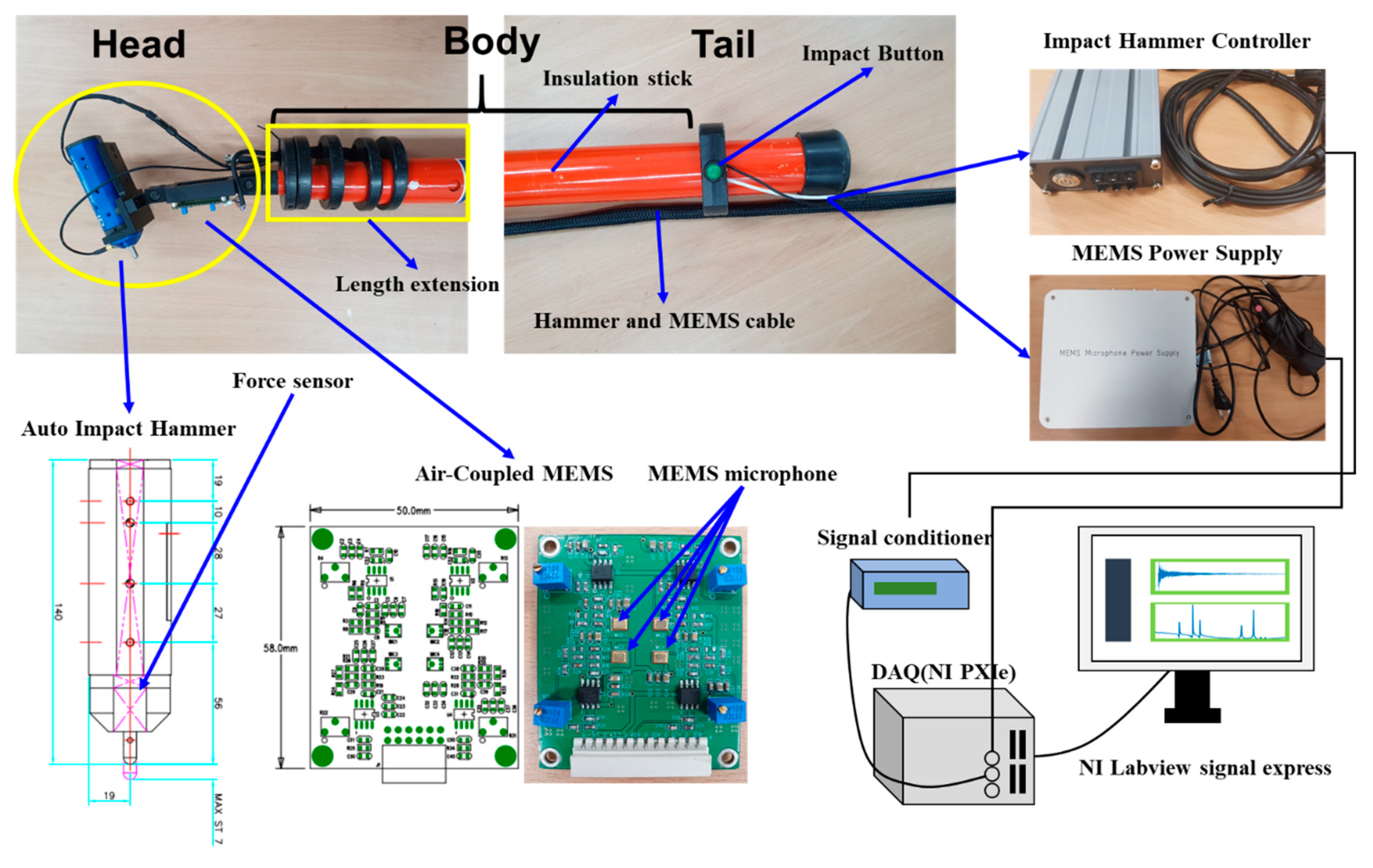

3. Developed Equipment and Experimental Setup

3.1. Schematic of Developed Equipment

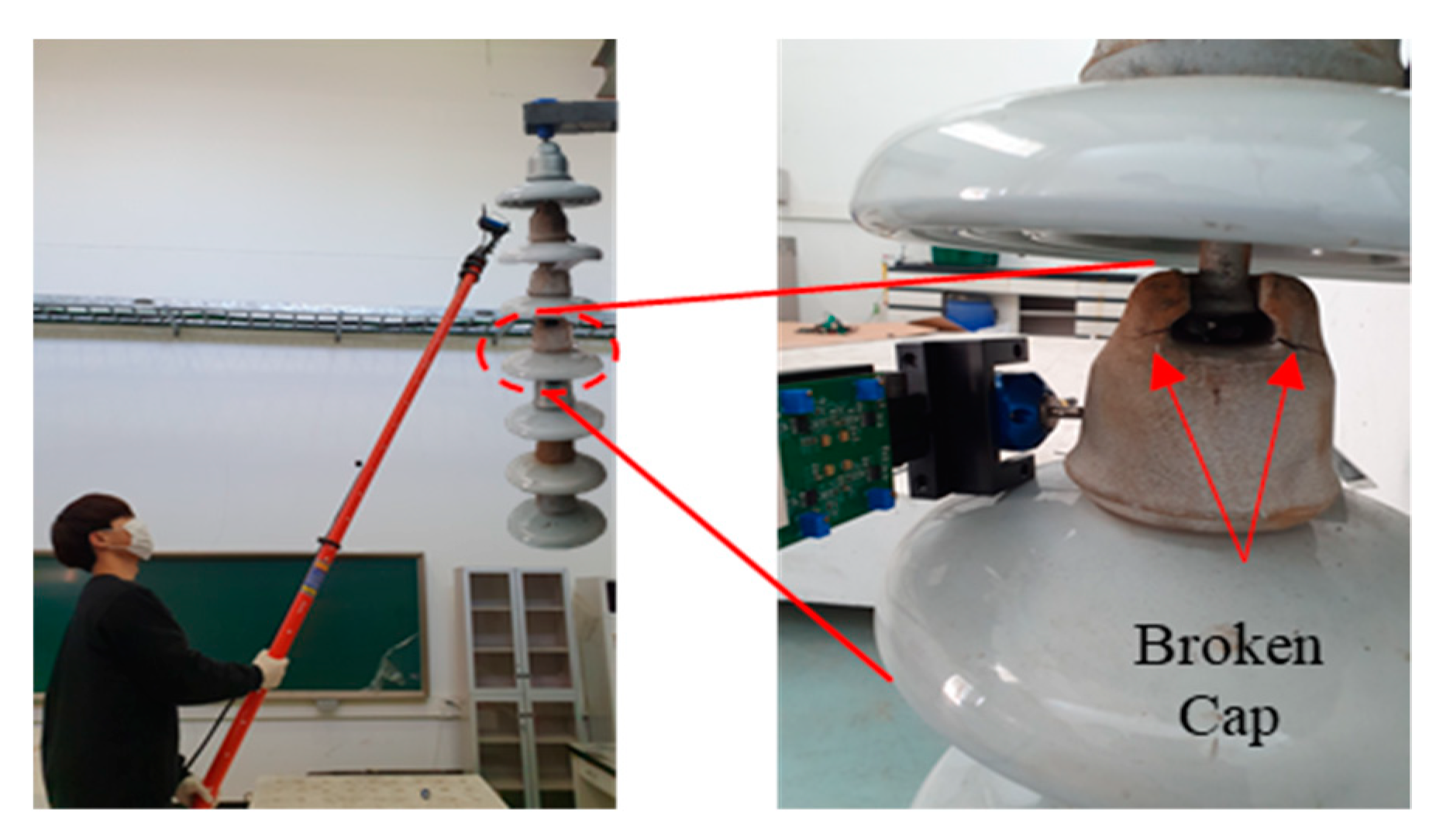

3.2. FRF Test Using Developed Equipment

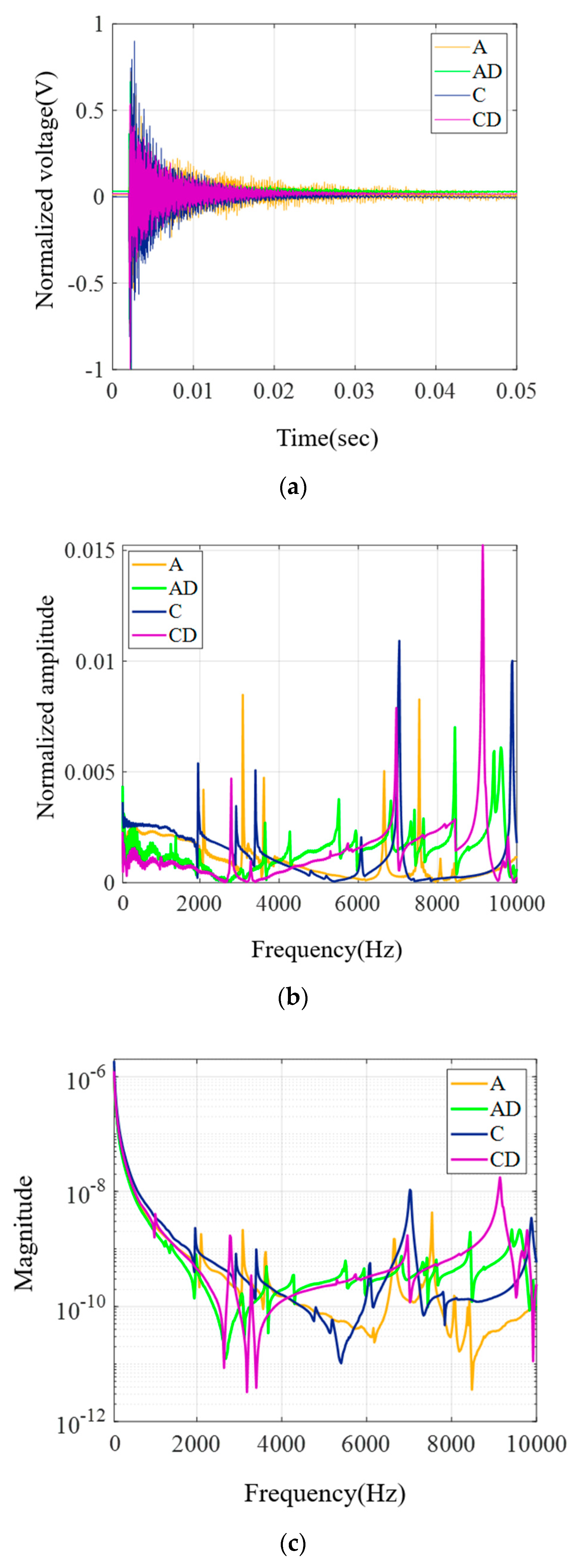

3.2.1. FRF Results of Porcelain Impact

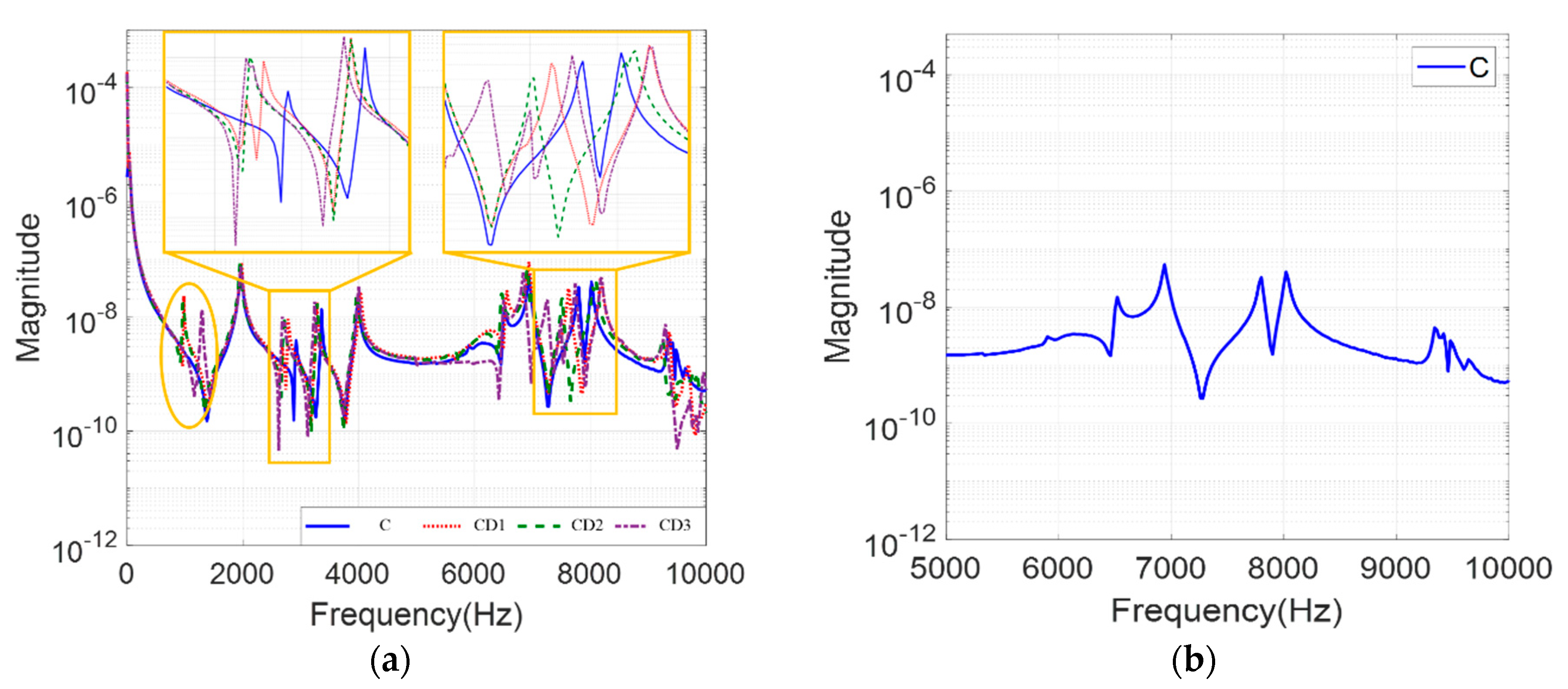

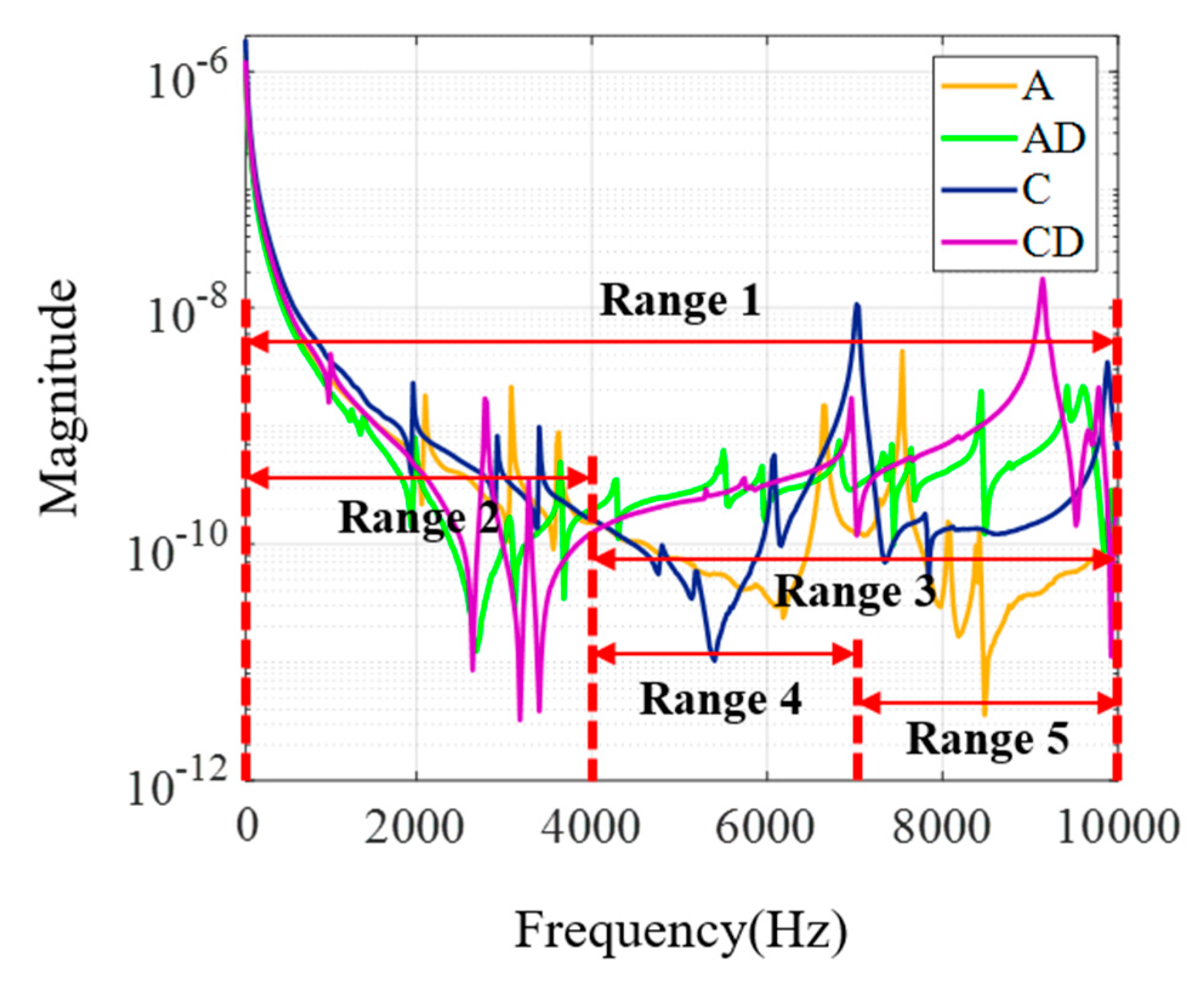

3.2.2. FRF Results of Cap Impact

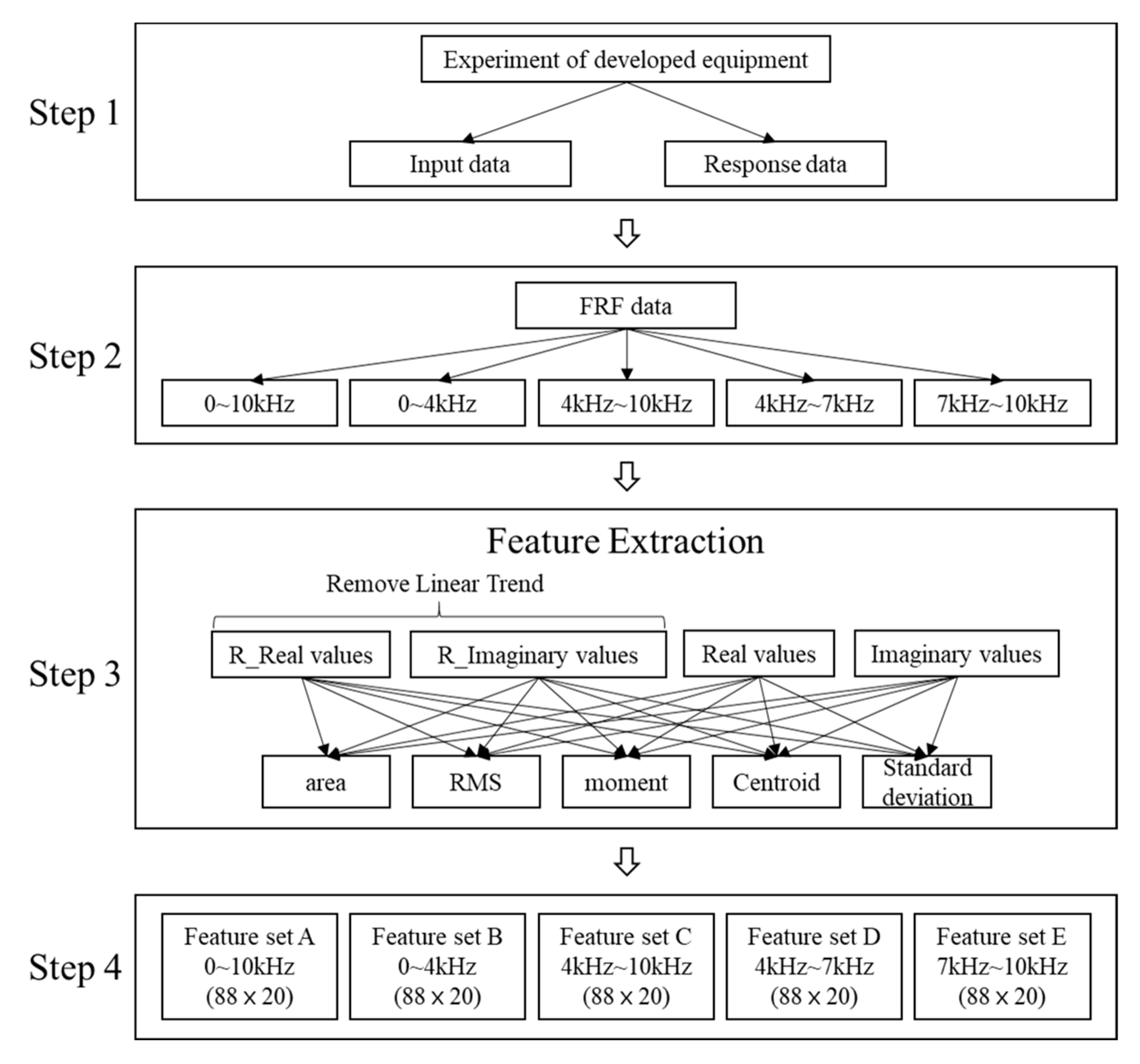

3.3. Procedure of Feature Extraction

4. Machine Learning Methods

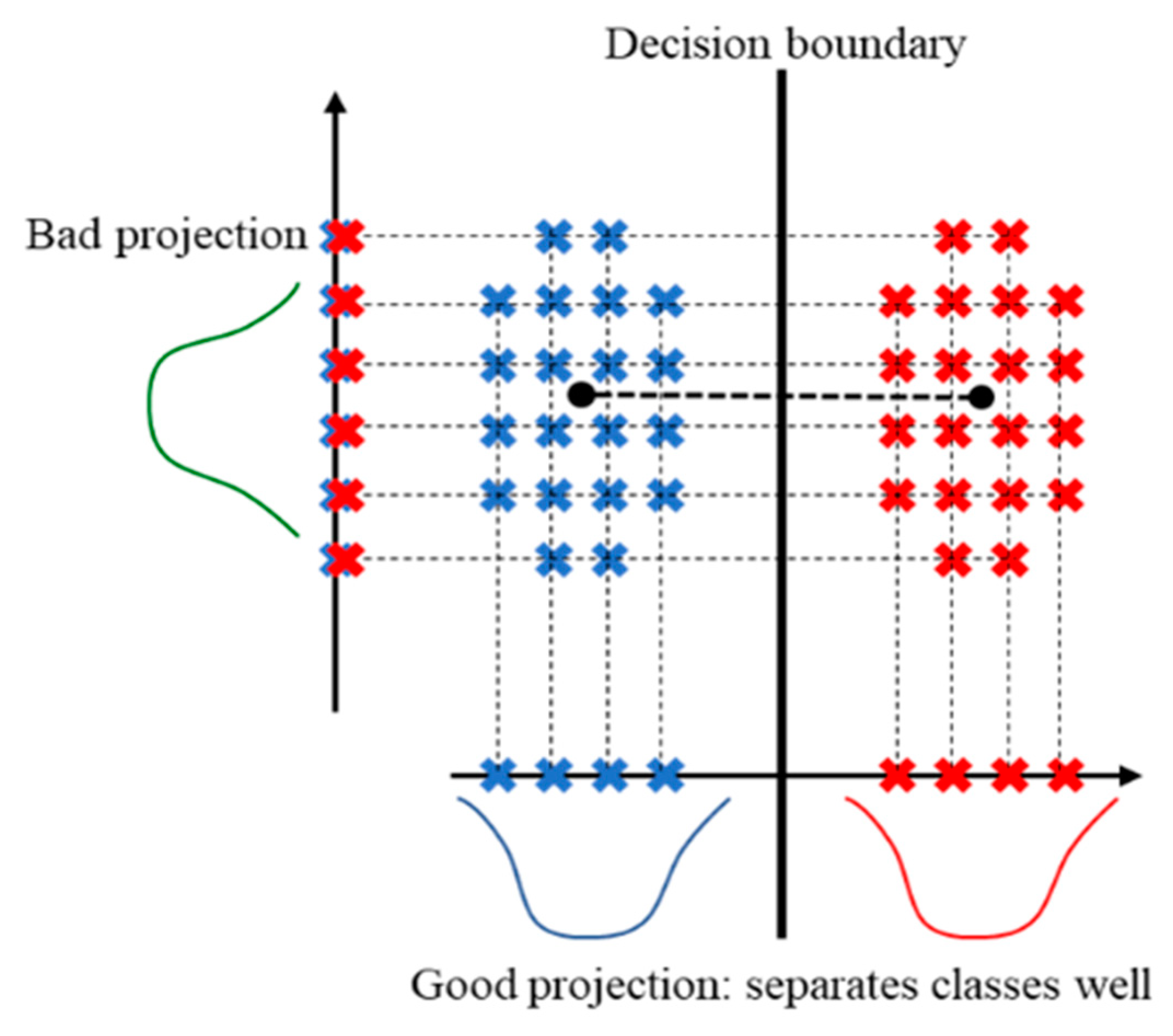

4.1. Neighborhood Component Analysis (NCA)

4.2. Support Vector Machine (SVM)

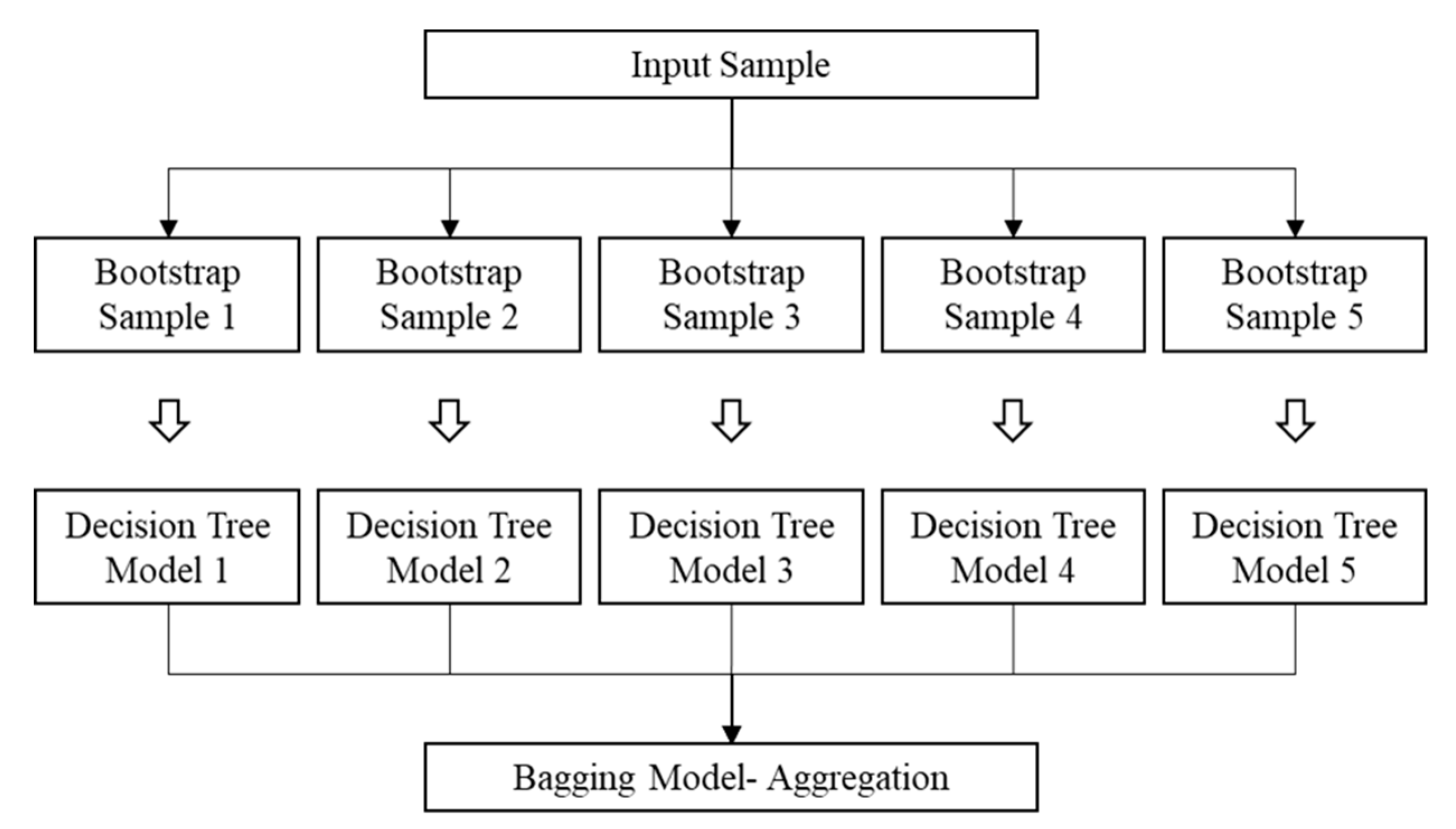

4.3. Bagging

4.4. k-Nearest Neighbor (kNN)

4.5. Discriminant Analysis (DA)

5. Analysis and Result

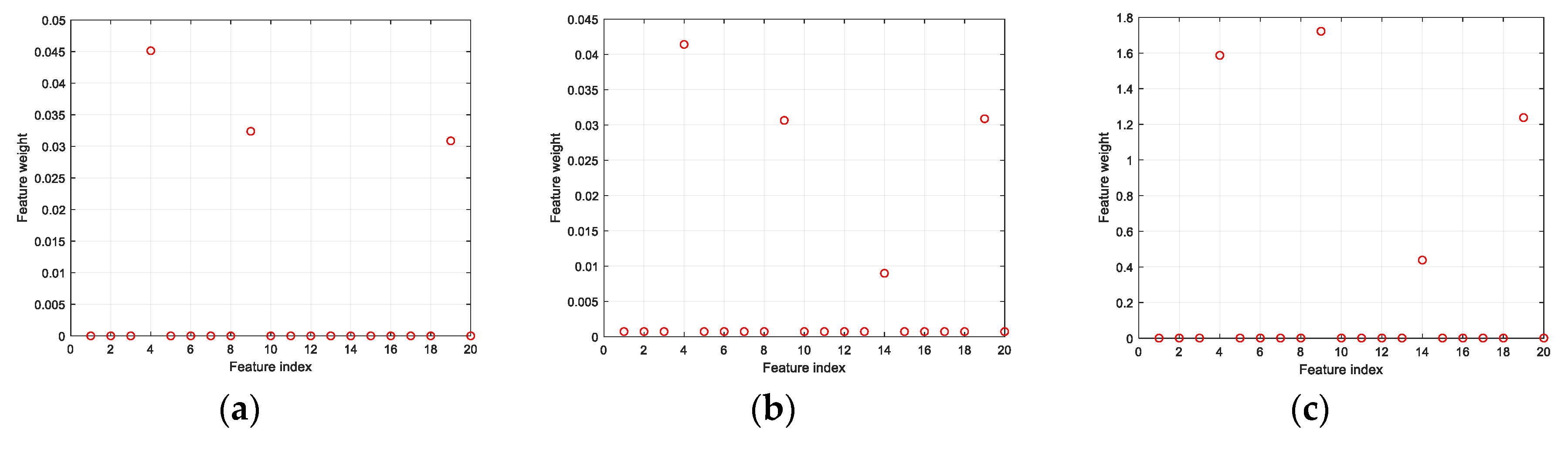

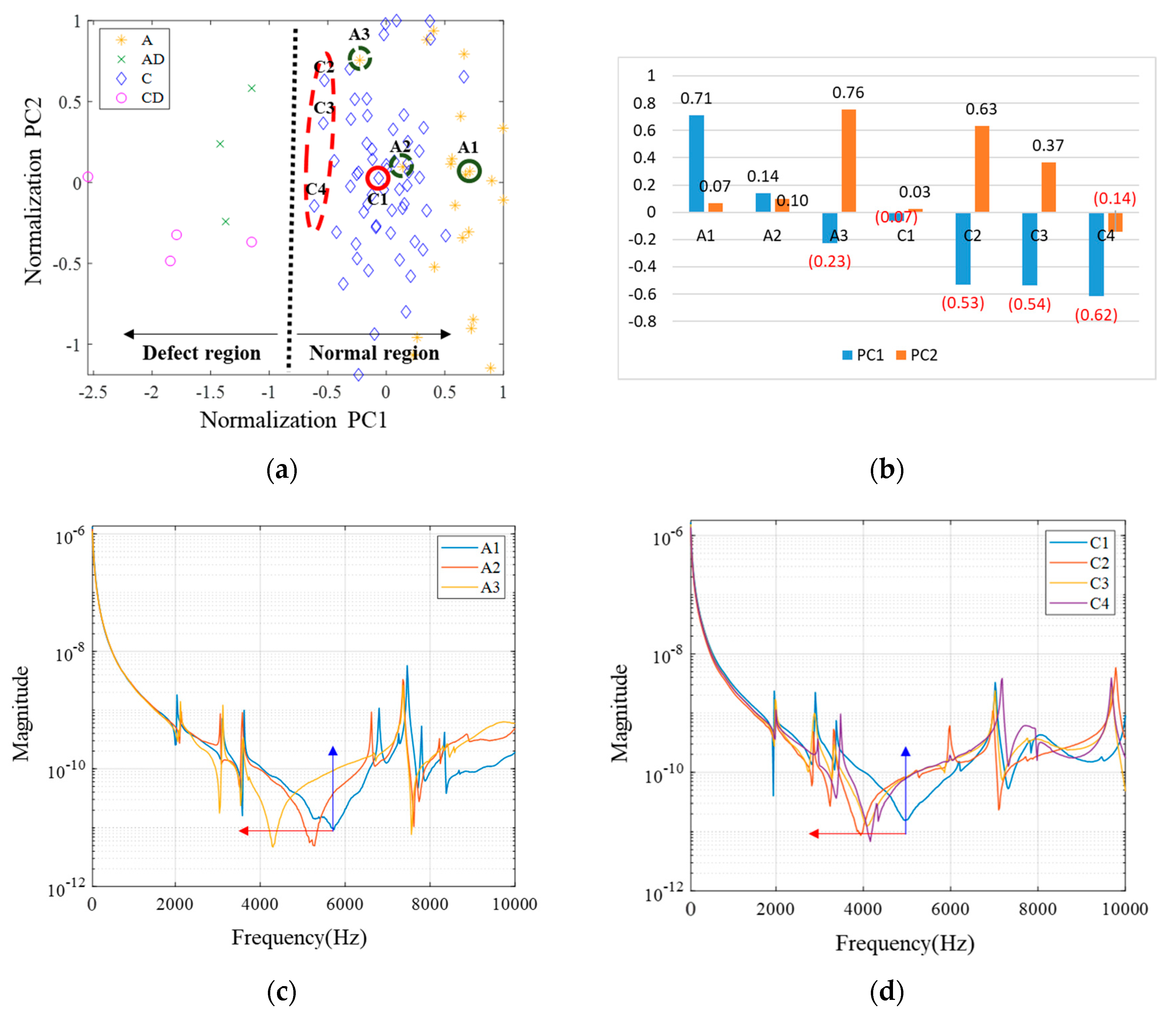

5.1. Feature Extraction Using NCA

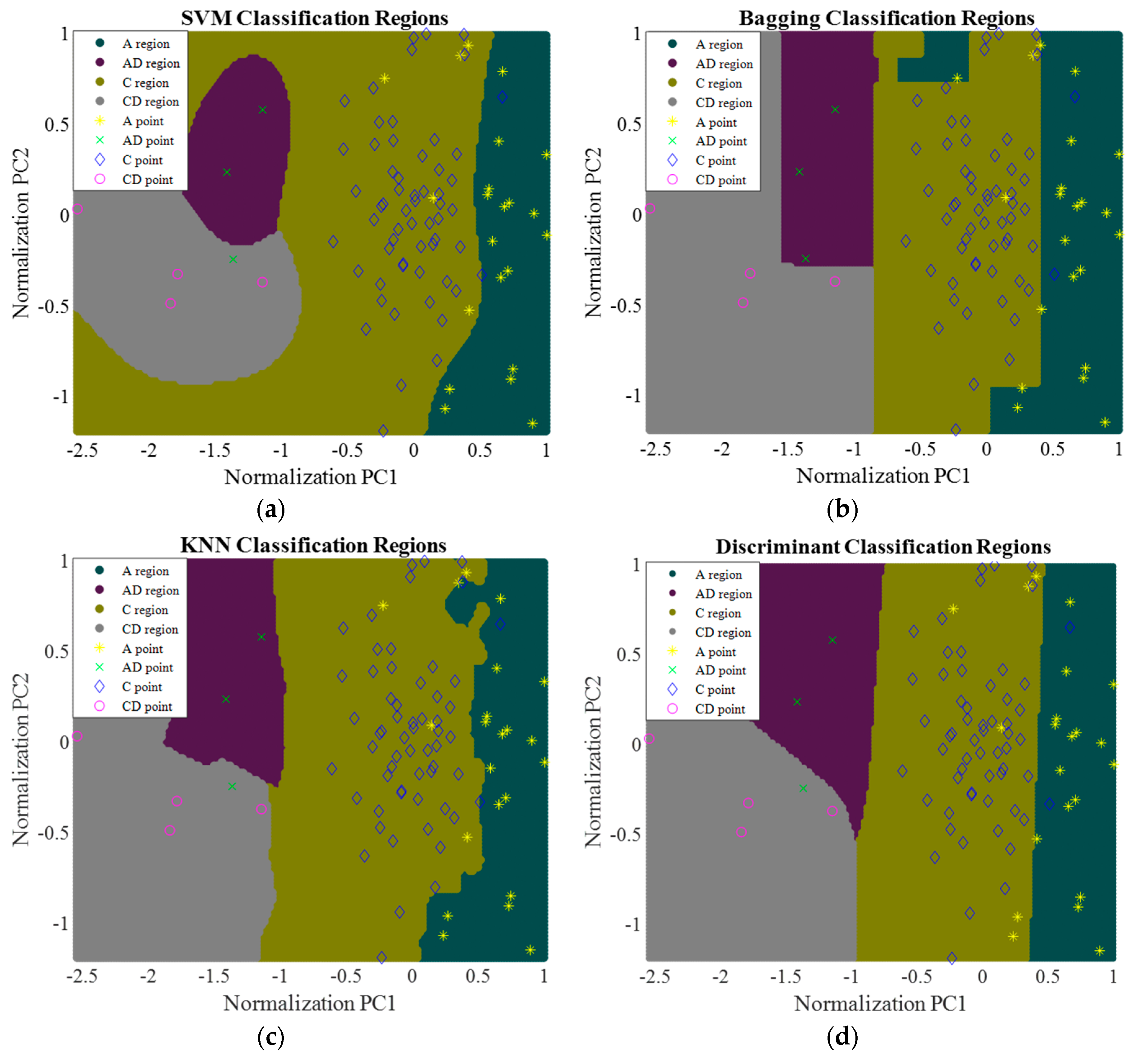

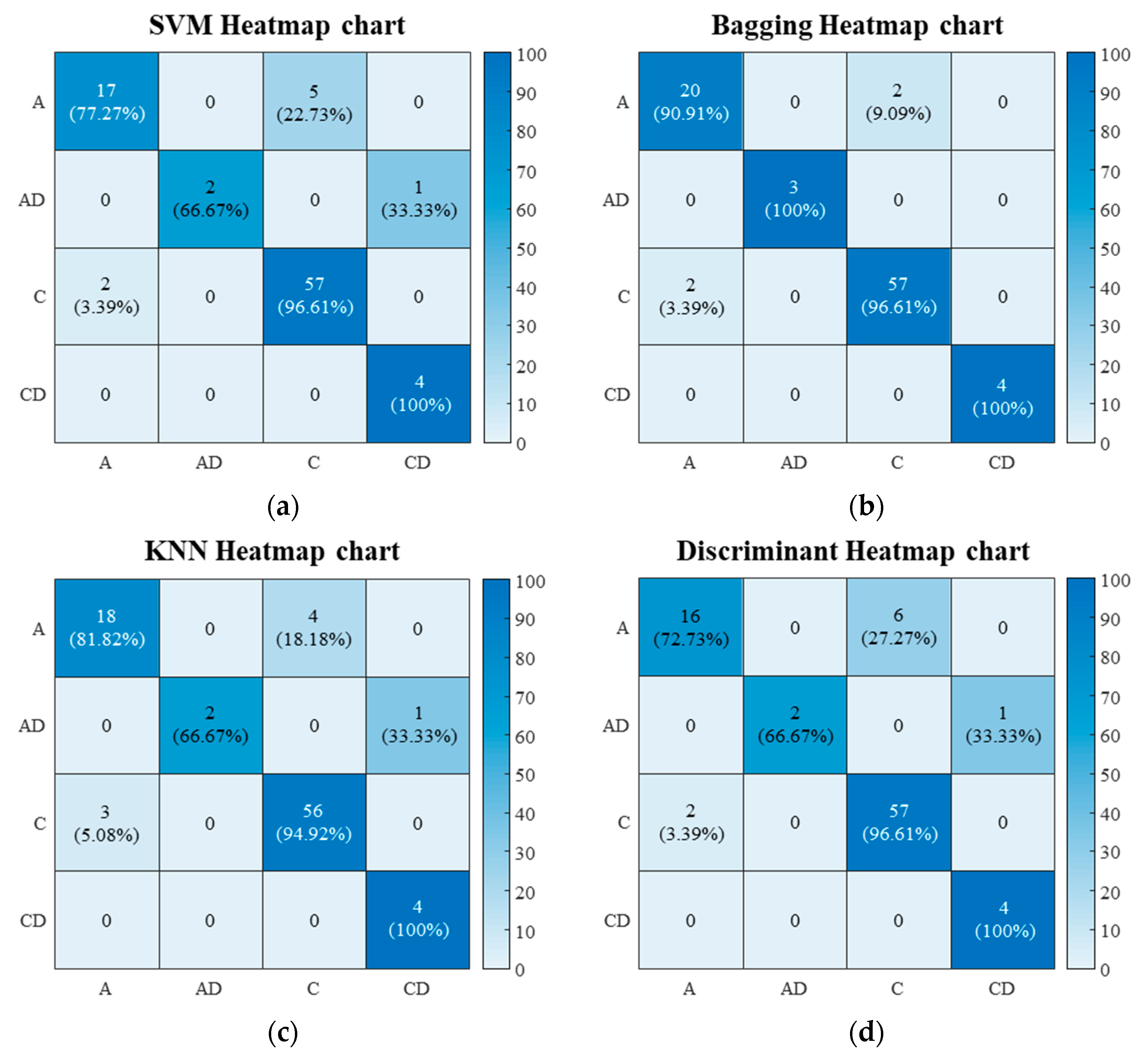

5.2. Machine Learning Analysis

6. Conclusions

- Field adaptable equipment was developed via the use of auto impact hammers and MEMS sensors to improve the convenience of measuring equipment and reduce weight.

- In the FRF test results, for damage to the cap, direct striking of the cap was more clearly distinguishable between normal and damaged caps than striking the porcelain section. Moreover, the accuracy of material and defect data classification was increased by setting the frequency region of interest from 4 kHz to 10 kHz for the FRF results of the caps.

- Four classification methods were used to set the post-distribution area of data through ML classification, and a model was developed to distinguish between normal and damaged cap data to an extent of 100%. Further, all models exhibited a high accuracy in classifying the material of normal data, and the bagging method had the best prediction ability in classifying the material of defect data.

- The distinction between normal and cap damage specimens was correct, but some data were found to exist within the distribution ranges of different classes, depending on the material. The reason for this is that porcelain insulators involve a manual process during manufacture, which may lead to manufacturing errors. Moreover, the FRF of the normal specimen present near the interface between the normal and the damaged area is like the FRF of the damaged cap specimen, and thus management of the porcelain insulator representing these waveforms is necessary. In the future, to develop a better predictive model, it would be necessary to precisely set the distribution area using various cap damage specimens according to the degree of damage.

Author Contributions

Funding

Conflicts of Interest

References

- Looms, J.S.T. Introduction. In Insulators for High Voltages, 7th ed.; Peter Peregrinus Ltd.: London, UK, 1988; pp. 1–3. [Google Scholar]

- Vaillancourt, G.H.; Bellerive, J.P.; St-Jean, M.; Jean, C. New live line tester for porcelain suspension insulators on high-voltage power lines. IEEE Trans. Power Deliv. 1994, 9, 208–219. [Google Scholar] [CrossRef]

- Momen, G.; Farzaneh, M. Survey of Micro/Nano Filler Use to Improve Silicone Rubber for Outdoor Insulators. Rev. Adv. Mater. Sci. 2011, 27, 1–13. [Google Scholar]

- Karady, G.G.; Shah, M.; Brown, R.L. Flashover mechanism of silicone rubber insulators used for outdoor insulation. IEEE Trans. Power Deliv. 1995, 10, 1965–1971. [Google Scholar] [CrossRef]

- Choi, I.H.; Kim, T.K.; Yoon, Y.B.; Kim, T.Y.; Nguyen, H.T.; Yi, J.S. A Study on the Life-Time Assessment Ways and Various Failure Types of 154 kV Porcelain Insulators Installed in South Korea. Trans. Electr. Electron. Mater. 2018, 19, 188–194. [Google Scholar] [CrossRef]

- Bardeen, A.W.; Sheadel, J.M. Corrosion as it affects insulator and conductor hardware. In Proceedings of the AIEE Winter General Meeting, New York, NY, USA, 30 January–3 February 1956; pp. 491–501. [Google Scholar]

- Cherney, E.A.; Am, D.E. Development and application of a hot-line suspension insulator tester. IEEE Trans. Power Appar. Syst. 1981, PAS-100, 1525–1528. [Google Scholar] [CrossRef]

- Padma, V.; Raghavan, V.S. Analysis of insulation degradation in Insulators using Partial Discharge analysis. In Proceedings of the 2011 3rd International Conference on Electronics Computer (ICECT), Kanyakumari, India, 8–10 April 2011; pp. 110–114. [Google Scholar]

- Vaillancourt, G.H.; Carignan, S.; Jean, C. Experience with the detection of faulty composite insulators on high-voltage power lines by the electric field measurement method. IEEE Trans. Power Deliv. 1998, 13, 661–666. [Google Scholar] [CrossRef]

- Cavallini, A.; Chandrasekar, S.; Montanari, G.C.; Puletti, F. Inferring ceramic insulator pollution by an innovative approach resorting to PD detection. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 23–29. [Google Scholar] [CrossRef]

- Ha, H.; Han, S.; Lee, J. Fault detection on transmission lines using a microphone array and an infrared thermal imaging camera. IEEE Trans. Instrum. Meas. 2012, 61, 267–275. [Google Scholar] [CrossRef]

- Miao, X.R.; Liu, X.Y.; Chen, J.; Zhuang, S.B.; Fan, J.W.; Jiang, H. Insulator Detection in Aerial Images for Transmission Line Inspection Using Single Shot Multibox Detector. IEEE Access 2019, 7, 9945–9956. [Google Scholar] [CrossRef]

- Li, J.C.; Dackermann, U.; Xu, Y.L.; Samali, B. Damage identification in civil engineering structures utilizing PCA-compressed residual frequency response functions and neural network ensembles. Struct. Control Health Monit. 2011, 18, 207–226. [Google Scholar] [CrossRef]

- Miletiev, R.; Simeonov, I.; Iontchev, E.; Yordanov, R. Time and frequency analysis of the vehicle suspension dynamics. Int. J. Syst. Appl. 2013, 7, 287–294. [Google Scholar]

- Christain, J.; Feser, K. Procedures for detecting winding displacements in power transformer by the transfer function method. IEEE Trans. Power Deliv. 2004, 19, 214–220. [Google Scholar] [CrossRef]

- Miyazaki, S.; Mizutani, Y.; Matsumoto, K.; Nakamura, S. On-Site Diagnosis of Transformer Winding by Frequency Response Analysis. IEEJ Trans. Power Energy 2010, 130, 451–459. [Google Scholar] [CrossRef]

- Miyazaki, S.; Mizutani, Y.; Taguchi, A.; Murakami, J.; Tsuji, N.; Takashima, M.; Kato, O. Diagnosis Criterion of Abnormality of Transformer Winding by Frequency Response Analysis (FRA). Electr. Eng. Jpn. 2017, 201, 25–34. [Google Scholar] [CrossRef]

- Kim, Y.S.; Shong, K.M.; Jeon, Y.J. A Study on the site vibration for the breakage analysis of glass insulators on the high-speed railway. IEEE Trans. Power Deliv. 2009, 24, 1809–1814. [Google Scholar] [CrossRef]

- Raghu, S.H.; Sriraam, N.J. Classification of focal and non-focal EEG signals using neighborhood component analysis and machine learning algorithms. Expert Syst. Appl. 2018, 113, 18–32. [Google Scholar] [CrossRef]

- Burges, C.J.C. A tutorial on support vector machines for pattern recognition. Data Min. Knowl. Discov. 1998, 2, 121–167. [Google Scholar] [CrossRef]

- Mantero, P.; Moser, G.; Serpico, S.B. Partially supervised classification of remote sensing images through SVM-based probability density estimation. IEEE Trans. Geosci. Remote Sens. 2005, 43, 559–570. [Google Scholar] [CrossRef]

- Rokach, L. Taxonomy for characterizing ensemble methods in classification tasks: A review and annotated bibliography. Comput. Stat. Data Anal. 2009, 53, 4046–4072. [Google Scholar] [CrossRef]

- Hsieh, S.L.; Hsieh, S.H.; Cheng, P.H.; Chen, C.H.; Hsu, K.P.; Lee, I.S.; Wang, Z.; Lai, F. Design Ensemble Machine Learning Model for Breast Cancer Diagnosis. J. Med. Syst. 2011, 36, 2841–2847. [Google Scholar] [CrossRef]

- FrancoLopez, H.; Ek, A.R.; Bauer, M.E. Estimation and mapping of forest stand density, volume and cover type using the k-Nearest Neighbors method. Remote Sens. Environ. 2001, 77, 251–274. [Google Scholar] [CrossRef]

- Belhumeur, P.N.; Hespanha, J.P.; Kriegman, D.J. Eigenfaces vs. fisherfaces: Recognition using class specific linear projection. IEEE Trans. Pattern Anal. Mach. Intell. 1997, 7, 711–720. [Google Scholar] [CrossRef]

- Choi, I.H.; Jung, Y.H.; Choi, J.H.; Lee, D.I. Artificial contaminated test method and leakage current characteristics of EHV insulators. Conf. JIEIE 2004, 16, 386–391. [Google Scholar]

- Choi, I.H.; Son, J.A.; Oh, T.K.; Yoon, Y.G. Damage Evaluation of Porcelain Insulators Using the Frequency Response Function. KIEEME 2019, 32, 122–128. [Google Scholar]

- Ham, S.H.; Popovics, J.S. Application of Micro-Electro-Mechanical Sensors Contactless NDT of Concrete Structures. Sensors 2015, 15, 9078–9096. [Google Scholar] [CrossRef]

- Kong, X.; Cai, C.S.; Hu, J. The State-of-the-Art on Framework of Vibration-Based Structural Damage Identification for Decision Making. Appl. Sci. 2017, 7, 497. [Google Scholar] [CrossRef]

- Yang, W.; Wang, K.; Zuo, W. Neighborhood component feature selection for high-dimensional data. J. Comput. 2012, 7, 161–168. [Google Scholar] [CrossRef]

- Vapnik, V.; Cortes, C. Support-Vector Networks; Kluwer Academic Publisher: Boston, MA, USA, 1995; Volume 20, pp. 273–297. [Google Scholar]

- Wei, C.; Huang, J.; Mansaray, L.R.; Li, Z.; Liu, W.; Han, J. Estimation and mapping of winter oilseed rape LAI from high spatial resolution satellite data based on a hybrid method. Remote Sens. 2017, 9, 488. [Google Scholar] [CrossRef]

| Categorization | Cristobalite | Alumina | Sum | |

|---|---|---|---|---|

| Total | 63 | 25 | 88 | |

| Normal | 59 | 22 | 81 | |

| Defect type | Sub total | 4 | 3 | 7 |

| Cap | 3 | 3 | 6 | |

| A. P | 1 | - | 1 | |

| Time | Accuracy | Precision | Recall | F1 Score | |

|---|---|---|---|---|---|

| SVM | 0.0744 | 90.91% | 90.35% | 85.14% | 87.67% |

| Bagging | 0.2501 | 95.45% | 96.88% | 96.88% | 96.88% |

| KNN | 0.0926 | 90.91% | 89.76% | 85.85% | 87.76% |

| DA | 0.0809 | 89.77% | 89.84% | 84.00% | 86.82% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, I.H.; Koo, J.B.; Son, J.A.; Yi, J.S.; Yoon, Y.G.; Oh, T.K. Development of Equipment and Application of Machine Learning Techniques Using Frequency Response Data for Cap Damage Detection of Porcelain Insulators. Appl. Sci. 2020, 10, 2820. https://doi.org/10.3390/app10082820

Choi IH, Koo JB, Son JA, Yi JS, Yoon YG, Oh TK. Development of Equipment and Application of Machine Learning Techniques Using Frequency Response Data for Cap Damage Detection of Porcelain Insulators. Applied Sciences. 2020; 10(8):2820. https://doi.org/10.3390/app10082820

Chicago/Turabian StyleChoi, In Hyuk, Ja Bin Koo, Ju Am Son, Jun Sin Yi, Young Geun Yoon, and Tae Keun Oh. 2020. "Development of Equipment and Application of Machine Learning Techniques Using Frequency Response Data for Cap Damage Detection of Porcelain Insulators" Applied Sciences 10, no. 8: 2820. https://doi.org/10.3390/app10082820

APA StyleChoi, I. H., Koo, J. B., Son, J. A., Yi, J. S., Yoon, Y. G., & Oh, T. K. (2020). Development of Equipment and Application of Machine Learning Techniques Using Frequency Response Data for Cap Damage Detection of Porcelain Insulators. Applied Sciences, 10(8), 2820. https://doi.org/10.3390/app10082820