Fabrication of Edge Rounded Polylactic Acid Biomedical Stents by the Multi-Axis Micro-Milling Process

Abstract

1. Introduction

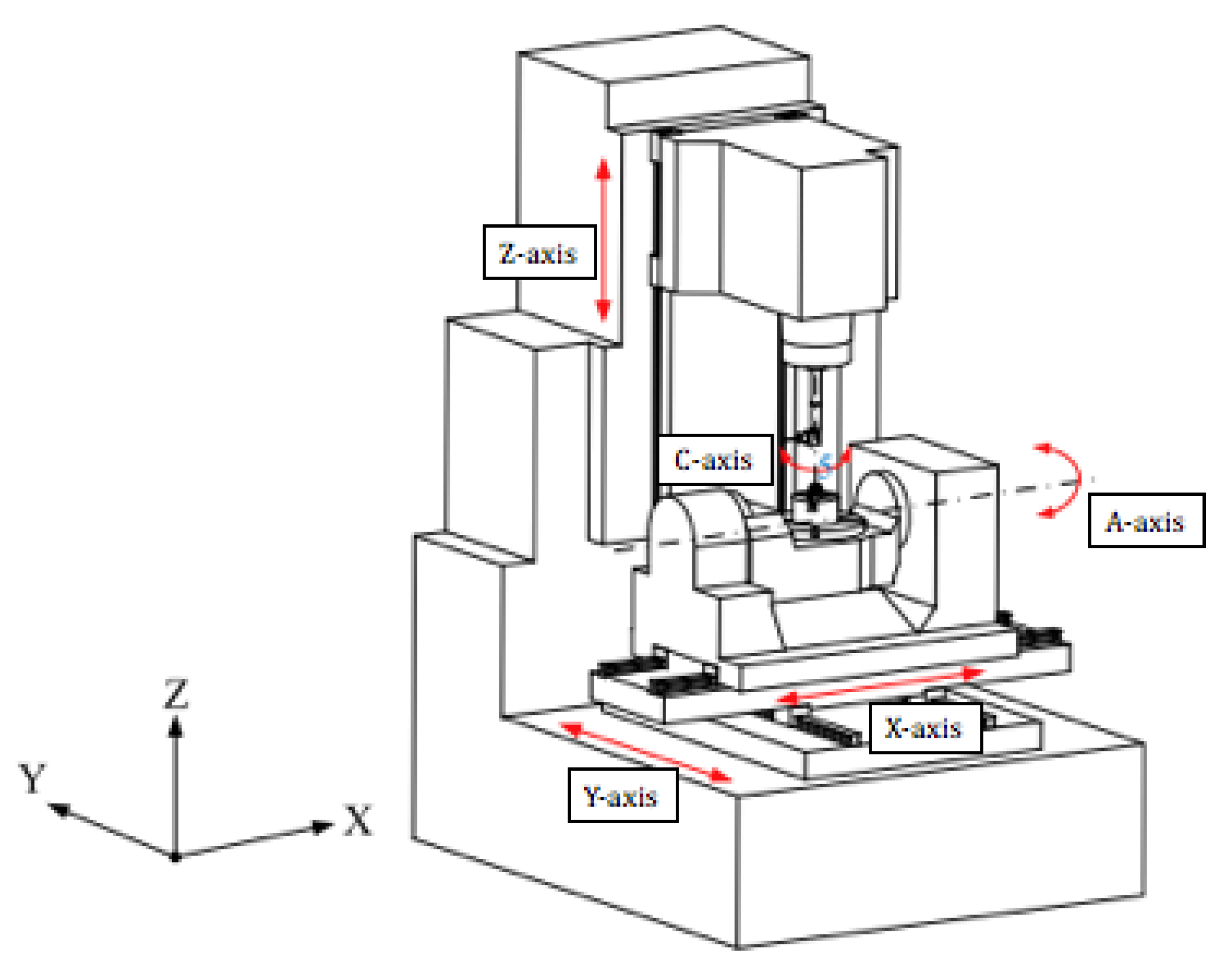

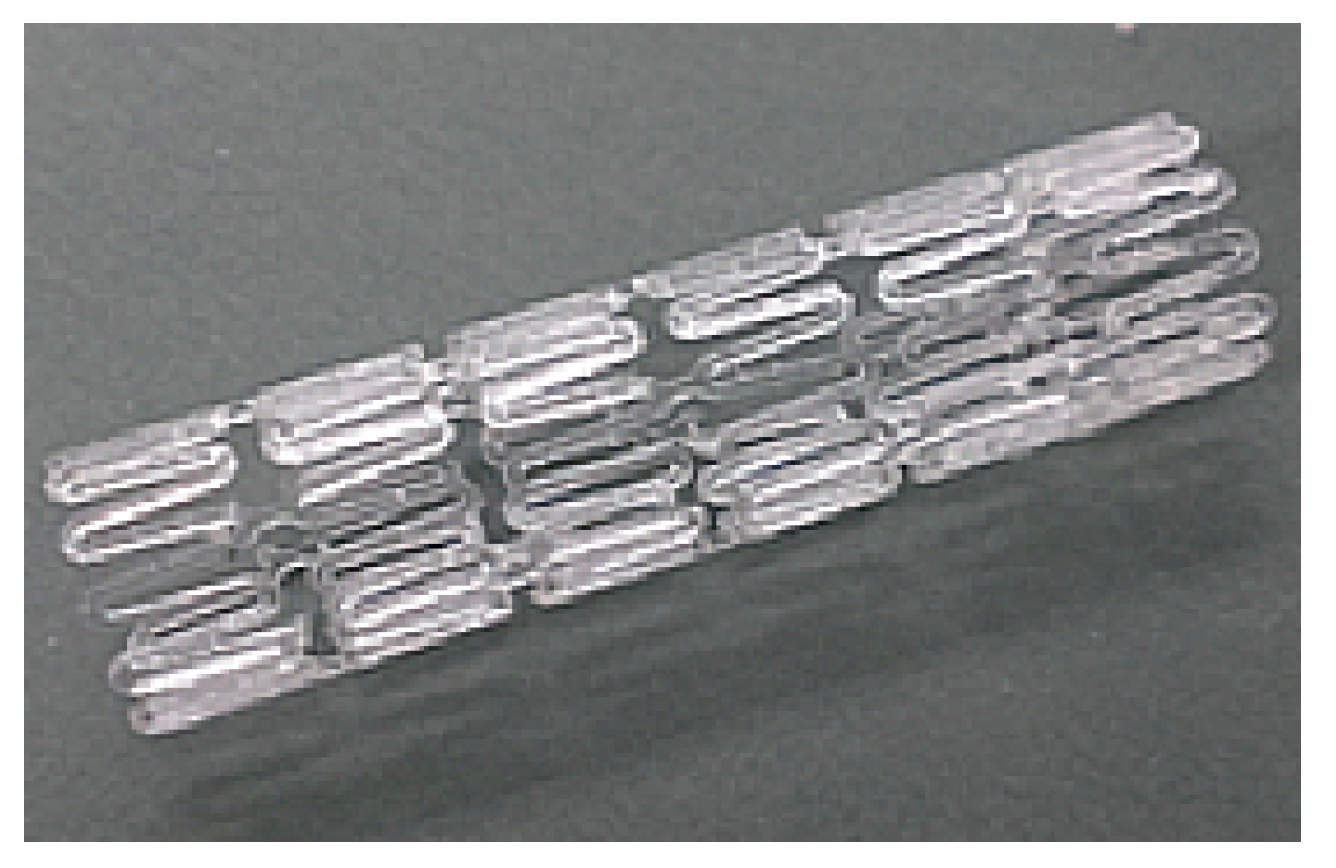

2. Experimental

2.1. Material and Design of the PLA Biomedical Stent

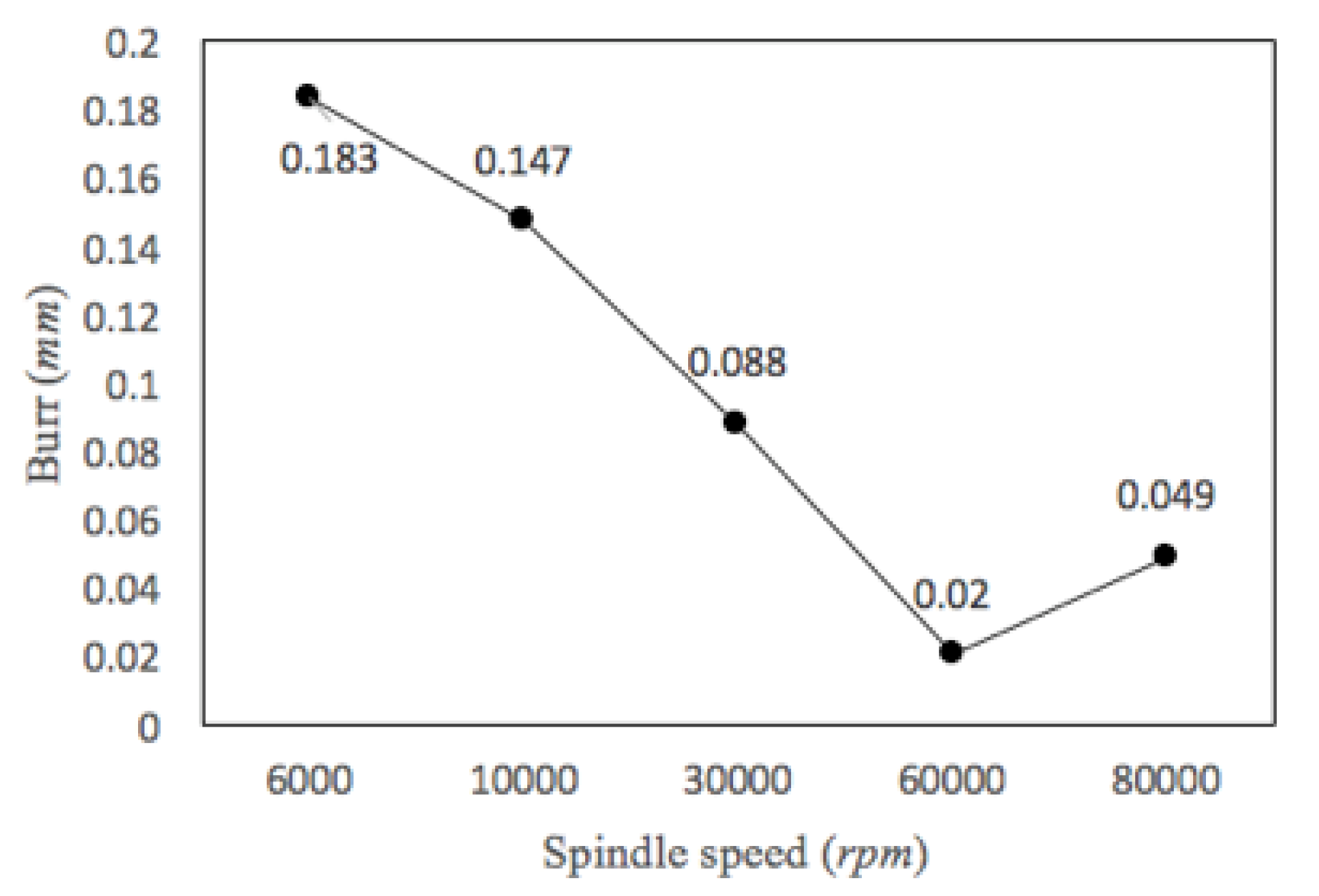

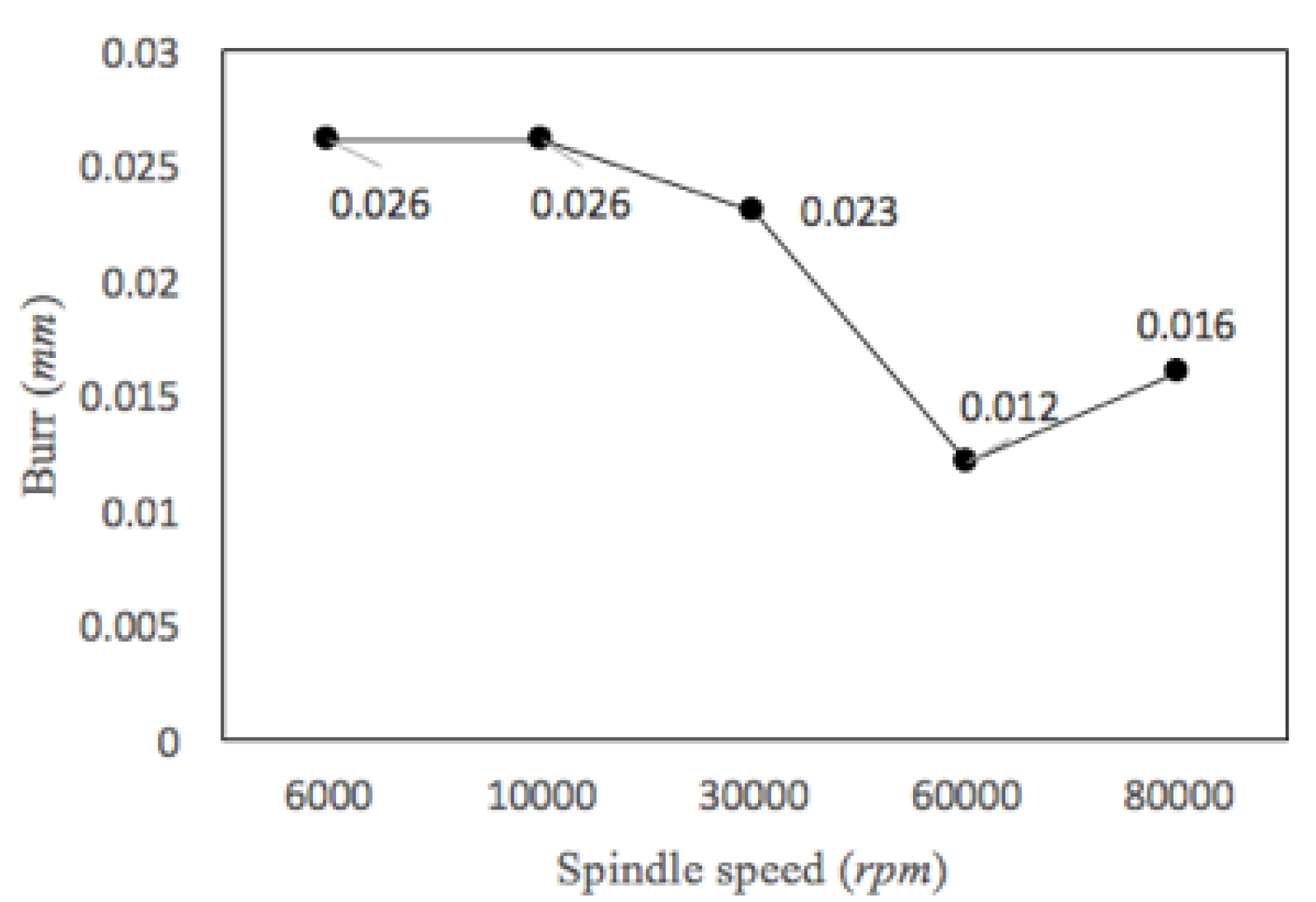

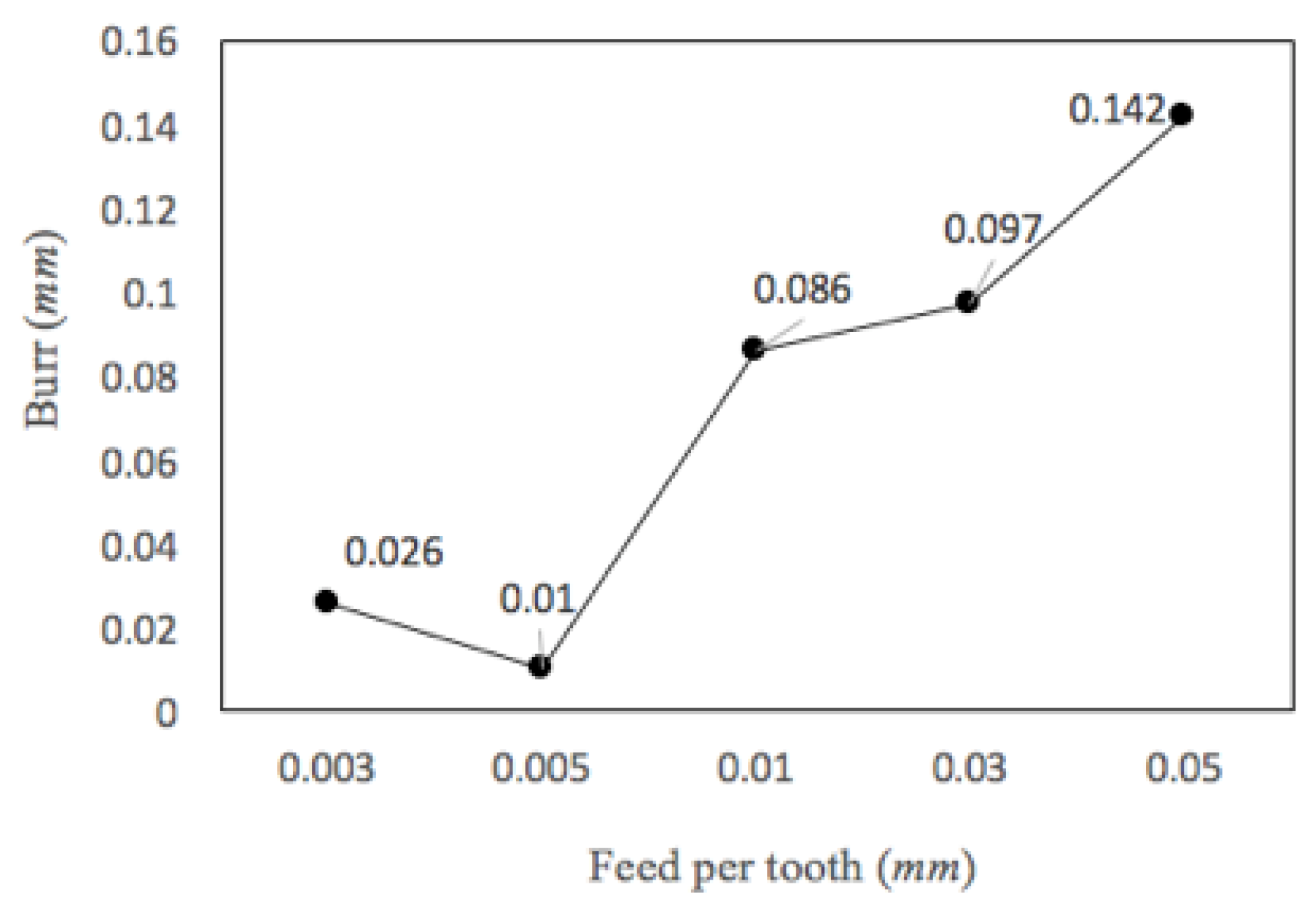

2.2. Experiment on PLA Cutting Parameter Optimization

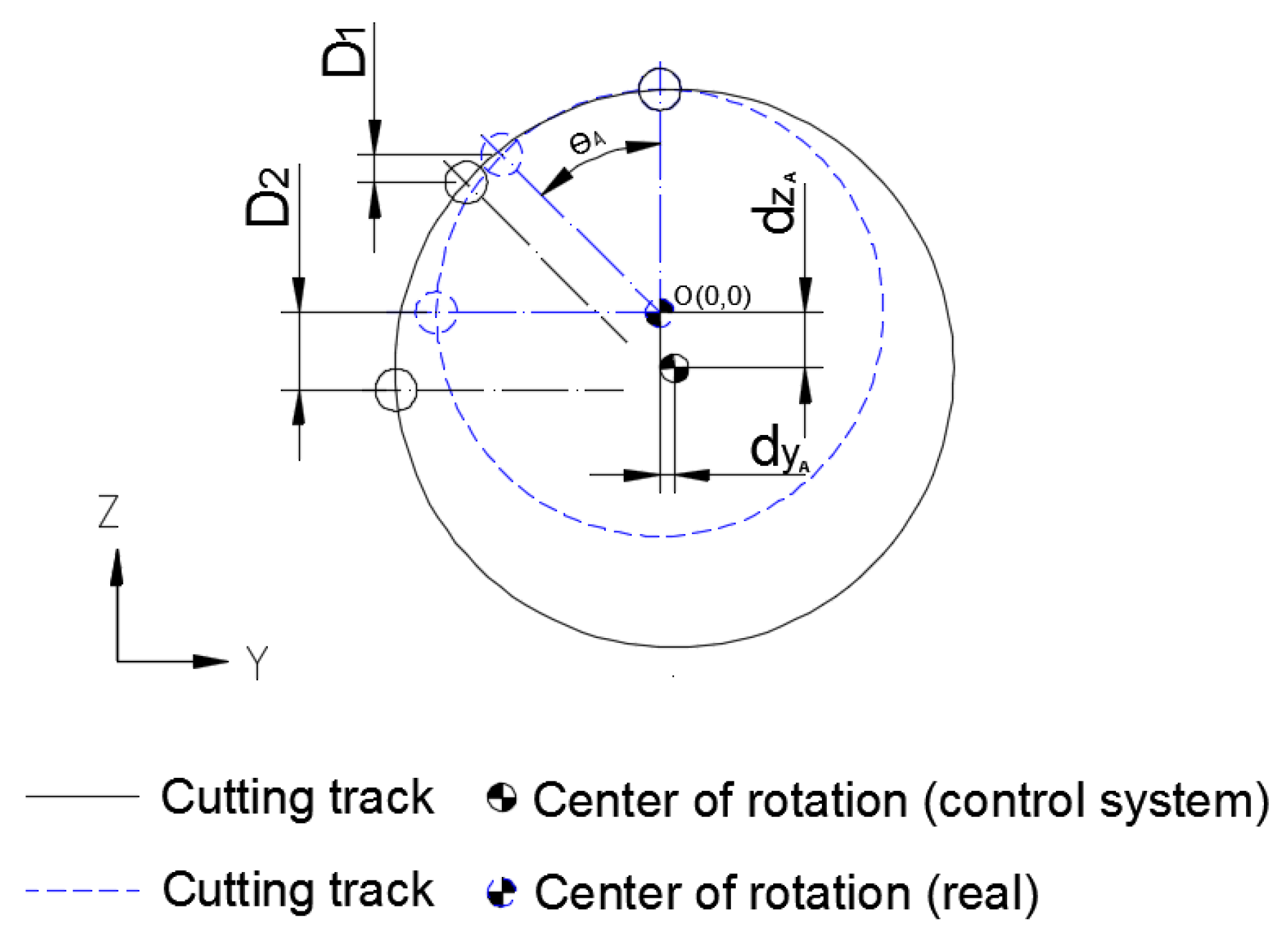

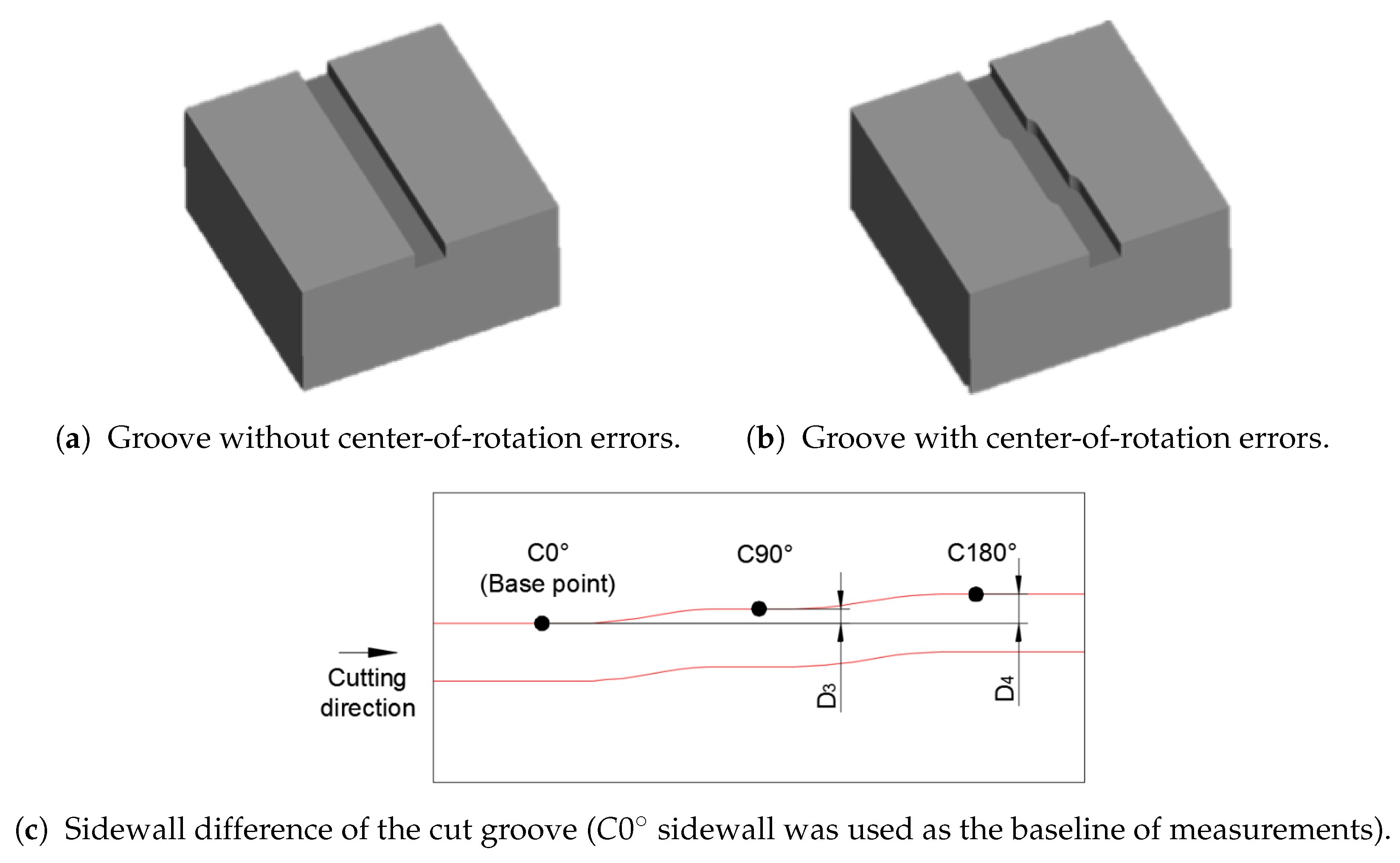

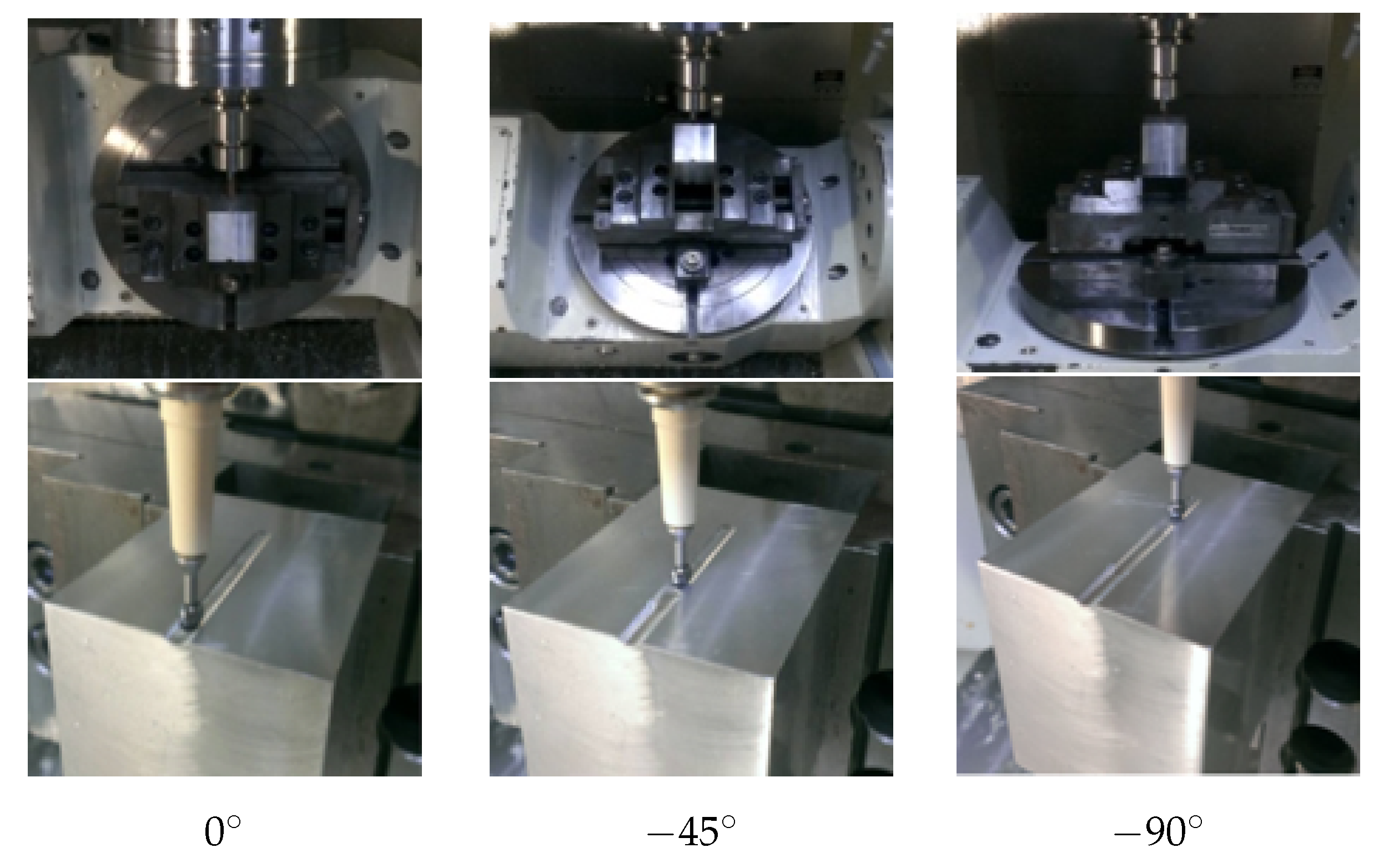

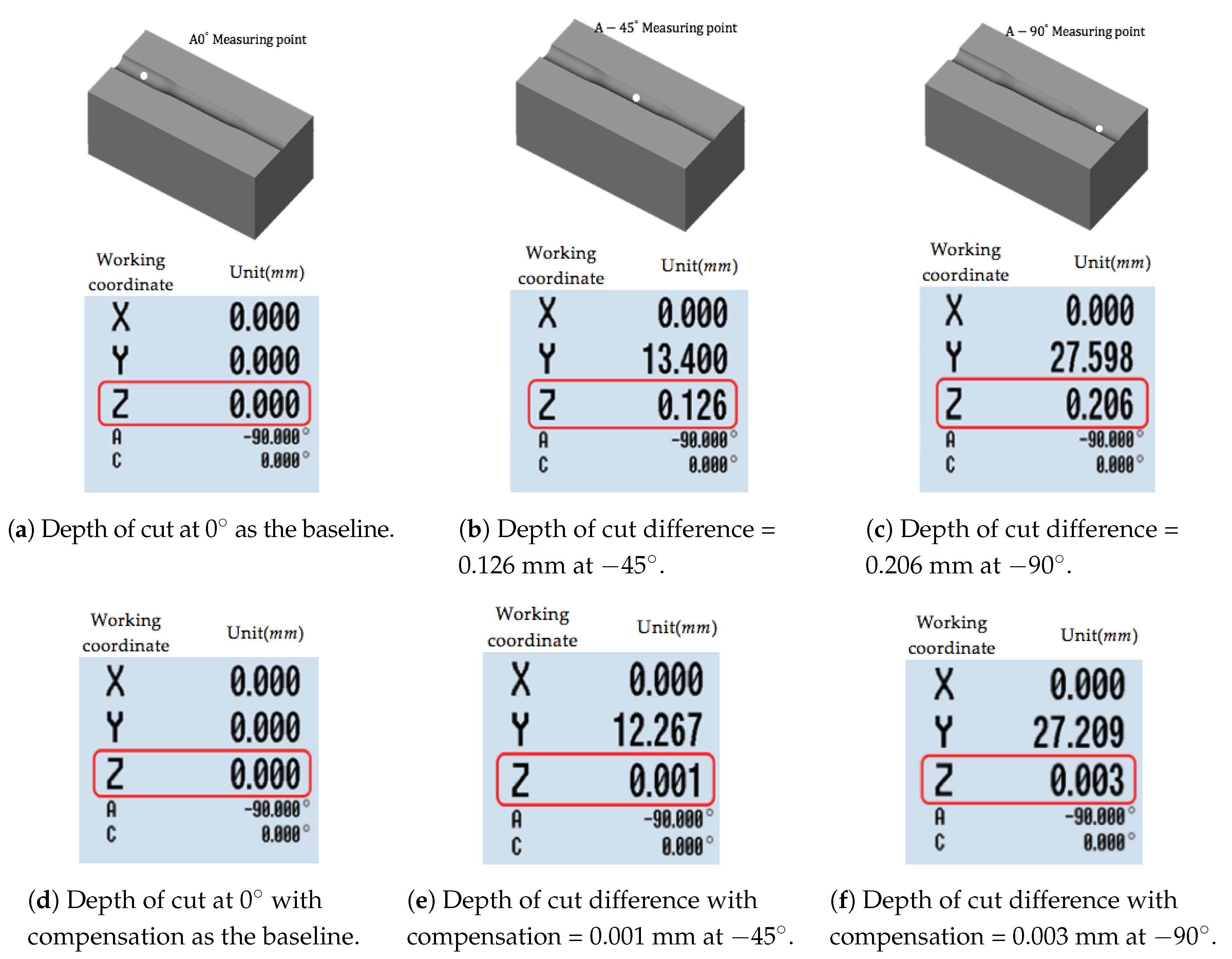

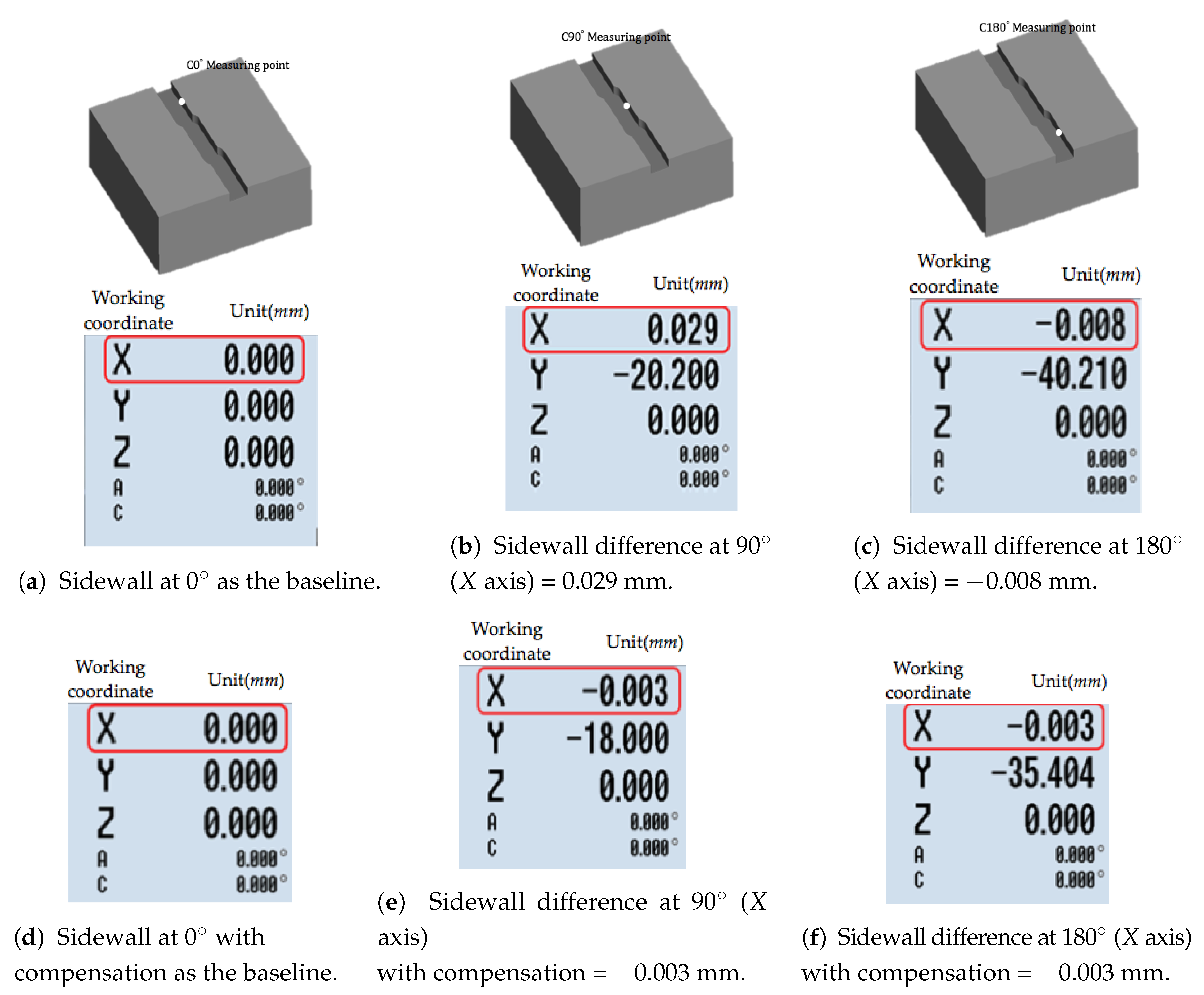

2.3. Center-of-Rotation Error Compensation

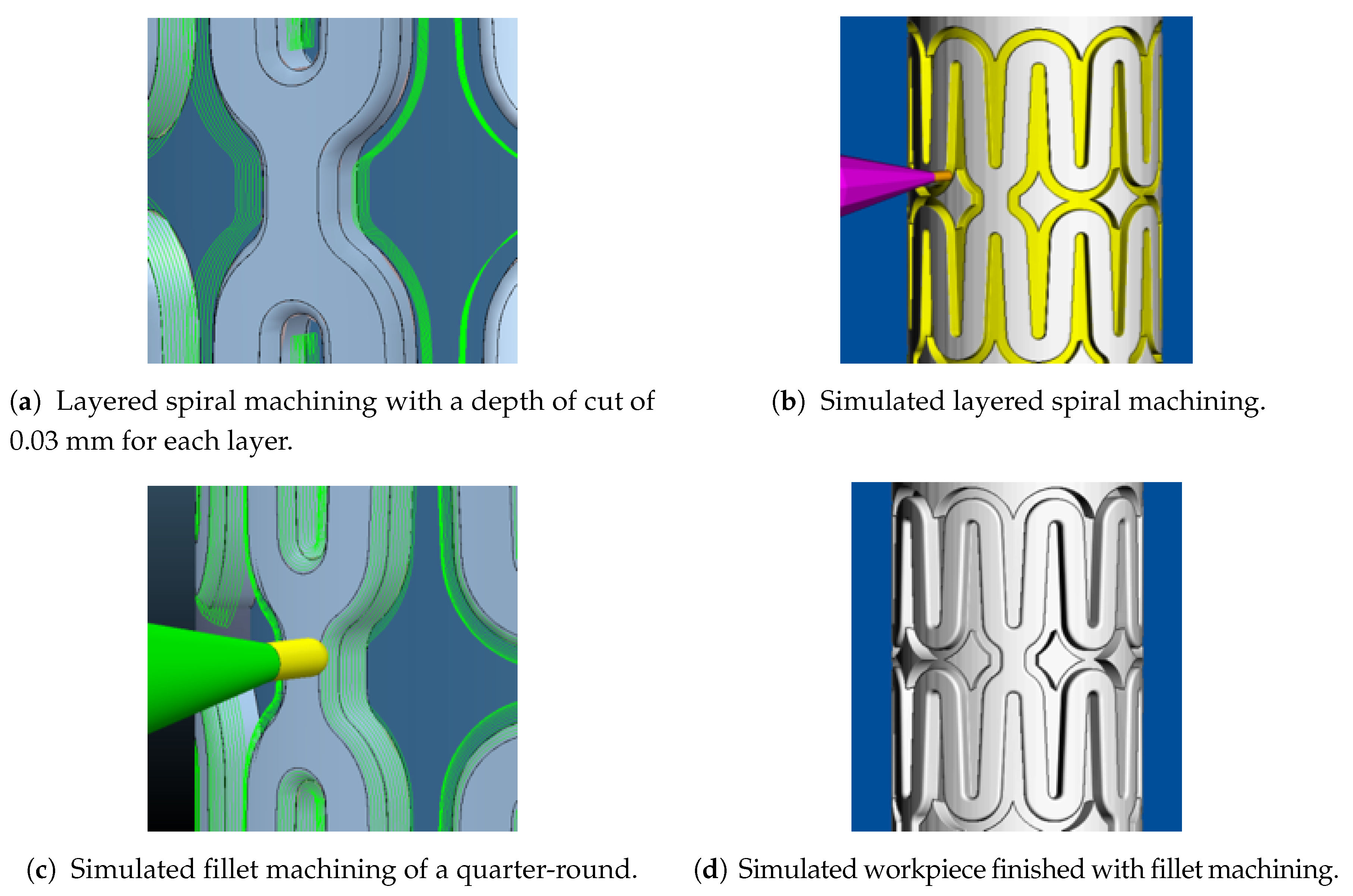

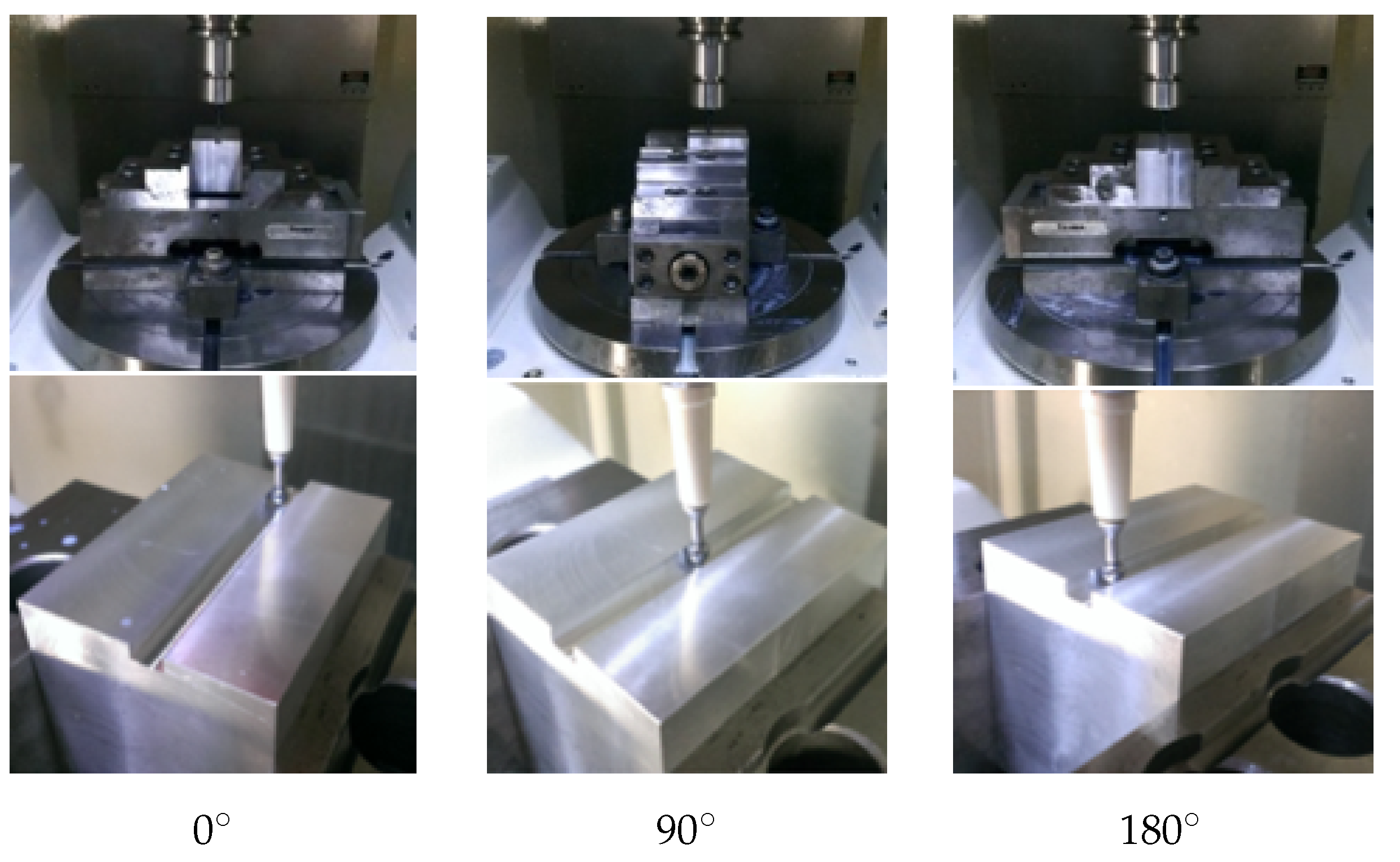

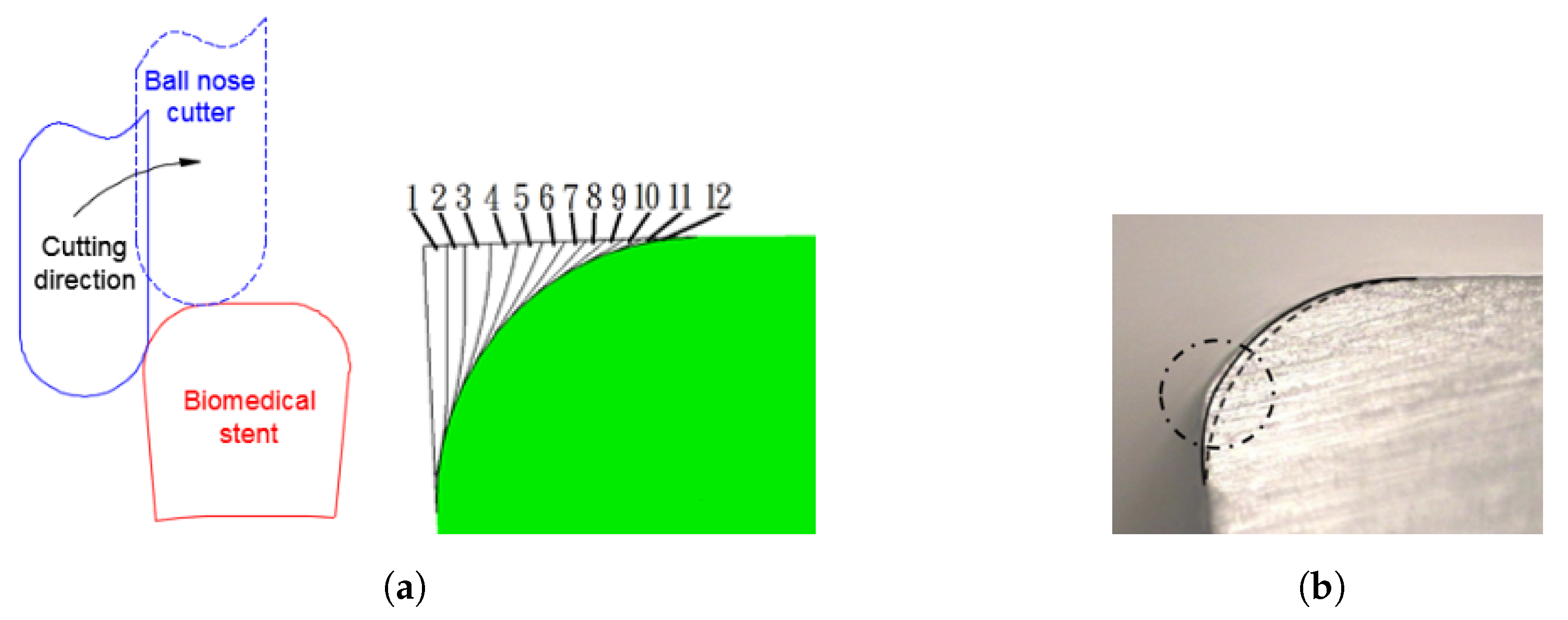

2.4. Cutting Path Planning in Five-Axis Computer-Aided Manufacturing (CAM) of Stents and Actual Stent Machining

3. Results and Discussion

3.1. Experiment on PLA Cutting Parameter Optimization

3.2. Compensation for Center-of-Rotation Errors

3.3. Cutting-Path Planning in Five-Axis CAM of Stents and Actual Stent Machining

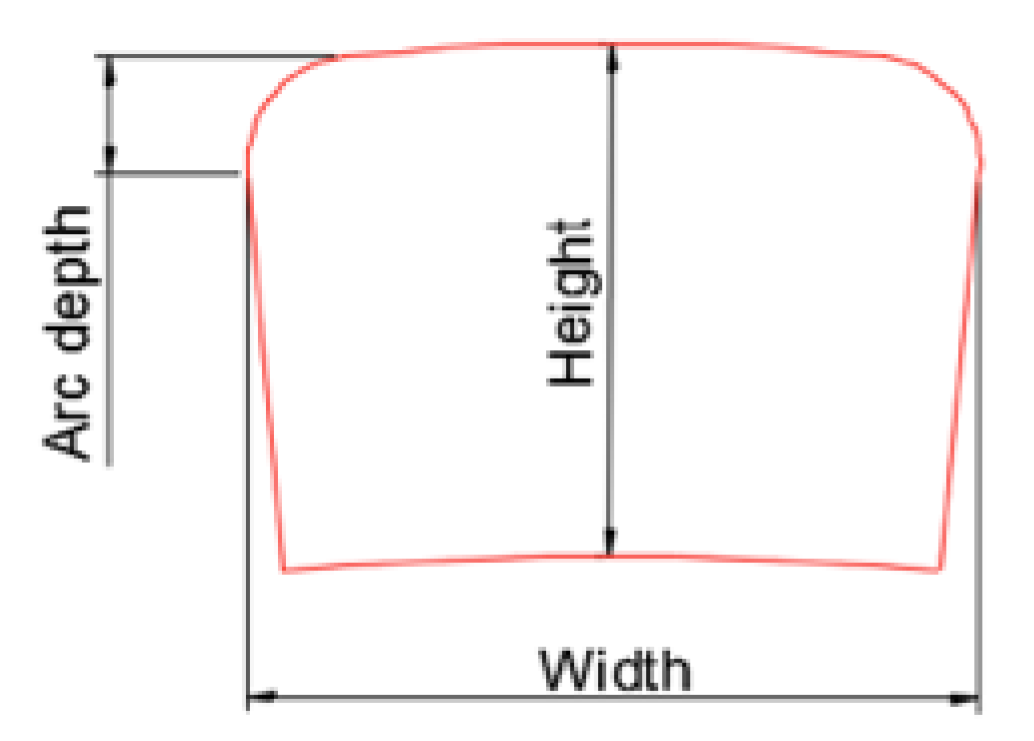

3.3.1. Cross-Section Height of the Stent

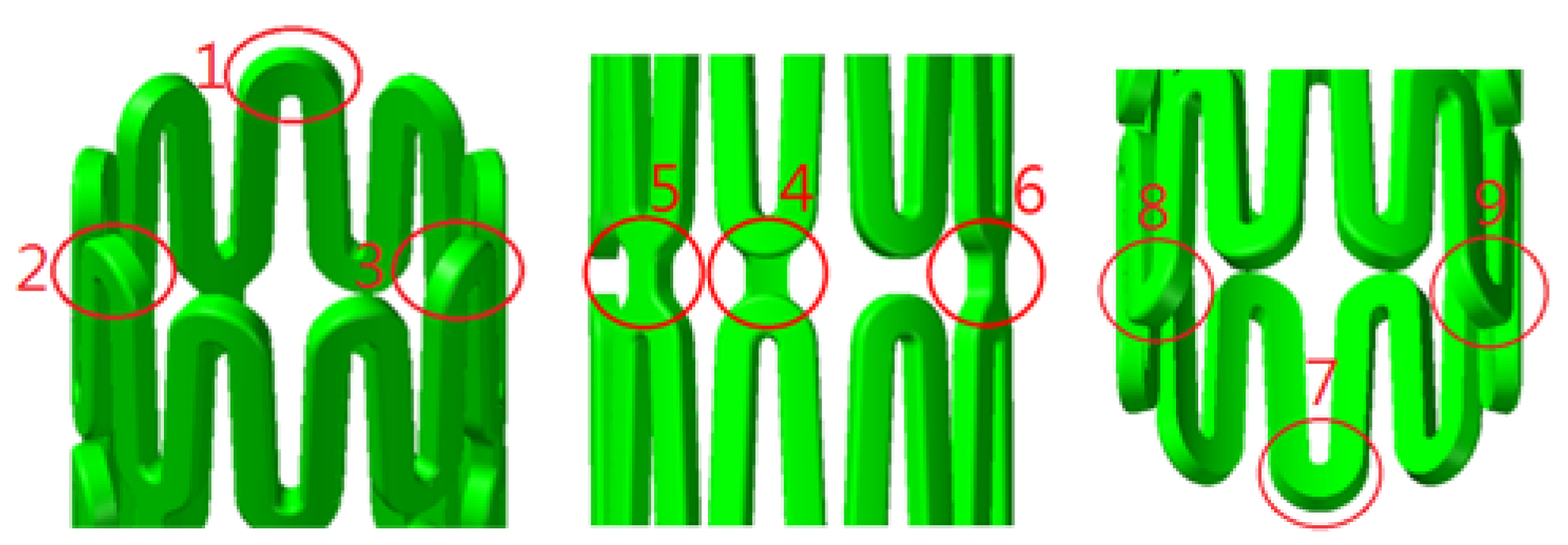

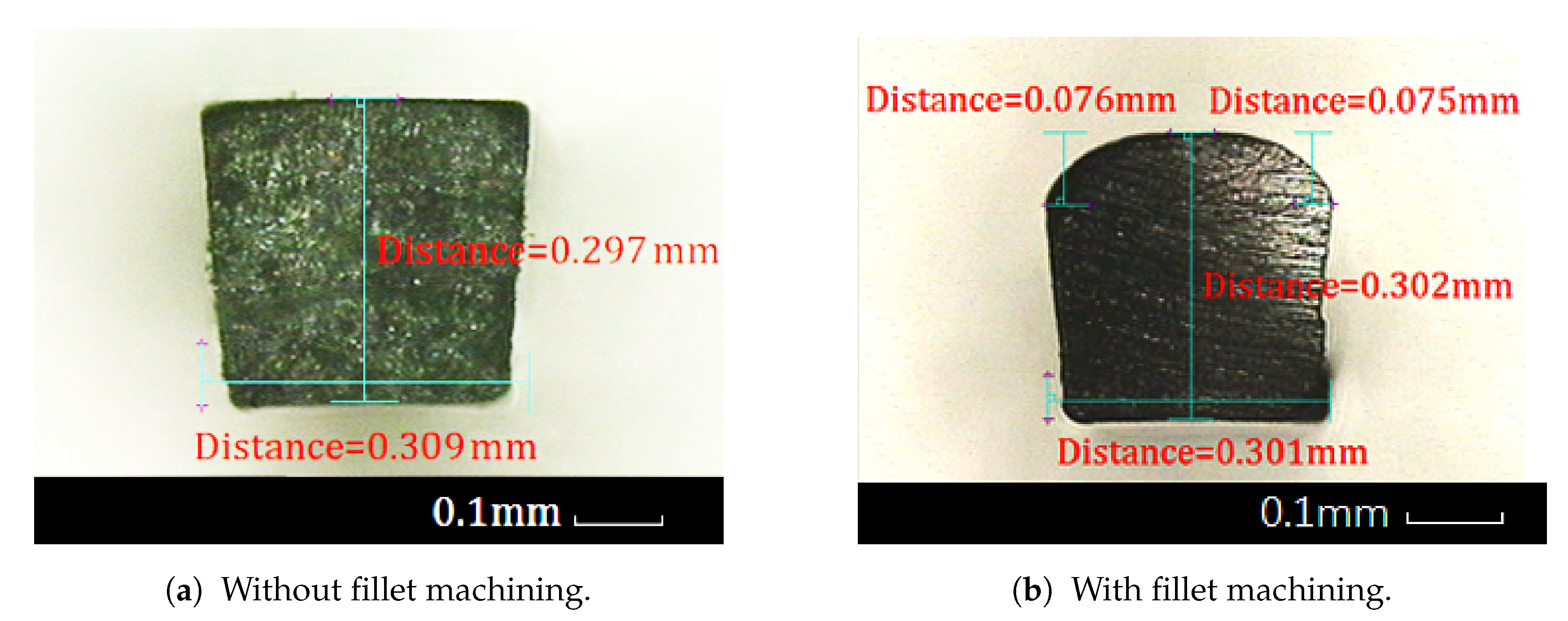

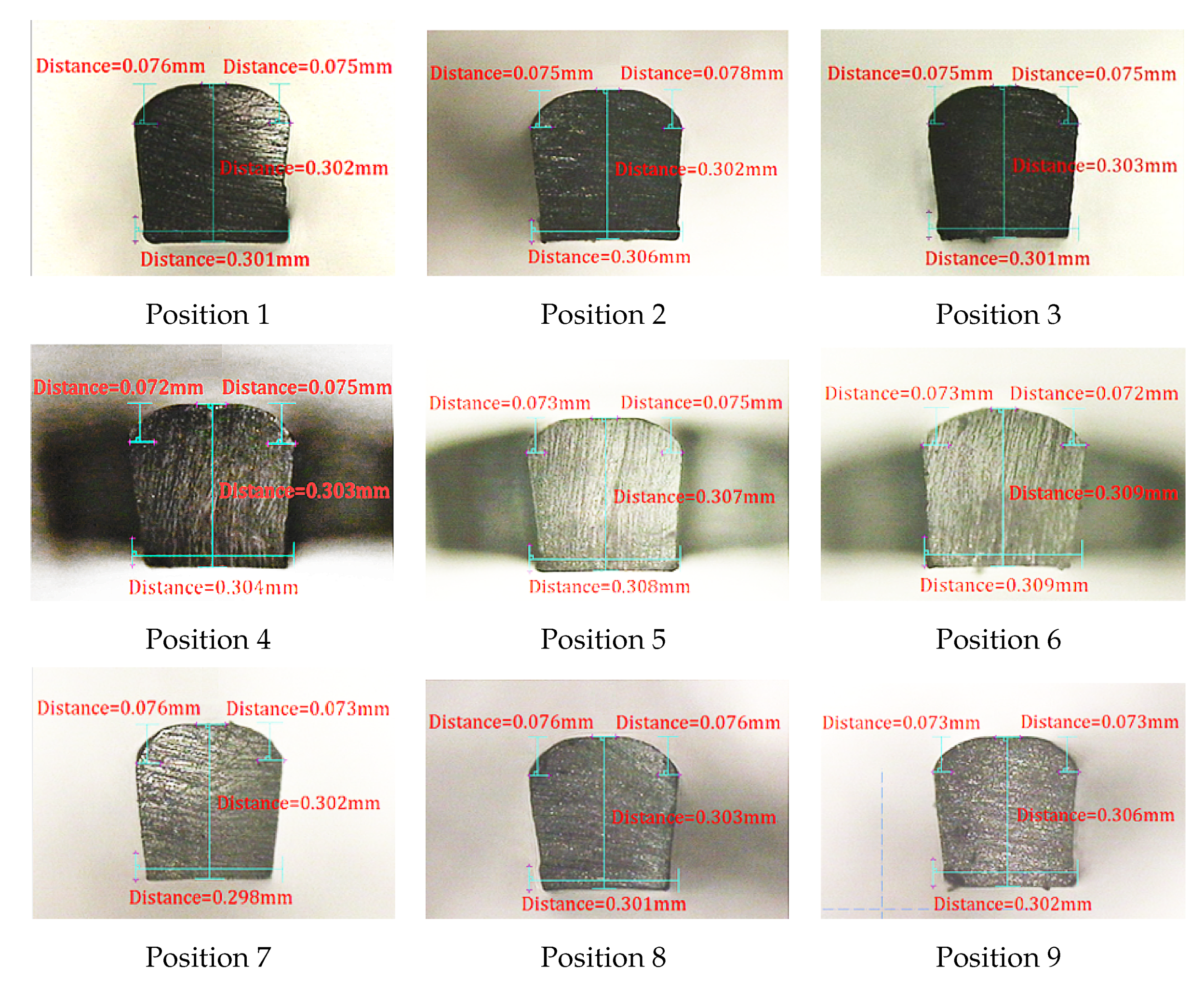

3.3.2. Cross-Section Width of the Stent

3.3.3. Stent Arc Homogeneity

3.3.4. Arc Dimension Errors

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Shabalovskaya, S. On the nature of the biocompatibility and on medical applications of NiTi shape memory and superelastic alloys. Biomed. Mater. Eng. 1996, 6, 267–289. [Google Scholar] [CrossRef] [PubMed]

- Hodgson, D.E.; Ming, W.H.; Biermann, R.J. Shape memory alloys. In Metals Handbook, 10th ed.; ASM International: Cleveland, OH, USA, 1990; Volume 2, pp. 897–902. [Google Scholar]

- Stoeckel, D.; Bonsignore, C.; Duda, S. A survey of stent designs. Minim. Invasive Therapy Allied Technol. 2002, 11, 137–147. [Google Scholar] [CrossRef] [PubMed]

- Hung, C.H.; Chang, F.Y.; Chang, T.L. Micromachining NiTi tubes for use in medical devices by using a femtosecond laser. Opt. Laser Eng. 2015, 66, 34–40. [Google Scholar] [CrossRef]

- Hung, C.H.; Chang, F.Y. Curve micromachining on the edges of nitinol biliary stent by ultrashort pulses laser. Opt. Laser Technol. 2017, 90, 1–6. [Google Scholar] [CrossRef]

- Liu, Z.W. Development of Post Treatment for Biomedical Nitinol Stents. Master’s Thesis, National Taiwan University of Science and Technology, Taipei, Taiwan, 2015. [Google Scholar]

- Bax, B.; Müssig, J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Lim, L.T.; Auras, R.; Rubino, M. Processing technologies for poly (lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Wang, J.S. A Geometry Driven Approach to Improving the Cutting Performance of Five-Axis Tool Paths. Master’s Thesis, National Taiwan University of Science and Technology, Taipei, Taiwan, 2013. [Google Scholar]

- Jung, Y.H.; Lee, D.W.; Kim, J.S.; Mok, H.S. NC post-processor for 5-axis milling machine of table-rotating/ tilting type. J. Mater. Process. Technol. 2002, 130–131, 641–646. [Google Scholar] [CrossRef]

- She, C.H.; Huang, Z.T. Postprocessor development of a five-axis machine tool with nutating head and table configuration. Int. J. Adv. Manuf. Technol. 2007, 38, 728–740. [Google Scholar] [CrossRef]

- She, C.H.; Chang, C.C. Development of a five-axis postprocessor system with a nutating head. J. Mater. Process. Technol. 2007, 187–188, 60–64. [Google Scholar] [CrossRef]

- Liao, M.Y. Using DBB for Measuring and Calibrating Gemetric Errors of 5-Axis CNC Machine Tools. Master’s Thesis, National Tsing Hua University, Hsinchu, Taiwan, 2005. [Google Scholar]

- Bryan, J.B. A simple method for testing measuring machines and machine tools. Precis. Eng. 1982, 4, 61–69. [Google Scholar] [CrossRef]

- Sono, M.; Sakaida, Y.; Kawai, T.; Takeuchi, Y. Development of tool setting error compensation method for 5-axis control ultraprecision machining. In Proceedings of the 20th Annual ASPE Meeting, Norfolk, VA, USA, 9–14 October 2005; p. 435. [Google Scholar]

- Yuan, Z.J.; Zhou, M.; Dong, S. Effect of diamond tool sharpness on minimum cutting thickness and cutting surface integrity in ultraprecision machining. J. Mater. Process. Technol. 1996, 62, 327–330. [Google Scholar] [CrossRef]

- Chae, J.; Park, S.S.; Freiheit, T. Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 2006, 46, 313–333. [Google Scholar] [CrossRef]

- Jardret, V.; Zahouani, H.; Loubeta, J.L.; Mathia, T.G. Understanding and quantification of elastic and plastic deformation during a scratch test. Wear 1998, 218, 8–14. [Google Scholar] [CrossRef]

- Bang, Y.B.; Lee, K.M.; Oh, S. 5-axis micro milling machine for machining micro parts. Int. J. Adv. Manuf. Technol. 2005, 25, 888–894. [Google Scholar] [CrossRef]

- Islam, S.; Ibrahim, R.; Khondoker, N. Effect of machining velocity in nanoscale machining operations. Mater. Sci. Eng. 2015, 78, 012030. [Google Scholar] [CrossRef]

- Eckman, N.; Saigal, A.; James, T.P. Determination of cutting edge separation point during micromachining of highly elastic materials. In Proceedings of the 15th International Conference on Experimental Mechanics, Porto, Portugal, 22–27 July 2012. [Google Scholar]

- Carr, J.W.; Feger, C. Ultraprecision machining of polymers. Precis. Eng. 1993, 15, 221–237. [Google Scholar] [CrossRef]

- Xiao, K.Q.; Zhang, L.C. The role of viscous deformation in the machining of polymers. Int. J. Mech. Sci. 2002, 44, 2317–2336. [Google Scholar] [CrossRef]

- Grabow, N.; Bunger, C.M.; Sternberg, K.; Mews, S.; Schmohl, K.; Schmitz, K.P. Mechanical Properties of a Biodegradable Balloon-expandable Stent from Poly(l-lactide) for Peripheral Vascular Applications. J. Med. Device 2007, 1, 84–88. [Google Scholar] [CrossRef]

- Stepak, B.; Antonczak, A.J.; Bartkowiak-Jowsa, M.; Filipiak, J.; Pezowicz, C.; Abramski, K.M. Fabrication of a polymer-based biodeg-radable stent using a CO2 laser. Arch. Civ. Mech. Eng. 2014, 14, 317–326. [Google Scholar] [CrossRef]

- Wang, C.H. Study of Properties and Cell Culture of Small-Diameter Synthetic PLA/PCL Vascular Scaffold via Electrospinning. Master’s Thesis, National Chiao Tung University, Hsinchu, Taiwan, 2002. [Google Scholar]

- Teng, P.T. Development of Biodegradable Polylactide Graft Stent Using Circular Thermal Imprint. Ph.D. Thesis, National Taiwan University of Science and Technology, Taipei, Taiwan, 2014. [Google Scholar]

- Kao, C.L. Development of 5-French Nitinol Biliary Stents. Master’s Thesis, National Taiwan University of Science and Technology, Taipei, Taiwan, 2017. [Google Scholar]

- Sheikh-Ahmad, J.Y. Machining of Polymer Composites; Springer: Boston, MA, USA, 2009. [Google Scholar]

- Litvin, F.L.; Fuentes, A. Gear Geometry and Applied Theory; Cambridge University Press: Cambridge, UK, 2004; pp. 1–32. [Google Scholar]

| Position | Width | Section Width | Section Width Errors | Section Width | Section Width Errors |

|---|---|---|---|---|---|

| (No.) | (Theoretical Value) | without Compensation | without Compensation | with Compensation | with Compensation |

| 1 | 0.3 | 0.301 | 0.001 | 0.301 | 0.001 |

| 2 | 0.3 | 0.301 | 0.001 | 0.306 | 0.006 |

| 3 | 0.3 | 0.305 | 0.005 | 0.301 | 0.001 |

| 4 | 0.3 | 0.305 | 0.005 | 0.304 | 0.004 |

| 5 | 0.3 | 0.312 | 0.012 | 0.308 | 0.008 |

| 6 | 0.3 | 0.313 | 0.013 | 0.309 | 0.009 |

| 7 | 0.3 | 0.303 | 0.003 | 0.298 | 0.002 |

| 8 | 0.3 | 0.307 | 0.007 | 0.301 | 0.001 |

| 9 | 0.3 | 0.303 | 0.003 | 0.302 | 0.002 |

| Position | Arc Depth | Arc Depth without | Arc Depth Errors | Arc Depth with | Arc Depth Errors |

|---|---|---|---|---|---|

| (No.) | (Theoretical Value) A | Compensation B | A–B | Compensation D | A–D |

| 1 | 0.1 | 0.106 | 0.006 | 0.077 | 0.023 |

| 2 | 0.1 | 0.063 | 0.037 | 0.074 | 0.026 |

| 3 | 0.1 | 0.055 | 0.045 | 0.076 | 0.024 |

| 4 | 0.1 | 0.098 | 0.002 | 0.075 | 0.025 |

| 5 | 0.1 | 0.059 | 0.041 | 0.073 | 0.027 |

| 6 | 0.1 | 0.064 | 0.036 | 0.076 | 0.024 |

| 7 | 0.1 | 0.104 | 0.004 | 0.079 | 0.021 |

| 8 | 0.1 | 0.063 | 0.037 | 0.074 | 0.026 |

| 9 | 0.1 | 0.054 | 0.046 | 0.074 | 0.026 |

| Number | Theoretical Removed | Actual Removed | Removed Thickness with |

|---|---|---|---|

| of Cutting | Thickness | Thickness | Considering 33% Rebound |

| 1 | 6.64 | 4.45 | 2.19 |

| 2 | 10.28 | 6.88 | 3.40 |

| 3 | 15.05 | 10.08 | 4.97 |

| 4 | 15.45 | 10.35 | 5.10 |

| 5 | 13.37 | 8.96 | 4.41 |

| 6 | 11.33 | 7.59 | 3.74 |

| 7 | 10.00 | 6.70 | 3.30 |

| 8 | 7.63 | 5.11 | 2.52 |

| 9 | 5.75 | 3.85 | 1.90 |

| 10 | 4.08 | 2.73 | 1.35 |

| 11 | 2.54 | 1.70 | 0.84 |

| 12 | 0.83 | 0.56 | 0.27 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, F.-Y.; Chen, Y.-C.; Liang, T.-H.; Cai, Z.-Y. Fabrication of Edge Rounded Polylactic Acid Biomedical Stents by the Multi-Axis Micro-Milling Process. Appl. Sci. 2020, 10, 2809. https://doi.org/10.3390/app10082809

Chang F-Y, Chen Y-C, Liang T-H, Cai Z-Y. Fabrication of Edge Rounded Polylactic Acid Biomedical Stents by the Multi-Axis Micro-Milling Process. Applied Sciences. 2020; 10(8):2809. https://doi.org/10.3390/app10082809

Chicago/Turabian StyleChang, Fuh-Yu, Yan-Chiau Chen, Te-Hsien Liang, and Zong-Yan Cai. 2020. "Fabrication of Edge Rounded Polylactic Acid Biomedical Stents by the Multi-Axis Micro-Milling Process" Applied Sciences 10, no. 8: 2809. https://doi.org/10.3390/app10082809

APA StyleChang, F.-Y., Chen, Y.-C., Liang, T.-H., & Cai, Z.-Y. (2020). Fabrication of Edge Rounded Polylactic Acid Biomedical Stents by the Multi-Axis Micro-Milling Process. Applied Sciences, 10(8), 2809. https://doi.org/10.3390/app10082809