Development and Performance Evaluation of Eco-Friendly POSS-Containing MQL Oil Coolant for Drilling Processes

Abstract

1. Introduction

2. Design of POSS-Containing MQL Oil

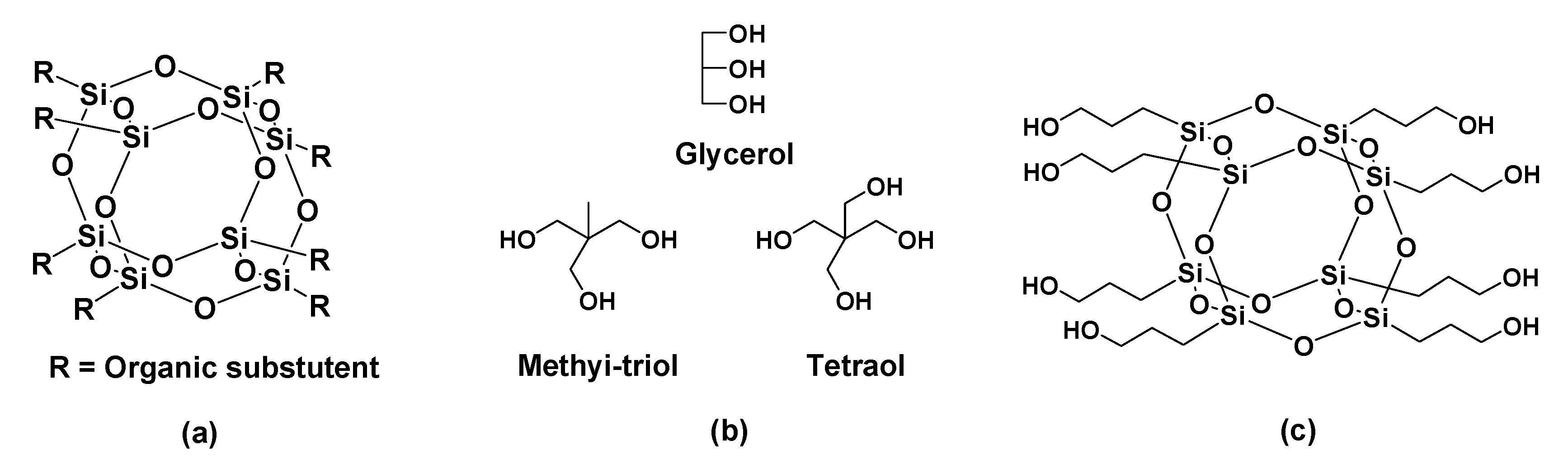

2.1. POSS

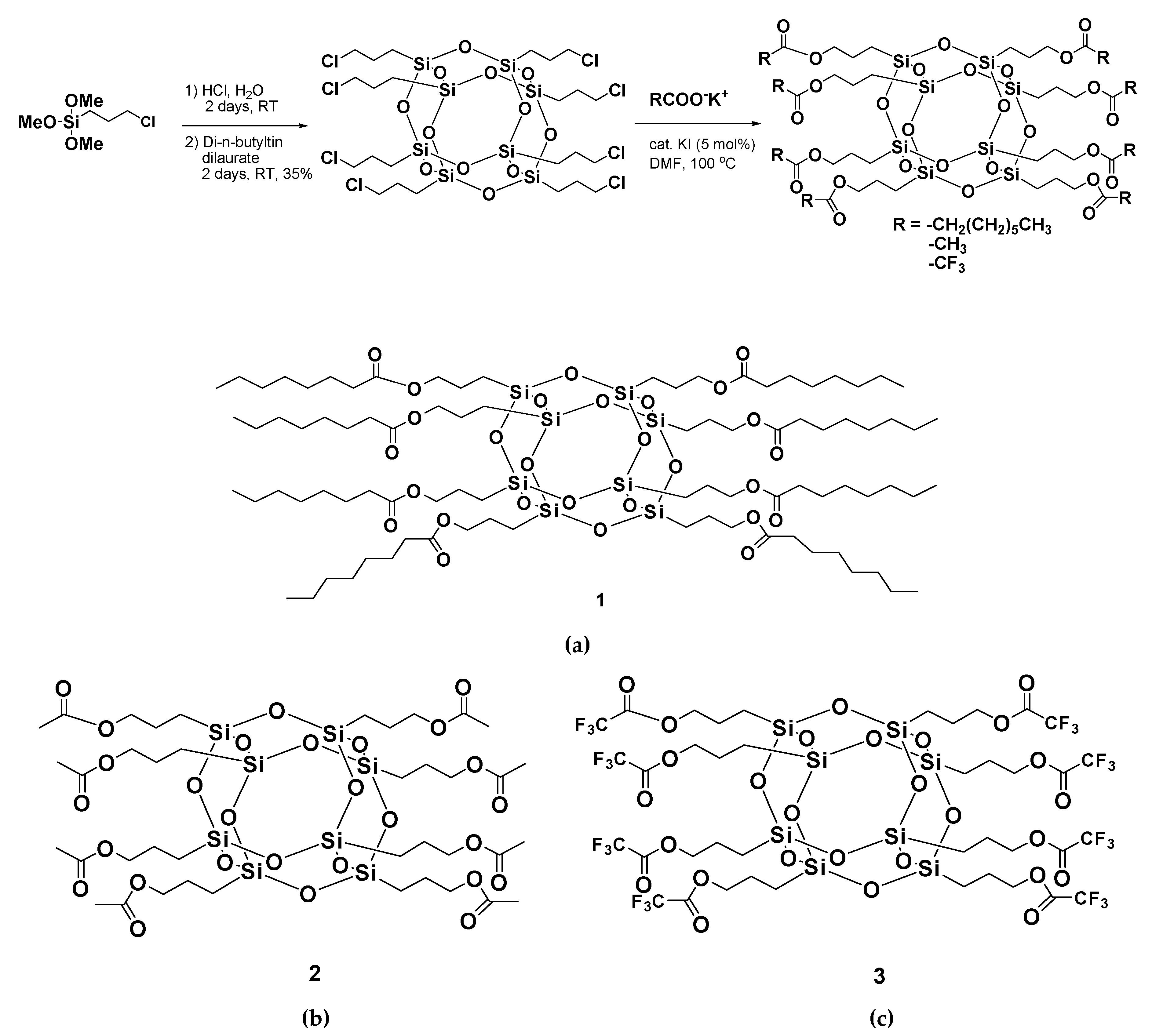

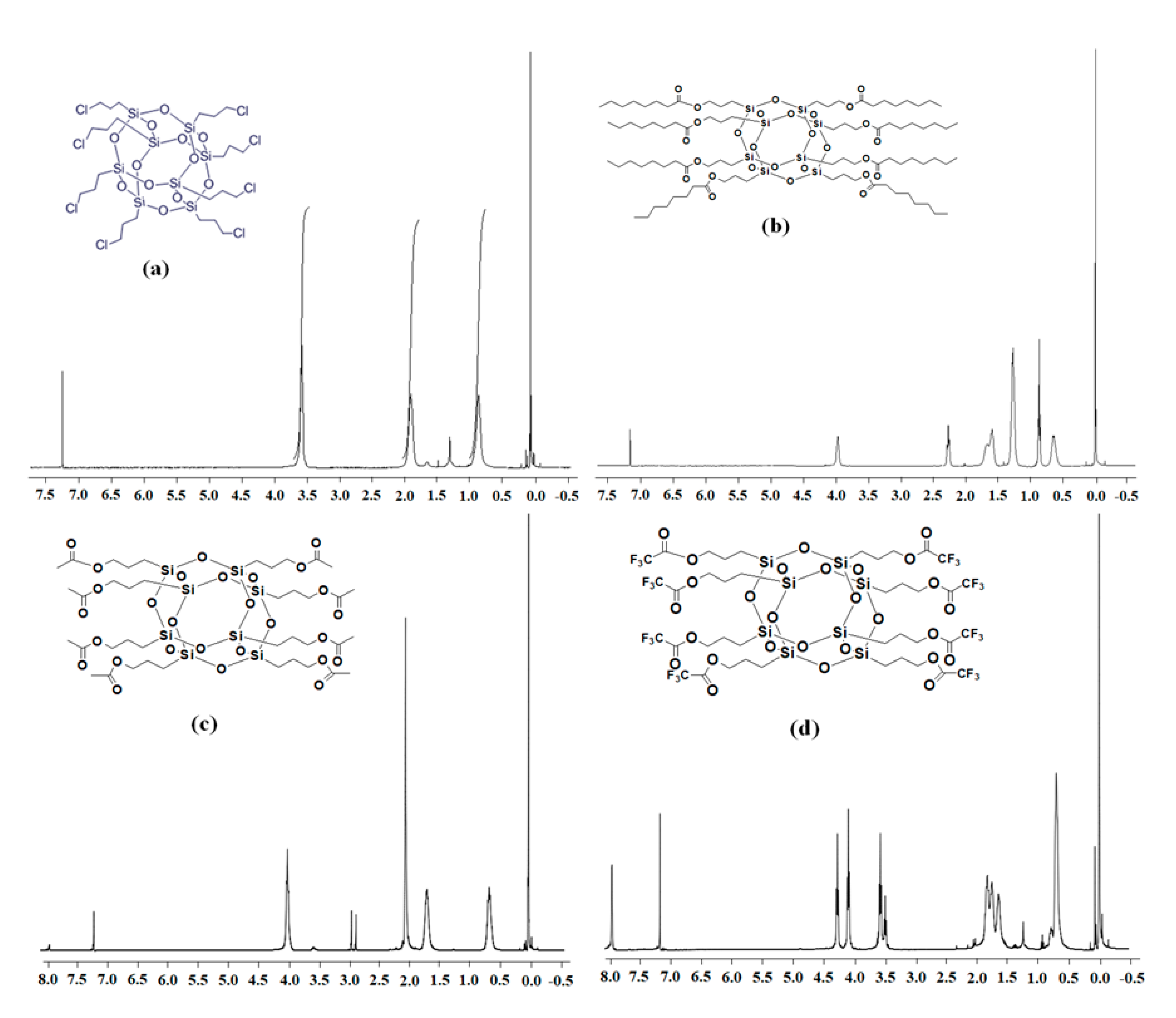

2.2. Synthesis of POSS Ester Compound

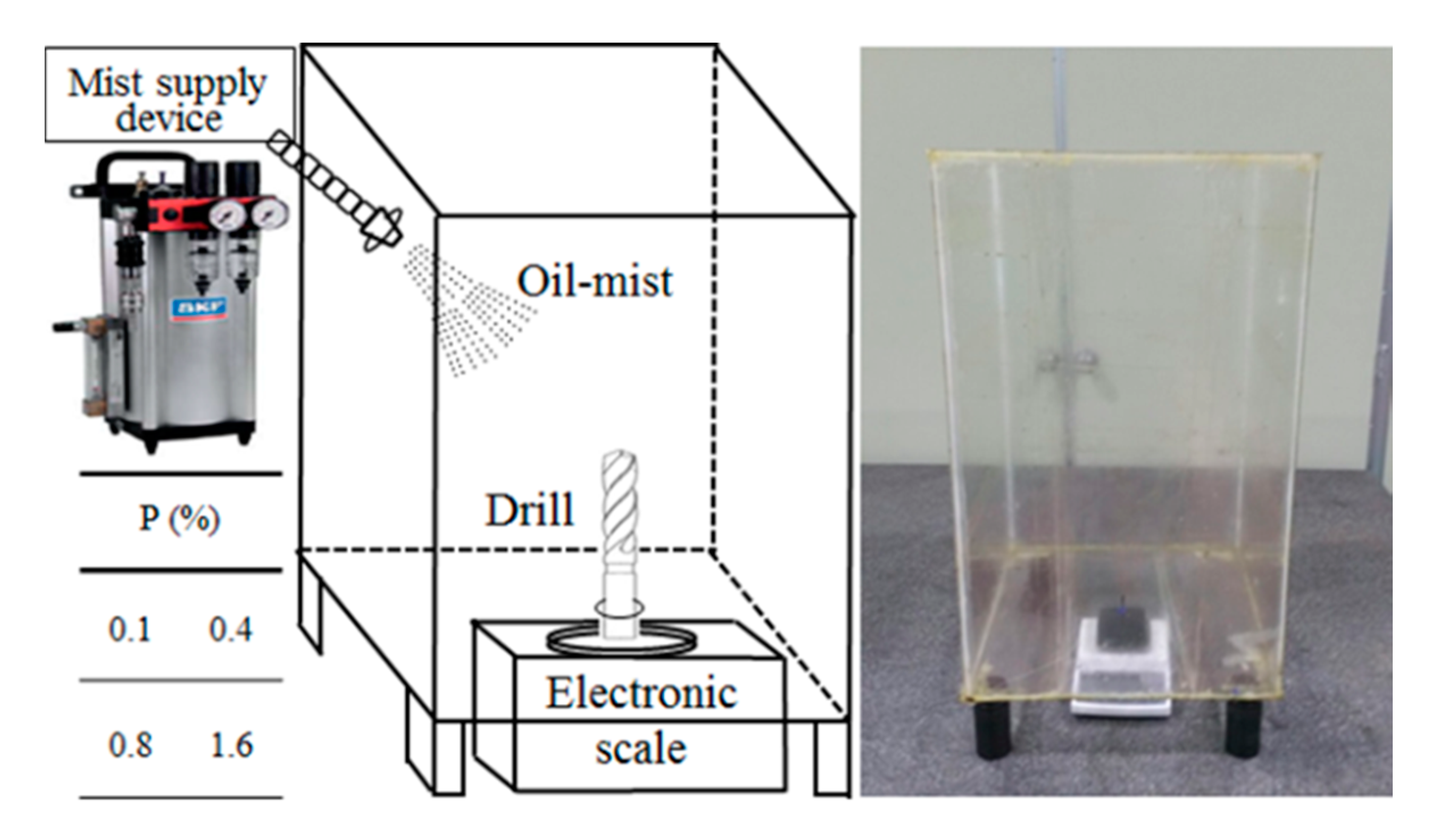

3. Apparatus and Methods

4. Effects of POSS-Containing MQL Oil

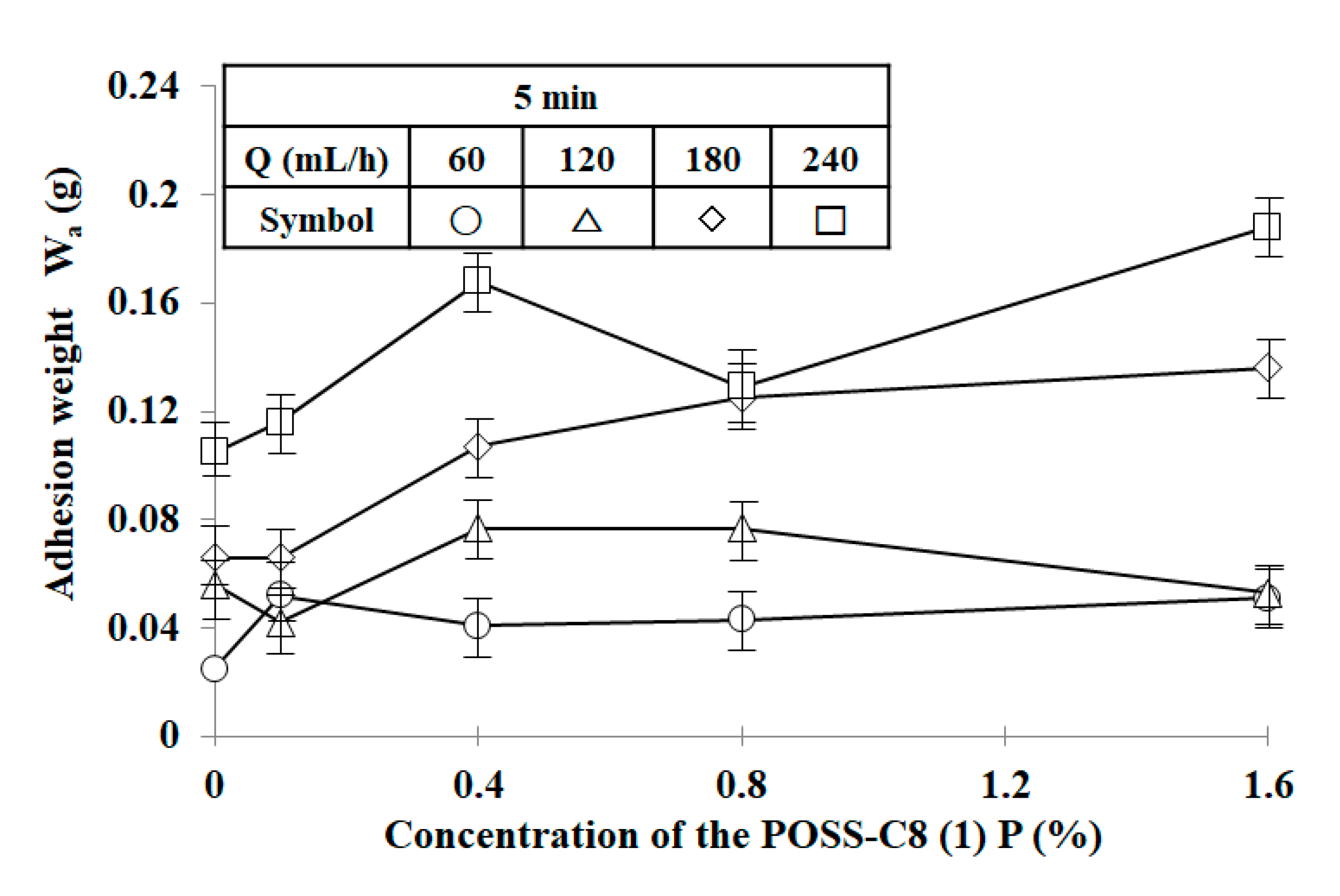

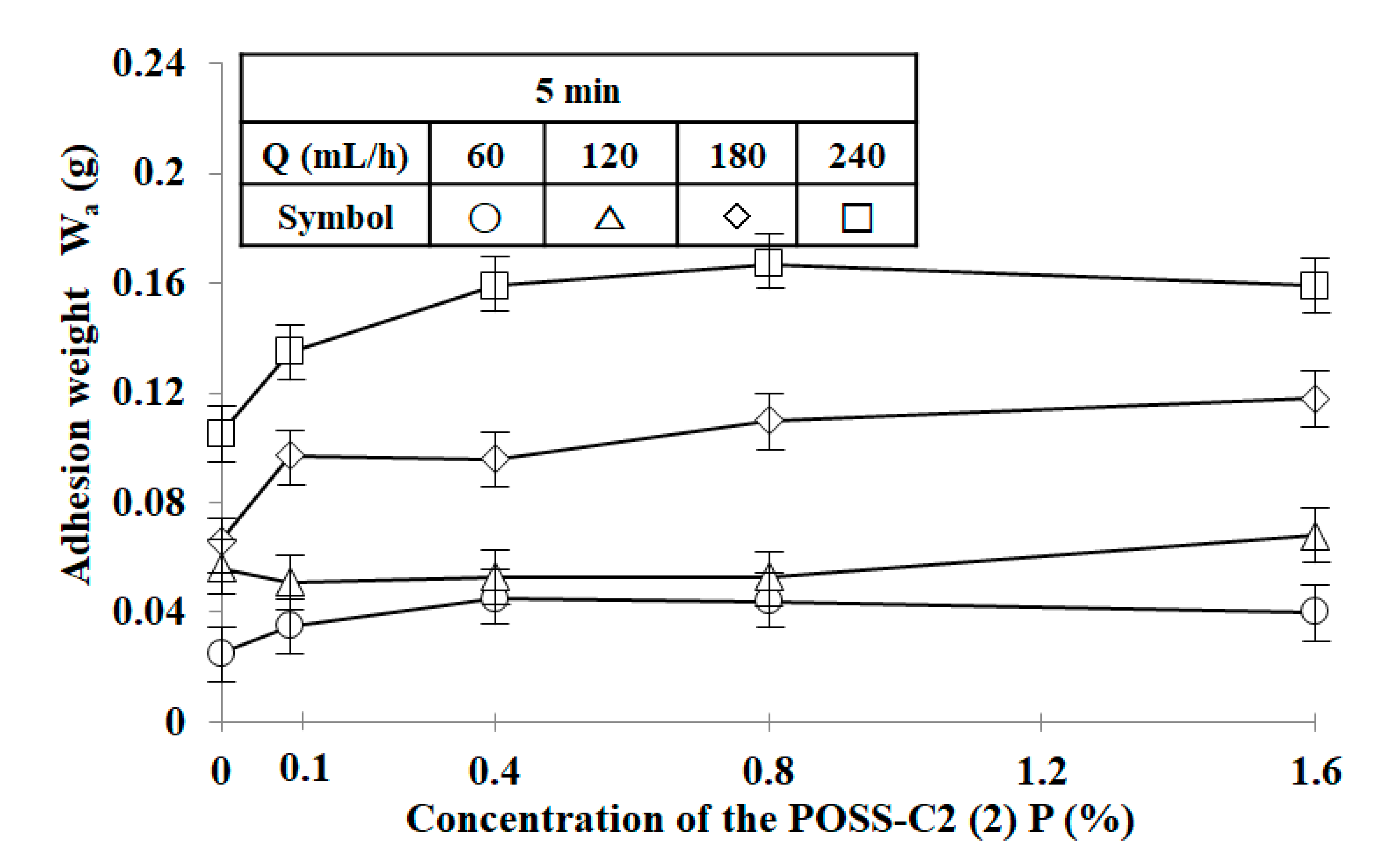

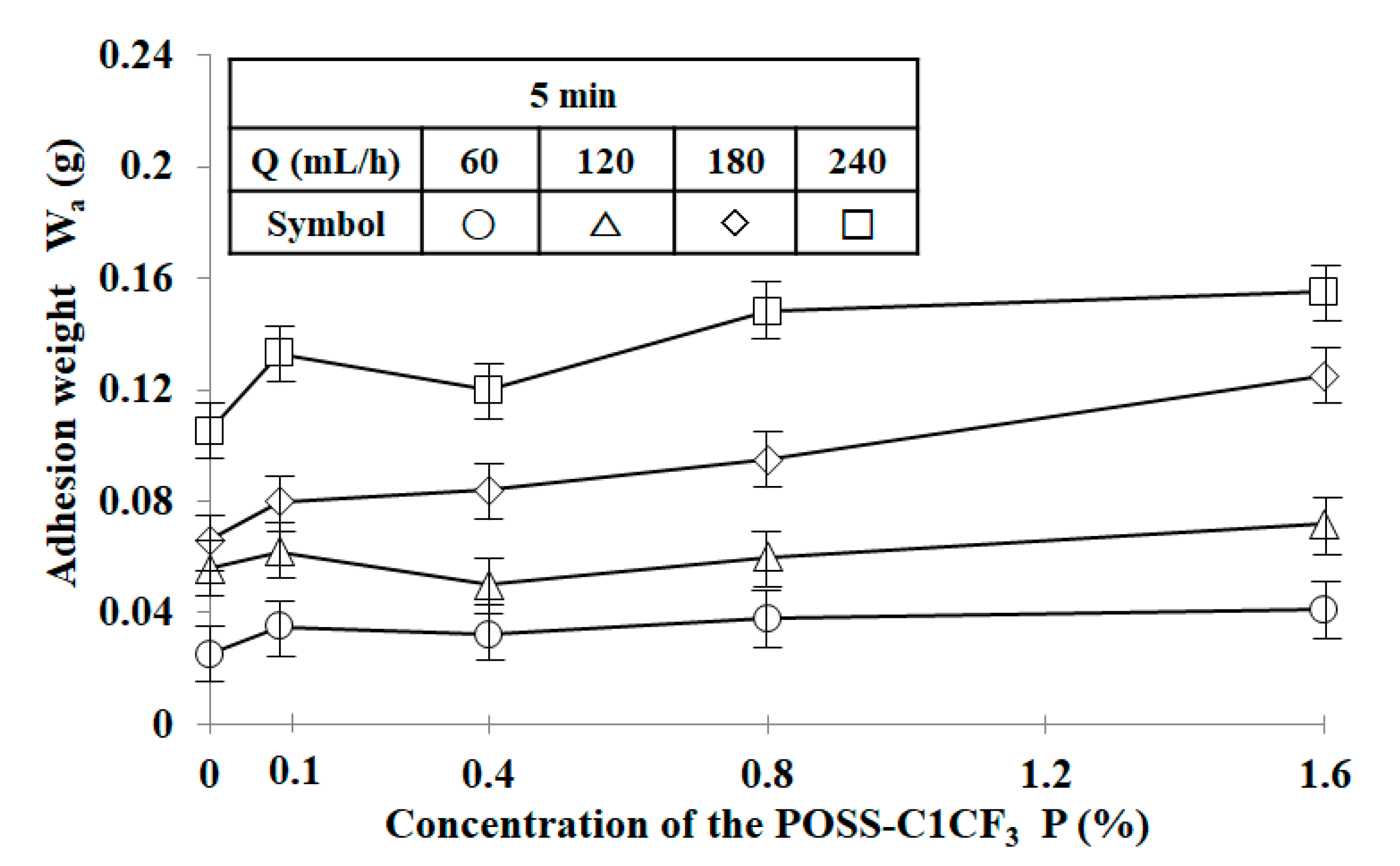

4.1. Adhesion Evaluation of POSS-Containing MQL Oil

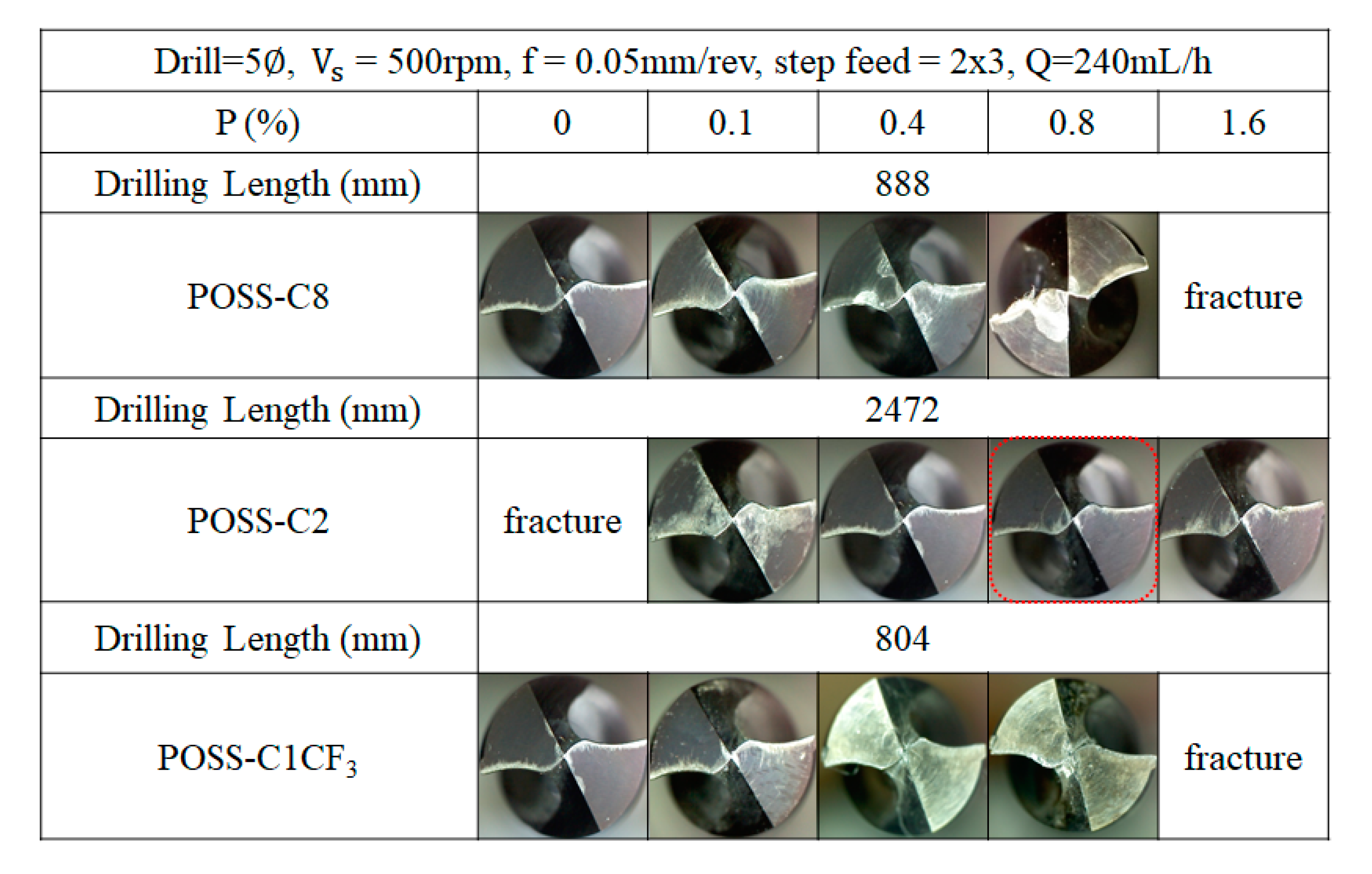

4.2. Drilling Evaluation of POSS-Containing MQL Oil

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Vs | Spindle speed (rpm) |

| F | Feed rate (mm/rev) |

| Ft | Thrust force (N) |

| Ff | Fluctuation width of thrust force (N) |

| L | Drilling length (mm) |

| Lf | Drilling length to fracture (mm) |

| P | Consistence of POSS ester compound (%) |

| Po | Oil mist pressure (bar) |

| Pa | Air pressure (bar) |

| Q | Oil mist flow rate (ml/h) |

| Wa | Average weight (g) |

References

- Choudhury, I.A.; El-Baradie, M.A. Machinability of nickel-base super alloys: A general review. J. Mater. Process. Tech. 1998, 77, 278–284. [Google Scholar] [CrossRef]

- Rahman, M.; Seah, W.K.H.; Teo, T.T. The machinability of Inconel 718. J. Mater. Process. Tech. 1997, 63, 199–204. [Google Scholar] [CrossRef]

- Nalbant, M.; Altın, A.; Gökkaya, H. The effect of coating material and geometry of cutting tool and cutting speed on machinability properties of Inconel 718 super alloys. Mater. Des. 2007, 28, 1719–1724. [Google Scholar] [CrossRef]

- Maiyar, L.M.; Ramanujam, R.; Venkatesan, K.; Jerald, J. Optimization of machining parameters for end milling of Inconel 718 super alloy using Taguchi based grey relational analysis. Procedia Eng. 2013, 64, 1276–1282. [Google Scholar] [CrossRef]

- Tian, X.; Zhao, J.; Zhao, J.; Gong, Z.; Dong, Y. Effect of cutting speed on cutting forces and wear mechanisms in high-speed face milling of Inconel 718 with Sialon ceramic tools. Int. J. Adv. Manuf. Technol. 2013, 69, 2669–2678. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.; Zhu, X.; Lv, H. Saw-tooth chip formation and its effect on cutting force fluctuation in turning of Inconel 718. Int. J. Precis. Eng. Man. 2013, 14, 957–963. [Google Scholar] [CrossRef]

- Woon, K.S.; Chaudhari, A.; Rahman, M.; Wan, S.; Kumar, A.S. The effects of tool edge radius on drill deflection and hole misalignment in deep hole gundrilling of Inconel-718. CIRP Ann. 2014, 63, 125–128. [Google Scholar] [CrossRef]

- Baghlani, V.; Mehbudi, P.; Akbari, J.; Sohrabi, M. Ultrasonic assisted deep drilling of Inconel 738LC superalloy. Procedia Cirp. 2013, 6, 571–576. [Google Scholar] [CrossRef]

- Ulutan, D.; Ozel, T. Machining induced surface integrity in titanium and nickel alloys: A review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Biermann, D.; Iovkov, I.; Blum, H.; Rademacher, A.; Taebi, K.; Suttmeier, F.T.; Klein, N. Thermal aspects in deep hole drilling of aluminium cast alloy using twist drills and MQL. Procedia CIRP 2012, 3, 245–250. [Google Scholar] [CrossRef]

- Kaynak, Y. Evaluation of machining performance in cryogenic machining of Inconel 718 and comparison with dry and MQL machining. Int. J. Adv. Manuf. Technol. 2014, 72, 919–933. [Google Scholar] [CrossRef]

- Tai, B.L.; Stephenson, D.A.; Furness, R.J.; Shih, A.J. Minimum quantity lubrication (MQL) in automotive powertrain machining. Procedia Cirp. 2014, 14, 523–528. [Google Scholar] [CrossRef]

- Ji, X.; Li, B.; Zhang, X.; Liang, S.Y. The effects of minimum quantity lubrication (MQL) on machining force, temperature, and residual stress. Int. J. Precis. Eng. Manu. 2014, 15, 2443–2451. [Google Scholar] [CrossRef]

- Wang, C.D.; Chen, M.; An, Q.L.; Wang, M.; Zhu, Y.H. Tool wear performance in face milling Inconel 182 using minimum quantity lubrication with different nozzle positions. Int. J. Precis. Eng. Manu. 2014, 15, 557–565. [Google Scholar] [CrossRef]

- Park, K.-H.; Yang, G.-D.; Lee, D.Y. Tool wear analysis on coated and uncoated carbide tools in Inconel machining. Int. J. Precis. Eng. Manu. 2015, 16, 1639–1645. [Google Scholar] [CrossRef]

- Sanchez, J.A.; Pombo, I.; Alberdi, R.; Izquierdo, B.; Ortega, N.; Plaza, S.; Martinez-Toledano, J. Machining evaluation of a hybrid MQL-CO 2 grinding technology. J. Clean. Prod. 2010, 18, 1840–1849. [Google Scholar] [CrossRef]

- Sanchez, C.; Belleville, P.; Popall, M.; Nicole, L. Applications of advanced hybrid organic–inorganic nanomaterials: From laboratory to market. Chem. Soc. Rev. 2011, 40, 696–753. [Google Scholar] [CrossRef]

- Sanchez, C.; Boissiere, C.; Grosso, D.; Laberty, C.; Nicole, L. Design, synthesis, and properties of inorganic and hybrid thin films having periodically organized nanoporosity. Chem. Mater. 2008, 20, 682–737. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, Z.; Fan, H.; Bittencourt, C.; Wan, J.; Dubois, P. A novel polyhedral oligomeric silsesquioxane-modified layered double hydroxide: Preparation, characterization and properties. Beilstein J. Nanotechnol. 2018, 9, 3053–3068. [Google Scholar] [CrossRef]

- Dudziec, B.; Żak, P.; Marciniec, B. Synthetic Routes to Silsesquioxane-Based Systems as Photoactive Materials and Their Precursors. Polymers 2019, 11, 504. [Google Scholar] [CrossRef]

- Marciniec, B.; Dutkiewicz, M.; Maciejewski, H.; Kubicki, M. New, effective method of synthesis and structural characterization of octakis (3-chloropropyl) octasilsesquioxane. Organometallics 2008, 27, 793–794. [Google Scholar] [CrossRef]

- Kumar, B.P.; Vijaykumar, B.V.D.; Raghavan, C.M.; Harshavardhan, S.J.; Yi, S.S.; Gandhi, S.; Shin, D.S. POSS-based luminescent hybrid material for enhanced photo-emitting properties. J. Mater. Sci. 2013, 48, 7533–7539. [Google Scholar] [CrossRef]

- Choi, K.M.; Harshavardhan, S.J.; Sridhar, C.; Vijaykumar, B.V.D.; Kumar, D.; Jang, K.; Shin, D.S. Synthesis of POSS Derived Organic-Inorganic Hybrid Esters for Insulating Oil Applications. Bull. Korean Chem. Soc. 2014, 35, 2769–2773. [Google Scholar] [CrossRef][Green Version]

- Park, K.B.; Cho, Y.T.; Jung, Y.G. Efficient MQL-based Drilling of Inconel 601. J. KSMPE 2018, 17, 1–8. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, K.B.; Shin, D.-S.; Cho, Y.T. Development and Performance Evaluation of Eco-Friendly POSS-Containing MQL Oil Coolant for Drilling Processes. Appl. Sci. 2020, 10, 2751. https://doi.org/10.3390/app10082751

Park KB, Shin D-S, Cho YT. Development and Performance Evaluation of Eco-Friendly POSS-Containing MQL Oil Coolant for Drilling Processes. Applied Sciences. 2020; 10(8):2751. https://doi.org/10.3390/app10082751

Chicago/Turabian StylePark, Ki Beom, Dong-Soo Shin, and Young Tae Cho. 2020. "Development and Performance Evaluation of Eco-Friendly POSS-Containing MQL Oil Coolant for Drilling Processes" Applied Sciences 10, no. 8: 2751. https://doi.org/10.3390/app10082751

APA StylePark, K. B., Shin, D.-S., & Cho, Y. T. (2020). Development and Performance Evaluation of Eco-Friendly POSS-Containing MQL Oil Coolant for Drilling Processes. Applied Sciences, 10(8), 2751. https://doi.org/10.3390/app10082751