Fuel Consumption Test Results for a Self-Adaptive, Maintenance-Free Wood Chipper Drive Control System

Abstract

1. Introduction

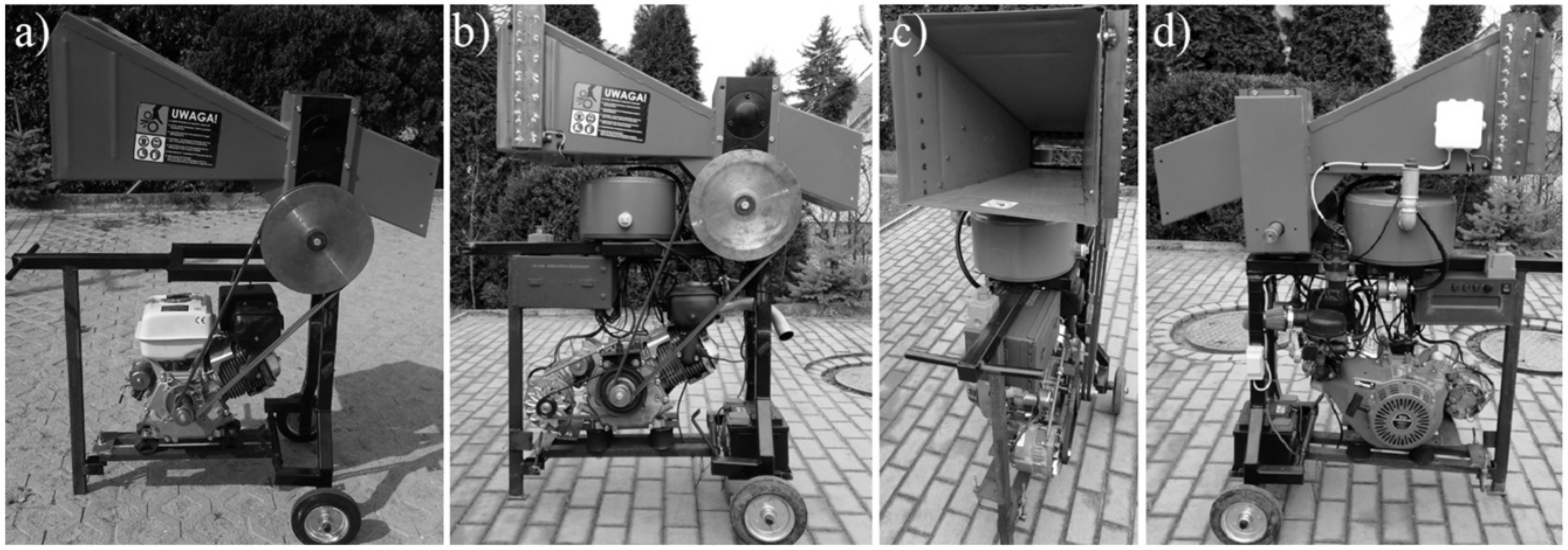

2. Materials and Methods

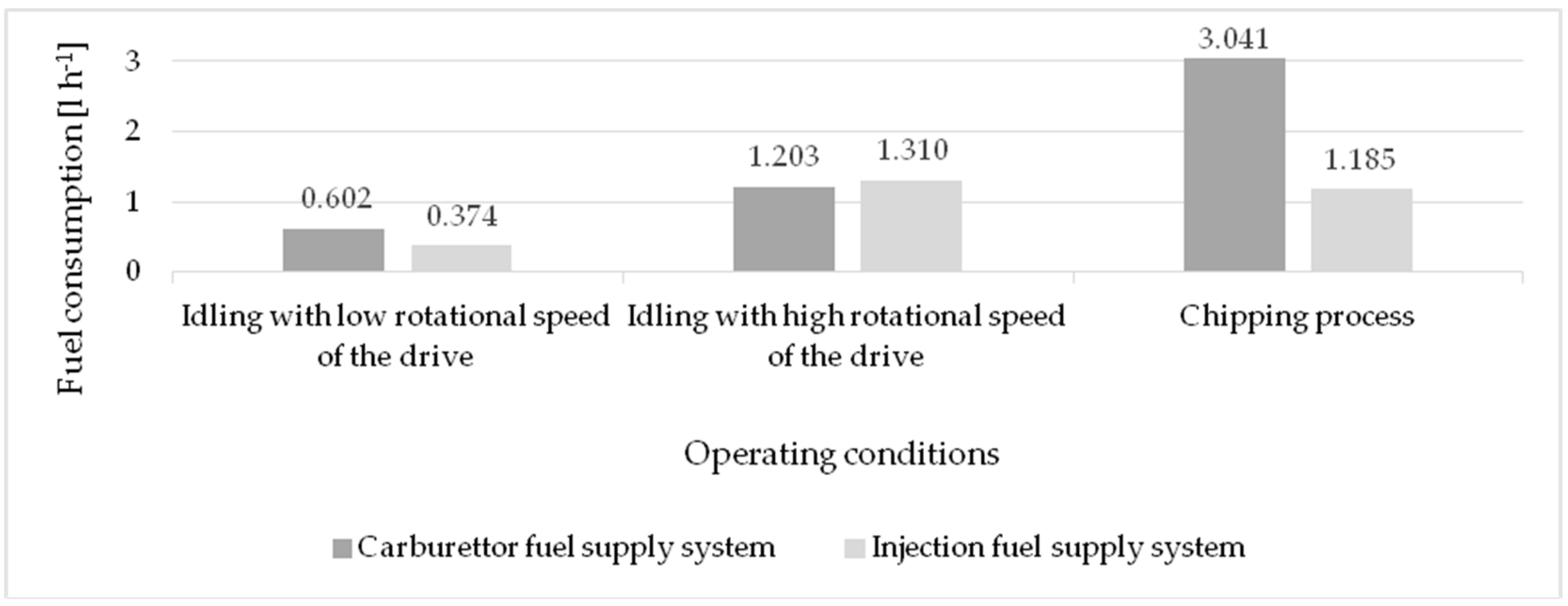

- Idling at low speed (1).

- Idling with maximum torque (2).

- Operation through a continuous chipping process (3).

- The first system–equipped with a carburetor fuel feed system and the classic control concept (A).

- The second system–equipped with an electronic injection system and the classic control concept (B).

- The third system–equipped with an electronic injection system after reequipping with a maintenance-free and adaptive rotation speed control system (C).

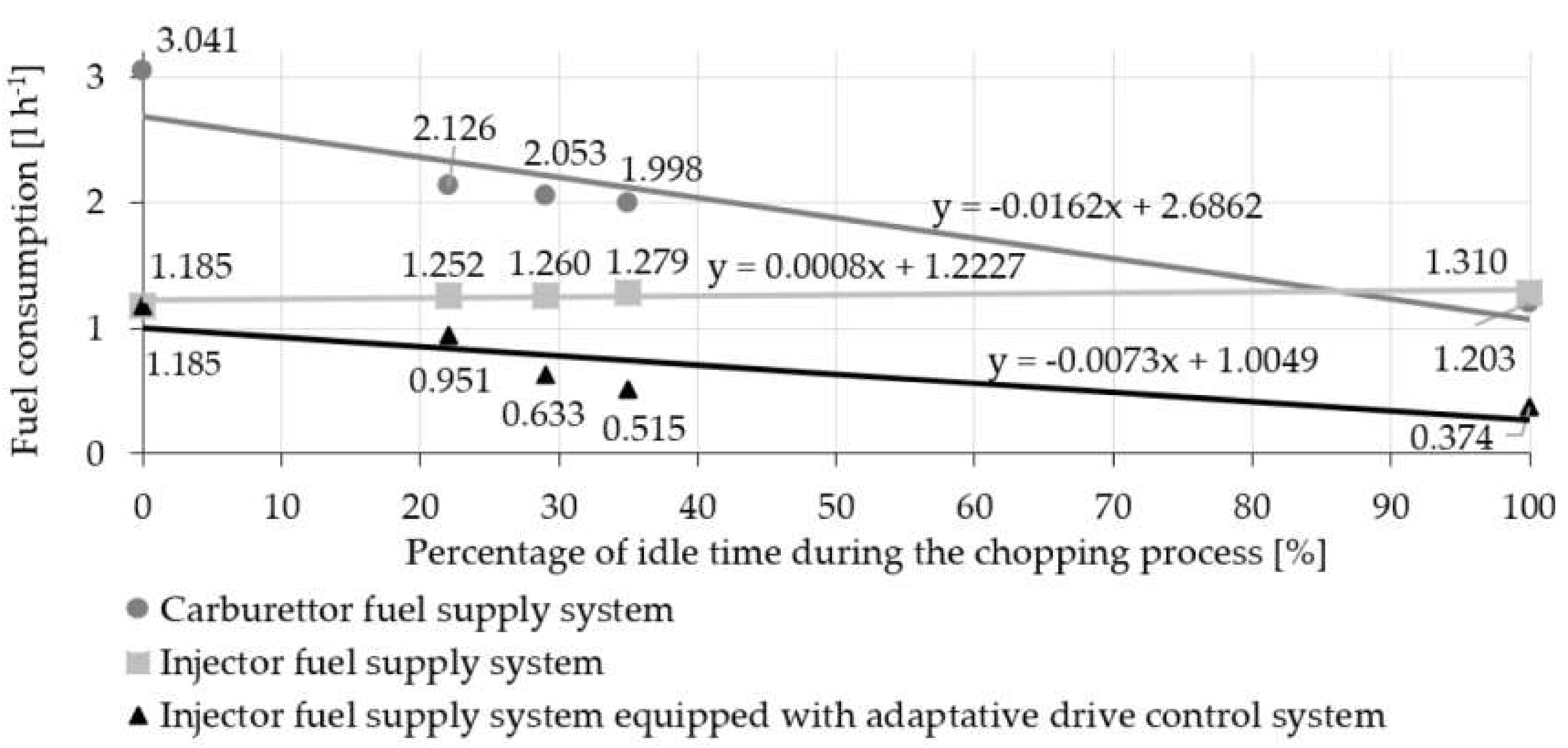

3. Results

4. Discussion

- 24% with a chipping/idle work ratio of 78% to 22%,

- 50% with a chipping/idle work ratio of 71% to 29%,

- 60% with a chipping/idle work ratio of 65% to 35%.

5. Conclusions

- Automatically attaining two idling states by changing the rotational speed, which ensures a reduction in fuel consumption and quantitative exhaust gas emissions,

- Limitation of the operator’s effort in terms of their intensity of attention,

- Reduction of the operator’s stress related to the costs of machine operation.

6. Patents

Author Contributions

Funding

Conflicts of Interest

References

- Haavikko, H.; Kärhä, K.; Hourula, M.; Palander, T. Attitudes of Small and Medium-Sized Enterprises towards Energy Efficiency in Wood Procurement: A Case Study of Stora Enso in Finland. Croat. J. For. Eng. 2019, 40, 107–123. [Google Scholar]

- Gałęzia, T. Energy balance and time-consumption of selected components in technological chain of forest biomass harvesting. Sylwan 2013, 157, 419–424. [Google Scholar]

- Calcante, A.; Facchinetti, D.; Pessina, D. Analysis of Hazardous Emissions of Hand-Operated Forestry Machines Fuelled with Standard Mix or Alkylate Gasoline. Croat. J. For. Eng. 2018, 39, 109–116. [Google Scholar]

- Acuna, M. Timber and biomass transport optimization: A review of planning issues, solution techniques and decision support tools. Croat. J. For. Eng. 2017, 38, 279–290. [Google Scholar]

- Mihelič, M.; Spinelli, R.; Poje, A. Production of Wood Chips from Logging Residue under Space-Constrained Conditions. Croat. J. For. Eng. 2018, 39, 223–232. [Google Scholar]

- Strandgard, M.; Mitchell, R.; Wiedemann, J. Comparison of Productivity, Cost and Chip Quality of Four Balanced Harvest Systems Operating in a Eucalyptus globulus Plantation in Western Australia. Croat. J. For. Eng. 2019, 40, 39–48. [Google Scholar]

- Spinelli, R.; de Arruda Moura, A.C. Productivity and Utilization Benchmarks for Chain Flail Delimber-Debarkers-Chippers Used in Fast-Growing Plantations. Croat. J. For. Eng. 2019, 40, 65–80. [Google Scholar]

- Macko, M.; Tyszczuk, K.; Śmigielski, G.; Mroziński, A. Utility of an unitary-shredding method to evaluate the conditions and selection of constructional features during grinding. In Proceedings of the MATEC Web of Conferences, Proceedings of the Machine Modelling and Simulations, Sklené Teplice, Slovak Republic, 5–8 September 2017; EDP Sciences: Lez Ili, France, 2018; Volume 157. [Google Scholar]

- Guerrini, L.; Tirinnanzi, A.; Guasconi, F.; Fagarazzi, C.; Baldi, F.; Masella, P.; Parenti, A. A Plackett-Burman Design to Optimize Wood Chipper Settings. Croat. J. For. Eng. 2019, 40, 81–87. [Google Scholar]

- Spinelli, R.; Magagnotti, N.; Schweier, J. Trends and perspectives in coppice harvesting. Croat. J. For. Eng. 2017, 38, 219–230. [Google Scholar]

- Baldauf, R.; Fortune, C.; Weinstein, J.; Wheeler, M.; Blanchard, F. Air contaminant exposures during the operation of lawn and garden equipment. J. Expo. Sci. Environ. Epidemiol. 2006, 16, 362–370. [Google Scholar] [CrossRef]

- Czerwiński, J.; Kurzwart, M.; Mayer, A.; Comte, P. Particle Emissions of Modern Handheld Machines; SAE Techn Paper; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Merkisz, J.; Lijewski, P.; Pielecha, J. PEMS-based investigations into exhaust emissions from non-road and rail vehicles. Comb. Eng. 2016, 166, 46–53. [Google Scholar]

- Liu, S.; Han, W.; Zeng, J.; Wang, J. Analysis of combustion and emission characteristics of electronic controlled low pressure injected small gasoline engine. Trans. Chin. Soc. Agric. Eng. 2016, 32, 92–97. [Google Scholar]

- Dimou, V.; Anezakis, V.; Demertzis, K.; Iliadis, L.S. Comparative analysis of exhaust emissions caused by chainsaws with soft computing and statistical approaches. Int. J. Environ. Scie. Technol. 2017, 3–14. [Google Scholar] [CrossRef]

- Lijewski, P.; Fuć, P.; Dobrzyński, M.; Markiewicz, F. Exhaust emissions from small engines in handheld devices. In Proceedings of the MATEC Web of Conferences, VII International Congress on Combustion Engines, Poznań, Poland, 27–29 June 2017; EDP Sciences: Lez Ili, France, 2017; Volume 118. [Google Scholar]

- Hooper, B.; Parker, R.; Todoroki, C. Exploring chainsaw operator occupational exposure to carbon monoxide in forestry. J. Occup. Environ. Hyg. 2017, 14, D1–D12. [Google Scholar] [CrossRef]

- Waluś, K.J.; Warguła, Ł.; Krawiec, P.; Adamiec, J.M. Legal regulations of restrictions of air pollution made by non-road mobile machinery—the case study for Europe: A review. Environ. Sci. Pollut. Res. 2018, 25, 3243–3259. [Google Scholar] [CrossRef] [PubMed]

- Warguła, Ł.; Waluś, K.J.; Krawiec, P.; Polasik, J. Electronic control injection-ignition systems in propulsion of non-road mobile machinery. J. Mech. Trans. Eng. 2018, 70, 61–78. [Google Scholar]

- Warguła, Ł.; Waluś, K.J.; Krawiec, P. Small engines spark ignited (SI) for non-road mobile machinery—review. In Proceedings of the Transport Means 2018: 22nd International Scientific Conference, Trakai, Lithuania, 3–5 October 2018; Kaunas University of Technology: Trakai, Lithuania, 2018. Part 2. pp. 585–591. [Google Scholar]

- Szpica, D.; Czaban, J. Operational assessment of selected gasoline and LPG vapour injector dosage regularity. Mechanika 2014, 20, 480–489. [Google Scholar] [CrossRef]

- Warguła, Ł.; Krawiec, P.; Waluś, K.J. The System and Method of Speed Control of Wood Chipper Drive; original title in Polish: Układ i sposób sterowania prędkością obrotową napędu rębaka do drewna; Poznan University of Technology: Poznań, Poland, 2017; p. 423369. [Google Scholar]

- Warguła, Ł.; Wojtkowiak, D.; Waluś, K.J.; Krawiec, P.; Wieczorek, B. The analysis of the efficiency of the control system of Wood chipper’s driver with spark-ignition engine based on Skoda combustion engine 1.4 59kW. In Proceedings of the Transport Means 2017: 21st International Scientific Conference, Juodkrante, Lithuania, 20–22 September 2017; Part 2. Kaunas University of Technology: Juodkrante, Lithuania, 2017; pp. 452–458. [Google Scholar]

- Regulation (EU). On Requirements for Emission Limit Values of Gaseous and Particulate Pollutants and Type-approval with Respect to Internal Combustion Engines for Mobile Machines Non-road, Amending Regulations (EU) No 1024/2012 and (EU) No 167/2013 and Amending and Repealing Directive 97/68/WE. No 2016/1628 of the European Parliament and of the Council of 14 September 2016. Off. J. Eur. Union 2016, L252, 53–117. [Google Scholar]

- Merkisz, J.; Lijewski, P.; Fuć, P.; Weymann, S. Exhaust emission tests from non-road vehicles conducted with the use of PEMS analyzers. Maint. Reliab. 2013, 15, 364–368. [Google Scholar]

- Lijewski, P.; Merkisz, J.; Fuć, P. The analysis of the operating conditions of farm machinery engines in regard to exhaust emissions legislation. Appl. Eng. Agric. 2013, 29, 445–452. [Google Scholar]

- Lijewski, P.; Merkisz, J.; Fuć, P. Research of exhaust emissions from a harvester diesel engine with the use of portable emission measurement system. Croat. J. For. Eng. 2013, 34, 113–122. [Google Scholar]

- Lijewski, P.; Merkisz, J.; Fuć, P.; Daszkiewicz, P. The Comparison of the Exhaust Emissions from an Agricultural Tractor and a Truck. Appl. Mech. Mater. 2013, 391, 196–201. [Google Scholar] [CrossRef]

- Lijewski, P.; Merkisz, J.; Fuć, P.; Siedlecki, M.; Ziółkowski, A. SAE Techn Paper; SAE: Warrendale, PA, USA, 2015.

- Lijewski, P.; Merkisz, J.; Fuć, P.; Ziółkowski, A.; Rymaniak, Ł.; Kusiak, W. Fuel consumption and exhaust emissions in the process of mechanized timber extraction and transport. Eur J For Res. 2017, 136, 153–160. [Google Scholar] [CrossRef]

- Fuć, P.; Lijewski, P.; Ziółkowski, A. Analysis of the CO2, NOx emission and fuel consumption from a heavy-duty vehicle designed for carriage of timber. IOP Conf. Ser. Mater. Sci. Eng. 2016, 148, 012065. [Google Scholar] [CrossRef]

- Szymlet, N.; Lijewski, P.; Fuć, P.; Sokolnicka, B.; Siedlecki, M. Comparative analysis of passenger car and non-road machinery specific emission in real operating conditions. In Proceedings of the 2018 International Interdisciplinary PhD Workshop (IIPhDW), Swinoujście, Poland, 9–12 May 2018; pp. 226–230. [Google Scholar]

- Warguła, Ł.; Waluś, J.K.; Krawiec, P. Determination of working conditions of mobile chipping wood machines in the aspect of innovative drive control systems. Sylwan 2019, 163, 765–772. [Google Scholar] [CrossRef]

- Cieślik, W.; Pielecha, I.; Borowski, P. Effects of start-stop system on the operations of driver system Urban traffic conditions. J. Mech. Trans. Eng. 2015, 67, 15–26. [Google Scholar]

- Warguła, Ł.; Waluś, K.J.; Krawiec, P.; Kukla, M. Research of the ignition advance angle characteristics on the example of a German GX 390 combustion engine. Autobusy Tech. Eksploat. Syst. Transp. 2017, 12, 1387–1391. [Google Scholar]

- Warguła, Ł. Innovative injection-ignition system in a non-road small engine—construction system. In Proceedings of the Transport Means 2019: 23rd International Scientific Conference, Palanga, Lithuania, 2–4 October 2019; Part 2. Kaunas University of Technology: Palanga, Lithuania, 2019; pp. 931–935. [Google Scholar]

- Warguła, Ł.; Kaczmarzyk, P.; Dziechciarz, A. The assessment of fire risk of non-road mobile wood chopping machines. J. Res. Appl. Agric. Eng. 2019, 64, 58–64. [Google Scholar]

- Bektas, I.; Alma, M.H.; As, N. Determination of the relationships between Brinell and Janka hardness of eastern beech (Fagus orientalis Lipsky). For. Prod. J. 2001, 51, 84. [Google Scholar]

- Green, D.W.; Begel, M.; Nelson, W. Janka Hardness Using Nonstandard Specimens; US Dept. of Agriculture, Forest Service, Forest Product Laboratory: Washington, DC, USA, 2006; p. 303. [Google Scholar]

- ISO; IEC; OIML. Guide to the Expression of Uncertainty in Measurement; ISO; IEC; OIML: Geneva, Switzerland, 1995; Volume 122, p. 137. [Google Scholar]

- International Organization for Standardization. International Vocabulary of Basic and General Terms in Metrology; ISO: Geneva, Switzerland, 1993. [Google Scholar]

- International Standard ISO 3534-1: (1993) (E/F) Statistics—Vocabulary and Symbols; ISO: Geneva, Switzerland, 1993.

- International Organization for Standarization. International Vocabulary of Basic and General Terms in Metrology, 2nd ed.; International Organization for Standarization: Geneva, Switzerland, 1993. [Google Scholar]

- Kendall, M.G.; Stuart, A. The Advanced Theory of Statistic; Charles Griffin & Company Limited: London, UK, 1966. [Google Scholar]

- Rychlik, A. Commercial vehicles fuel consumption measurement methods. Maint. Reliab. 2006, 4, 37–41. [Google Scholar]

- Serdecki, W. Testing of Internal Combustion Engines; Poznan University of Technology: Poznań, Poland, 2012; ISBN 978-83-7775-105-3. [Google Scholar]

- Setlak, R.; Fice, M. Start&Stop system in Mild Hybrid drive and it’s influence to fuel reduction in NEDC tests. Zeszyty Problemowe Politechniki Śląskiej, Maszyny Elektryczne 2011, 90, 151–156. [Google Scholar]

- Green Car Congress. Pike Research Forecasts Global Stop-start Vehicle Sales to Reach 37M Units Annually by 2020; 2011, 16:1 ratio over HEVs. Available online: www.greencarcongress.com/2011/06/ssv-20110601.html (accessed on 2 October 2018).

| Distance between the Pile of Branches and the Chipper | Percentage of Time for the Different Operating States Chipping/Idle Work |

|---|---|

| 0.5 m | 78%/22% |

| 1.5 m | 71%/29% |

| 2.5 m | 65%/35% |

| Operating Conditions | |||

|---|---|---|---|

| Test No. | Idle Work with Low Rotational Speed (1) | Idle Work with High Rotational Speed (High Torque) (2) | Continuous Chipping (3) |

| Average Fuel Consumption [l h−1] | |||

| AVG | 0.602 | 1.203 | 3.041 |

| SD | 0.0054 | 0.0056 | 0.1214 |

| I | 0.0120 | 0.0124 | 0.2704 |

| Operating Conditions | |||

|---|---|---|---|

| Test No. | Idle Work with Low Rotational Speed (1) | Idle Work with High Rotational Speed (High Torque) (2) | Continuous Chipping (3) |

| Average fuel consumption [l h−1] | |||

| AVG | 0.374 | 1.310 | 1.185 |

| SD | 0.0073 | 0.0063 | 0.0265 |

| I | 0.0162 | 0.0140 | 0.0590 |

| Operating Conditions | |||

|---|---|---|---|

| Test No. | Percentage of Time for the Different Operating States: Chipping/Idle Work | ||

| 78%/22% | 71%/29% | 65%/35% | |

| Average Fuel Consumption [l h−1] | |||

| AVG | 2.126 | 2.053 | 1.998 |

| SD | 0.0670 | 0.0506 | 0.0513 |

| I | 0.1492 | 0.1128 | 0.1143 |

| Operating Conditions | |||

|---|---|---|---|

| Test No. | Percentage of Time for Different Operating States: Chipping/Idle Work | ||

| 78%/22% | 71%/29% | 65%/35% | |

| Average Fuel Consumption [l h−1] | |||

| AVG | 1.252 | 1.260 | 1.279 |

| SD | 0.0117 | 0.0136 | 0.0115 |

| I | 0.0261 | 0.0303 | 0.0255 |

| Operating Conditions | |||

|---|---|---|---|

| Test No. | Percentage of Time for the Different Operating States: Chipping/Idle Work | ||

| 78%/22% | 71%/29% | 65%/35% | |

| Average Fuel Consumption [l h−1] | |||

| AVG | 0.951 | 0.633 | 0.515 |

| SD | 0.0509 | 0.0484 | 0.0432 |

| I | 0.1135 | 0.1080 | 0.0962 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warguła, Ł.; Krawiec, P.; Waluś, K.J.; Kukla, M. Fuel Consumption Test Results for a Self-Adaptive, Maintenance-Free Wood Chipper Drive Control System. Appl. Sci. 2020, 10, 2727. https://doi.org/10.3390/app10082727

Warguła Ł, Krawiec P, Waluś KJ, Kukla M. Fuel Consumption Test Results for a Self-Adaptive, Maintenance-Free Wood Chipper Drive Control System. Applied Sciences. 2020; 10(8):2727. https://doi.org/10.3390/app10082727

Chicago/Turabian StyleWarguła, Łukasz, Piotr Krawiec, Konrad Jan Waluś, and Mateusz Kukla. 2020. "Fuel Consumption Test Results for a Self-Adaptive, Maintenance-Free Wood Chipper Drive Control System" Applied Sciences 10, no. 8: 2727. https://doi.org/10.3390/app10082727

APA StyleWarguła, Ł., Krawiec, P., Waluś, K. J., & Kukla, M. (2020). Fuel Consumption Test Results for a Self-Adaptive, Maintenance-Free Wood Chipper Drive Control System. Applied Sciences, 10(8), 2727. https://doi.org/10.3390/app10082727