Experimental Investigation on the Use of Waste Elastomeric Polymers for Bitumen Modification

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of PMBs

2.2. Chemical Characterization of Components and PMBs

2.3. Preliminary Characterization of PMBs

2.4. Advanced Performance-Related Characterization of PMBs

3. Results and Discussion

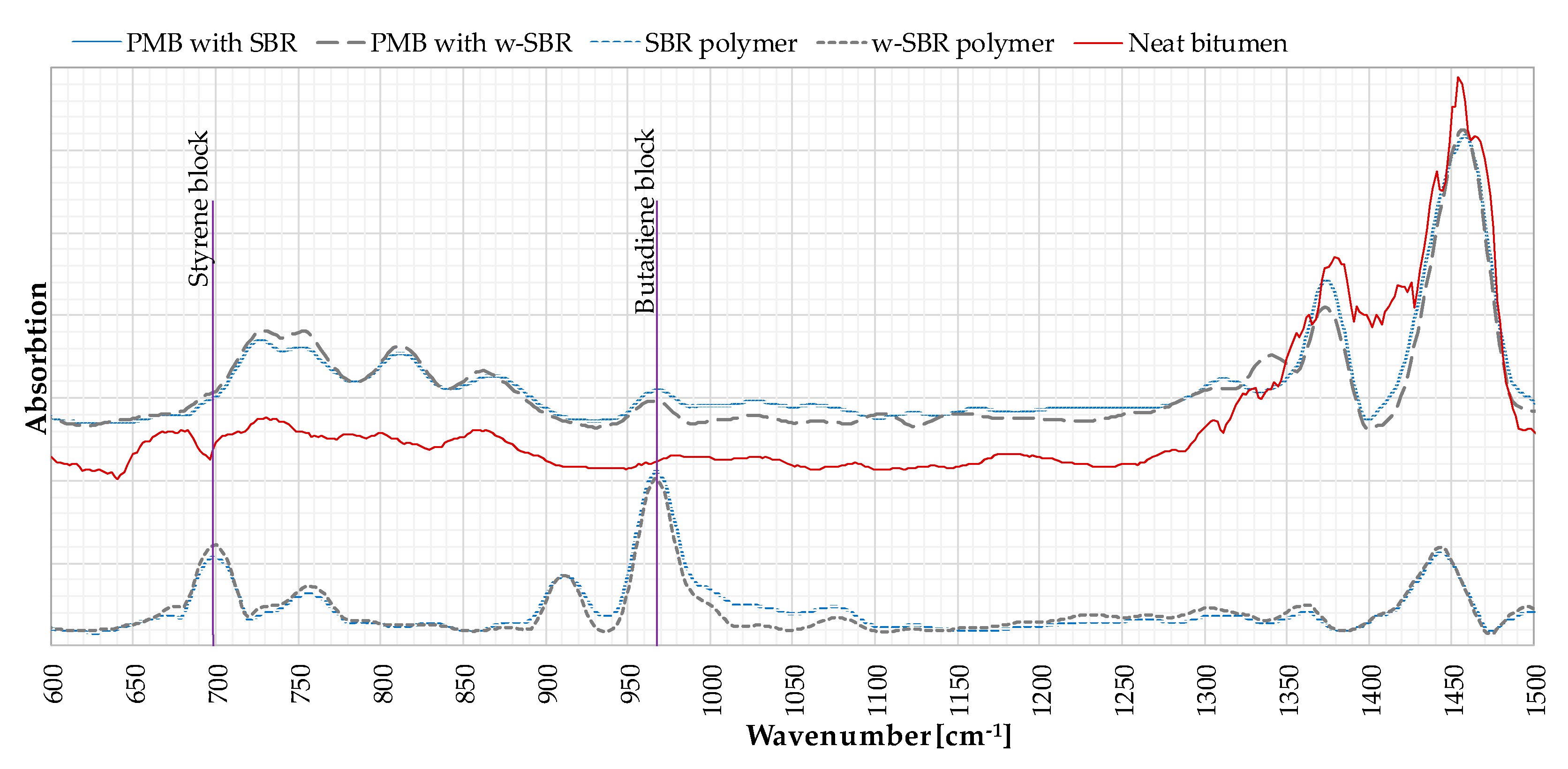

3.1. Results of Chemical Characterization Tests

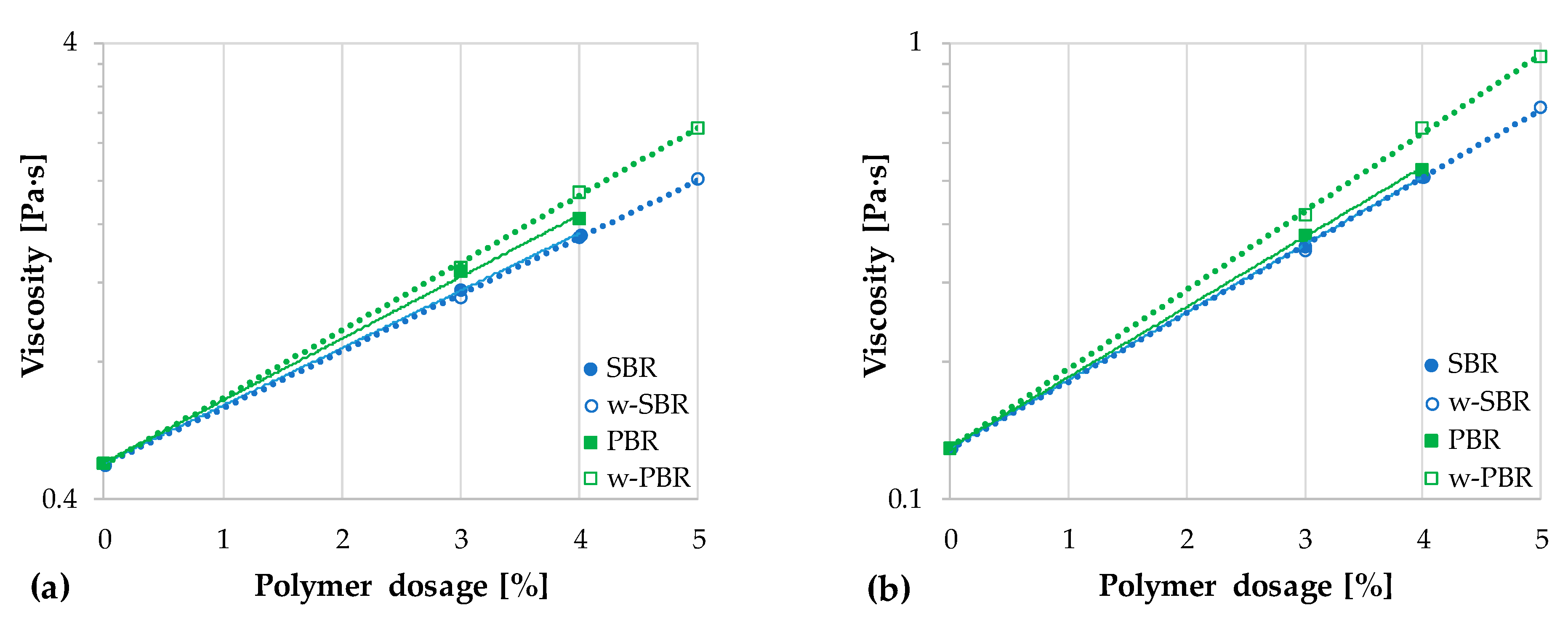

3.2. Results of Preliminary Characterization Tests

3.3. Results of Advanced Performance-Related Characterization Tests

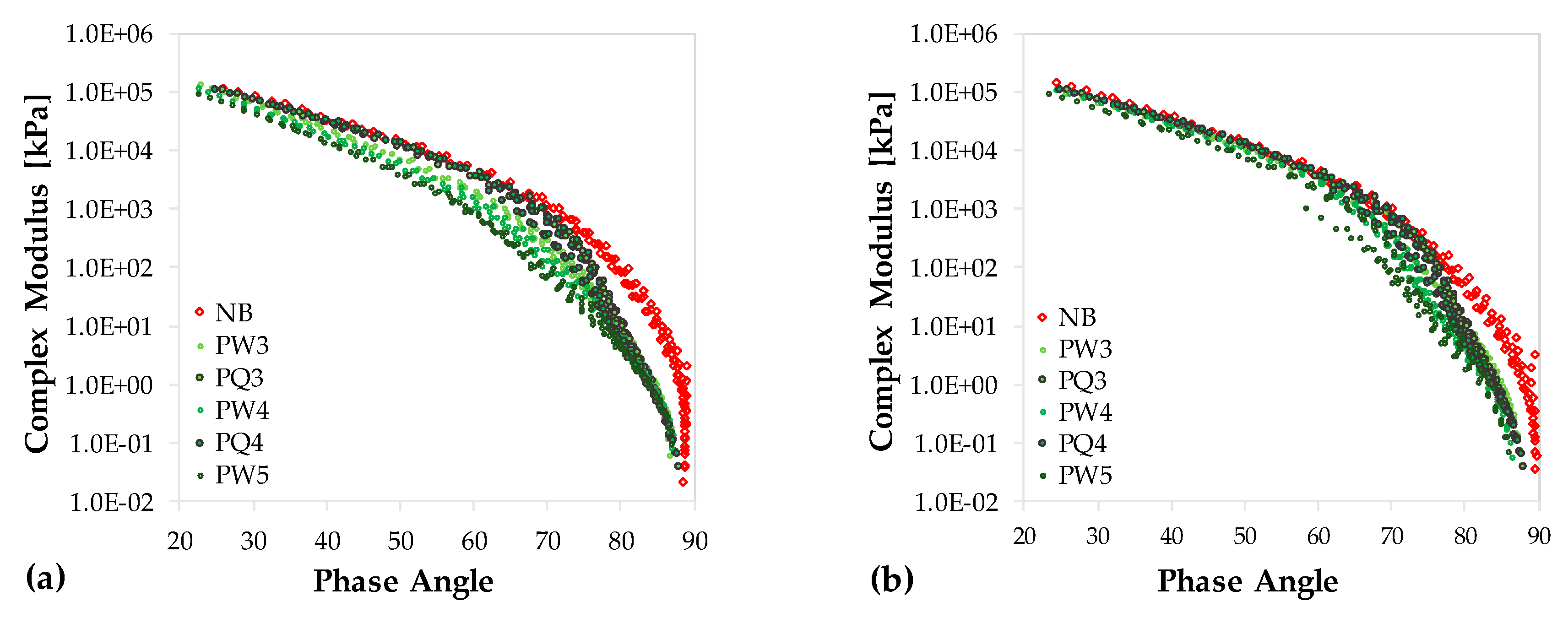

3.3.1. SAOS Tests

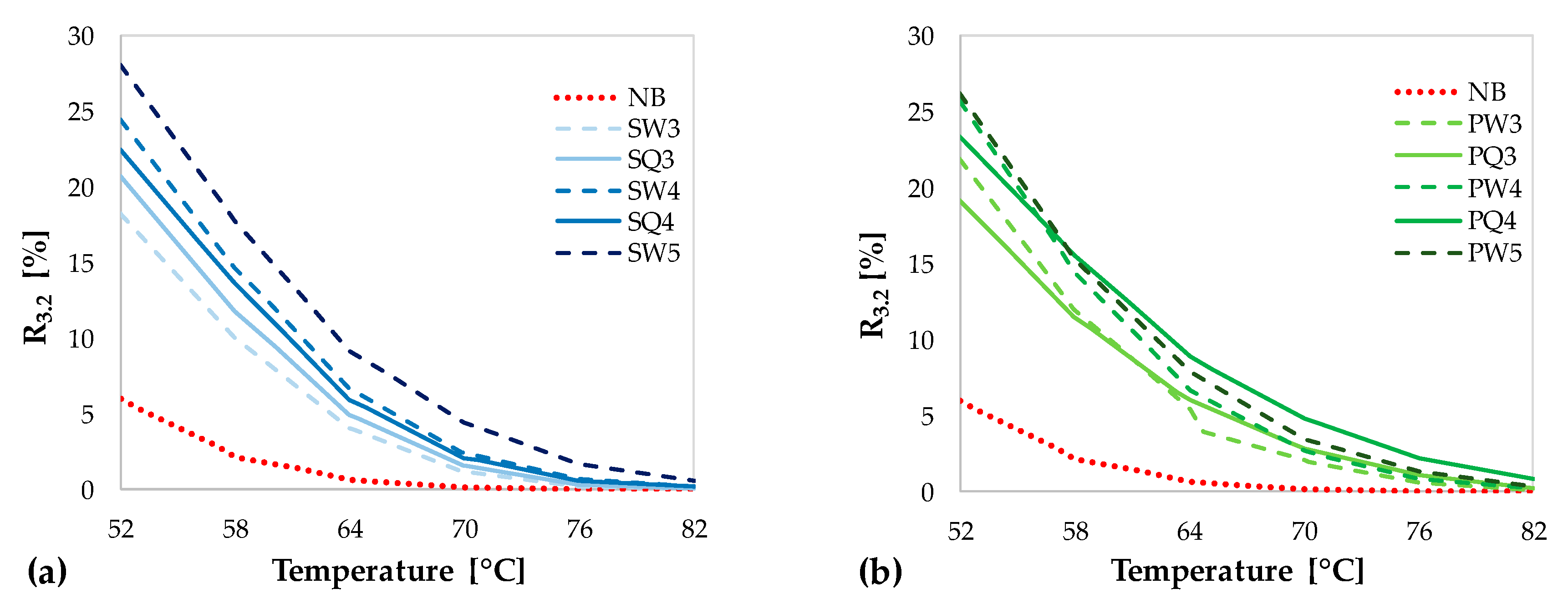

3.3.2. MSCR Tests

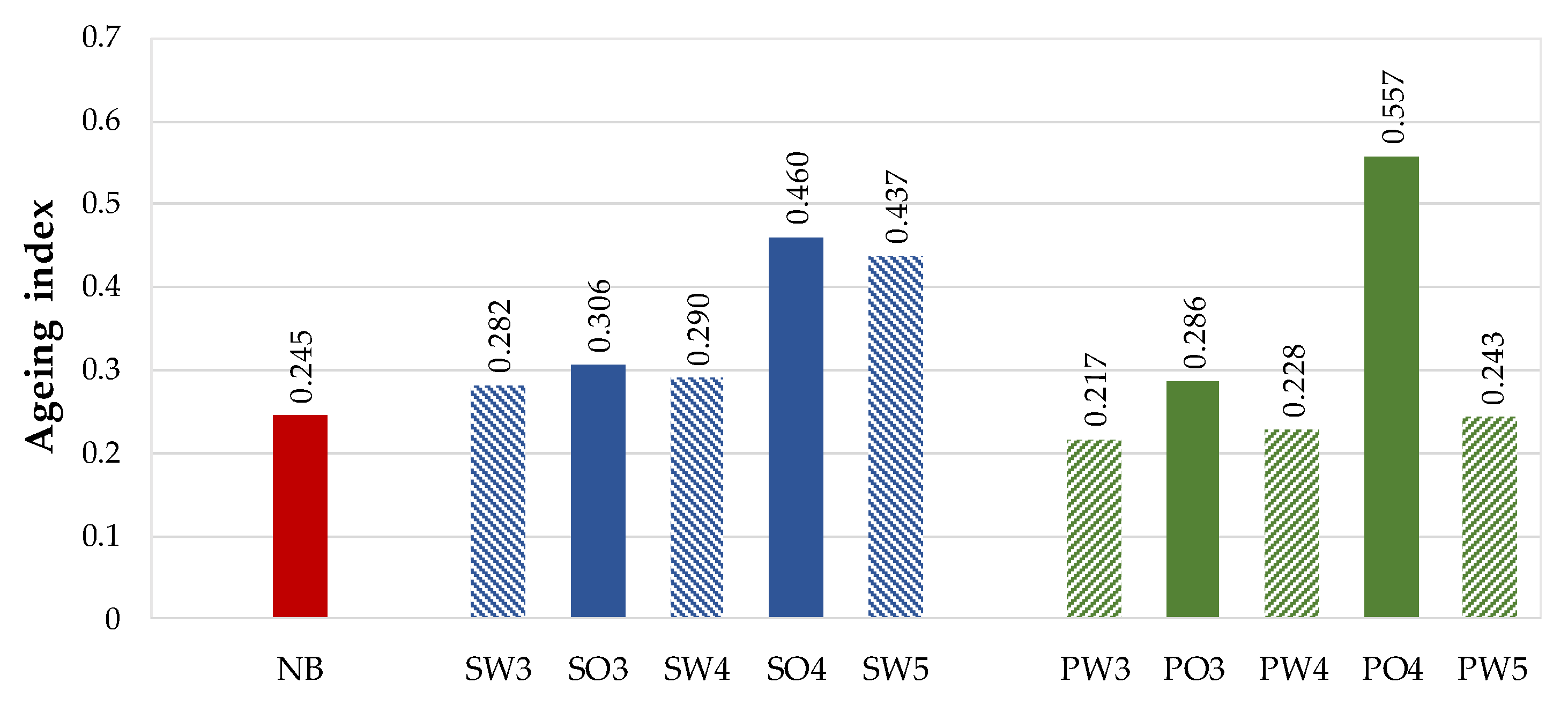

3.3.3. LAS Tests

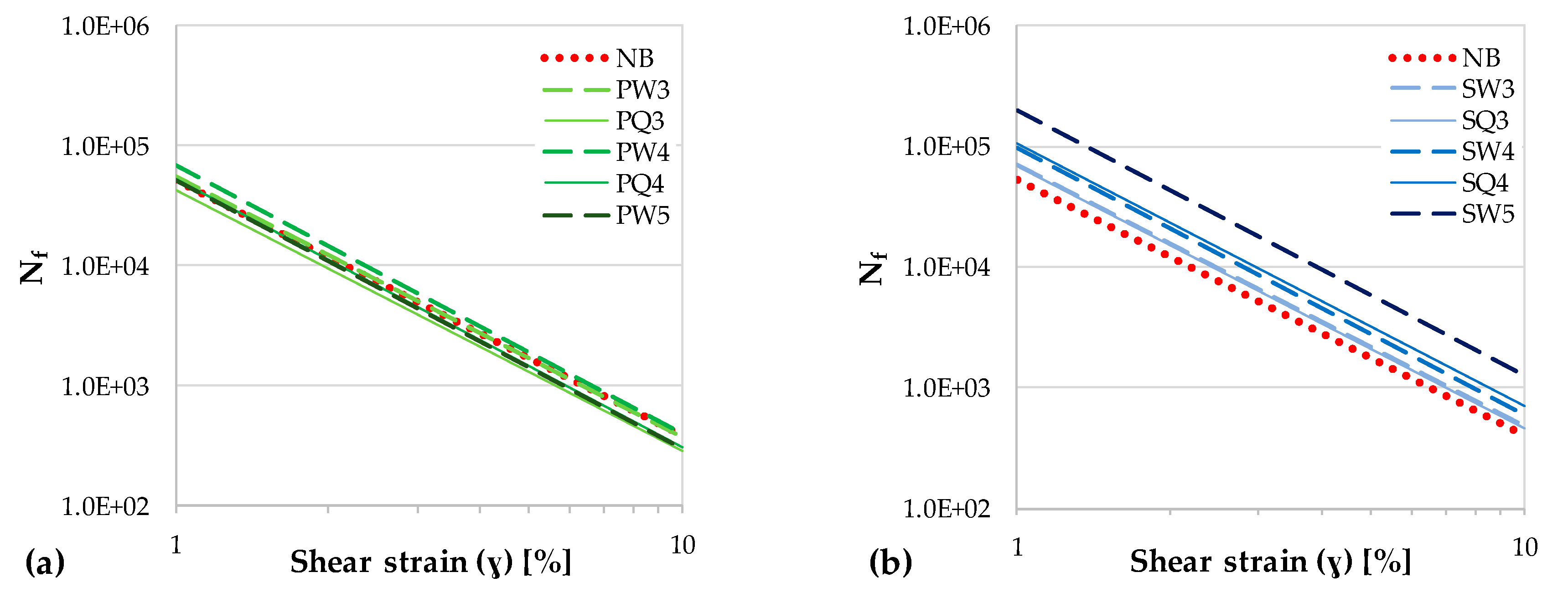

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Rossi, C.O. Bitumen and Bitumen Modification: A Review on Latest Advances. App. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Becker, Y.; Mendez, M.P.; Rodríguez, Y. Polymer modified asphalt. Vis. Tecnol. 2001, 9, 39–50. [Google Scholar]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Behnood, A.; Modiri Gharehveran, M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- McNally, T. (Ed.) Polymer Modified Bitumen: Properties and Characterisation; Woodhead Publishing Ltd.: Cambridge, UK, 2011. [Google Scholar]

- Vamegh, M.; Ameri, M. Rutting performance of road pavement asphalt binders modified by polymers. Proc. Inst. Civ. Eng. 2019, 1–8. [Google Scholar] [CrossRef]

- Zhang, B.; Xi, M.; Zhang, D.; Zhang, H.; Zhang, B. The effect of styrene-butadiene-rubber/montmorillonite modification on the characteristics and properties of asphalt. Constr. Build. Mater. 2009, 23, 3112–3117. [Google Scholar] [CrossRef]

- Lee, Y.J.; France, L.M.; Hawley, M.C. The effect of network formation on the rheological properties of SBR modified asphalt binders. Rubber Chem. Technol. 1997, 70, 256–263. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. Influence of aging on thermal behavior and characterization of SBR compound-modified asphalt. J. Therm. Anal. Calorim. 2014, 115, 1211–1218. [Google Scholar] [CrossRef]

- Liang, P.; Liang, M.; Fan, W.; Zhang, Y.; Qian, C.; Ren, S. Improving thermo-rheological behavior and compatibility of SBR modified asphalt by addition of polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 139, 183–192. [Google Scholar] [CrossRef]

- Zhao, D.; Lei, M.; Yao, Z. Evaluation of polymer-modified hot-mix asphalt: Laboratory characterization. J. Mater. Civ. Eng. 2009, 21, 163–170. [Google Scholar] [CrossRef]

- Tsantilis, L.; Dalmazzo, D.; Baglieri, O.; Santagata, E. Effect of SBS molecular structure on the rheological properties of ternary nanomodified bituminous binders. Constr. Build. Mater. 2019, 222, 183–192. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J. The research for high-performance SBR compound modified asphalt. Constr. Build. Mater. 2010, 24, 410–418. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Wu, Y.; Sun, W.; Wang, Y. Thermal behaviour and improved properties of SBR and SBR/natural bitumen modified bitumens. Iran. Polym. J. 2009, 18, 465–478. [Google Scholar]

- Ameri, M.; Yeganeh, S.; Valipour, P.E. Experimental evaluation of fatigue resistance of asphalt mixtures containing waste elastomeric polymers. Constr. Build. Mater. 2019, 198, 638–649. [Google Scholar] [CrossRef]

- Yousefi, A.A. Rubber-modified bitumens. Iran. Polym. J. 2002, 11, 303–309. [Google Scholar]

- Daryaee, D.; Ameri, M.; Mansourkhaki, A. Utilizing of waste polymer modified bitumen in combination with rejuvenator in high reclaimed asphalt pavement mixtures. Constr. Build. Mater. 2020, 235, 117516. [Google Scholar] [CrossRef]

- Yousefi, A.A. Polymer-modified bitumen from the wastes of petrochemical plants. Iran. Polym. J. 2009, 18, 207–215. [Google Scholar]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interfac. 2015, 224, 72–112. [Google Scholar] [CrossRef]

- Nivitha, M.R.; Prasad, E.; Krishnan, J.M. Ageing in modified bitumen using FTIR spectroscopy. Int. J. Pavement Eng. 2016, 17, 565–577. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interfac. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Leroy, G. Bitumen analysis by thin layer chromatography (Iatroscan). In Proceedings of the 4th Eurobitume Congress, Madrid, Spain, 4–6 October 1989; pp. 166–170. [Google Scholar]

- Ecker, A. The application of iatroscan-technique for analysis of bitumen. Petrol. Coal 2001, 1, 51–53. [Google Scholar]

- Santagata, E.; Baglieri, O.; Dalmazzo, D.; Tsantilis, L. Rheological and chemical investigation on the damage and healing properties of bituminous binders. J. Assoc. Asphalt Pav. 2009, 28, 567. [Google Scholar]

- Weigel, S.; Stephan, D. Differentiation of bitumen according to the refinery and ageing state based on FTIR spectroscopy and multivariate analysis methods. Mater. Struct. 2018, 51, 130. [Google Scholar] [CrossRef]

- Christensen, D.W.; Anderson, D.A. Interpretation of dynamic mechanical test data for paving grade asphalt cements (with discussion). J. Assoc. Asphalt Pav. 1992, 61, 67–116. [Google Scholar]

- Ferry John, D. Viscoelastic Properties of Polymers, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- D’Angelo, J.; Dongré, R. Superpave binder specifications and their performance relationship to modified binders. In Proceedings of the Forty-Seventh Annual Conference of the Canadian Technical Asphalt Association (CTAA), Calgary, Alberta, 2002; pp. 91–103. [Google Scholar]

- Santagata, E.; Baglieri, O.; Dalmazzo, D.; Tsantilis, L. Evaluation of the anti-rutting potential of polymer-modified binders by means of creep-recovery shear tests. Mater. Struct. 2013, 46, 1673–1682. [Google Scholar] [CrossRef]

- D’Angelo, J.A. The relationship of the MSCR test to rutting. Road Mater. Pavement 2009, 10 (Suppl. 1), 61–80. [Google Scholar] [CrossRef]

- Hintz, C.; Bahia, H. Simplification of linear amplitude sweep test and specification parameter. Transport. Res. Rec. 2013, 2370, 10–16. [Google Scholar] [CrossRef]

- Safaei, F.; Castorena, C.; Kim, Y.R. Linking asphalt binder fatigue to asphalt mixture fatigue performance using viscoelastic continuum damage modeling. Mech. Time-Depend. Mat. 2016, 20, 299–323. [Google Scholar] [CrossRef]

- Wang, C.; Xie, W.; Chen, Y.; Diab, A.; You, Z. Refining the Calculation Method for Fatigue Failure Criterion of Asphalt Binder from Linear Amplitude Sweep Test. J. Mater. Civ. Eng. 2017, 30, 04017286. [Google Scholar] [CrossRef]

- Shen, S.; Chiu, H.M.; Huang, H. Characterization of fatigue and healing in asphalt binders. J. Mater. Civ. Eng. 2010, 22, 846–852. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Chiappinelli, G. Fatigue and healing properties of nano-reinforced bituminous binders. Int. J. Fatigue 2015, 80, 30–39. [Google Scholar] [CrossRef]

- Masson, J.F.; Pelletier, L.; Collins, P. Rapid FTIR method for quantification of styrene-butadiene type copolymers in bitumen. J. Appl. Polym. Sci. 2001, 79, 1034–1041. [Google Scholar] [CrossRef]

- Fawcett, A.H.; McNally, T.M. A dynamic mechanical and thermal study of various rubber–bitumen blends. J. Appl. Polym. Sci. 2000, 77, 586–601. [Google Scholar] [CrossRef]

- Airey, G.D. Use of black diagrams to identify inconsistencies in rheological data. Road Mater. Pavement 2002, 3, 403–424. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Dalmazzo, D. Rheological characterization of bituminous binders modified with carbon nanotubes. Procedia Soc. Behav. 2012, 53, 546–555. [Google Scholar] [CrossRef]

| Polymer Characteristic | SBR | PBR |

|---|---|---|

| Mooney viscosity (MU) | 46–58 | 41–49 |

| Volatile material (%) | <0.75 | <0.75 |

| Ash content (%) | <1.0 | <0.3 |

| Bounded styrene (%) | 22.5–24.5 | - |

| Cis content (%) | - | >96.0 |

| Tensile strength (35 min curing) (kg/cm2) | >250 | >150 |

| Ultimate elongation (35 min curing) (%) | >350 | >440 |

| Binder Code | Polymer Type | Polymer Quality | Polymer Dosage (%) |

|---|---|---|---|

| NB | - | - | 0 |

| SW3 | SBR | Waste | 3.0 |

| SQ3 | Premium quality | 3.0 | |

| SW4 | Waste | 4.0 | |

| SQ4 | Premium quality | 4.0 | |

| SW5 | Waste | 5.0 | |

| PW3 | PBR | Waste | 3.0 |

| PQ3 | Premium quality | 3.0 | |

| PW4 | Waste | 4.0 | |

| PQ4 | Premium quality | 4.0 | |

| PW5 | Waste | 5.0 |

| Ageing State | Saturates [%] | Aromatics [%] | Resins [%] | Asphaltenes [%] | Ic |

|---|---|---|---|---|---|

| Unaged | 4.2 | 62.1 | 12.6 | 21.0 | 0.34 |

| RTFO-aged | 4.0 | 57.2 | 16.2 | 22.6 | 0.36 |

| Binder Code | Penetration at 25 °C [dmm] | Viscosity at 135 °C [Pa∙s] | Viscosity at 165 °C [Pa∙s] |

|---|---|---|---|

| NB | 62 | 0.48 | 0.13 |

| SW3 | 60 | 1.11 | 0.35 |

| SQ3 | 59 | 1.16 | 0.36 |

| SW4 | 56 | 1.5 | 0.51 |

| SQ4 | 56 | 1.52 | 0.51 |

| SW5 | 54 | 2.01 | 0.72 |

| PW3 | 64 | 1.29 | 0.42 |

| PQ3 | 65 | 1.26 | 0.38 |

| PW4 | 62 | 1.88 | 0.65 |

| PQ4 | 61 | 1.65 | 0.53 |

| PW5 | 63 | 2.61 | 0.93 |

| Ageing State | Binder Code | TR | C1 [-] | C2 [°C] | Gg [Pa] | ωc [rad/s] | R [kPa] |

|---|---|---|---|---|---|---|---|

| Virgin | NB | 20 | 14.05 | 120.31 | 4.98 × 108 | 380.19 | 1.19 |

| RTFO | NB | 20 | 14.29 | 116.03 | 3.38 × 108 | 93.33 | 1.23 |

| Virgin | SW3 | 20 | 11.67 | 95.41 | 4.52 × 108 | 279.12 | 1.31 |

| SQ3 | 20 | 12.04 | 98.41 | 4.51 × 108 | 240.43 | 1.34 | |

| SW4 | 20 | 11.69 | 93.97 | 5.21 × 108 | 193.54 | 1.47 | |

| SQ4 | 20 | 12.00 | 96.62 | 4.64 × 108 | 159.04 | 1.48 | |

| SW5 | 20 | 11.70 | 91.67 | 4.65 × 108 | 104.09 | 1.55 | |

| RTFO | SW3 | 20 | 13.37 | 108.76 | 4.35 × 108 | 78.79 | 1.46 |

| SQ3 | 20 | 13.07 | 101.06 | 4.87 × 108 | 73.46 | 1.47 | |

| SW4 | 20 | 12.63 | 95.64 | 5.08 × 108 | 56.04 | 1.57 | |

| SQ4 | 20 | 12.68 | 98.74 | 5.34 × 108 | 73.10 | 1.54 | |

| SW5 | 20 | 13.18 | 105.99 | 4.68 × 108 | 45.50 | 1.66 | |

| Virgin | PW3 | 20 | 11.74 | 97.54 | 3.93 × 108 | 232.69 | 1.35 |

| PQ3 | 20 | 11.84 | 96.42 | 3.88 × 108 | 219.05 | 1.30 | |

| PW4 | 20 | 11.29 | 88.67 | 4.94 × 108 | 162.26 | 1.48 | |

| PQ4 | 20 | 12.60 | 101.31 | 4.02 × 108 | 93.56 | 1.41 | |

| PW5 | 20 | 10.78 | 83.23 | 5.16 × 108 | 130.90 | 1.63 | |

| RTFO | PW3 | 20 | 14.05 | 110.00 | 4.42 × 108 | 50.53 | 1.48 |

| PQ3 | 20 | 13.21 | 103.00 | 3.96 × 108 | 62.73 | 1.39 | |

| PW4 | 20 | 13.67 | 107.28 | 4.11 × 108 | 37.06 | 1.56 | |

| PQ4 | 20 | 12.54 | 96.46 | 4.07 × 108 | 52.15 | 1.51 | |

| PW5 | 20 | 12.67 | 98.37 | 3.69 × 108 | 31.74 | 1.64 |

| Binder Code | High Tc from G*/sinδ Criterion (Unaged Samples) [°C] | High Tc from MSCR Criteria (RTFO-Aged Samples) [°C] | |||

|---|---|---|---|---|---|

| “S” | “H” | “V” | “E” | ||

| NB | 68.9 | 66.8 | 61.4 | 56.9 | 52.9 |

| SW3 | 71.9 | 69.9 | 64.2 | 59.8 | 55.5 |

| SQ3 | 72.2 | 70.0 | 64.5 | 60.1 | 55.8 |

| SW4 | 74.4 | 69.9 | 64.2 | 59.8 | 55.6 |

| SQ4 | 74.3 | 70.7 | 64.9 | 60.4 | 56.0 |

| SW5 | 76.6 | 71.9 | 66.1 | 61.5 | 57.2 |

| PW3 | 72.7 | 70.3 | 64.7 | 60.3 | 56.2 |

| PQ3 | 72.1 | 69.0 | 63.4 | 58.9 | 54.6 |

| PW4 | 75.2 | 71.4 | 65.9 | 61.4 | 57.2 |

| PQ4 | 76.3 | 70.9 | 65.2 | 60.7 | 56.3 |

| PW5 | 77.1 | 72.2 | 66.2 | 61.6 | 57.3 |

| Parameter | NB | SW3 | SQ3 | SW4 | SQ4 | SW5 | PW3 | PQ3 | PW4 | PQ4 | PW5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 5.3 × 104 | 6.9 × 104 | 6.8 × 104 | 9.7 × 104 | 1.1 × 105 | 2.0 × 105 | 5.7 × 104 | 4.4 × 104 | 6.8 × 104 | 5.3 × 104 | 5.2 × 104 |

| B | 2.122 | 2.157 | 2.162 | 2.217 | 2.180 | 2.193 | 2.175 | 2.182 | 2.224 | 2.238 | 2.229 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeganeh, S.; Ameri, M.; Dalmazzo, D.; Santagata, E. Experimental Investigation on the Use of Waste Elastomeric Polymers for Bitumen Modification. Appl. Sci. 2020, 10, 2671. https://doi.org/10.3390/app10082671

Yeganeh S, Ameri M, Dalmazzo D, Santagata E. Experimental Investigation on the Use of Waste Elastomeric Polymers for Bitumen Modification. Applied Sciences. 2020; 10(8):2671. https://doi.org/10.3390/app10082671

Chicago/Turabian StyleYeganeh, Sadegh, Mahmoud Ameri, Davide Dalmazzo, and Ezio Santagata. 2020. "Experimental Investigation on the Use of Waste Elastomeric Polymers for Bitumen Modification" Applied Sciences 10, no. 8: 2671. https://doi.org/10.3390/app10082671

APA StyleYeganeh, S., Ameri, M., Dalmazzo, D., & Santagata, E. (2020). Experimental Investigation on the Use of Waste Elastomeric Polymers for Bitumen Modification. Applied Sciences, 10(8), 2671. https://doi.org/10.3390/app10082671