Method for Volume of Irregular Shape Pellets Estimation Using 2D Imaging Measurement

Abstract

1. Introduction

2. Materials and Methods

3. Results

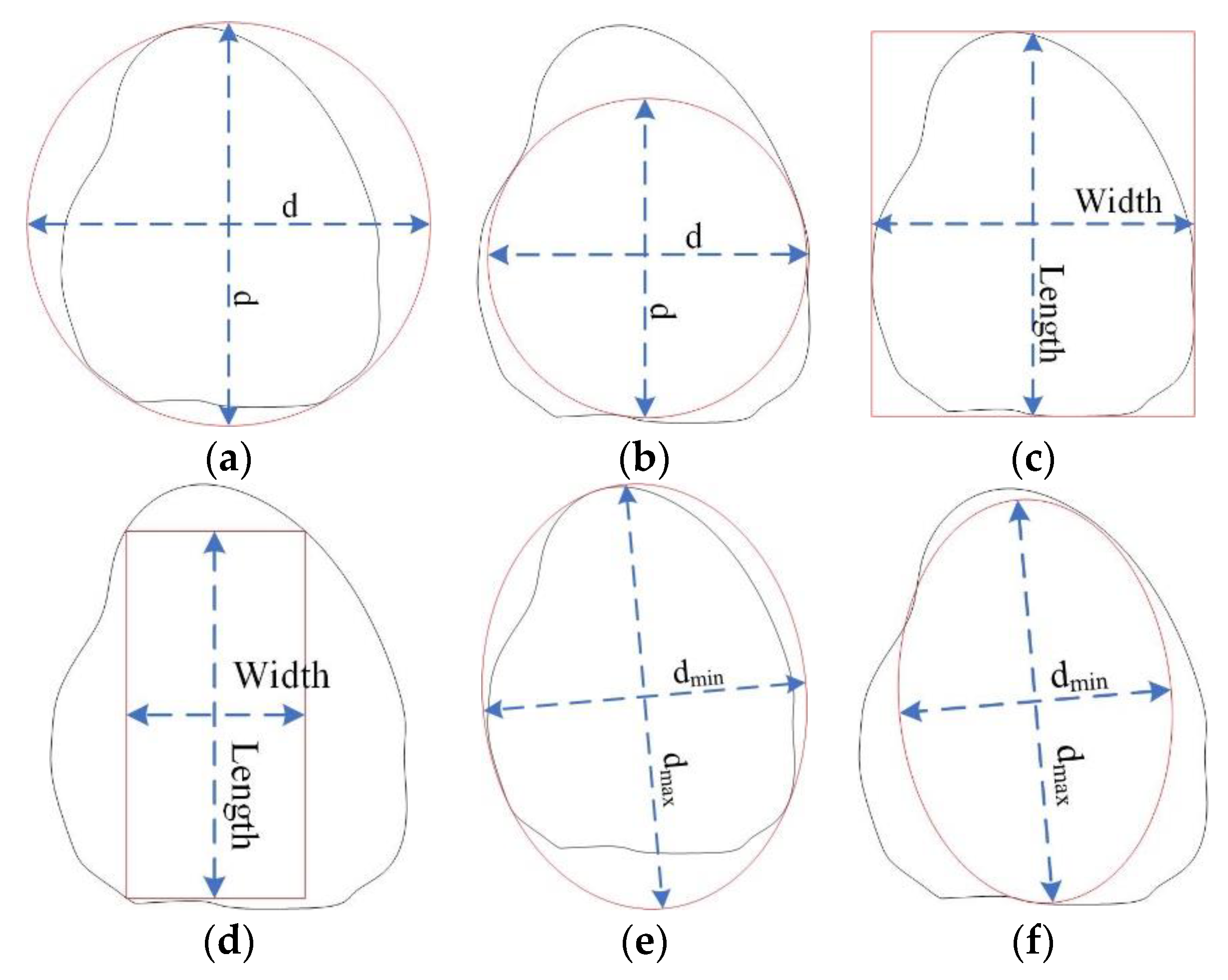

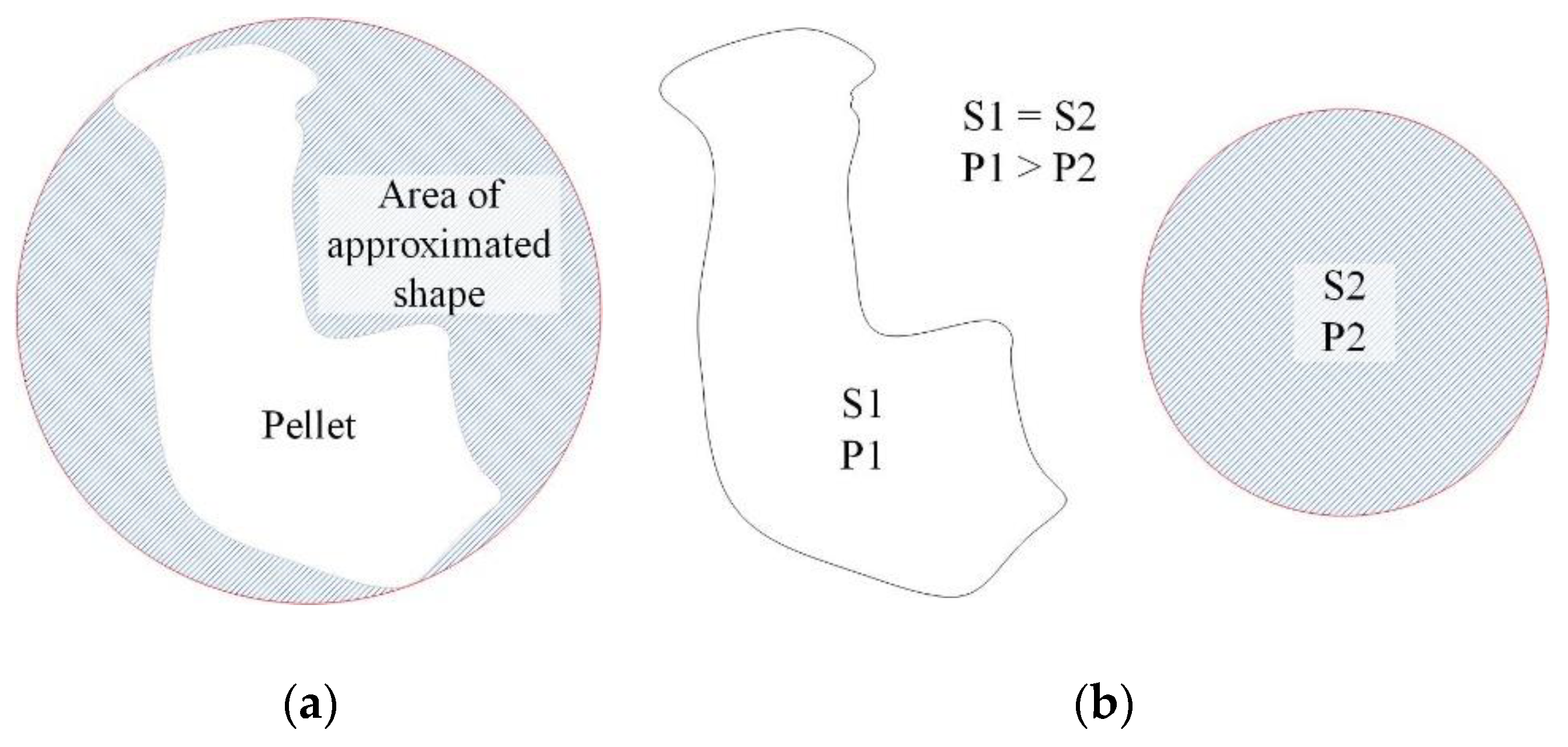

3.1. Evaluation of Shape of Pellets

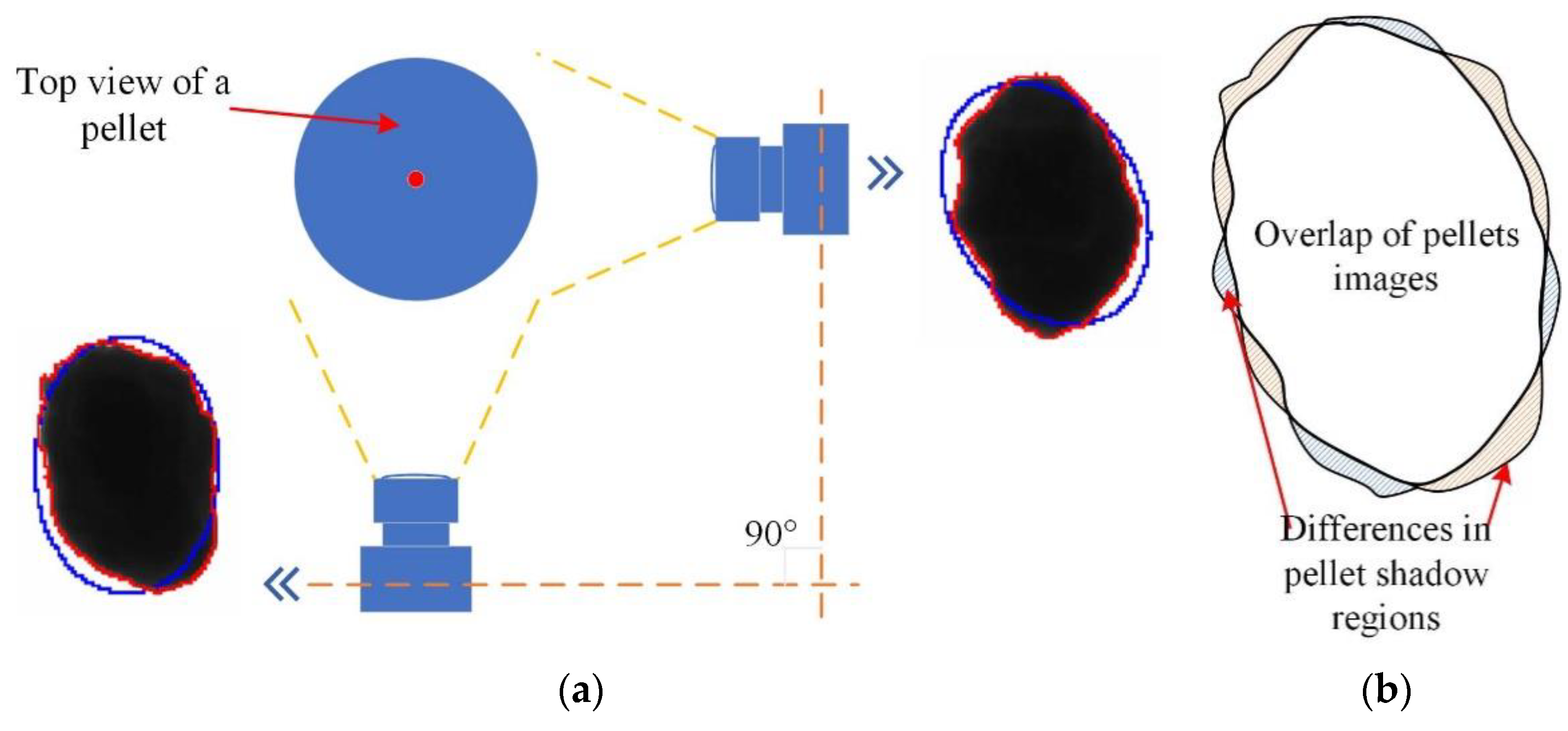

3.2. Estimation of Pellet Volume by Dividing Them into Circular Layers

3.3. Estimation of Pellet Volume by Dividing Them into Elliptical Layers

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Markovic, S.; Stojanovic, Z.S. Determination of Particle Size Distributions by Laser Diffraction. Tech. New Mater. 2012, 21, 11–20. [Google Scholar]

- Witt, W.; Heuer, M.; Schaller, M. In-line particle sizing for process control in new dimensions. China Particuol. 2004, 2, 185–188. [Google Scholar] [CrossRef]

- Cornillault, J. Particle Size Analyzer. Appl. Opt. 1972, 11, 265. [Google Scholar] [CrossRef] [PubMed]

- Coghill, P.; Millen, M.; Sowerby, B. On-line measurement of particle size in mineral slurries. Miner. Eng. 2002, 15, 83–90. [Google Scholar] [CrossRef]

- McClements, D.J. Ultrasonic Measurements in Particle Size Analysis. In Encyclopedia of Analytical Chemistry: Applications, Theory and Instrumentation; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Wan, Q.; Jiang, W. Near field acoustic holography (NAH) theory for cyclostationary sound field and its application. J. Sound Vib. 2006, 290, 956–967. [Google Scholar] [CrossRef]

- Findlay, W.P.; Peck, G.R.; Morris, K.R. Determination of fluidized bed granulation end point using near-infrared spectroscopy and phenomenological analysis. J. Pharm. Sci. 2005, 94, 604–612. [Google Scholar] [CrossRef]

- Petrak, D. Simultaneous Measurements of Particle Size and Velocity with Spatial Filtering Technique In Comparison With Coulter Multisizer and Laser Doppler Velocimetry. In Proceedings of the 4th International Conference on Multiphase Flow, New Orleans, LA, USA, 27 May–1 June 2001; Available online: https://www.parsum.de/wp-content/uploads/2017/10/ConfMPF882.pdf (accessed on 1 March 2020).

- Dieter, P.; Stefan, D.; Günter, E.; Michael, K. In-line particle sizing for real-time process control by fibre-optical spatial filtering technique (SFT). Adv. Powder Technol. 2011, 22, 203–208. [Google Scholar] [CrossRef]

- Bishop, D. A sedimentation method for the determination of the particle size of finely divided materials (such as hydrated lime). Bur. Stand. J. Res. 1934, 12, 173. [Google Scholar] [CrossRef]

- Maab, S.; Rojahn, J.; Emmerich, J.; Kraume, M. On-Line Monitoring Of Fluid Particle Size Distributions In Agitated Vessels Using Automated Image Analysis. In Proceedings of the 14th European Conference on Mixing, Warszawa, Poland, 10–13 September 2012; Available online: https://pdfs.semanticscholar.org/dce5/c4ca8f3f676f6a65132654ff59351b11ee88.pdf (accessed on 1 March 2020).

- Lu, Z.; Hu, X.; Lu, Y. Particle Morphology Analysis of Biomass Material Based on Improved Image Processing Method. Int. J. Anal. Chem. 2017, 2017, 1–9. [Google Scholar] [CrossRef]

- Hijazi, B.; Cool, S.; Vangeyte, J.; Mertens, K.; Cointault, F.; Paindavoine, M.; Pieters, J. High Speed Stereovision Setup for Position and Motion Estimation of Fertilizer Particles Leaving a Centrifugal Spreader. Sensors 2014, 14, 21466–21482. [Google Scholar] [CrossRef]

- Närvänen, T.; Seppälä, K.; Antikainen, O.; Yliruusi, J. A New Rapid On-Line Imaging Method to Determine Particle Size Distribution of Granules. AAPS PharmSciTech 2008, 9, 282–287. [Google Scholar] [CrossRef] [PubMed]

- Laitinen, N.; Antikainen, O.; Yliruusi, J. Characterization of particle sizes in bulk pharmaceutical solids using digital image information. AAPS PharmSciTech 2003, 4, 383–391. [Google Scholar] [CrossRef] [PubMed]

- Watano, S.; Numa, T.; Miyanami, K.; Osako, Y. On-line Monitoring of Granule Growth in High Shear Granulation by an Image Processing System. Chem. Pharm. Bull. 2000, 48, 1154–1159. [Google Scholar] [CrossRef] [PubMed]

- Kumari, R.; Rana, N. Particle Size and Shape Analysis using Imagej with Customized Tools for Segmentation of Particles. Int. J. Eng. Res. 2015, 4, 247–250. [Google Scholar]

- Mazzoli, A.; Favoni, O. Particle size, size distribution and morphological evaluation of airborne dust particles of diverse woods by Scanning Electron Microscopy and image processing program. Powder Technol. 2012, 225, 65–71. [Google Scholar] [CrossRef]

- Habrat, M.; Mlynarczuk, M. Object Retrieval in Microscopic Images of Rocks Using the Query by Sketch Method. Appl. Sci. 2019, 10, 278. [Google Scholar] [CrossRef]

- Okarma, K. Current Trends and Advances in Image Quality Assessment. Elektronika ir Elektrotechnika 2019, 25, 77–84. [Google Scholar] [CrossRef]

- Laucka, A.; Adaskeviciute, V.; Valinevicius, A.; Andriukaitis, D. Research of the Equipment Calibration Methods for Fertilizers Particles Distribution by Size Using Image Processing Measurement Method. In Proceedings of the 2018 23rd International Conference on Methods & Models in Automation & Robotics (MMAR), Międzyzdroje, Poland, 27–30 August 2018; pp. 407–412. [Google Scholar]

- Vrbančič, G.; Podgorelec, V. Automatic Classification of Motor Impairment Neural Disorders from EEG Signals Using Deep Convolutional Neural Networks. Elektronika ir Elektrotechnika 2018, 24, 3–7. [Google Scholar] [CrossRef]

- Forristal, D. Fertiliser Prills or Granules: Which Spread Best? The IFJ Article. 2014. Available online: https://www.teagasc.ie/media/website/publications/2014/Fertiliser_Prills_or_granules.pdf (accessed on 1 March 2020).

- Particle Size Result Interpretation: Number vs. Volume Distributions. Available online: https://www.horiba.com/scientific/products/particle-characterization/education/general-information/data-interpretation/number-vs-volume-distributions/ (accessed on 1 March 2020).

- ISO 9276-2:2001: Representation of Results of Particle Size Analysis—Part 2: Calculation of Average Particle Sizes/Diameters and Moments from Particle Size Distributions. Available online: https://www.iso.org/standard/33997.html (accessed on 1 March 2020).

- ASTM E 799-03 Standard Practice for Determining Data Criteria and Processing for Liquid Drop Size Analysis. Available online: https://www.astm.org/Standards/E799.htm (accessed on 1 March 2020).

- International Standard ISO 20998-1:2006 “Measurement and Characterization of Particles by Acoustic Methods”. Available online: https://www.iso.org/standard/39869.html (accessed on 1 March 2020).

- Stewart, L.; Bandel, V.A. Uniform Lime and Fertilizer Spreading. Publication about Fertilizers Equipment and Production Process. Available online: https://extension.umd.edu/sites/extension.umd.edu/files/_images/programs/anmp/EB_254_Uniform%20Lime%20and%20Fertilizer%20Spreading.pdf (accessed on 1 March 2020).

- Das, S.C.; Behara, S.R.B.; Morton, D.A.V.; Larson, I.; Stewart, P. Importance of particle size and shape on the tensile strength distribution and de-agglomeration of cohesive powders. Powder Technol. 2013, 249, 297–303. [Google Scholar] [CrossRef]

- Yu, H.; Ding, Y.; Liu, Z.; Fu, X.; Dou, X.; Yang, C. Development and Evaluation of a Calibrating System for the Application Rate Control of a Seed-Fertilizer Drill Machine with Fluted Rollers. Appl. Sci. 2019, 9, 5434. [Google Scholar] [CrossRef]

- Jannat, E.; Arif, A.A.; Hasan, M.M.; Zarziz, A.B.; Rashid, H.A. Granulation techniques & its updated modules. Pharma Innov. J. 2016, 5, 134–141. Available online: https://pdfs.semanticscholar.org/9595/861fa792566927030aabdc9d0cb63a55ce59.pdf (accessed on 1 March 2020).

- Le, T.-T.; Miclet, D.; Héritier, P.; Piron, E.; Chateauneuf, A.; Berducat, M. Morphology characterization of irregular particles using image analysis. Application to solid inorganic fertilizers. Comput. Electron. Agric. 2018, 147, 146–157. [Google Scholar] [CrossRef]

- Igathinathane, C.; Pordesimo, L.; Columbus, E.; Batchelor, W.; Methuku, S.; Cannayen, I. Shape identification and particles size distribution from basic shape parameters using ImageJ. Comput. Electron. Agric. 2008, 63, 168–182. [Google Scholar] [CrossRef]

- Laucka, A.; Adaskeviciute, V.; Andriukaitis, D. Research of the Equipment Self-Calibration Methods for Different Shape Fertilizers Particles Distribution by Size Using Image Processing Measurement Method. Symmetry 2019, 11, 838. [Google Scholar] [CrossRef]

- Hogg, R. A Spheroid Model for the Role of Shape in Particle Size Analysis. KONA Powder Part. J. 2015, 32, 227–235. [Google Scholar] [CrossRef]

- Riddle, D.F. Calculus and Analytic Geometry; Wadsworth Publishing Company, Inc.: Belmont, CA, USA, 1979; p. 505. ISBN 9780534006266. [Google Scholar]

- Rashidi, M.; Gholami, M. Determination of kiwifruit volume using ellipsoid approximation and Image-processing methods. Int. J. Agric. Biol. 2008, 10, 375–380. Available online: https://www.researchgate.net/publication/228409809_Determination_of_kiwifruit_volume_using_ellipsoid_approximation_and_image-processing_methods (accessed on 2 March 2020).

- Sabliov, C.M.; Boldor, D.; Keener, K.M.; Farkas, B.E. Image processing method to determine surface area and volume of axi-symmetric agricultural products. Int. J. Food Prop. 2002, 5, 641–653. [Google Scholar] [CrossRef]

- Lech, P.; Okarma, K. Prediction of the Optical Character Recognition Accuracy based on the Combined Assessment of Image Binarization Results. Elektronika ir Elektrotechnika 2015, 21, 62–65. [Google Scholar] [CrossRef]

- Khitas, M.; Ziet, L.; Bouguezel, S. Improved Degraded Document Image Binarization Using Median Filter for Background Estimation. Elektronika ir Elektrotechnika 2018, 24, 82–87. [Google Scholar] [CrossRef]

- Andriukaitis, D.; Laucka, A.; Valinevicius, A.; Zilys, M.; Markevicius, V.; Navikas, D.; Sotner, R.; Petrzela, J.; Jerabek, J.; Herencsar, N.; et al. Research of the Operator’s Advisory System Based on Fuzzy Logic for Pelletizing Equipment. Symmetry 2019, 11, 1396. [Google Scholar] [CrossRef]

| Water Displacement Method | Method for Dividing Pellets into Circular Layers | ΔV2, cm3 | ΔV3, cm3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Sample no. | Length of pellet, mm | Width of pellet, mm | Volume V1, cm3 | Length of pellet, mm | Width of pellet, mm | Volume V2, cm3 | Volume V3 1, cm3 | , cm3 | , cm3 |

| 1 | 80.4 | 18.0 | 13.8 | 81.11 | 18.37 | 14.11 | 14.33 | 0.31 | 0.52 |

| 2 | 68.3 | 17.6 | 13.4 | 69.38 | 17.86 | 13.18 | 11.58 | 0.22 | 1.82 |

| 3 | 49.1 | 20.7 | 13.6 | 49.65 | 21.09 | 13.36 | 11.56 | 0.24 | 2.04 |

| 4 | 53.4 | 20.6 | 13.8 | 53.90 | 21.26 | 13.85 | 12.75 | 0.05 | 1.05 |

| 5 | 56.1 | 20.8 | 14.0 | 56.46 | 21.09 | 14.00 | 13.14 | 0.01 | 0.86 |

| 6 | 61.4 | 18.6 | 13.2 | 62.41 | 19.22 | 12.93 | 12.07 | 0.27 | 1.13 |

| 7 | 74.0 | 18.2 | 14.0 | 74.14 | 18.54 | 14.01 | 13.34 | 0.01 | 0.66 |

| 8 | 74.7 | 17.8 | 14.0 | 75.16 | 18.03 | 14.01 | 12.79 | 0.01 | 1.21 |

| 9 | 66.9 | 19.1 | 14.4 | 67.17 | 19.22 | 14.20 | 12.99 | 0.20 | 1.41 |

| 10 | 64.8 | 18.3 | 13.8 | 65.13 | 18.71 | 13.58 | 11.93 | 0.22 | 1.87 |

| MAE, cm3 | 1.258 | 0.153 | |||||||

| SSE | 6.872 | 1.711 | |||||||

| σ2 | 0.687 | 0.171 | |||||||

| RMSE | 1.351 | 0.191 | |||||||

| Sample no. | Sample Position | Volume V1 2, cm3 | Volume V2 3, cm3 | , cm3 | Volume V3 4, cm3 | , cm3 | Volume V4 5, cm3 | , cm3 | Volume V5 6, cm3 | , cm3 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Largest area 1 | 12.8 | 14.60 | 1.80 | 14.27 | 1.47 | 20.09 | 7.29 | 19.02 | 6.22 |

| Rotated by 90° | 10.2 | 2.6 | 11.29 | 1.51 | ||||||

| 2 | Largest area 1 | 13.6 | 14.94 | 1.34 | 14.69 | 1.09 | 19.56 | 5.96 | 19.3 | 5.7 |

| Rotated by 90° | 11.89 | 1.71 | 13.06 | 0.54 | ||||||

| 3 | Largest area 1 | 12.4 | 13.67 | 1.27 | 13.40 | 1.00 | 18.07 | 5.67 | 17.87 | 5.47 |

| Rotated by 90° | 10.61 | 1.79 | 12.29 | 0.11 | ||||||

| 4 | Largest area 1 | 15.8 | 14.70 | 1.10 | 14.60 | 1.20 | 15.45 | 0.35 | 14.51 | 1.29 |

| Rotated by 90° | 15.5 | 0.3 | 16.18 | 0.38 | ||||||

| 5 | Largest area 1 | 13.4 | 13.32 | 0.08 | 13.23 | 0.17 | 15.14 | 1.74 | 14.94 | 1.54 |

| Rotated by 90° | 12.44 | 0.96 | 13.61 | 0.21 | ||||||

| 6 | Largest area 1 | 14.6 | 15.00 | 0.40 | 14.87 | 0.27 | 17.46 | 2.86 | 17.06 | 2.46 |

| Rotated by 90° | 13.78 | 0.82 | 14.79 | 0.19 | ||||||

| 7 | Largest area 1 | 13.2 | 13.27 | 0.07 | 13.10 | 0.10 | 15.79 | 2.59 | 15.61 | 2.41 |

| Rotated by 90° | 11.73 | 1.47 | 13.11 | 0.09 | ||||||

| 8 | Largest area 1 | 14.0 | 14.27 | 0.27 | 14.14 | 0.14 | 16.65 | 2.65 | 16.46 | 2.46 |

| Rotated by 90° | 12.83 | 1.17 | 13.99 | 0.01 | ||||||

| 9 | Largest area 1 | 14.4 | 13.70 | 0.70 | 13.70 | 0.70 | 13.79 | 0.61 | 13.63 | 0.77 |

| Rotated by 90° | 14.28 | 0.12 | 14.4 | 0 | ||||||

| 10 | Largest area 1 | 14.6 | 14.28 | 0.32 | 14.20 | 0.40 | 16.04 | 1.44 | 15.82 | 1.22 |

| Rotated by 90° | 13.63 | 0.97 | 14.7 | 0.1 | ||||||

| Largest area | MAE | 0.735 | 0.654 | 3.116 | 2.954 | |||||

| RMSE | 0.932 | 0.811 | 3.851 | 3.537 | ||||||

| Rotated by 90° | MAE | 0.735 | 0.654 | 1.191 | 0.314 | |||||

| RMSE | 0.932 | 0.811 | 1.380 | 0.532 | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laucka, A.; Andriukaitis, D.; Valinevicius, A.; Navikas, D.; Zilys, M.; Markevicius, V.; Klimenta, D.; Sotner, R.; Jerabek, J. Method for Volume of Irregular Shape Pellets Estimation Using 2D Imaging Measurement. Appl. Sci. 2020, 10, 2650. https://doi.org/10.3390/app10082650

Laucka A, Andriukaitis D, Valinevicius A, Navikas D, Zilys M, Markevicius V, Klimenta D, Sotner R, Jerabek J. Method for Volume of Irregular Shape Pellets Estimation Using 2D Imaging Measurement. Applied Sciences. 2020; 10(8):2650. https://doi.org/10.3390/app10082650

Chicago/Turabian StyleLaucka, Andrius, Darius Andriukaitis, Algimantas Valinevicius, Dangirutis Navikas, Mindaugas Zilys, Vytautas Markevicius, Dardan Klimenta, Roman Sotner, and Jan Jerabek. 2020. "Method for Volume of Irregular Shape Pellets Estimation Using 2D Imaging Measurement" Applied Sciences 10, no. 8: 2650. https://doi.org/10.3390/app10082650

APA StyleLaucka, A., Andriukaitis, D., Valinevicius, A., Navikas, D., Zilys, M., Markevicius, V., Klimenta, D., Sotner, R., & Jerabek, J. (2020). Method for Volume of Irregular Shape Pellets Estimation Using 2D Imaging Measurement. Applied Sciences, 10(8), 2650. https://doi.org/10.3390/app10082650