Seismic Retrofitting of Traditional Masonry with Pultruded FRP Profiles

Abstract

Featured Application

Abstract

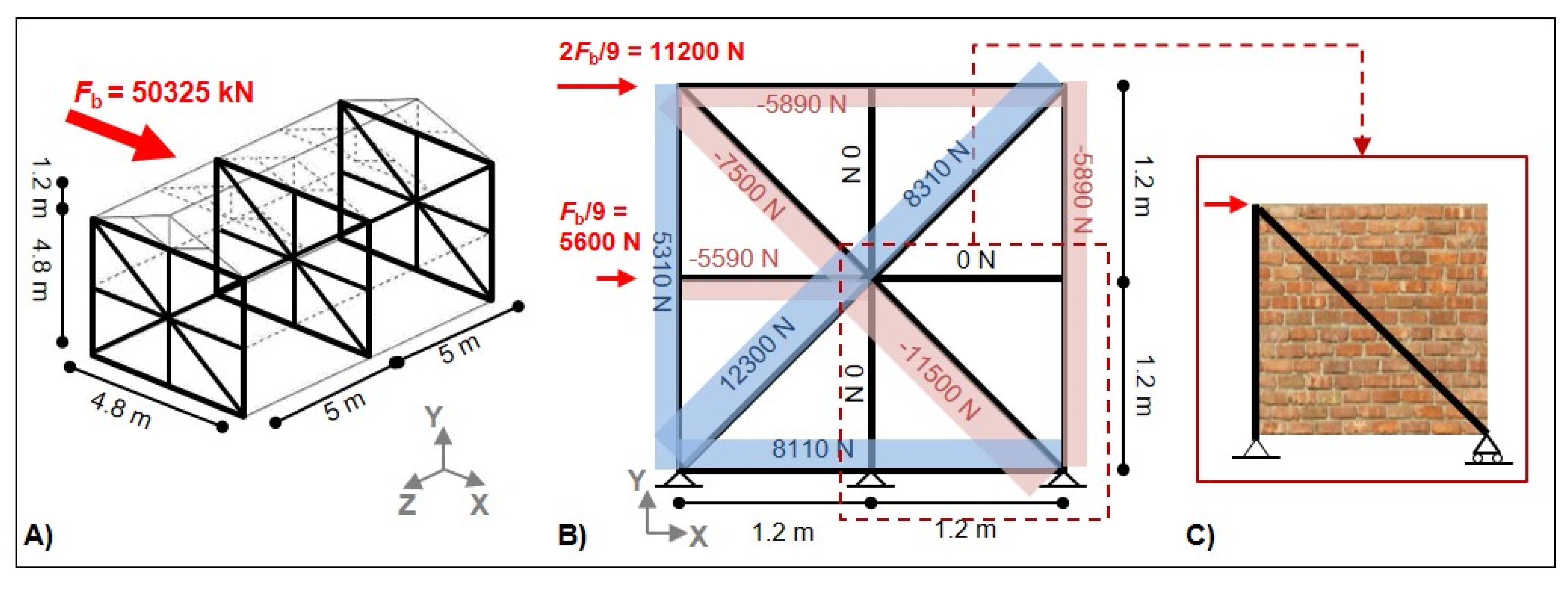

1. Introduction

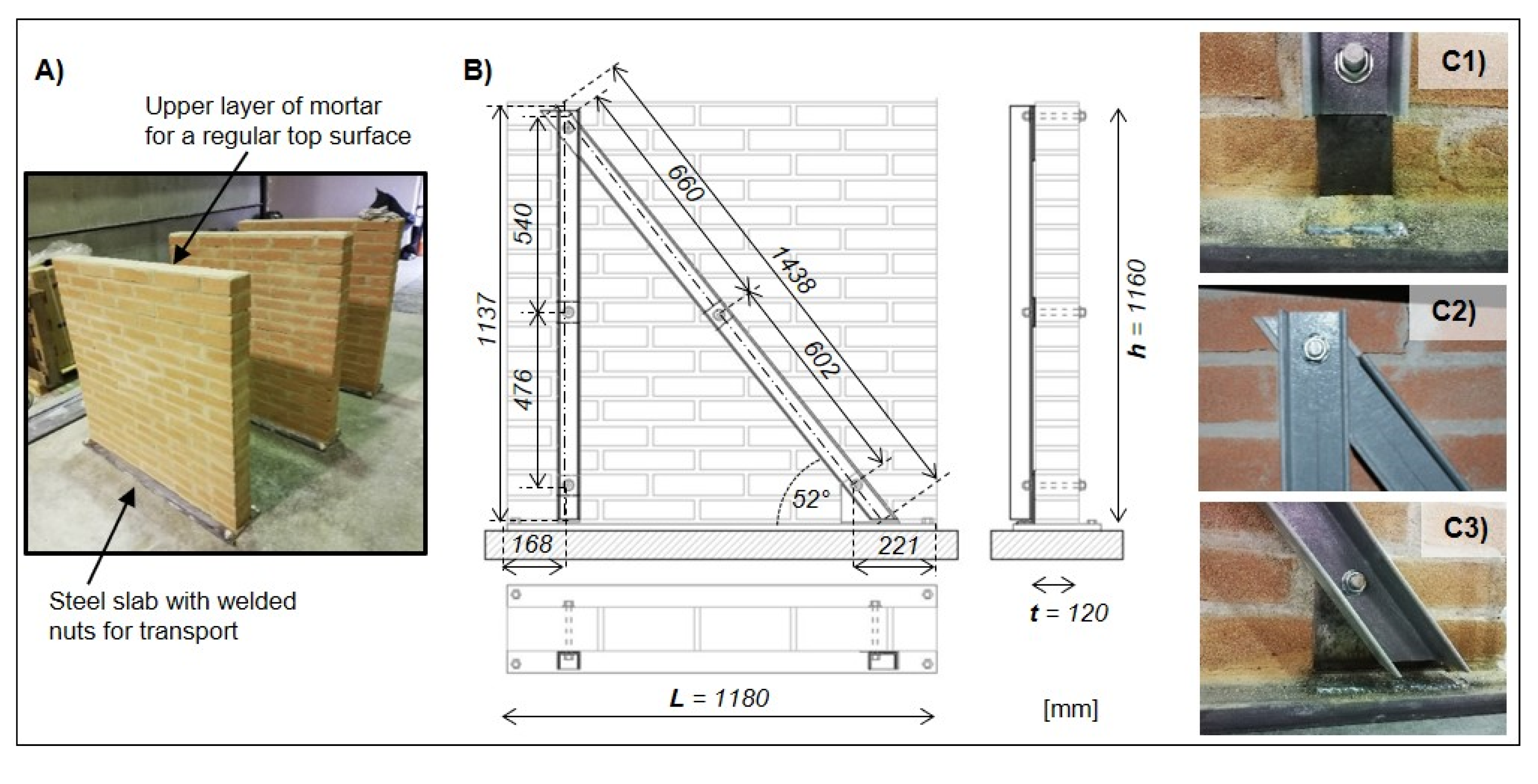

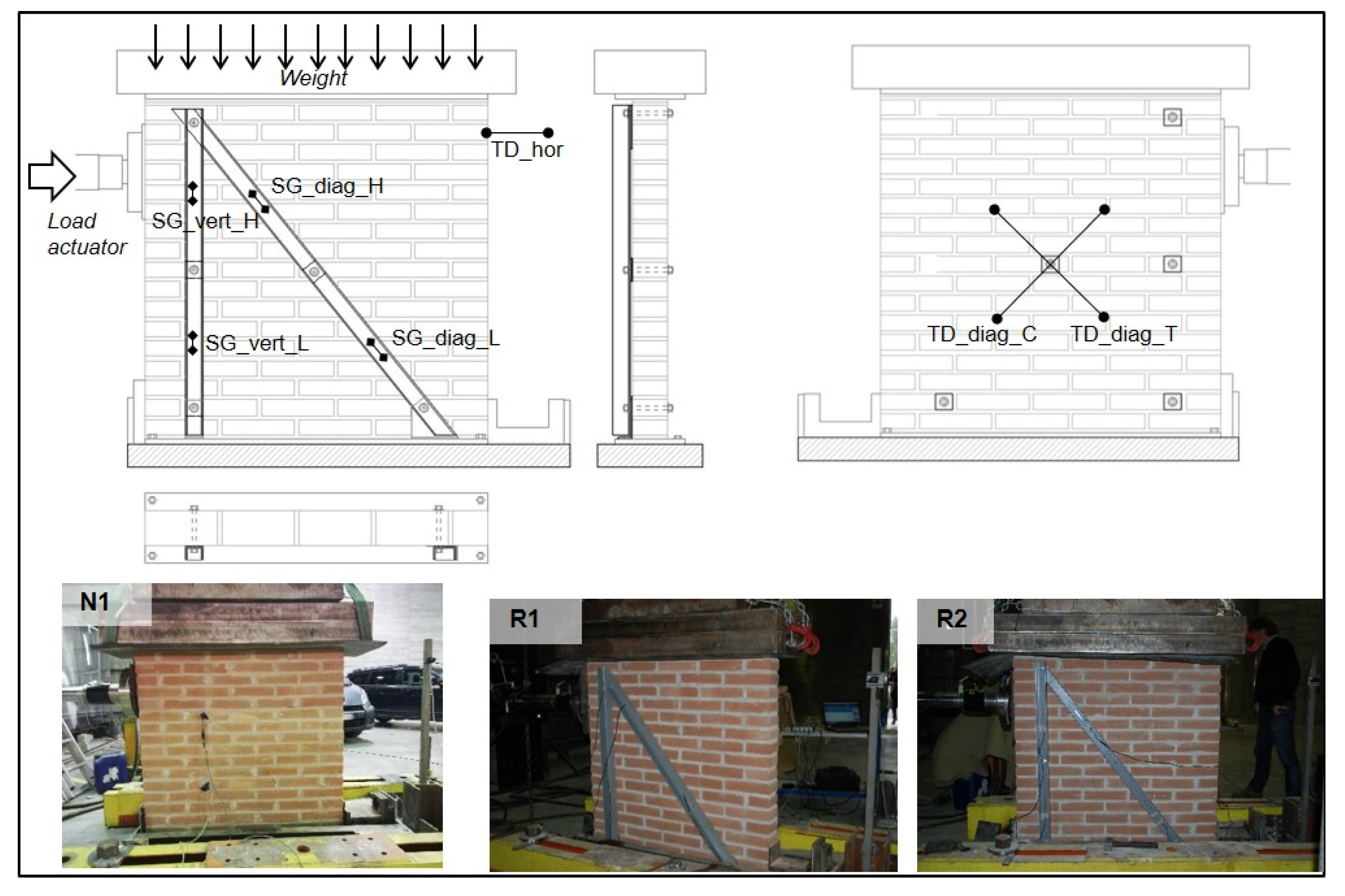

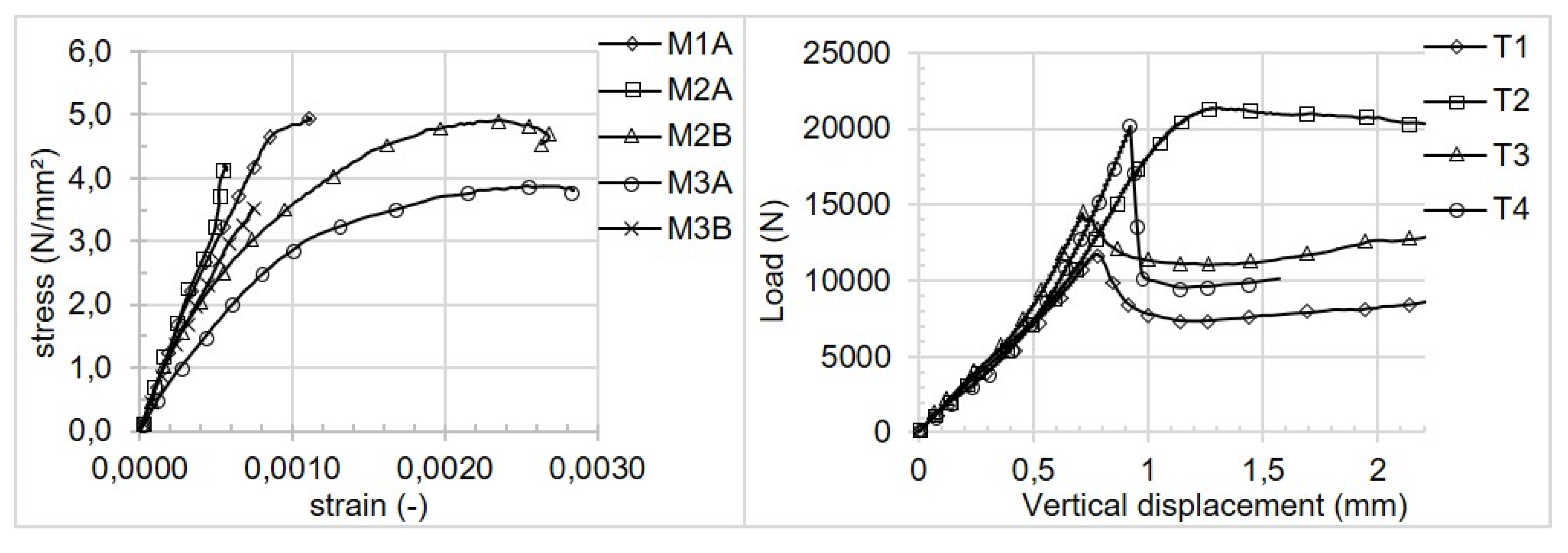

2. Materials and Methods

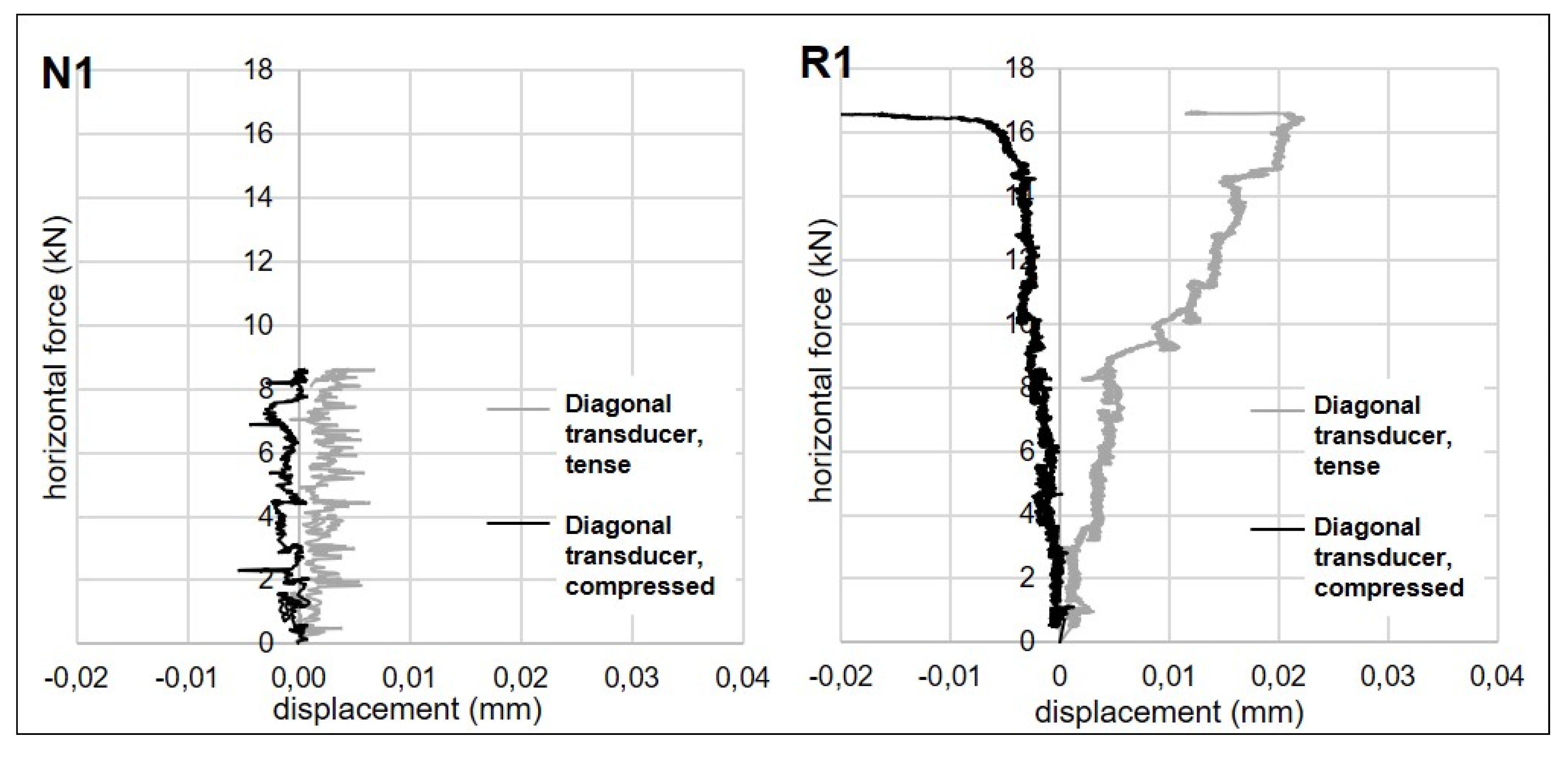

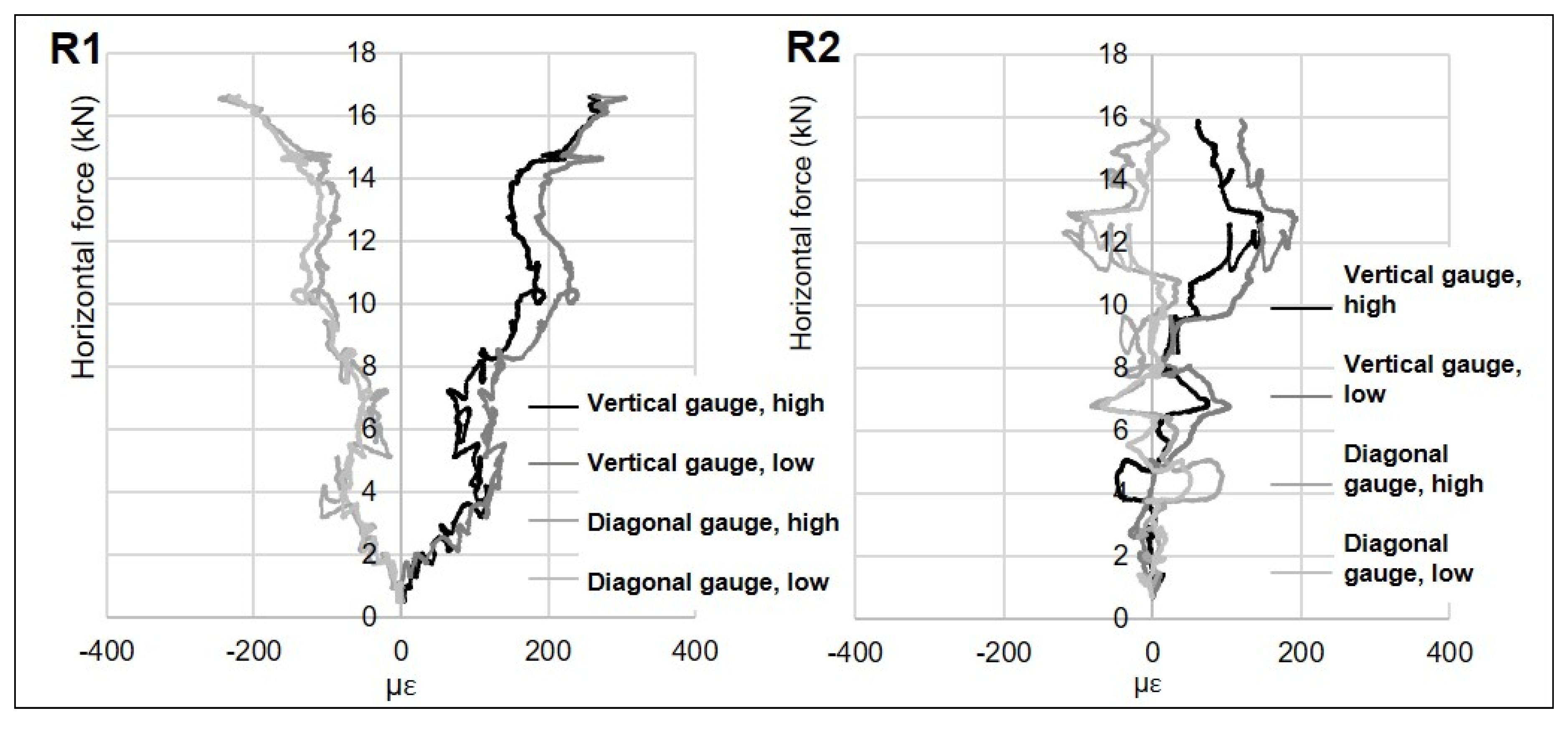

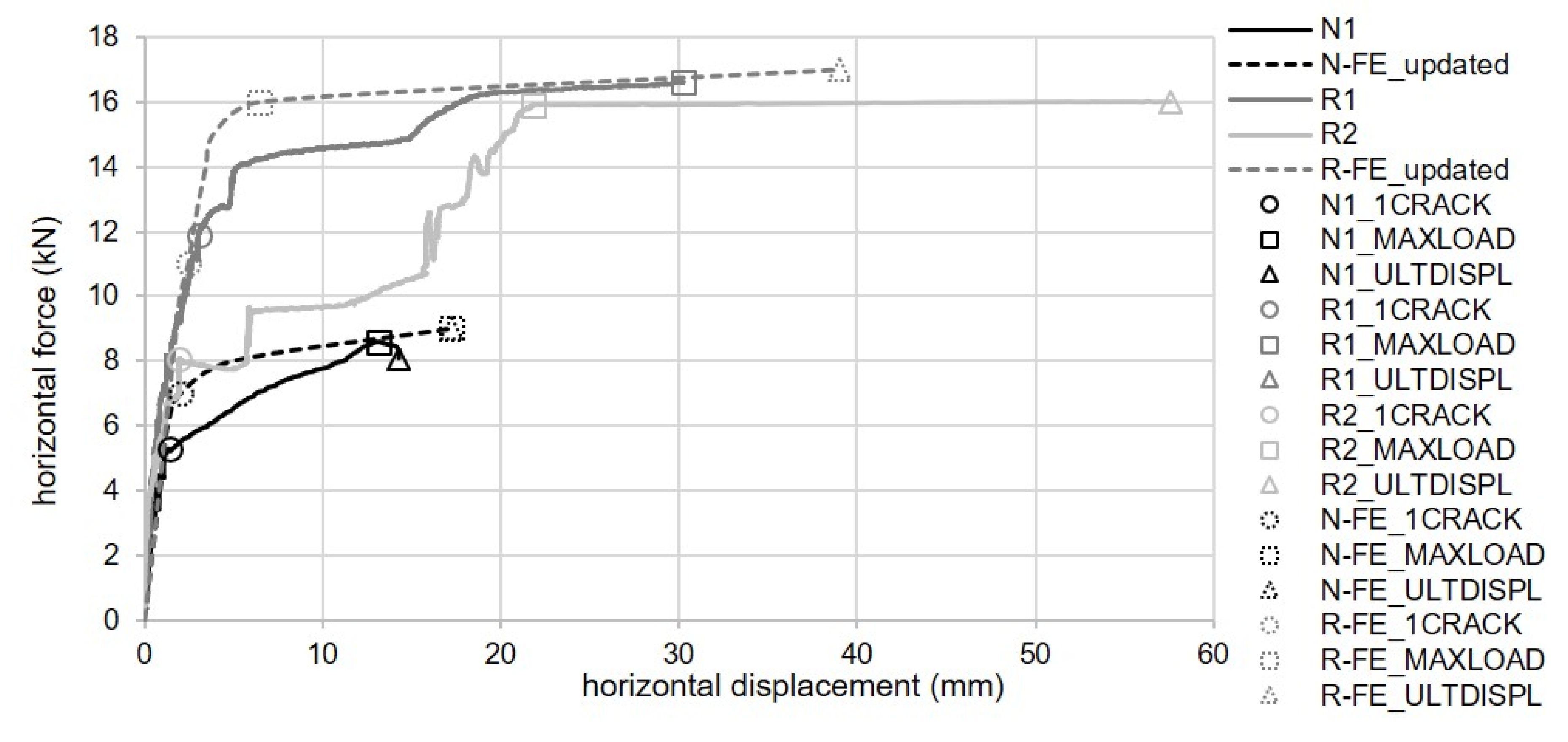

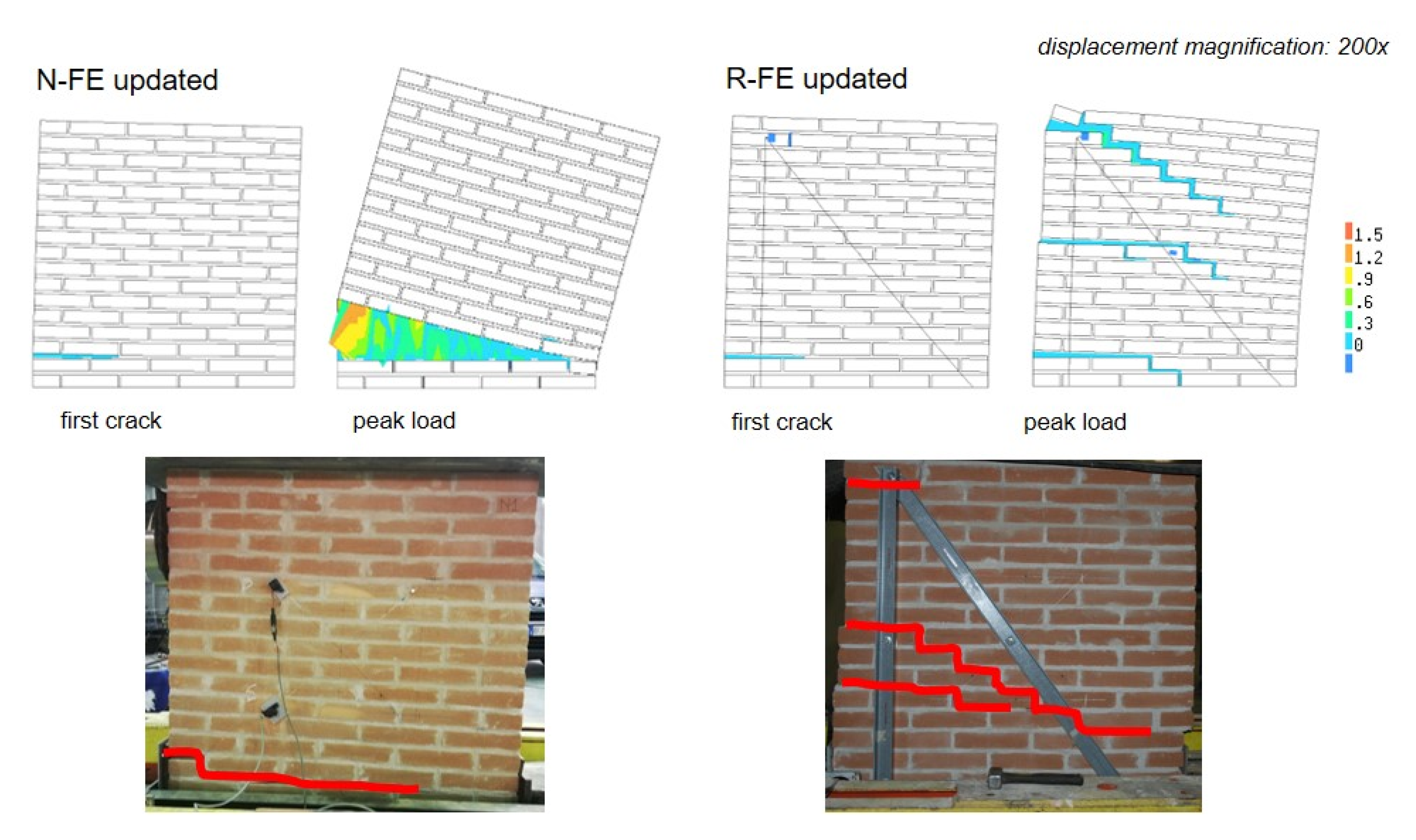

3. Results

4. Discussion

5. Conclusions

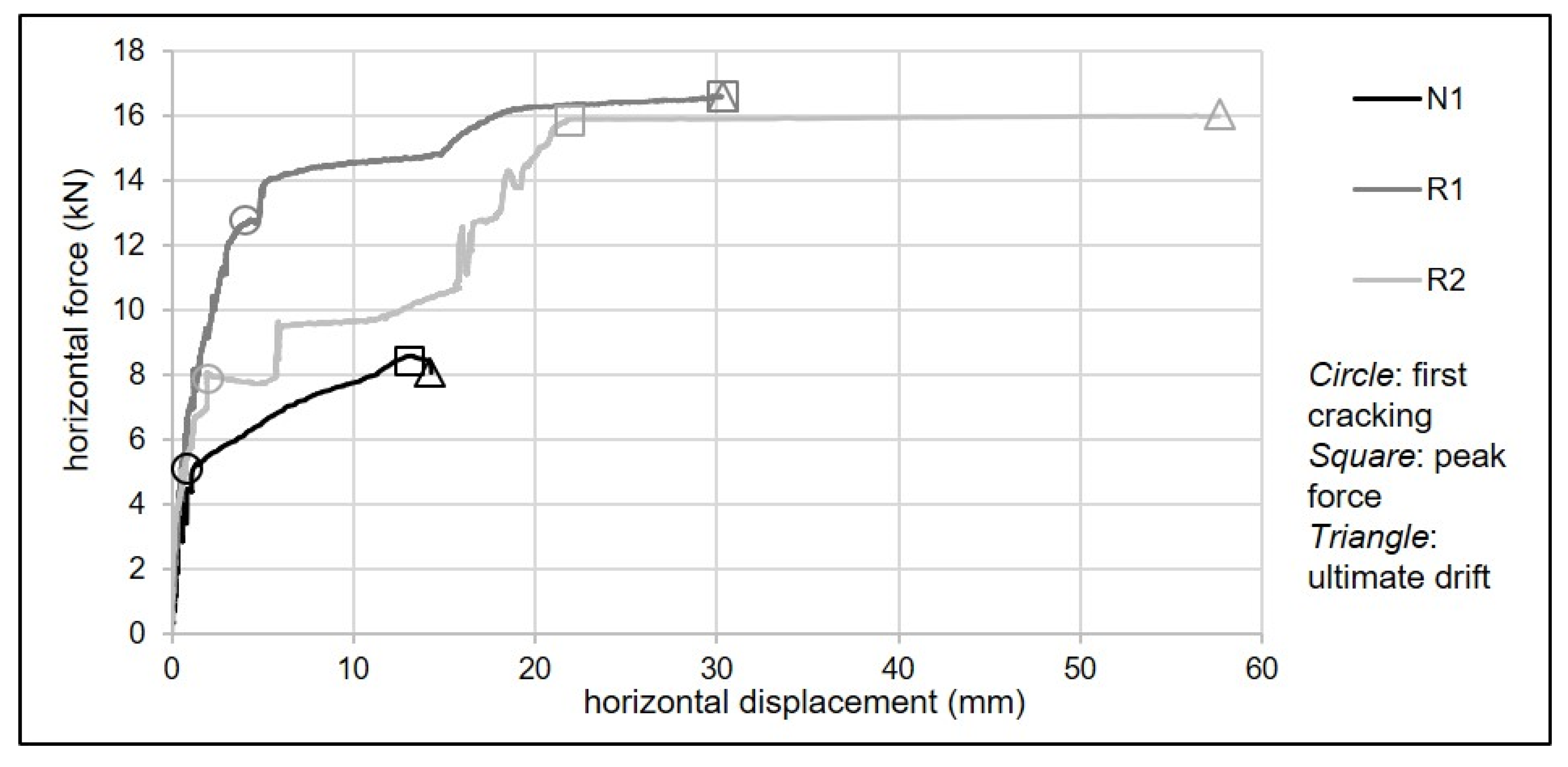

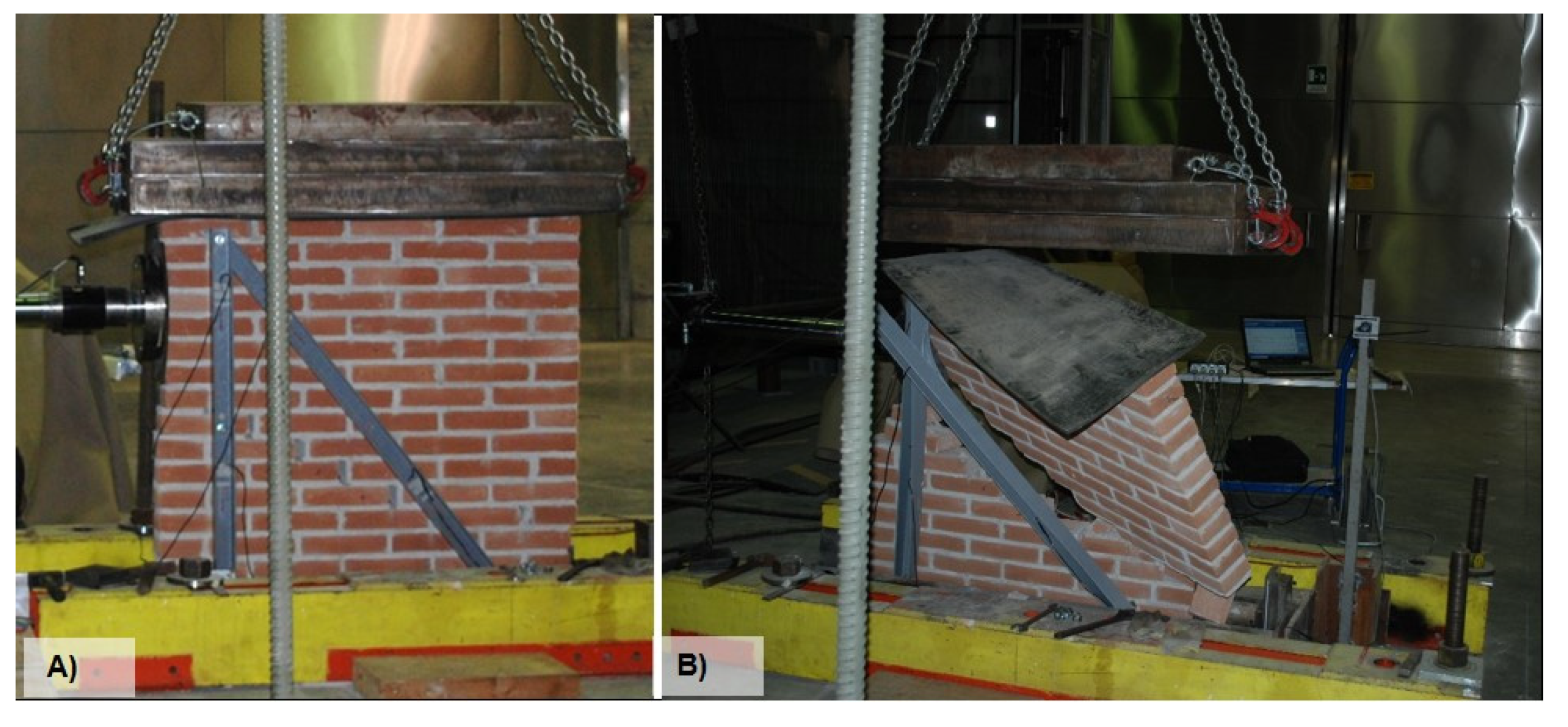

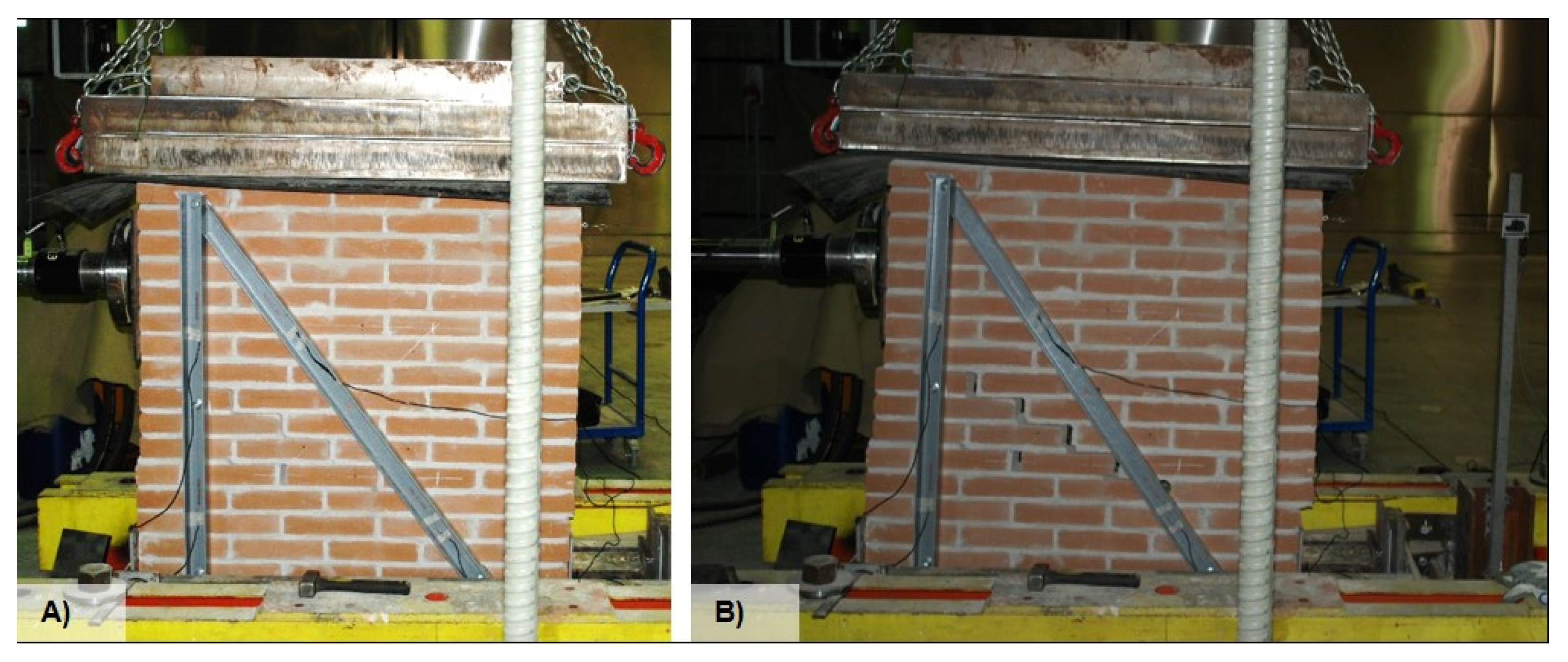

- The retrofit solution brings on a substantial increase in strength (minimum +53% at first crack, +85% at the peak and +98% at the ultimate load) of the investigated masonry sample. The failure mode turns to a mixed mechanism, between central diagonal cracking and central bed joint sliding. The proposed solution brings on a significant improvement in the mechanical performance of traditional brick masonry with hydraulic lime mortar joints;

- The improvement in drift capacity of R1 and R2 is clear, but the increase in the ultimate drift after retrofit is not fully clarified by the described testing program. The two tests have produced large differences (i.e., +112% and +303%). The geometric imperfection of sample R1 (out-of-plumb) is deemed responsible for the sudden collapse under testing, and has prevented the sample from reaching an ultimate drift as high as R2 did. Further tests are surely required to explore the proposed retrofit solution in more detail and with increased reliability;

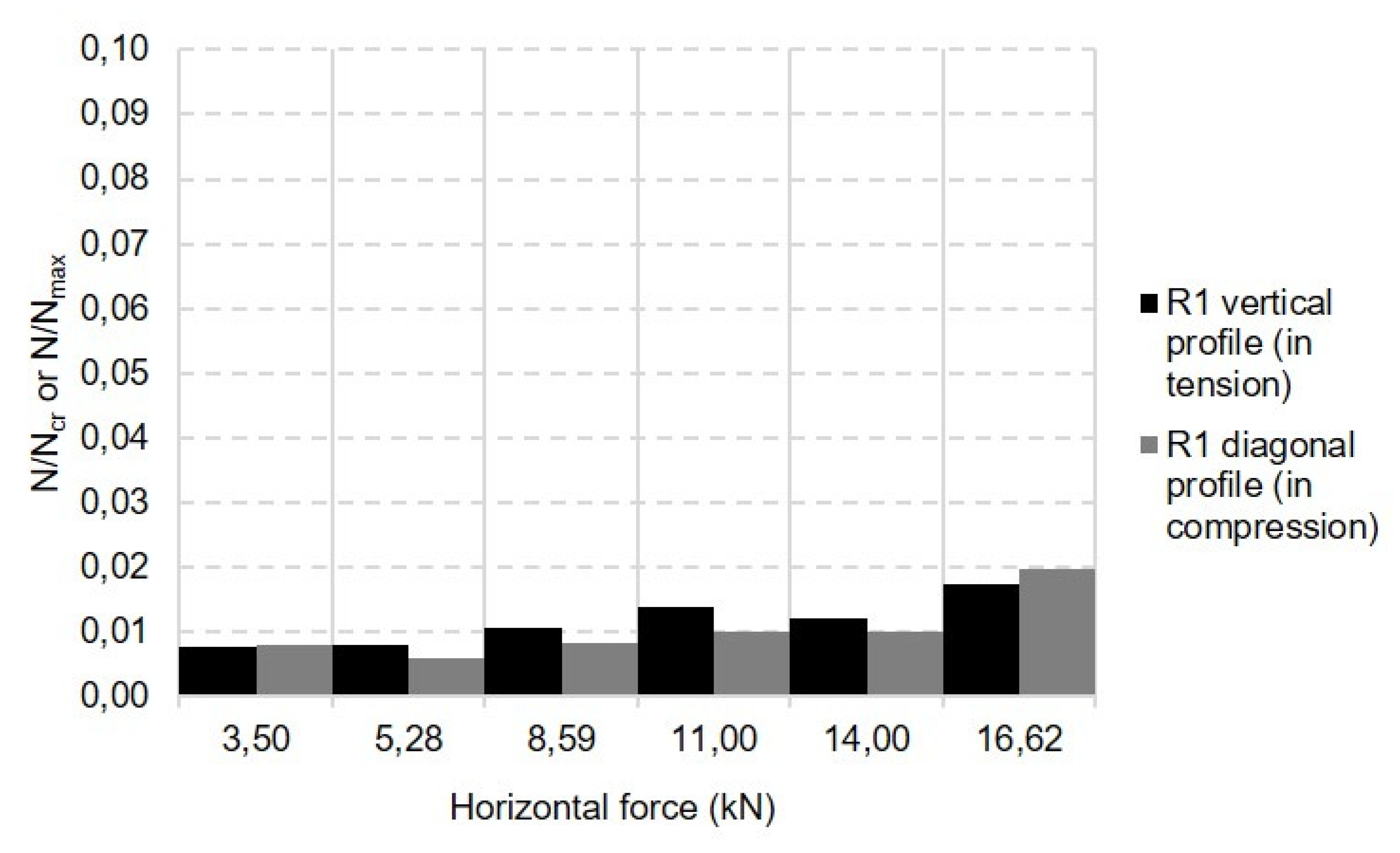

- The design of the fastenings, according to the American Concrete Institute’s (ACI) recommendations, is definitely on the safe side, since no sign of masonry rupture, bar plasticization or hole bearing was detected after the tests. However, this aspect deserves more attention in the future steps of the research, because it is crucial in improving the exploitation of the high stiffness and strength of FRP profiles;

- The assumption of the partial half-scale has allowed us to obtain promising results regarding the effectiveness of the proposed retrofit solution, at a limited cost and with relatively manageable laboratory samples; however, a comparison with full-scale behavior would allow for the more detailed design of frame profiles and connections;

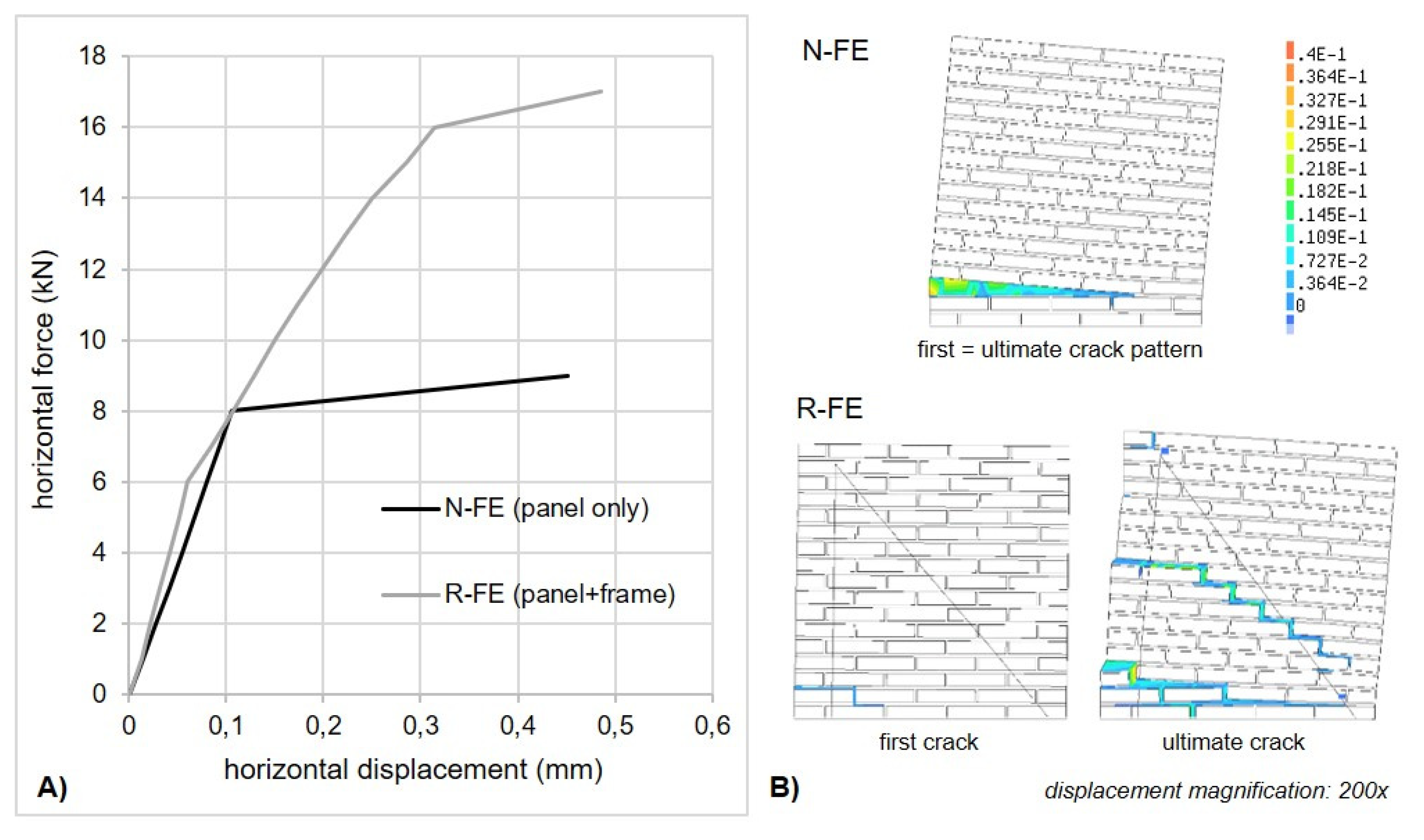

- As for the FE model of the case study, an update—consisting of the implementation of experimental data to describe the joint’s shear stiffness—was essential to improve the model’s capability to catch the experimental load–drift behavior with enough accuracy. In this way, the model has shown rather good agreement with the experimental values of elastic stiffness, maximum load and magnitude of displacements, and most of all the crack pattern and strength gain of the masonry wallette after retrofit (89%, both from the tests and the FE model). This is to be considered the initial state of a predictive model for the next phases of the research, which will be useful to evaluate the pre- and post-retrofit behavior of other case studies. In fact, the residual discrepancy between the FE model and the experimental cases, especially between the first crack and the peak, should be reduced. This could be done by increasing the number of tests on one side, and by accounting for different types of nonlinearities on the other—e.g., plasticity-based models instead of cracking. This task will be duly undertaken in the next steps of the research.

Funding

Acknowledgments

Conflicts of Interest

References

- Dubină, D. (Ed.) Seismic retrofitting of existing structures using steel-based solutions. In Minutes of International Workshop Organised within the Framework of FRS2-CT-2014-00022 STEELEARTH, Timişoara, Romȃnia, 23th November 2015; Politehnica University of Timisoara: Timişoara, Romȃnia, 2015. [Google Scholar]

- Sugano, S. State-of-the-art in techniques for rehabilitation of buildings. In Proceedings of the 11th WCEE—World Conference on Earthquake Engineering, Acapulco, Mexico, 23–28 June 1996. Paper No. 2175. [Google Scholar]

- Buonocore, G.; Gesualdo, A.; Monaco, M.; Savino, M.T. Improvement of Seismic Performance of Unreinforced Masonry Buildings using Steel Frames. In Proceedings of the 12th International Conference on Computational Structures Technology, Naples, Italy, 2–5 September 2014; p. 117. [Google Scholar]

- Rai, D.C.; Goel, S.C. Seismic strengthening of unreinforced masonry piers with steel elements. Earthq. Spectra 1996, 4, 845–862. [Google Scholar] [CrossRef]

- Papalou, A. Strengthening of masonry structures using steel frames. Int. J. Eng. Tech. 2013, 2, 50–56. [Google Scholar] [CrossRef][Green Version]

- Lorenzo Jurina—Torre San Dalmazio a Pavia. Available online: http://jurina.it/1992/01/01/torre-san-dalmazio-a-pavia (accessed on 3 February 2020).

- Consolidamento Chiesa di San Giacomo Apostolo a S. Croce di Magliano. Available online: https://www.santacroceonline.com/2012/news/lug/1_15/sangiacomo/chiesasangiacomo.pdf (accessed on 3 February 2020).

- TekPe Engineers—Seismic Retrofit Projects by TPE. Available online: http://www.tekpeengineers.com/seismic-retrofit.html (accessed on 3 February 2020).

- Dmytro, D.; Jason, I.; Lisa, M.; Mike, G.; Arturo, S.; Ilaria, S.; Guido, M.; Jocelyn, D.; Shelley, L.; Jose, C.; et al. Performance of masonry buildings and churches in the 22 February 2011 Christchurch earthquake. Bull. New Zeal Soc. Earthq. Eng. 2011, 44, 279–296. [Google Scholar]

- Casalegno, C.; Russo, S.; Sciarretta, F. Numerical analysis of a masonry panel reinforced with pultruded FRP frames. Mech. Compos. Mat. 2018, 2, 207–220. [Google Scholar] [CrossRef]

- Boscato, G.; Costantini, G.; Scafuri, V. Seismic Design of Pultruded FRP Structures as Ancillary and/or Independent Solution. Key Eng. Mater. 2017, 747, 586–593. [Google Scholar] [CrossRef]

- Top Glass Sponsor Della “Glass House” all’Università di Venezia. Available online: https://www.topglass.it/notizia-padiglione-iuav/ (accessed on 3 February 2020).

- Kiora Footbridge. Available online: https://compositesuk.co.uk/system/files/documents/Case%20Study%20-%20Kiora%20Sluice%20Footbridge.pdf (accessed on 3 February 2020).

- Nehdi, M.; El Damatty, A.; Rahimi, R. Investigation on lap-joint behavior of GFRP plates bonded to silica fume and rice husk ash concrete. Int. J. Adh. Adhes 2003, 23, 323–333. [Google Scholar] [CrossRef]

- Bedon, C.; Louter, C. Numerical investigation on structural glass beams with GFRP-embedded rods, including effects of pre-stress. Compos. Struct. 2018, 184, 650–661. [Google Scholar] [CrossRef]

- Boscato, G. Comparative study on dynamic parameters and seismic demand of pultruded FRP members and structures. Compos. Struct. 2017, 174, 399–419. [Google Scholar] [CrossRef]

- Russo, S. Performance of a PFRP structure covering a historic building struck by an earthquake. In Proceedings of the ACIC 2011, Coventry, UK, 6–8 September 2011. [Google Scholar]

- BIA. Anchor Bolts for Brick Masonry; Technical Note No. 44; Brick Industry Association: Reston, Virginia, USA, 1986. [Google Scholar]

- McGinley, W. Design of anchor bolts in masonry. Prog. Struct. Eng. Mater. 2006, 8, 155–164. [Google Scholar] [CrossRef]

- Muñoz, R.; Lourenço, P.B.; Moreira, S. Experimental results on mechanical behavior of metal anchors in historic stone masonry. Constr. Buil. Mater. 2018, 163, 643–655. [Google Scholar] [CrossRef]

- Sciarretta, F.; Russo, S.; Casalegno, C. Experimental analysis of failure mechanisms in masonry-PFRP profiles connections. Adv. Civil. Eng. 2018, 2018, 5475347. [Google Scholar] [CrossRef]

- Specification for Ancillary Components for Masonry Part 1: Wall Ties, Tension Straps, Hangers and Brackets; EN 845-1:2013+A1:2016; Comité Européen de Normalisation: Brussels, Belgium, 2016.

- Masonry Standards Joint Committee (MSJC). Building Code Requirements for Masonry Structures (ACI 530-02/ASCE 5-02/TMS 402-02; The Masonry Society: Longmont, CO, USA, 2005. [Google Scholar]

- Cecchi, A.; Russo, S.; Sciarretta, F. Preliminary investigation on FRP profiles for the structural retrofit of masonry structures. Key Eng. Mater. 2017, 747, 77–84. [Google Scholar] [CrossRef]

- Sciarretta, F.; Russo, S. FE modelling and experimental investigation on adhesive joints between clay brick and pultruded FRP profiles. Constr. Build. Mater. 2019, 226, 601–615. [Google Scholar] [CrossRef]

- Sciarretta, F.; Russo, S. Half-scale tests on masonry panels strengthened with Pultruded FRP frames. Key Eng. Mater. 2019, 817, 95–102. [Google Scholar] [CrossRef]

- Eurocode 8—Design of Structures for Earthquake Resistance. Part 1: General Rules, Seismic Actions and Rules for Building; EN 1998-1:2005; Comité Européen de Normalisation: Brussels, Belgium, 2005.

- Taghdi, M.; Bruneau, M.; Saatcioglu, M. Analysis and design of low-rise masonry and concrete walls retrofitted using steel strips. ASCE J. Struct. Eng. 2000, 126, 1026–1032. [Google Scholar] [CrossRef]

- Methods of Test for Masonry Units—Part 1: Determination of Compressive Strength; EN 772-1:2015; Comité Européen de Normalisation: Brussels, Belgium, 2015.

- Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; EN 1015-11:2006; Comité Européen de Normalisation: Brussels, Belgium, 2006.

- Methods of Test for Masonry—Part 3: Determination of Initial shear Strength; EN 1052-3:2007; Comité Européen de Normalisation: Brussels, Belgium, 2007.

- Hendry, A.W. Structural Brickwork; Macmillan: London, UK; Basingstoke, UK, 1981. [Google Scholar]

- Brencich, A.; Corradi, M.; Gambarotta, L.; Mantegazza, G.; Sterpi, E. Compressive strength of solid caly brick masonry under eccentric loading. Proc. Br. Mason Soc. 2002, 9, 37–46. [Google Scholar]

- Tassios, T.P. Meccanica Delle Murature; Liguori: Naples, Italy, 1988. [Google Scholar]

- Thorning, H. (Ed.) Fiberline Design Manual, 2nd ed.; Fiberline Composites A/S: Kolding, Denmark, 2003. [Google Scholar]

| Elements | Quantity | Dimensions 1:1 (m) | Unit mass | Total Mass 1:2 (kg) |

|---|---|---|---|---|

| Wooden trusses | 5 | 0.15 × 0.15, total length 14.04 | 650 kg/m³ | 148 |

| Wooden lintels | 9 | 0.1 × 0.1, total length 10.00 | 650 kg/m³ | 73 |

| Clay tiles and tablets | 1 | roof surface 2.68 × 10 × 2 pitches | 70 kg/m² | 469 |

| Floor (dead and live load) | 1 | 10 × 5 | 660 kg/m² | 3960 |

| External walls | 2 | (10 + 4.8) × 4.8 × 0.25, 30% holes | 1550 kg/m³ | 4530 |

| Internal wall | 1 | 4.8 × 4.8 × 0.25, 15% holes | 1550 kg/m³ | 897 |

| Total mass of the whole building | 10077 | |||

| Property | Value |

|---|---|

| Longitudinal compressive elastic modulus Ez,c (N/mm²) | 20,000 |

| Poisson’s coefficient νxz | 0.25 |

| Longitudinal tensile elastic modulus (N/mm²) | 30,000 |

| Longitudinal flexural elastic modulus (N/mm²) | 30,000 |

| Longitudinal compressive strength (N/mm²) | 300 |

| Longitudinal tensile strength (N/mm²) | 400 |

| Longitudinal flexural strength (N/mm²) | 400 |

| Shear strength (N/mm²) | 30 |

| Material | Property | Value | Source |

|---|---|---|---|

| Brick | Compressive strength fbc (N/mm²) | 20.00 | Destructive testing |

| Elastic modulus Eb (N/mm²) | 5700 | Destructive testing | |

| Poisson’s ratio νb (-) | 0.18 | producer’s data | |

| Mortar | Compressive strength fmc (N/mm²) | 4.40 | Destructive testing |

| Flexural strength fmf (N/mm²) | 0.92 | Destructive testing | |

| Elastic modulus Em (N/mm²) | 5690 | Destructive testing | |

| Poisson’s ratio νm (-) | 0.25 | producer’s data | |

| Masonry | Compressive strength fwc (N/mm²) | 14.96 | Equation (3) |

| Elastic modulus Ew (N/mm²) | 4878 | Equation (4) | |

| Joint shear strength at σ0 = 0.1 N/mm² τ0.1 (N/mm²) | 0.56 | Destructive testing | |

| Joint peak shear displacement dpeak (mm) | 1.6 | Destructive testing |

| Case | First Crack | Maximum Force | Ultimate Displacement | |||

|---|---|---|---|---|---|---|

| P1 (kN) | d1 (mm) | Pmax (kN) | d2 (mm) | Pu (kN) | du (mm) | |

| N1 | 5.275 | 1.401 | 8.594 | 13.165 | 8.081 | 14.287 |

| N-FE | 8.000 | 0.106 | 8.000 | 0.106 | 9.000 | 0.452 |

| R1 | 11.899 (+125%) | 3.034 (+117%) | 16.621 (+93%) | 30.277 (+130%) | 16.621 (+106%) | 30.277 (+112%) |

| R2 | 8.068 (+53%) | 1.951 (+39%) | 15.904 (+85%) | 21.818 (+66%) | 16.010 (+98%) | 57.603 (+303%) |

| R-FE | 6.000 | 0.060 | 16.000 | 0.315 | 17.000 | 0.485 |

| Case | Elastic Stiffness | Maximum Load | Ultimate Displacement | Maximum Load Increase with Retrofit | |

|---|---|---|---|---|---|

| Unretrofitted | FE preliminary/EXP | +2003% | +5% | −97% | |

| FE updated/EXP | −9% | +5% | +21% | ||

| Retrofitted | FE preliminary/EXP * | +2483% | +5% | −99% | ±0% |

| FE updated/EXP * | +10% | +5% | −12% | ±0% | |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sciarretta, F. Seismic Retrofitting of Traditional Masonry with Pultruded FRP Profiles. Appl. Sci. 2020, 10, 2489. https://doi.org/10.3390/app10072489

Sciarretta F. Seismic Retrofitting of Traditional Masonry with Pultruded FRP Profiles. Applied Sciences. 2020; 10(7):2489. https://doi.org/10.3390/app10072489

Chicago/Turabian StyleSciarretta, Francesca. 2020. "Seismic Retrofitting of Traditional Masonry with Pultruded FRP Profiles" Applied Sciences 10, no. 7: 2489. https://doi.org/10.3390/app10072489

APA StyleSciarretta, F. (2020). Seismic Retrofitting of Traditional Masonry with Pultruded FRP Profiles. Applied Sciences, 10(7), 2489. https://doi.org/10.3390/app10072489