Improving the Performance of EDM through Relief-Angled Tool Designs

Abstract

1. Introduction

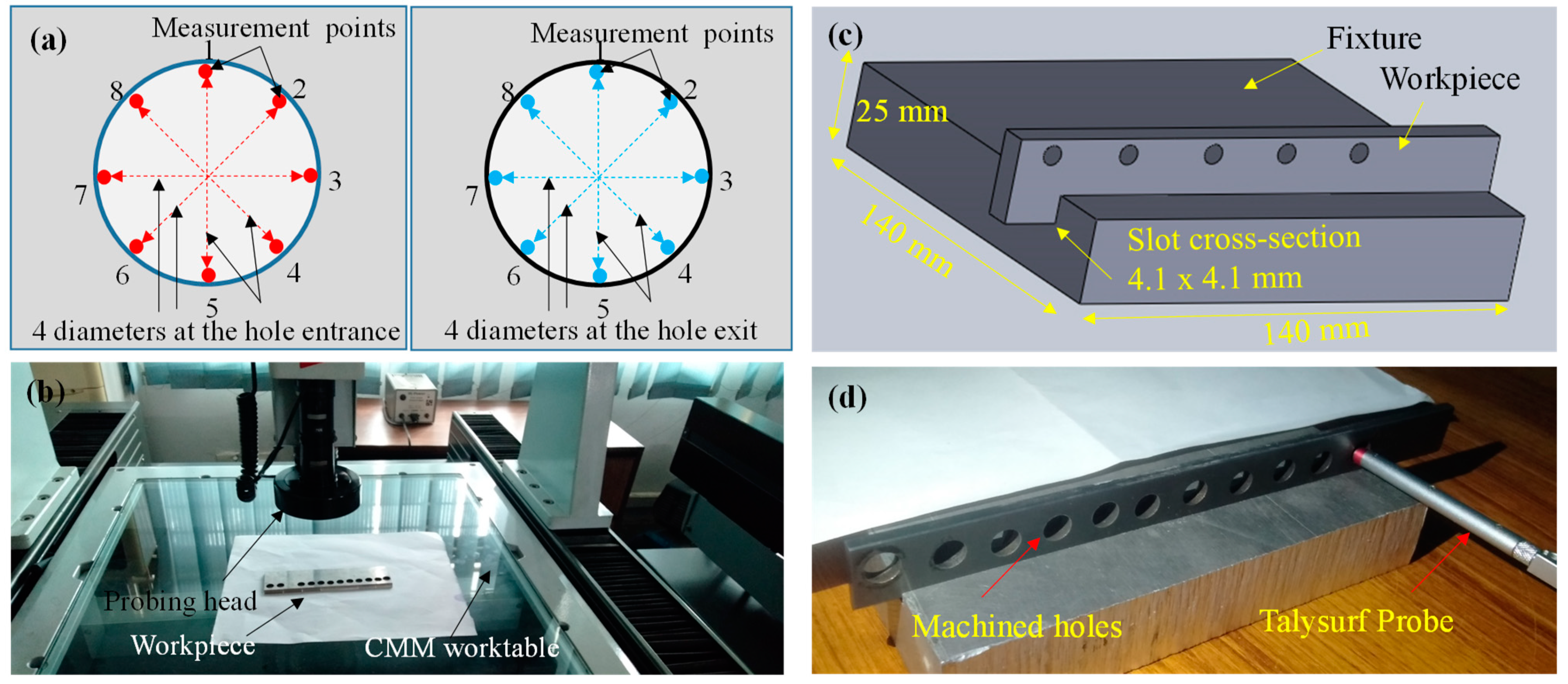

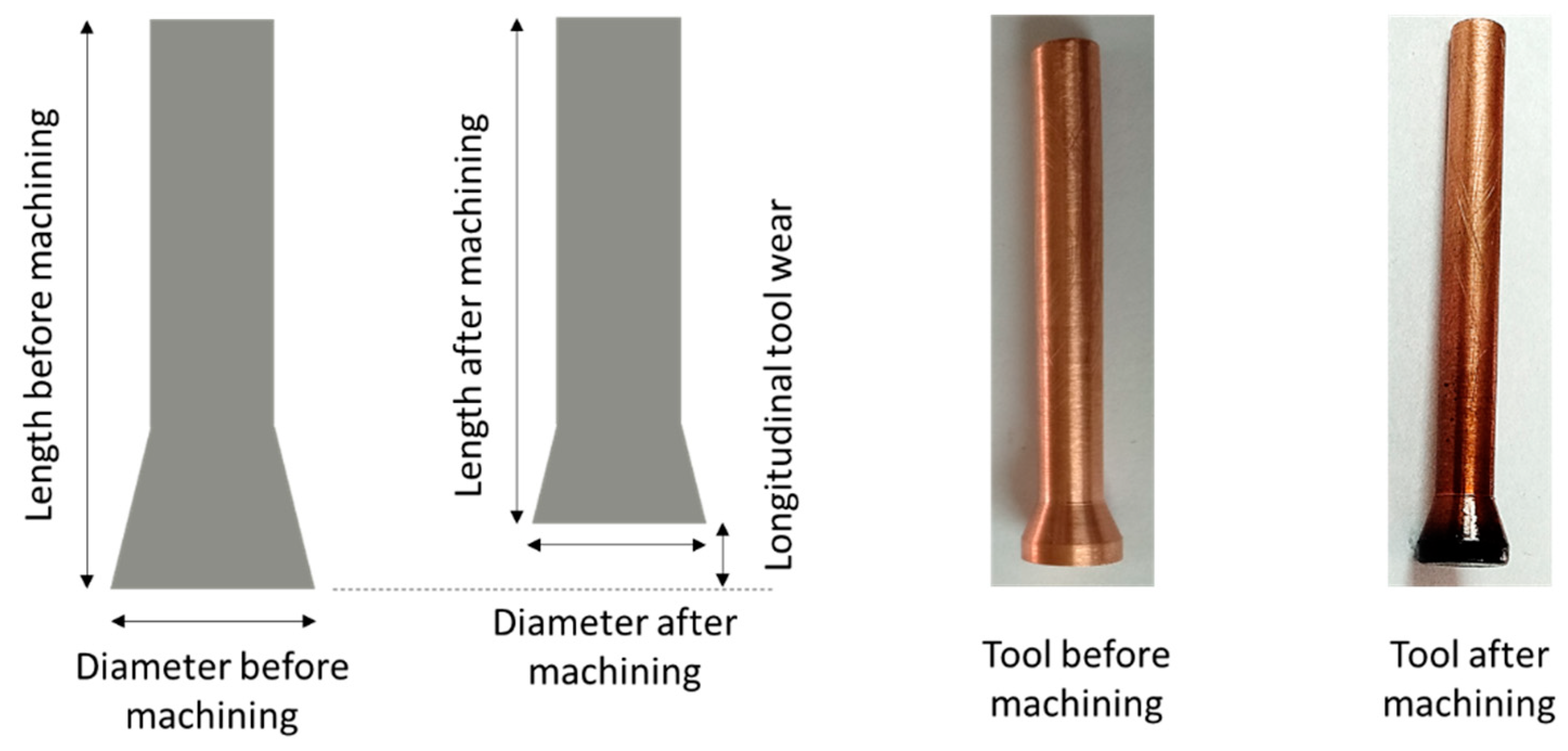

2. Materials and Methods

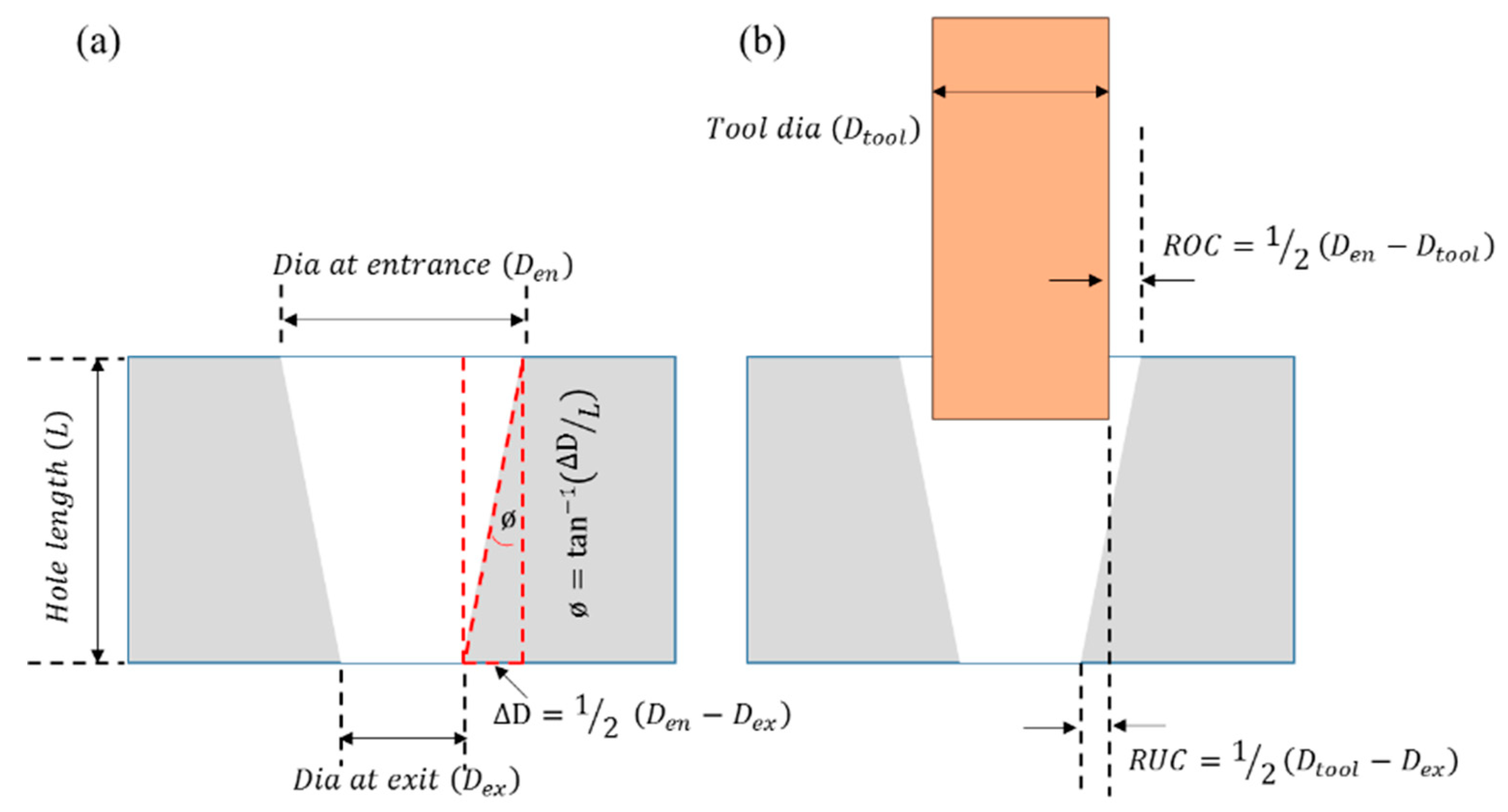

- is the diameter at the hole entrance;

- is the diameter at the hole exit;

- is the half of the difference between both the diamters ( and );

- is the hole length.

- is the diameter of machined hole at the entrance;

- is the diameter of hole at the exit;

- is the diameter of the tool electrode.

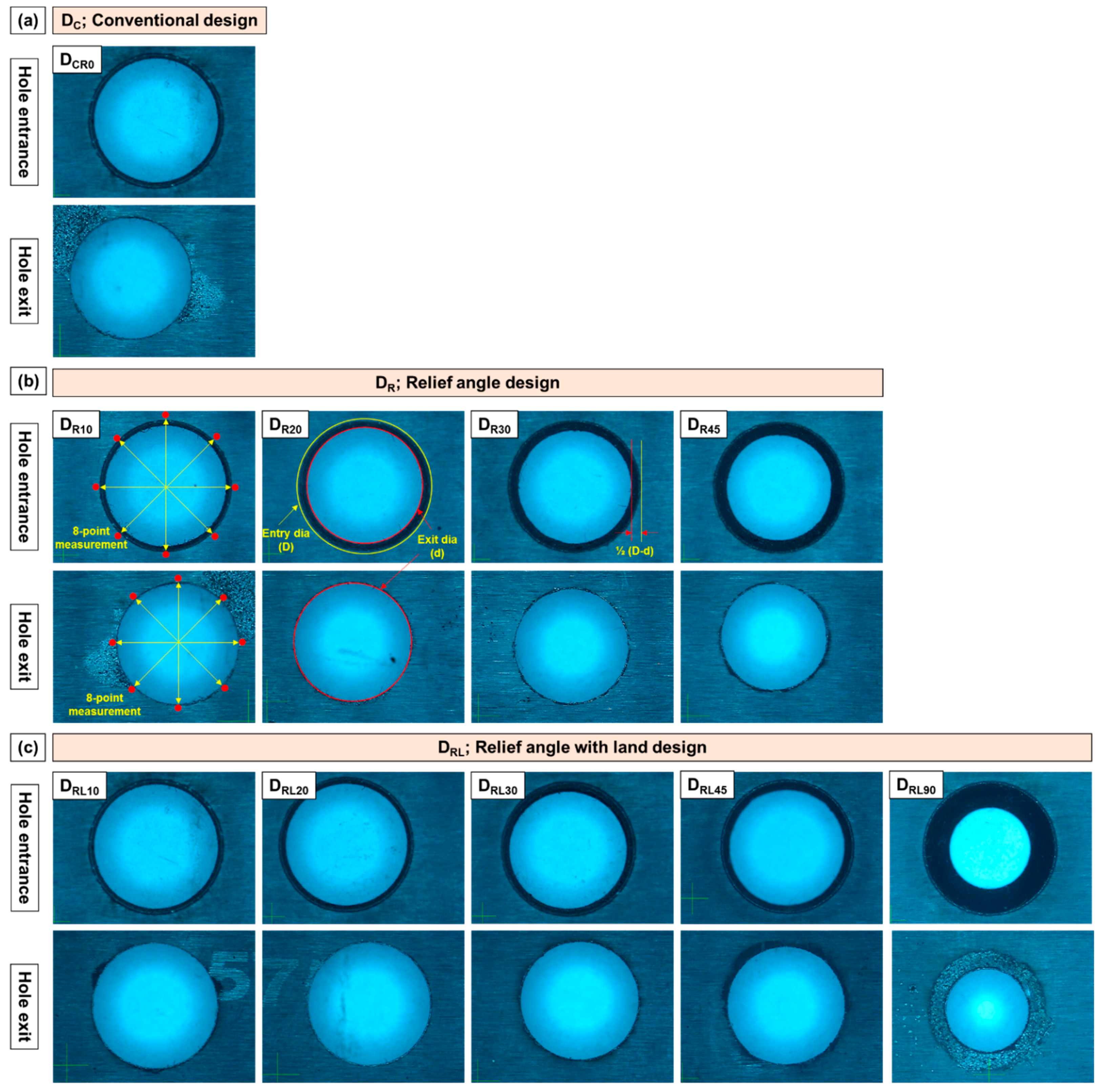

3. Results and Discussion

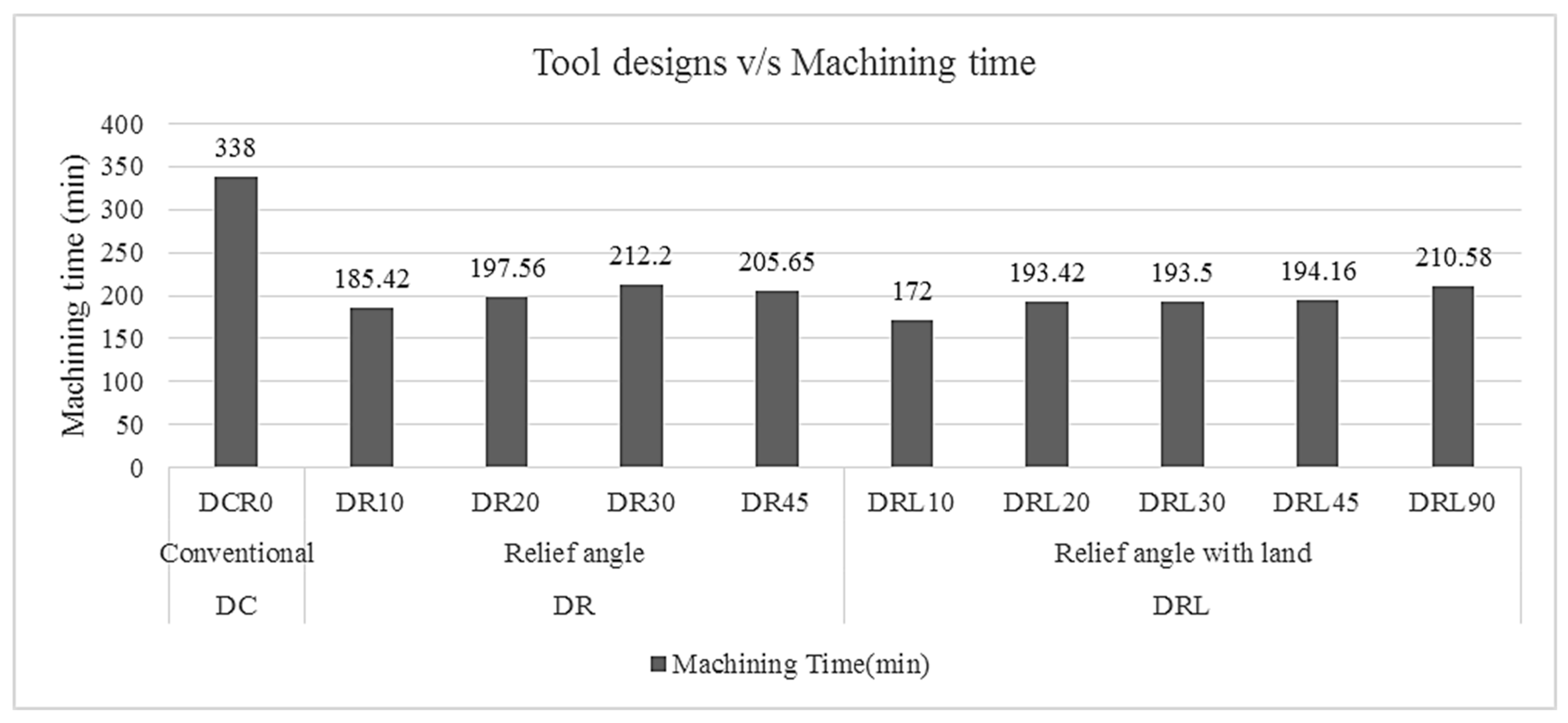

3.1. Effect of Electrode Design on Machining Time (MT)

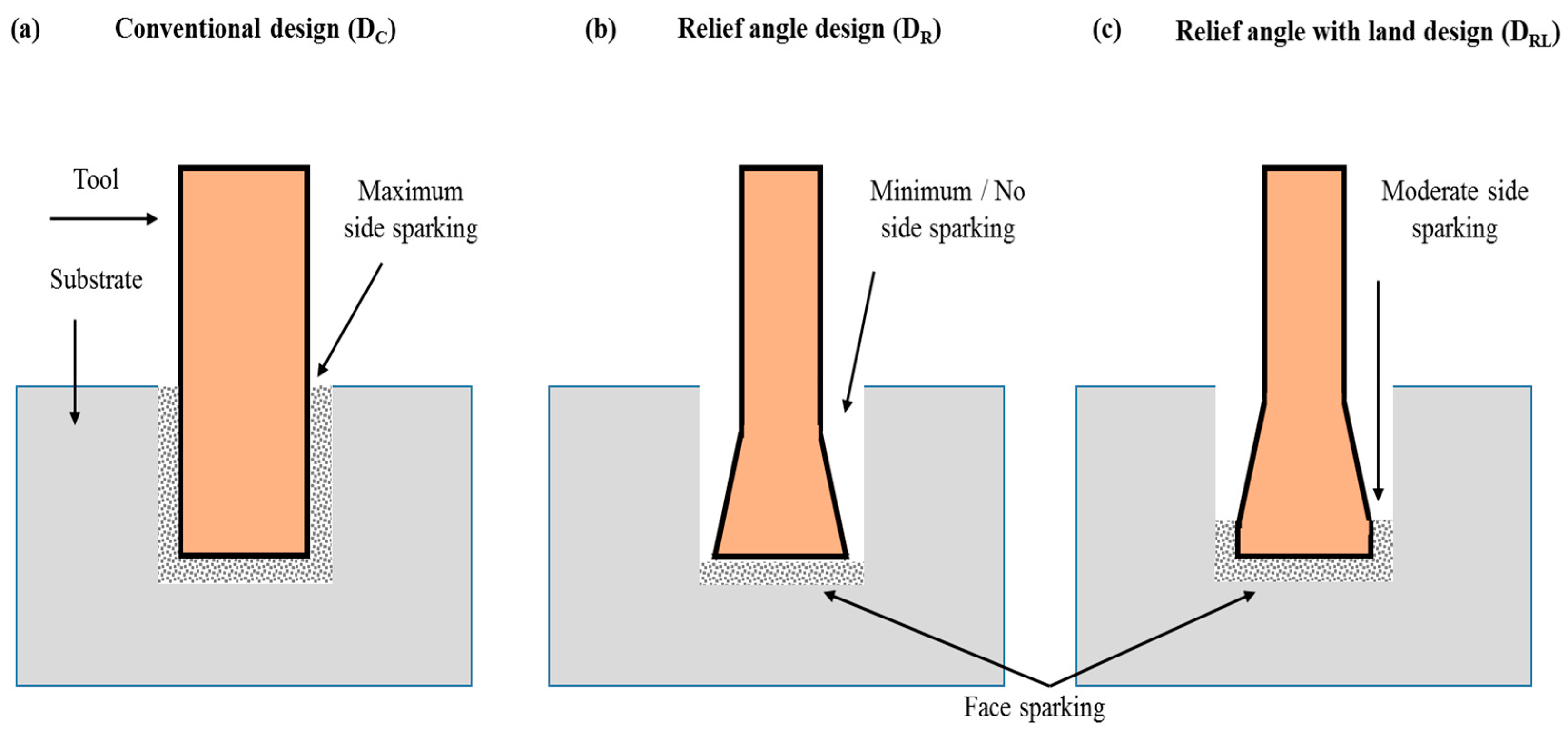

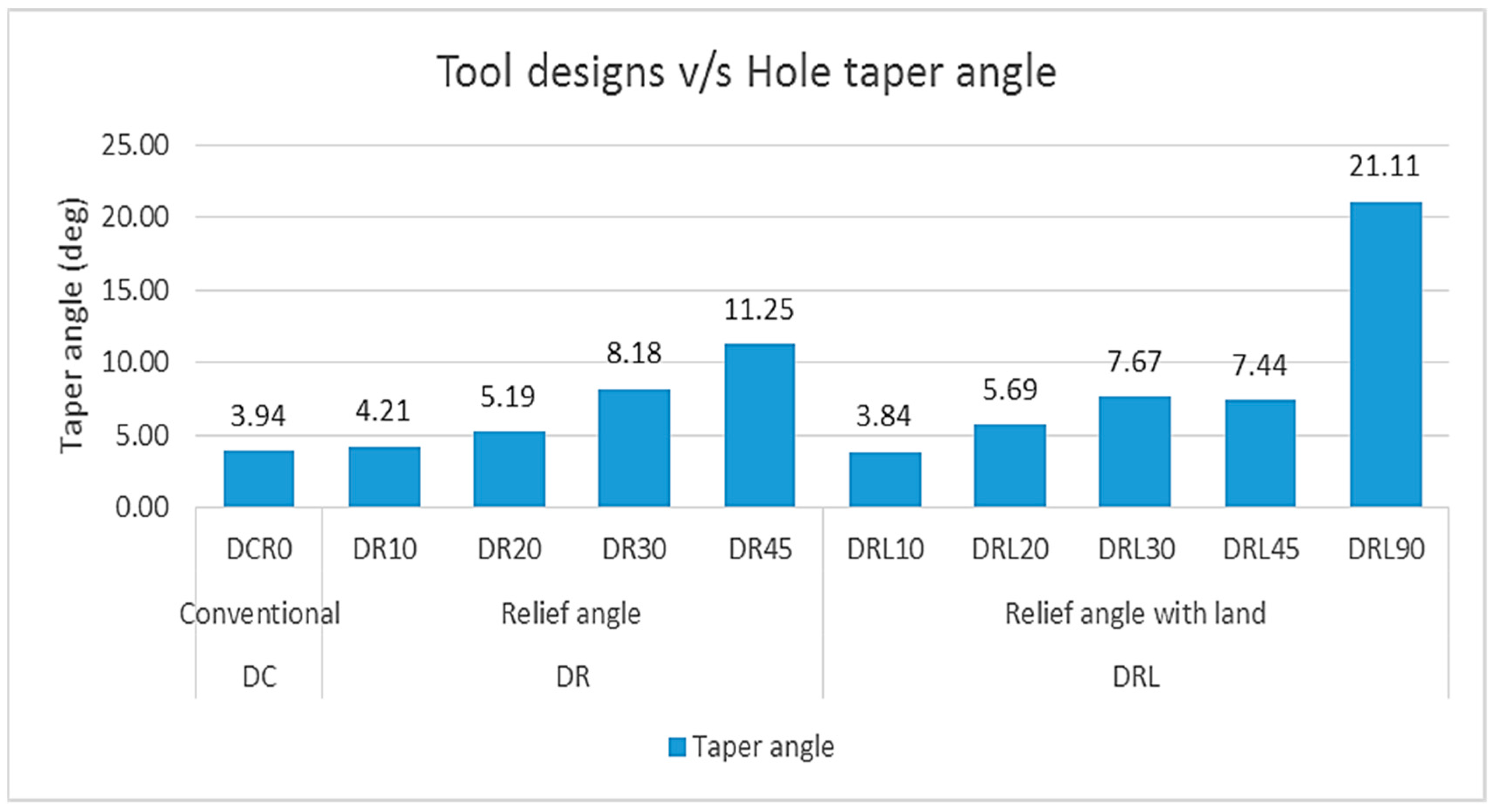

3.2. Effect of Electrode Design on Taper Angle (ø)

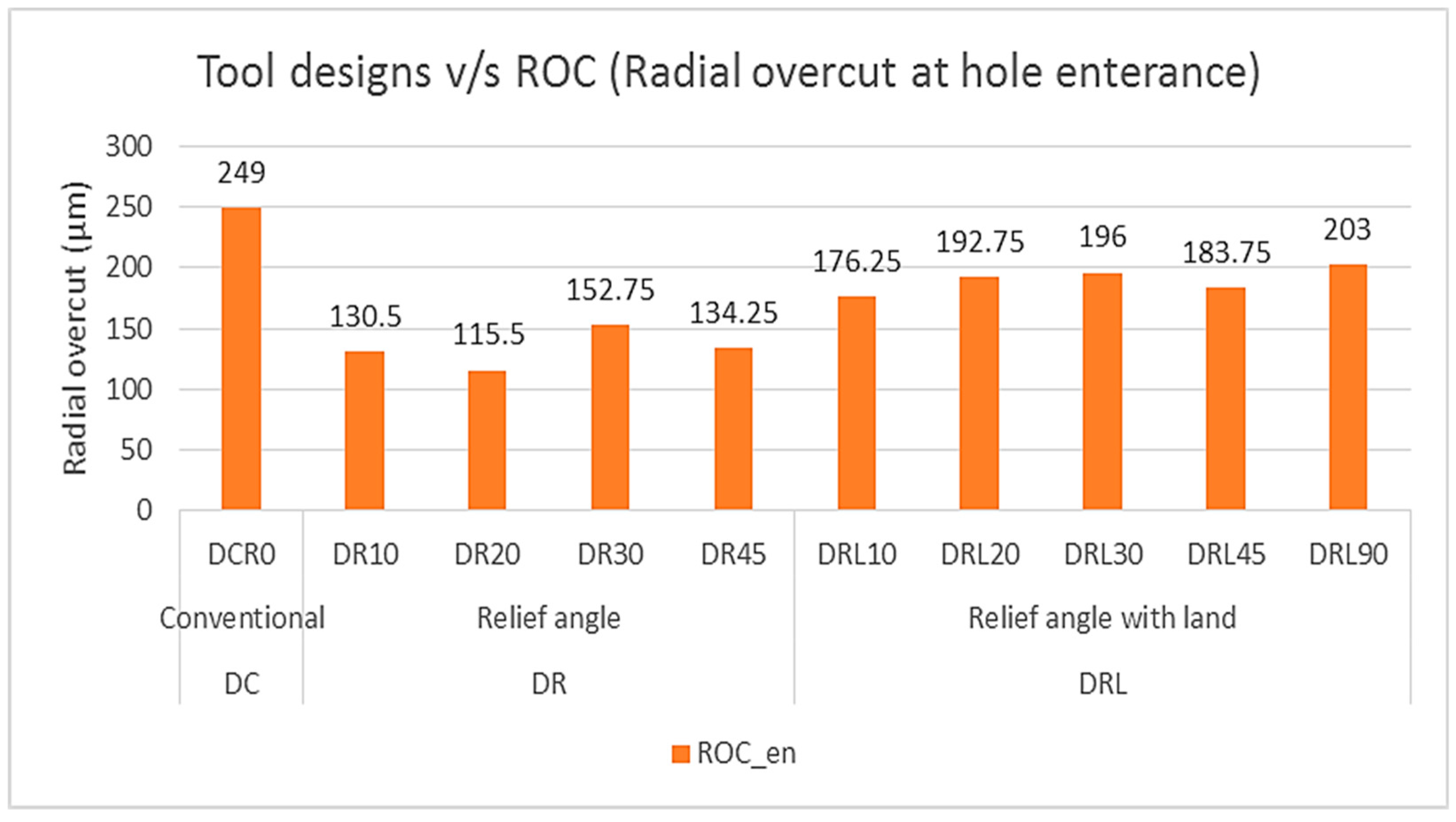

3.3. Effect of Electrode Design on Radial Overcut at Hole Entrance (ROC_en)

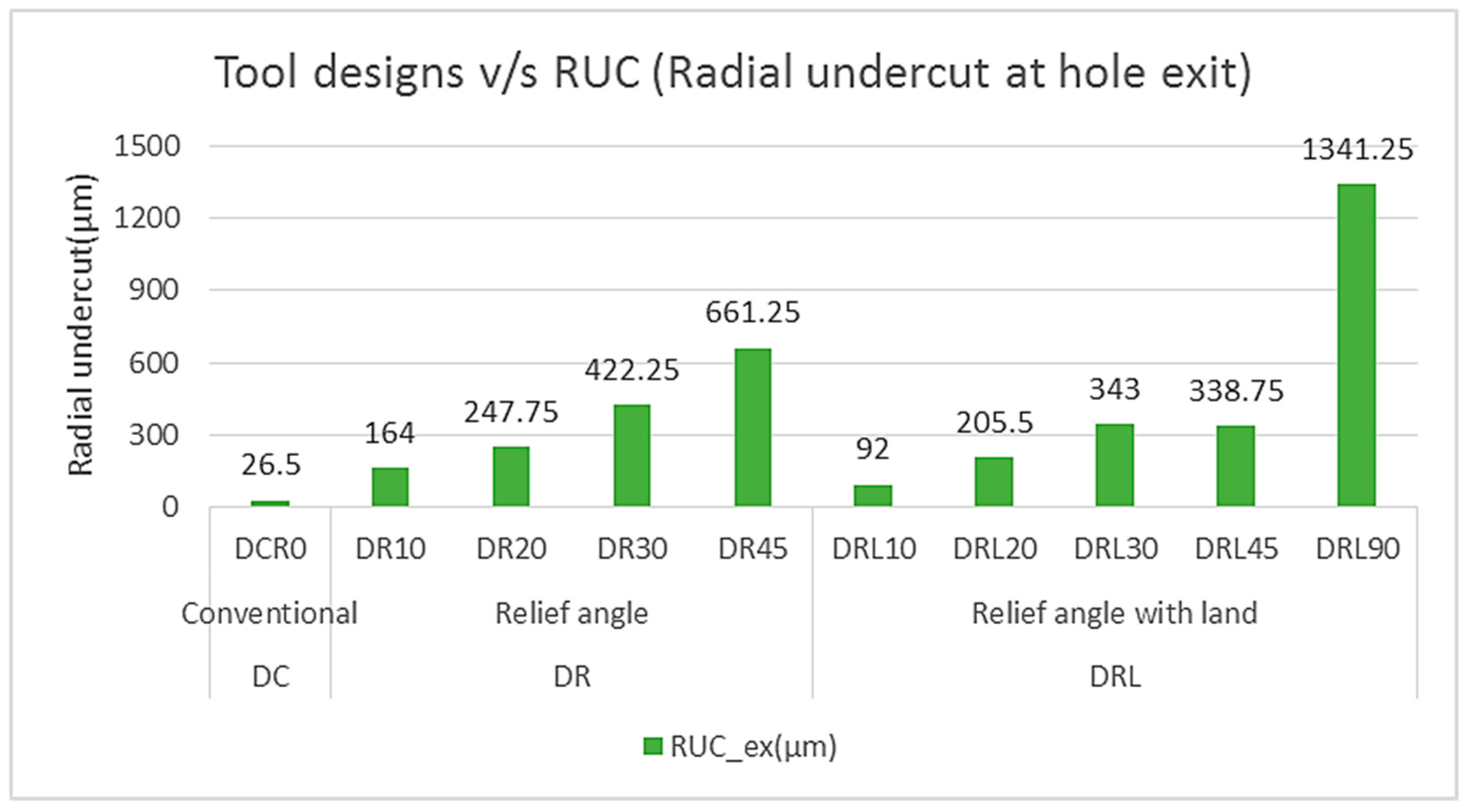

3.4. Effect of Electrode Design on Radial Undercut at the Hole Entrance (RUC_ex)

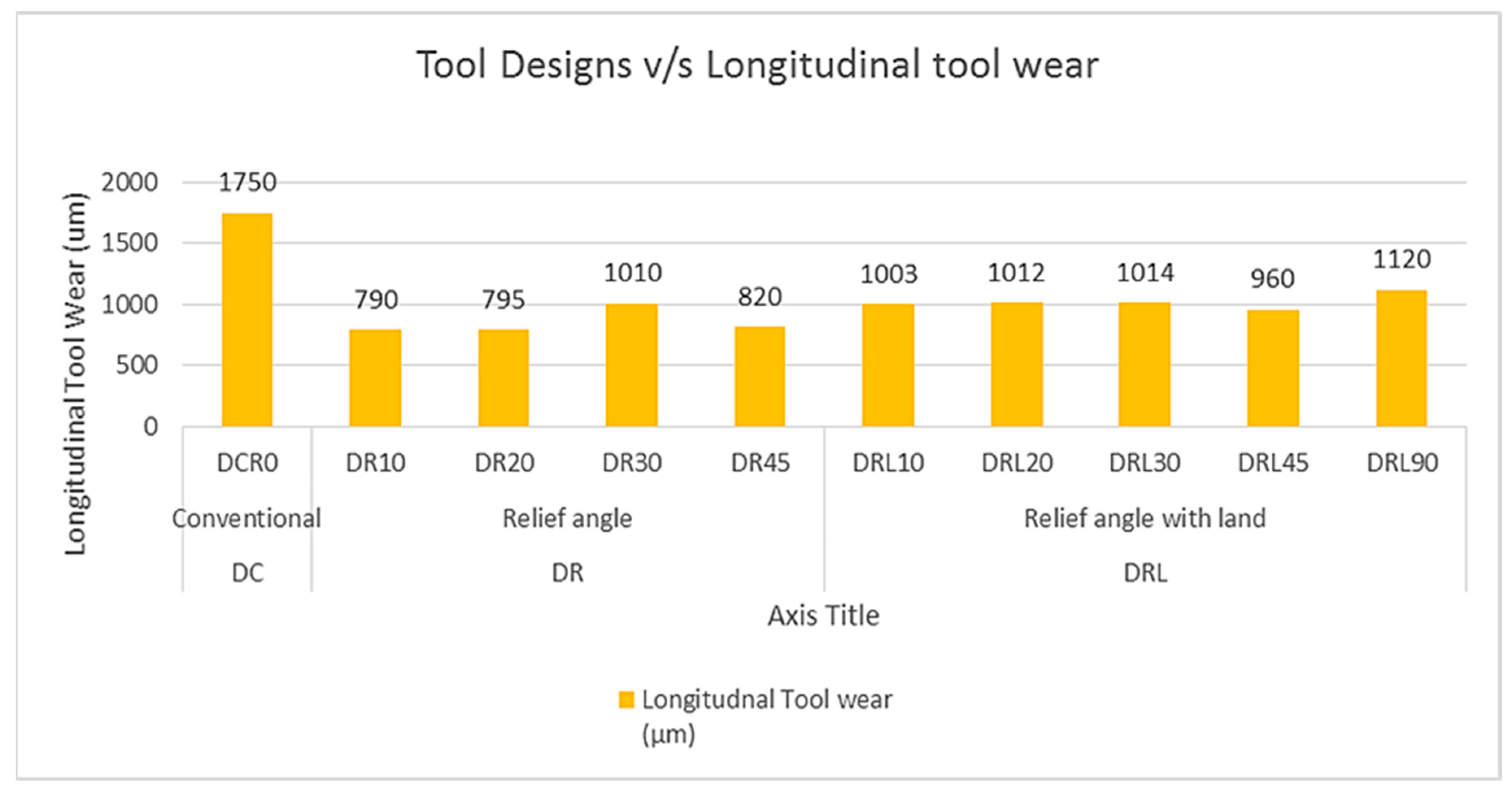

3.5. Effect of Electrode Design on Longitudinal Tool Wear (TLW)

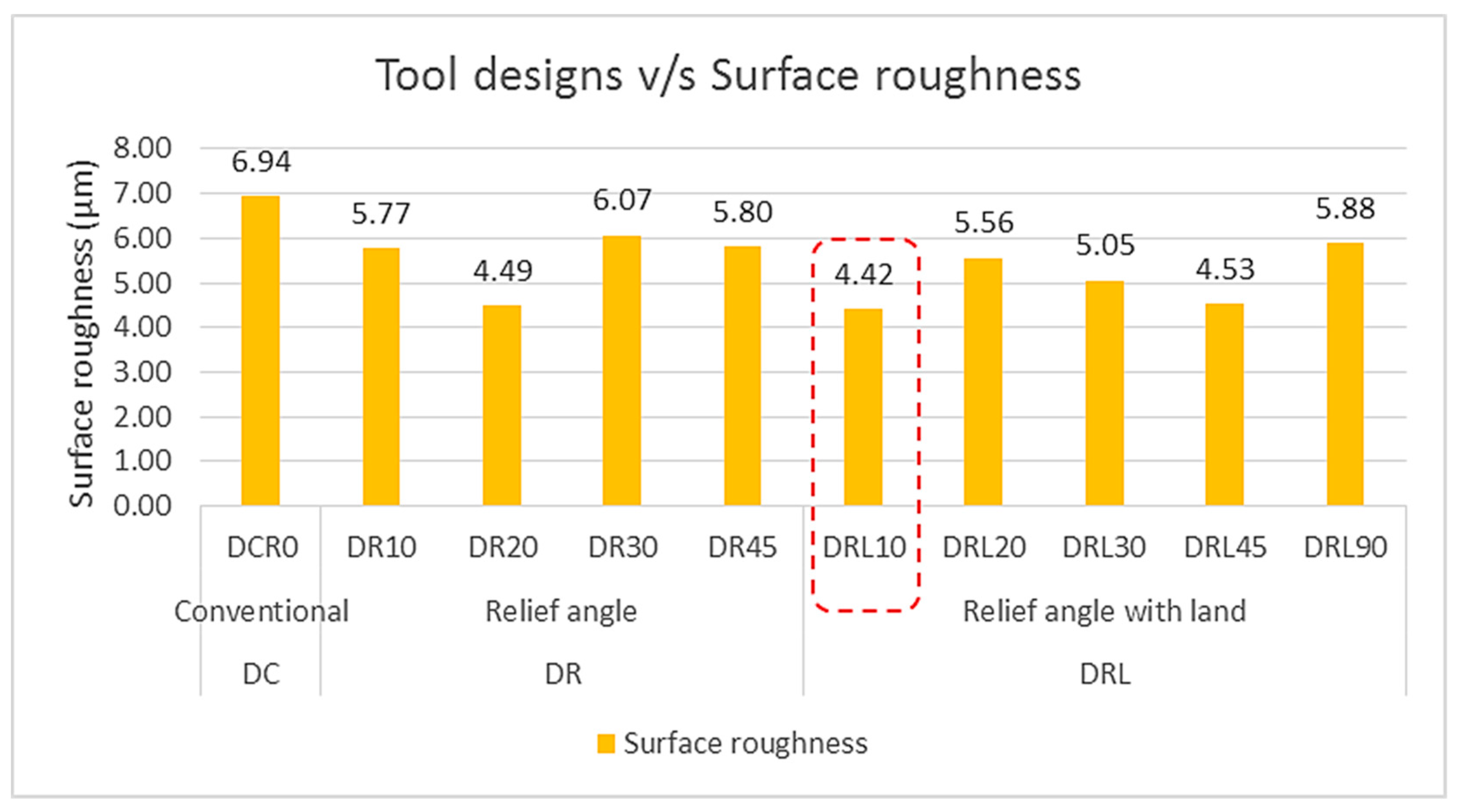

3.6. Effect of Electrode Design on Surface Roughness (SR)

4. Conclusions

- Machining of WC was still difficult and time consuming through electric discharge machining. However, the difficulty level could be considerably reduced if design modifications in the tool design were introduced.

- The machining results in terms of all the six performance characteristics (MT, ø, ROC_en, RUC_ex, LTW, and SR) were found to be relatively better when the newly designed tools (DR and DRL) were employed during EDM of WC. The leading phenomenon behind the improved machining characteristics was the result of the differences in the surface areas available for sparking (see the discussion associated with Figure 6)

- The tool electrode with conventional cylindrical design (DC) took remarkably high machining time (338 min) to finish the through hole. A significant reduction in machining time could be realized by modified tool designs (DR and DRL). The design having a 10 degree relief angle with 1 mm land thickness (DRL10) was found to be the most preferred tool capable of machining the hole in 172 min. A 49% reduction in the machining time could be realized if DRL10 was employed during EDM of WC, thus, improving the productivity of the EDM process. In this way, the difficulty level in machining of WC could be soundly reduced.

- Regarding the hole taper angle (ø), as the relief angle increased the corresponding taperness in holes’ sidewalls also increased. The tool having 10 degree relief with a land thickness of 1 mm (DRL10) produced the hole with minimum taper angle amounting to 3.84°.

- There was a clear difference in the radial overcut at the hole entrance when the modified tool designs were employed. The tools with relief angle (DR) were found to be better than the conventional cylindrical tool in order to get the smaller overcut at the hole entrance. On the other, the undercut at the exit plane of the hole was smallest in the case of conventional tool design (DC).

- Longitudinal tool wear (LTW) of modified tool designs was found to be substantially less than the tool wear in the case of the conventional tool design (DC). The minimum longitudinal tool wear was observed in the case of the 10 degree relief angle (DR10) with an amount of 790 µm.

- There was close competition among the performance of all the electrode designs in the case of the roughness of the inner surfaces of the machined holes. However, the modified tool designs produced the surfaces with smaller roughness as compared to the roughness caused by the conventional tool design (DC). Moreover, the minimum roughness of Ra 4.42 µm resulted again by the tool DRL10, i.e., tool having a relief angle of 10° with a land thickness of 1 mm.

- The tool design DRL10 could be considered as the most appropriate tool design capable of resulting significantly improved results for most of the five performance characteristics taken in this study.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, S.H.; Li, X. Study of the surface integrity of the machined workpiece in the EDM of tungsten carbide. J. Mater. Process. Technol. 2003, 139, 315–321. [Google Scholar] [CrossRef]

- Kung, K.-Y.; Horng, J.-T.; Chiang, K.-T. Material removal rate and electrode wear ratio study on the powder mixed electrical discharge machining of cobalt-bonded tungsten carbide. Int. J. Adv. Manuf. Technol. 2009, 40, 95–104. [Google Scholar] [CrossRef]

- Dewangan, S.; Chattopadhyaya, S.; Hloch, S. Critical Damage Analysis of WC-Co Tip of Conical Pick due to Coal Excavation in Mines. Available online: https://www.hindawi.com/journals/amse/2015/292046/ (accessed on 13 December 2019).

- Mahamat, A.T.Z.; Rani, A.M.A.; Husain, P. Machining of Cemented Tungsten Carbide using EDM. J. Appl. Sci. 2011, 11, 1784–1790. [Google Scholar] [CrossRef][Green Version]

- Puertas, I.; Luis, C.J. Optimization of EDM conditions in the manufacturing process of B4C and WC-Co conductive ceramics. Int. J. Adv. Manuf. Technol. 2012, 59, 575–582. [Google Scholar] [CrossRef]

- Jahan, M.P.; Wong, Y.S.; Rahman, M. A comparative study on the performance of sinking and milling micro-EDM for nanofinishing of tungsten carbide. Int. J. Nanomanuf. 2010, 6, 190–206. [Google Scholar] [CrossRef]

- Jahan, M.P.; Wong, Y.S.; Rahman, M. A study on the fine-finish die-sinking micro-EDM of tungsten carbide using different electrode materials. J. Mater. Process. Technol. 2009, 209, 3956–3967. [Google Scholar] [CrossRef]

- Lee, S.H.; Li, X.P. Study of the effect of machining parameters on the machining characteristics in electrical discharge machining of tungsten carbide. J. Mater. Process. Technol. 2001, 115, 344–358. [Google Scholar] [CrossRef]

- Ahmed, N.; Ishfaq, K.; Rafaqat, M.; Pervaiz, S.; Anwar, S.; Salah, B. EDM of Ti-6Al-4V: Electrode and polarity selection for minimum tool wear rate and overcut. Mater. Manuf. Process. 2019, 34, 769–778. [Google Scholar] [CrossRef]

- Kumar, P.; Parkash, R. Experimental investigation and optimization of EDM process parameters for machining of aluminum boron carbide (Al–B4C) composite. Mach. Sci. Technol. 2016, 20, 330–348. [Google Scholar] [CrossRef]

- Singh, J.; Sharma, R.K. Multi-objective optimization of green powder-mixed electrical discharge machining of tungsten carbide alloy. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 2774–2786. [Google Scholar] [CrossRef]

- Wang, C.; Qiang, Z. Comparison of Micro-EDM Characteristics of Inconel 706 between EDM Oil and an Al Powder-Mixed Dielectric. Available online: https://www.hindawi.com/journals/amse/2019/5625360/ (accessed on 13 December 2019).

- Ekmekci, B.; Yaşar, H.; Ekmekci, N. A Discharge Separation Model for Powder Mixed Electrical Discharge Machining. J. Manuf. Sci. Eng. 2016, 138, 081006. [Google Scholar] [CrossRef]

- Singh, J.; Sharma, R.K. Implementation of Taguchi method with hybrid decision making tools for prediction of surface characteristics for powder-mixed EDM of WC. Perspect. Sci. 2016, 8, 455–458. [Google Scholar] [CrossRef]

- Vishwakarma, U.K.; Dvivedi, A.; Kumar, P. Finite Element Modeling of Material Removal Rate in Powder Mixed Electrical Discharge Machining of Al-SiC Metal Matrix Composites. In Materials Processing Fundamentals; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 151–158. ISBN 978-1-118-66219-9. [Google Scholar]

- Sharma, R.K.; Singh, J. Determination of multi-performance characteristics for powder mixed electric discharge machining of tungsten carbide alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 303–312. [Google Scholar] [CrossRef]

- Jahan, M.P.; Saleh, T.; Rahman, M.; Wong, Y.S. Development, Modeling, and Experimental Investigation of Low Frequency Workpiece Vibration-Assisted Micro-EDM of Tungsten Carbide. J. Manuf. Sci. Eng. 2010, 132, 054503. [Google Scholar] [CrossRef]

- Abdullah, A.; Shabgard, M.R. Effect of ultrasonic vibration of tool on electrical discharge machining of cemented tungsten carbide (WC-Co). Int. J. Adv. Manuf. Technol. 2008, 38, 1137–1147. [Google Scholar] [CrossRef]

- Singh, P.; Yadava, V.; Narayan, A. Comparison of machining performance of hole-sinking micro-EDM without and with ultrasonic vibration on titanium alloy. Int. J. Precis. Technol. 2017, 7, 205–221. [Google Scholar] [CrossRef]

- Hsu, W.-H.; Chien, W.-T. Effect of Electrical Discharge Machining on Stress Concentration in Titanium Alloy Holes. Materials 2016, 9, 957. [Google Scholar] [CrossRef]

- Dave, H.K.; Mathai, V.J.; Mayanak, M.K.; Raval, H.K.; Desai, K.P. Study on effect of process parameters on overcut and tool wear rate during micro-electro-discharge slotting process. Int. J. Adv. Manuf. Technol. 2016, 85, 2049–2060. [Google Scholar] [CrossRef]

- Selvarajan, L.; Narayanan, C.S.; Jeyapaul, R. Optimization of Process Parameters to Improve Form and Orientation Tolerances in EDM of MoSi2-SiC Composites. Mater. Manuf. Process. 2015, 30, 954–960. [Google Scholar] [CrossRef]

- Chiang, H.N.; Wang, J.J.J. An analysis of overcut variation and coupling effects of dimensional variable in EDM process. Int. J. Adv. Manuf. Technol. 2011, 55, 935–943. [Google Scholar] [CrossRef]

- Moghanizadeh, A. Reducing side overcut in EDM process by changing electrical field between tool and work piece. Int. J. Adv. Manuf. Technol. 2017, 90, 1035–1042. [Google Scholar] [CrossRef]

- Ahmed, N.; Anwar, S.; Ishfaq, K.; Rafaqat, M.; Saleh, M.; Ahmad, S. The potentiality of sinking EDM for micro-impressions on Ti-6Al-4V: Keeping the geometrical errors (axial and radial) and other machining measures (tool erosion and work roughness) at minimum. Sci. Rep. 2019, 9, 17218. [Google Scholar] [CrossRef]

- Cui, J.; Chu, Z. Composite Motion Design Procedure for Vibration Assisted Small-Hole EDM Using One Voice Coil Motor. Available online: https://www.hindawi.com/journals/sv/2016/4179296/ (accessed on 13 December 2019).

- Cheema, M.S.; Dvivedi, A.; Sharma, A.K.; Biswas, S. Multicriteria Optimization of Rotary Tool Electric Discharge Machining on Metal Matrix Composite. In Materials Processing Fundamentals; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 159–168. ISBN 978-1-118-66219-9. [Google Scholar]

- Goiogana, M.; Elkaseer, A. Self-Flushing in EDM Drilling of Ti6Al4V Using Rotating Shaped Electrodes. Materials 2019, 12, 989. [Google Scholar] [CrossRef] [PubMed]

- Chou, S.-H.; Wang, A.-C. Investigating and removing the re-sticky debris on tungsten carbide in electrical discharge machining. Int. J. Adv. Manuf. Technol. 2014, 71, 1151–1158. [Google Scholar] [CrossRef]

- Yadav, V.K.; Kumar, P.; Dvivedi, A. Performance enhancement of rotary tool near-dry EDM of HSS by supplying oxygen gas in the dielectric medium. Mater. Manuf. Process. 2019, 34, 1832–1846. [Google Scholar] [CrossRef]

- Zou, L.; Huang, Y.; Zhou, M.; Duan, L. Investigation on diamond tool wear in ultrasonic vibration-assisted turning die steels. Mater. Manuf. Process. 2017, 32, 1505–1511. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, 6th ed.; Wiley: Hoboken, NJ, USA, 2016; ISBN 978-1-119-12880-9. [Google Scholar]

| Element | Percentage |

|---|---|

| W | 88.3 |

| Fe | 0.16 |

| C | 4.9 |

| Co | 5.9 |

| Ni | 0.31 |

| Properties | Values | Units |

|---|---|---|

| Density | 15.5 | g/cm3 |

| Hardness | 92.3 | HRA |

| Toughness | 50 | kg/mm2 |

| Tensile strength | 179 | kg/mm2 |

| Compressive strength | 410 | kg/mm2 |

| Melting Point | 3140 | °C |

| Thermal conductivity | 0.502 | W/cm-°C |

| Thermal coefficient of expansion | 5.5 × 10−6 | K−1 |

| Specific heat | 39.8 | J/molK |

| Electrical Resistivity | 17 × 10−6 | Ohm cm |

| Parameter | Values | Units | |

|---|---|---|---|

| Electrodes | Tool | Copper | − |

| Workpiece | Tungsten carbide | − | |

| EDM parameters | Discharge current | 30 A | A |

| Spark Voltage | 5 V | V | |

| Pulse on-time | 100 | µs | |

| Pulse off-time | 50 | µs | |

| Electrode Polarity | Work | +ve | |

| Tool | −ve | ||

| Servo sensitivity | 3 | − | |

| Spark-flushing time ratio | 1 | − | |

| Dielectric | Kerosene oil | − | |

| Flushing mode | Continuous | − |

| Design Type | Design Name | Design Symbol | Design Dimensions | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Angle | Height | Diameter | |||||||

| Relief Angle; Ɵ (deg) | Land Height; LH (mm) | Face Height; FH (mm) | Shank Height; SH (mm) | Total Height; H (mm) | Face Diameter; FD (mm) | Shank Diameter; SD (mm) | |||

| DC | Conventional | DCR0 | 0 | 0 | 0 | 50.00 | 50 | 8 | 8 |

| DR | Relief angle | DR10 | 10 | 0 | 8.50 | 41.50 | 50 | 8 | 5 |

| DR20 | 20 | 0 | 4.12 | 45.87 | 50 | 8 | 5 | ||

| DR30 | 30 | 0 | 2.60 | 47.40 | 50 | 8 | 5 | ||

| DR45 | 45 | 0 | 1.50 | 48.50 | 50 | 8 | 5 | ||

| DRL | Relief angle with land | DRL10 | 10 | 1 | 8.50 | 40.50 | 50 | 8 | 5 |

| DRL20 | 20 | 1 | 4.12 | 44.87 | 50 | 8 | 5 | ||

| DRL30 | 30 | 1 | 2.60 | 46.40 | 50 | 8 | 5 | ||

| DRL45 | 45 | 1 | 1.50 | 47.50 | 50 | 8 | 5 | ||

| DRL90 | 90 | 1 | 0 | 49.00 | 50 | 8 | 5 | ||

| Responses | Minimum Value | Tool Ranking | ||

|---|---|---|---|---|

| Rank 1 | Rank 2 | Rank 3 | ||

| Machining Time; MT (min) | 172.00 | DRL10 | DR10 | DRL20 |

| Taper Angle; ø (deg) | 3.84 | DRL10 | DCR0 | DR10 |

| Radial overcut; ROC_en (µm) | 115.50 | DR20 | DR10 | DR45 |

| Radial undercut; RUC_ex (µm) | 26.50 | DCR0 | DRL10 | DR10 |

| Longitudinal tool wear; LTW (µm) | 790 | DR10 | DR20 | DR45 |

| Surface Roughness; SR (µm) | 4.42 | DRL10 | DR20 | DRL45 |

| The most common tool design | DRL10 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad Mufti, N.; Rafaqat, M.; Ahmed, N.; Qaiser Saleem, M.; Hussain, A.; Al-Ahamri, A.M. Improving the Performance of EDM through Relief-Angled Tool Designs. Appl. Sci. 2020, 10, 2432. https://doi.org/10.3390/app10072432

Ahmad Mufti N, Rafaqat M, Ahmed N, Qaiser Saleem M, Hussain A, Al-Ahamri AM. Improving the Performance of EDM through Relief-Angled Tool Designs. Applied Sciences. 2020; 10(7):2432. https://doi.org/10.3390/app10072432

Chicago/Turabian StyleAhmad Mufti, Nadeem, Madiha Rafaqat, Naveed Ahmed, Muhammad Qaiser Saleem, Amjad Hussain, and Abdulrahman M. Al-Ahamri. 2020. "Improving the Performance of EDM through Relief-Angled Tool Designs" Applied Sciences 10, no. 7: 2432. https://doi.org/10.3390/app10072432

APA StyleAhmad Mufti, N., Rafaqat, M., Ahmed, N., Qaiser Saleem, M., Hussain, A., & Al-Ahamri, A. M. (2020). Improving the Performance of EDM through Relief-Angled Tool Designs. Applied Sciences, 10(7), 2432. https://doi.org/10.3390/app10072432