An Investigation into Bolt Anchoring Performance during Tunnel Construction in Bedded Rock Mass

Abstract

1. Introduction

2. Experimental Procedure

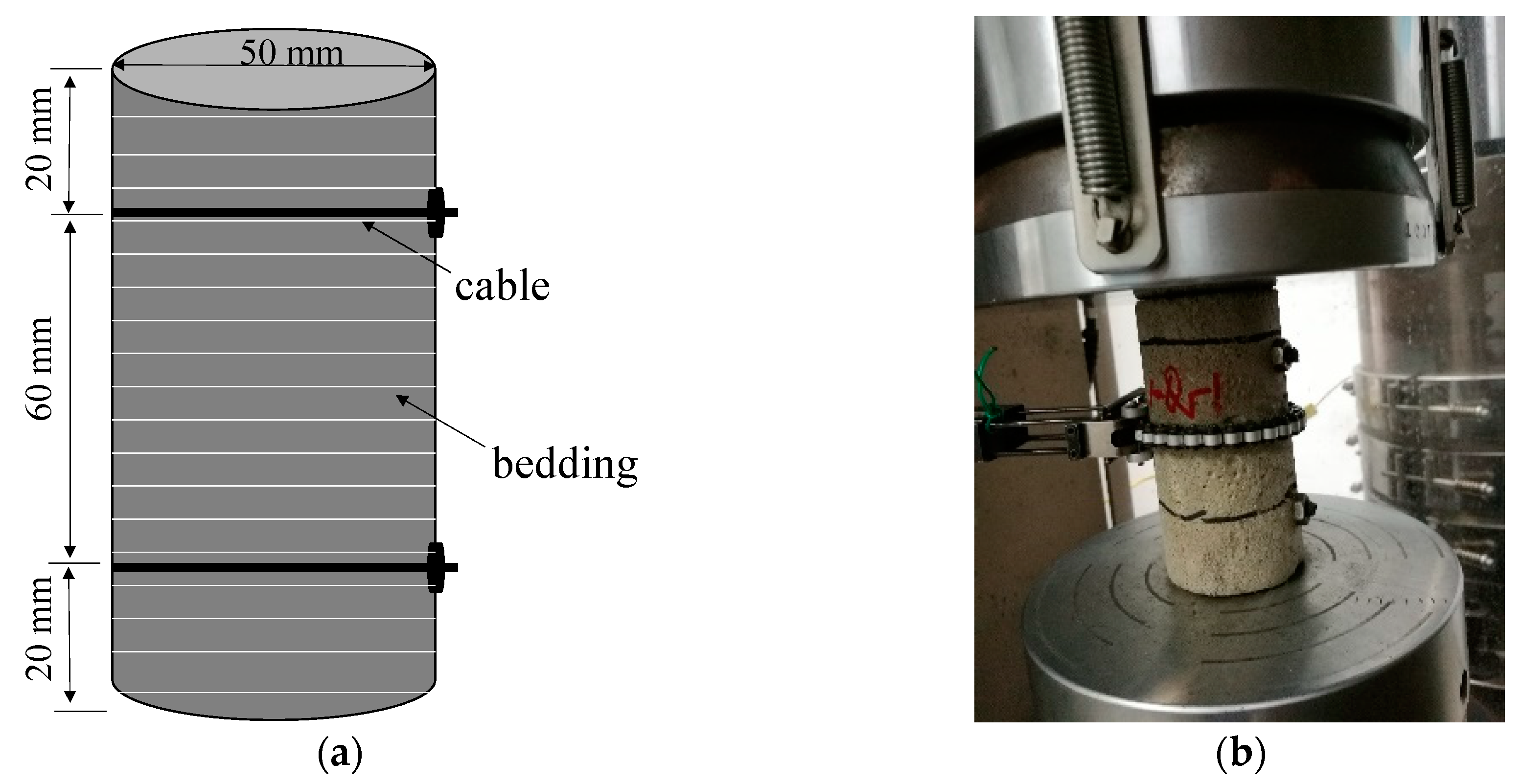

2.1. Uniaxial Compression Testing

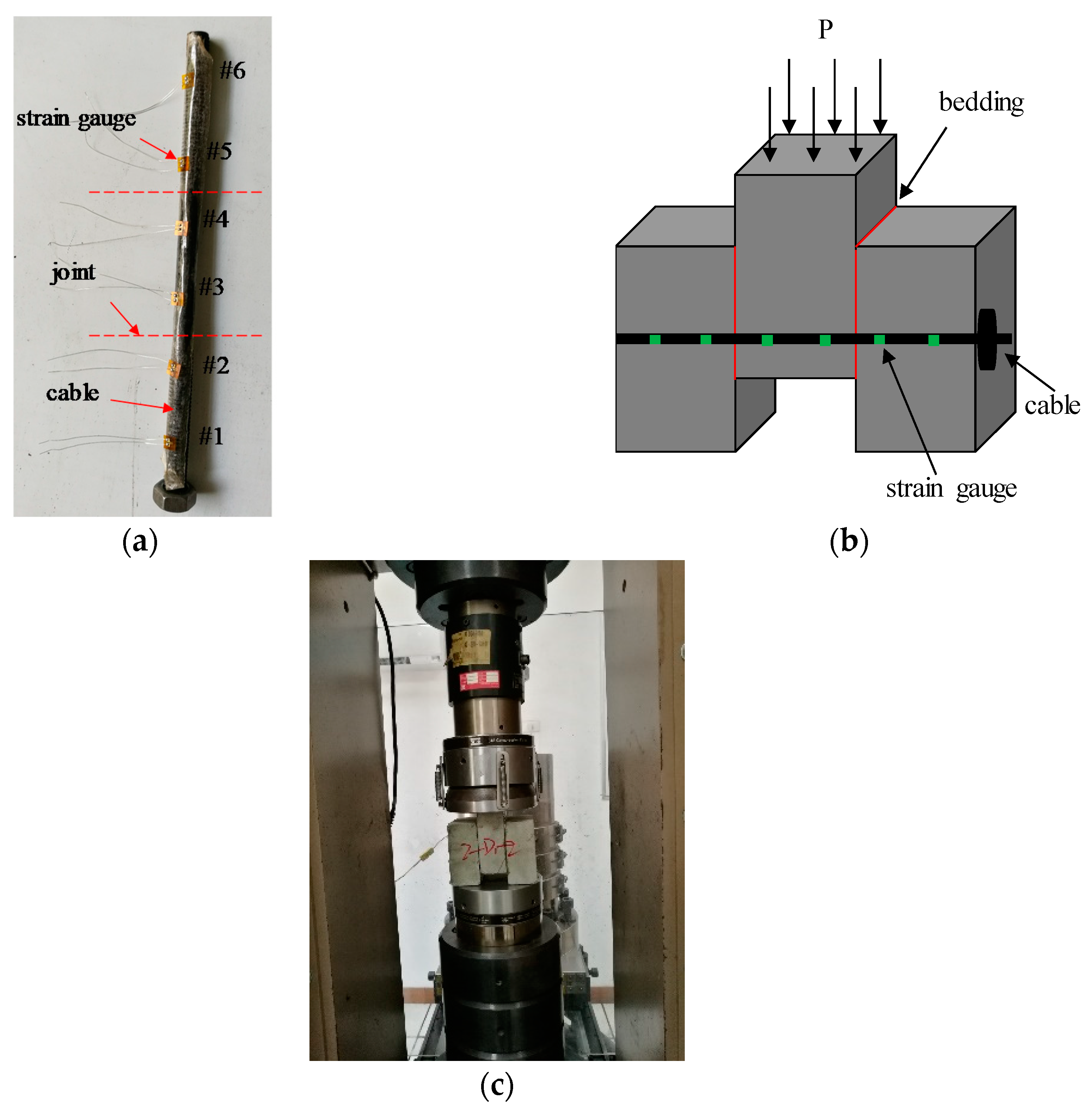

2.2. Shear Testing

3. Experimental Results

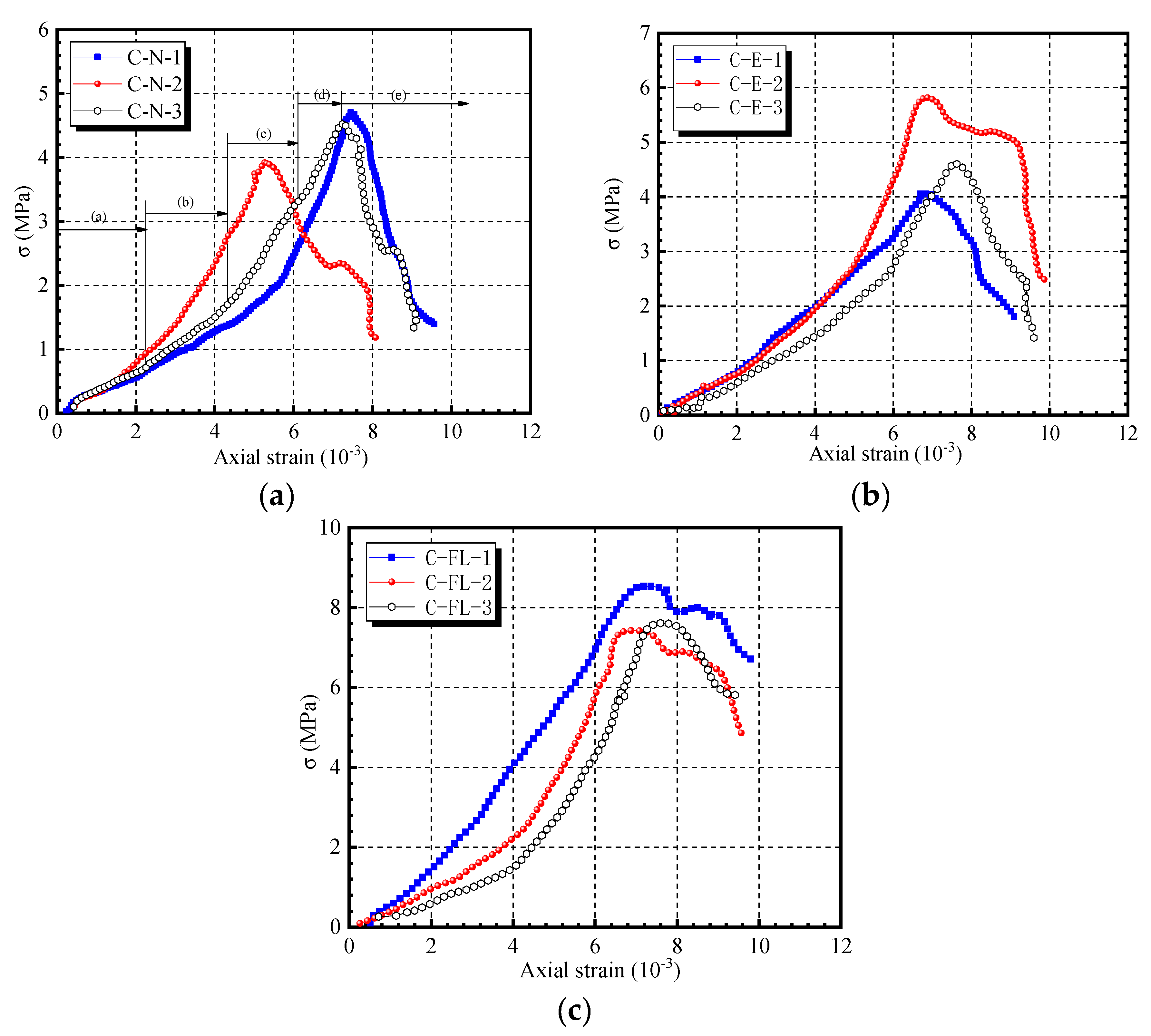

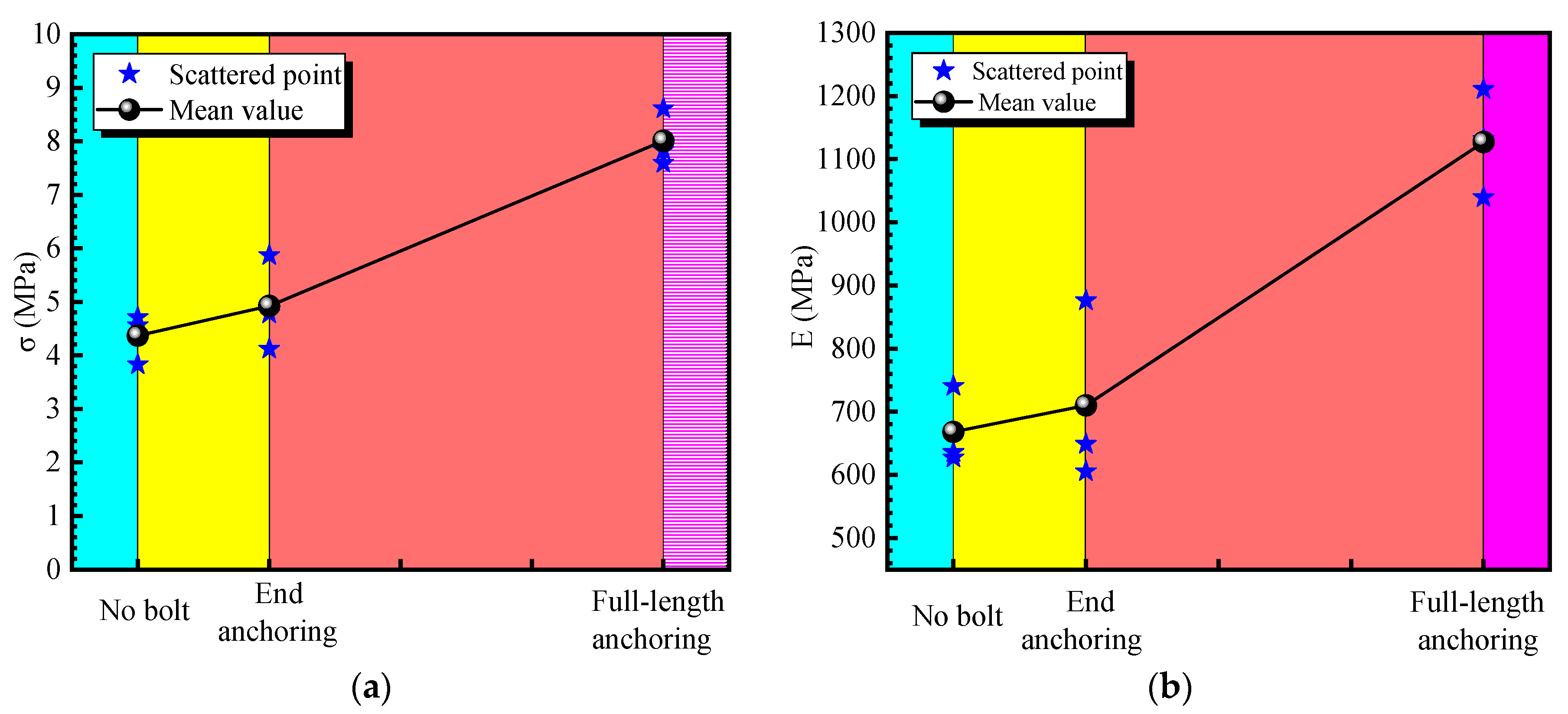

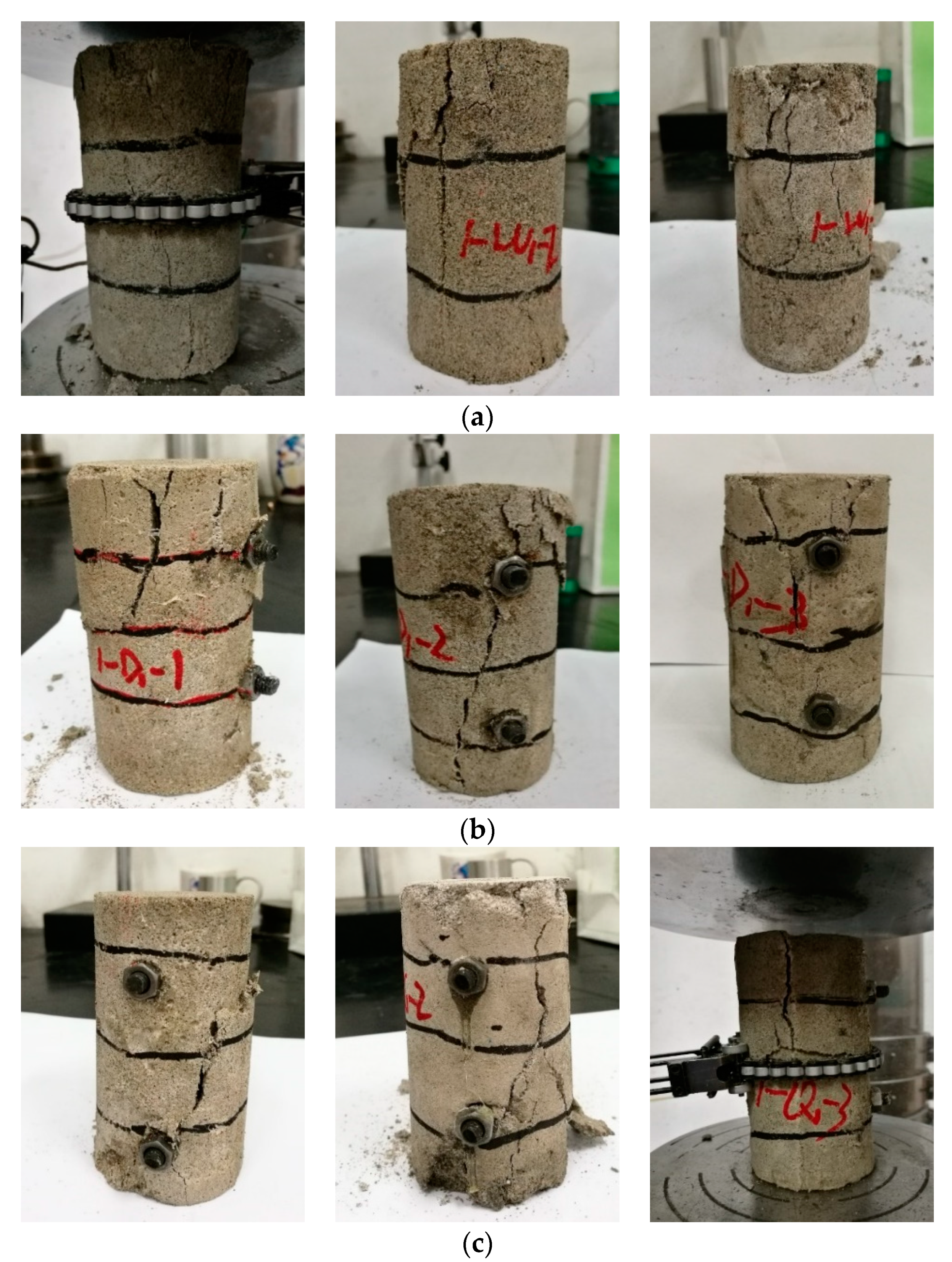

3.1. Uniaxial Compression Testing

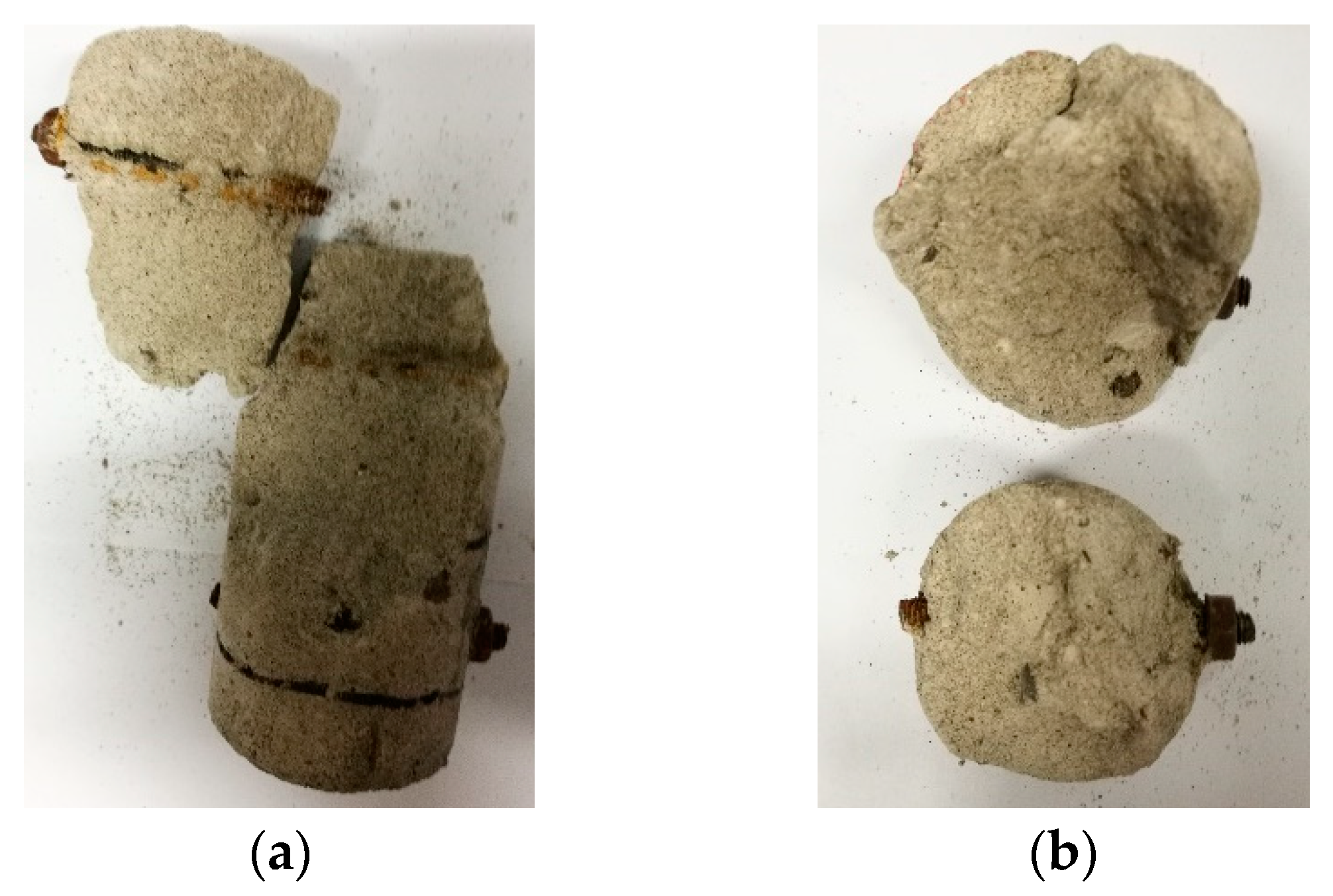

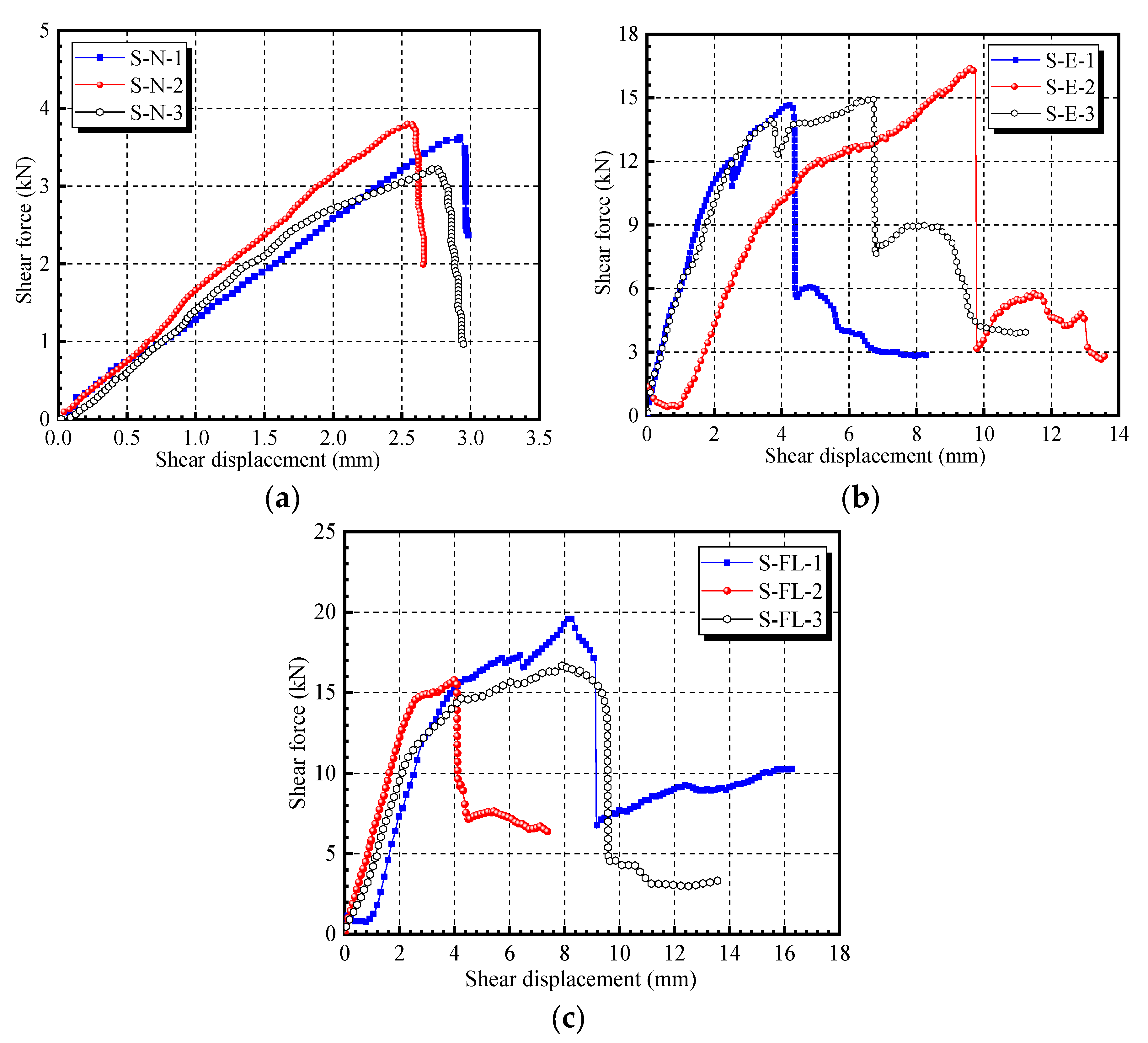

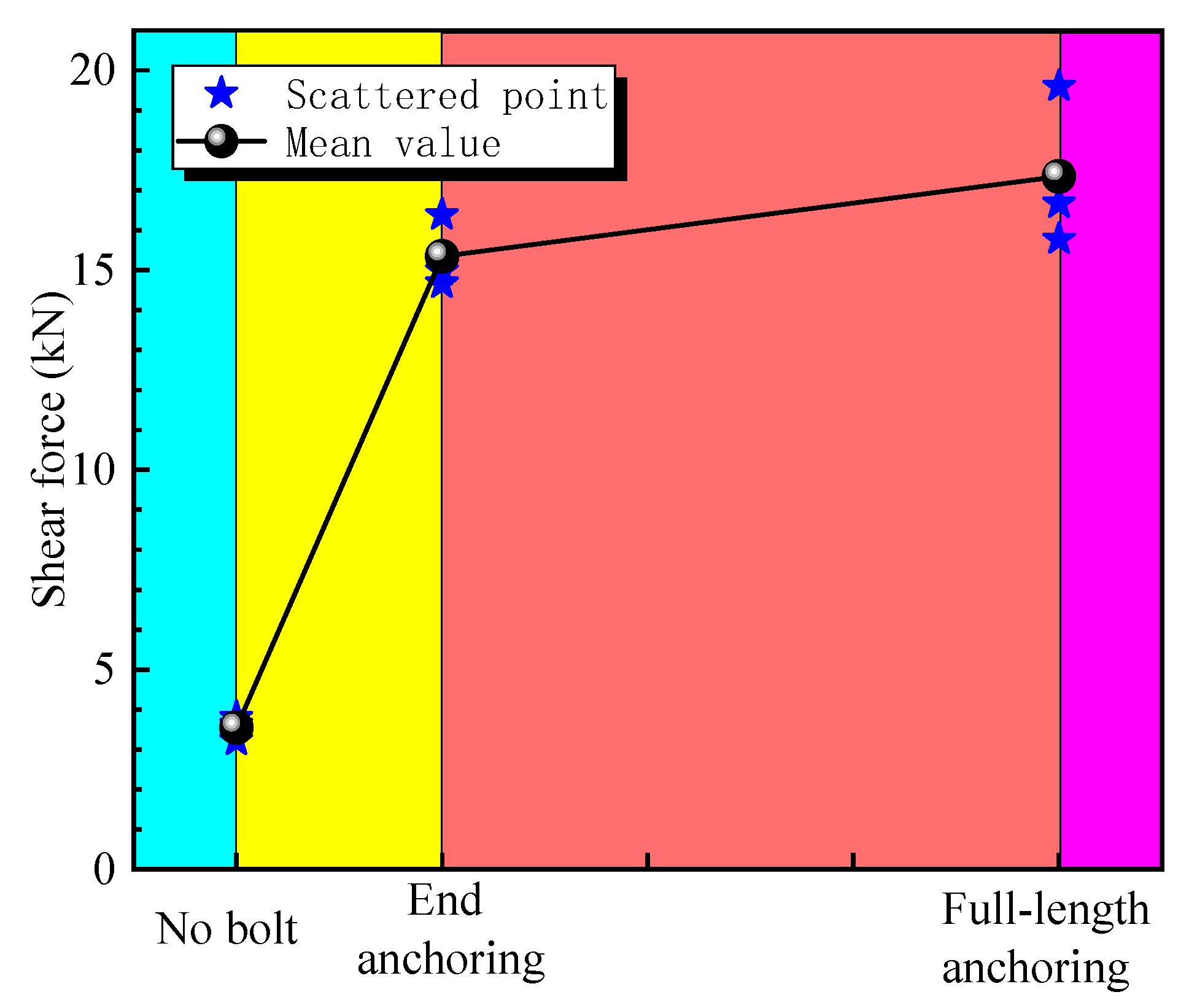

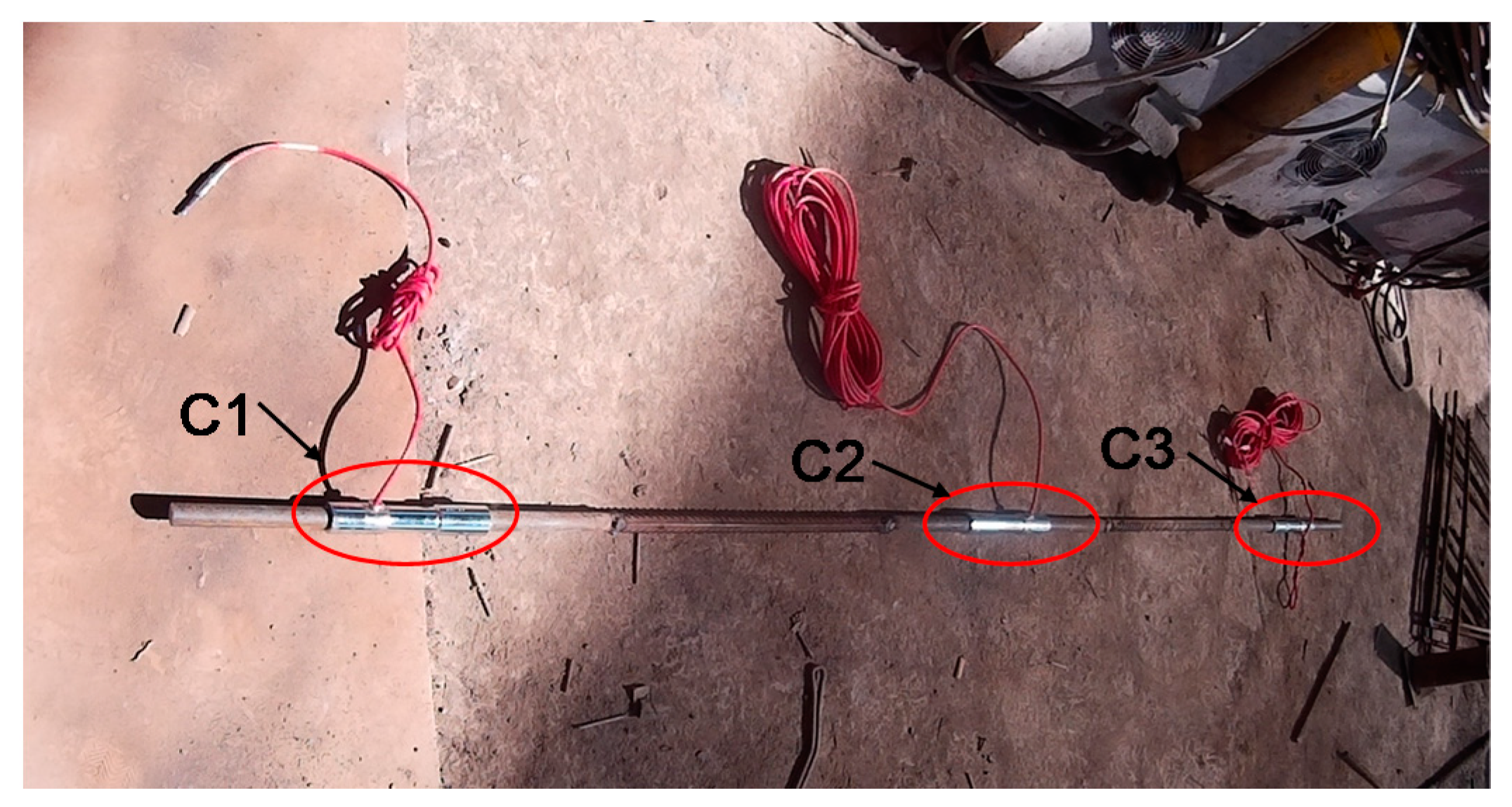

3.2. Shear Testing

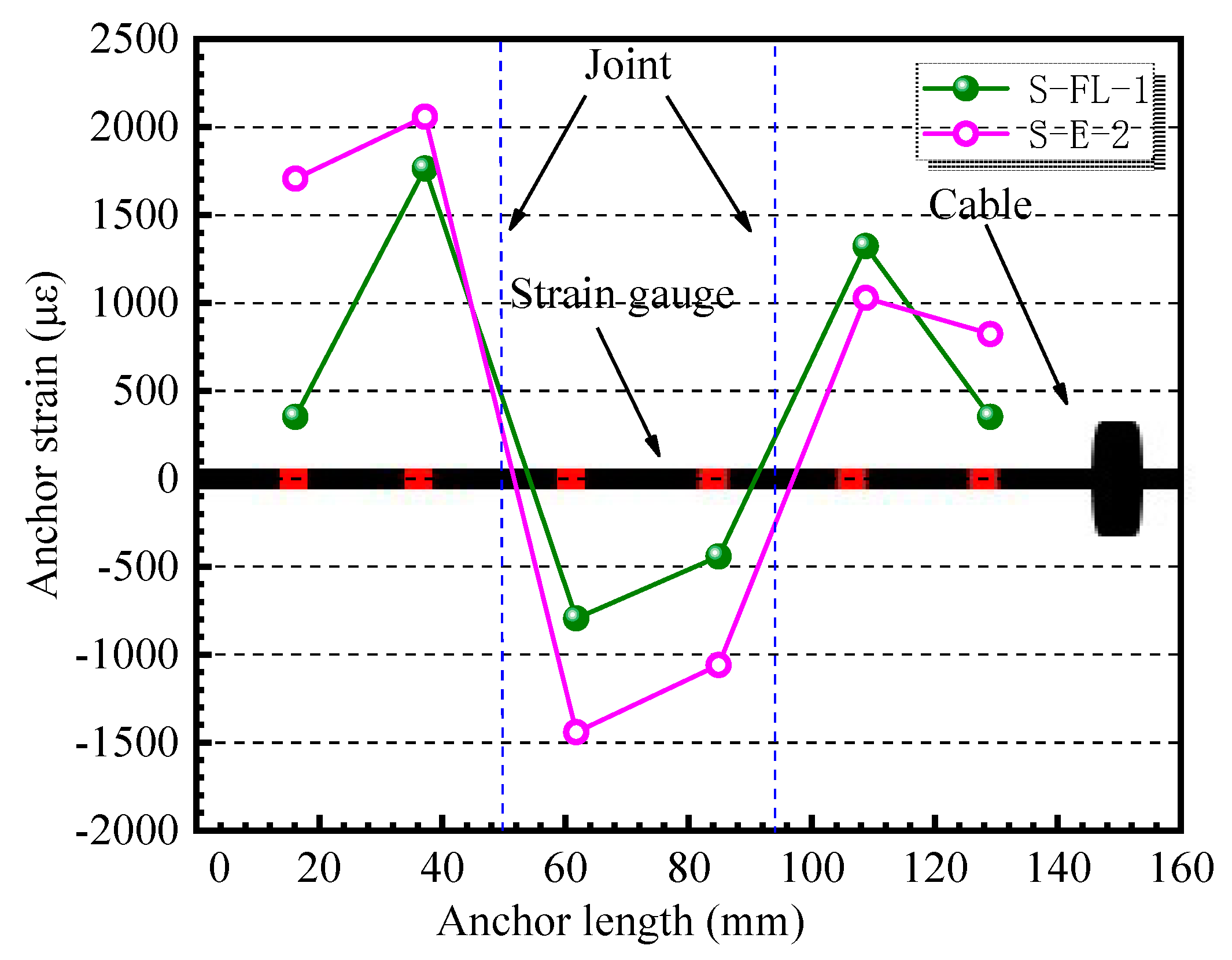

- The maximum value of the bolt axial force is near the joint plane and is anti-symmetrically distributed at both sides of the joint plane.

- The axial force of the bolt for full-length anchoring is mainly concentrated near the joint plane. It decreases rapidly with increasing distance from the joint plane, and its distribution is relatively uniform.

- Plastic hinges are produced near the joint plane, which can effectively stop the further spread of the stress force. One end of the plastic hinge bears the tensile stress, while the other end bears the pressure stress.

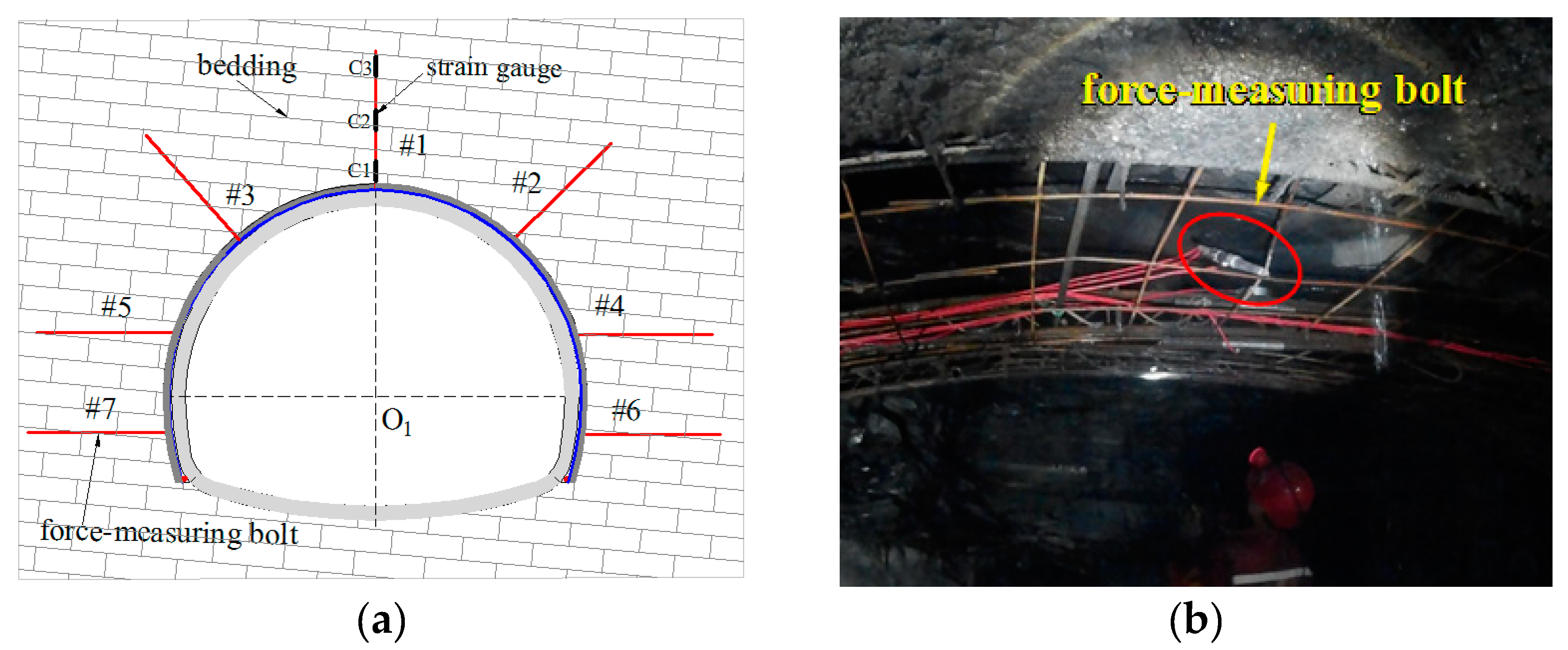

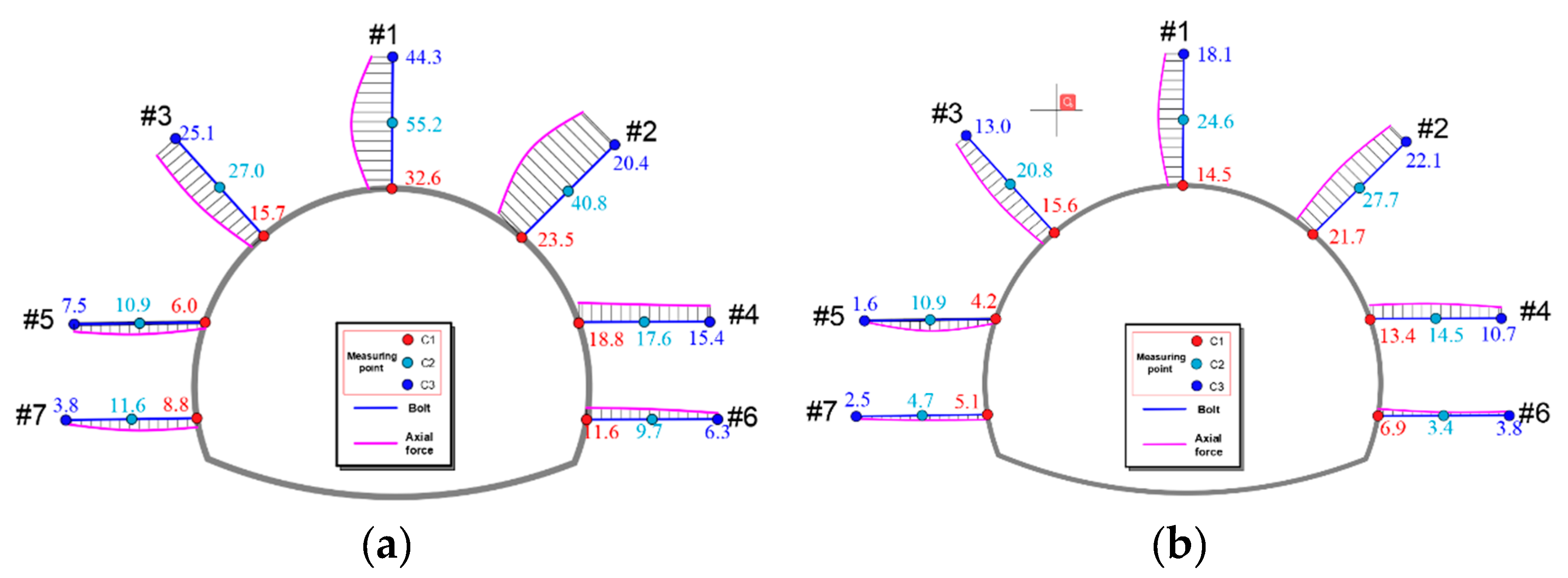

4. Field Application

4.1. Project Description

4.2. Bolt Arrangement at the Construction Site

5. Discussion

6. Conclusions

- (1)

- With respect to the anchored specimen strength and strain, the reinforcing mechanism of the bolt for the rock was divided into two aspects: the anchoring agent bonding and restoring the surrounding rock near the reinforcing zone, and the bolt body resistance supporting and improving the stress state of the rock. The combined action of those two aspects increased the strength parameters of the anchored specimen.

- (2)

- Failure of the anchored specimen changed from shear splitting failure with no anchoring into shear failure where the failure plane slid parallel to the axial direction of the bolt or shear dislocation failure along the soft–hard interface.

- (3)

- Via anchoring of the joint rock mass, the bolt could significantly enhance the shear-bearing capacity of the rock mass and increase the stability of the surrounding rock. Compared to the end anchoring bolt, the bolt for full-length anchoring can form an “anchoring area” of a greater range and provide greater support resistance than the end anchoring bolt; therefore, it had a better coupling effect on the surrounding rock with a greater resistance increase. This occurrence enabled the surrounding rock to bear more load.

- (4)

- Full-length anchoring can provide more support resistance and have a better anchoring effect on the surrounding rock of a bedded rock tunnel. However, the grouting quality is often difficult to guarantee due to the impact of the bolt insertion angle, so it is necessary to pay attention to the filling quality of the anchoring agent, especially at the vault of the tunnel.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Chen, L.; Zhu, Y.; Zhou, Z.; Chen, S. Stress field distribution and deformation law of large deformation tunnel excavation in soft rock mass. Appl. Sci. 2019, 9, 865. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, L.; Zhang, H.; Zhou, Z.; Chen, S. Physical and mechanical characteristics of soft rock tunnel and the effect of excavation on supporting structure. Appl. Sci. 2019, 9, 1517. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Zhang, H.; Tan, Y.J.; Yang, H.Y. Natural wind utilization in the vertical shaft of a super—Long highway tunnel and its energy saving effect. Build. Environ. 2018, 145, 140–152. [Google Scholar] [CrossRef]

- Zhang, Z.; Luo, C.; Zhang, H.; Gong, R. Rockburst identification method based on energy storage limit of surrounding rock. Energies 2020, 13, 343. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, L.; Chen, S.G.; Sun, J.C.; Yang, J.S. The spatiotemporal distribution law of microseismic events and rockburst characteristics of the deeply buried tunnel group. Energies 2018, 11, 3257. [Google Scholar] [CrossRef]

- Li, P.L.; Lu, Y.Q.; Lai, J.X.; Liu, H.Q. A comparative study of protective schemes for shield tunneling adjacent to pile groups. Adv. Civ. Eng. 2020, 2020, 1874137. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, Y.; Chen, L.; Hu, W.; Chen, S. The prevention and control mechanism of rockburst hazards and its application in the construction of a deeply buried tunnel. Appl. Sci. 2019, 9, 3629. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Li, H.Y.; Yang, H.Y.; Wang, B. Failure modes and face instability of shallow tunnels under soft grounds. Int. J. Damage Mech. 2019, 28, 566–589. [Google Scholar] [CrossRef]

- Liu, T.; Zhong, Y.J.; Feng, Z.H.; Xu, W.; Song, F.T. New construction technology of a shallow tunnel in boulder-cobble mixed grounds. Adv. Civ. Eng. 2020, 2020, 5686042. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Shi, X.Q.; Wang, B.; Li, H.Y. Stability of NATM tunnel faces in soft surrounding rocks. Comput. Geotechnol. 2018, 96, 90–102. [Google Scholar] [CrossRef]

- Bjurstrom, S. Shear strength of hard rock joints reinforced by grouted untensioned bolts. Proc. 3rd Cong. ISRM Denver 1974, 2, 1194–1199. [Google Scholar]

- Cai, Y.; Esaki, T.; Jiang, Y. An analytical model to predict axial load in grouted rock bolt for soft rock tunnelling. Tunn. Undergr. Space Technol. 2004, 19, 607–618. [Google Scholar] [CrossRef]

- Cai, Y.; Jiang, Y.; Djamaluddin, I.; Iura, T.; Esaki, T. An analytical model considering interaction behavior of grouted rock bolts for convergence–confinement method in tunneling design. Int. J. Rock Mech. Min. Sci. 2015, 76, 112–126. [Google Scholar] [CrossRef]

- Carranza-Torres, C. Analytical and numerical study of the mechanics of rockbolt reinforcement around tunnels in rock masses. Rock Mech. Rock Eng. 2009, 42, 175–228. [Google Scholar] [CrossRef]

- Farmer, I. Stress distribution along a resin grouted rock anchor. Proc. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1975, 12, 347–351. [Google Scholar] [CrossRef]

- Freeman, T. The behaviour of fully-bonded rock bolts in the Kielder experimental tunnel. Tunn. Tunn. Int. 1978, 10, 37–40. [Google Scholar]

- Liu, Q.; Lei, G.; Peng, X. Advance and review on the anchoring mechanism in deep fractured rock mass. Chin. J. Rock Mech. Eng. 2016, 35, 312–332. [Google Scholar]

- Ma, S.; Nemcik, J.; Aziz, N. An analytical model of fully grouted rock bolts subjected to tensile load. Constr. Build. Mater. 2013, 49, 519–526. [Google Scholar] [CrossRef]

- Windsor, C. Rock reinforcement systems. Int. J. Rock Mech. Min. Sci. 1997, 34, 919–951. [Google Scholar] [CrossRef]

- Yang, S.; Li, H.; Zhu, H. Reinforcement of bolt in joints. Rock Soil Mech.-Wuhan- 2002, 23, 604–607. [Google Scholar]

- Zhang, B.; Li, S.; Xia, K.; Yang, X.; Zhang, D.; Wang, S.; Zhu, J. Reinforcement of rock mass with cross-flaws using rock bolt. Tunn. Undergr. Space Technol. 2016, 51, 346–353. [Google Scholar] [CrossRef]

- Spang, K.; Egger, P. Action of fully-grouted bolts in jointed rock and factors of influence. Rock Mech. Rock Eng. 1990, 23, 201–229. [Google Scholar] [CrossRef]

- Haas, C.J. Shear resistance of rock bolts. Trans. Soc. Min. Eng. AIME 1976, 260, 32–40. [Google Scholar]

- Yoshinaka, R.; Sakaguchi, S.; Shimizu, T.; Arai, H.; Kato, E. Experimental study on the rock bolt reinforcement in discontinuous rocks. In Proceedings of the 6th ISRM Congress, Montreal, QC, Canada, 30 August–3 September 1987. [Google Scholar]

- Ferrero, A.M. The shear strength of reinforced rock joints. Proc. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 595–605. [Google Scholar] [CrossRef]

- Kim, H.-J.; Hu, J.-W.; Hwang, W.-S. Cyclic testing for structural detail improvement of CFT column-foundation connections. Sustainability 2015, 7, 5260–5281. [Google Scholar] [CrossRef]

- Pellet, F.; Egger, P. Analytical model for the mechanical behaviour of bolted rock joints subjected to shearing. Rock Mech. Rock Eng. 1996, 29, 73–97. [Google Scholar] [CrossRef]

- Grasselli, G. 3D behaviour of bolted rock joints: Experimental and numerical study. Int. J. Rock Mech. Min. Sci. 2005, 42, 13–24. [Google Scholar] [CrossRef]

- Jalalifar, H.; Aziz, N. Experimental and 3D numerical simulation of reinforced shear joints. Rock Mech. Rock Eng. 2010, 43, 95–103. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, Q. Analysis of deformation characteristics of prestressed anchor bolt based on shear test. Rock Soil Mech. 2014, 35, 2231–2240. [Google Scholar]

- Teng, J.Y.; Zhang, Y.N.; Tang, J.X.; Zhang, C.; Li, C.L. Mechanical behaviors of anchored bedding rock under uniaxial compression. Rock Soil Mech. 2017, 38, 1974–1982+1998. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Li, L.; Wang, J. Failure mechanism of tunnel lining joints and bolts with uneven longitudinal ground settlement. Tunn. Undergr. Space Technol. 2014, 40, 300–308. [Google Scholar] [CrossRef]

- Ge, X.; Liu, J. Study on the shear Resistance Behaviour of Bolted Rock Joints. Chin. J. Geotech. Eng. 1988, 1, 8–19. [Google Scholar]

- Chen, W.; Jia, Z.; Zhao, Y.; Liu, L.; Zhou, J.; Lin, X. Analysis of axial and transverse effects of rock bolt during shearing process. Rock Soil Mech. 2015, 36, 143–148. [Google Scholar]

- Liu, A.; Ju, W.; Hu, H.; Wang, X. Experimental study on the effect of bolt prestress on the-shear behavior of jionted rockmass. J. China Coal Soc. 2013, 38, 391–396. [Google Scholar]

- Zhang, B.; Shucai, L.; Xueying, Y. Bolting effect and failure modes of jointed rock masses with cross-cracks. Chin. J. Rock Mech. Eng. 2014, 33, 996–1003. [Google Scholar]

- Chen, L.; Zhang, C.; Yu, F. Experimental study of flexural behavior of anchored rock. Rock Soil Mech. 2014, 35, 3451–3459. [Google Scholar]

- Chen, L.; Tan, Y.; Zang, C. Test study of mechanical properties and failure characteristics of anchored rock. Rock Soil Mech. 2014, 35, 413–422. [Google Scholar]

- Yang, B.; Xiao, M.; Luo, N.; Wang, X. Research on mechanical characteristic of anchor bolt in process of shearing. J. Huazhong Univ. Sci. Technol. Nat. Sci. 2019, 47, 127–132. [Google Scholar]

- Zhang, X.; Wang, S.; Zhao, Y.; Sun, X. Non-uniform stress anchor element based on static and dynamic loading tests on bonded anchor bolt of end anchorage. Rock Soil Mech. 2016, 37, 269–278. [Google Scholar]

- Zhu, W.X.; Jing, H.W.; Yang, L.J.; Pan, B.; Su, H.J. Strength and deformation behaviors of bedded rock mass under bolt reinforcement. Int. J. Min. Sci. Technol. 2018, 28, 593–599. [Google Scholar] [CrossRef]

- Ulusay, R. The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer: Berlin, Germany, 2014. [Google Scholar]

- Li, C.; Stillborg, B. Analytical models for rock bolts. Int. J. Rock Mech. Mining Sci. 1999, 36, 1013–1029. [Google Scholar] [CrossRef]

| Material | Size/mm | Tensile Strength/MPa | Shear Strength/MPa | Anchoring Force/MPa |

|---|---|---|---|---|

| Normal bolt | Φ16~22 | 200~600 | 260~600 | ≥50 |

| Selected screw | Φ5 | 800 | 400 | 30~40 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Liu, Y.; Teng, J.; Zhang, H.; Chen, X. An Investigation into Bolt Anchoring Performance during Tunnel Construction in Bedded Rock Mass. Appl. Sci. 2020, 10, 2329. https://doi.org/10.3390/app10072329

Zhang Z, Liu Y, Teng J, Zhang H, Chen X. An Investigation into Bolt Anchoring Performance during Tunnel Construction in Bedded Rock Mass. Applied Sciences. 2020; 10(7):2329. https://doi.org/10.3390/app10072329

Chicago/Turabian StyleZhang, Zhiqiang, Yin Liu, Junyang Teng, Heng Zhang, and Xin Chen. 2020. "An Investigation into Bolt Anchoring Performance during Tunnel Construction in Bedded Rock Mass" Applied Sciences 10, no. 7: 2329. https://doi.org/10.3390/app10072329

APA StyleZhang, Z., Liu, Y., Teng, J., Zhang, H., & Chen, X. (2020). An Investigation into Bolt Anchoring Performance during Tunnel Construction in Bedded Rock Mass. Applied Sciences, 10(7), 2329. https://doi.org/10.3390/app10072329