Investigation of Ytterbium Incorporation in Lithium Niobate for Active Waveguide Devices

Abstract

Featured Application

Abstract

1. Introduction

2. Experimental Methods

2.1. Sample Preparation

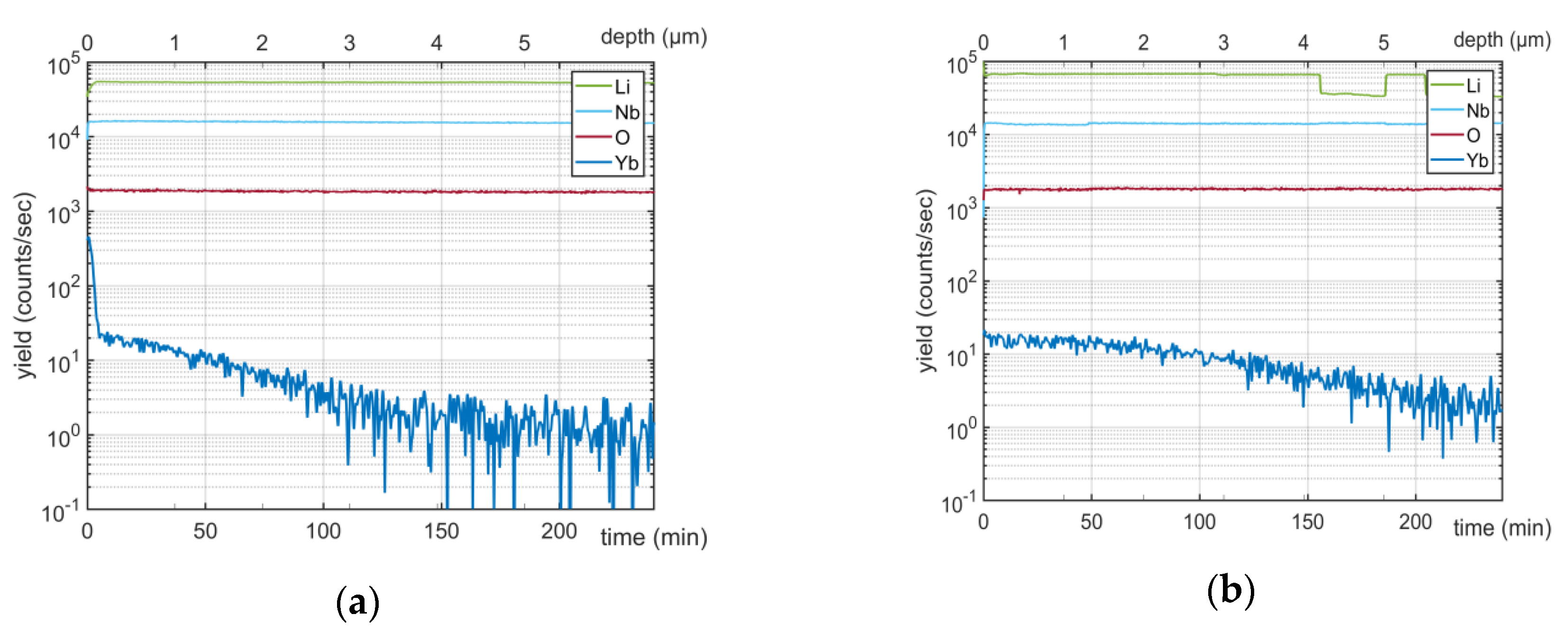

2.2. SNMS Measurements

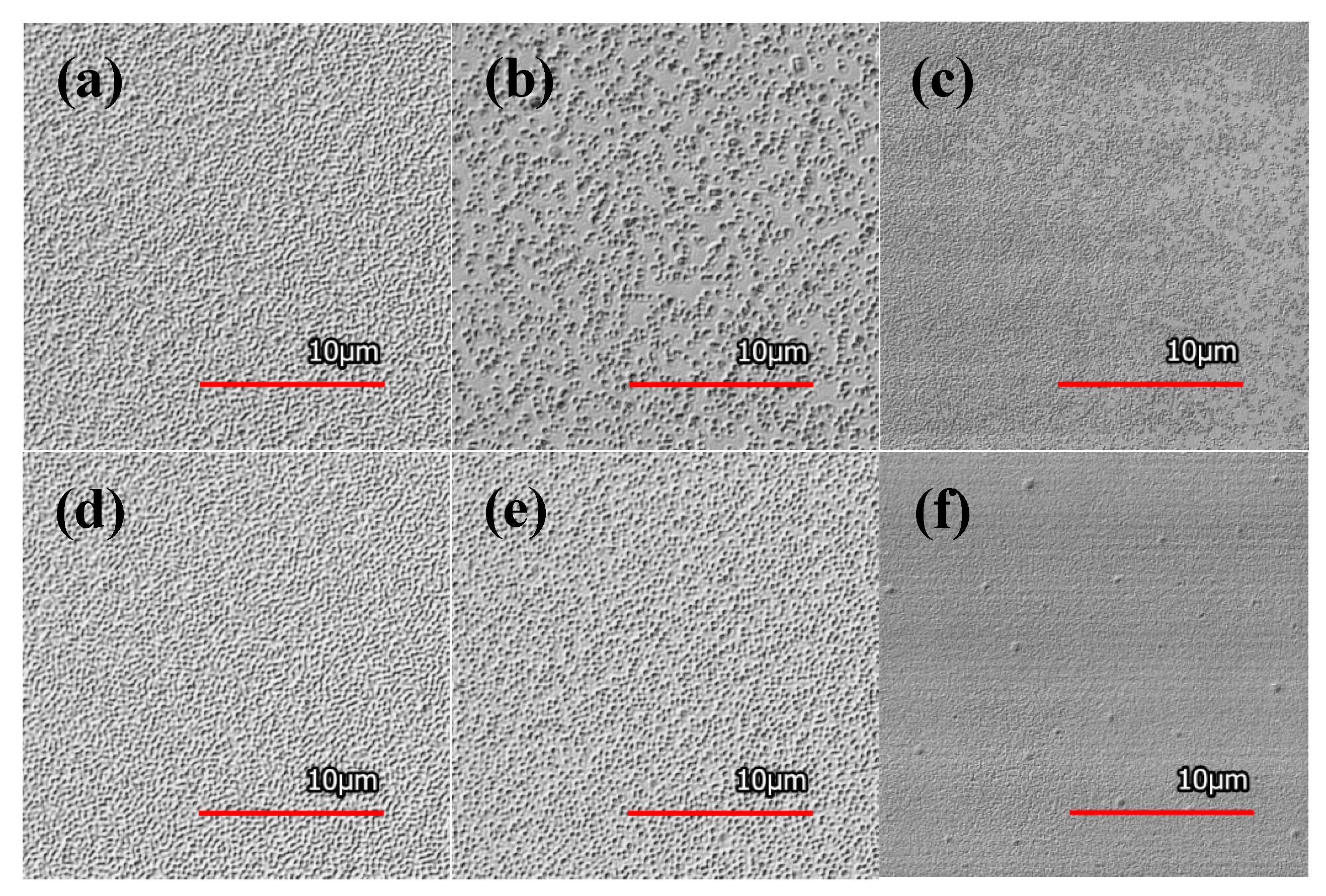

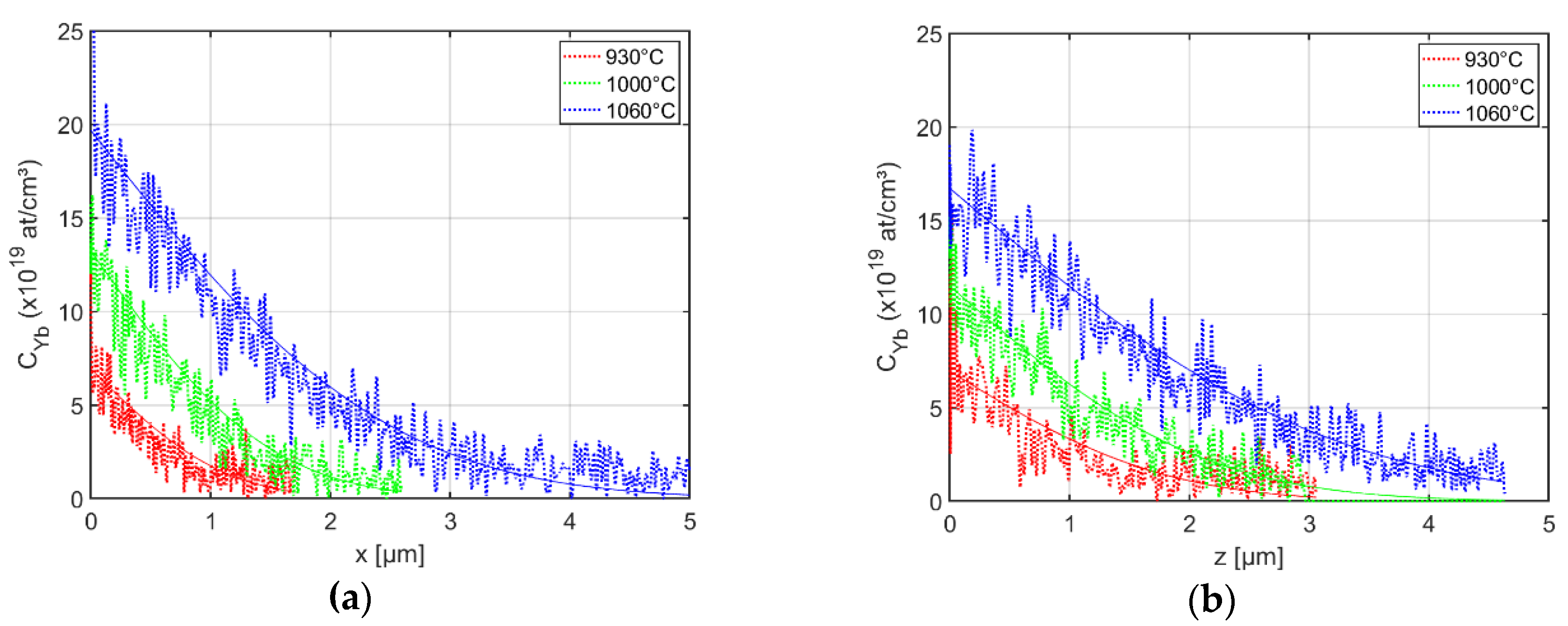

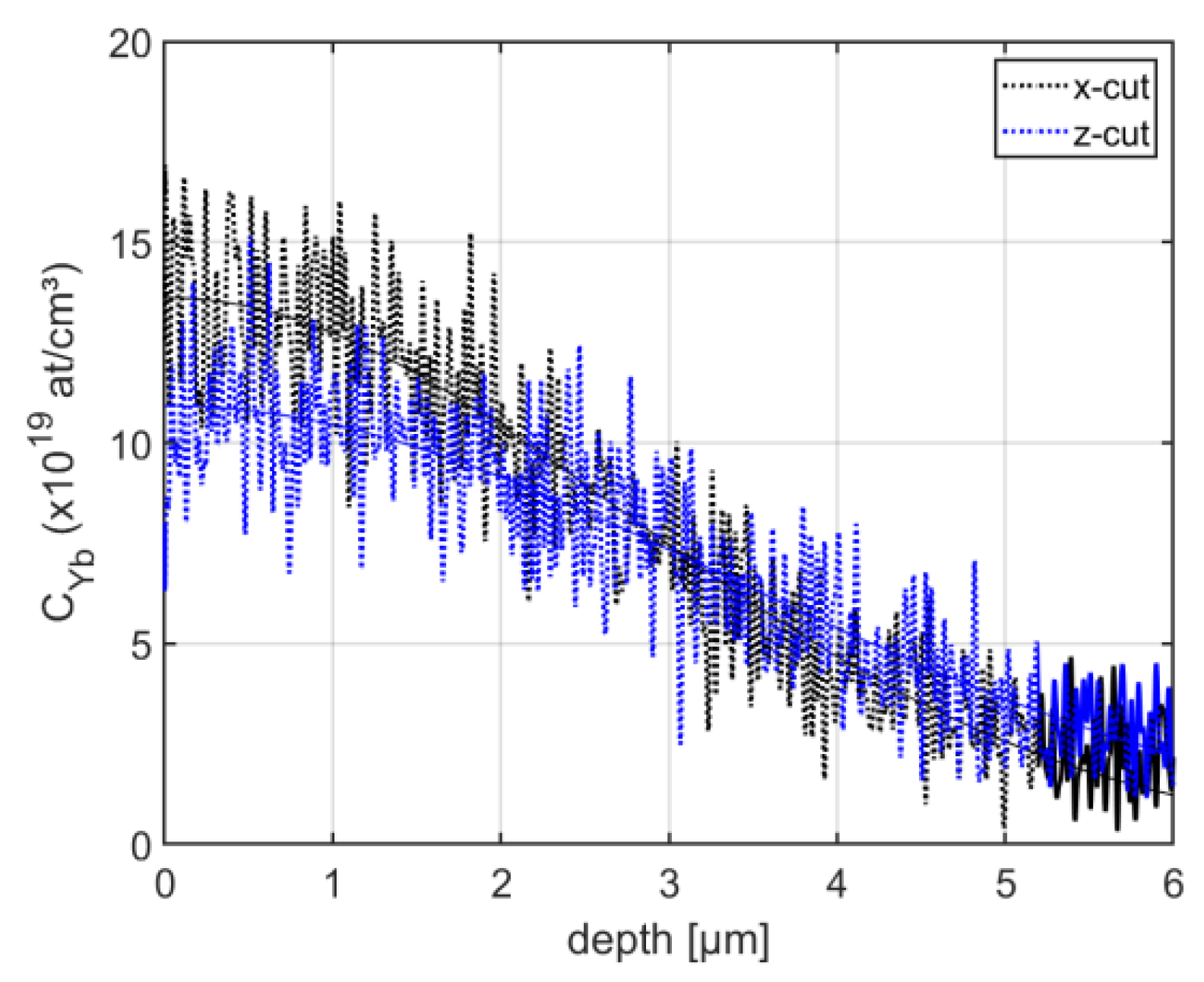

3. Results and Discussion

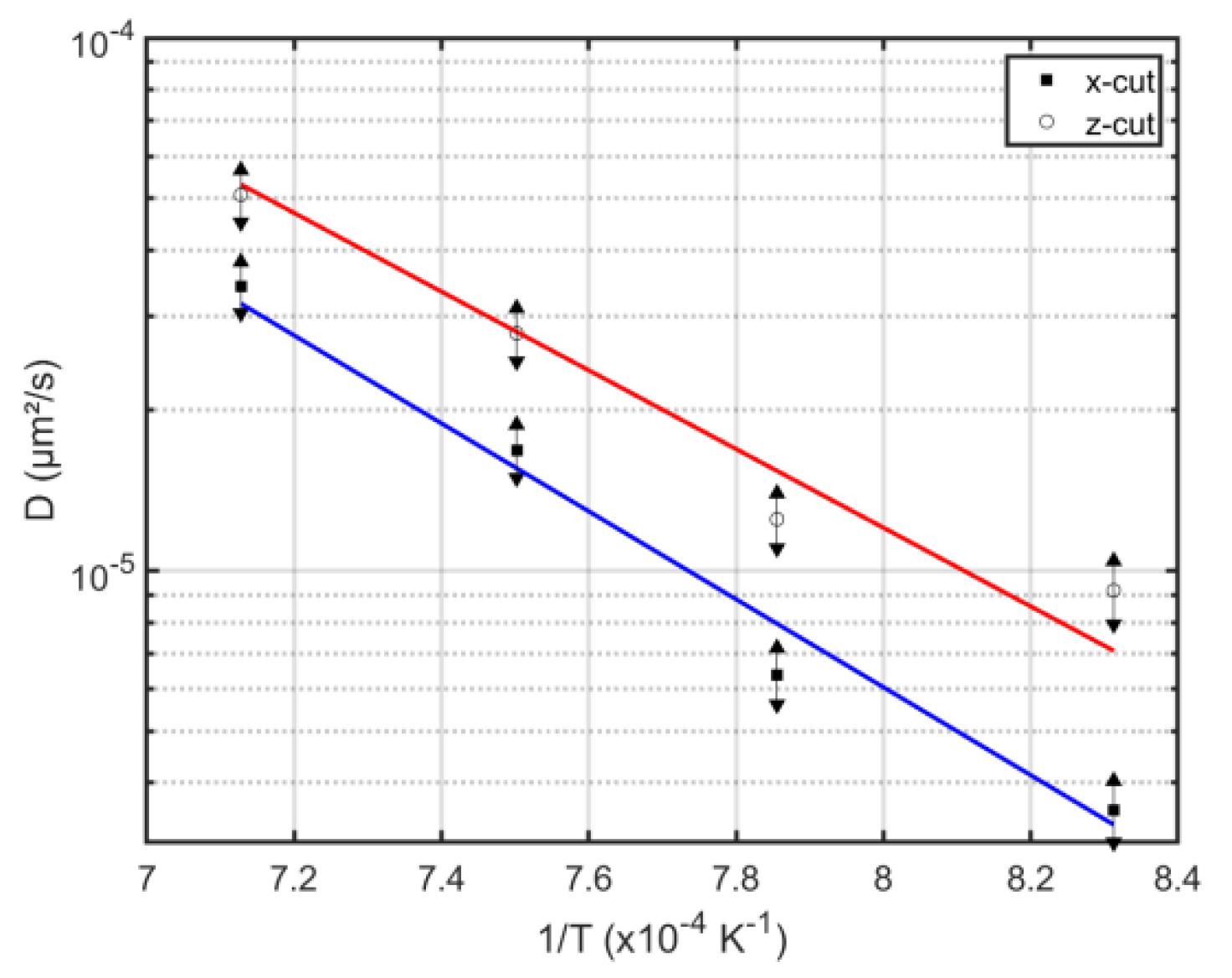

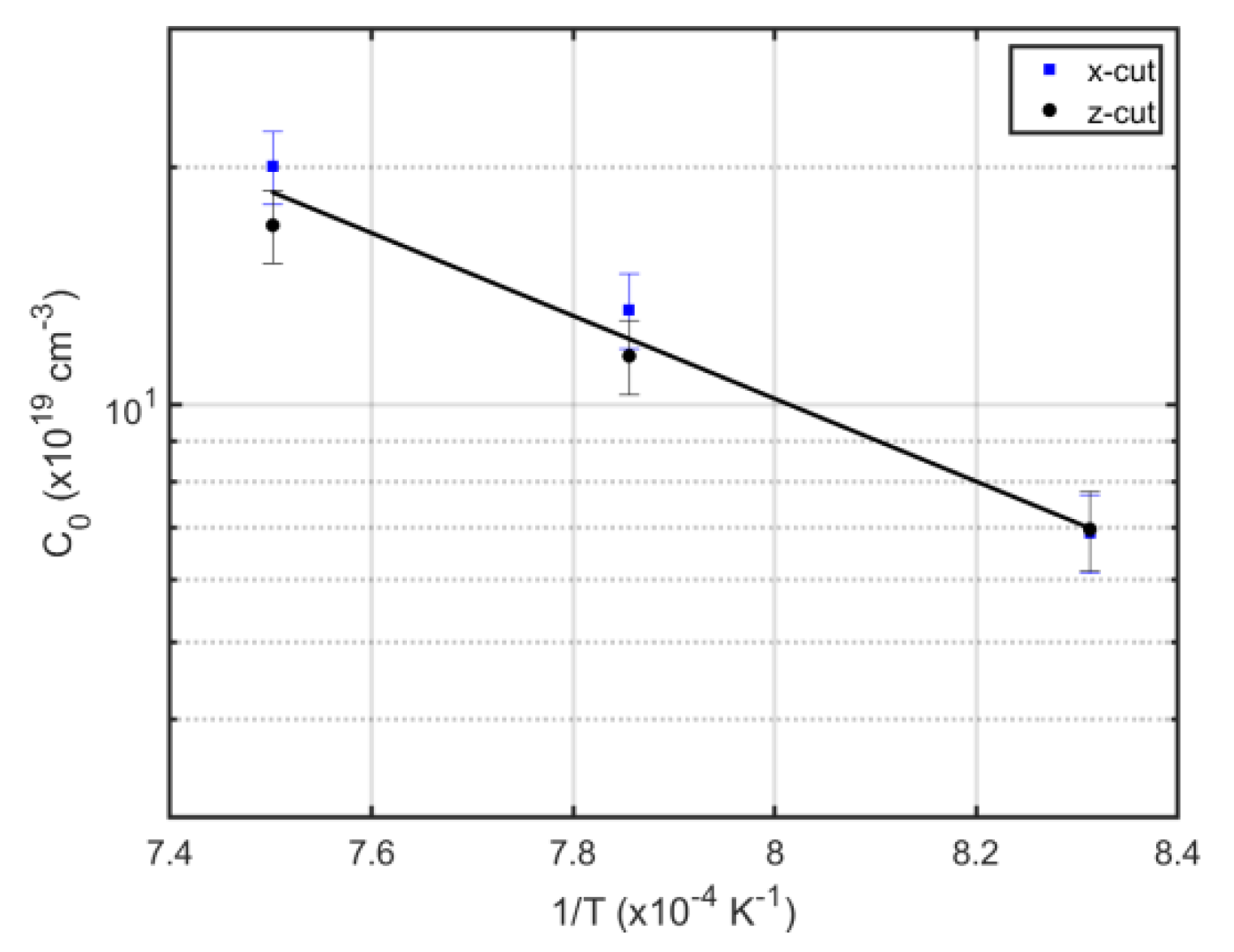

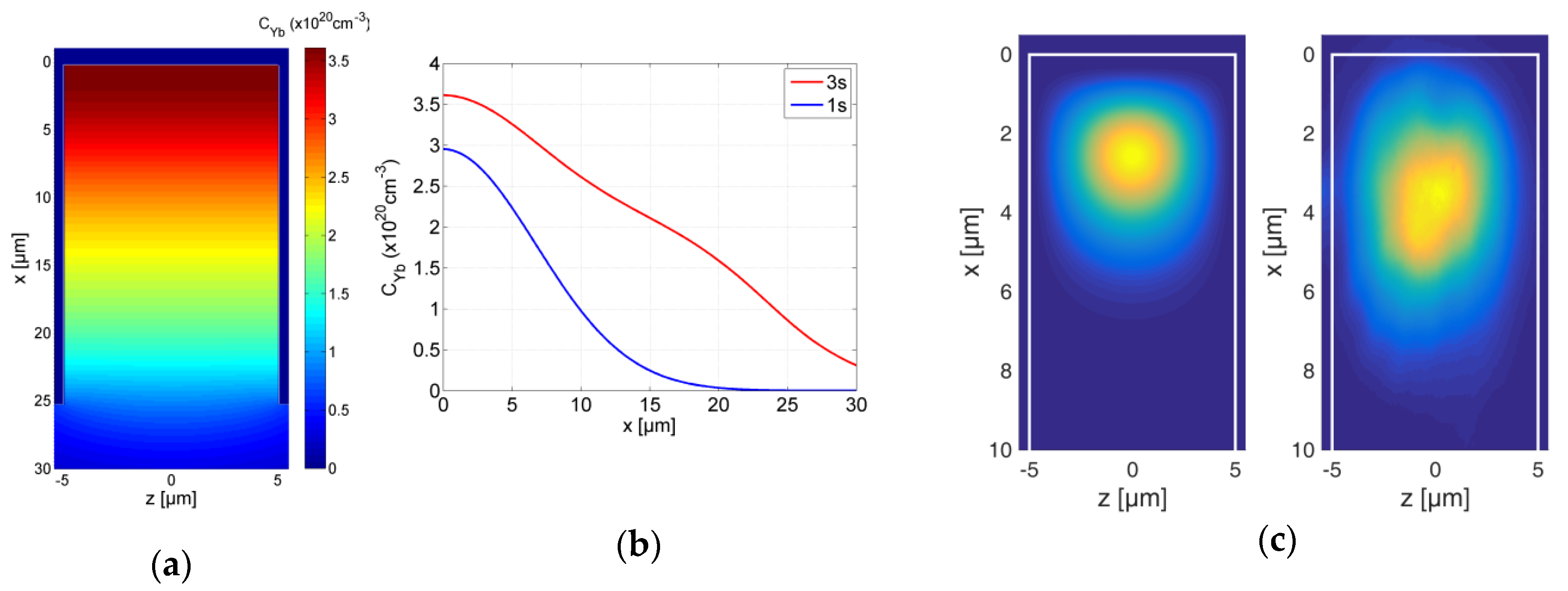

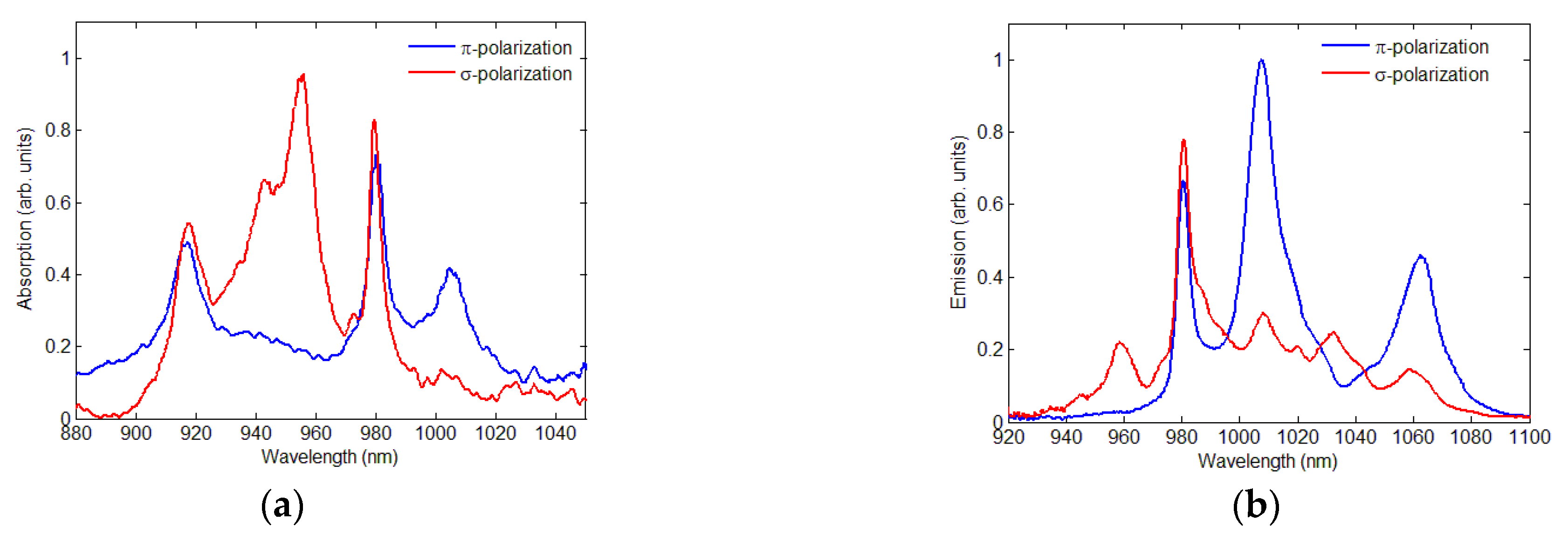

Diffusion Theory

4. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Hu, H.; Ricken, R.; Sohler, W.; Wehrspohn, R.B. Lithium Niobate Ridge Waveguides Fabricated by Wet Etching. IEEE Photon Technol. Lett. 2007, 19, 417–419. [Google Scholar] [CrossRef]

- Hu, H.; Ricken, R.; Sohler, W. Low-loss ridge waveguides on lithium niobate fabricated by local diffusion doping with titanium. Appl. Phys. A 2010, 98, 677–679. [Google Scholar] [CrossRef]

- Volk, M.F.; Suntsov, S.; Rüter, C.E.; Kip, D. Low loss ridge waveguides in lithium niobate thin films by optical grade diamond blade dicing. Opt. Express 2016, 24, 1386–1391. [Google Scholar] [CrossRef]

- Courjal, N.; Guichardaz, B.; Ulliac, G.; Rauch, J.-Y.; Sadani, B.; Lu, H.; Bernal, M.-P. High aspect ratio lithium niobate ridge waveguides fabricated by optical grade dicing. J. Phys. D Appl. Phys. 2011, 44, 305101. [Google Scholar] [CrossRef]

- Gerthoffer, A.; Guyot, C.; Qiu, W.; Ndao, A.; Bernal, M.-P.; Courjal, N. Strong reduction of propagation losses in LiNbO3 ridge waveguides. Opt. Mater. 2014, 38, 37–41. [Google Scholar] [CrossRef]

- Cai, L.; Wang, Y.; Hu, H. Low-loss waveguides in a single-crystal lithium niobate thin film. Opt. Lett. 2015, 40, 3013–3016. [Google Scholar] [CrossRef] [PubMed]

- Becker, C.; Oesselke, T.; Pandavenes, J.; Ricken, R.; Rochhausen, K.; Schreiber, G.; Sohler, W.; Suche, H.; Wessel, R.; Balsamo, S.; et al. Advanced Ti:Er:LiNbO3 waveguide lasers. IEEE J. Sel. Top. Quantum Electron. 2000, 6, 101–113. [Google Scholar] [CrossRef]

- Lallier, E.; Pocholle, J.; Papuchon, M.; Grezes-Besset, C.; Pelletier, E.; De Micheli, M.; Li, M.; He, Q.; Ostrowsky, D. Laser oscillation of single-mode channel waveguide in Nd:MgO:LiNbO3. Electron. Lett. 1989, 25, 1491. [Google Scholar] [CrossRef]

- De Micheli, M.; Lallier, E.; Grezes-Besset, C.; Pelletier, E.; Pocholle, J.P.; Li, M.J.; He, Q.; Papuchon, M.; Ostrowsky, D.B. Nd:MgO:LiNbO3 waveguide laser and amplifier. Opt. Lett. 1990, 15, 682–684. [Google Scholar] [CrossRef]

- Di Paolo, R.E.; Cantelar, E.; Pernas, P.; Pedrola, G.L.; Cussó, F. Continuous wave waveguide laser at room temperature in Nd[sup 3+]-doped Zn:LiNbO[sub 3]. Appl. Phys. Lett. 2001, 79, 4088–4090. [Google Scholar] [CrossRef][Green Version]

- Siebenmorgen, J.; Calmano, T.; Petermann, K.; Huber, G.; Huber, G. Highly efficient Yb:YAG channel waveguide laser written with a femtosecond-laser. Opt. Express 2010, 18, 16035–16041. [Google Scholar] [CrossRef] [PubMed]

- Okhotnikov, O.G.; Gomes, L.; Xiang, N.; Jouhti, T.; Grudinin, A.B. Mode-locked ytterbium fiber laser tunable in the 980-1070-nm spectral range. Opt. Lett. 2003, 28, 1522–1524. [Google Scholar] [CrossRef]

- Malinowski, A.; Piper, A.; Price, J.H.V.; Furusawa, K.; Jeong, Y.; Nilsson, J.; Richardson, D. Ultrashort-pulse Yb3+-fiber-based laser and amplifier system producing >25-W average power. Opt. Lett. 2004, 29, 2073–2075. [Google Scholar] [CrossRef] [PubMed]

- Jones, J.K.; De Sandro, J.P.; Hempstead, M.; Shepherd, D.P.; Large, A.C.; Tropper, A.C.; Wilkinson, J. Channel waveguide laser at 1 µm in Yb-indiffused LiNbO3. Opt. Lett. 1995, 20, 1477–1479. [Google Scholar] [CrossRef] [PubMed]

- Fujimura, M.; Tsuchimoto, H.; Suhara, T. Yb:LiNbO3 Annealed/Proton-Exchanged Waveguide Lasers Pumped by InGaAs Laser Diode at 980 nm Wavelength. Jpn. J. Appl. Phys. 2007, 46, 5447–5449. [Google Scholar] [CrossRef]

- Pal, S.; Das, B.K.; Sohler, W. Photorefractive damage resistance in Ti:PPLN waveguides with ridge geometry. Appl. Phys. A 2015, 120, 737–749. [Google Scholar] [CrossRef]

- Suntsov, S.; Rüter, C.E.; Kip, D. Er:Ti:LiNbO3 ridge waveguide optical amplifiers by optical grade dicing and three-side Er and Ti in-diffusion. Appl. Phys. B Laser Opt. 2017, 123, 118. [Google Scholar] [CrossRef]

- Kip, D.; Brüske, D.; Suntsov, S.; Rüter, C.E. Efficient ridge waveguide amplifiers and lasers in Er-doped lithium niobate by optical grade dicing and three-side Er and Ti in-diffusion. Opt. Express 2017, 25, 29374. [Google Scholar]

- Brüske, D.; Suntsov, S.; Rüter, C.E.; Kip, D. Efficient Nd:Ti:LiNbO3 ridge waveguide lasers emitting around 1085 nm. Opt. Express 2019, 27, 8884–8889. [Google Scholar] [CrossRef]

- Fujimura, M.; Tsuchimoto, H.; Suhara, T. Yb-diffused LiNbO/sub 3/ annealed/proton-exchanged waveguide lasers. IEEE Photon Technol. Lett. 2004, 17, 130–132. [Google Scholar] [CrossRef]

- Amin, J.; Aust, J.; Veasey, D.; Sanford, N. Dual wavelength, 980 nm-pumped, Er/Yb-codoped waveguide laser in Ti:LiNbO3. Electron. Lett. 1998, 34, 456. [Google Scholar] [CrossRef]

- Burns, G.; O’Kane, D.F.; Title, R.S. Optical and Electron-Spin-Resonance Spectra ofYb3+,Nd3+, andCr3+in LiNbO3 and LiTaO3. Phys. Rev. 1968, 167, 314–319. [Google Scholar] [CrossRef]

| Temperature (°C) | Time (h) | C0 × 1019 (ions/cm3) | Cmax × 1019 (ions/cm3) | derf (µm) | dexp (µm) |

|---|---|---|---|---|---|

| z-cut | |||||

| 930 | 30 | 6.96 ± 0.10 | 1.99 ± 0.13 | ||

| 1000 | 30 | 11.53 ± 0.09 | 2.32 ± 0.14 | ||

| 1060 | 30 | 16.89 ± 0.10 | 3.47 ± 0.19 | ||

| 1130 | 30 | 10.94 ± 0.05 | 4.68 ± 0.26 | ||

| x-cut | |||||

| 930 | 30 | 6.89 ± 0.10 | 1.24 ± 0.08 | ||

| 1000 | 30 | 13.21 ± 0.12 | 1.66 ± 0.10 | ||

| 1060 | 30 | 20.06 ± 0.12 | 2.70 ± 0.15 | ||

| 1130 | 30 | 13.62 ± 0.06 | 3.84 ± 0.21 |

| D0 ( × 10-8 cm²/s) | EA (eV) | |

|---|---|---|

| Diffusion in z-direction | 9.7 ± 0.8 | 1.46 ± 0.07 |

| Diffusion in x-direction | 24.1 ± 1.9 | 1.64 ± 0.07 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rüter, C.E.; Brüske, D.; Suntsov, S.; Kip, D. Investigation of Ytterbium Incorporation in Lithium Niobate for Active Waveguide Devices. Appl. Sci. 2020, 10, 2189. https://doi.org/10.3390/app10062189

Rüter CE, Brüske D, Suntsov S, Kip D. Investigation of Ytterbium Incorporation in Lithium Niobate for Active Waveguide Devices. Applied Sciences. 2020; 10(6):2189. https://doi.org/10.3390/app10062189

Chicago/Turabian StyleRüter, Christian E., Dominik Brüske, Sergiy Suntsov, and Detlef Kip. 2020. "Investigation of Ytterbium Incorporation in Lithium Niobate for Active Waveguide Devices" Applied Sciences 10, no. 6: 2189. https://doi.org/10.3390/app10062189

APA StyleRüter, C. E., Brüske, D., Suntsov, S., & Kip, D. (2020). Investigation of Ytterbium Incorporation in Lithium Niobate for Active Waveguide Devices. Applied Sciences, 10(6), 2189. https://doi.org/10.3390/app10062189