Mechanical Integrity Analysis of a Printed Circuit Heat Exchanger with Channel Misalignment

Abstract

1. Introduction

2. Numerical Simulation

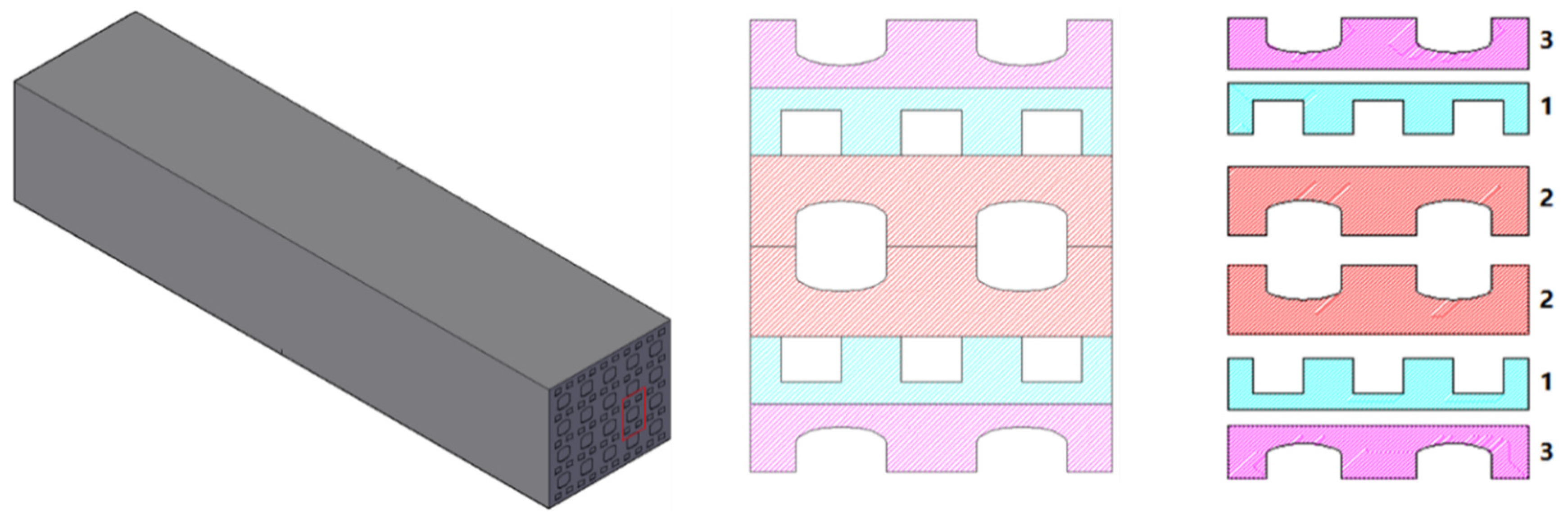

2.1. Approach and PCHE Design

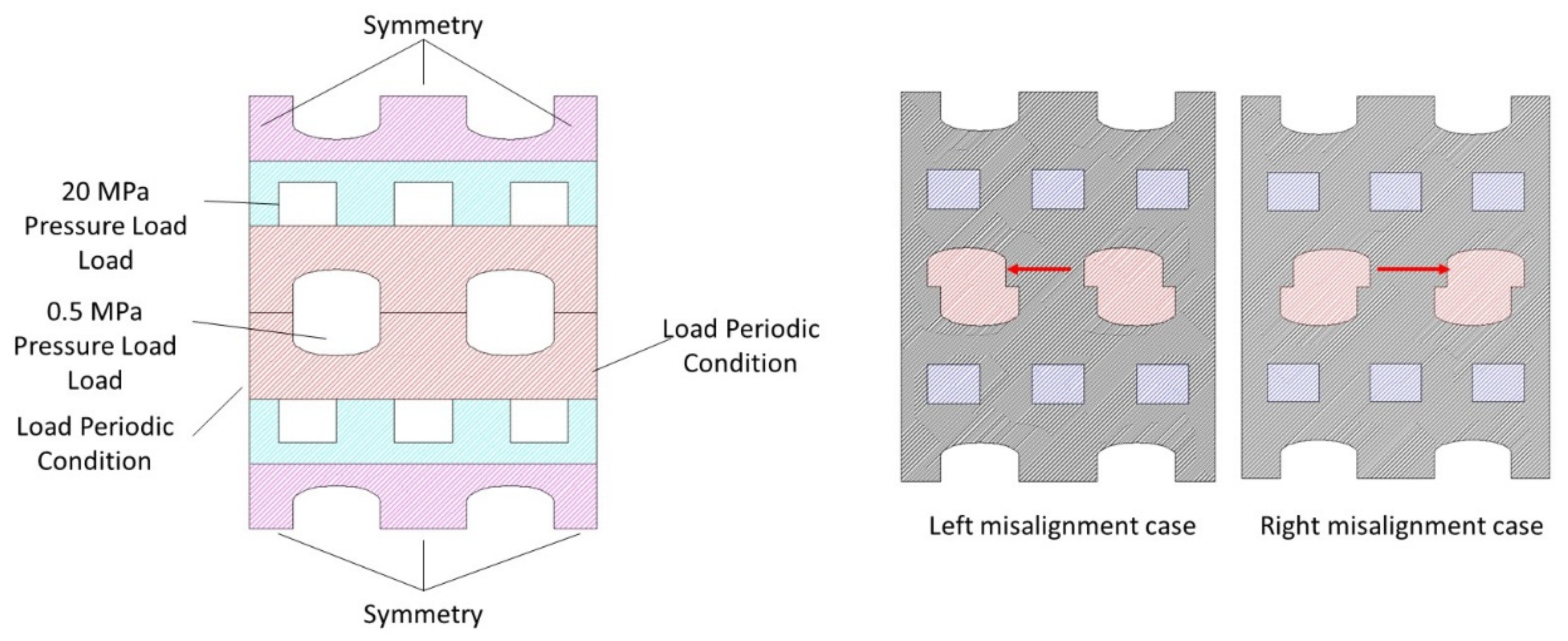

2.2. Boundary Conditions

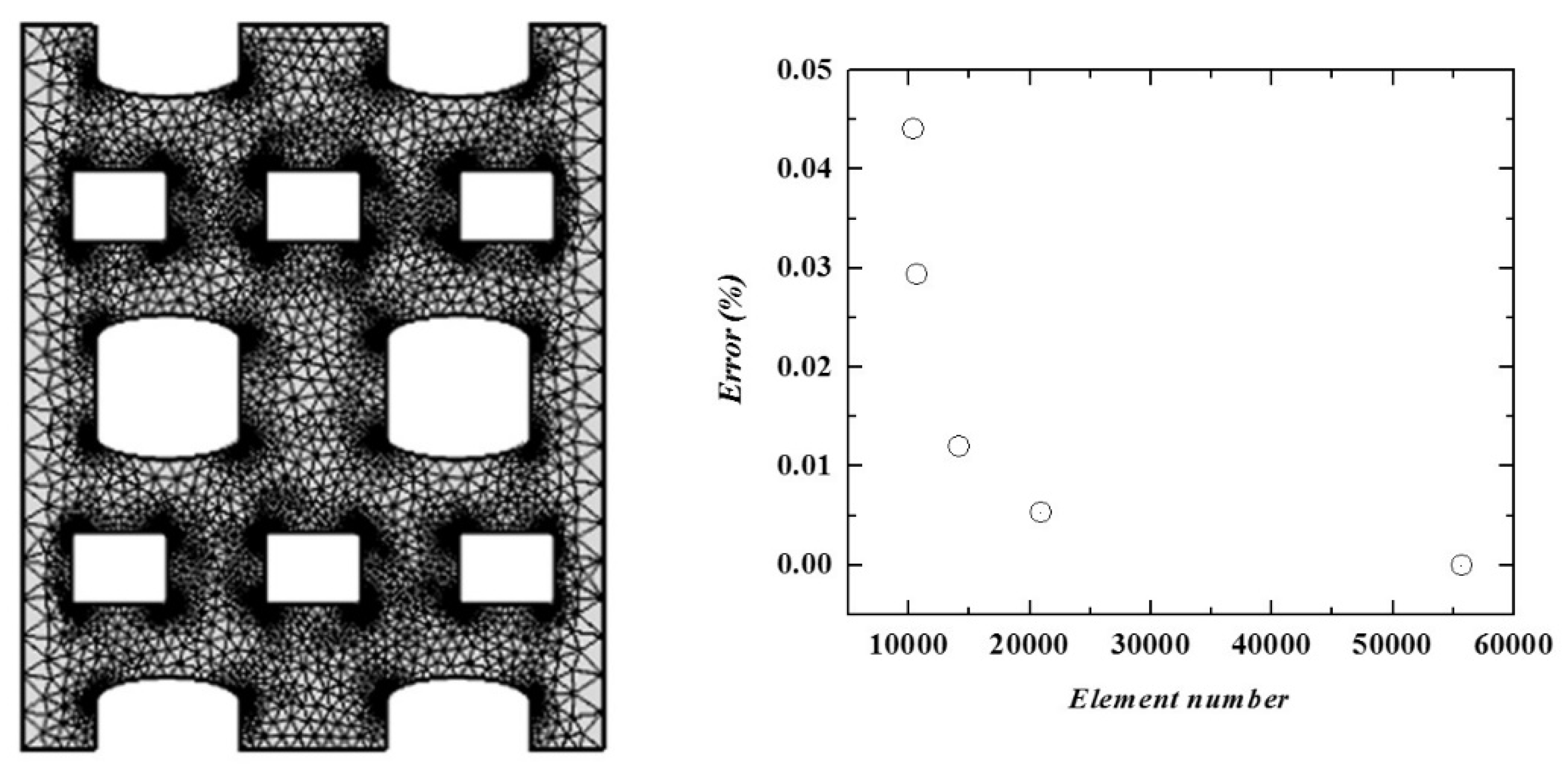

2.3. Mesh Independent Test

3. Results and Discussion

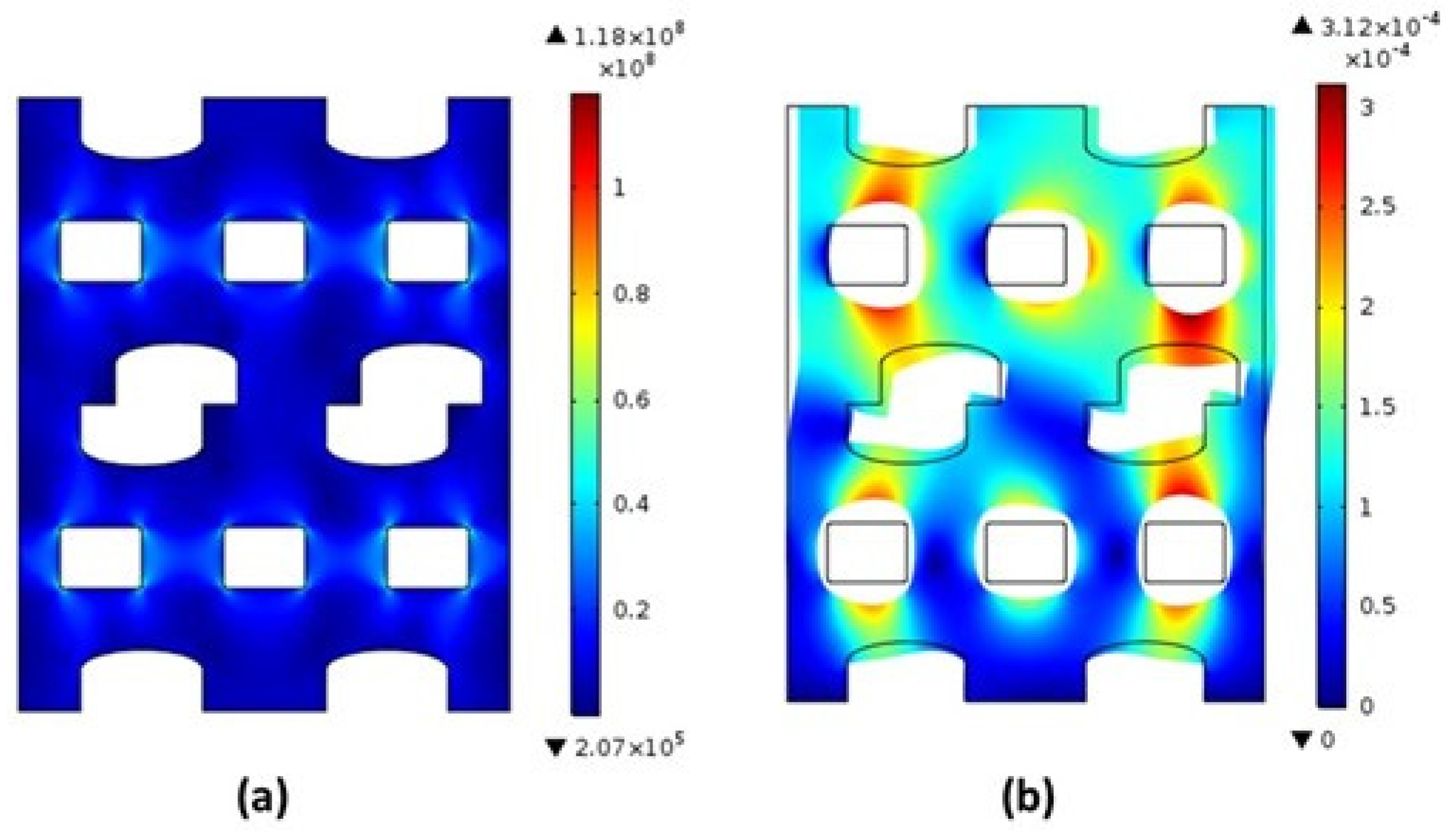

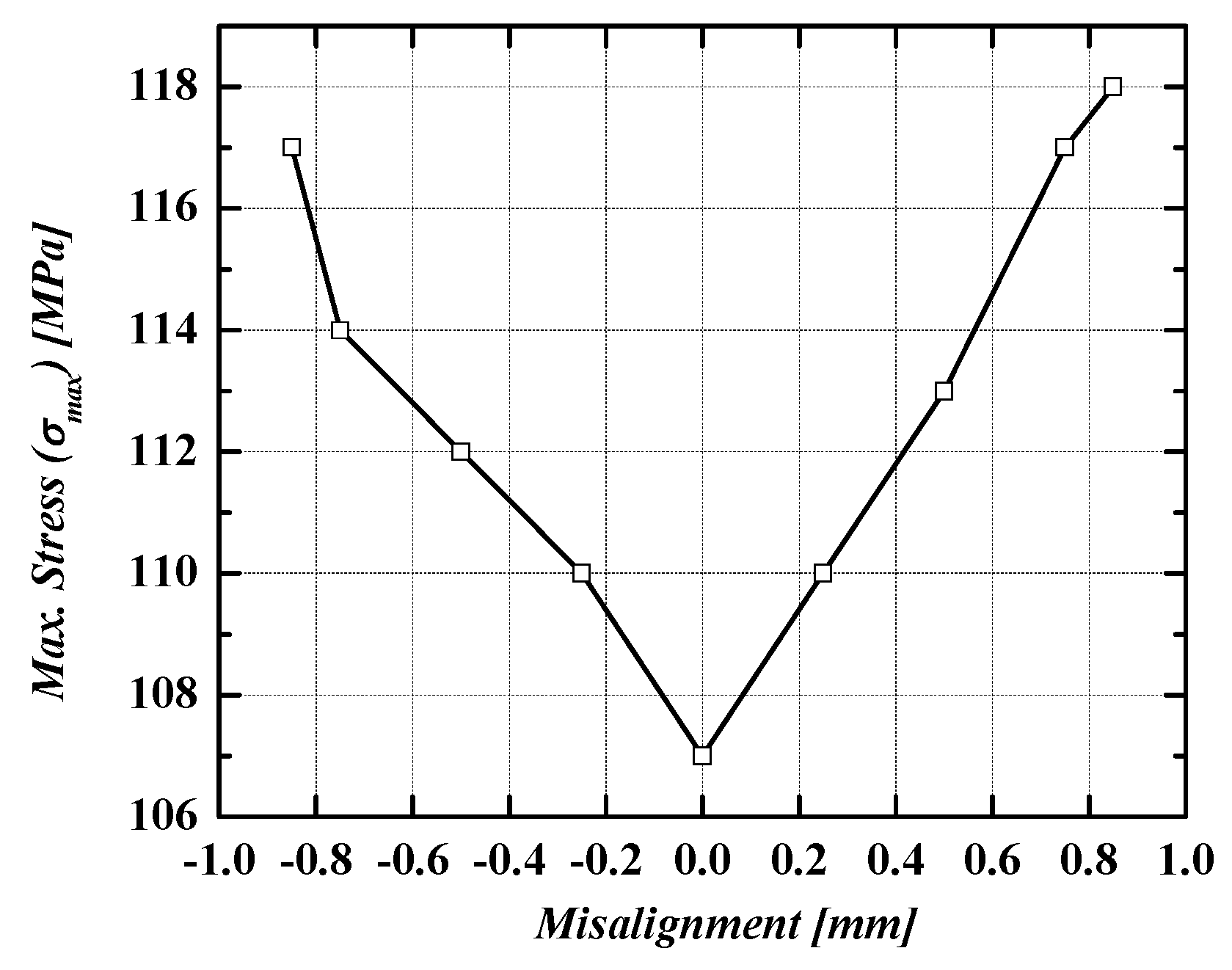

3.1. Stress Distribution at the Surface

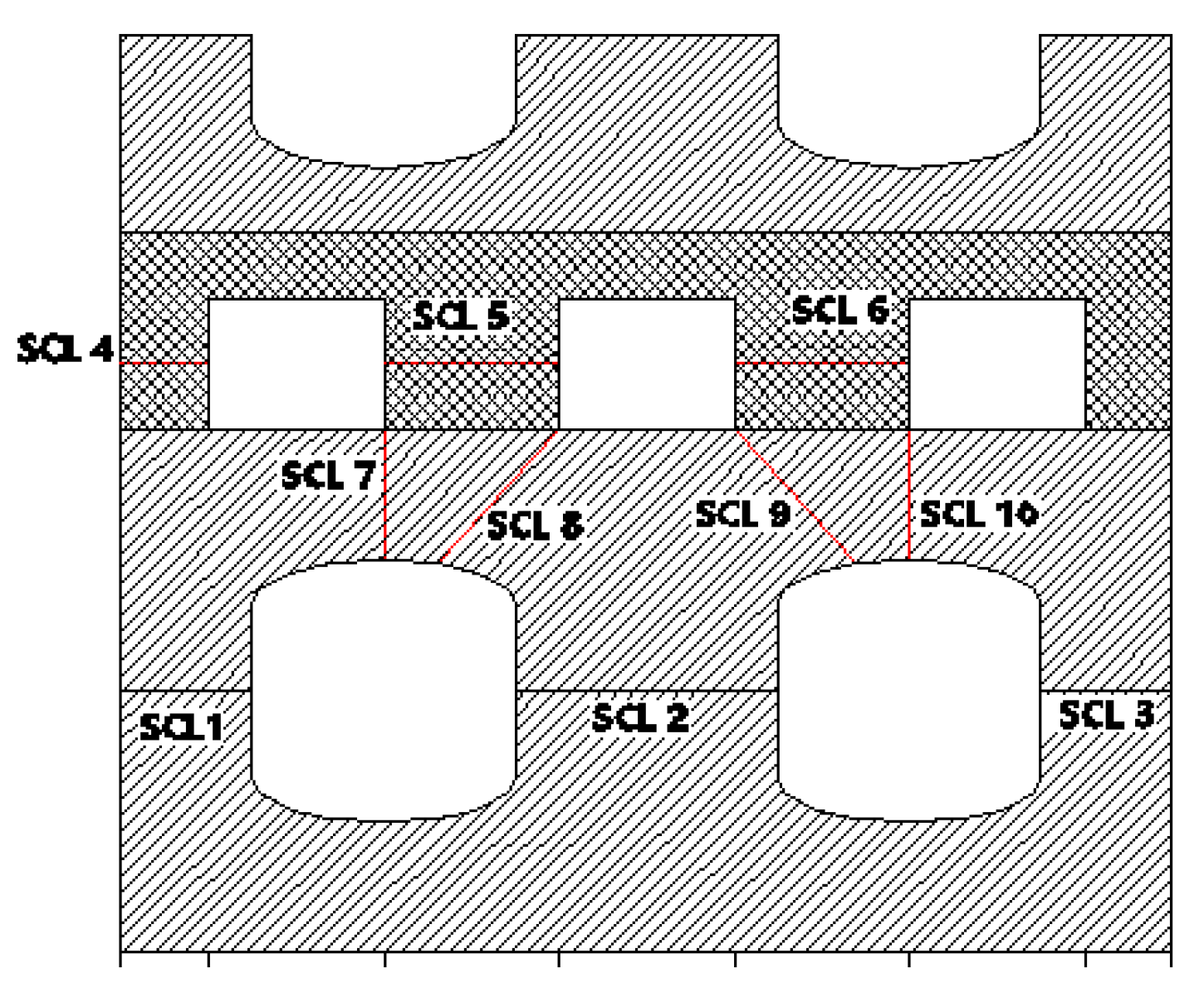

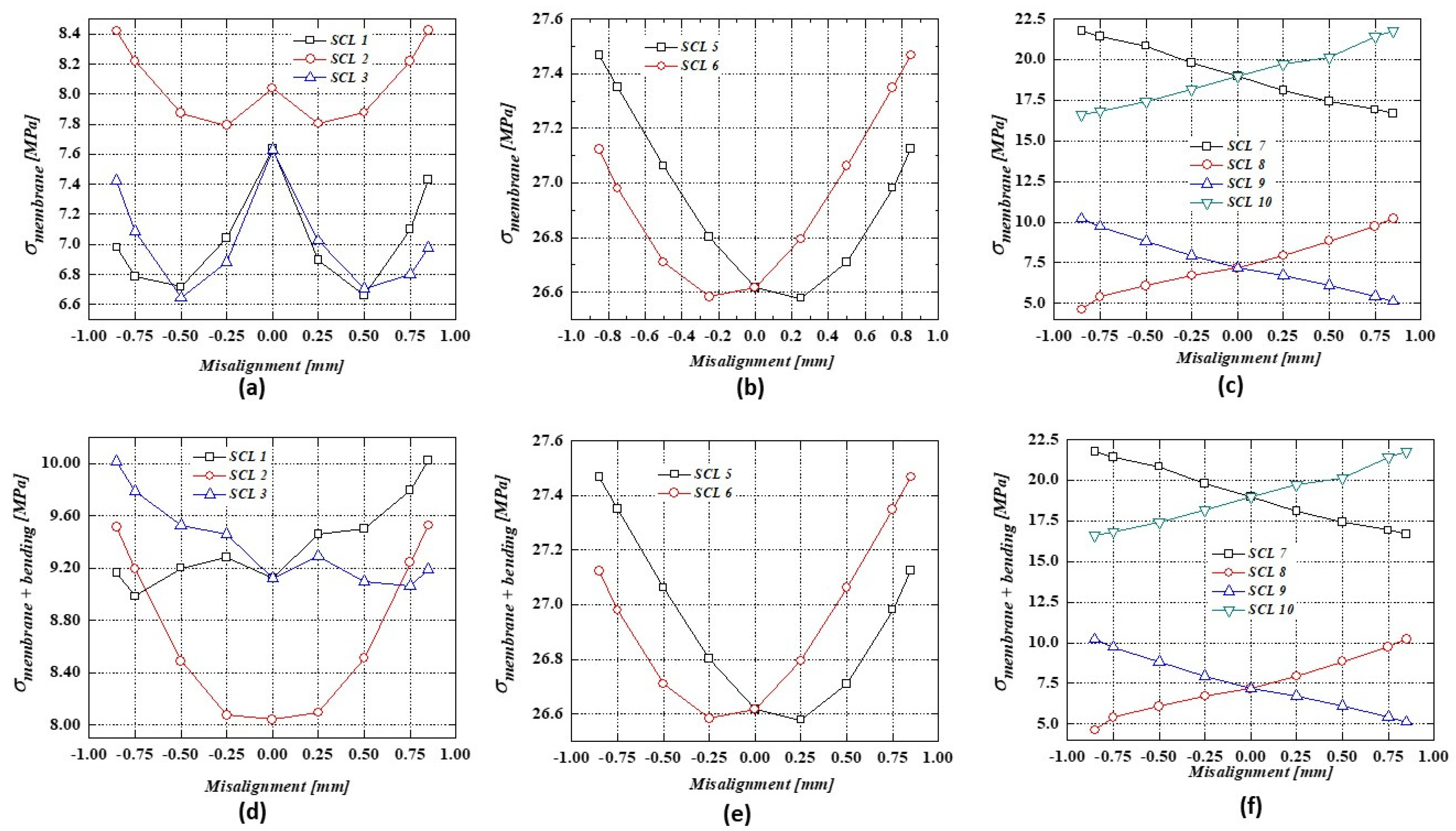

3.2. Stress at Stress Classification Line (SCL)

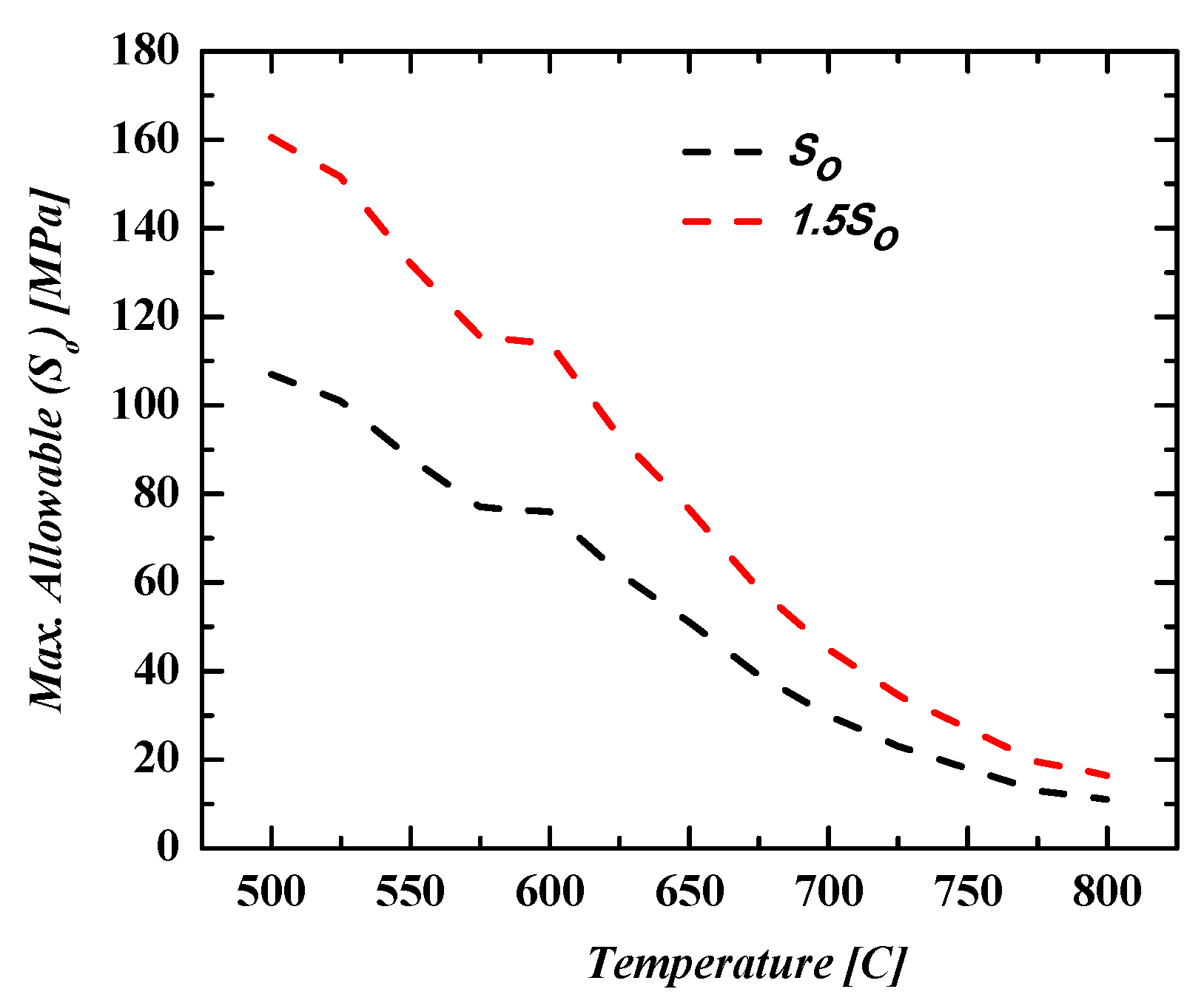

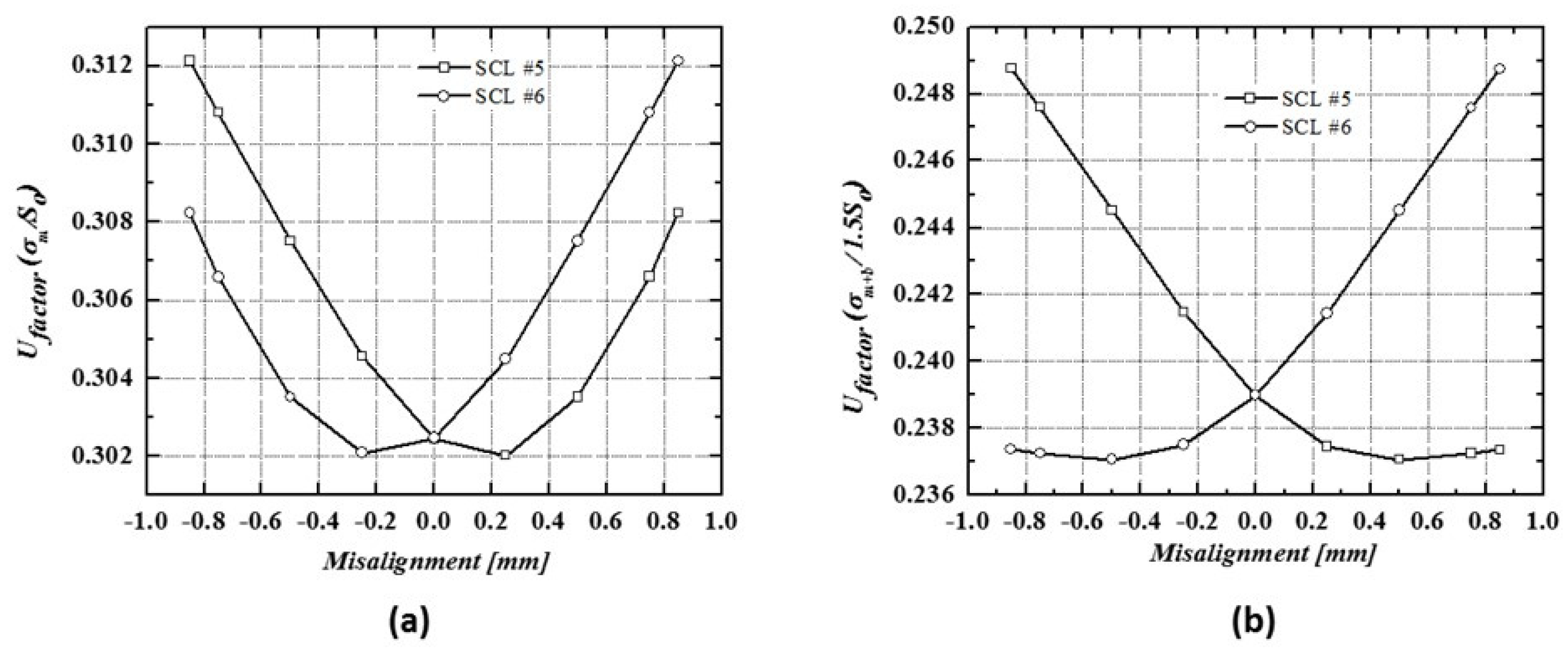

3.3. The Utilization Factor Increases as the Misalignment Increases

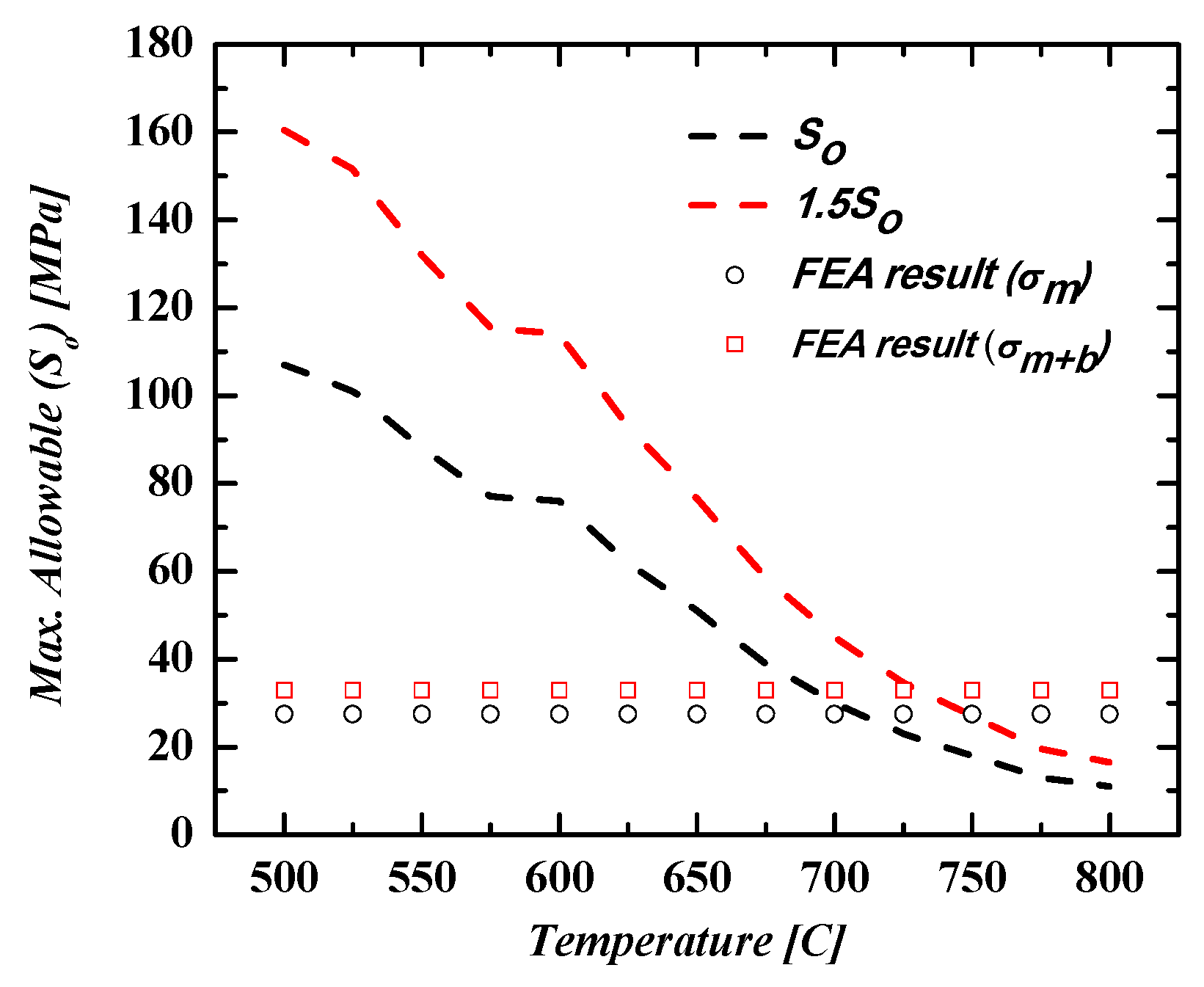

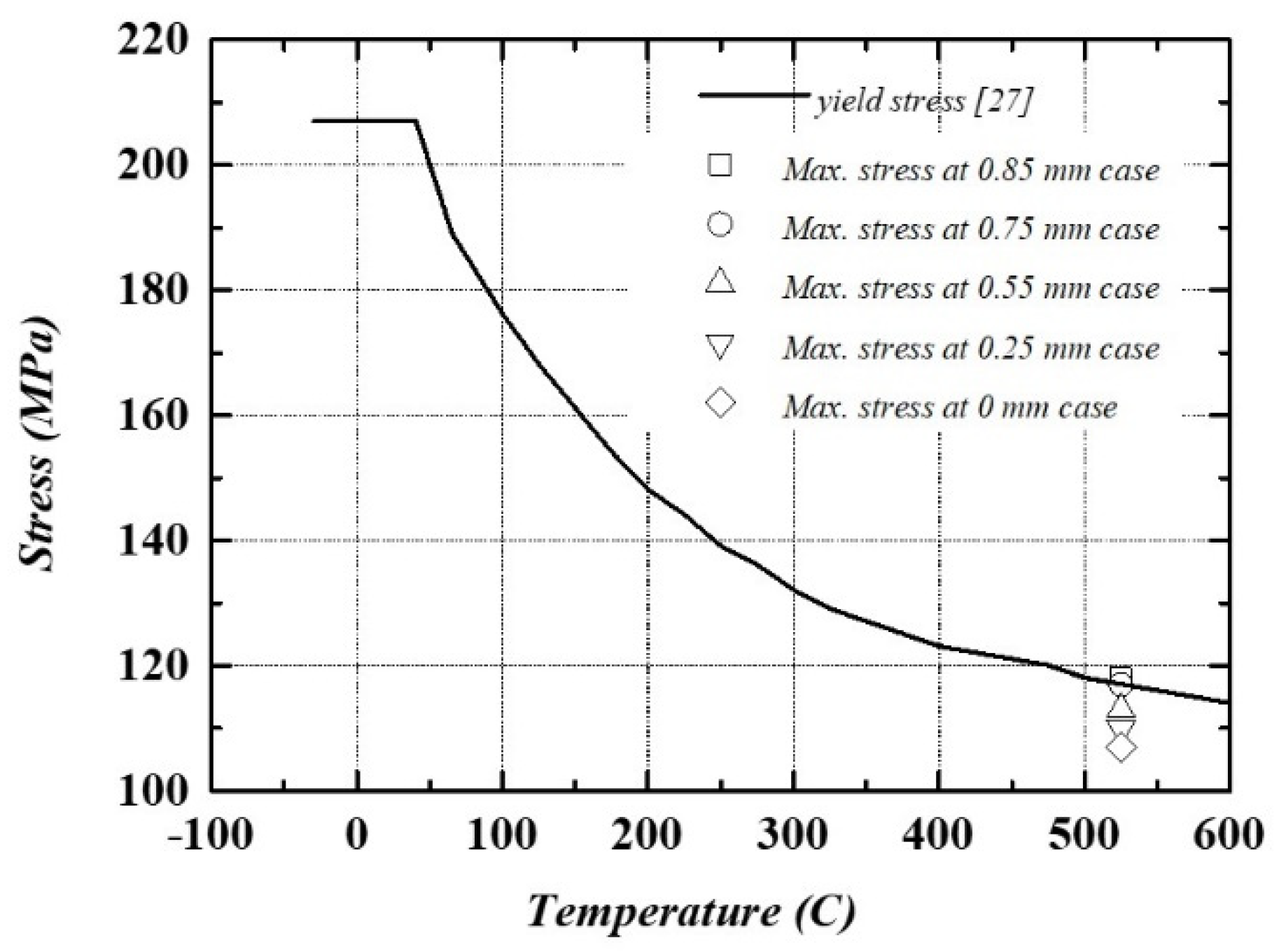

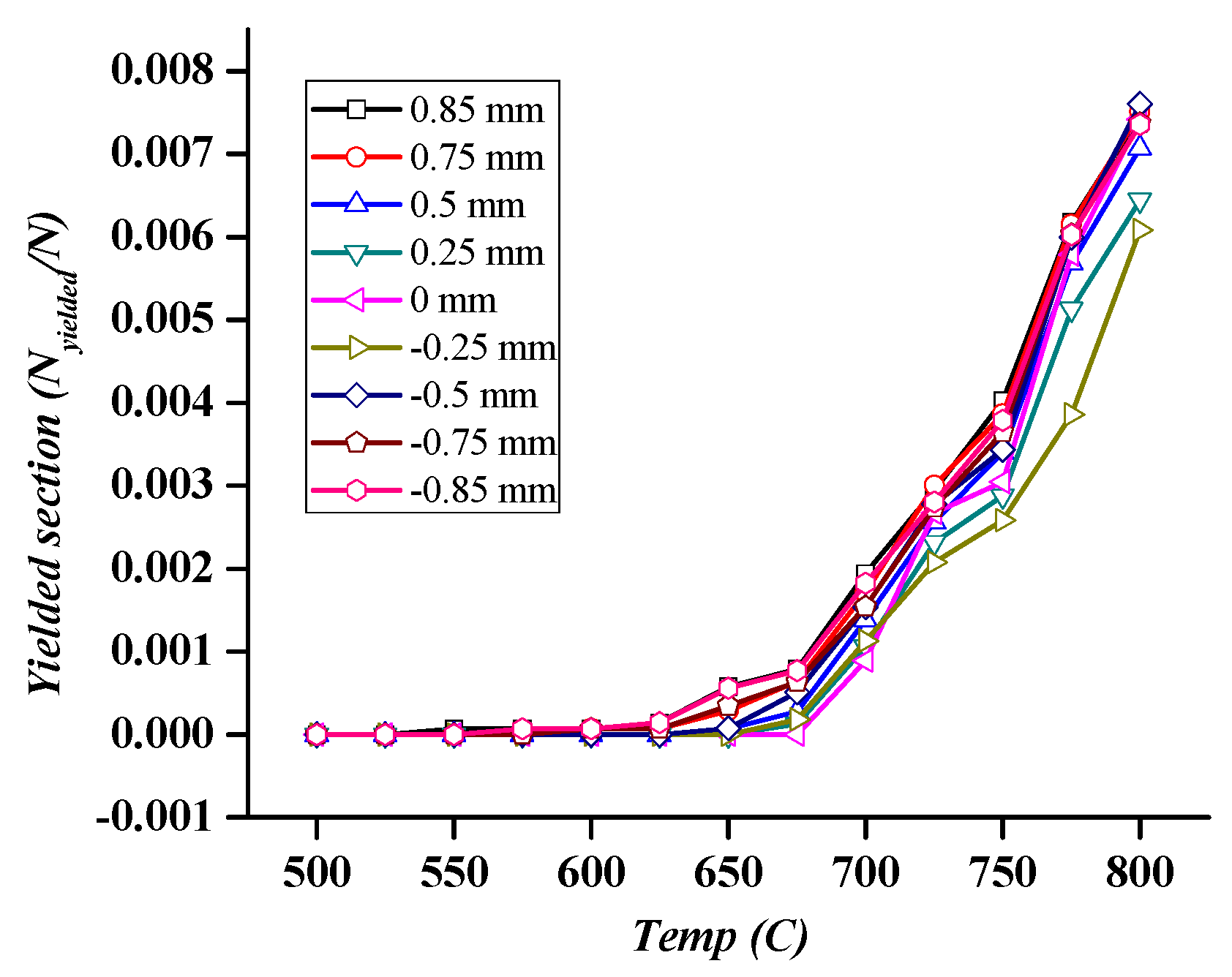

3.4. Yielding Section under Design Loading

4. Conclusions

- The highest stress intensity was located at the tip edge of the water channel for the higher-pressure intensity compared to that in the sodium channel;

- The stress intensity increases as the misalignment increases, causing the utilization factor to increase, which is less safe compared to the condition without misalignment;

- The proposed geometry design can comply with the design limit condition up to 700° C in terms of the ASME code. This means the for the SFR application, which has an average temperature of 550° C, the geometry design can comply with the design limit conditions. However, the design can comply with the acceptance criteria up to 725° C under 30% misalignment condition;

- The study shows that the design of PCHEs needs to be more precise regarding welding and assembly processes, due to decreasing utilization factor. More strict construction and assembly process monitoring, especially during stacking and welding processes, is needed to avoid this utilization factor degradation due to misalignment conditions.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Abbreviations | |

| ASME | American Society of Mechanical Engineers |

| PCHE | Printed Circuit Heat Exchanger |

| FEM | Finite Element Method |

| SCO2 | Supercritical Carbon dioxide |

| SFR | Sodium Fast-cooled reactor |

| TES | Thermal Energy Storage |

| IHX | Intermediate Heat Exchanger |

| HTGR | High-Temperature Gas Reactor |

| SCL | Stress Classification Line |

| Symbol | |

| Sm | The Lowest Stress Intensity value at a given temperature |

| K | Factor K |

| So | Maximum allowable stress intensity |

| Smt | Maximum allowable stress intensity value time dependent |

| Pm | Primary membrane stress intensity [MPa] |

| PL | Primary membrane stress local [MPa] |

| Pb | Primary bending stress [MPa] |

| Uf | Utilization factor as the ratio of stress intensity to the maximum allowable stress |

| m | Misalignment case (mm) |

| σij,m | Membrane Stress |

| σij,b | Bending Stress |

| σe | Equivalent Stress |

| σx | Stress tensor in x direction |

| σy | Stress tensor in y direction |

| σz | Stress tensor in z direction |

| Sy | Yield Stress |

References

- Ҫengel, Y.A. Heat Exchanger. In Heat Transfer a Practical Approach, 2nd ed.; McGraw Hill: New York, NY, USA, 2004; pp. 667–704. [Google Scholar]

- Thulukkanam, K. Heat Exchangers Introduction, Classification, and Selection. In Heat Exchanger Design Handbook, 2nd ed.; CRC Press: New York, NY, USA, 2013; pp. 1–34. [Google Scholar]

- Asadi, M.; Xie, G.; Sunden, B. A review of heat transfer and pressure drop characteristics of single and two phases microchannel. Int. J Heat Mass Transf. 2014, 79, 34–53. [Google Scholar] [CrossRef]

- Chen, M.; Sun, X.; Christensen, R.N.; Shi, S.; Skavdahl, I.; Utgikar, V.; Sabharwall, P. Experimental and numerical study of a printed circuit heat exchanger. Ann. Nucl. Energy 2016, 97, 221–231. [Google Scholar] [CrossRef]

- Chen, M.; Sun, X.; Christensen, R.N.; Shi, S.; Skavdahl, I.; Utgikar, V.; Sabharwall, P. Pressure drop and heat transfer characteristic of a high-temperature printed circuit heat exchanger. Appl. Therm. Eng. 2016, 108, 1409–1417. [Google Scholar] [CrossRef]

- Li, X.; Le Pierres, R.; Dewson, S.J. Heat Exchanger for the next generation of Nuclear reactors. In Proceedings of the International Congress on Advances in Nuclear Power Plants, Reno, NV, USA, 4–8 June 2006; pp. 201–209. [Google Scholar]

- Patil, R.; Anand, S. Thermo- structural fatigue analysis of shell and tube type heat exchanger. Int. J. Press. Vessel. Pip. 2017, 155, 35–42. [Google Scholar] [CrossRef]

- Mylavarapu, S.K.; Sun, X.; Glosup, R.E.; Christensen, R.N.; Patterson, M.W. Thermal Hydraulic Performance testing of Printed Circuit heat exchangers in a high-temperature helium test facility. Appl. Therm. Eng. 2014, 65, 605–614. [Google Scholar] [CrossRef]

- Kim, J.H.; Baek, S.; Jeong, S.; Jung, J. Hydraulic Performance of a microchannel PCHE. Appl. Therm. Eng. 2010, 30, 2157–2162. [Google Scholar] [CrossRef]

- Sung, J.; Lee, J.Y. Effect of tangled channels on the heat transfer in a printed circuit heat exchanger. Int. J. Heat Mass Transf. 2017, 115, 647–656. [Google Scholar] [CrossRef]

- Yoon, S.H.; No, H.C.; Kang, G.B. Assessment of straight, zigzag, S-shape, and airfoil PCHEs for intermediate heat exchangers of HTGRs and SFRs. Nucl. Eng. Des. 2014, 270, 334–343. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, J.I. Structural assessment of intermediate printed circuit heat exchanger for sodium-cooled fast reactor with supercritical CO2 cycle. Ann. Nucl. Energy 2014, 73, 84–95. [Google Scholar] [CrossRef]

- Song, K.N.; Hong, S.D. Structural Integrity Evaluation of a Lab-Scale PCHE Proto-type under the Test Conditions of HELP. Sci. Tech. Nucl. Install. 2013, 2013, 520145. [Google Scholar] [CrossRef]

- Mizokami, Y.; Igari, T.; Kawashima, F.; Sakakibara, N.; Tanihira, M.; Yuhara, T.; Hiroe, T. Development of structural design procedure of plate-fin heat exchanger for HTGR. Nucl. Eng. Des. 2012, 255, 248–262. [Google Scholar] [CrossRef]

- Mochizuki, H.; Takano, M. Heat transfer in heat exchangers of sodium cooled fast reactor systems. Nucl. Eng. Des. 2008, 239, 295–307. [Google Scholar] [CrossRef]

- Nestell, J.; (MPR Associates, Inc., Washington DC, USA); Sham, T.L.; (Oak Ridge National Laboratory, Tennessee, USA). ASME Code Considerations for the Compact Heat Exchanger. Personal Communication. 2015. [Google Scholar]

- Miwa, Y.; Noishiki, K.; Suzuki, T.; Takatsuki, K. Manufacturing technology of Diffusion-bonded Compact Heat Exchanger (DCHE). Kobelco Tech. Rev. 2013, 32, 51–56. [Google Scholar]

- Kozak, D.; Konjatić, P.; Matejiček, F.; Damjanović, D. Weld Misalignment influence on the structural integrity of cylindrical pressure vessel. Struct. Integr. Life 2009, 10, 153–159. [Google Scholar]

- Brabin, T.A.; Christoper, T.; Rao, B.N. Finite Element analysis of cylindrical pressure vessels having a misalignment in a circumferential joint. Int. J. Press. Vessel. Pip. 2010, 87, 197–201. [Google Scholar] [CrossRef]

- Morgan, W.C.; Bizon, P.T. Comparison of Experimental and Theoretical Stresses at a Mismatch in a Circumferential Joint in a Cylindrical Pressure Vessel; Technical Note; Lewis Research Center: Cleveland, OH, USA, 1966. [Google Scholar]

- Gomez, E. ASME Section III Stress Analysis of a Heat Exchanger Tube Sheet with a misdrilled Hole and Irregular or Thin Ligaments. In Proceedings of the ASME 2013 Pressure Vessel and Piping Conference, Paris, France, 14–18 July 2013; pp. 1–8. [Google Scholar]

- Liu, X.; Song, W.; Yan, Z.; Qiang, W.; Pan, H. Misalignment effect on stress concentration of thickness mismatched plate structures. Proc. Str. Integr. 2016, 2, 2038–2045. [Google Scholar] [CrossRef][Green Version]

- ASME. An International Code 2015 ASME Boiler & Pressure Vessel Code Section III. Rules for Construction of Nuclear Facility Components Division 5 High Temperature Reactors; The American Society of Mechanical Engineer: New York, NY, USA, 2015. [Google Scholar]

- Bartel, N.; Chen, M.; Utgikar, V.P.; Sun, X.; Kim, I.H.; Christensen, R.; Sabharwall, P. Comparative analysis of compact heat exchangers for application as the intermediate heat exchanger for advanced nuclear reactors. Ann. Nucl. Energy 2015, 81, 143–149. [Google Scholar] [CrossRef]

- Yoo, J.; Chang, J.; Lim, J.Y.; Cheon, J.S.; Lee, T.H.; Kim, S.K.; Lee, K.L.; Joo, H.K. Overall System Description and Safety Characteristics of Prototype Gen IV Sodium Cooled Fast Reactor in Korea. Nucl. Eng. Tech. 2016, 48, 1059–1070. [Google Scholar] [CrossRef]

- ASME. An International Code 2015 ASME Boiler & Pressure Vessel Code Section VIII. Rules for Construction of Pressure Vessel Division 2; The American Society of Mechanical Engineer: New York, NY, USA, 2015. [Google Scholar]

- ASME. An International Code 2015 ASME Boiler & Pressure Vessel Code Section II Part D. Materials; The American Society of Mechanical Engineer: New York, NY, USA, 2015. [Google Scholar]

| No | Materials | Tmax (°C) |

|---|---|---|

| 1 | Carbon steel | 370 |

| 2 | Low alloy steel | 370 |

| 3 | Martensitic stainless steel | 370 |

| 4 | Austenitic stainless steel | 425 |

| 5 | Nickel–chromium–iron | 425 |

| 6 | Nickel–copper | 425 |

| Case # | Misalignment (m) | |

|---|---|---|

| Right direction | Left direction | |

| Case 1 | 0 mm | - |

| Case 2 | 0.25 mm | 0.25 mm |

| Case 3 | 0.5 mm | 0.5 mm |

| Case 4 | 0.75 mm | 0.75 mm |

| Case 5 | 0.85 mm | 0.85 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simanjuntak, A.P.; Lee, J.Y. Mechanical Integrity Analysis of a Printed Circuit Heat Exchanger with Channel Misalignment. Appl. Sci. 2020, 10, 2169. https://doi.org/10.3390/app10062169

Simanjuntak AP, Lee JY. Mechanical Integrity Analysis of a Printed Circuit Heat Exchanger with Channel Misalignment. Applied Sciences. 2020; 10(6):2169. https://doi.org/10.3390/app10062169

Chicago/Turabian StyleSimanjuntak, Armanto P., and Jae Young Lee. 2020. "Mechanical Integrity Analysis of a Printed Circuit Heat Exchanger with Channel Misalignment" Applied Sciences 10, no. 6: 2169. https://doi.org/10.3390/app10062169

APA StyleSimanjuntak, A. P., & Lee, J. Y. (2020). Mechanical Integrity Analysis of a Printed Circuit Heat Exchanger with Channel Misalignment. Applied Sciences, 10(6), 2169. https://doi.org/10.3390/app10062169