Controlled-Atmosphere Sintering of KNbO3

Abstract

1. Introduction

2. Materials and Methods

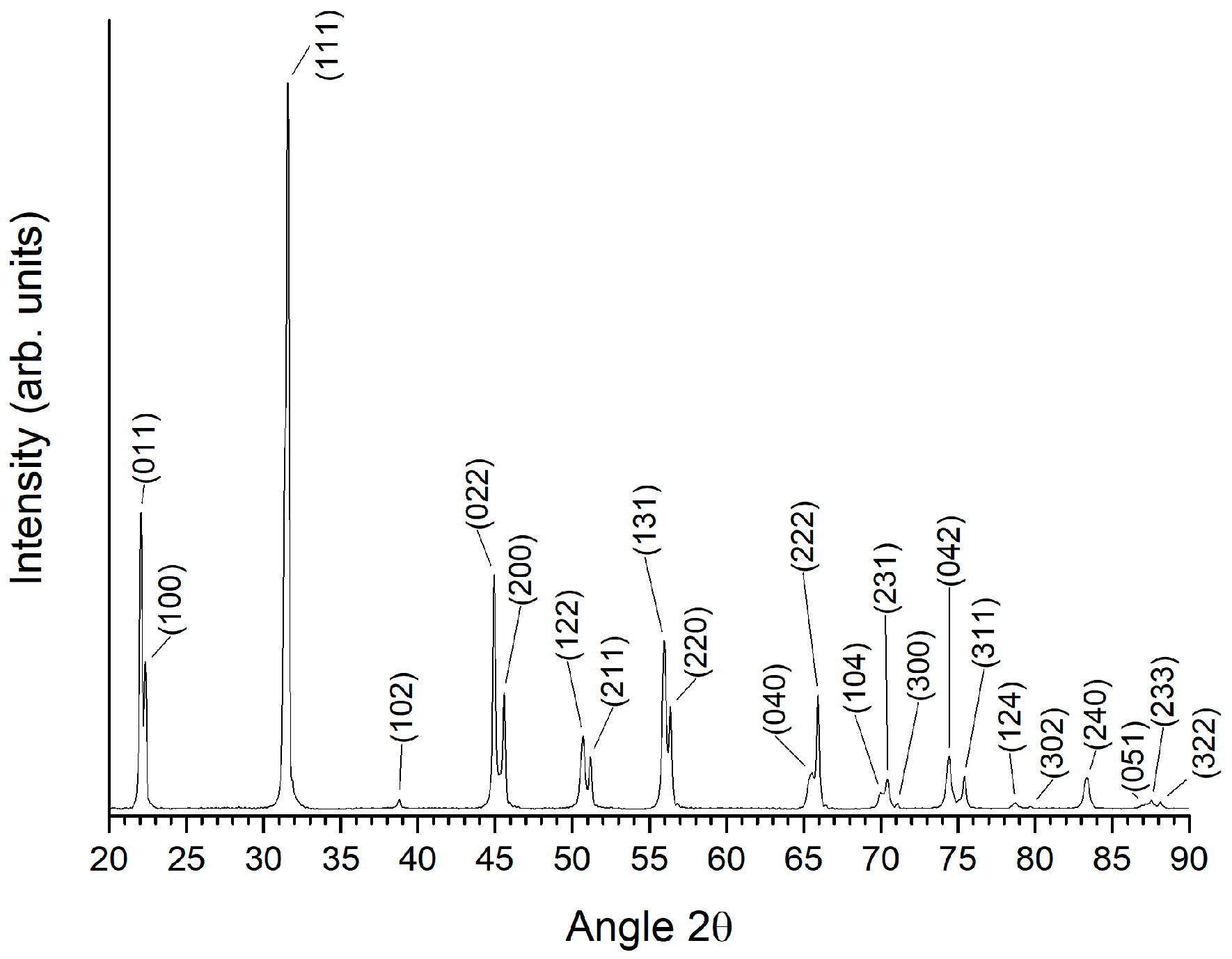

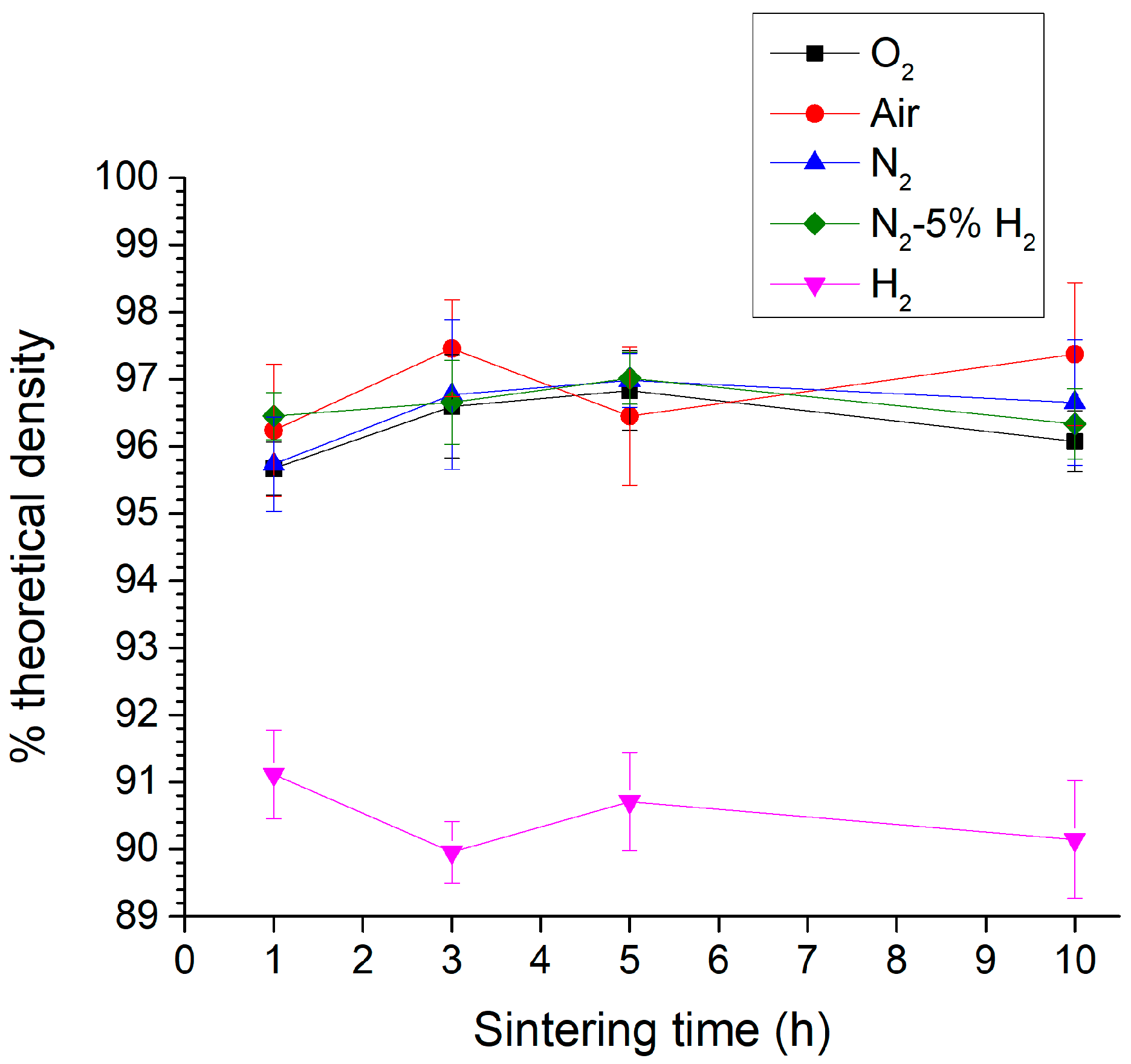

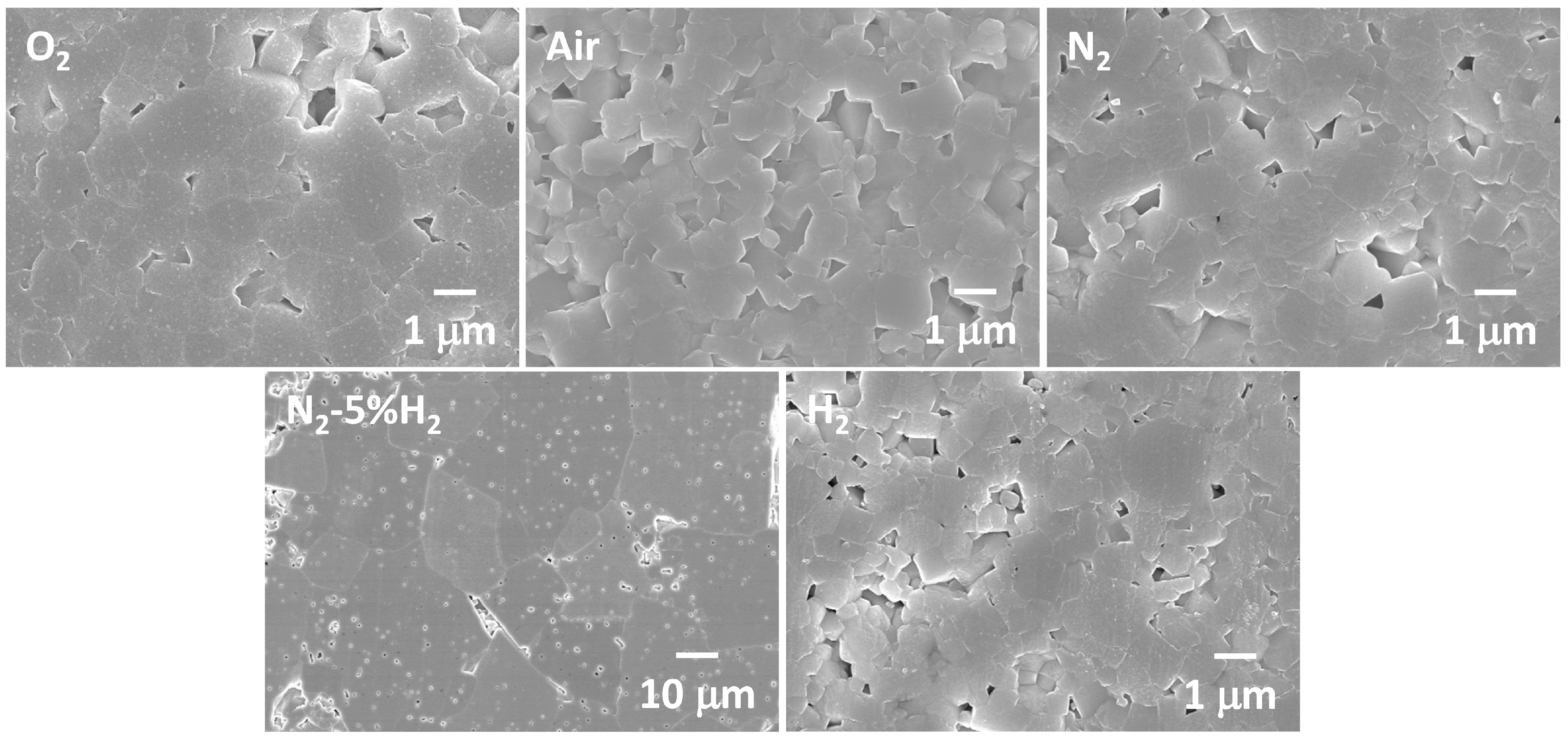

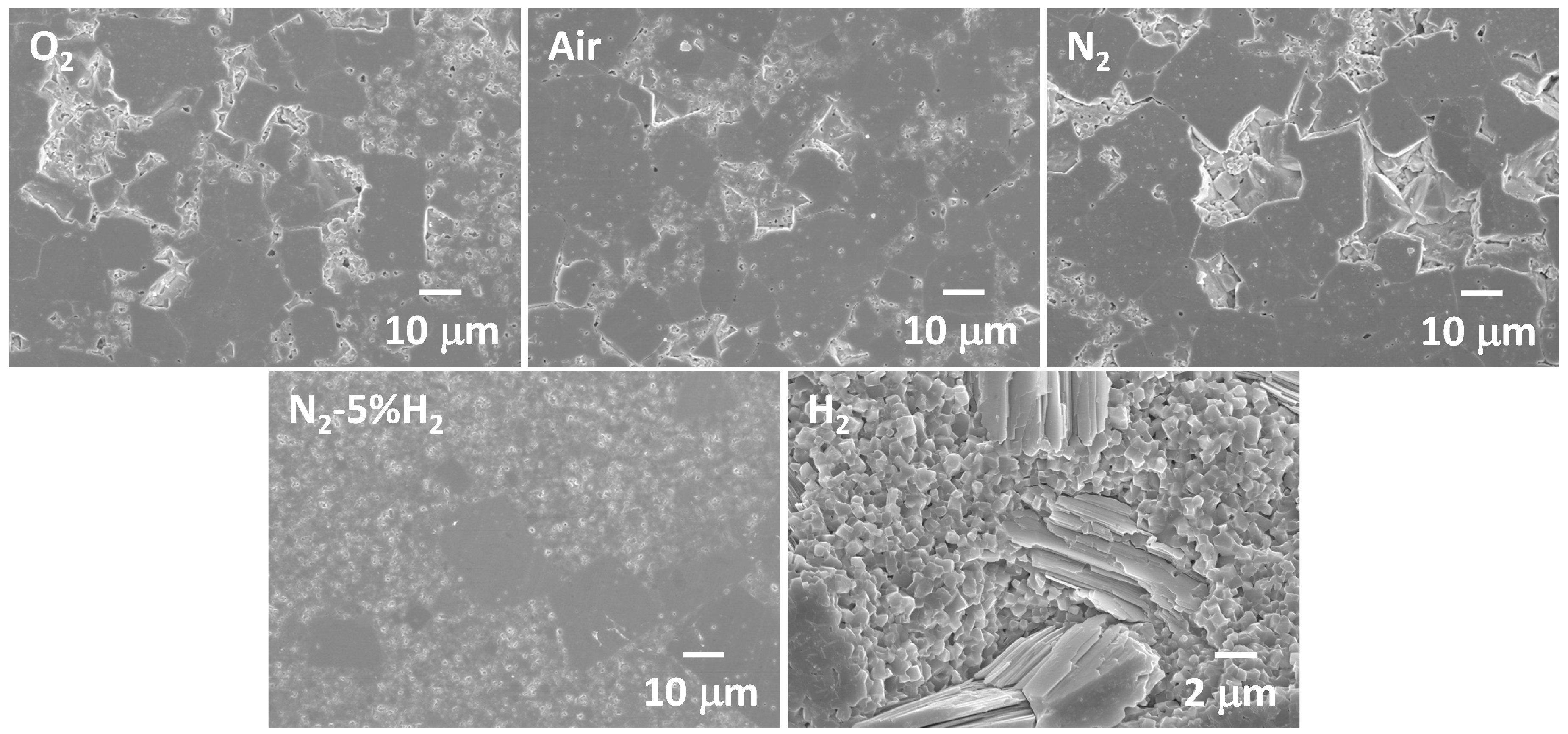

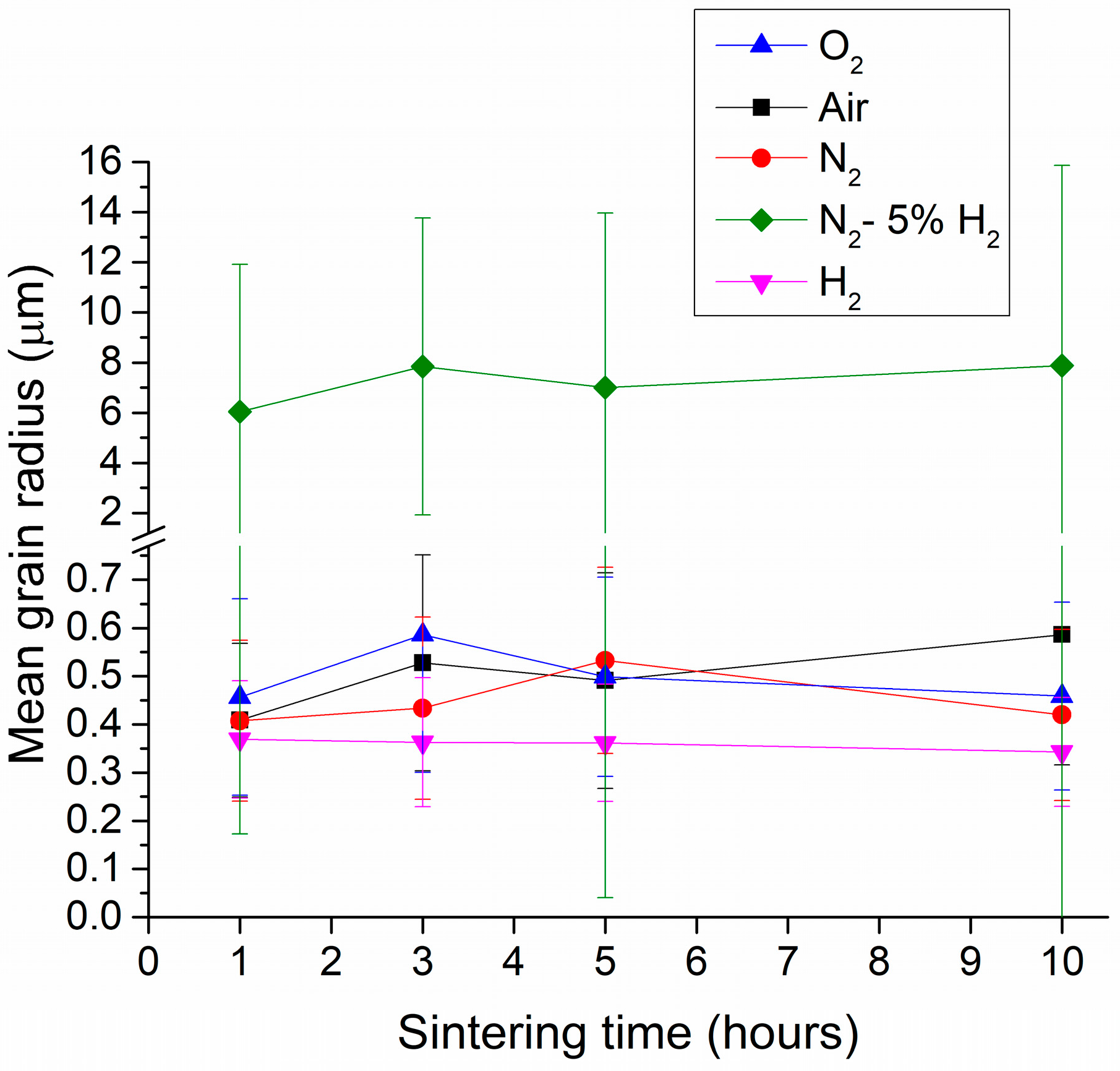

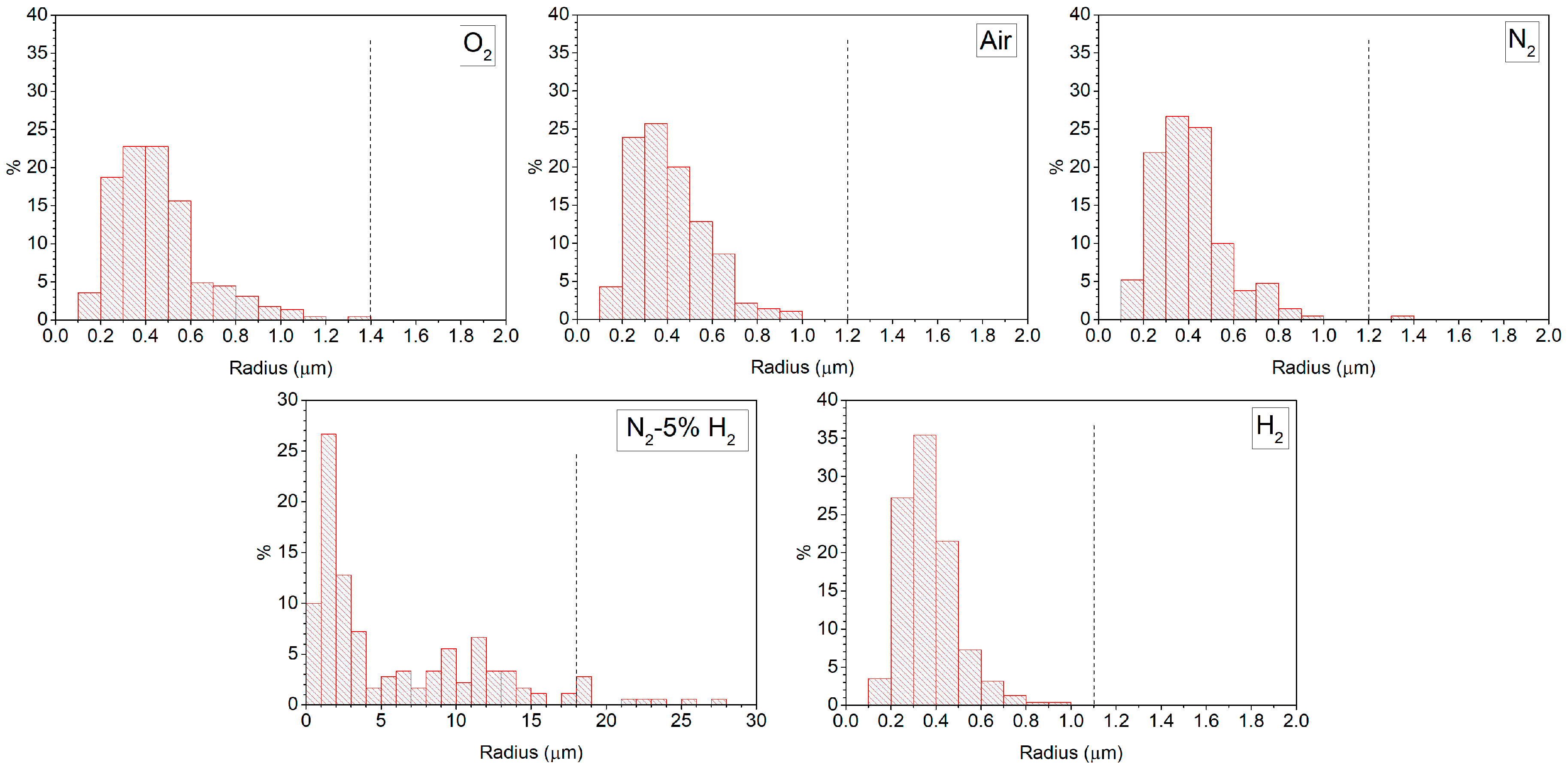

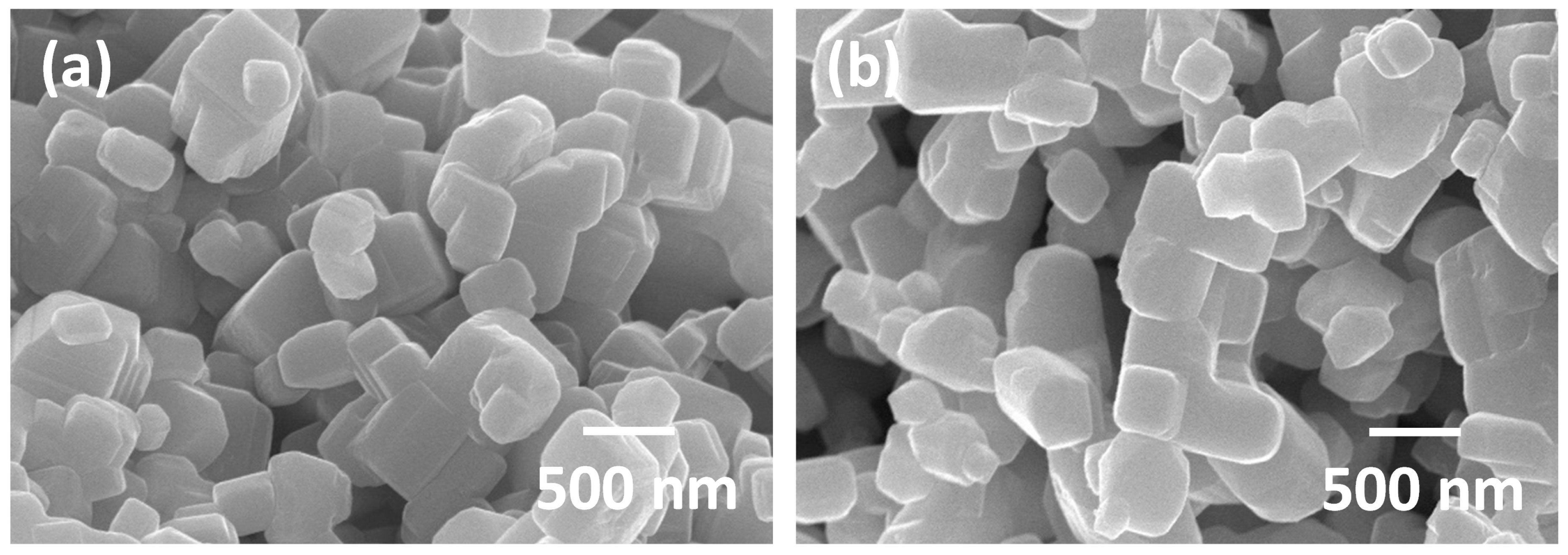

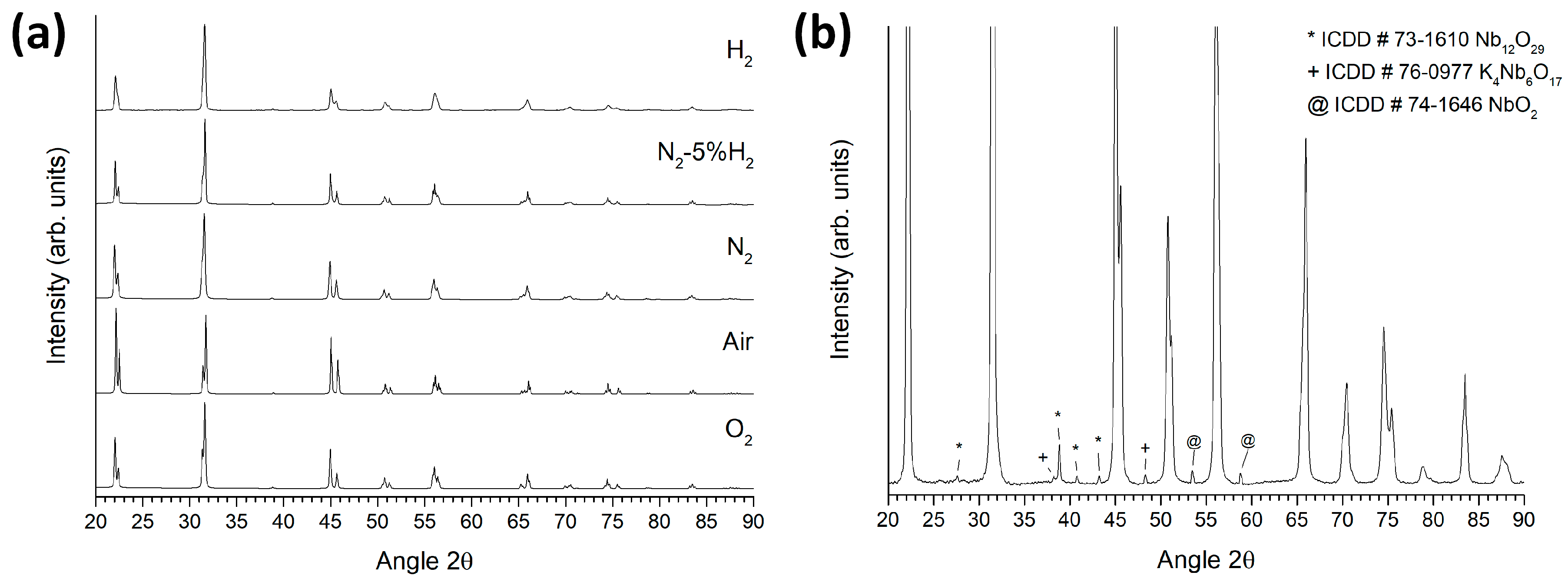

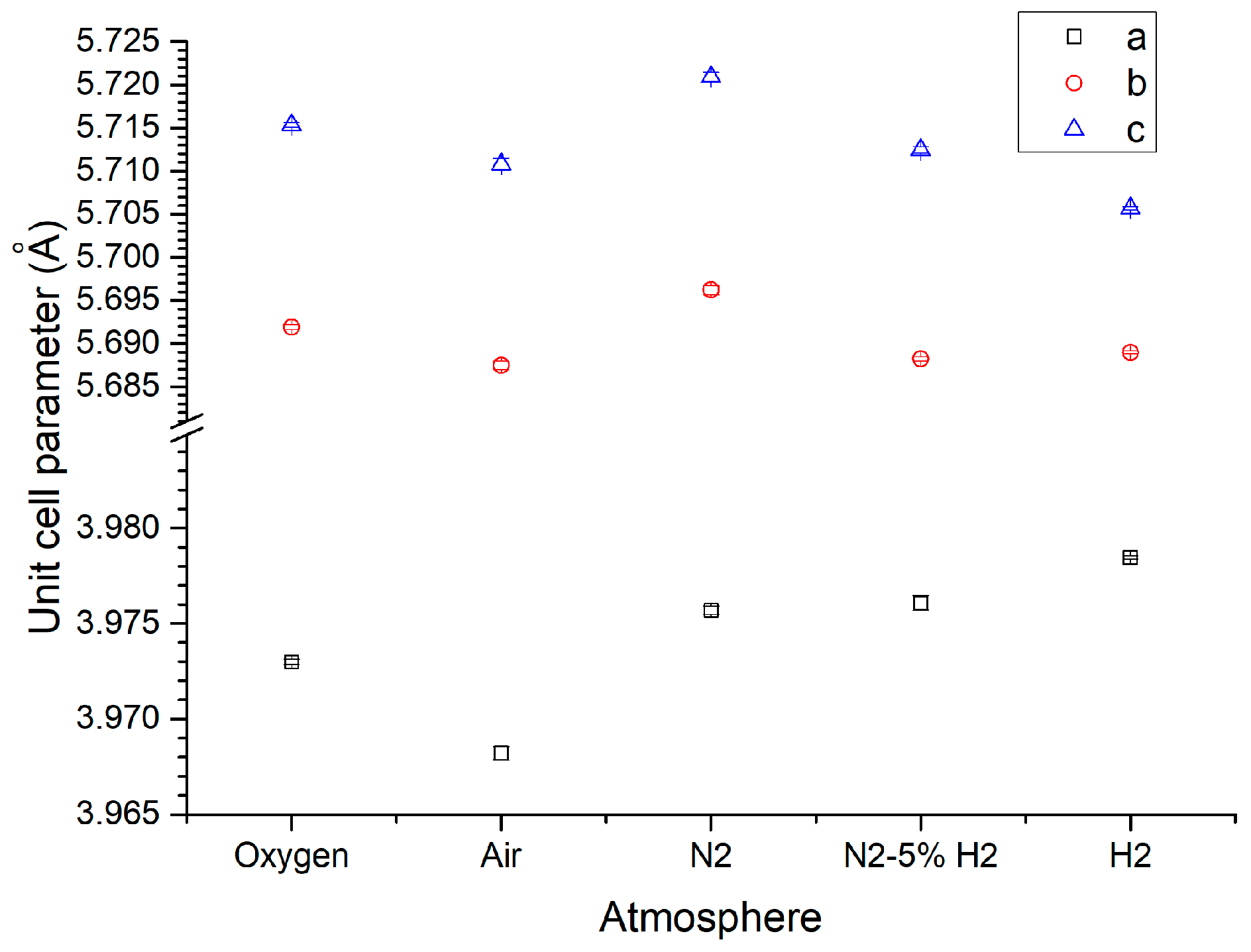

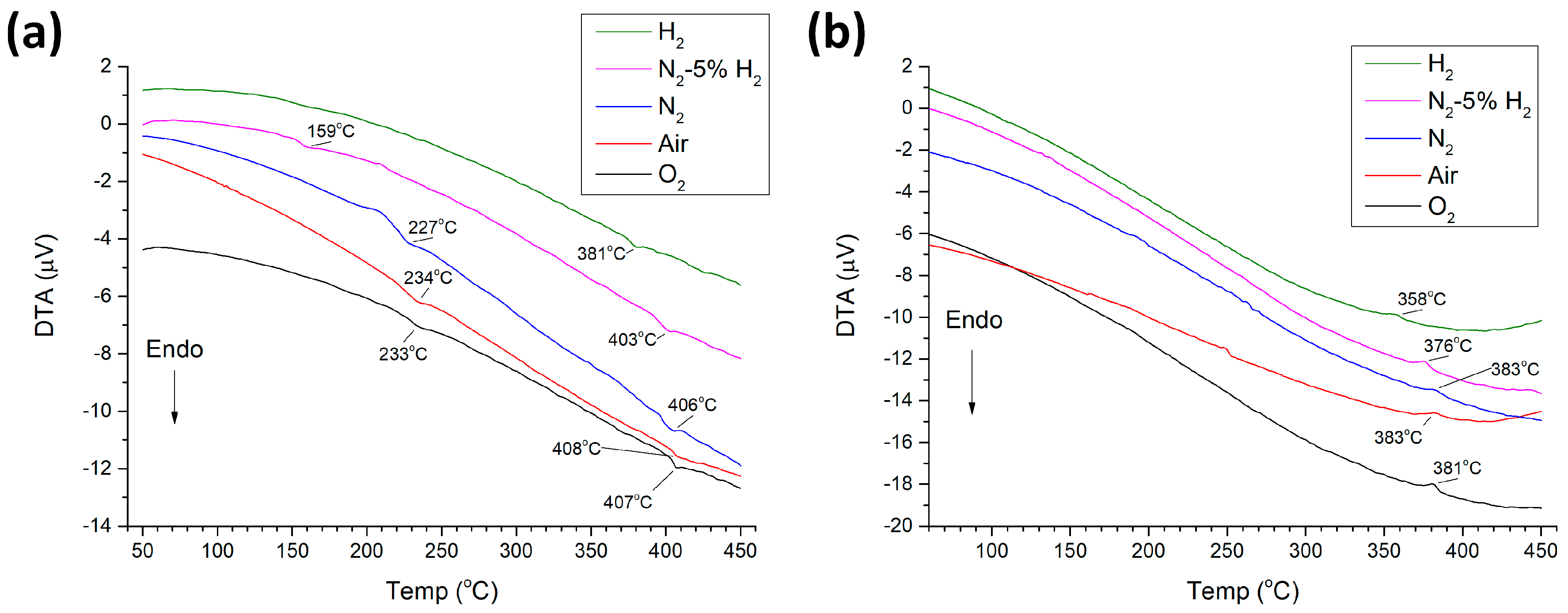

3. Results

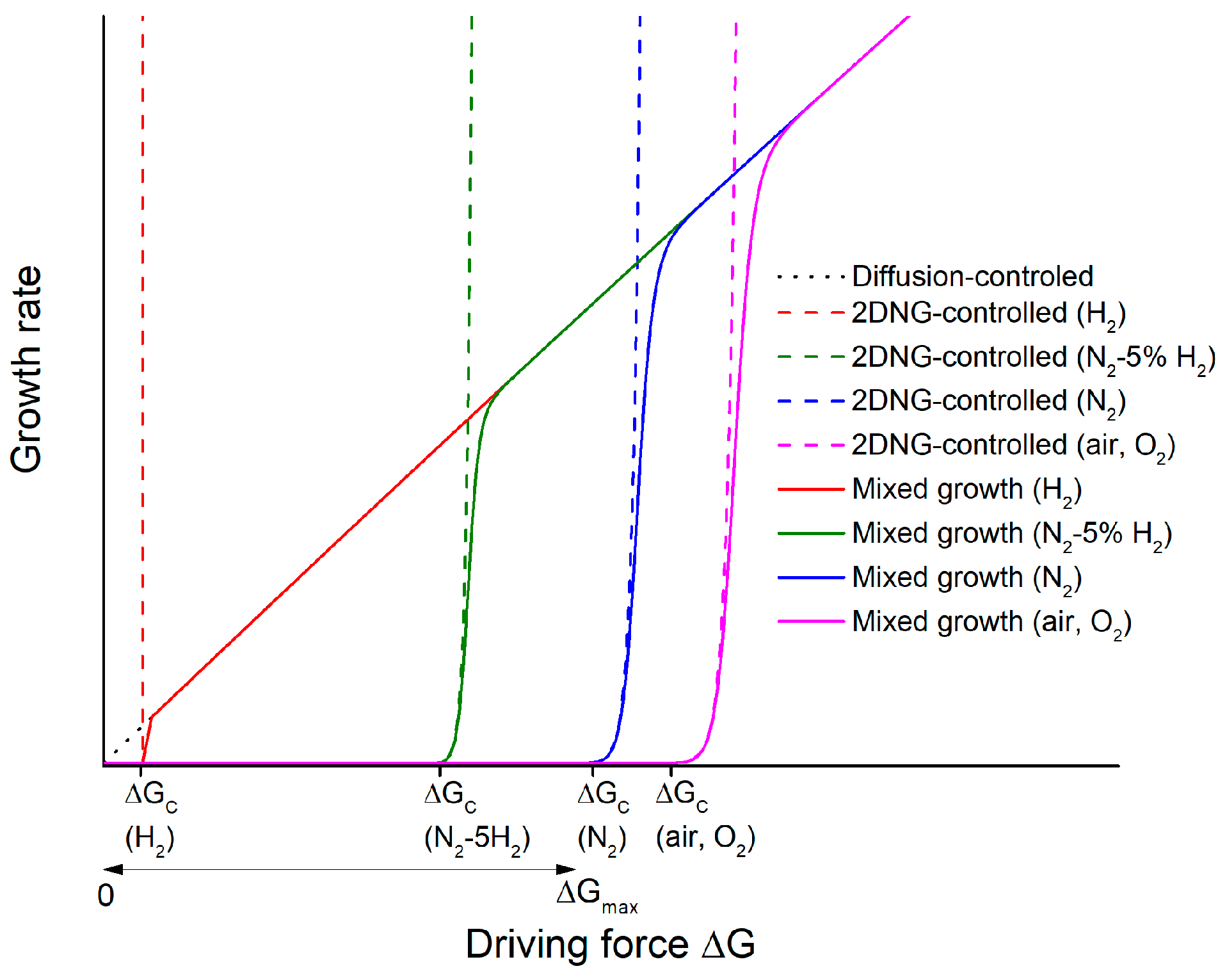

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jaffe, B.; Cook, W.R.; Jaffe, H. Perovskite niobates and tantalates. In Piezoelectric Ceramics; Academic Press: London, UK, 1971; pp. 185–212. [Google Scholar]

- Tennery, V.J.; Hang, K.W. Thermal and X-Ray diffraction studies of the NaNbO3–KNbO3 system. J. Appl. Phys. 1968, 39, 4749–4753. [Google Scholar] [CrossRef]

- Wood, E.A. Polymorphism in potassium niobate, sodium niobate, and other ABO3 compounds. Acta Crystallogr. 1951, 4, 353–362. [Google Scholar] [CrossRef]

- Hewat, A.W. Cubic-tetragonal-orthorhombic-rhombohedral ferroelectric transitions in perovskite potassium niobate: Neutron powder profile refinement of the structures. J. Phys. C Solid State Phys. 1973, 6, 2559–2572. [Google Scholar] [CrossRef]

- Kakimoto, K.-i.; Masuda, I.; Ohsato, H. Solid-solution structure and piezoelectric property of knbo3 ceramics doped with small amounts of elements. Jpn. J. Appl. Phys. 2004, 43, 6706–6710. [Google Scholar] [CrossRef]

- Baier-Saip, J.A.; Ramos-Moor, E.; Cabrera, A.L. Raman study of phase transitions in KNbO3. Solid State Commun. 2005, 135, 367–372. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, K.J. Characterization of the electro-optic modulation properties of a yz-cut potassium niobate single crystal. J. Korean Phys. Soc. 2019, 75, 40–44. [Google Scholar] [CrossRef]

- Kim, I.; Lee, D.; Lee, K.J. Integrated electro-optic platform using ferroelectric crystals with the point symmetry of orthorhombic mm2. Curr. Appl. Phys. 2019, 19, 1046–1051. [Google Scholar] [CrossRef]

- Yu, D.; Liu, Z.; Zhang, J.; Li, S.; Zhao, Z.; Zhu, L.; Liu, W.; Lin, Y.; Liu, H.; Zhang, Z. Enhanced catalytic performance by multi-field coupling in KNbO3 nanostructures: Piezo-photocatalytic and ferro-photoelectrochemical effects. Nano Energy 2019, 58, 695–705. [Google Scholar] [CrossRef]

- Pascual-Gonzalez, C.; Schileo, G.; Murakami, S.; Khesro, A.; Wang, D.; Reaney, I.M.; Feteira, A. Continuously controllable optical band gap in orthorhombic ferroelectric KNbO3-BiFeO3 ceramics. Appl. Phys. Lett. 2017, 110, 172902. [Google Scholar] [CrossRef]

- Li, C.; Jiang, K.; Jiang, J.; Hu, Z.; Liu, A.; Hu, G.; Shi, W.; Chu, J. Enhanced photovoltaic response of lead-free ferroelectric solar cells based on (K,Bi)(Nb,Yb)O3 films. Phys. Chem. Chem. Phys. 2020, 22, 3691–3701. [Google Scholar] [CrossRef]

- Pascual-Gonzalez, C.; Schileo, G.; Khesro, A.; Sterianou, I.; Wang, D.; Reaney, I.M.; Feteira, A. Band gap evolution and a piezoelectric-to-electrostrictive crossover in (1−x)KNbO3–x(Ba0.5Bi0.5)(Nb0.5Zn0.5)O3 ceramics. J. Mater. Chem. C 2017, 5, 1990–1996. [Google Scholar] [CrossRef]

- Balakrishnaiah, R.; Kim, D.W.; Yi, S.S.; Kim, K.D.; Kim, S.H.; Jang, K.; Lee, H.S.; Jeong, J.H. Frequency upconversion fluorescence studies of Er3+/Yb3+-codoped KNbO3 phosphors. Thin Solid Films 2009, 517, 4138–4142. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, D.-J.; Jang, W.-Y.; Moon, A.; Lim, K.-S.; Lee, M. Upconversion Emission in Er and Cr Co-Doped KNbO3 Phosphors. Jpn. J. Appl. Phys. 2011, 50, 06GH11. [Google Scholar] [CrossRef]

- Fang, T.-H.; Hsiao, Y.-J.; Chang, Y.-S.; Chang, Y.-H. Photoluminescent characterization of KNbO3:Eu3+. Mater. Chem. Phys. 2006, 100, 418–422. [Google Scholar] [CrossRef]

- Fisher, J.G.; Thuan, U.T.; Farooq, M.U.; Chandrasekaran, G.; Jung, Y.D.; Hwang, E.C.; Lee, J.J.; Lakshmanan, V.K. Prostate cancer cell-specific cytotoxicity of sub-micron potassium niobate powder. J. Nanosci. Nanotechnol. 2018, 18, 3141–3147. [Google Scholar] [CrossRef]

- Ladj, R.; Magouroux, T.; Eissa, M.; Dubled, M.; Mugnier, Y.; Dantec, R.L.; Galez, C.; Valour, J.-P.; Fessi, H.; Elaissari, A. Aminodextran-coated potassium niobate (KNbO3) nanocrystals for second harmonic bio-imaging. Coll. Surf. A Physicochem. Eng. Asp. 2013, 439, 131–137. [Google Scholar] [CrossRef]

- Nakayama, Y.; Pauzauskie, P.J.; Radenovic, A.; Onorato, R.M.; Saykally, R.J.; Liphardt, J.; Yang, P. Tunable nanowire nonlinear optical probe. Nature 2007, 447, 1098–1101. [Google Scholar] [CrossRef]

- Cai, F.H.; Yu, J.X.; Qian, J.; Wang, Y.; Chen, Z.; Huang, J.Y.; Ye, Z.Z.; He, S.L. Use of tunable second-harmonic signal from KNbO3 nanoneedles to find optimal wavelength for deep-tissue imaging. Laser Photon. Rev. 2014, 8, 865–874. [Google Scholar] [CrossRef]

- Wada, S.; Muraoka, K.; Kakemoto, H.; Tsurumi, T.; Kumagai, H. Enhanced piezoelectric properties of potassium niobate single crystals by domain engineering. Jpn. J. Appl. Phys. 2004, 43, 6692–6700. [Google Scholar] [CrossRef]

- Kakimoto, K.-I.; Masuda, I.; Ohsato, H. Lead-free KNbO3 piezoceramics synthesized by pressure-less sintering. J. Eur. Ceram. Soc. 2005, 25, 2719–2722. [Google Scholar] [CrossRef]

- Matsumoto, K.; Hiruma, Y.; Nagata, H.; Takenaka, T. Electric-field-induced strain in Mn-doped KNbO3 ferroelectric ceramics. Ceram. Int. 2008, 34, 787–791. [Google Scholar] [CrossRef]

- Kim, D.-H.; Joung, M.-R.; Seo, I.-T.; Hur, J.; Kim, J.-H.; Kim, B.-Y.; Lee, H.-J.; Nahm, S. Low-temperature sintering and piezoelectric properties of CuO-Added KNbO3 ceramics. J. Am. Ceram. Soc. 2014, 97, 3897–3903. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, D.-H.; Seo, I.-T.; Hur, J.; Lee, J.-H.; Kim, B.-Y.; Nahm, S. Effect of CuO on the ferroelectric and piezoelectric properties of lead-free KNbO3 ceramics. Sens. Actuators A Phys. 2015, 234, 9–16. [Google Scholar] [CrossRef]

- Kim, D.-H.; Joung, M.-R.; Seo, I.-T.; Hur, J.; Kim, J.-H.; Kim, B.-Y.; Lee, H.-J.; Nahm, S. Influence of sintering conditions on piezoelectric properties of KNbO3 ceramics. J. Eur. Ceram. Soc. 2014, 34, 4193–4200. [Google Scholar] [CrossRef]

- Matsumoto, K.; Hiruma, Y.; Nagata, H.; Takenaka, T. Piezoelectric properties of pure and mn-doped potassium niobate ferroelectric ceramics. Jpn. J. Appl. Phys. 2006, 45, 4479–4483. [Google Scholar] [CrossRef]

- Kato, H.; Ishida, M.; Akiyama, Y. Effects of K4CuNb8O23 and GeO2 addition on microstructure and piezoelectric properties in KNbO3 ceramics. Jpn. J. Appl. Phys. 2019, 58, SLLD03. [Google Scholar] [CrossRef]

- Ullah, S.; Ullah, I.; Iqbal, Y.; Manan, A.; Ali, S.; Khan, A. Influence of P2O5 and SiO2 addition on the phase, microstructure, and electrical properties of KNbO3. Iran. J. Sci. Technol. Trans. A Sci. 2019, 43, 1981–1987. [Google Scholar] [CrossRef]

- Qiu, J.H.; Zhao, T.X.; Chen, Z.H.; Wang, X.Q.; Yuan, N.Y.; Ding, J.N. Piezoelectric and pyroelectric properties of (001) oriented KNbO3 film. Solid State Commun. 2018, 284–286, 1–4. [Google Scholar] [CrossRef]

- Swami, M.; Verma, O.N.; Tomar, V.; Kumar, M.; Srivastav, K.K.; Sathe, V.; Jha, P.A.; Singh, P. Correlation between piezoelectric and magnetic properties of Fe and Sm co-substituted potassium niobate piezoelectric ceramics. Phys. Chem. Chem. Phys. 2018, 20, 18800–18810. [Google Scholar] [CrossRef]

- Hikita, K.; Hiruma, Y.; Nagata, H.; Takenaka, T. Shear-Mode Piezoelectric Properties of KNbO3-Based Ferroelectric Ceramics. Jpn. J. Appl. Phys. 2009, 48, 07GA05. [Google Scholar] [CrossRef]

- Tan, Z.; Peng, Y.T.; An, J.; Zhang, Q.M.; Zhu, J.G. Intrinsic origin of enhanced piezoelectricity in alkali niobate-based lead-free ceramics. J. Am. Ceram. Soc. 2019, 102, 5262–5270. [Google Scholar] [CrossRef]

- Tashiro, S.; Nagamatsu, H.; Nagata, K. Sinterability and Piezoelectric Properties of KNbO3 Ceramics after Substituting Pb and Na for K. Jpn. J. Appl. Phys. 2002, 41, 7113–7118. [Google Scholar] [CrossRef]

- Nagata, H.; Matsumoto, K.; Hirosue, T.; Hiruma, Y.; Takenaka, T. Fabrication and Electrical Properties of Potassium Niobate Ferroelectric Ceramics. Jpn. J. Appl. Phys. 2007, 46, 7084–7088. [Google Scholar] [CrossRef]

- Nagata, H.; Sato, S.; Hiruma, Y.; Takenaka, T. Fabrication of Dense KNbO3 Ceramics Derived from KHCO3 as a Starting Material. Appl. Phys. Express 2012, 5, 011502. [Google Scholar] [CrossRef]

- Kobayashi, K.; Doshida, Y.; Mizuno, Y.; Randall, C.A. Piezoelectric and dielectric properties of Sn-doped (Na0.5K0.5)NbO3 ceramics processed under low oxygen partial pressure atmosphere. Jpn. J. Appl. Phys. 2014, 53, 011501. [Google Scholar] [CrossRef]

- Kobayashi, K.; Doshida, Y.; Mizuno, Y.; Randall, C.A. A route forwards to narrow the performance gap between pzt and lead-free piezoelectric ceramic with low oxygen partial pressure processed (Na0.5K0.5)NbO3. J. Am. Ceram. Soc. 2012, 95, 2928–2933. [Google Scholar] [CrossRef]

- Huan, Y.; Wang, X.; Wei, T.; Xie, J.; Ye, Z.; Zhao, P.; Li, L. Defect engineering of high-performance potassium sodium niobate piezoelectric ceramics sintered in reducing atmosphere. J. Am. Ceram. Soc. 2017, 100, 2024–2033. [Google Scholar] [CrossRef]

- Kawada, S.; Kimura, M.; Higuchi, Y.; Takagi, H. (K,Na)NbO3-based multilayer piezoelectric ceramics with nickel inner electrodes. Appl. Phys. Express 2009, 2, 111401. [Google Scholar] [CrossRef]

- Hayashi, H.; Kawada, S.; Kimura, M.; Nakai, Y.; Tabata, T.; Shiratsuyu, K.; Nada, K.; Takagi, H. Reliability of nickel inner electrode lead-free multilayer piezoelectric ceramics. Jpn. J. Appl. Phys. 2012, 51, 09LD01. [Google Scholar] [CrossRef]

- Liu, C.; Liu, P.; Kobayashi, K.; Randall, C. Base metal Co-fired (Na,K)NbO3 structures with enhanced piezoelectric performance. J. Electroceram. 2014, 32, 301–306. [Google Scholar] [CrossRef]

- Kobayashi, K.; Doshida, Y.; Mizuno, Y.; Randall, C.A. Possibility of cofiring a nickel inner electrode in a (na0.5k0.5)nbo3–lif piezoelectric actuator. Jpn. J. Appl. Phys. 2013, 52, 09KD07. [Google Scholar] [CrossRef]

- Vendrell, X.; García, J.E.; Rubio-Marcos, F.; Ochoa, D.A.; Mestres, L.; Fernández, J.F. Exploring different sintering atmospheres to reduce nonlinear response of modified KNN piezoceramics. J. Eur. Ceram. Soc. 2013, 33, 825–831. [Google Scholar] [CrossRef]

- Fisher, J.G.; Kang, S.J.L. Microstructural changes in (Na0.5K0.5)NbO3 ceramics sintered in various atmospheres. J. Eur. Ceram. Soc. 2009, 29, 2581–2588. [Google Scholar] [CrossRef]

- Fisher, J.G.; Rout, D.; Moon, K.S.; Kang, S.J.L. High-temperature X-ray diffraction and Raman spectroscopy study of (K0.5Na0.5)NbO3 ceramics sintered in oxidizing and reducing atmospheres. Mater. Chem. Phys. 2010, 120, 263–271. [Google Scholar] [CrossRef]

- Fisher, J.G.; Choi, S.Y.; Kang, S.J.L. Influence of sintering atmosphere on abnormal grain growth behaviour in potassium sodium niobate ceramics sintered at low temperature. J. Korean Ceram. Soc. 2011, 48, 641–647. [Google Scholar] [CrossRef]

- Fisher, J.G.; Rout, D.; Moon, K.S.; Kang, S.J.L. Structural changes in potassium sodium niobate ceramics sintered in different atmospheres. J. Alloys Compd. 2009, 479, 467–472. [Google Scholar] [CrossRef]

- International Centre for Diffraction Data Powder Diffraction File #71-0946. Available online: http://www.icdd.com/ (accessed on 20 March 2020).

- Samardzžija, Z.; Bernik, S.; Marinenko, R.B.; Malič, B.; Čeh, M. An EPMA study on KNbO3 and NaNbO3 single crystals–potential reference materials for quantitative microanalysis. Microchim. Acta 2004, 145, 203–208. [Google Scholar] [CrossRef]

- Moon, K.S.; Kang, S.J.L. Coarsening behaviour of round-edged cubic grains in the Na1/2Bi1/2TiO3-BaTiO3 System. J. Am. Ceram. Soc. 2008, 91, 3191–3196. [Google Scholar] [CrossRef]

- Malič, B.; Razpotnik, H.; Koruza, J.; Kokalj, S.; Cilenšek, J.; Kosec, M. Linear Thermal Expansion of Lead-Free Piezoelectric K0.5Na0.5NbO3 Ceramics in a Wide Temperature Range. J. Am. Ceram. Soc. 2011, 94, 2273–2275. [Google Scholar] [CrossRef]

- Kang, S.J.L. Normal grain growth and second-phase particles. In Sintering: Densification, Grain Growth & Microstructure; Elsevier Butterworth Heinemann: Oxford, UK, 2005; pp. 91–96. [Google Scholar]

- Chiang, Y.M.; Birnie, D.; Kingery, W.D. Chapter 5 Microstructure. In Physical Ceramics: Principles for Ceramic Science and Engineering; John Wiley & Sons: New York, NY, USA, 1997; pp. 351–513. [Google Scholar]

- Kang, S.J.L.; Jung, Y.I.; Jung, S.H.; Fisher, J.G. Interface structure-dependent grain growth behaviour in polycrystals. In Microstructural Design of Advanced Engineering Materials; Molodov, D.A., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; pp. 299–322. [Google Scholar]

- Jo, W.; Kim, D.Y.; Hwang, N.M. Effect of interface structure on the microstructural evolution of ceramics. J. Am. Ceram. Soc. 2006, 89, 2369–2380. [Google Scholar] [CrossRef]

- Jung, Y.I.; Yoon, D.Y.; Kang, S.J.L. Coarsening of polyhedral grains in a liquid matrix. J. Mater. Res. 2009, 24, 2949–2959. [Google Scholar] [CrossRef]

- Searcy, A.W.; Bullard, J.W. Thermodynamics and kinetics of surface area changes of faceted particles. J. Am. Ceram. Soc. 1994, 77, 2314–2318. [Google Scholar] [CrossRef]

- Kang, S.J.L. Grain shape and grain growth in a liquid matrix. In Sintering: Densification, Grain Growth & Microstructure; Elsevier Butterworth Heinemann: Oxford, UK, 2005; pp. 205–226. [Google Scholar]

- Choi, S.Y.; Kang, S.J.L. Sintering kinetics by structural transition at grain boundaries in barium titanate. Acta Mater. 2004, 52, 2937–2943. [Google Scholar] [CrossRef]

- Markov, I.V. Crystal-ambient phase equilibrium. In Crystal Growth for Beginners: Fundamentals of Nucleation, Crystal Growth and Epitaxy, 2nd ed.; World Scientific: Singapore, 2003; pp. 1–76. [Google Scholar]

- Burton, W.K.; Cabrera, N.; Frank, F.C. The growth of crystals and the equilibrium structure of their surfaces. Philos. Trans. R. Soc. A 1951, 243, 299–358. [Google Scholar]

- Hirth, J.P.; Pound, G.M. Growth and evaporation of liquids and dislocation-free crystals. In Condensation and Evaporation: Nucleation and Growth Kinetics; Pergamon Press: Oxford, UK, 1963; pp. 77–106. [Google Scholar]

- Markov, I.V. Nucleation. In Crystal Growth for Beginners: Fundamentals of Nucleation, Crystal Growth and Epitaxy, 2nd ed.; World Scientific: Singapore, 2003; pp. 77–180. [Google Scholar]

- Peteves, S.D.; Abbaschian, R. Growth kinetics of solid-liquid Ga interfaces: Part I. Experimental. Metall. Trans. A 1991, 22, 1259–1270. [Google Scholar] [CrossRef]

- Peteves, S.D.; Abbaschian, R. Growth kinetics of solid-liquid Ga interfaces: Part II. Theoretical. Metall. Trans. A 1991, 22, 1271–1286. [Google Scholar] [CrossRef]

- An, S.M.; Yoon, B.K.; Chung, S.Y.; Kang, S.J.L. Nonlinear driving force-velocity relationship for the migration of faceted boundaries. Acta Mater. 2012, 60, 4531–4539. [Google Scholar] [CrossRef]

- Kang, S.J.L.; Lee, M.G.; An, S.M. Microstructural evolution during sintering with control of the interface structure. J. Am. Ceram. Soc. 2009, 92, 1464–1471. [Google Scholar] [CrossRef]

- Fisher, J.G.; Kang, S.-J.L. Strategies and practices for suppressing abnormal grain growth during liquid phase sintering. J. Am. Ceram. Soc. 2019, 102, 717–735. [Google Scholar] [CrossRef]

- Kizuka, T. Atomic processes of grain-boundary migration and phase transformation in zinc oxide nanocrystallites. Philos. Mag. Lett. 1999, 79, 417–422. [Google Scholar] [CrossRef]

- Koo, J.B.; Yoon, D.Y. Abnormal grain growth in bulk Cu—The dependence on initial grain size and annealing temperature. Metall. Mater. Trans. A 2001, 32, 1911–1926. [Google Scholar] [CrossRef]

- Merkle, K.L.; Thompson, L.J. Atomic-scale observation of grain boundary motion. Mater. Lett. 2001, 48, 188–193. [Google Scholar] [CrossRef]

- Merkle, K.L.; Thompson, L.J.; Phillipp, F. Collective effects in grain boundary migration. Phys. Rev. Lett. 2002, 88, 225501. [Google Scholar] [CrossRef] [PubMed]

- Yoon, D.Y.; Park, C.W.; Koo, J.B. The step growth hypothesis for abnormal grain growth. In Ceramic Interfaces 2; Institute of Materials: London, UK, 2001; pp. 3–21. [Google Scholar]

- Lee, S.B.; Kim, Y.-M. Kinetic roughening of a Σ5 tilt grain boundary in SrTiO3. Acta Mater. 2009, 57, 5264–5269. [Google Scholar] [CrossRef]

- Jung, S.H.; Yoon, D.Y.; Kang, S.J.L. Mechanism of abnormal grain growth in ultrafine-grained nickel. Acta Mater. 2013, 61, 5685–5693. [Google Scholar] [CrossRef]

- Jung, S.H.; Kang, S.J.L. An explanation for the formation of polyhedral abnormal grains in single-phase systems. Scr. Mater. 2014, 82, 49–52. [Google Scholar] [CrossRef]

- Jung, S.H.; Kang, S.J.L. Repetitive grain growth behaviour with increasing temperature and grain boundary roughening in a model nickel system. Acta Mater. 2014, 69, 283–291. [Google Scholar] [CrossRef]

- Kang, S.J.L.; Ko, S.Y.; Moon, S.Y. Mixed control of boundary migration and the principle of microstructural evolution. J. Ceram. Soc. Jpn. 2016, 124, 259–267. [Google Scholar] [CrossRef]

- Farooq, M.U.; Fisher, J.G. Growth of (Na0.5K0.5)NbO3–SrTiO3 lead-free piezoelectric single crystals by the solid state crystal growth method and their characterization. Ceram. Int. 2014, 40, 3199–3207. [Google Scholar] [CrossRef]

- Jo, W.; Hwang, N.M.; Kim, D.Y. Effect of Crystal Shape on the Grain Growth during Liquid Phase Sintering of Ceramics. J. Korean Ceram. Soc. 2006, 43, 728–733. [Google Scholar]

- Popovič, A.; Bencze, L.; Koruza, J.; Malič, B. Vapour pressure and mixing thermodynamic properties of the KNbO3–NaNbO3 system. RSC Advances 2015, 5, 76249–76256. [Google Scholar] [CrossRef]

- Wortis, M. Equilibrium Crystal Shapes and Interfacial Phase Transitions. In Chemistry and Physics of Solid Surfaces VII; Vanselow, R., Howe, R., Eds.; Springer: Berlin/Heidelberg, Germany, 1988; pp. 367–405. [Google Scholar]

- Jeong, H.-C.; Williams, E.D. Steps on surfaces: Experiment and theory. Surf. Sci. Rep. 1999, 34, 171–294. [Google Scholar] [CrossRef]

- West, A.R. Solid State Chemistry and its Applications, 2nd ed.; John Wiley & Sons Ltd.: Chichester, UK, 2014; pp. 87–124. [Google Scholar]

- Panlener, R.J.; Blumenthal, R.N. Ti-Rich Nonstoichiometric BaTiO3: III, High-Temperature Thermodynamic and X-Ray Diffraction Measurements. J. Am. Ceram. Soc. 1971, 54, 610–613. [Google Scholar] [CrossRef]

- Härdtl, K.H.; Wernicke, R. Lowering the curie temperature in reduced BaTiO3. Solid State Commun. 1972, 10, 153–157. [Google Scholar] [CrossRef]

- Khattak, C.P.; Cox, D.E. Structural studies of the (La, Sr) CrO3 system. Mater. Res. Bull. 1977, 12, 463–471. [Google Scholar] [CrossRef]

- Salje, E.; Bismayer, U.; Wruck, B.; Hensler, J. Influence of lattice imperfections on the transition temperatures of structural phase transitions: The plateau effect. Phase Transitions 1991, 35, 61–74. [Google Scholar] [CrossRef]

- Lee, S.; Liu, Z.-K.; Kim, M.-H.; Randall, C.A. Influence of nonstoichiometry on ferroelectric phase transition in BaTiO3. J. Appl. Phys. 2007, 101, 054119. [Google Scholar] [CrossRef]

- Bhaumik, I.; Ganesamoorthy, S.; Bhatt, R.; Karnal, A.K.; Wadhawan, V.K.; Gupta, P.K.; Kitamura, K.; Takekawa, S.; Nakamura, M. The ferroelectric phase transition in lithium tantalate single crystals: A composition-dependence study. J. Appl. Phys. 2008, 103, 014108. [Google Scholar] [CrossRef]

- Ellingham Diagrams. Available online: http://web.mit.edu/2.813/www/readings/Ellingham_diagrams.pdf (accessed on 28 February 2020).

- Shigemi, A.; Wada, T. Enthalpy of formation of various phases and formation energy of point defects in perovskite-type NaNbO3 by first-principles calculation. Jpn. J. Appl. Phys. 2004, 43, 6793. [Google Scholar] [CrossRef]

- Shigemi, A.; Wada, T. Evaluations of phases and vacancy formation energies in KNbO3 by first-principles calculation. Jpn. J. Appl. Phys. 2005, 44, 8048. [Google Scholar] [CrossRef]

- Popovič, A.; Bencze, L.; Koruza, J.; Malič, B.; Kosec, M. Knudsen effusion mass spectrometric approach to the thermodynamics of Na2O–Nb2O5 system. Int. J. Mass Spectrom. 2012, 309, 70–78. [Google Scholar] [CrossRef]

- International Centre for Diffraction Data Powder Diffraction File #76-0977. Available online: http://www.icdd.com/ (accessed on 20 March 2020).

- Rubio-Marcos, F.; Fernandez, J.F.; Ochoa, D.A.; García, J.E.; Rojas-Hernandez, R.E.; Castro, M.; Ramajo, L. Understanding the piezoelectric properties in potassium-sodium niobate-based lead-free piezoceramics: Interrelationship between intrinsic and extrinsic factors. J. Eur. Ceram. Soc. 2017, 37, 3501–3509. [Google Scholar] [CrossRef]

- Song, H.-C.; Cho, K.-H.; Park, H.-Y.; Ahn, C.-W.; Nahm, S.; Uchino, K.; Park, S.-H.; Lee, H.-G. Microstructure and Piezoelectric Properties of (1−x)(Na0.5K0.5)NbO3–xLiNbO3 Ceramics. J. Am. Ceram. Soc. 2007, 90, 1812–1816. [Google Scholar] [CrossRef]

- Huo, S.; Yuan, S.; Tian, Z.; Wang, C.; Qiu, Y. Grain Size Effects on the Ferroelectric and Piezoelectric Properties of Na0.5K0.5NbO3 Ceramics Prepared by Pechini Method. J. Am. Ceram. Soc. 2012, 95, 1383–1387. [Google Scholar] [CrossRef]

- Shen, Z.-Y.; Zhen, Y.; Wang, K.; Li, J.-F. Influence of Sintering Temperature on Grain Growth and Phase Structure of Compositionally Optimized High-Performance Li/Ta-Modified (Na,K)NbO3 Ceramics. J. Am. Ceram. Soc. 2009, 92, 1748–1752. [Google Scholar] [CrossRef]

- Cheol Woo, A.; Chee Sung, P.; Dwight, V.; Sahn, N.; Dong Heon, K.; Kyoo Sik, B.; Shashank, P. Correlation between Phase Transitions and Piezoelectric Properties in Lead-Free (K,Na,Li)NbO3 –BaTiO3 Ceramics. Jpn. J. Appl. Phys. 2008, 47, 8880. [Google Scholar]

- Iamsasri, T.; Tutuncu, G.; Uthaisar, C.; Wongsaenmai, S.; Pojprapai, S.; Jones, J.L. Electric field-induced phase transitions in Li-modified Na0.5K0.5NbO3 at the polymorphic phase boundary. J. Appl. Phys. 2015, 117, 024101. [Google Scholar] [CrossRef]

- Ochoa, D.A.; Esteves, G.; Jones, J.L.; Rubio-Marcos, F.; Fernández, J.F.; García, J.E. Extrinsic response enhancement at the polymorphic phase boundary in piezoelectric materials. Appl. Phys. Lett. 2016, 108, 142901. [Google Scholar] [CrossRef]

- Moulson, A.J.; Herbert, J.M. Chapter 5 dielectrics and insulators. In Electroceramics: Materials, Properties, Applications, 2nd ed.; John Wiley & Sons: Chichester, UK, 2005; pp. 243–337. [Google Scholar]

- Wang, Z.; Huan, Y.; Feng, Y.; Qiu, Y.; Wei, T.; Zuo, R. Design of p-type NKN-based piezoelectric ceramics sintered in low oxygen partial pressure by defect engineering. J. Am. Ceram. Soc. 2020, in press. [Google Scholar] [CrossRef]

| Element | Matrix Grains | Secondary Phase |

|---|---|---|

| K | 22.3 ± 5.1 | 18.8 ± 8.1 |

| Nb | 24.1 ± 5.9 | 29.6 ± 12.3 |

| O | 53.6 ± 10.5 | 51.6 ± 20.4 |

| K/Nb ratio | 0.9 ± 0.1 | 0.6 ± 0.0 |

| Sintering Atmosphere | Orthorhombic-Tetragonal Phase Transition Temperature (°C) | Tetragonal-Cubic Phase Transition Temperature (°C) | Cubic-Tetragonal Phase Transition Temperature (°C) |

|---|---|---|---|

| O2 | 233 | 407 | 381 |

| Air | 234 | 408 | 383 |

| N2 | 227 | 406 | 383 |

| N2-5% H2 | 159 | 403 | 376 |

| H2 | - | 381 | 358 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trung, D.T.; Fisher, J.G. Controlled-Atmosphere Sintering of KNbO3. Appl. Sci. 2020, 10, 2131. https://doi.org/10.3390/app10062131

Trung DT, Fisher JG. Controlled-Atmosphere Sintering of KNbO3. Applied Sciences. 2020; 10(6):2131. https://doi.org/10.3390/app10062131

Chicago/Turabian StyleTrung, Doan Thanh, and John G. Fisher. 2020. "Controlled-Atmosphere Sintering of KNbO3" Applied Sciences 10, no. 6: 2131. https://doi.org/10.3390/app10062131

APA StyleTrung, D. T., & Fisher, J. G. (2020). Controlled-Atmosphere Sintering of KNbO3. Applied Sciences, 10(6), 2131. https://doi.org/10.3390/app10062131