Adsorption Cold Storage for Mobile Applications

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

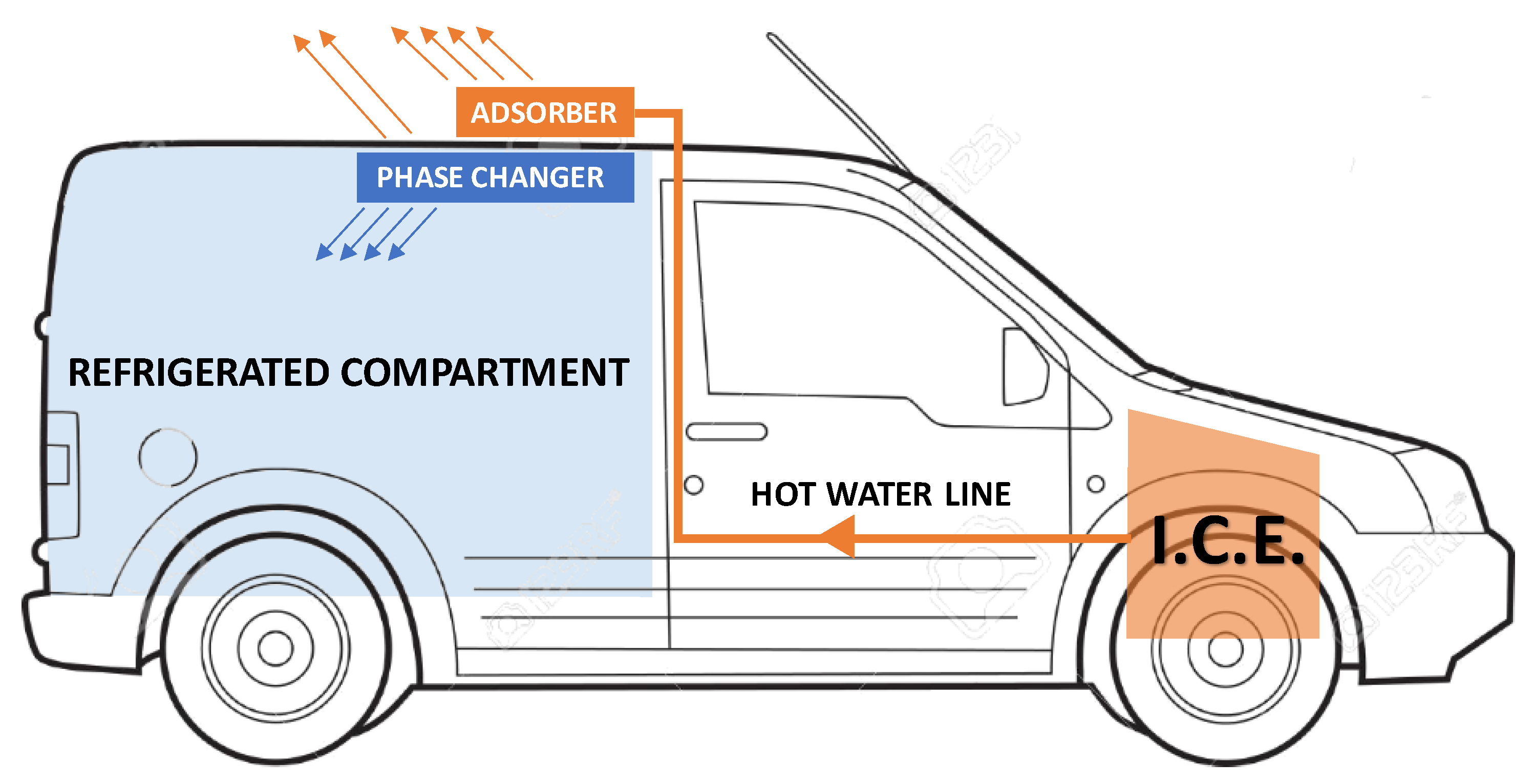

2.1. Concept Description

2.2. Design of the Adsorber

2.3. The Phase Changer

2.4. The Hydraulic Circuit

2.5. Testing Procedure

- The average discharge power during each cycle, calculated as the mean power during the discharge phase.

- The stored energy for mass unit of the adsorbent, calculated as the ratio of the total energy stored during each test and the total mass of adsorbent:

- The thermal COP of the system; in this case, corresponds to the storage efficiency of the system, since it is the ratio between the cooling energy recovered and the energy used as input.

2.5.1. Testing Procedure for a Pelletized Adsorber

2.5.2. Testing Procedure with the Composite Adsorber Based on an Aluminum, Porous Structure and a SAPO-34 Coating

- Initial “mapping” tests, aimed at defining the achievable energy capacity under different boundary conditions.

- “Charge effect” tests, aimed at defining the possible benefits arising from realizing the charge of the system with a low condensation temperature. Such tests were realized in various boundary conditions as well, in order to obtain information useful for different applications.

- Four temperature tests, during which the charging of the system with a low condensation temperature, the release of adsorption heat, and the removal of heat at different temperatures have been analyzed.

- Heat of desorption is provided at the temperature of the heat source—HT (high temperature);

- Heat of condensation and heat of adsorption are released at the same temperature—MT (medium temperature);

- Heat of evaporation is provided at a temperature level suitable for the user—LT (low temperature).

3. Results

3.1. Trend of a Typical Test

3.2. Testing Results for a Pelletized Adsorber

3.3. Testing Results with a Composite Adsorber Based on an Aluminum, Porous Structure and a SAPO-34 Coating

3.3.1. “Deep Charge” Tests

- Heat of desorption is provided at the temperature of the heat source, HT;

- Heat of condensation is released at a low temperature, LT;

- Heat of adsorption is released at the temperature of adsorption, MT;

- Heat of evaporation is provided at a temperature level suitable for the user, LT.

3.3.2. Four Temperatures Tests

- Heat of desorption is provided at the temperature of the heat source, HT;

- Heat of condensation is released at 10 °C;

- Heat of adsorption is released at the temperature of adsorption, Ta;

- Heat of evaporation is provided at a temperature level suitable for the user, LT.

3.4. Comparison between the Adsorbers

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| cp | Specific heat, kJ/(kgK) |

| Mass flow rate, kg/s | |

| Mass flow rate to the evaporator, kg/s | |

| Adsorbent material mass, kg | |

| Average Power, W | |

| Stored energy into the evaporator, kJ | |

| COP | Coefficient of Performance, - |

| Inlet temperature to the evaporator, K | |

| Outlet temperature to the evaporator, K | |

| Inlet temperature to the adsorber, K | |

| Outlet temperature to the adsorber, K | |

| Discharge time, s | |

| Charge time, s |

References

- Barberi, P.; Bossmann, T.F.; Laurent, F. METIS Studies Study S6 Decentralised Heat Pumps: System Benefits under Different Technical Configurations; European Commission, Directorate-General for Energy: Brussels, Belgium, 2019. [CrossRef]

- Intergovernmental Panel on Climate Change; Groupe D’experts Intergouvernemental sur L’évolution du Climat. IPCC/TEAP Special Report on Safeguarding the Ozone Layer and the Global Climate System: Issues Related to Hydrofluorocarbons and Perfluorocarbons; Cambridge University Press: Cambridge, UK, 2005; 478p. [Google Scholar]

- European Environment Agency. ADEME (2003), ENERDATA, ISI-FhG, Energy Efficiency in the European Union 1990–2001; SAVE-ODYSSEE Project on Energy Efficiency Indicators; EEA: Copenhagen, Denmark, 2003.

- Tassou, S.A.; De-Lille, G.; Ge, Y.T. Food transport refrigeration—Approaches to reduce energy consumption and environmental impacts of road transport. Appl. Therm. Eng. 2009, 29, 1467–1477. [Google Scholar] [CrossRef]

- Magnetto, D.; de Boer, R.; Vasta, S. TOPMACS: Thermally Operated Mobile Air Conditioning Systems. In Vehicle Thermal Management Systems Conference and Exhibition; Institution of Mechanical Engineers—VTMS 10; Elsevier: Amsterdam, The Netherlands, 2011; pp. 635–647. [Google Scholar]

- Vasta, S.; Freni, A.; Sapienza, A.; Costa, F.; Restuccia, G. Development and lab-test of a mobile adsorption air-conditioner. Int. J. Refrigeration 2012, 35, 701–708. [Google Scholar] [CrossRef]

- Guelpa, E.; Verda, V. Thermal energy storage in district heating and cooling systems: A review. Appl. Energy 2019, 252, 113474. [Google Scholar] [CrossRef]

- Bataineh, K.; Taamneh, Y. Review and recent improvements of solar sorption cooling systems. Energy Build. 2016, 128, 22–37. [Google Scholar] [CrossRef]

- Aydin, D.; Casey, S.P.; Riffat, S. The latest advancements on thermochemical heat storage systems. Renew. Sustain. Energy Rev. 2015, 41, 356–367. [Google Scholar] [CrossRef]

- Engel, G. Sorption cold storage for thermal management of the battery of a hybrid vehicle. Energy Procedia 2018, 155, 149–155. [Google Scholar] [CrossRef]

- Yu, N.; Wang, R.Z.; Wang, L.W. Theoretical and experimental investigation of a closed sorption thermal storage prototype using LiCl/water. Energy 2015, 93, 1523–1534. [Google Scholar] [CrossRef]

- Jiang, L.; Roskilly, A.P.; Wang, R.Z.; Wang, L.W.; Lu, Y.J. Analysis on innovative modular sorption and resorption thermal cell for cold and heat cogeneration. Appl. Energy 2017, 204, 767–779. [Google Scholar] [CrossRef]

- Vasta, S.; Brancato, V.; la Rosa, D.; Palomba, V.; Restuccia, G.; Sapienza, A.; Frazzica, A. Adsorption heat storage: State-of-the-art and future perspectives. Nanomaterials 2018, 8, 522. [Google Scholar] [CrossRef] [PubMed]

- Sapienza, A.; Palomba, V.; Gullì, G.; Frazzica, A.; Vasta, S. A new management strategy based on the reallocation of ads-/desorption times: Experimental operation of a full-scale 3 beds adsorption chiller. Appl. Energy 2017, 1081–1090. [Google Scholar] [CrossRef]

| Full Scale | Parameter | Value | |

| Storage Capacity | 2 kWh | ||

| Discharge Time | 2 h | ||

| Avg. Power | 1 kW | ||

| Water needed | 2.9 l | ||

| Design temperatures | Adsorber | Phase Changer | |

| Charge | 95 °C | 35 °C | |

| Discharge | 35 °C | 10 °C | |

| Useful ΔX | 15% | ||

| Amount of Zeolite | 19.4 kg | ||

| Spec. Zeolite density | 800 g/l foam | ||

| Foam Volume | 24.2 l | ||

| Volume of tubes | 2.4 l | ||

| Total volume | 26.6 l | ||

| Required storage time | > 1 h | ||

| Specific Capacity | 75 Wh/l | ||

| Specific Power | 28 W/l | ||

| Prototype (lab-scale) | Parameter | Value | |

| Portion of product | 25% | ||

| Storage Capacity | 500 Wh | ||

| Avg. Power | 250 W | ||

| Volume of foam | 6.1 l | ||

| Total volume | 6.7 l | ||

| Adsorber Design | |||

|---|---|---|---|

| Theoretical | Real | ||

| Total Capacity | Wh | 500 | 636.40 |

| Total Capacity | kJ | 1800 | 2291.04 |

| Water latent heat | kJ/kg | 2272 | 2272 |

| Water to be evaporated | kg | 0.792 | 1.008 |

| Expected adsorption capacity | kg/kg | 0.15 | 0.15 |

| Minimum zeolite mass | kg | 5.28 | 6.72 |

| Foam density | kg/l | 0.8 | 0.8 |

| Minimum adsorber volume | l | 6.60 | 8.40 |

| Monitored Parameter | |

|---|---|

| T in/out Adsorber; | T liquid phase into Phase Changer; |

| T in/out Phase Changer (CON/EVAP); | Adsorber HTF (Heat Transfer Fluid) flow rate; |

| Phase changer HTF flow rate; | Adsorber pressure; |

| Phase changer Pressure; | T shell; |

| T ambient. | |

| Parameter | Value |

|---|---|

| Charge/discharge time (s) | 2700, 3600, 4500 |

| High temperature inlet (°C) | 90 |

| Medium temperature inlet (°C) | 25, 28, 30, 33, 35, 38, 40 |

| Low temperature inlet (°C) | 10, 15, 18, 20, 22 |

| Adsorber Flow rate (kg/min) | 12 |

| Phase changer flow rate (kg/min) | 10 |

| Parameter | Value |

|---|---|

| Charge/discharge time (s) | 600, 750, 900, 1200 |

| High temperature inlet (°C) | 85, 90 |

| Medium temperature inlet (°C) | 28, 30, 33, 35, 38 |

| Low temperature inlet (°C) | 5, 10, 12, 15, 18, 20 |

| Adsorber Flow rate (kg/min) | 8, 12, 15 |

| Phase changer flow rate (kg/min) | 5, 10, 15, 18 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasta, S.; Palomba, V.; La Rosa, D.; Bonanno, A. Adsorption Cold Storage for Mobile Applications. Appl. Sci. 2020, 10, 2044. https://doi.org/10.3390/app10062044

Vasta S, Palomba V, La Rosa D, Bonanno A. Adsorption Cold Storage for Mobile Applications. Applied Sciences. 2020; 10(6):2044. https://doi.org/10.3390/app10062044

Chicago/Turabian StyleVasta, Salvatore, Valeria Palomba, Davide La Rosa, and Antonino Bonanno. 2020. "Adsorption Cold Storage for Mobile Applications" Applied Sciences 10, no. 6: 2044. https://doi.org/10.3390/app10062044

APA StyleVasta, S., Palomba, V., La Rosa, D., & Bonanno, A. (2020). Adsorption Cold Storage for Mobile Applications. Applied Sciences, 10(6), 2044. https://doi.org/10.3390/app10062044