Conjugate Heat Transfer Analysis of PCM Suspensions in a Circular Tube under External Cooling Convection: Wall Conduction Effects

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

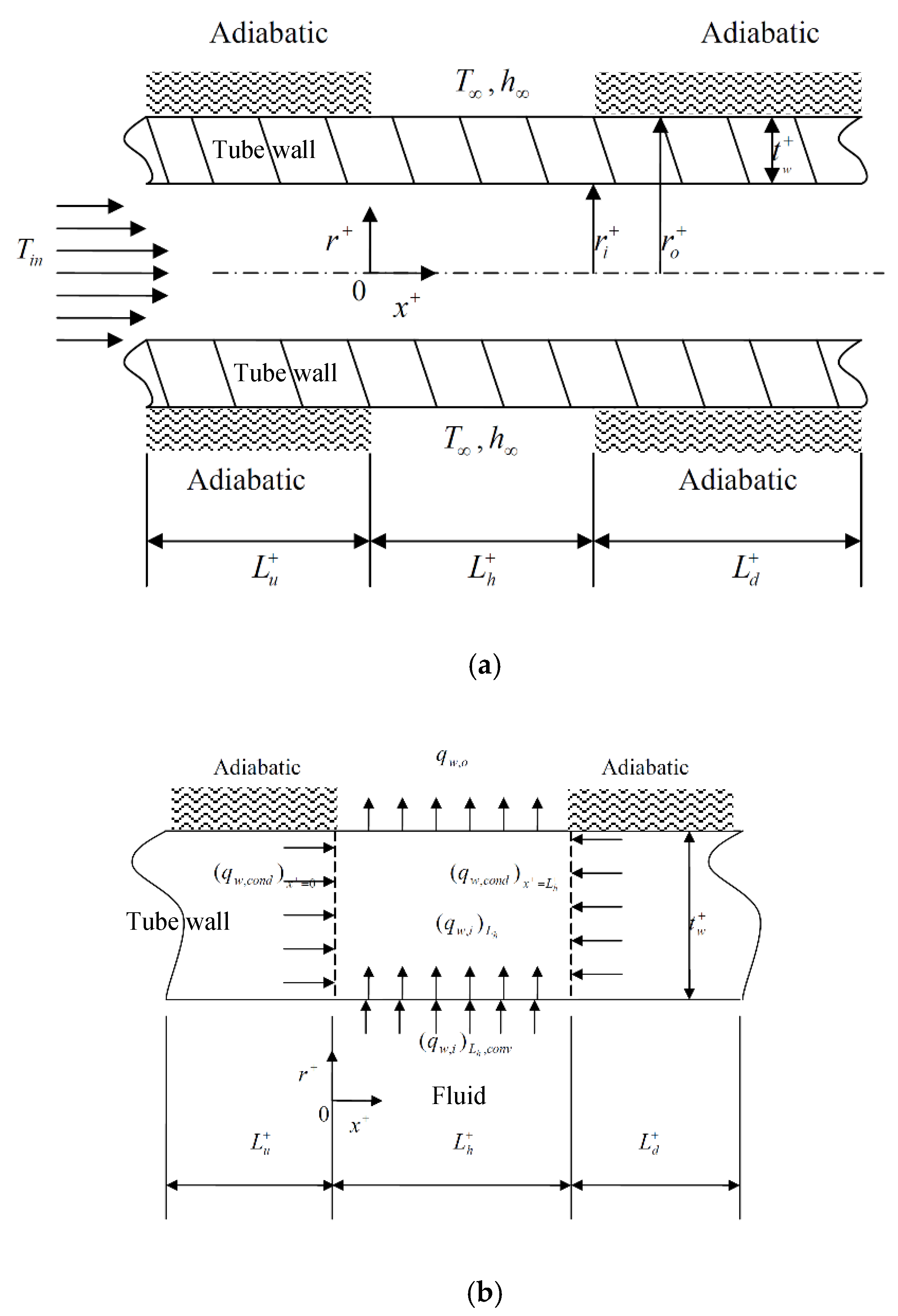

2.1. Problem Formulation

- The working fluid is a suspension of PCM particles. The PCM particles can be completely solid phase, completely liquid phase, or a mixture of solid and liquid phases.

- A uniform diameter is assumed for the PCM particles suspended in the working fluid.

- All of the physical properties of the PCM suspension are assumed to be constant.

- The PCM suspension is regarded as a thin mixture.

- The PCM suspension is regarded as an incompressible Newtonian fluid.

- Viscous dissipation is neglected.

- The PCM particles are neutral and evenly distributed in the working fluid.

- The PCM suspension enters the tube in fully developed laminar flow.

- The flow and temperature distribution of the PCM suspension in the tube are radially axisymmetric.

- The change in the density of the PCM particles during solid-liquid phase changes is neglected.

2.2. Dimensionless Thermal Quantities of Interest

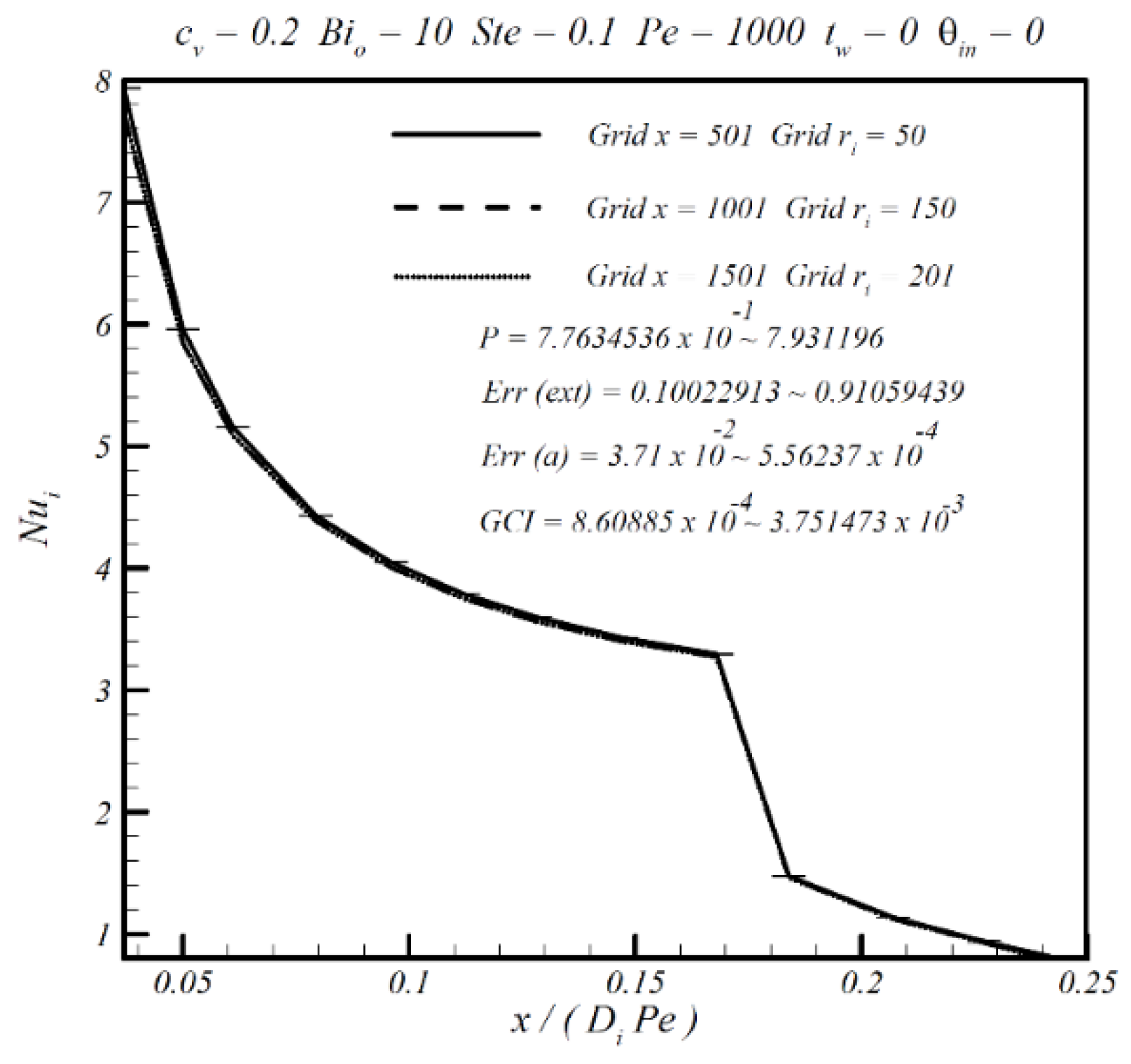

2.3. Numerical Method

3. Results and Discussion

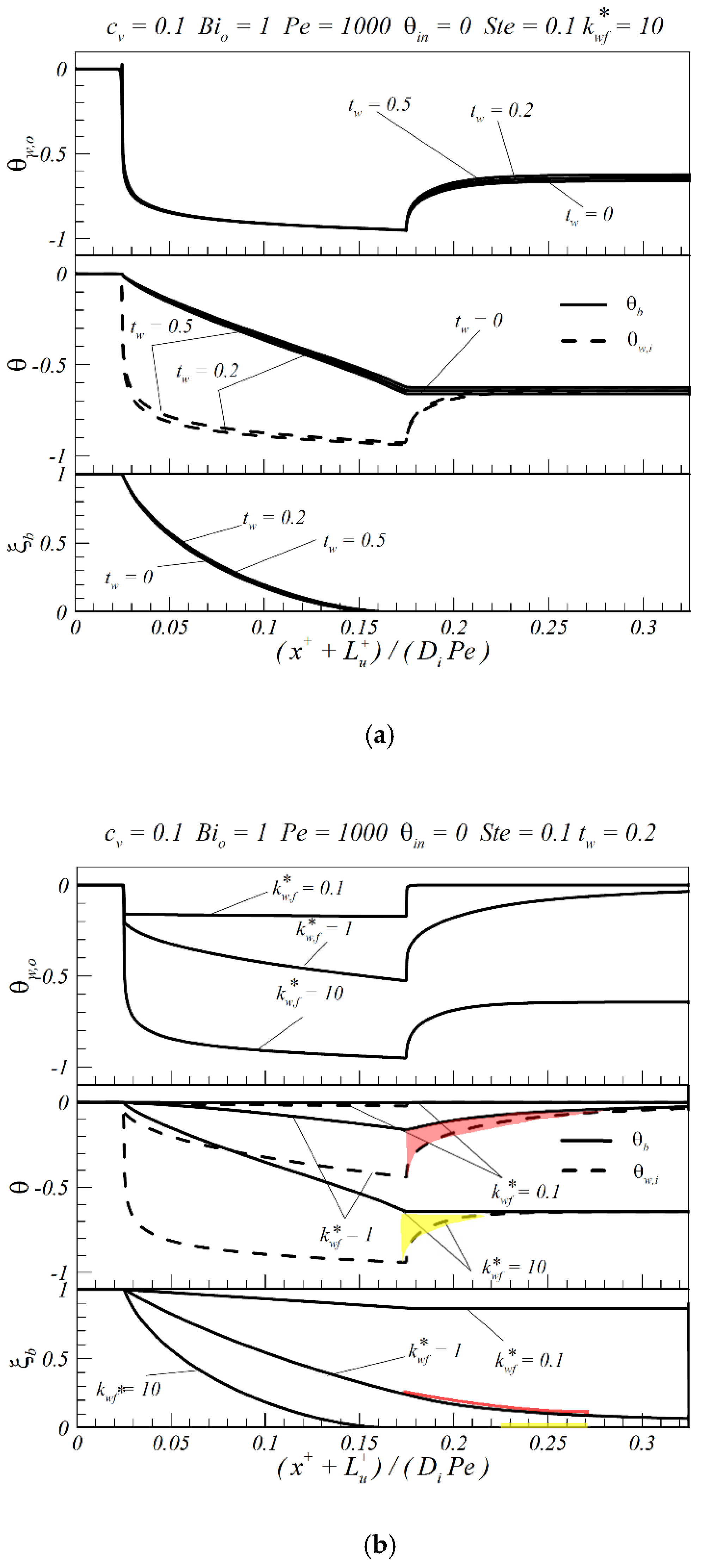

3.1. Tube Wall and Fluid Temperature

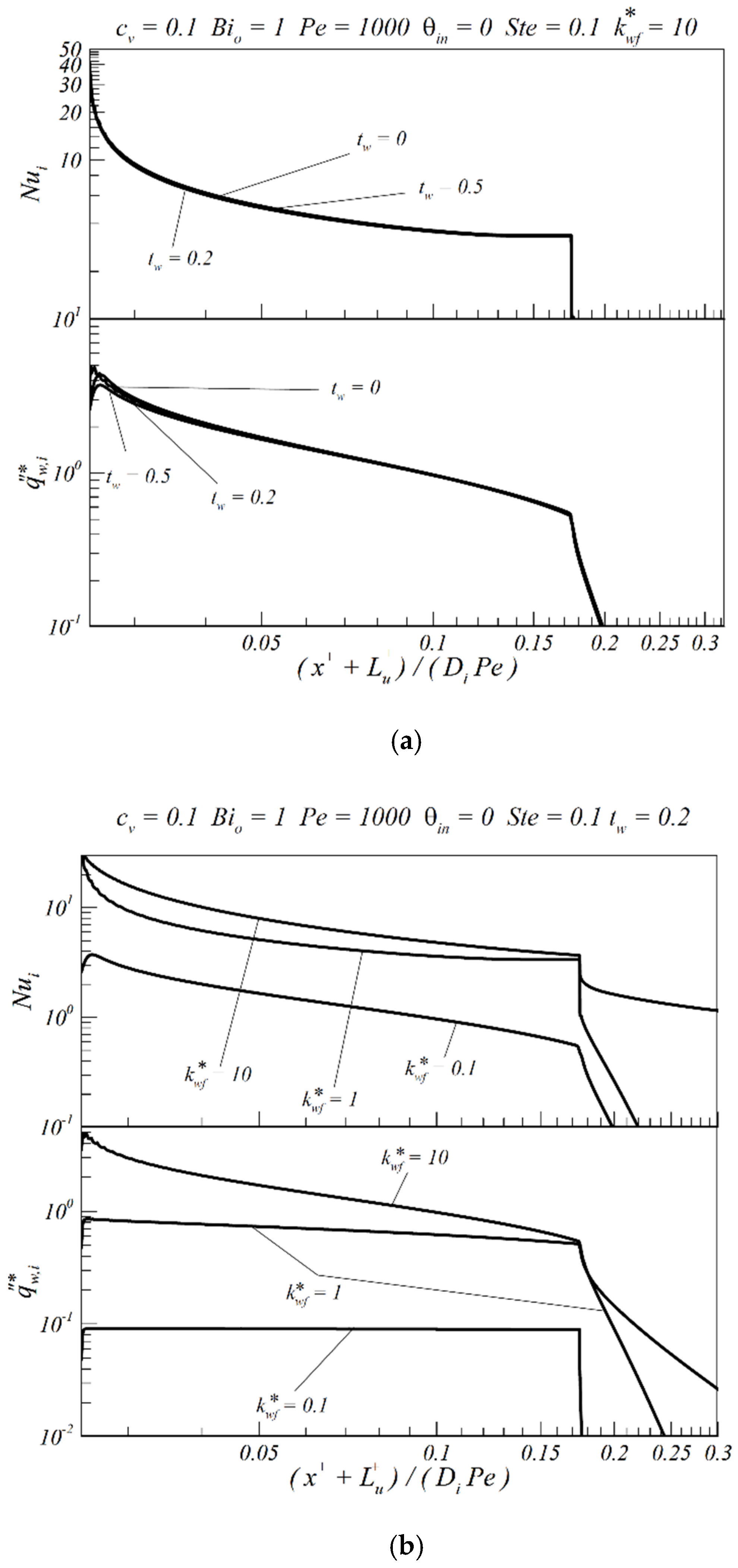

3.2. Heat Transfer Characteristics of Inner and Outer Tube Wall Surfaces

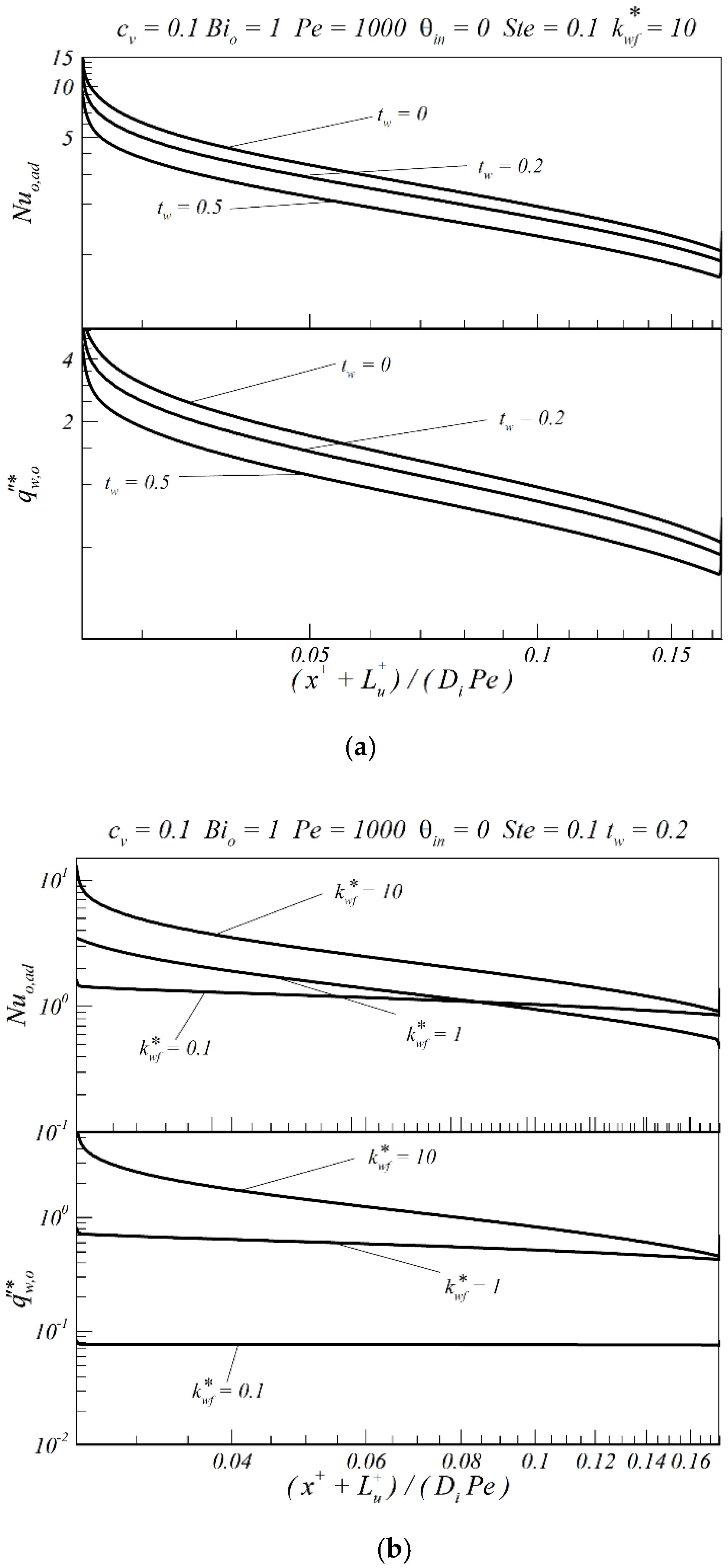

3.3. Analysis of Various Heat Transfer Contributions

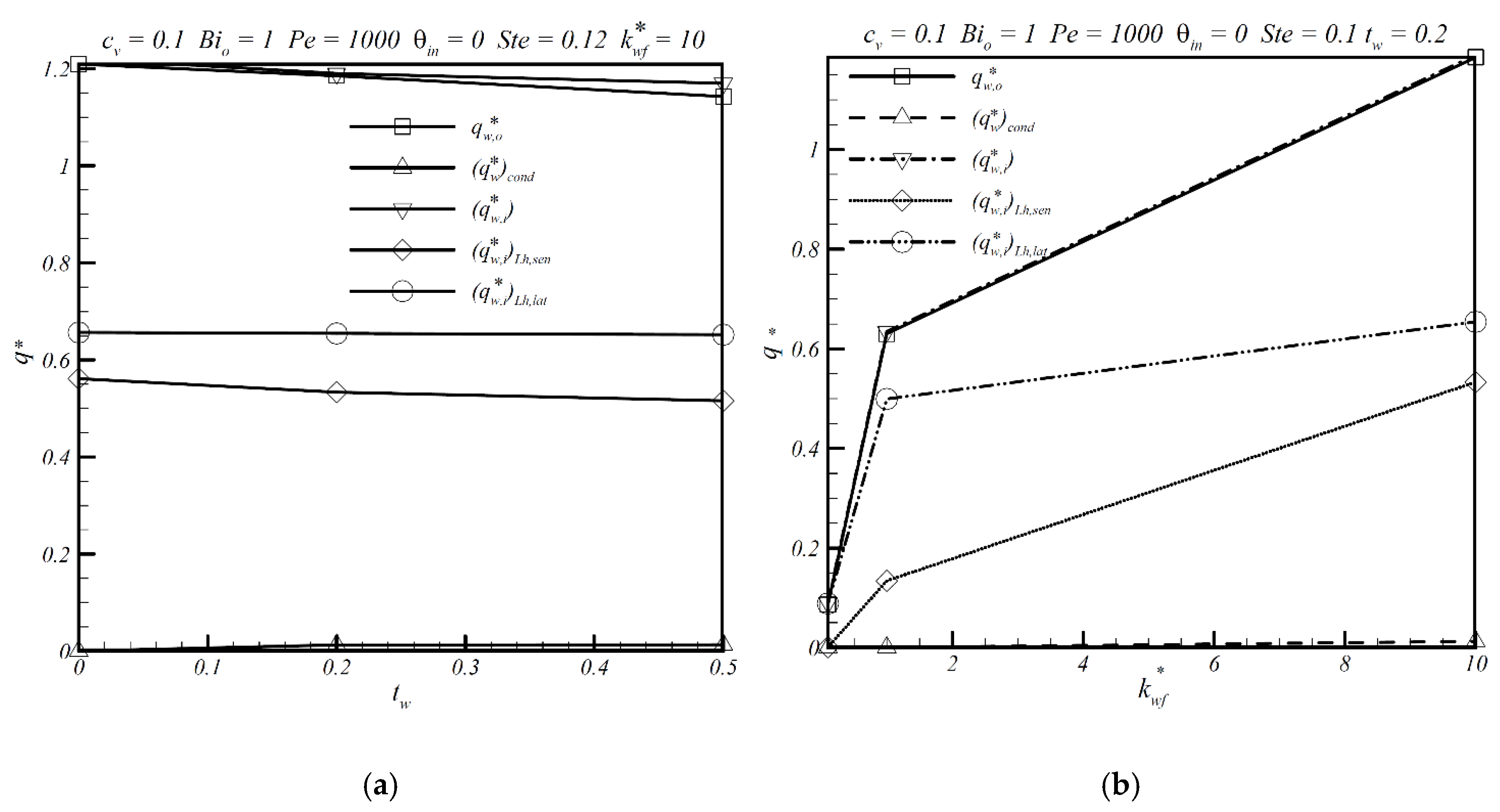

4. Conclusions

- (1)

- The most significant of the considered parameters appears to be , which affects the temperature of the outer tube wall, the temperature of the inner tube wall, the average temperature of the fluid, and the volumetric liquid fraction in a PCM particle. The various contributions to the heat transfer and have a comparatively minor effect on the aforementioned variables.

- (2)

- For high , the tube wall and fluid are significantly affected by postcooling in the downstream adiabatic section. Therefore, a substantial increase in creates an indirectly cooled region downstream of the heat exchange section where the PCM particles have completed solidification. Thus, there is a significant increase in the latent heat released in the solidification process and thus the efficacy of wall temperature control over the cooled section or even the heated section.

- (3)

- The results of the study show that wall conduction effects must be suitably accounted for to describe heat transfer in PCM suspensions in a circular tube under external cooling convection.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| a | parameter |

| b | parameter |

| Bio | Biot number at the outer surface of the tube (=) |

| Bip | Biot number of a PCM particle (=) |

| specific heat (kJ/kg K) | |

| specific heat ratio (=) | |

| specific heat ratio (=) | |

| specific heat ratio (=) | |

| cv | volumetric fraction of PCM particles |

| dimensionless diameter of a PCM particle (=) | |

| diameter of a PCM particle (m) | |

| Fourier number (=) | |

| h | heat transfer coefficient (W/m2 K); enthalpy of suspension (kJ/kg) |

| latent heat of fusion (J/kg) | |

| k | thermal conductivity (W/m K) |

| thermal conductivity ratio (=) | |

| thermal conductivity ratio (=) | |

| thermal conductivity ratio (=) | |

| length of downstream section (m) | |

| dimensionless length of the downstream section (=) | |

| length of heated section (m) | |

| dimensionless length of the heated section (=) | |

| length of upstream section (m) | |

| dimensionless length of the upstream section (=) | |

| Pe | Peclet number (=2) |

| Nu | Nusselt number (=) |

| q | heat transfer rate (W) |

| local heat flux (W/m2) | |

| local dimensionless heat flux (=) | |

| dimensionless heat transfer rate (=) | |

| radial coordinate | |

| radius of a PCM particle (m) | |

| r | dimensionless coordinate (=) |

| Ste | modified Stefan number (=). |

| t | time (sec) |

| dimensionless tube wall thickness (=) | |

| tube wall thickness (=-) (m) | |

| T | temperature (K) |

| u | dimensionless axial velocity (=) |

| u+ | axial velocity (m/s) |

| U | overall heat transfer coefficient (W/m2 K) |

| x | dimensionless axial coordinate (=) |

| axial coordinate | |

| Greek symbols | |

| thermal diffusivity (m/s2) | |

| θ | dimensionless temperature (=()/()) |

| ρ | density (kg/m3) |

| density ratio (=) | |

| density ratio (=) | |

| density ratio (= | |

| ξ | volumetric liquid fraction in a PCM particle |

| Subscripts | |

| b | bulk fluid |

| bf | bulk-to-base fluid ratio |

| cond | heat conduction |

| conv | convection |

| d | downstream |

| f | suspending fluid |

| h | heated section |

| i | inner surface of the tube |

| in | inlet |

| l | liquid phase of PCM |

| lat | latent heat |

| heated section | |

| m | melting point |

| o | outer surface of the tube |

| p | particle |

| pf | particle-to-fluid ratio |

| sen | sensible heat |

| u | upstream |

| w | tube wall |

| wf | wall-to-fluid ratio |

| ambient | |

| Superscripts | |

| – | surface-averaged quantity |

| * | ratio of quantities |

| + | dimensional quantity |

References

- Ho, C.J.; Chen, Y.Z.; Tu, F.-J.; Lai, C.-M. Thermal performance of water-based suspensions of phase change nanocapsules in a natural circulation loop with a mini-channel heat sink and heat source. Appl. Therm. Eng. 2014, 64, 376–384. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Alkan, C.; Chimenos, J.M.; Fernández, A.I. Comparison of microencapsulated phase change materials prepared at laboratory containing the same core and different shell material. Appl. Sci. 2017, 7, 723. [Google Scholar] [CrossRef]

- Yang, L.; Liu, S.; Zheng, H. A comprehensive review of hydrodynamic mechanisms and heat transfer characteristics for microencapsulated phase change slurry (MPCS) in circular tube. Renew. Sustain. Energy Rev. 2019, 114, 109312. [Google Scholar] [CrossRef]

- Peng, G.; Dou, G.; Hu, Y.; Sun, Y.; Chen, Z. Phase change material (PCM) microcapsules for thermal energy storage. Adv. Polym. Tech. 2020, 3, 1–20. [Google Scholar] [CrossRef]

- Zhu, C.; Lin, Y.; Fang, G. Preparation and thermal properties of microencapsulated stearyl alcohol with silicon dioxide shell as thermal energy storage materials. Appl. Therm. Eng. 2020, 169, 114943. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, J.-Y.; Niu, J. PCM-in-water emulsion for solar thermal applications: The effects of emulsifiers and emulsification conditions on thermal performance, stability and rheology characteristics. Sol. Energy Mater. Sol. Cells 2016, 147, 211–224. [Google Scholar] [CrossRef]

- Ho, C.J.; Hsu, H.-I.; Ho, T.-A.; Lai, C.-M. Thermal performance of a vertical U-shaped thermosyphon containing a phase-change material suspension fluid. Energies 2017, 10, 974. [Google Scholar] [CrossRef]

- Cabaleiro, D.; Agresti, F.; Barison, S.; Marcos, M.A.; Prado, J.I.; Rossi, S.; Bobbo, S.; Fedele, L. Development of paraffinic phase change material nanoemulsions for thermal energy storage and transport in low-temperature applications. Appl. Therm. Eng. 2019, 159, 113868. [Google Scholar] [CrossRef]

- Inaba, H.; Kim, M.J.; Horibe, A. Cold heat storage characteristics of latent heat microcapsule-water mixture flowing in a pipe with constant temperature wall. Trans. Jpn. Soc. Mech. Eng. B 2002, 68, 2606–2613. [Google Scholar] [CrossRef][Green Version]

- Ho, C.J.; Lin, J.F.; Chiu, S.Y. Heat transfer of solid-liquid phase-change material suspensions in circular pipes: Effects of wall conduction. Numer. Heat Transf. A Appl. 2004, 45, 171–190. [Google Scholar] [CrossRef]

- Ho, C.J.; Huang, J.B.; Tsai, P.S.; Yang, Y.M. Water-based suspensions of Al2O3 nanoparticles and MEPCM particles on convection effectiveness in a circular tube. Int. J. Therm. Sci. 2011, 50, 736–748. [Google Scholar] [CrossRef]

- Dammel, F.; Stephan, P. Heat transfer to suspensions of microencapsulated phase change material flowing through minichannels. J. Heat Transf. 2012, 134, 020907. [Google Scholar] [CrossRef]

- Ho, C.J.; Huang, J.B.; Chen, C.P.; Tsai, P.S.; Yang, Y.M. Forced convection performance of a MEPCM suspension through an iso-flux heated circular tube: An experimental study. Heat Mass Transf. 2012, 48, 487–496. [Google Scholar] [CrossRef]

- Ho, C.J.; Lee, C.-Y.; Yamada, M. Experiments on laminar cooling characteristics of a phase change nanofluid flow through an iso-flux heated circular tube. Int. J. Heat Mass Tranf. 2018, 118, 1307–1315. [Google Scholar] [CrossRef]

- Ren, Q.; Guo, P.; Zhu, J. Thermal management of electronic devices using pin-fin based cascade microencapsulated PCM/expanded graphite composite. Int. J. Heat Mass Tranf. 2020, 149, 119199. [Google Scholar] [CrossRef]

- Charunyakorn, P.; Sengupta, S.; Roy, S.K. Forced convection heat transfer in microencapsulated phase change material slurries: Flow in circular ducts. Int. J. Heat Mass Transf. 1991, 34, 819–833. [Google Scholar] [CrossRef]

- Leonard, B.P. A stable and accurate convective modelling procedure based on quadratic upstream interpolation, Comput. Meth. Appl. Mech. Eng. 1979, 19, 59–98. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, C.J.; Wang, Z.C.; Chen, R.H.; Lai, C.-M. Conjugate Heat Transfer Analysis of PCM Suspensions in a Circular Tube under External Cooling Convection: Wall Conduction Effects. Appl. Sci. 2020, 10, 2034. https://doi.org/10.3390/app10062034

Ho CJ, Wang ZC, Chen RH, Lai C-M. Conjugate Heat Transfer Analysis of PCM Suspensions in a Circular Tube under External Cooling Convection: Wall Conduction Effects. Applied Sciences. 2020; 10(6):2034. https://doi.org/10.3390/app10062034

Chicago/Turabian StyleHo, C. J., Z.C. Wang, R.H. Chen, and Chi-Ming Lai. 2020. "Conjugate Heat Transfer Analysis of PCM Suspensions in a Circular Tube under External Cooling Convection: Wall Conduction Effects" Applied Sciences 10, no. 6: 2034. https://doi.org/10.3390/app10062034

APA StyleHo, C. J., Wang, Z. C., Chen, R. H., & Lai, C.-M. (2020). Conjugate Heat Transfer Analysis of PCM Suspensions in a Circular Tube under External Cooling Convection: Wall Conduction Effects. Applied Sciences, 10(6), 2034. https://doi.org/10.3390/app10062034