A Numerical Assessment on the Influences of Material Toughness on the Crashworthiness of a Composite Fuselage Barrel

Abstract

1. Introduction

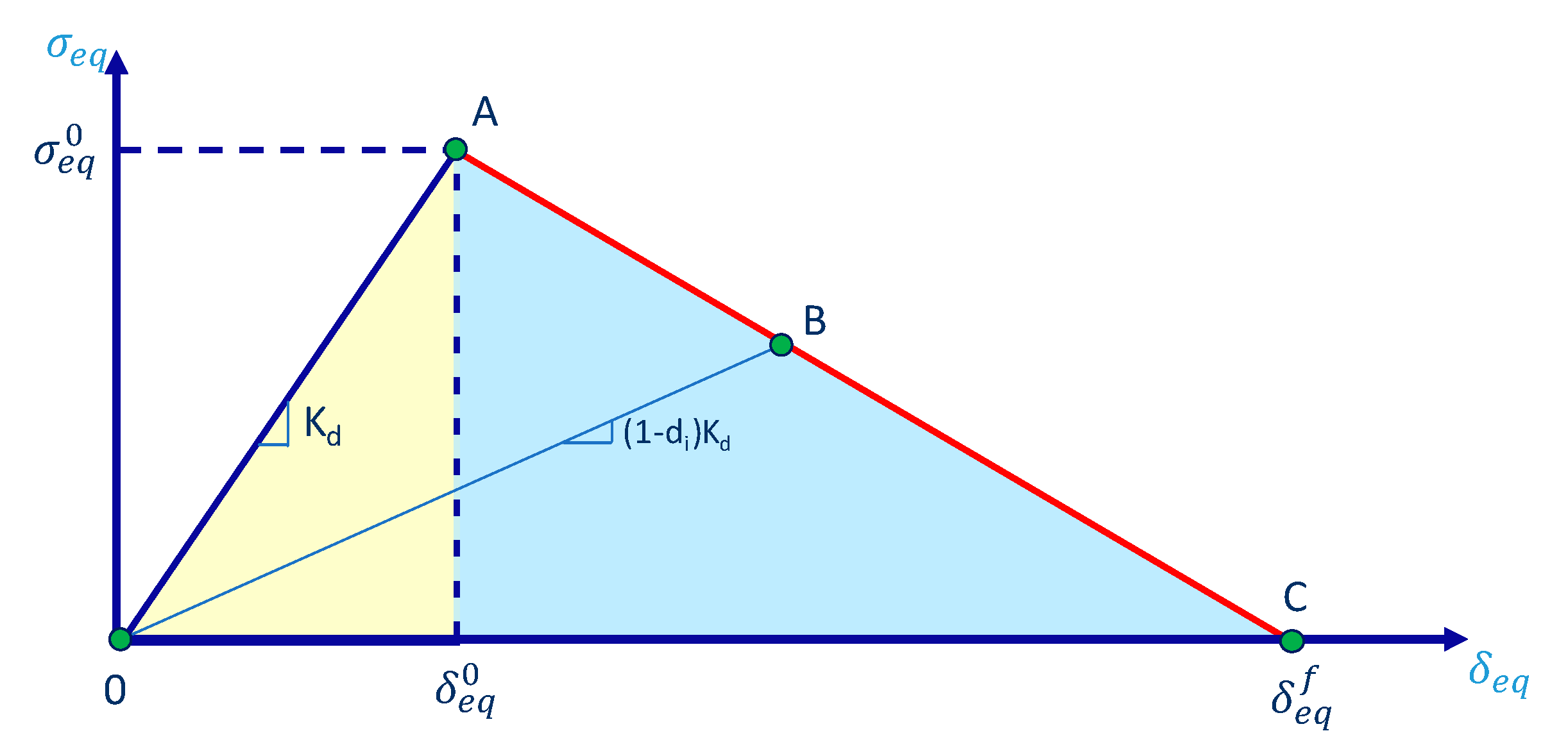

2. Theoretical Background: Material Damage Model

3. Fuselage Barrel Test Case: Geometrical Description and Finite Element Model

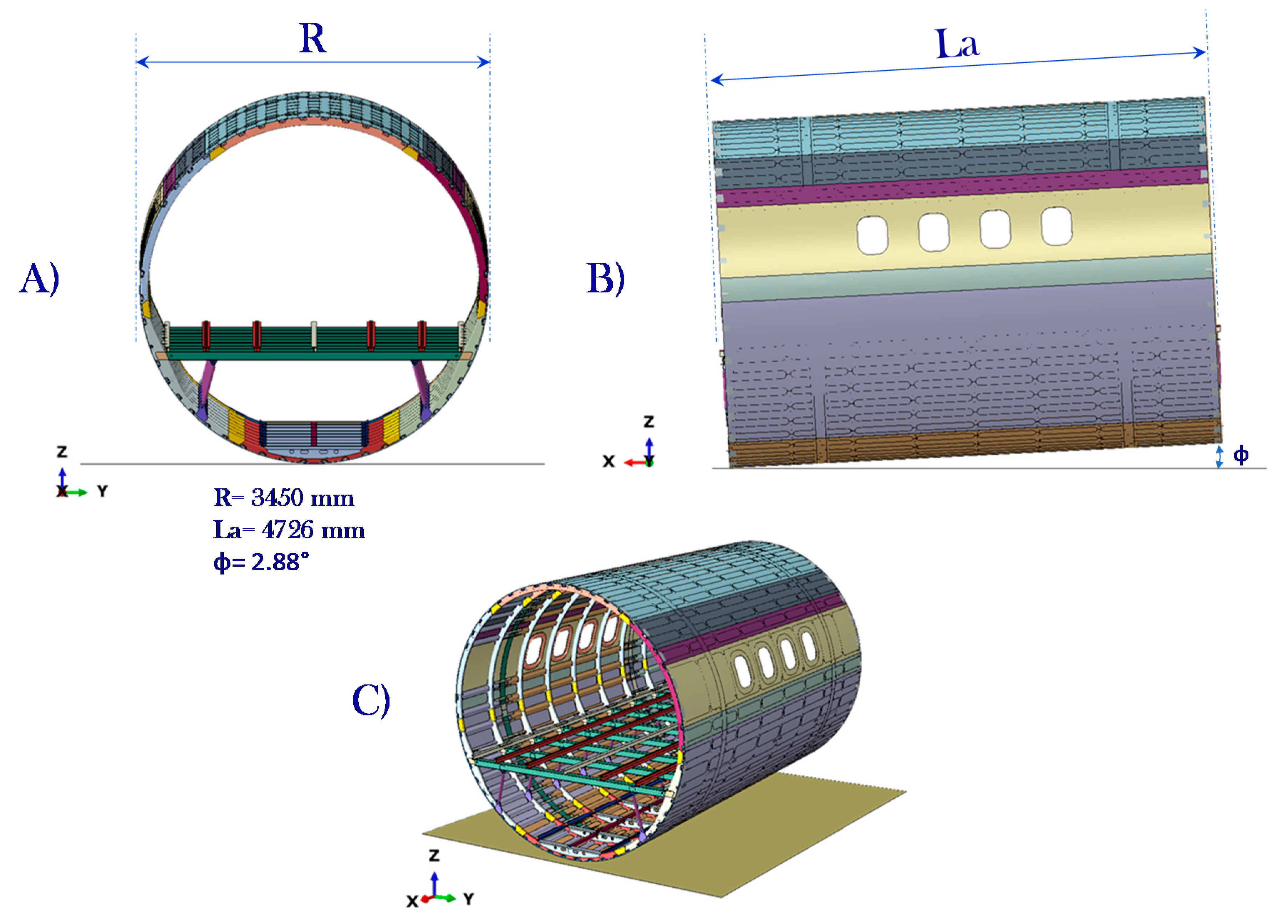

3.1. Geometrical Description

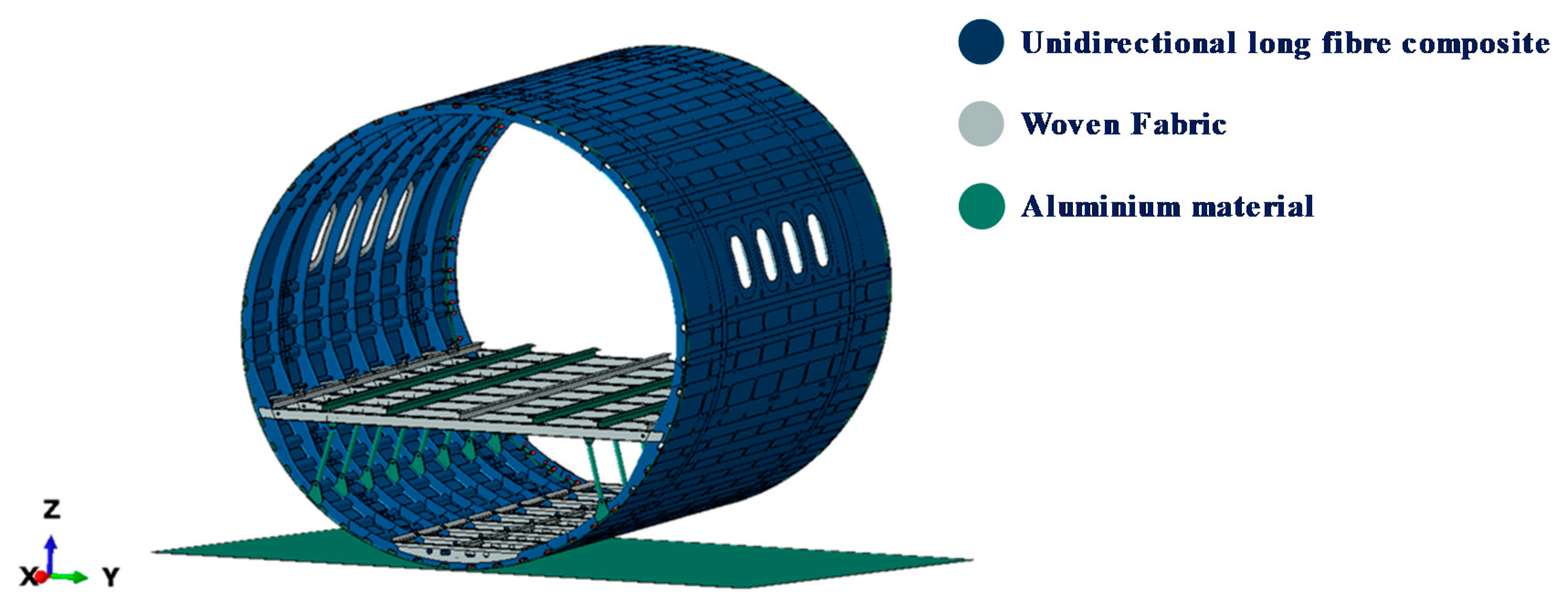

3.2. Material System

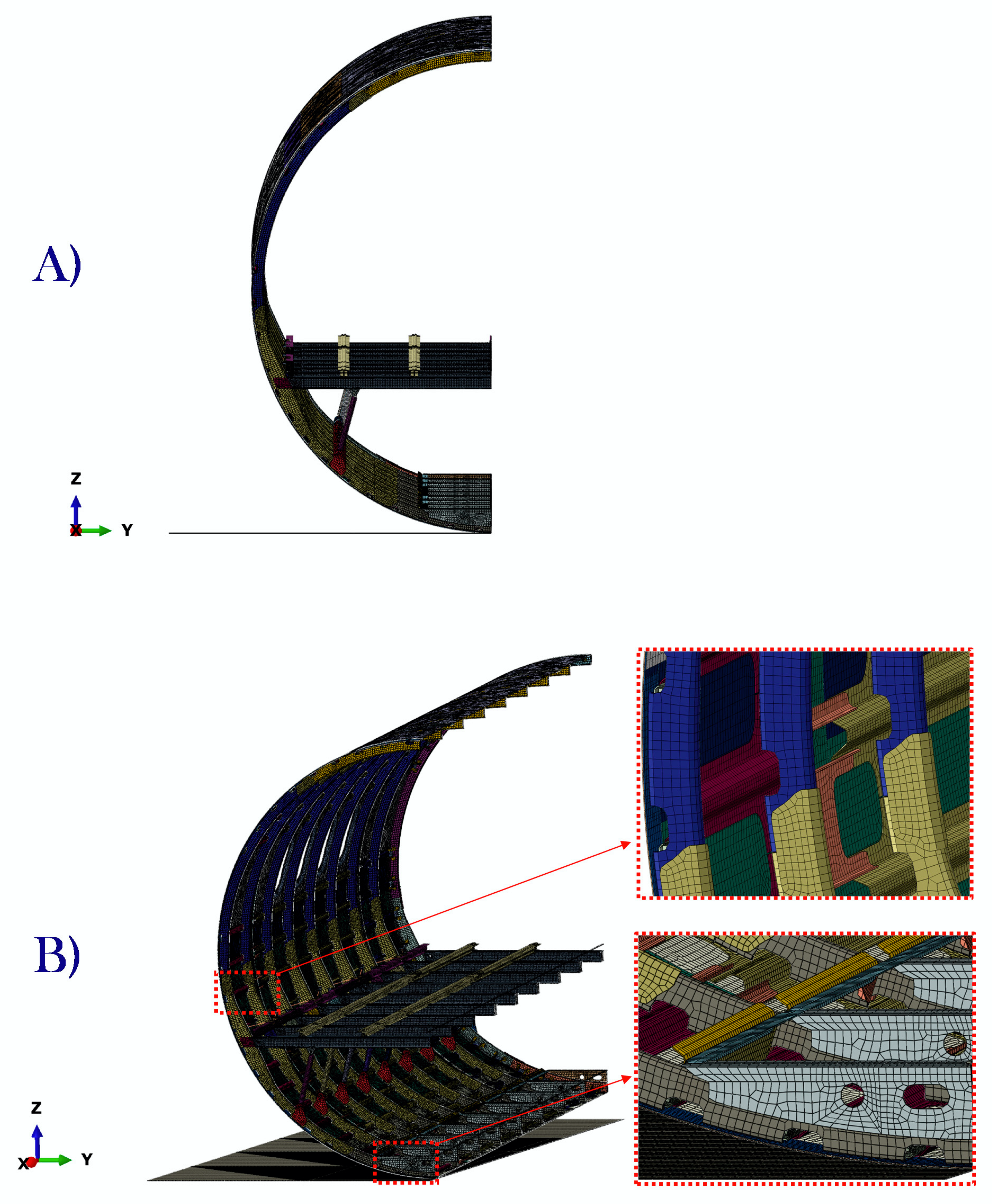

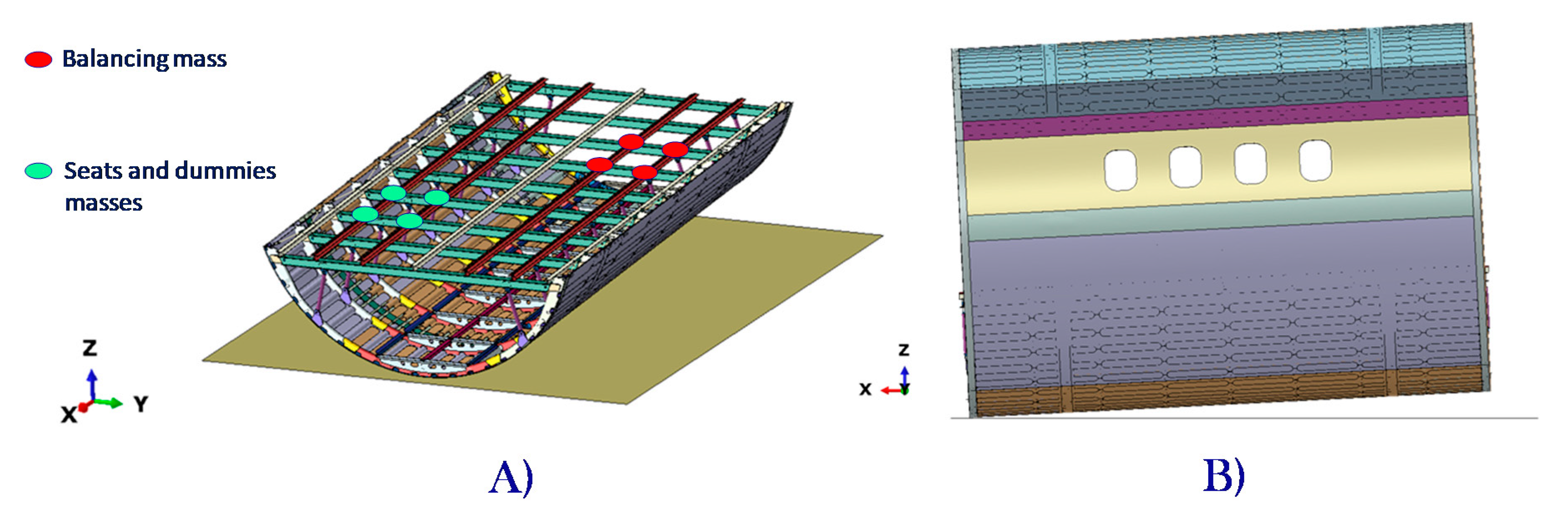

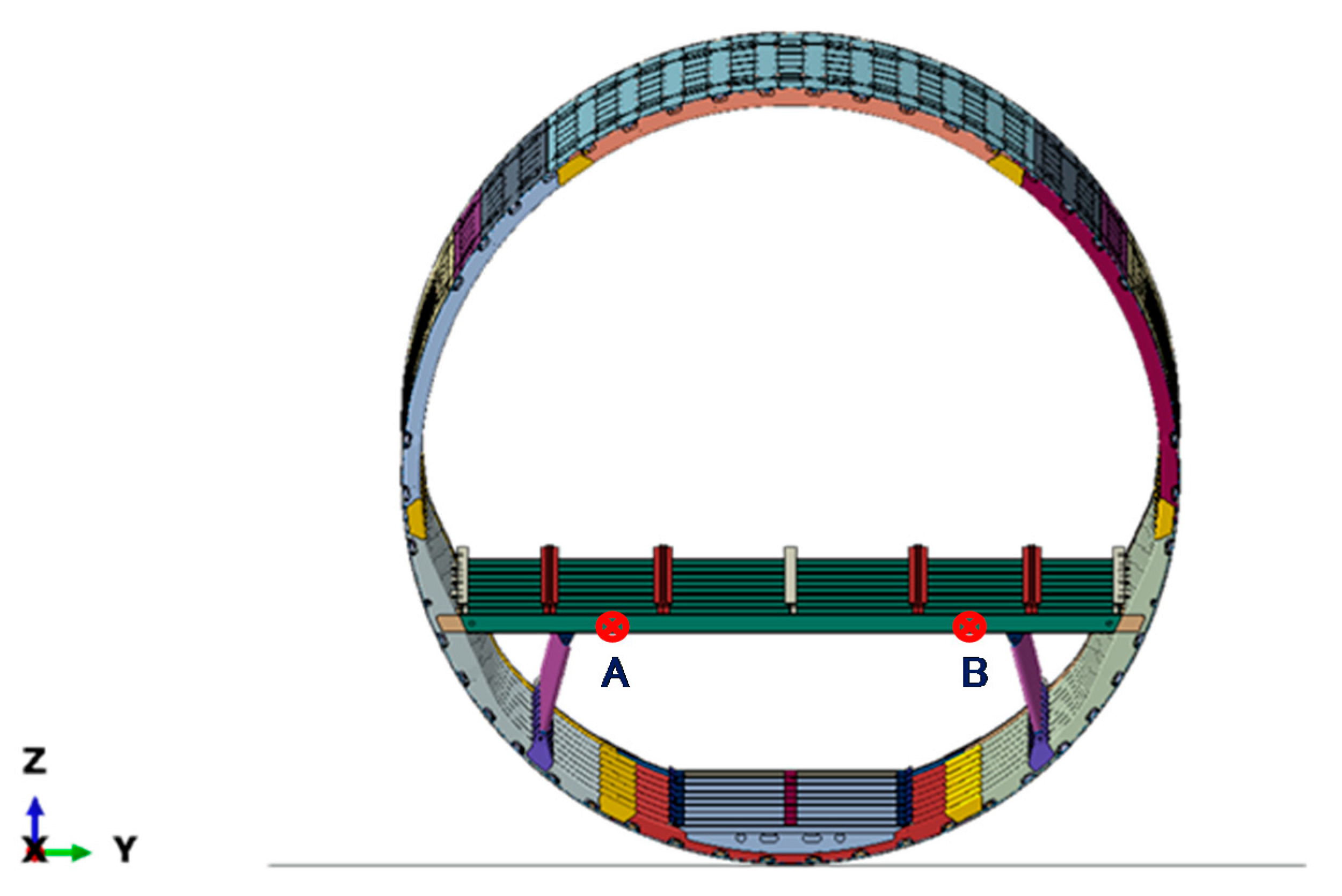

3.3. Finite Element Description

3.4. Boundary Conditions

4. Numerical Results

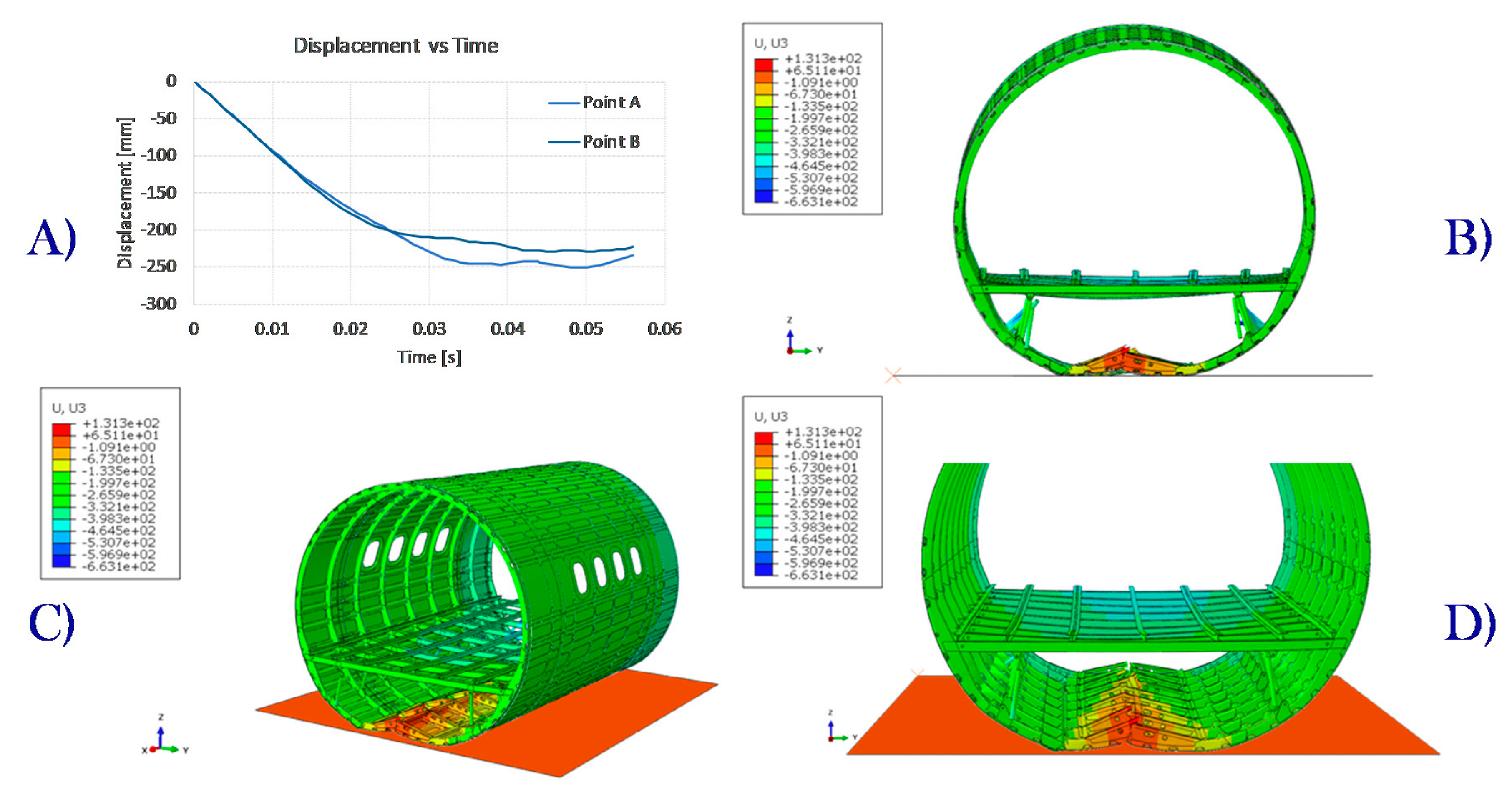

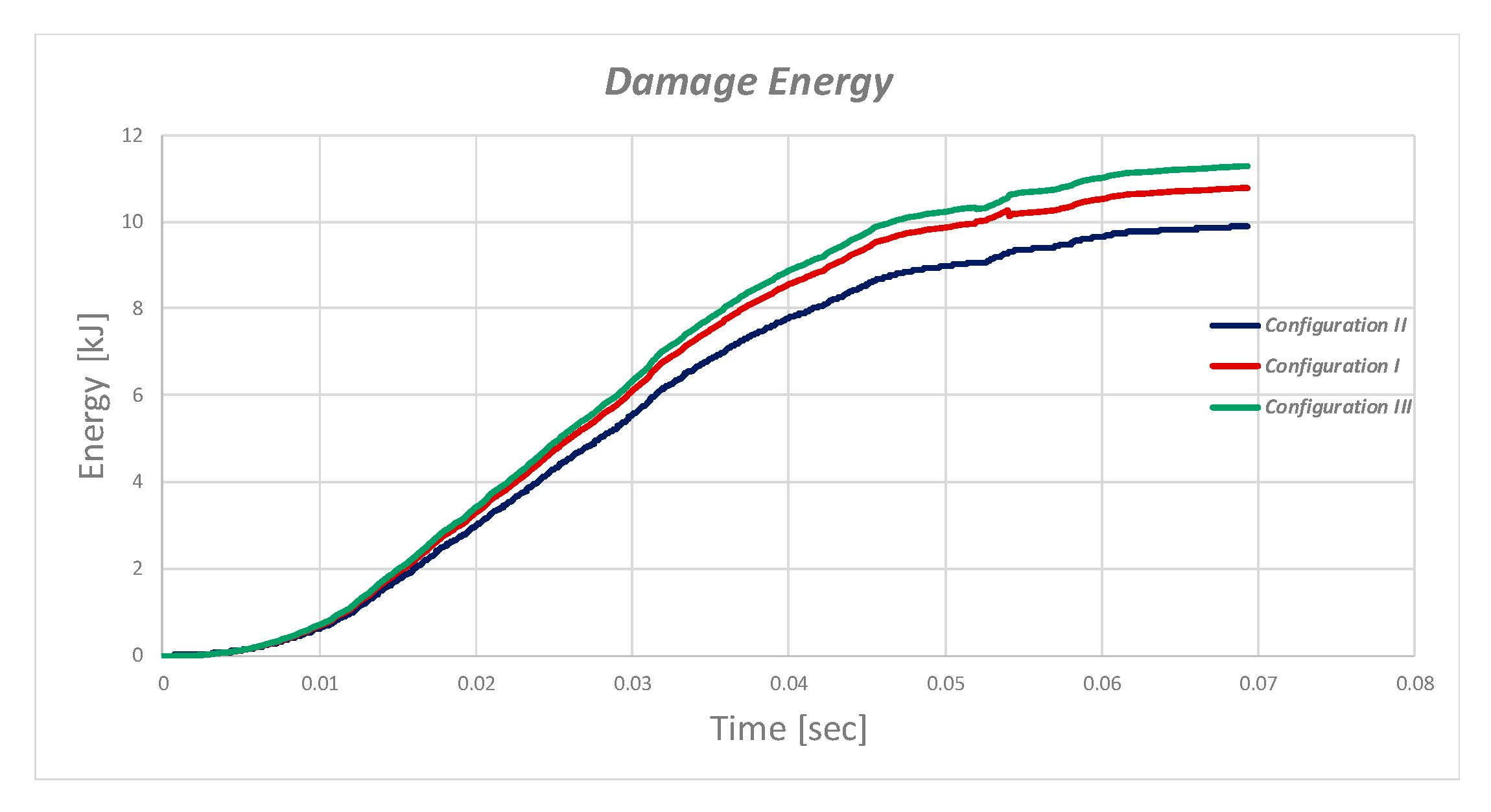

4.1. Configuration I

4.2. Configuration II

4.3. Configuration III

4.4. Configuration Comparison

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Heimbs, S.; Vogt, D.; Hartnack, R.; Schlattmann, J.; Maier, M. Numerical simulation of aircraft interior components under crash loads. Int. J. Crashworthiness 2008, 13, 511–521. [Google Scholar] [CrossRef]

- Obergefell, L.A.; Gardner, T.R.; Kaleps, I.; Fleck, J.T. Articulated total body model Enhancements. In AAMRL-TR-88-043 User’s Guide; Armstrong Aerospace Medical Research Laboratory: Dayton, HO, USA, 1988; p. 2. [Google Scholar]

- Ruan, J.; Zhou, C.; Khalil, T.; King, A. Techniques and Applications of Finite Element Analysis of the Biomechanical Response of the Human Head to Impact; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- De Jager, M.K.J.; Sauren, A.A.H.J.; Thunnissen, J.G.M.; Wismans, J.S.H.M. A three-dimensional head-neck model: Validation for frontal and lateral impacts. SAE Trans. 1994, 103, 1660–1676. [Google Scholar]

- Mertz, H.J.; Prasad, P.; Nusholtz, G. Head Injury Risk Assessment for Forehead Impacts. SAE Tech. Pap. Ser. 1996, 105, 26–46. [Google Scholar]

- Hashemi, S.M.R.; Walton, A.C. A systematic approach to aircraft crashworthiness and impact surface material models. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2000, 214, 265–280. [Google Scholar] [CrossRef]

- Kindervater, C.M. The crashworthiness of composite aerospace structures. In Proceedings of the Workshop the Crashworthiness of Composite Transportation Structures, Crowthorne, UK, 3 October 2002. [Google Scholar]

- Carden, H.D.; Boitnott, R.L.; Fasanella, E.L. Behavior of composite/metal aircraft structual elements and components under crash type loads. In Proceedings of the 17th Congress of the International Council of Aeronautical Sciences, Stockholm, Sweden, 9–14 September 1990. [Google Scholar]

- Jackson, K.E.; Boitnott, R.L.; Fasanella, E.L.; Jones, L.E.; Lyle, K.H. A history of full-scale aircraft and rotorcraft crash testing and simulation at NASA Langley research center. In Proceedings of the 4th Triennial International Aircraft Fire and Cabin Safety Research Conference, Lisbon, Portugal, 15–18 November 2004. [Google Scholar]

- Logue, T.V.; McGuire, R.J.; Reinhardt, J.W.; Vu, T.V. Vertical Drop Test of a Narrow-Body Fuselage Section with Overhead Stowage Bins and Auxiliary Fuel Tank System on Board; Report DOT/FAA/CT-94/116; U.S. Department of Transportation; Federal Aviation Administration: Atlantic City, NJ, USA, 1995. [Google Scholar]

- Abramowitz, A.; Smith, T.G.; Vu, T. Vertical Drop Test of a Narrow-Body Transport Fuselage Section with a Conformable Auxiliary Fuel Tank Onboard; Report DOT/FAA/AR-00/56; U.S. Department of Transportation; Federal Aviation Administration: Atlantic City, NJ, USA, 2000. [Google Scholar]

- Byar, A.D.; Ko, J.; Rassaian, M. 737 fuselage section drop test simulation using LS-Dyna finite element method, ICRASH 2008. In Proceedings of the International Crashworthiness Conference, Kyoto, Japan, 22–25 June 2008. [Google Scholar]

- Kumakura, I.; Minegishi, M.; Iwasaki, K.; Shoji, H.; Yoshimoto, N.; Terada, H.; Sashikuma, H.; Isoe, A.; Yamaoka, T.; Katayama, N.; et al. Vertical Drop Test of a Transport Fuselage Section. In Proceedings of the SAE World Aviation Congress, Phoenix, AZ, USA, 6–8 May 2002. [Google Scholar]

- Kumakura, I.; Minegishi, M.; Iwasaki, K.; Shoji, H.; Miyaki, H.; Yoshimoto, N.; Sashikuma, H.; Katayama, N.; Isoe, A.; Hayashi, T.; et al. Summary of Vertical Drop Tests of YS-11 Transport Fuselage Sections. In Proceedings of the SAEWorld Aviation Congress, Montreal, QC, Canada, 9–11 September 2003. [Google Scholar]

- Deletombe, E.; Delsart, D.; Fabis, J.; Langrand, B.; Ortiz, R. Recent developments in computer modelling, materials characterisation and experimental validation with respect to crash dynamics. In Proceedings of the 4th Triennial International Aircraft Fire and Cabin Safety Research Conference, Lisbon, Portugal, 15–18 November 2004. [Google Scholar]

- Waimer, M.; Kohlgr¨uber, D.; Hachenberg, D.; Voggenreiter, H. The kinematics model—A numerical method for the development of a crashworthy composite fuselage design of transport aircraft. In Proceedings of the 6th Triennial International Aircraft Fire and Cabin Safety Research Conference, Atlantic City, NJ, USA, 25–28 October 2010. [Google Scholar]

- Fen, Z.; Hao, P.; Zou, T. Research development of crashworthiness simulation evaluation on civil aircraft. Procedia Eng. 2011, 17, 286–291. [Google Scholar]

- Kindervater, C.M.; Kohlgr¨uber, D.; Johnson, A. Composite vehicle structural crashworthiness—A status of design methodology and numerical simulation techniques. Int. J. Crashworthiness 1999, 4, 213–230. [Google Scholar] [CrossRef]

- Adams, A.; Lankarani, H.M. A modern aerospace modeling approach for evaluation of aircraft fuselage crashworthiness. Int. J. Crashworthiness 2003, 8, 401–413. [Google Scholar] [CrossRef]

- Byar, A.; Awerbuch, J.; Lau, A.; Tan, T. Finite element simulation of a vertical drop test of a Boeing 737 fuselage section. In Proceedings of the 3rd Triennial International Aircraft Fire and Cabin Safety Research Conference, Atlantic City, NJ, USA, 1–4 August 2001. [Google Scholar]

- Jackson, K.E.; Fasanella, E.L. Crash simulation of a vertical drop test of a B737 fuselage section with overhead bins and luggage. In Proceedings of the 3rd Triennial International Aircraft Fire and Cabin Safety Research Conference, Atlantic City, NJ, USA, 1–4 August 2001. [Google Scholar]

- Rassaian, M.; Byar, A.; Ko, J. Numerical simulation of 737 fuselage section drop test. In Proceedings of the NAFEMS World Congress, Crete, Greece, 16–19 June 2009. [Google Scholar]

- Wiggenraad, J.; Michielsen, A.; Santoro, D.; Lepage, F.; Kindervater, C.; Beltrán, F.; Al-Khalil, M. Finite element methodologies development to simulate the behaviour of composite fuselage structure and correlation with drop test. Air Space Eur. 2001, 3, 228–233. [Google Scholar] [CrossRef]

- Middendorf, P.; Heimbs, S. Crash simulation of composite structures. Compos. Mater 2007, 2, 18–22. [Google Scholar]

- Califano, A. Modelling the Fatigue Behavior of Composites under Spectrum Loading; AIP Publishing: University Park, MD, USA, 2018. [Google Scholar]

- Riccio, A.; Damiano, M.; Raimondo, A.; Di Felice, G.; Sellitto, A. A fast numerical procedure for the simulation of inter-laminar damage growth in stiffened composite panels. Compos. Struct. 2016, 145, 203–216. [Google Scholar] [CrossRef]

- Riccio, A.; Di Costanzo, C.; Di Gennaro, P.; Sellitto, A.; Raimondo, A. Intra-laminar progressive failure analysis of composite laminates with a large notch damage. Eng. Fail. Anal. 2017, 73, 97–112. [Google Scholar] [CrossRef]

- Riccio, A.; Sellitto, A.; Saputo, S.; Russo, A.; Zarrelli, M.; LoPresto, V. Modelling the damage evolution in notched omega stiffened composite panels under compression. Compos. Part B Eng. 2017, 126, 60–71. [Google Scholar] [CrossRef]

- Liu, X.; Guo, J.; Bai, C.; Sun, X.; Mou, R. Drop test and crash simulation of a civil airplane fuselage section. Chin. J. Aeronaut. 2015, 28, 447–456. [Google Scholar] [CrossRef]

- Kuraishi, A.; Tsai, S.W.; Liu, K.K. A progressive quadratic failure criterion, part B. Compos. Sci. Technol. 2002, 62, 1683–1695. [Google Scholar] [CrossRef]

- Spahn, J.; Andrä, H.; Kabel, M.; Muller, R. A multiscale approach for modeling progressive damage of composite materials using fast Fourier transforms. Comput. Methods Appl. Mech. Eng. 2014, 268, 871–883. [Google Scholar] [CrossRef]

- Pineda, E.J.; Waas, A.M.; Bednarcyk, B.A.; Collier, C.S.; Yarrington, P.W. Progressive damage and failure modeling in notched laminated fiber reinforced composites. Int. J. Fract. 2009, 158, 125–143. [Google Scholar] [CrossRef]

- Basu, S.; Waas, A.; Ambur, D.R. Prediction of progressive failure in multidirectional composite laminated panels. Int. J. Solids Struct. 2007, 44, 2648–2676. [Google Scholar] [CrossRef]

- Apalak, Z.G.; Apalak, M.K.; Genç, M.S. Progressive Damage Modeling of an Adhesively Bonded Unidirectional Composite Single-lap Joint in Tension at the Mesoscale Level. J. Thermoplast. Compos. Mater. 2006, 19, 671–702. [Google Scholar] [CrossRef]

- Ridha, M.; Wang, C.H.; Chen, B.; Tay, T. Modelling complex progressive failure in notched composite laminates with varying sizes and stacking sequences. Compos. Part A: Appl. Sci. Manuf. 2014, 58, 16–23. [Google Scholar] [CrossRef]

- Pineda, E.J.; Waas, A. Modelling progressive failure of fibre reinforced laminated composites: Mesh objective calculations. Aeronaut. J. 2012, 116, 1221–1246. [Google Scholar] [CrossRef]

- Pineda, E.J.; Waas, A.M. Numerical implementation of a multiple-ISV thermodynamically-based work potential theory for modeling progressive damage and failure in fiber-reinforced laminates. Int. J. Fract. 2013, 182, 93–122. [Google Scholar] [CrossRef]

- Laurin, F.; Carrere, N.; Maire, J.-F. A multiscale progressive failure approach for composite laminates based on thermodynamical viscoelastic and damage models. Compos. Part A Appl. Sci. Manuf. 2007, 38, 198–209. [Google Scholar] [CrossRef]

- Lapczyk, I.; Hurtado, J.A. Progressive damage modeling in fiber-reinforced materials. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2333–2341. [Google Scholar] [CrossRef]

- Murakami, S.; Kamiya, K. Constitutive and damage evolution equations of elastic-brittle materials based on irreversible thermodynamics. Int. J. Mech. Sci. 1997, 39, 473–486. [Google Scholar] [CrossRef]

- Donadon, M.V.; Falzon, B.G.; Iannucci, L.; Hodgkinson, J.M. Intralaminar toughness characterisation of unbalanced hybrid plain weave laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1597–1611. [Google Scholar] [CrossRef]

- Pappas, G.; Botsis, J. Intralaminar fracture of unidirectional carbon/epoxy composite: Experimental results and numerical analysis. Int. J. Solids Struct. 2016, 85, 114–124. [Google Scholar] [CrossRef]

- Iwamoto, M.; Ni, Q.-Q.; Fujiwara, T.; Kurashiki, K. Intralaminar fracture mechanism in unidirectional CFRP composites. Eng. Fract. Mech. 1999, 64, 721–745. [Google Scholar] [CrossRef]

- Hashin, Z. Failure Criteria for Unidirectional Fiber Composites. J. Appl. Mech. 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Abaqus Theory Manual Version 6.16. Dassault System France 2016. Available online: http://www.abaqus.com (accessed on 5 April 2019).

| Load Condition | Equivalent Stress | Equivalent Displacement |

|---|---|---|

| Fibre Tension | ||

| Fibre Compression | ||

| Matrix Tension | ||

| Matrix Compression |

| Fibre Composite Material | |

|---|---|

| Young’s Modulus, E11 [MPa] | 137,500 |

| Young’s Modulus, E22 [MPa] | 8200 |

| Shear Modulus, G12 [MPa] | 3950 |

| Shear Modulus, G13 [MPa] | 3950 |

| Shear Modulus, G23 [MPa] | 3950 |

| Poisson’s Ratio, ν12 = ν13 = ν23 | 0.35 |

| Fibre Tensile Strength F1t [MPa] | 1890 |

| Fibre Compressive Strength F1c [MPa] | 1008 |

| Matrix Tensile Strength F2t [MPa] | 86.5 |

| Matrix Compressive Strength F2c [MPa] | 112 |

| In-Plane Shear Strength, S12 [MPa] | 95 |

| Out-Plane Shear Strength, S23 [MPa] | 100 |

| Density [ton/mm3] | 1.9 e−9 |

| Ply Thickness [mm] | 0.129 |

| Woven Fabric Material | |

|---|---|

| Young’s Modulus, E11 [MPa] | 55,000 |

| Young’s Modulus, E22 [MPa] | 55,000 |

| Shear Modulus, G12 [MPa] | 3363 |

| Shear Modulus, G13 [MPa] | 3363 |

| Shear Modulus, G23 [MPa] | 3363 |

| Poisson’s Ratio, ν12 = ν13 = ν23 | 0.30 |

| Fibre Tensile Strength F1t [MPa] | 650 |

| Fibre Compressive Strength F1c [MPa] | 650 |

| Matrix Tensile Strength F2t [MPa] | 650 |

| Matrix Compressive Strength F2c [MPa] | 650 |

| In-Plane Shear Strength, S12 [MPa] | 150 |

| Out-Plane Shear Strength, S23 [MPa] | 150 |

| Density [ton/mm3] | 1.97 e−9 |

| Ply Thickness [mm] | 0.25 |

| Aluminium Al2025 | |

| Young’s Modulus, E [MPa] | 70,000 |

| Poisson’s ratio, ν12 = ν13 = ν23 | 0.33 |

| Yield stress [MPa] | 369 |

| Ultimate Tensile Stress [MPa] | 469 |

| Density [ton/mm3] | 2.7 e−9 |

| Stacking Sequence | |

|---|---|

| Skin | [90/45/0/45]s |

| Stringer | [45/45/0/0/90/0/0]s |

| Frames | [90/45/0/45/-45/90/45/45/0/-45/45/-45]s |

| Components in Woven Fabric Material | [0/45/0/-45]s |

| I | UNIDIRECTIONAL UD | 24 | 10 | 3 | 6 |

| I | Woven | 8 | 8 | 8 | 8 |

| II | UNIDIRECTIONAL UD | 44 | 16 | 3 | 6 |

| II | Woven | 12 | 12 | 12 | 12 |

| III | UNIDIRECTIONAL UD | 26 | 12 | 3 | 6 |

| III | Woven | 6 | 6 | 6 | 6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riccio, A.; Saputo, S.; Sellitto, A.; Di Caprio, F. A Numerical Assessment on the Influences of Material Toughness on the Crashworthiness of a Composite Fuselage Barrel. Appl. Sci. 2020, 10, 2019. https://doi.org/10.3390/app10062019

Riccio A, Saputo S, Sellitto A, Di Caprio F. A Numerical Assessment on the Influences of Material Toughness on the Crashworthiness of a Composite Fuselage Barrel. Applied Sciences. 2020; 10(6):2019. https://doi.org/10.3390/app10062019

Chicago/Turabian StyleRiccio, A., S. Saputo, A. Sellitto, and F. Di Caprio. 2020. "A Numerical Assessment on the Influences of Material Toughness on the Crashworthiness of a Composite Fuselage Barrel" Applied Sciences 10, no. 6: 2019. https://doi.org/10.3390/app10062019

APA StyleRiccio, A., Saputo, S., Sellitto, A., & Di Caprio, F. (2020). A Numerical Assessment on the Influences of Material Toughness on the Crashworthiness of a Composite Fuselage Barrel. Applied Sciences, 10(6), 2019. https://doi.org/10.3390/app10062019