Abstract

This paper studies a new convenient method to prepare microfibrillated cellulose from a bleached eucalyptus kraft pulp. First, the wood pulp was reacted with urea to produce cellulose carbamate (CC), and then the CC was treated with colloid mill in an acidic medium. A feasible preparation process for CC was to soak the pulp with the urea solution, and then the cellulose pulp was dewatered, dried, and reacted with urea at high temperatures above the melting point of urea. The Kjeldahl method, infrared spectroscopy, and solid 13C NMR were used to confirm the effectiveness of the reaction. On the basis of CC with the degree of substitution, DS = 0.123, the aqueous suspension with 2% content of CC at pH values of 1, 3, or 7 was severally ground by a colloid milling. After centrifugation, the nanocellulose carbamate fiber (CCNF) in the supernatant was obtained. X-ray diffraction showed that CC and CCNF had the same crystal form as the cellulose pulp, but the crystallinity decreased successively. The nanometer diameter of the CCNF fiber was observed with scanning electron microscopy. Results showed that when the pH value of the CC suspension decreased during the colloid milling, the crystallinity of the CCNF decreased along with the decrease of fiber diameter, and the zeta potential of the supernatant increased. This indicated that carbamate side groups of CC were protonated at low pHs and the cation repulsion between cellulose molecular chains enhanced the driving force of the pulp separation to CCNF. Interestingly, the thermal stability of CCNF is comparable to that of the original cellulose, and the enhancement effect of CCNF on starch can be clearly observed even at a relatively low loading of CCNF.

1. Introduction

As a renewable resource and a biodegradable raw material, cellulose derivatives are attracting more and more attention in the context of increasingly depleted oil resources and environmental protection. It is estimated that bioenergy will replace 30% of the oil source by 2025 [1]. As one of the most important materials of cellulose derivatives, cellulose nanofibers have the advantages of high hydrophilicity, high young’s modulus, high strength, and large specific surface area, which provide a broader space for the development of cellulose nanofiber composites, and cellulose nanofibers are now favored by more and more industries.

Polymer nanocomposites are composed of polymers as matrix and nanomaterials as filler. Cellulose nanofibers are a kind of excellent filler, which is widely used as an enhancement element in various materials, such as starch and cellulose matrices [2,3]. There are three kinds of cellulose nanofibers: cellulose nanocrystal, cellulose nanofiber, and microfibrillated cellulose (MFC). Among them, MFC has a higher aspect ratio and entangled structure, which become a novel nano-reinforcing material with great potential [4,5].

The dimensions and morphology of MFC vary greatly, mainly depending on the degree of fibrillation and any pretreatment involved. Usually, the preparation of MFC includes enzymatic hydrolysis [6], multipass high-pressure homogenization [7], direct mechanical fibrillation [8], or a combination of the aforementioned ways. The direct mechanical fibrillation is mainly for preparation of MFC, which is achieved by a homogenizing process with high pressure for dilute slurries of cellulose pulp. The fibers are subjected to a large pressure drop with shearing and impact forces [9,10,11]. The principle of the physical-mechanical method is to break cellulose pulp into fibrils by mechanical forces. In addition to the high-pressure homogenization method [12,13], other physical methods are usually adopted, including the fine grinding method [14], freezing crushing method [15,16], and ultra-high frequency ultrasonic method [17,18]. In our laboratory, NaOH was used to a mercerize eucalyptus kraft pulp, and then MFC was obtained by ball-milling method. Due to the strong impact force of ball-milling, the obtained nanocellulose had a large dispersion in diameter and a relatively short length [2].

To reduce the energy consumption of the physical-mechanical method, some pretreatments for cellulose modification were developed. For example, after ionization [19] or TEMPO oxidation [20] of cellulose pulp, the electrostatic repulsion between cellulose molecules would facilitate the mechanical treatment to crack the fiber bundles and improve the stability of the MFC dispersion. For example, when the substitution degree of carboxymethylation of a cellulose pulp was 0.1, the energy consumption of following high pressure homogenization can be dropped to 500 kWh/ton [11].

Inspired by the pretreatment and ionization of cellulose, we used cellulose carbamate (CC) as a precursor of cellulose nanofiber. CC is the intermediate of the Carbocel process [21,22], which is used to produce rayon and cellophane, and thus has received a lot of attention [23,24]. The starting point of this study is to prepare CC from lignocellulose of eucalyptus and investigate the preparation conditions. The intent is to loosen the bulk structure of cellulose through the carbamate reaction, and then make the amino group of CC with a positive charge under acidic conditions, so as to facilitate the following mechanical splitting. The colloid milling was used instead of high-pressure homogenization, and the nanocellulose carbamate fibers (CCNF) within 100 nm in diameter were obtained. A starch/CCNF composite film was prepared to test the enhancement of CCNF on the polymer.

2. Materials and Methods

2.1. Materials

Bleached eucalyptus kraft pulp (90–92.5% α-cellulose, 750–850 intrinsic viscosity) was supplied by the Yunjinglin Paper Co. LTD (Yunnan, China). Corn starch (14% moisture, 25% amylose) was provided by Baoji Starch Company (Baoji, China) with the viscosity average molecular weight of 1.55 × 107 g/mL. The pulp and starch were used as received. All reagents were of analytical grade, and deionized water was used in all experiments.

2.2. Preparation of CC by a Solid Phase Method

The carbamate reaction was based on the method of Fu et al. [25] with slight modification. The eucalyptus kraft pulp was dried in an oven at 102 °C to a constant weight. Then, the dried pulp with weight Wcell was placed into a certain concentration of aqueous urea solution, mixed evenly and stored at room temperature for 24 h. The wood pulp soaked in the urea solution was wrapped in a gauze and centrifuged, and then was dried at 60 °C in the oven again. The dried pulp with urea was weighed as Wtotal, and the urea weight participated in the reaction, Wurea = Wtotal − Wcell.

In the solid-state reaction of the reactants in an airtight container, the reaction took place in an oven for a certain time at a certain temperature to generate CC, and then the resultant was washed with deionized water and dried. The reaction material weight ratio, Wurea/Wcell; reaction temperature; and time were changed, as shown in Table 1.

Table 1.

Conditions and results of cellulose carbamate (CC) synthesis.

The reactions that occurred in the solid-phase preparation of CC include the formation of the intermediate HNCO from urea and the reaction of isocyanic acid with hydroxyl groups of cellulose to form CC [26].

2.3. Determination of Nitrogen Content—Kjeldahl Method

Sample CC was heated and decomposed by concentrated sulfuric acid on the graphite furnace digestion instrument (Model: SH420, Hannon Co. Ltd., Jinan, China), and then the nitrogen content (N%) of CC was determined by automatic Kjeldahl apparatus (Model: K1100, Hannon Co. Ltd., Jinan, China).

The degree of substitution of cellulose hydroxyl groups [27] can be calculated from the nitrogen content of cellulose,

where DS represents the degree of substitution of cellulose surface hydroxyl groups; Numbers 14 and 162 are the molar masses of N and the cellulose structural unit, respectively. Number 43 is the molar mass difference between the carbamate group -O-CO-NH2 (60) and the substituted group -OH of cellulose (17).

2.4. Preparation of CCNF by Colloid Milling

Sample CC was preliminarily cut short by a household cooking machine (Model: JYL-G12E, Joyoung Co. Ltd., Jinan, China), and sieved through a 40-mesh screen, and then was dispersed in deionized water at a concentration of 2 wt%. The pretreated CC slurry was ground by a vertical colloid mill (Model: JM50, Chenghua packaging machinery Co., Shantou, China). The clearance between the rotor and the stator of the colloid mill is in a range of 0.1 to 5 mm, with 10 stages adjustable, and the rotating speed is 3000 rpm. Meanwhile, the pH of the CC suspension was adjusted to 1, 3, and 7, respectively, with dilute sulfuric acid. The grinding process started from the large clearance to the small. The CC sample suspension underwent grinding once at each clearance stage, and then was repeatedly milled 10 times at the minimum clearance. After grinding, the slurry was centrifuged by using a centrifugal machine (Model: LD-4, Kexi instrument Co. Ltd., Guangzhou, China) for 15 min at 4000 rpm. The centrifugal precipitate was removed, and the solid content of the supernatant was tested by dry weighting method. The supernatant was sealed in plastic containers and refrigerated at 3 °C before use.

2.5. Zeta Potential Determination

The content of cellulose in the supernatant was adjusted to 0.1% by addition of deionized water. The zeta potential of the supernatant was determined with Zetasizer Nano ZS90 (Malvern Instruments, Malvern, UK) under the condition of 25 °C.

2.6. Film-Forming of Starch/CCNF Nanocomposites

A certain content of CCNF (0, 0.5, 1, 2, 3, and 4 wt% based on starch, respectively) and glycerol (15 wt% based on starch), together with starch CS keeping the total solid content at 4 wt% in a certain amount of deionized water, were stirred at 350 rpm in a three-necked flask at room temperature for 30 min. The mixture was heated up to 95 °C under stirring at 160 rpm and the temperature was kept constant for 30 min. After gelatinization of starch, the paste of 80 mL was taken into a flat glass tray (210 × 150 mm) to obtain CS/CCNF nanocomposite film by the way of solution casting. The tray was put in an oven and was dried at 55 °C for 4 h. After drying, the film was peeled off from the glass and cut into 10 × 100 mm sized bars and was conditioned in a desiccator with a relative humidity (RH) of 68% (in the atmosphere over CuCl2 saturated aqueous solution) for 72 h prior to further tests and analyses.

2.7. Characterization

2.7.1. Fourier Transform Infrared (FTIR) Spectroscopy

Sample CC and cellulose were laminated separately with potassium bromide, and the Fourier Transform Infrared (FTIR) spectroscopy was performed using a FTS3000 FTIR Spectrum Scanner (Agilent, Hercules, CA, USA). All the spectra were recorded in transmission mode during 28 scans with a resolution of 4 cm−1 in the range of 4000 to 500 cm−1.

2.7.2. Nuclear Magnetic Resonance (NMR) Spectroscopy

Cellulose carbamate and the pulp were dried and powdered with a cooking machine (Model: JYL-G12E, Joyoung Co Ltd., Jinan, China), and then analyzed by a solid NMR spectrometer (Model: AVANCE III 500 MHz, Bruker Co Ltd., Fallanden, Switzerland).

2.7.3. X-ray Diffraction (XRD)

X-ray diffraction (XRD) patterns of the pulp, CC, and CCNF were recorded by use of an X-ray diffractometer (Model: D/MAX-III, Philips Co. Ltd., Amsterdam, Holland) at a wavelength of 0.1539 nm. The samples were exposed to the X-ray beam under the X-ray generator running at 40 kV and 30 mA. The XRD patterns were detected at ambient temperature in the angular region of 2θ from 5° to 45° with a scanning rate of 2° min−1. Software Jade 6.0 software was used to calculate the crystallinity of different samples by using the following equations [28],

where Xr (%) is the degree of crystallinity, Sc is the area of crystal peak, and Sa is the area of non-crystal peak.

2.7.4. Scanning Electron Microscope (SEM)

The suspension of CCNF was diluted to 0.1 wt% with deionized water, spin-coated on a conductive adhesive tape, and dried. The samples were coated with gold (the thickness of the applied gold layer was ~20 nm) and then examined with a scanning electron microscope (FE-SEM, Inspect F, FEI, Hillsboro, OR, USA) under an acceleration voltage of 15 kV or 5 kV for observation of the CCNF or the composite film, respectively.

2.7.5. Thermogravimetric Analysis (TGA)

The thermal properties were conducted on a thermal analyzer (Model: TG 209 F3, Netzsch Co Ltd., Selb, Germany). The relative mass loss of samples (5–7 mg) was recorded from 50 °C to 700 °C at a heating rate of 10 °C min−1.

2.7.6. Zeta Potential

The zeta potential of the cellulose carbamate was measured using Malvern Zetasizer Nano ZSP.

2.7.7. Tensile Measurement

After being conditioned in the desiccator at RH 68% for 72 h, the CS/CCNF nanocomposite films of 10 mm × 100 mm in size were taken out. The tensile properties of the film bars were tested with a tensile testing instrument (Model: UTM-1432, Jinjian Testing Instrument Co. Ltd., Chengde, China). The initial distance between the fixtures was 50 mm with the crosshead speed of 100 mm min−1. For each data point, the average values with standard deviations were obtained from at least ten samples.

2.7.8. Statistical Analysis

All of our experiment data were repeated five times and the experimental data were expressed as the mean ± standard deviation. Tukey’s multiple comparison test (p < 0.05) was utilized for locating the difference between the means.

3. Results and Discussion

3.1. Preparation Conditions of CC

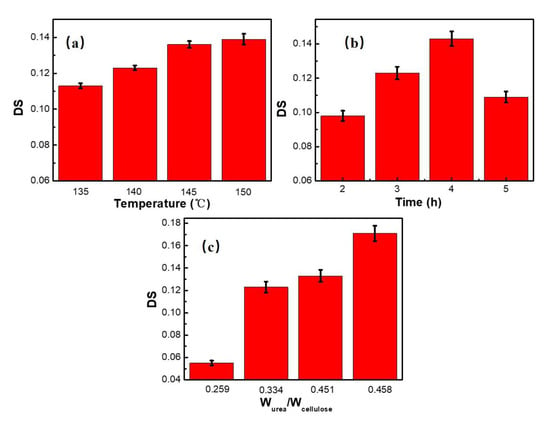

For preparation of CC, the influences of reaction conditions on the degree of substitution are shown in Figure 1a. The experimental data presented a slow upward trend of the DS with the increase of temperature in the range of 135 °C and 150 °C for 3 h, in a weight ratio of Wurea/Wcell = 0.334. We noted from Equations (1) and (2) that the reaction between urea and cellulose first goes through a deammoniating process of urea into isocyanic acid at high temperature, and then the HNCO reacts with cellulose to form CC. A high temperature above the melting point (132.7 °C) of urea was an important factor for CC synthesis for two reasons: One is that above the melting point of urea the solid–solid system became a liquid–solid reaction, which can enhance the contact between the reactants. The other reason is that above the melting point of urea, the reactive HNCO can be obtained in large quantities by the decomposition of urea [29]. However, urea is unstable at high temperature and the thermal decomposition products involve many by-products that are unfavorable for the synthesis of CC. For example, when heated to 150–240 °C at a heating rate of 10 K/min, an ~73% weight–loss ratio of urea occurred along with the formation of the by-products, such as biuret, triuret, cyanuric acid, ammonia, carbon dioxide, and so on [30]. In addition, when the temperature was higher than 145 °C, the color of CC was yellowing due to the Maillard reaction. Therefore, too high temperature was not needed for the production of CC. When the temperature was 145 °C, the DS of CC reached 0.136.

Figure 1.

Relationship between the CC degree of substitution and carbamate reaction conditions: temperature (time: 3 h and Wurea/Wcellulose: 0.334) (a), time (temperature: 140 °C and Wurea/Wcellulose: 0.334) (b), and weight ratio of urea/cellulose (time: 3 h and temperature: 140 °C) (c).

Under conditions of weight ratio Wurea/Wcell at 0.334 and the reaction temperature at 140 °C, the DS increased with time up to 0.143 at 4 h, and after that decreased rapidly. As the pyrolysis of cellulose at 140 °C is negligible [31], and the thermochemical reactions of urea and its pyrolysis products are affected by high temperature and by oxygen [29,30], the phenomenon of decreased DS at reaction time 5 h in Figure 1b could be explained by the thermal degradation of carbamate of CC. Therefore, the reaction time should be controlled within 4 h. Later in this article, we will analyze the thermogravimetric performance of CC. In Figure 1c, the influence of material weight ratio on substitution degree of CC was also shown. When the urea/cellulose weight ratio increased from 0.259 to 0.334, DS rapidly increased from 0.055 to 0.123.

3.2. Confirmation of Carbamation of Cellulose

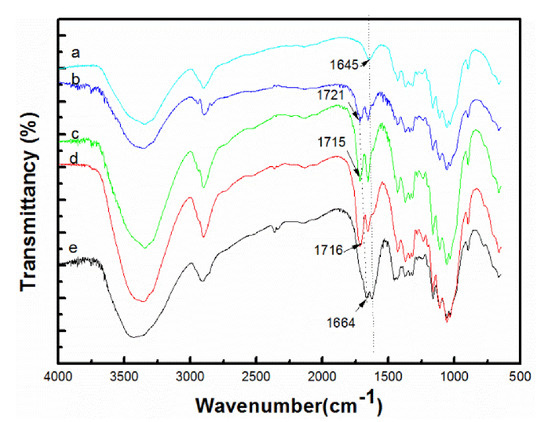

To confirm the successful modification of cellulose, Fourier Transform Infrared Spectroscopy (FTIR) of the original cellulose and CC with different DS were performed, and the results are shown in Figure 2. The obvious absorption peak at 1715 cm−1 for the CC sample was assigned to the stretching vibration of the carbonyl group of the carbamate [32,33]. This indicated that urea had successfully reacted with cellulose to form CC.

Figure 2.

FTIR of (a) cellulose (bleached eucalyptus kraft pulp), (b) CC (DS = 0.143), (c) CC (DS = 0.133), (d) CC (DS = 0.123), and (e) CC (DS = 0.098).

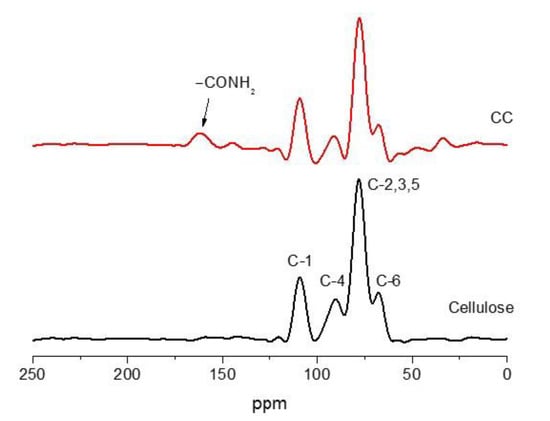

NMR spectroscopy has been proven to be a convenient and reliable method to elucidate the chemical structure of modified cellulose CC [31]. The solid-state NMR carbon spectra of the cellulose and cellulose carbamate were determined in the form of solid powder, as shown in Figure 3. Typical chemical shifts of cellulose carbamate was observed, in which the carbon shift of C-1 was at 110 ppm, C-4 at 88 ppm, C-2, C-3 and C-5 at 74.1 ppm, and C-6 at 64 ppm [20]. Significant signal of carbonyl carbon appeared at 161 ppm [34]. The results showed that carbamate groups were successfully introduced into the cellulose skeleton.

Figure 3.

Solid-state 13C-NMR spectra of cellulose and cellulose carbamate (DS = 0.123).

3.3. Preparation and Structures of CCNF

In this study, a colloid mill was used to split CC of 2% in a suspension into cellulose nanofibers under mechanical action, instead of the traditional high-pressure homogenizer [35]. In the processing parts of the colloid mill, there is a high-speed rotating rotor and a stationary stator matched. The processing material is ground in a spiral motion from the inlet to the outlet of the grinding area and is driven by its own weight or the pressure of the external pump through its clearance between the rotor and the stator. Different from the pressure-type homogenizer, the colloid mill is a kind of centrifugal equipment, in which a powerful vortex shear force of friction is generated. In this way, it can effectively crush particle material to achieve the effect of ultra-fine grinding. Therefore, it has the advantage of simple structure, simple equipment maintenance, and low energy consumption, which is suitable for processing high viscosity materials and large particles materials.

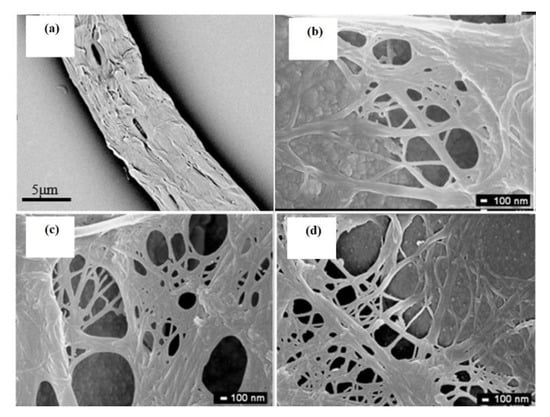

As the amino group of CC can capture protons to become cations in an acidic medium [36], the electrostatic repulsion between cationic CC molecules will contribute to the mechanical splitting of cellulose during colloid milling. The pH of 2% CC (DS = 0.123) suspensions was adjusted with or without dilute sulfuric acid to 1, 3, and 7, respectively. After colloid milling, the pH value was basically unchanged due to the low content of the CC suspension. As expected, the zeta potential of the supernatant increased as the pH decreased, as shown in Table 2. Also, Figure 4 clearly shows SEM photos of CCNF from the supernatant after centrifugation of CC suspensions, which had been colloid-milled at different pH values. CCNF diameter decreased with the decrease of pH of the CC suspension ground (Table 2). It is because that the amino -NH2 of -OCONH2 on CC is transformed into a cation of -NH3+ under acidic conditions. Due to the repulsive interaction of the same cation charges, cellulose chains were more likely to be cleaved under the action of high shear force. The results also confirmed the conclusion that the ionized modified cellulose pulp is easier to be split up, such as anionic modification [19] and cationic modification with N-(2-3-epoxypropyl) trimethylammonium chloride [37].

Table 2.

The crystallinity of cellulose before and after modifications and zeta potential in supernatant of the CC (DS = 0.123) after grinding at different pH values.

Figure 4.

SEM images of original cellulose (a) and nanocellulose carbamates fibers (CCNF) from CC with DS = 0.123 ground at pH = 7 (b), pH = 3 (c), pH = 1 (d).

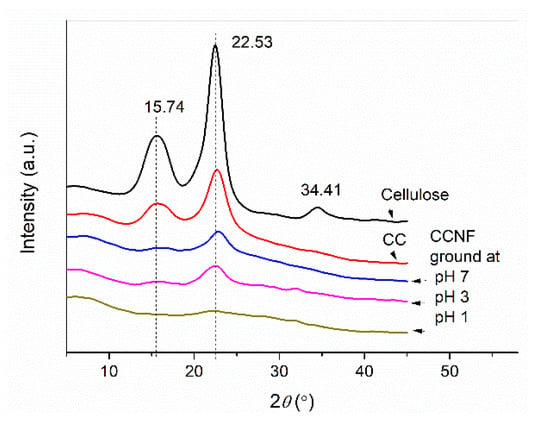

The crystalline structures of a polymer can be obtained by X-ray diffraction (XRD). The XRD patterns of cellulose and modified cellulose are shown in Figure 5. The diffraction peaks of eucalyptus lignocellulose are 15.74°, 22.53°, and 34.41° in 2θ angles, corresponding well to the crystalline form of cellulose I [38,39]. The CC with DS 0.123 and CCNFs ground at different pH values had a similar diffraction pattern to the original cellulose, indicating that the carbamation occurred mainly at the surface and in amorphous regions, without greatly affecting the inner crystalline structure of cellulose. However, the crystallinity decreased with the processing steps (carbamation and colloid milling), and also with the decrease in pH in the colloid milling, as presented in Table 2. This can be ascribed to two reasons: First, it can be due to that the crystal of the original cellulose disintegrated during the processes, but no new recrystallization occurred. Second, with decreasing pH in the colloid milling, more hydroxyl groups of cellulose were substituted, which affected the inner crystalline structure of cellulose.

Figure 5.

XRD patterns of eucalyptus lignocellulose, CC (DS = 0.123), and CCNF samples ground at different pH values.

As can be seen from Figure 5, after the reaction of eucalyptus cellulose with urea, the degree of crystallinity was lowered by 42.71%. This means that at high temperatures the molten urea can enter part of the crystal regions of the cellulose [40]. The data in Table 2 also present a significant reduction in crystallinity of the cellulose carbamate after colloid milling, which suggests that the hydration enhanced by the cationization of CC in an acidic milling media, combined with the high grinding mechanical force, greatly reduced the crystallization of cellulose.

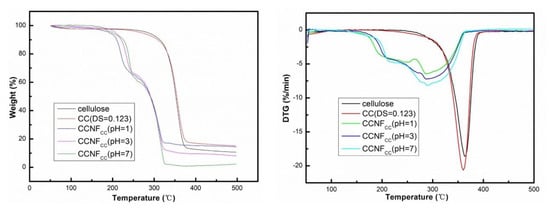

3.4. Thermal Properties of Cellulose and CC

Thermogravimetric curves of Thermogravimetric (TG)/ Differential thermal gravity (DTG) for the original cellulose pulp, cellulose carbamate, and nanocelluloses are shown in Figure 6. The cellulose and CC simply displayed a major thermal decomposition temperature region at ~250–363 °C. After introduction of carbamate group, the maximum thermal decomposition rate of CC was at 359 °C, lower than that of original cellulose at 363 °C. The slight decrease in its thermal stability can be attributed to the reduction in the crystallinity of CC, a lower DP, or side-groups participating to the degradation reaction (Table 2); whereas for the nanocelluloses, it was obvious that they presented a stepwise degradation behavior, which involved two processes between 200 and 400 °C. The lower temperature degradation process corresponds to the temperature.

Figure 6.

TG/DTG curves of the original cellulose, cellulose carbamates (DS = 0.123).

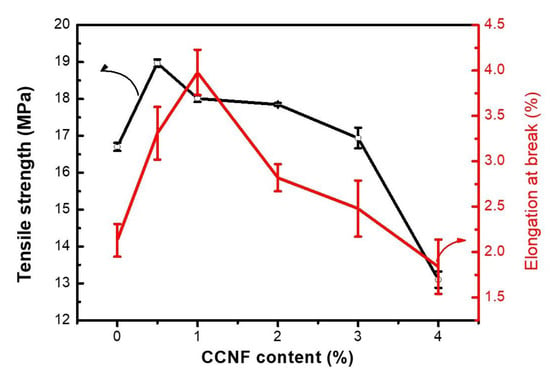

3.5. Mechanical Properties of CCNF/CS Nanocomposite Films

The CCNF prepared under pH 1 was used as filler in the CS film, which was plasticized by glycerol. The mechanical properties of the CS/CCNF composite film with CCNF content of 0.5, 1, 2, 3, or 4 wt% are presented in Figure 7. When CCNF was added to starch, the tensile strength and elongation at break of CS/CCNF composite films were significantly increased at first, then reached a turning point, and then were gradually decreased with the increase of CCNF content. The turning point for strength was at 0.5% of the CCNF, and for breaking elongation at 1%. Generally, cellulose nanofiber is an excellent polymer filler for reinforcing [41]. In a previous study [42] of our research group on starch/nanocellulose composite film, the tensile strength increased with the increase of the filler content up to 20%. The difference between the data of this study and previous studies may be explained by the huge difference in crystallinity: the crystallinity of CCNF obtained in this study is only ~2% (Table 2), whereas common cellulose nanofibers have high crystallinity, such as 80–90% for bacterial cellulose nanofiber and 90% for nanocrystalline cellulose [11]. This means that the CCNF with lower crystallinity may not be applicable to polymer reinforcement.

Figure 7.

Tensile properties of CS/CCNF films with different CCNF contents.

4. Conclusions

In this paper, a novel method to prepare cellulose nanofibers was studied. For this purpose, CC was synthesized by use of wood pulp and urea. The mechanism after weak modification had been proved to be the modification of carbamate and the cationization of carbamate groups of cellulose in acidic media, which could transform the attractive interaction between cellulose chains into the repulsion between identical charges, marked by the lower crystallinity of CC and the much lower that of CCNF and by the higher zeta potential of the resultant colloidal supernatant. This is useful for mechanical splitting of cellulose fibers by the colloid milling, resulting in nano-diameter CCNF fibers.

The CCNF obtained by the method in this paper has a low crystallinity, which reduces the thermal stability of CC relative to the wood pulp. The CCNF also had a low degree of enhancement as filler in starch matrix in comparison with the ordinary cellulose nanofibers with higher crystallinity. Cellulose nanofibers are important nanomaterials for sustainable development. Therefore, we will study the influence of CC substitution degree on the crystallinity of CCNF in detail on the basis of this study. In addition, the application of the cationic CCNF could open up a new technical field in the future. For example, the cationic CCNF with low crystallinity may be employed as an environmentally friendly dispersant or flocculant for solid powders.

Author Contributions

Conceptualization, P.Z. and M.Z.; Methodology, Y.W.; Formal analysis, Y.W.; investigation, A.Y.; Writing—original draft preparation, Y.W.; Writing—review and editing, M.Z. and P.Z.; Funding acquisition, M.Z. and P.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the National Natural Science Foundation of China (No.51903178) and the Graduate Program Construction Project Funding of Sichuan University (2017KCSJ036).

Acknowledgments

We also appreciate the efforts of the journal editor for editing this paper.

Conflicts of Interest

The authors have declared no conflicts of interest.

References

- Gelfand, I.; Sahajpal, R.; Zhang, X.Z.; Izaurralde, R.C.; Gross, K.L.; Robertson, G.P. Sustainable bioenergy production from marginal lands in the US Midwest. Nature 2013, 493, 514–517. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, K.; Zhou, M.; Wei, Y.J.; Cheng, F.; Lin, Y.; Zhu, P.X. High-performance starch films reinforced with microcrystalline cellulose made from eucalyptus pulp via ball milling and mercerization. Starch/Stӓrke 2019, 71, 1800218. [Google Scholar] [CrossRef]

- Cheng, G.; Zhu, P.X.; Li, J.L.; Cheng, F.; Lin, Y.; Zhou, M. All-cellulose films with excellent strength and toughness via a facile approach of dissolution-regeneration. J. Appl. Polym. Sci. 2019, 136, 46925. [Google Scholar] [CrossRef]

- Borrega, M.; Orelma, H. Cellulose Nanofibril (CNF) Films and Xylan from Hot Water Extracted Birch Kraft Pulps. Appl. Sci. 2019, 9, 3436. [Google Scholar] [CrossRef]

- Zhang, L.; Zheng, S.; Hu, Z.; Zhong, L.; Wang, Y.; Zhang, X.; Xue, J. Preparation of Polyvinyl Alcohol/Bacterial-Cellulose-Coated Biochar–Nanosilver Antibacterial Composite Membranes. Appl. Sci. 2020, 10, 752. [Google Scholar] [CrossRef]

- Cheng, G.; Zhou, M.; Henriksson, M.; Henriksson, G.; Berglund, L.; Lindström, T. An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur. Polym. 2007, 43, 3434–3441. [Google Scholar]

- Li, J.; Wei, X.; Wang, Q.; Chen, J.; Chang, G.; Kong, L.; Su, J.; Liu, Y. Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydr. Polym. 2012, 90, 1609–1613. [Google Scholar] [CrossRef]

- Wang, Q.Q.; Zhu, J.Y.; Gleisner, R.; Kuster, T.A.; Baxa, U.; McNeil, S.E. Morphological development of cellulose fibrils of a bleached eucalyptus pulp by mechanical fibrillation. Cellulose 2012, 19, 1631–1643. [Google Scholar] [CrossRef]

- Khalil, H.A.; Bhat, A.H.; Yusra, A.I. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A new family of nature-based materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef]

- Zimmermann, T.; Bordeanu, N.; Strub, E. Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr. Polym. 2010, 79, 1086–1093. [Google Scholar] [CrossRef]

- Dufresne, A.; Cavaille, J.Y.; Vignon, M.R. Mechanical behavior of sheets prepared from sugar beet cellulose microfibril. J. Appl. Polym. Sci. 1997, 64, 1185–1194. [Google Scholar] [CrossRef]

- Iwamoto, S.; Nakagaito, A.N.; Yano, H. Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl. Phys. A Mater. Sci. Process. 2007, 89, 461–466. [Google Scholar] [CrossRef]

- Chakraborty, A.; Sain, M.; Kortschot, M. Cellulose microfibrils: A novel method of preparation using high shear refining and cryocrushing. Holzforschung 2005, 98, 102–107. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Cellulose microfibrils: A novel method of preparation using high shear refining and cryocrushing. BioResour. Technol. 2008, 99, 1664–1671. [Google Scholar] [CrossRef] [PubMed]

- Johnson, R.K.; Zink-Sharp, A.; Renneckar, S.H.; Glasser, W.G. A new bio-based nanocomposite: Fibrillated TEMPO-oxidized celluloses in hydroxypropylcellulose matrix. Cellulose 2009, 16, 227–238. [Google Scholar] [CrossRef]

- Wang, S.; Cheng, Q. A novel process to isolate fibrils from cellulose fibers by high-intensity ultrasonication, part 1: Process optimization. J. Appl. Polym. Sci. 2009, 113, 1270–1275. [Google Scholar] [CrossRef]

- Lindström, T.; Aulin, C. Market and technical challenges and opportunities in the area of innovative new materials and composites based on nanocellulosics. Scand. J. For. Res. 2014, 29, 345–351. [Google Scholar] [CrossRef]

- Fukuzumi, H.; Saito, T.; Iwata, T.; Kumamoto, Y.; Isogai, A. Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 2009, 10, 162–165. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Fu, F.; Zhou, J.; Zhou, X.; Zhang, L.N.; Li, D.; Kondo, T. Green Method for Production of Cellulose Multifilament from Cellulose Carbamate on a Pilot Scale. ACS Sustain. Chem. Eng. 2014, 2, 2363–2370. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, J.; Wang, Y.; Zhang, L.N.; Lin, X. An efficient transformation of cellulose into cellulose carbamates assisted by microwave irradiation. Cellulose 2010, 17, 1115–1125. [Google Scholar] [CrossRef]

- Gan, S.; Zakaria, S.; Chia, C.H.; Chen, R.S.; Ellis, A.V.; Kaco, H. Highly porous regenerated cellulose hydrogel and aerogel prepared from hydrothermal synthesized cellulose carbamate. PLoS ONE 2017, 12, e0173743. [Google Scholar] [CrossRef]

- Fu, F.; Xu, M.; Wang, H.; Wang, Y.; Ge, H.; Zhou, J. Improved synthesis of cellulose carbamates with minimum urea based on an easy scale-up method. ACS Sustain. Chem. Eng. 2015, 3, 1510–1517. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, C.; Zhang, Y.; Wu, H. Synthesis and characterization of cellulose carbamate from wood pulp, assisted by supercritical carbon dioxide. Bioresource 2013, 8, 1398–1408. [Google Scholar] [CrossRef]

- Paajanen, A.; Vaari, J. High-temperature decomposition of the cellulose molecule: A stochastic molecular dynamics study. Cellulose 2017, 24, 2713–2725. [Google Scholar] [CrossRef]

- French, A.D.; Cintrón, M.S. Cellulose polymorphy, crystallite size, and the Segal crystallinity index. Cellulose 2013, 20, 583–588. [Google Scholar] [CrossRef]

- Wang, D.; Hui, S.; Liu, C. Mass loss and evolved gas analysis in thermal decomposition of solid urea. Fuel 2017, 207, 268–273. [Google Scholar] [CrossRef]

- Brack, W.; Heine, B.; Birkhold, F.; Kruse, M.; Schoch, G.; Tischer, S.; Deutschmann, O. Kinetic modeling of urea decomposition based on systematic thermogravimetric analyses of urea and its most important by-products. Chem. Eng. Sci. 2014, 106, 1–8. [Google Scholar] [CrossRef]

- Zhou, H.; Long, Y.; Meng, A.; Chen, S.; Li, Q.; Zhang, Y. A novel method for kinetics analysis of pyrolysis of hemicellulose, cellulose, and lignin in TGA and macro-TGA. RSC Adv. 2015, 5, 26509–26516. [Google Scholar] [CrossRef]

- Labafzadeh, S.R.; Kavakka, J.S.; Vyavaharkar, K.; Sievänen, K.; Kilpeläinen, I. Preparation of cellulose and pulp carbamates through a reactive dissolution approach. RSC Adv. 2014, 4, 22434–22441. [Google Scholar] [CrossRef]

- Fu, F.; Yang, Q.; Zhou, J.; Hu, H.; Jia, B.; Zhang, L.N. Structure and properties of regenerated cellulose filaments prepared from cellulose carbamate–NaOH/ZnO aqueous solution. ACS Sustain. Chem. Eng. 2014, 2, 2604–2612. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, J.; Song, Y.; Zhang, L.N. An efficient and environmentally friendly method for the synthesis of cellulose carbamate by microwave heating. Macromol. Rapid Commun. 2009, 30, 1504–1508. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Pignon, F.; Belgacem, M.N. Morphological properties of nanofibrillated cellulose produced using wet grinding as an ultimate fibrillation process. J. Mater. Sci. 2015, 50, 531–541. [Google Scholar] [CrossRef]

- Kurouchi, H.; Kawamoto, K.; Sugimoto, H.; Nakamura, S.; Otani, Y.; Ohwada, T. Activation of electrophilicity of stable Y-delocalized carbamate cations in intramolecular aromatic substitution reaction: Evidence for formation of diprotonated carbamates leading to generation of isocyanates. J. Org. Chem. 2012, 77, 9313–9328. [Google Scholar] [CrossRef]

- Olszewska, A.; Eronen, P.; Johansson, L.S.; Malho, J.M.; Ankerfors, M.; Lindström, T.; Ruokolainen, J.; Laine, J.; Österberg, M. The behaviour of cationic nanofibrillar cellulose in aqueous media. Cellulose 2011, 18, 1213–1226. [Google Scholar] [CrossRef]

- Oudiani, A.E.; Chaabouni, Y.; Msahli, S.; Sakli, F. Crystal transition from cellulose I to cellulose II in NaOH treated Agave americana L. fibre. Carbohydr. Polym. 2011, 86, 1221–1229. [Google Scholar] [CrossRef]

- Ishikawa, A.; Okano, T. Fine structure and tensile properties of ramie fibres in the crystalline form of cellulose I, II, IIII and IVI. Polymer 1997, 38, 463–468. [Google Scholar] [CrossRef]

- Oh, S.Y.; Yoo, D.I.; Shin, Y.; Kim, H.C.; Kim, H.Y.; Chung, Y.S.; Park, W.H.; Youk, J.H. Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr. Res. 2005, 340, 2376–2391. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Rojas, O.J.; Lucia, L.A.; Mohini, S. Cellulosic nanocomposites: A review. BioResource 2008, 3, 929. [Google Scholar]

- Cheng, G.; Zhou, M.; Wei, Y.J.; Cheng, F.; Zhu, P.X. Comparison of mechanical reinforcement effects of cellulose nanocrystal, cellulose nanofiber and microfibrillated cellulose in starch composites. Polym. Compos. 2019, 40, E365–E372. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).