An Analytical Approach to Cutter Edge Temperature Prediction in Milling and Its Application to Trochoidal Milling

Abstract

1. Introduction

2. Prediction of Cutter Edge Temperature in Milling

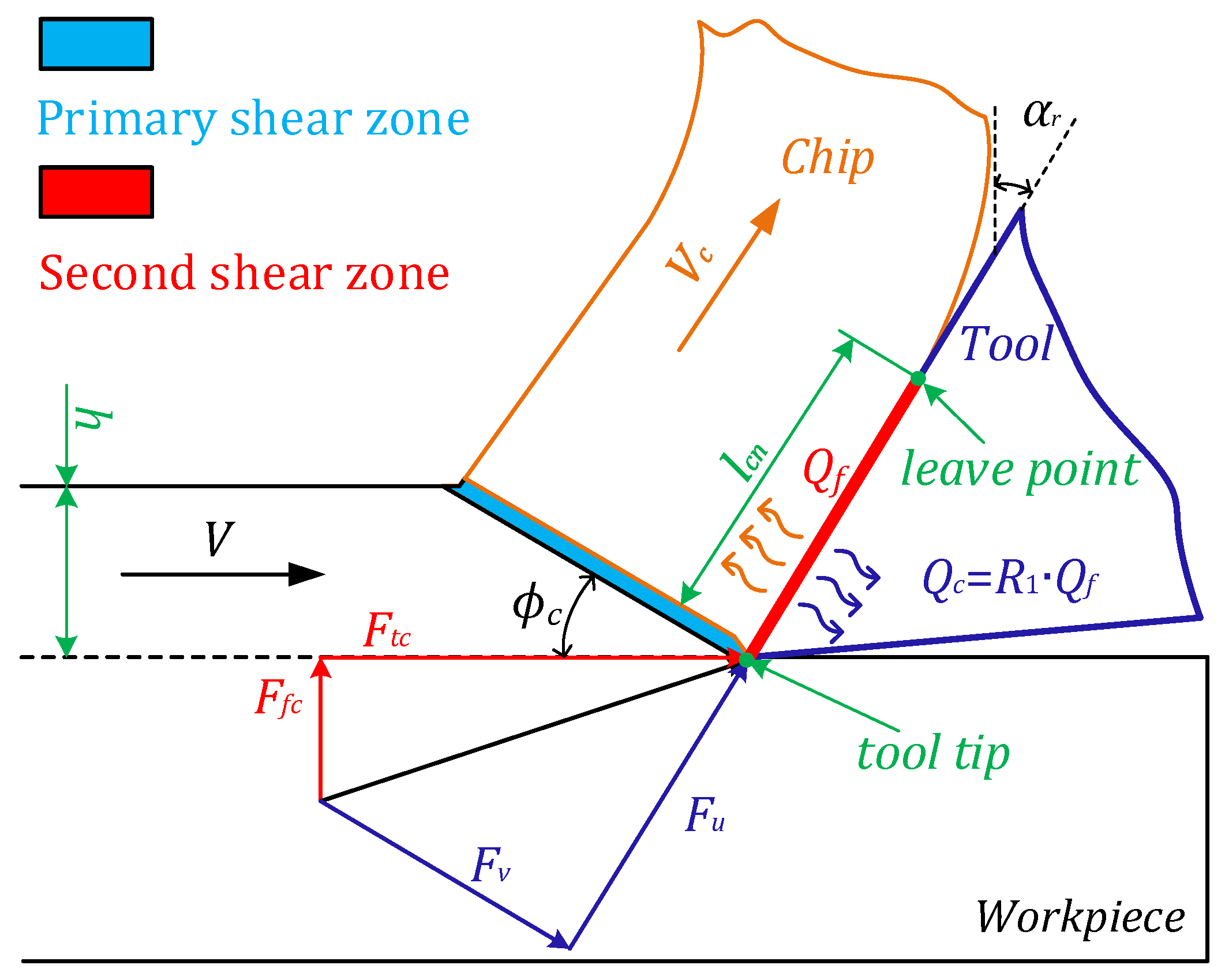

2.1. Calculation of Heat Flux Into the Cutter

2.2. Calculation of Cutter Edge Temperature in Milling

2.3. Engagement Patterns in Trochoidal Milling

3. Verification of the Proposed Method

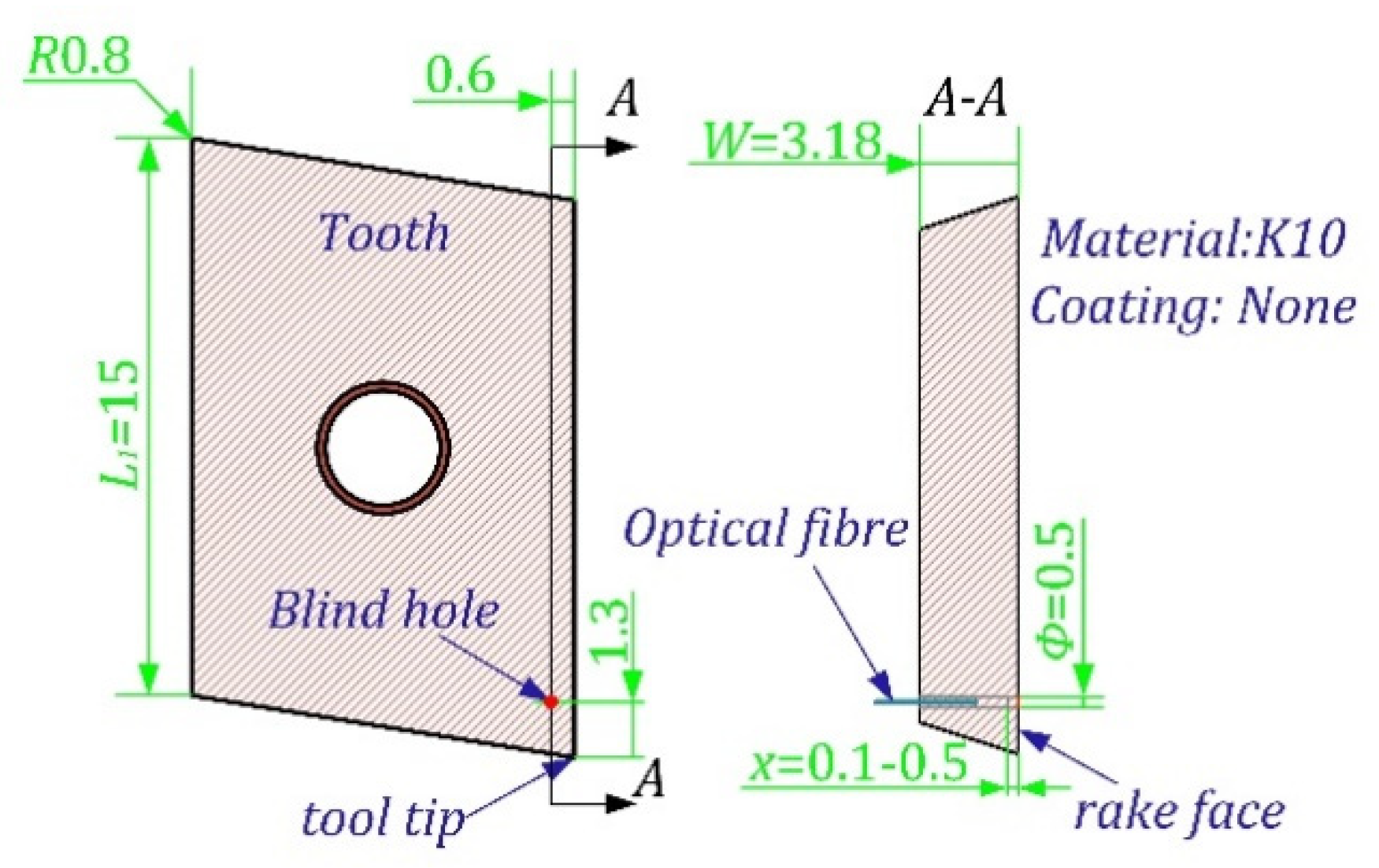

3.1. Specifications in Simulation and Experiment

3.2. Calibration of Energy Partition Coefficient

3.3. Comparison between Proposed Method and Sato’s Results

4. Results and Discussion

4.1. Cutter Edge Temperature in One Trochoidal Cycle

4.2. Comparison between Temperatures in Trochoidal and Side Milling

4.3. Thermal Shock in Trochoidal and Side Milling

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Otkur, M.; Lazoglu, I. Trochoidal milling. Int. J. Mach. Tools Manuf. 2007, 47, 1324–1332. [Google Scholar] [CrossRef]

- Wu, S.; Ma, W.; Li, B.; Wang, C. Trochoidal machining for the high-speed milling of pockets. J. Mater. Process. Technol. 2016, 233, 29–43. [Google Scholar]

- Zhang, X.H.; Peng, F.Y.; Qiu, F.; Yan, R.; Li, B. Prediction of cutting force in trochoidal milling based on radial depth of cut. Adv. Mater. Res. 2014, 852, 457–462. [Google Scholar] [CrossRef]

- Deng, Q.; Mo, R.; Chen, Z.C.; Chang, Z. A new approach to generating trochoidal tool paths for effective corner machining. Int. J. Adv. Manuf. Technol. 2018, 95, 3001–3012. [Google Scholar] [CrossRef]

- Li, Z.; Xu, K.; Tang, K. A new trochoidal pattern for slotting operation. Int. J. Adv. Manuf. Technol. 2019, 102, 1153–1163. [Google Scholar] [CrossRef]

- Ibaraki, S.; Yamaji, I.; Matsubara, A. On the removal of critical cutting regions by trochoidal grooving. Precis. Eng. 2010, 34, 467–473. [Google Scholar] [CrossRef]

- Uhlmann, E.; Fürstmann, P.; Rosenau, B.; Gebhard, S.; Gerstenberger, R.; Müller, G. The potential of reducing the energy consumption for machining TiAl6V4 by using innovative metal cutting processes. In Proceedings of the 11th Global Conference on Sustainable Manufacturing, Berlin, Germany, 23–25 September 2013. [Google Scholar]

- Pleta, A.; Ulutan, D.; Mears, L. Investigation of trochoidal milling in nickel-based superalloy inconel 738 and comparison with end milling. In Proceedings of the ASME 2014 International Manufacturing Science and Engineering Conference collocated with the JSME 2014 International Conference on Materials and Processing and the 42nd North American Manufacturing Research Conference, Detroit, MN, USA, 9–13 June 2014. [Google Scholar]

- Oh, N.S.; Woo, W.S.; Lee, C.M. A study on the machining characteristics and energy efficiency of Ti-6Al-4V in laser-assisted trochoidal milling. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 37–45. [Google Scholar] [CrossRef]

- Rauch, M.; Duc, E.; Hascoet, J.Y. Improving trochoidal tool paths generation and implementation using process constraints modelling. Int. J. Mach. Tools Manuf. 2009, 49, 375–383. [Google Scholar] [CrossRef]

- Ferreira, J.C.; Ochoa, D.M. A method for generating trochoidal tool paths for 2½D pocket milling process planning with multiple tools. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2013, 227, 1287–1298. [Google Scholar] [CrossRef]

- Salehi, M.; Blum, M.; Fath, B.; Akyol, T.; Haas, R.; Ovtcharova, J. Epicycloidal versus trochoidal milling-Comparison of cutting force, tool tip vibration, and machining cycle time. Procedia CIRP 2016, 46, 230–233. [Google Scholar] [CrossRef]

- Wang, Q.H.; Wang, S.; Jiang, F.; Li, J.R. Adaptive trochoidal toolpath for complex pockets machining. Int. J. Prod. Res. 2016, 54, 5976–5989. [Google Scholar] [CrossRef]

- Li, Z.; Chen, L.; Xu, K.; Gao, Y.; Tang, K. Five-axis Trochoidal Flank Milling of Deep 3D Cavities. Comput. Aided Des. 2020, 119, 102775. [Google Scholar] [CrossRef]

- Yan, R.; Li, H.; Peng, F.; Tang, X.; Xu, J.; Zeng, H. Stability prediction and step optimization of Trochoidal milling. J. Manuf. Sci. Eng. Trans. ASME 2017, 139, 091006. [Google Scholar] [CrossRef]

- Niaki, F.A.; Pleta, A.; Mears, L.; Potthoff, N.; Bergmann, J.A.; Wiederkehr, P. Trochoidal milling: Investigation of dynamic stability and time domain simulation in an alternative path planning strategy. Int. J. Adv. Manuf. Technol. 2019, 102, 1405–1419. [Google Scholar] [CrossRef]

- Takeyama, H.; Murata, R. Basic investigation of tool wear. J. Eng. Ind. 1963, 85, 33–37. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Stephenson, D.A. Assessment of steady-state metal cutting temperature models based on simultaneous infrared and thermocouple data. J. Eng. Ind. Trans. ASME 1991, 113, 121–128. [Google Scholar] [CrossRef]

- Stephenson, D.A.; Ali, A. Tool temperatures in interrupted metal cutting. J. Eng. Ind. Trans. ASME 1992, 114, 127–136. [Google Scholar]

- Stephenson, D.A.; Jen, T.C.; Lavine, A.S. Cutting tool temperatures in contour turning: Transient analysis and experimental verification. J. Manuf. Sci. Eng. Trans. ASME 1997, 119, 494–501. [Google Scholar] [CrossRef]

- Toh, C.K. Comparison of chip surface temperature between up and down milling orientations in high speed rough milling of hardened steel. J. Mater. Process. Technol. 2005, 167, 110–118. [Google Scholar] [CrossRef]

- Lazoglu, I.; Altintas, Y. Prediction of tool and chip temperature in continuous and interrupted machining. Int. J. Mach. Tools Manuf. 2002, 42, 1011–1022. [Google Scholar] [CrossRef]

- Ulutan, D.; Lazoglu, I.; Dinc, C. Three-dimensional temperature predictions in machining processes using finite difference method. J. Mater. Process. Technol. 2009, 209, 1111–1121. [Google Scholar] [CrossRef]

- Palanisamy, P.; Rajendran, I.; Shanmugasundaram, S.; Saravanan, R. Prediction of cutting force and temperature rise in the end-milling operation. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2006, 220, 1577–1587. [Google Scholar] [CrossRef]

- Armendia, M.; Garay, A.; Villar, A.; Davies, M.A.; Arrazola, P.J. High bandwidth temperature measurement in interrupted cutting of difficult to machine materials. CIRP Ann. Manuf. Technol. 2010, 59, 97–100. [Google Scholar] [CrossRef]

- Jiang, F.; Liu, Z.; Wan, Y.; Shi, Z. Analytical modeling and experimental investigation of tool and workpiece temperatures for interrupted cutting 1045 steel by inverse heat conduction method. J. Mater. Process. Technol. 2013, 213, 887–894. [Google Scholar] [CrossRef]

- Wu, B.H.; Cui, D.; He, X.D.; Zhang, D.H.; Tang, K. Cutting tool temperature prediction method using analytical model for end milling. Chin. J. Aeronaut. 2016, 29, 1788–1794. [Google Scholar]

- Shaw, M.C.; Cookson, J.O. Metal Cutting Principles, 2nd ed.; Oxford University Press: New York, NY, USA, 2005; pp. 206–207. [Google Scholar]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat generation and temperature prediction in metal cutting: A review and implications for high speed machining. Int. J. Mach. Tools Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Budak, E.; Altintas, Y.; Armarego, E.J.A. Prediction of milling force coefficients from orthogonal cutting data. J. Manuf. Sci. Eng. Trans. ASME 1996, 118, 216–224. [Google Scholar] [CrossRef]

- Karaguzel, U.; Bakkal, M.; Budak, E. Modeling and measurement of cutting temperatures in milling. Procedia CIRP 2016, 46, 173–176. [Google Scholar] [CrossRef]

- Hou, Z.B.; He, S.J.; Li, S.X. Solid Heat Conduction; Shanghai Science and Technology Press: Shanghai, China, 1984. [Google Scholar]

- Hahn, D.W.; Özisik, M.N. Heat Conduction, 3rd ed.; John Wiley Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Sato, M.; Tamura, N.; Tanaka, H. Temperature variation in the cutting tool in end milling. J. Manuf. Sci. Eng. Trans. ASME 2011, 133, 021005. [Google Scholar] [CrossRef]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and wear of cutting tools in high-speed machining of Inconel 718 and Ti-6Al-6V-2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- Kountanya, R. Cutting tool temperatures in interrupted cutting—The effect of feed-direction modulation. J. Manuf. Process. 2008, 10, 47–55. [Google Scholar] [CrossRef]

| Input Parameters | ||

| Symbol | Unit | Remark |

| hi | mm | Sampled Un-deformed chip thickness, i = 1, 2,…, m |

| V | m/s | Cutting speed |

| αr | ° | Rake angle |

| μ | Friction coefficient between rake face and chip | |

| Evaluation Results | ||

| Symbol | Unit | Remark |

| Ftci | N | The cutting force in horizontal direction of cutting speed, under a specified un-deformed thickness hi |

| Ffci | N | The cutting force in vertical direction of cutting speed, under a specified un-deformed thickness hi |

| lcni | mm | The chip tool contact under a specified un-deformed thickness hi |

| ° | The shear angle of the given tool-workpiece pair under the given cutter parameters | |

| V m/min | fz mm/z | ae mm | ap mm | n rev/min | R mm |

|---|---|---|---|---|---|

| 214 | 0.105 | 21 | 2 | 1310 | 26 |

| Depth | Predicted Max T | Measured Max T | Difference of Max T |

|---|---|---|---|

| 0.1 mm | 399.7 | 407.9 | −2.05% |

| 0.2 mm | 381 | 359.7 | 5.59% |

| 0.3 mm | 358 | 296.4 | 17.21% |

| 0.4 mm | 330.6 | 231.7 | 29.92% |

| 0.5 mm | 302.5 | 211.6 | 30.5% |

| V m/min | fz mm/z | ap mm | n rev/min | R mm | c mm | r mm |

|---|---|---|---|---|---|---|

| 214 | 0.105 | 2 | 1310 | 26 | 4 | 5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Q.; Mo, R.; Chen, Z.C.; Chang, Z. An Analytical Approach to Cutter Edge Temperature Prediction in Milling and Its Application to Trochoidal Milling. Appl. Sci. 2020, 10, 1746. https://doi.org/10.3390/app10051746

Deng Q, Mo R, Chen ZC, Chang Z. An Analytical Approach to Cutter Edge Temperature Prediction in Milling and Its Application to Trochoidal Milling. Applied Sciences. 2020; 10(5):1746. https://doi.org/10.3390/app10051746

Chicago/Turabian StyleDeng, Qi, Rong Mo, Zezhong C. Chen, and Zhiyong Chang. 2020. "An Analytical Approach to Cutter Edge Temperature Prediction in Milling and Its Application to Trochoidal Milling" Applied Sciences 10, no. 5: 1746. https://doi.org/10.3390/app10051746

APA StyleDeng, Q., Mo, R., Chen, Z. C., & Chang, Z. (2020). An Analytical Approach to Cutter Edge Temperature Prediction in Milling and Its Application to Trochoidal Milling. Applied Sciences, 10(5), 1746. https://doi.org/10.3390/app10051746