Synthesis and Selected Properties of Ester Elastomer Containing Sorbitol

Abstract

1. Introduction

2. Material and Methods

2.1. Synthesis of Poly(sorbitol Sebacate-Co-Butylene Sebacate) (PSBS)

2.2. Methods

2.2.1. Fourier-Transform Infrared Spectroscopy (FTIR)

2.2.2. Differential Scanning Calorimetry (DSC)

2.2.3. Dynamic Thermomechanical Analysis (DMTA)

2.2.4. Mechanical Properties

2.2.5. Gel Fraction

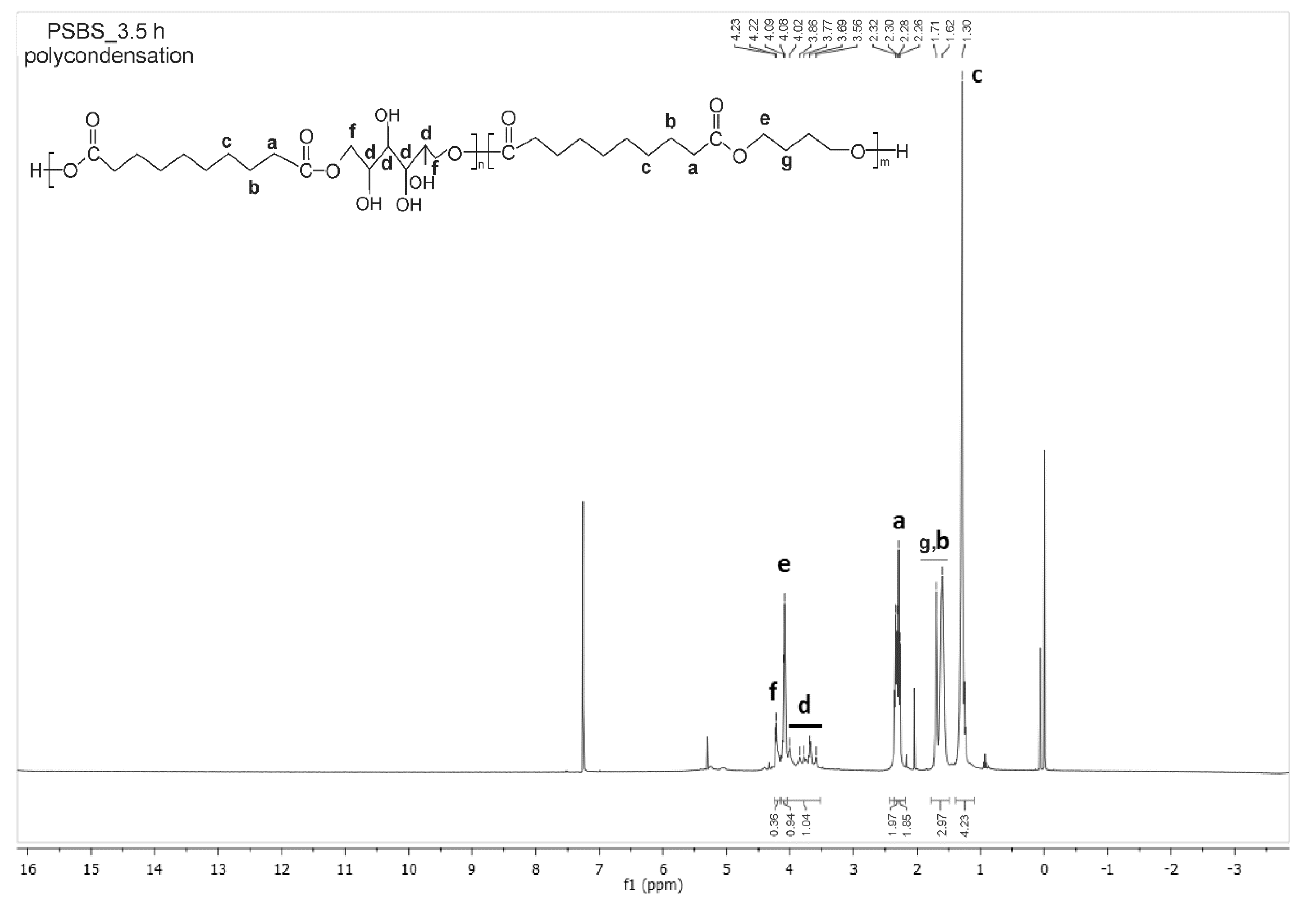

2.2.6. 1H Nuclear Magnetic Resonance Spectroscopy (NMR)

3. Results and Discussion

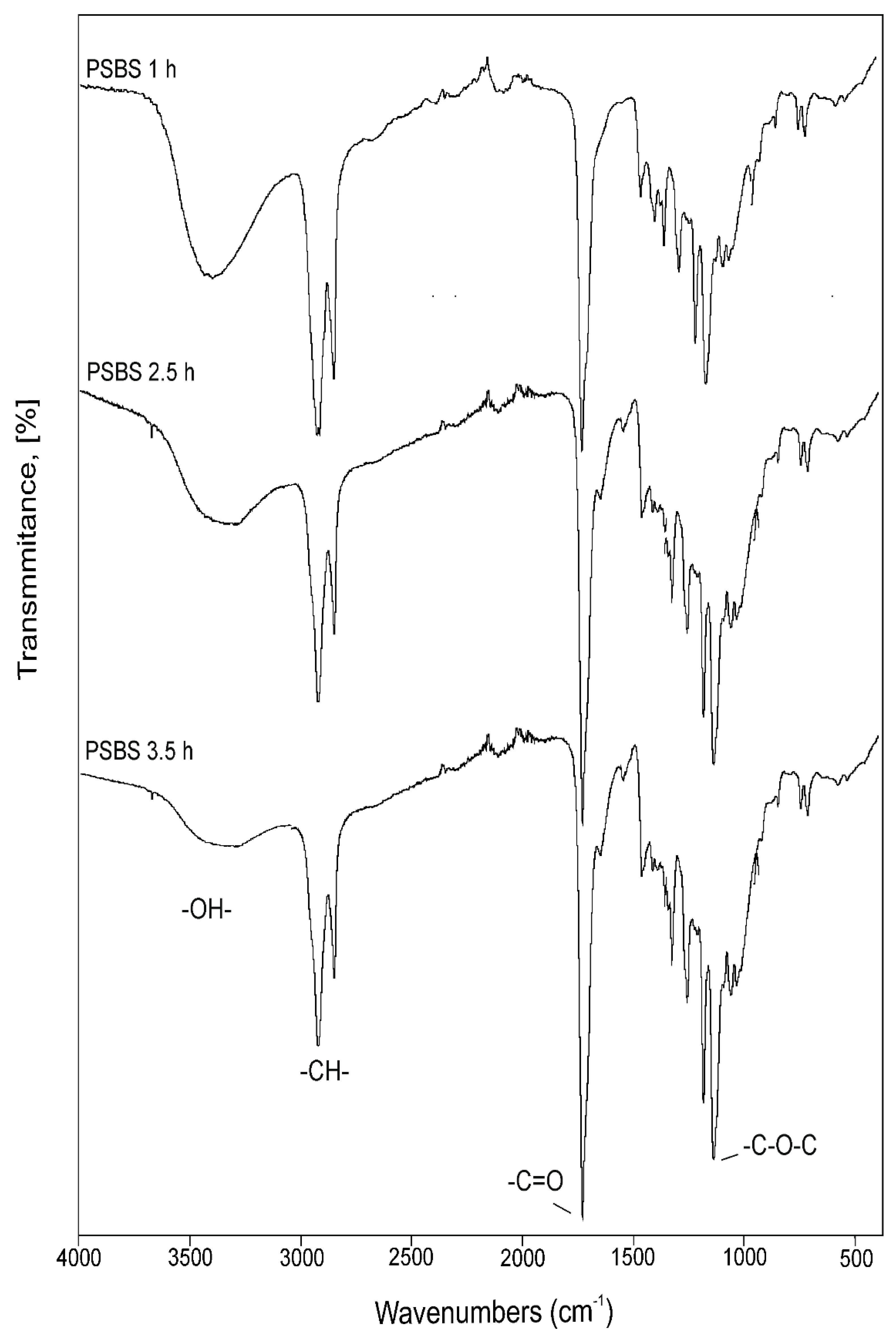

3.1. Fourier-Transform Infrared Spectroscopy (FTIR)

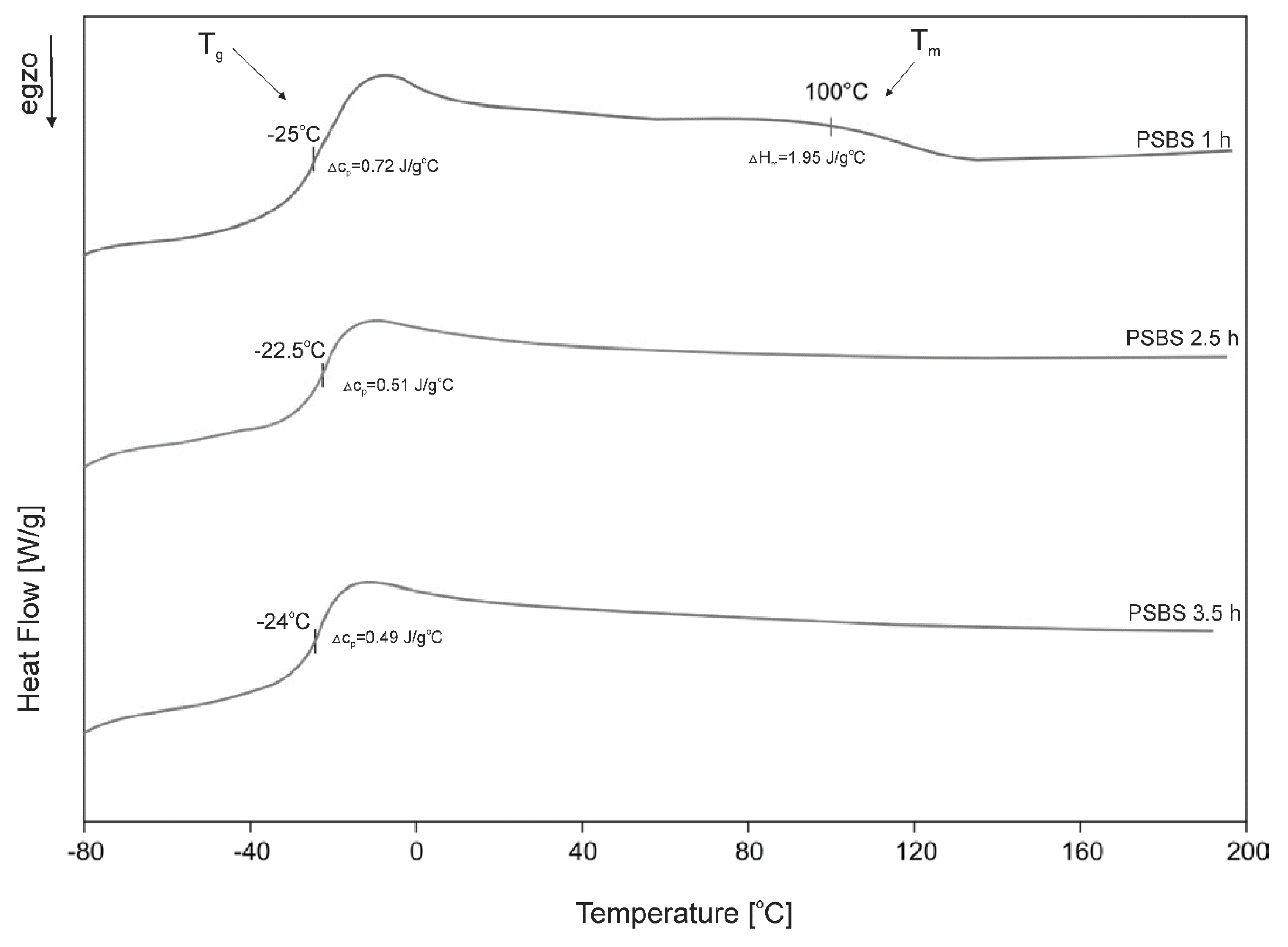

3.2. Differential Scanning Calorimetry (DSC)

3.3. Dynamic Thermomechanical Analysis (DMTA)

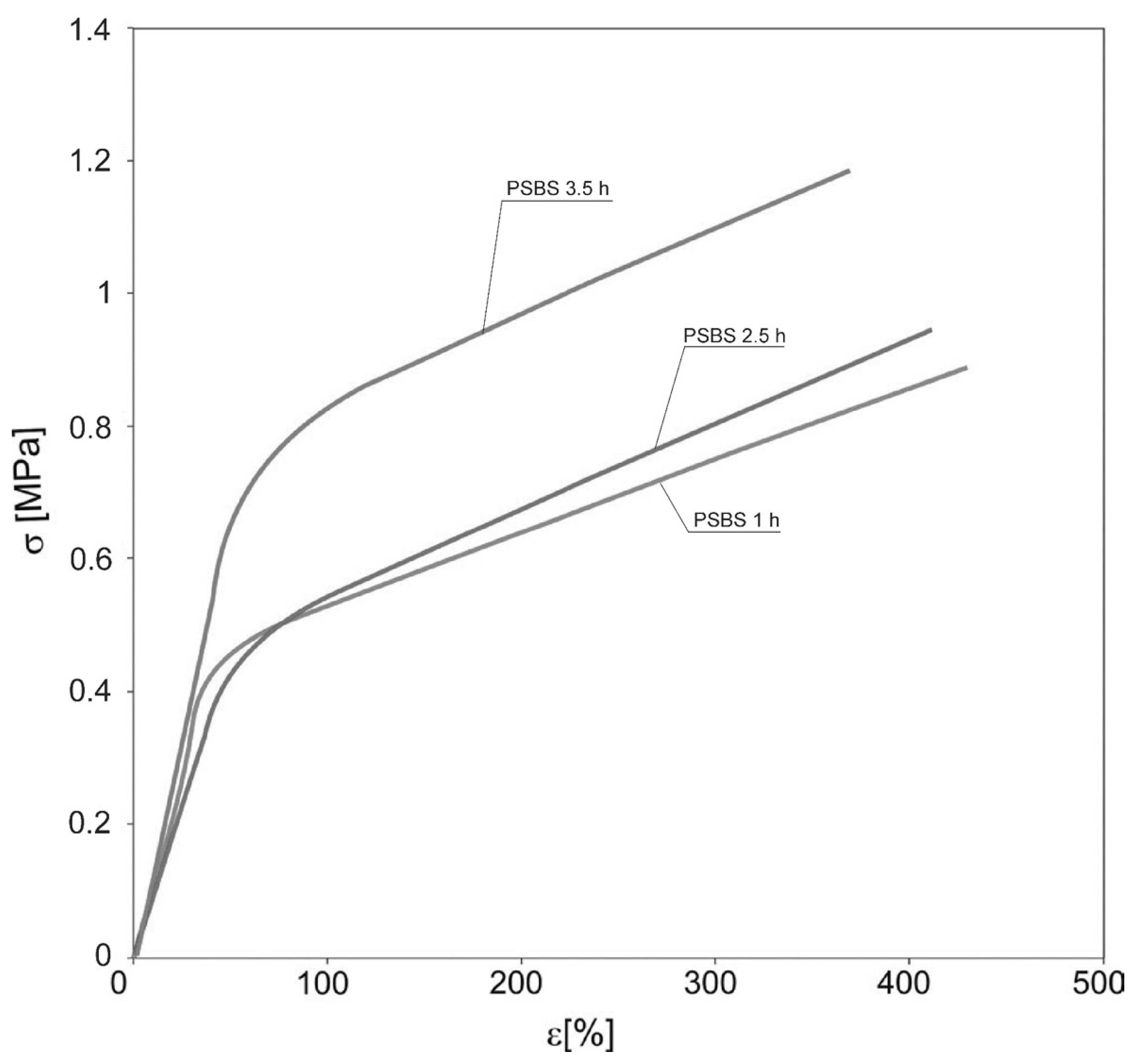

3.4. Mechanical Properties

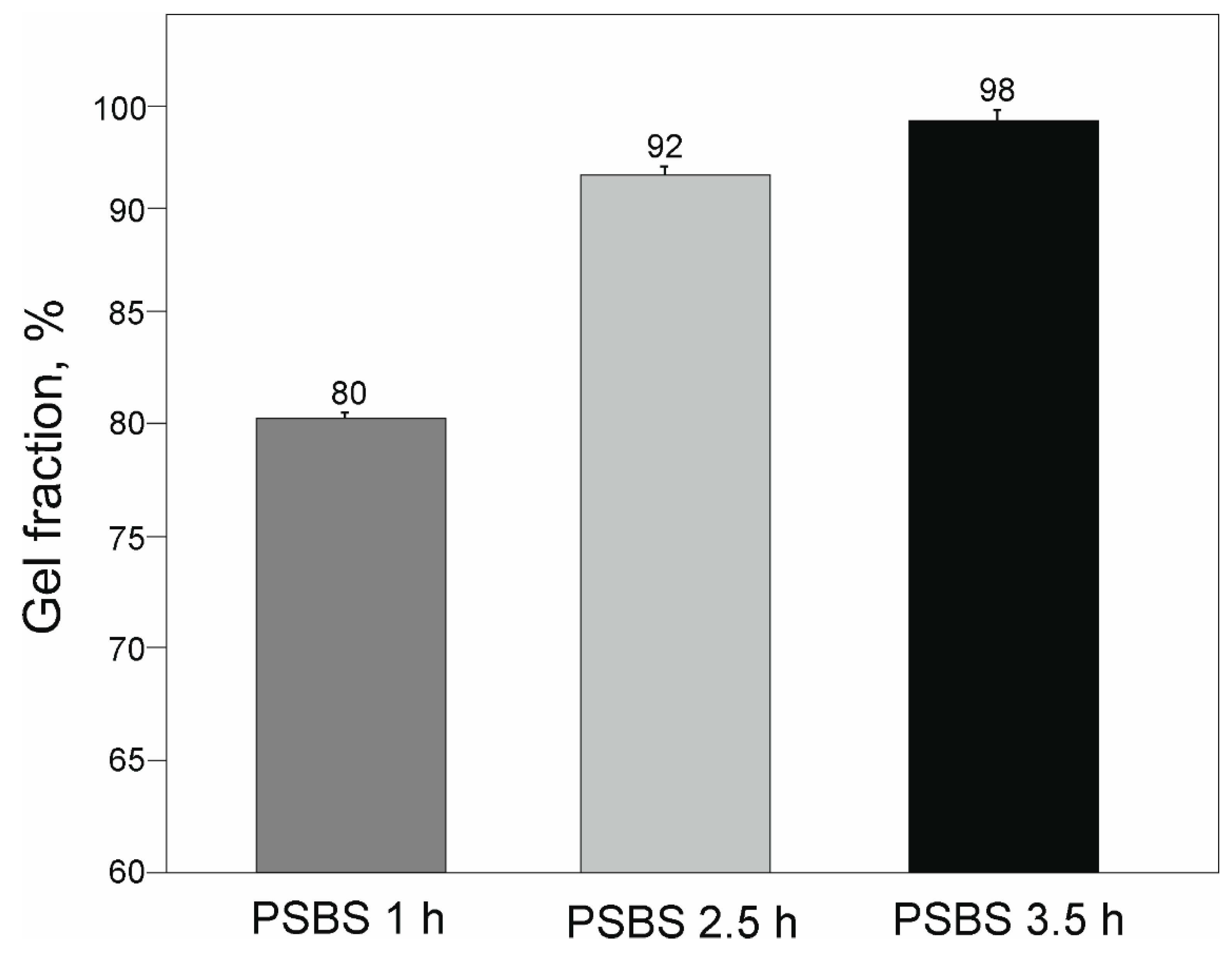

3.5. Gel Fraction

3.6. 1H Nuclear Magnetic Resonance Spectroscopy (NMR)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Neeley, W.L.; Redenti, S.; Klassen, H.; Tao, S.; Desai, T.; Young, M.J.; Langer, R. A microfabricated scaffold for retinal progenitor cell grafting. Biomaterials 2008, 29, 418–426. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.J.; Chen, C.; Sun, M.Z.; Ai, C.H.; Lu, X.L.; Zheng, Y.F.; Yang, B.F.; Dong, D.L. The application of poly (glycerol-sebacate) as biodegradable drug carrier. Biomaterials 2009, 30, 5209–5214. [Google Scholar] [CrossRef] [PubMed]

- Zaky, S.H.; Lee, K.W.; Gao, J.; Jensen, A.; Verdelis, K.; Wang, Y.; Almarza, A.J.; Sfeir, C. Poly (glycerol sebacate) elastomer supports bone regeneration by its mechanical properties being closer to osteoid tissue rather than to mature bone. Acta Biomater. 2017, 54, 95–106. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.Z.; Bismarck, A.; Hansen, U.; Junaid, S.; Tran, M.Q.; Harding, S.E.; Ali, N.N.; Boccaccini, A.R. Characterisation of a soft elastomer poly(glycerol sebacate) designed to match the mechanical properties of myocardial tissue. Biomaterials 2008, 29, 47–57. [Google Scholar] [CrossRef]

- Motlagh, D.; Yang, J.; Lui, K.Y.; Webb, A.R.; Ameer, G.A. Hemocompatibility evaluation of poly(glycerol-sebacate) in vitro for vascular tissue engineering. Biomaterials 2006, 27, 4315–4324. [Google Scholar] [CrossRef]

- Bettinger, C.J.; Orrick, B.; Misra, A.; Langer, R.; Borenstein, J.T. Microfabrication of poly (glycerol-sebacate) for contact guidance applications. Biomaterials 2006, 27, 2558–2565. [Google Scholar] [CrossRef]

- Kemppainen, J.M.; Hollister, S.J. Tailoring the mechanical properties of 3D-designed poly(glycerol sebacate) scaffolds for cartilage applications. J. Biomed. Mater. Res. Part A 2010, 94, 9–18. [Google Scholar] [CrossRef]

- Rosenbalm, T.N.; Teruel, M.; Day, C.S.; Donati, G.L.; Morykwas, M.; Argenta, L.; Kuthirummal, N.; Levi-Polyachenko, N. Structural and mechanical characterization of bioresorbable, elastomeric nanocomposites from poly(glycerol sebacate)/nanohydroxyapatite for tissue transport applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016, 104, 1366–1373. [Google Scholar] [CrossRef]

- Liang, S.L.; Cook, W.D.; Thouas, G.A.; Chen, Q.Z. The mechanical characteristics and in vitro biocompatibility of poly(glycerol sebacate)-Bioglass® elastomeric composites. Biomaterials 2010, 31, 8516–8529. [Google Scholar] [CrossRef]

- Sundback, C.A.; Shyu, J.Y.; Wang, Y.; Faquin, W.C.; Langer, R.S.; Vacanti, J.P.; Hadlock, T.A. Biocompatibility analysis of poly(glycerol sebacate) as a nerve guide material. Biomaterials 2005, 26, 5454–5464. [Google Scholar] [CrossRef]

- Kumar, A.; Kulshrestha, A.S.; Gao, W.; Gross, R.A. Versatile route to polyol polyesters by lipase catalysis. Macromolecules 2003, 36, 8219–8221. [Google Scholar] [CrossRef]

- Bruggeman, J.P.; de Bruin, B.J.; Bettinger, C.J.; Langer, R. Biodegradable poly(polyol sebacate) polymers. Biomaterials 2008, 29, 4726–4735. [Google Scholar] [CrossRef] [PubMed]

- Barrett, D.G.; Yousaf, M.N. Thermosets synthesized by thermal polyesterification for tissue engineering applications. Soft Matter 2010, 6, 5026–5036. [Google Scholar] [CrossRef]

- Kavimani, V.; Jaisankar, V. Synthesis and Characterisation of Sorbitol Based Copolyesters for Biomedical Applications. J. Phys. Sci. Appl. 2014, 4, 507–515. [Google Scholar]

- Piątek-hnat, M. Influence of the addition of citric acid on the physico-chemical properties of poly(sorbitol sebacate-co- butylene sebacate). Int. J. Sci. Eng. Res. 2018, 9, 1092–1094. [Google Scholar]

- Lee, S.H.; Shin, S.R.; Lee, D.S. Sorbitol as a chain extender of polyurethane prepolymers to prepare self-healable and robust polyhydroxyurethane elastomers. Molecules 2018, 23, 2515. [Google Scholar] [CrossRef]

- Tham, W.H.; Wahit, M.U.; Kadir, M.R.A.; Wong, T.W. Mechanical and thermal properties of biodegradable hydroxyapatite/poly(sorbitol sebacate malate) composites. Songklanakarin J. Sci. Technol. 2013, 35, 57–61. [Google Scholar]

- Bruggeman, J.P.; Bettinger, C.J.; Langer, R. Biodegradable xylitol-based elastomers: In vivo behavior and biocompatibility. , J. Biomed. Mater. Res. Part A 2010, 95, 92–104. [Google Scholar] [CrossRef]

- Bruggeman, J.P.; Bettinger, C.J.; Nijst, C.L.E.; Kohane, D.S.; Langer, R. Biodegradable xylitol-based polymers. Adv. Mater. 2008, 20, 1922–1927. [Google Scholar] [CrossRef]

- Deepa, K.; Jaisankar, V. A Study on Xylitol Based Copolyester for In vitro Degradation Applications. Int. J. Chem. Technol. Res. 2018, 11, 69–76. [Google Scholar] [CrossRef]

- Hu, J.; Gao, W.; Kulshrestha, A.; Gross, R.A. “Sweet polyesters”: Lipase-catalyzed condensation-polymerizations of alditols. ACS Symp. Ser. 2008, 999, 275–284. [Google Scholar]

- Moorhoff, C.; Li, Y.; Cook, W.D.; Braybrook, C.; Chen, Q.Z. Characterization of the prepolymer and gel of biocompatible poly(xylitol sebacate) in comparison with poly(glycerol sebacate) using a combination of mass spectrometry and nuclear magnetic resonance. Polym. Int. 2015, 64, 668–688. [Google Scholar] [CrossRef]

- Sonseca, Á.; Camarero-Espinosa, S.; Peponi, L.; Weder, C.; Foster, E.J.; Kenny, J.M.; Giménez, E. Mechanical and shape-memory properties of poly(mannitol sebacate)/cellulose nanocrystal nanocomposites. J. Polym. Sci. Part A Polym. Chem. 2014, 52, 3123–3133. [Google Scholar] [CrossRef]

- Selvam, S.; Pithapuram, M.V.; Victor, S.P.; Muthu, J. Injectable in situ forming xylitol-PEG-based hydrogels for cell encapsulation and delivery. Colloids Surfaces B Biointerfaces 2015, 126, 35–43. [Google Scholar] [CrossRef]

- Li, Y.; Thouas, G.A.; Chen, Q. Novel elastomeric fibrous networks produced from poly(xylitol sebacate)2:5 by core/shell electrospinning: Fabrication and mechanical properties. J. Mech. Behav. Biomed. Mater. 2014, 40, 210–221. [Google Scholar] [CrossRef][Green Version]

- Li, Y.; Chen, Q.Z. Fabrication of mechanically tissue-like fibrous poly(xylitol sebacate) using core/shell electrospinning technique. Adv. Eng. Mater. 2015, 17, 324–329. [Google Scholar] [CrossRef]

- Firoozi, N.; Kang, Y. A Highly Elastic and Autofluorescent Poly(xylitol-dodecanedioic Acid) for Tissue Engineering. ACS Biomater. Sci. Eng. 2019, 5, 1257–1267. [Google Scholar] [CrossRef]

- Akiyama, H.; Yoshida, M. Photochemically reversible liquefaction and solidification of single compounds based on a sugar alcohol scaffold with multi azo-arms. Adv. Mater. 2012, 24, 2353–2356. [Google Scholar] [CrossRef]

- Sugane, K.; Takahashi, H.; Shimasaki, T.; Teramoto, N.; Shibata, M. Stereocomplexation, Thermal and Mechanical Properties of Conetworks Composed of Star-Shaped L-Lactide, D-Lactide and ε-Caprolactone Oligomers Utilizing Sugar Alcohols as Core Molecules. Polymers 2017, 9, 582. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piątek-Hnat, M.; Bomba, K.; Pęksiński, J. Synthesis and Selected Properties of Ester Elastomer Containing Sorbitol. Appl. Sci. 2020, 10, 1628. https://doi.org/10.3390/app10051628

Piątek-Hnat M, Bomba K, Pęksiński J. Synthesis and Selected Properties of Ester Elastomer Containing Sorbitol. Applied Sciences. 2020; 10(5):1628. https://doi.org/10.3390/app10051628

Chicago/Turabian StylePiątek-Hnat, Marta, Kuba Bomba, and Jakub Pęksiński. 2020. "Synthesis and Selected Properties of Ester Elastomer Containing Sorbitol" Applied Sciences 10, no. 5: 1628. https://doi.org/10.3390/app10051628

APA StylePiątek-Hnat, M., Bomba, K., & Pęksiński, J. (2020). Synthesis and Selected Properties of Ester Elastomer Containing Sorbitol. Applied Sciences, 10(5), 1628. https://doi.org/10.3390/app10051628