Model-Based Virtual Components in Event-Based Controls: Linking the FMI and IEC 61499

Abstract

1. Introduction

2. Related Work

2.1. Functional Mock-Up Interface

2.2. Distributed Control Systems Using IEC 61499

2.3. Model-Based Control Engineering

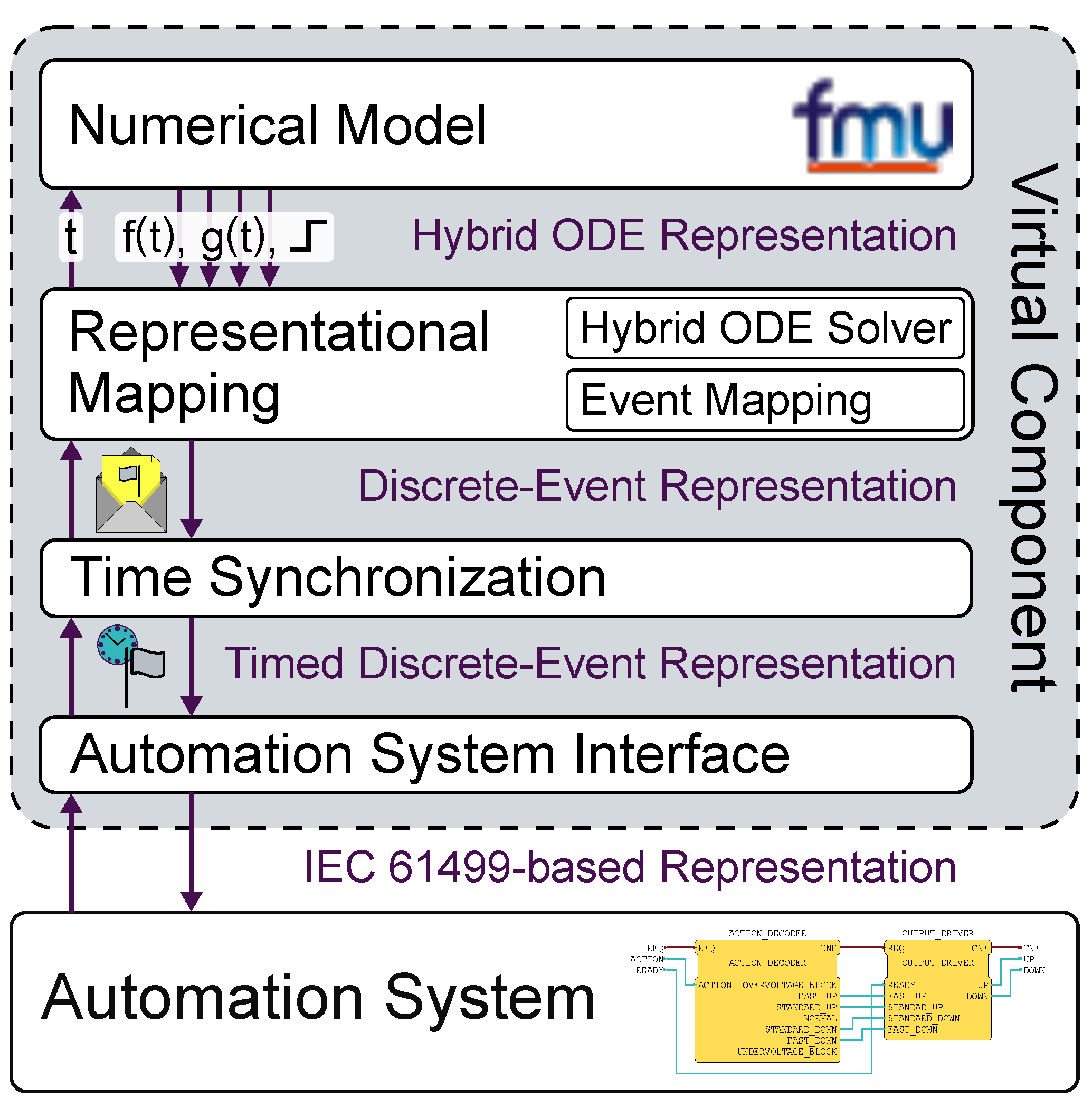

3. Generic Virtual Components

3.1. System Model

- the virtual component can be accessed via a dedicated FB,

- communication is restricted to the occurrence of events,

- each event e is triggered at a particular instant of time [27], and that

- e holds a set of variables that are either sent to the virtual component or to the automation system.

- Representational mapping: A generic virtual component has to map the hybrid representation defined by the FMI to discrete events that can be exchanged within the automation system. Such a mapping comprises the numerical computation of the state of the FMU based on its ODEs and the algorithm mapping possibly continuous in- and out-puts to discrete events e. The algorithm will be discussed in more detail in the following sections.

- Time synchronization: Since IEC 61499 events do not include a notion of time, the current progress of simulation time has to be synchronized, e.g., to the clock of a controller. Synchronization may also influence the range of feasible approaches for representational mapping since such a projection may have to be conducted in real time.

- Automation system interface: The actual integration of the virtual component into the automation system is implemented in the automation system interface, e.g., via a network connection. It is assumed that the automation system interface simply relays discrete events e without changing their abstract semantics.

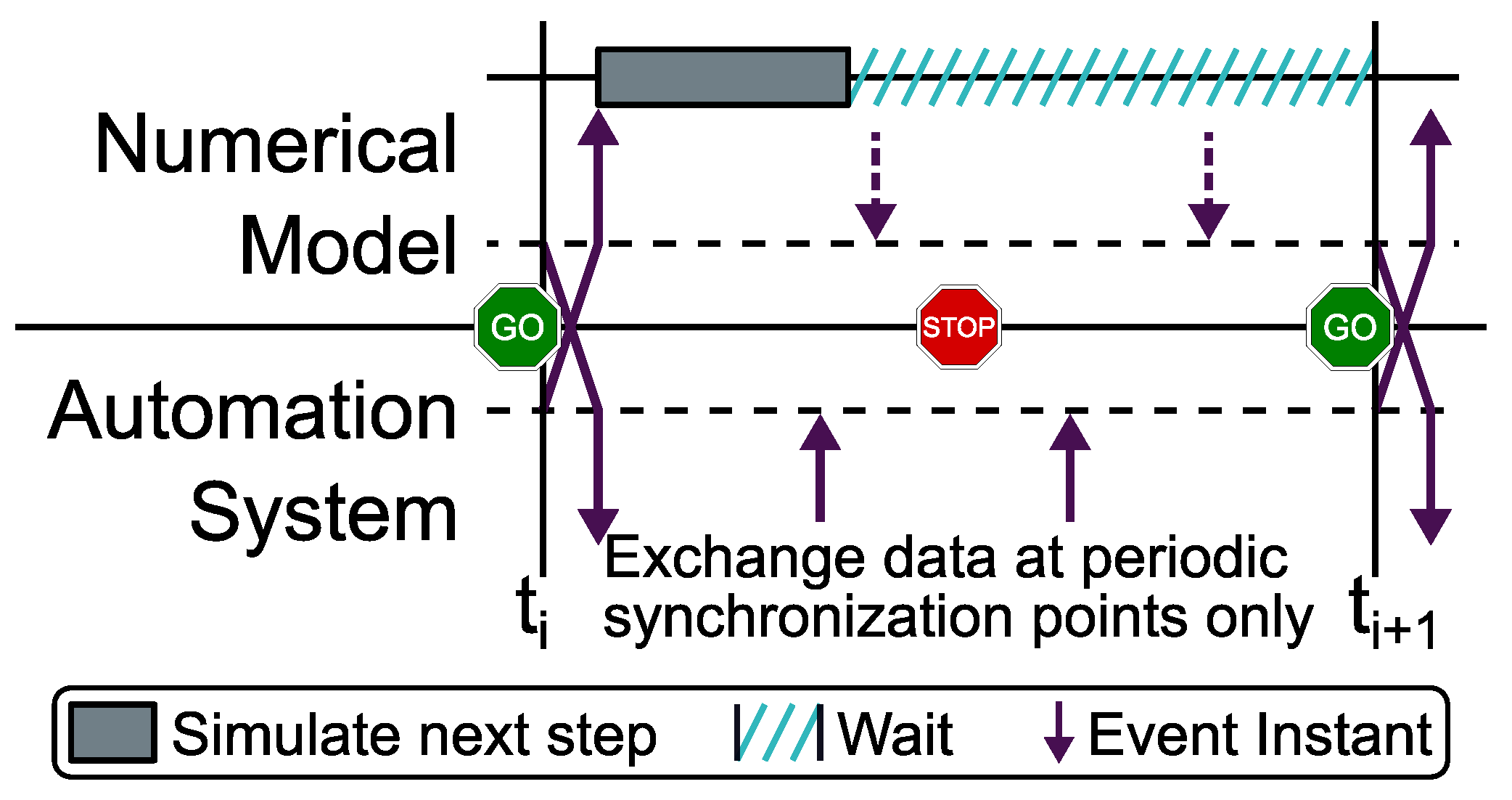

3.2. Periodic Event Mapping

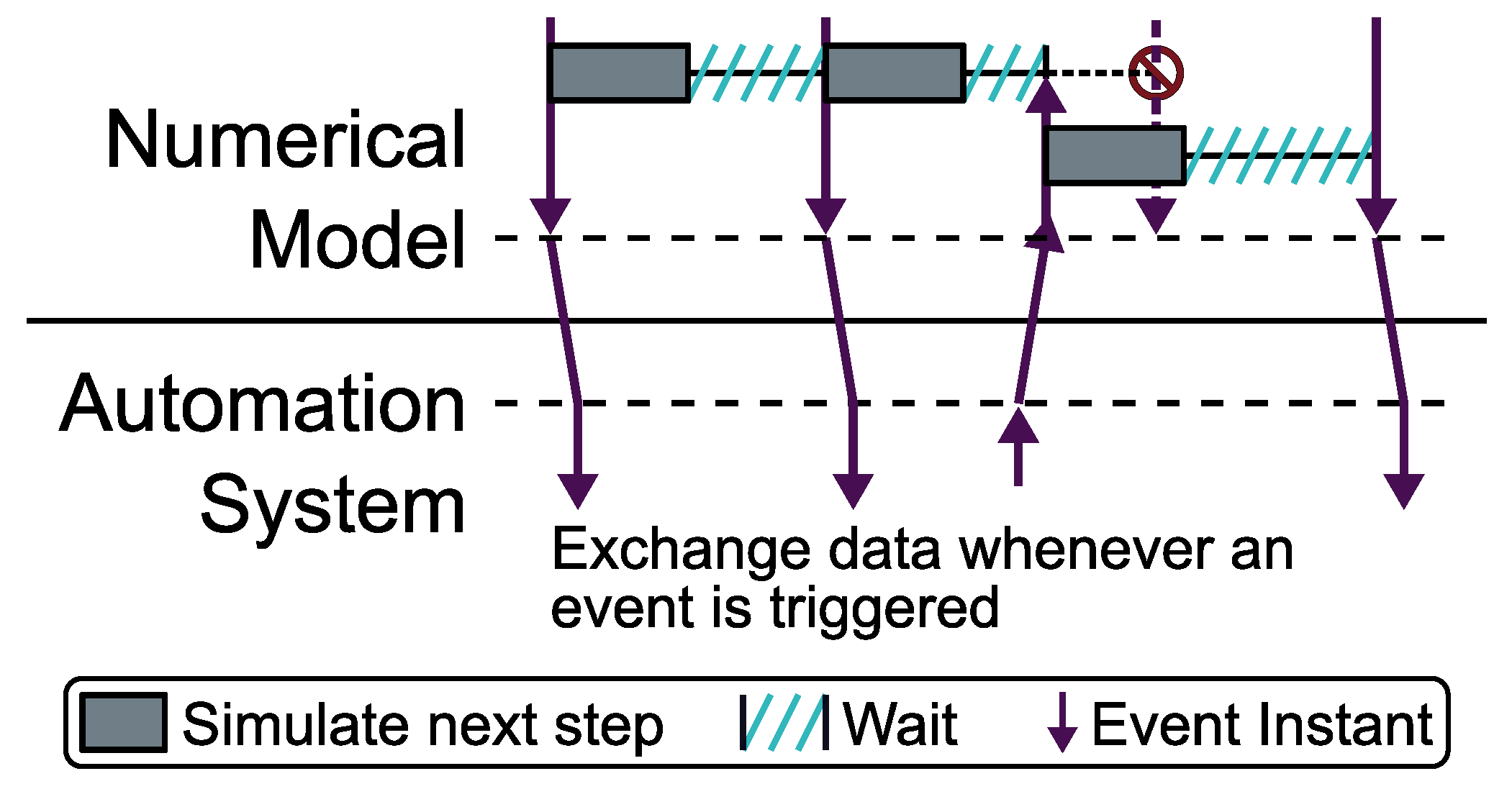

3.3. Predictive Event Mapping

3.4. Implementation Aspects

3.4.1. Unified Best-Effort Operation

3.4.2. Automation System Interface

3.4.3. Representational Mapping

3.4.4. Time Synchronization

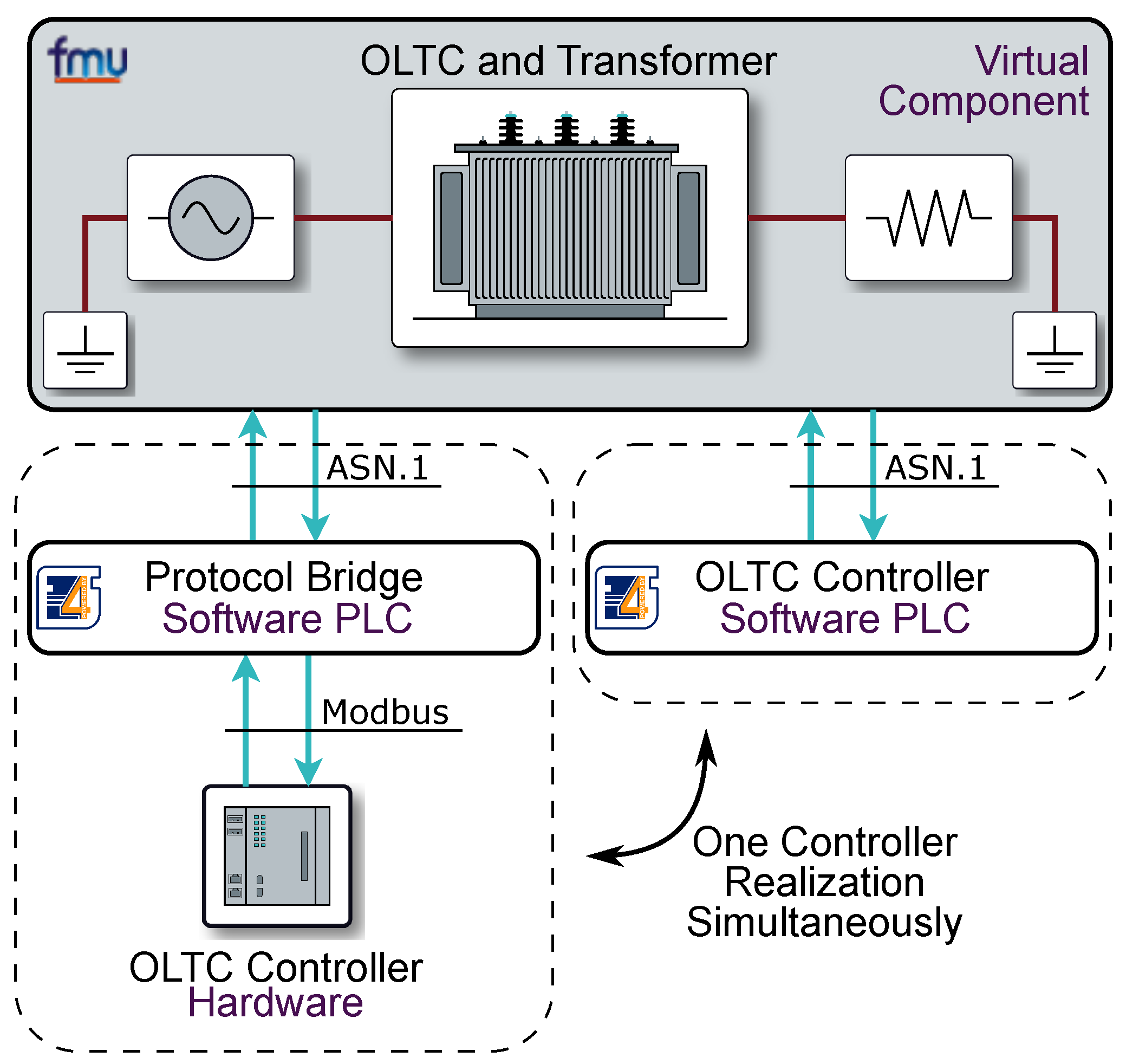

4. Experimental Evaluation

4.1. Experiment Description

4.1.1. Component Models

4.1.2. Controller Hardware

4.1.3. Software PLC Controller

4.1.4. Configuration

4.2. Timing Evaluation Method

4.2.1. Timing Record Fusion

4.2.2. Timing Metrics

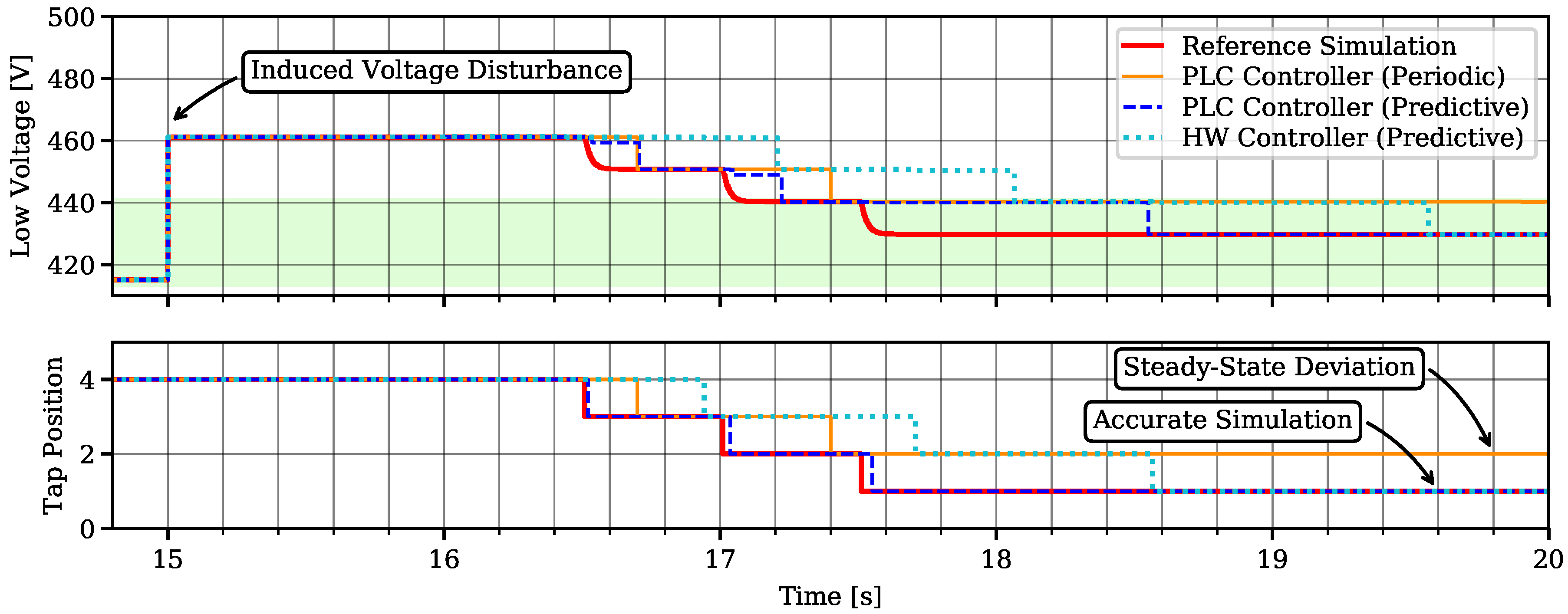

4.3. Results and Discussion

4.3.1. Timing

4.3.2. Simulation Outcome

5. Conclusions

- only soft real-time operation was feasible, in general,

- predictive operation introduced strict bounds of a delay-free synchronization that were rarely met in practice, and

- periodic event mapping always had to delay and accumulate events.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| BFB | Basic Function Block |

| CFB | Composite Function Block |

| FB | Function Block |

| FMU | Functional Mock-up Unit |

| FMI | Functional Mock-up Interface |

| HIL | Hardware-in-the-Loop |

| ODE | Ordinary Differential Equation |

| OLTC | On-Load Tap Changer |

| PLC | Programmable Logic Controller |

| RTI | Run-time Infrastructure |

| SCADA | Supervisory Control and Data Acquisition |

| SIFB | Service Interface Function Block |

| SSD | Service Sequence Diagram |

| WCET | Worst Case Execution Time |

References

- Nieße, A.; Tröschel, M.; Sonnenschein, M. Designing dependable and sustainable Smart Grids–How to apply Algorithm Engineering to distributed control in power systems. Environ. Model. Softw. 2014, 56, 37–51. [Google Scholar] [CrossRef]

- Yang, C.H.; Zhabelova, G.; Yang, C.W.; Vyatkin, V. Cosimulation Environment for Event-Driven Distributed Controls of Smart Grid. IEEE Trans. Ind. Inform. 2013, 9, 1423–1435. [Google Scholar] [CrossRef]

- Lin, H.; Sambamoorthy, S.; Shukla, S.; Thorp, J.; Mili, L. Power system and communication network co-simulation for smart grid applications. In Proceedings of the 2011 IEEE PES Innovative Smart Grid Technologies (ISGT 2011), Anaheim, CA, USA, 17–19 January 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Viehweider, A.; Lauss, G.; Lehfuss, F. Stabilization of Power Hardware-in-the-Loop simulations of electric energy systems. Simul. Model. Pract. Theory 2011, 19, 1699–1708. [Google Scholar] [CrossRef]

- Heinzl, B.; Raich, P.; Preyser, F.; Kastner, W. Simulation-based Assessment of Energy Efficiency in Industry: Comparison of Hybrid Simulation Approaches. IFAC-PapersOnLine 2018, 51, 689–694. [Google Scholar] [CrossRef]

- Blochwitz, T.; Otter, M.; Arnold, M.; Bausch, C.; Clauß, C.; Elmqvist, H.; Junghanns, A.; Mauss, J.; Monteiro, M.; Neidhold, T.; et al. The functional mockup interface for tool independent exchange of simulation models. In Proceedings of the 8th International Modelica Conference, Dresden, Germany, 20–22 March 2011; pp. 20–22. [Google Scholar]

- Widl, E.; Müller, W.; Elsheikh, A.; Hörtenhuber, M.; Palensky, P. The FMI++ library: A high-level utility package for FMI for model exchange. In Proceedings of the 2013 Workshop on Modeling and Simulation of Cyber-Physical Energy Systems (MSCPES), Berkeley, CA, USA, 20–22 May 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Müller, W.; Widl, E. Linking FMI-based components with discrete event systems. In Proceedings of the 2013 IEEE International Systems Conference (SysCon), Orlando, FL, USA, 15–18 April 2013; pp. 676–680. [Google Scholar] [CrossRef]

- Strasser, T.; Stifter, M.; Andrén, F.; Palensky, P. Co-Simulation Training Platform for Smart Grids. IEEE Trans. Power Syst. 2014, 29, 1989–1997. [Google Scholar] [CrossRef]

- Müller, S.C.; Georg, H.; Küch, M.; Wietfeld, C. INSPIRE—Co-Simulation of Power and ICT Systems for Evaluation of Smart Grid Applications. At-Automatisierungstechnik 2014, 62, 315–324. [Google Scholar] [CrossRef]

- Awais, M.U.; Palensky, P.; Mueller, W.; Widl, E.; Elsheikh, A. Distributed hybrid simulation using the HLA and the Functional Mock-up Interface. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 7564–7569. [Google Scholar] [CrossRef]

- Modelica Association Project Functional Mock-up Interface. In Functional Mock-Up Interface for Model Exchange; 2010; Available online: https://svn.modelica.org/fmi/branches/public/specifications/v1.0/FMI_for_ModelExchange_v1.0.pdf (accessed on 26 February 2020).

- Modelica Association Project Functional Mock-up Interface. In Functional Mock-Up Interface for Model Exchange and Co-Simulation; 2014; Available online: https://svn.modelica.org/fmi/branches/public/specifications/v2.0/FMI_for_ModelExchange_and_CoSimulation_v2.0.pdf (accessed on 26 February 2020).

- Eker, J.; Janneck, J.W.; Lee, E.A.; Liu, J.; Liu, X.; Ludvig, J.; Neuendorffer, S.; Sachs, S.; Xiong, Y. Taming heterogeneity—The Ptolemy approach. Proc. IEEE 2003, 91, 127–144. [Google Scholar] [CrossRef]

- IEC 61499-1/Ed.2: Function Blocks—Part 1: Architecture; IEC: Geneva, Switzerland, 2012.

- Vyatkin, V. The IEC 61499 standard and its semantics. IEEE Ind. Electron. Mag. 2009, 3, 40–48. [Google Scholar] [CrossRef]

- Strasser, T.; Zoitl, A.; Christensen, J.H.; Sünder, C. Design and Execution Issues in IEC 61499 Distributed Automation and Control Systems. IEEE Trans. Syst. Man Cybern. Part C: Appl. Rev. 2011, 41, 41–51. [Google Scholar] [CrossRef]

- Vyatkin, V. IEC 61499 as Enabler of Distributed and Intelligent Automation: State-of-the-Art Review. IEEE Trans. Ind. Inform. 2011, 7, 768–781. [Google Scholar] [CrossRef]

- Strasser, T.; Auinger, F.; Zoitl, A. Development, implementation and use of an IEC 61499 function block library for embedded closed loop control. In Proceedings of the INDIN ‘04 2004 2nd IEEE International Conference on Industrial Informatics, Berlin, Germany, 24–26 June 2004; pp. 594–599. [Google Scholar] [CrossRef]

- Lindgren, P.; Lindner, M.; Lindner, A.; Vyatkin, V.; Pereira, D.J.; Pinho, L.M. A Real-Time Semantics for the IEC 61499 standard. In Proceedings of the 2015 IEEE 20th International Conference on Emerging Technologies & Factory Automation (ETFA 2015), Luxembourg, 8–11 September 2015. [Google Scholar]

- Yang, C.H.; Vyatkin, V.; Cheng Pang, V. Model-Driven Development of Control Software for Distributed Automation: A Survey and an Approach. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 292–305. [Google Scholar] [CrossRef]

- Zehetner, J.; Stettinger, G.; Kokal, H.; Toye, B. Echtzeit-Co-Simulation für die Regelung eines Motorprüfstands. ATZ Automob. Z. 2014, 116, 40–45. [Google Scholar] [CrossRef]

- Gunnarsson, S. Evaluation of FMI-Based Workflow for Simulation and Testing of Industrial Automation Applications. Master’s Thesis, Department of Automatic Control, Lund University, Lund, Sweden, 2016. [Google Scholar]

- Erwall, C.; Mårtensson, O. Model-Based Design of Industrial Automation Solutions Using FMI. Master’s Thesis, Department of Automatic Control, Lund University, Lund, Sweden, 2016. [Google Scholar]

- Spiegel, M.H.; Leimgruber, F.; Widl, E.; Gridling, G. On using FMI-based models in IEC 61499 control applications. In Proceedings of the 2015 Workshop on Modeling and Simulation of Cyber-Physical Energy Systems (MSCPES), Seattle, WA, USA, 13 April 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Hegny, I.; Wenger, M.; Zoitl, A. IEC 61499 based simulation framework for model-driven production systems development. In Proceedings of the 2010 IEEE Conference on Emerging Technologies and Factory Automation (ETFA), Bilbao, Spain, 13–16 September 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Kopetz, H. Real-Time Systems; Design Principles for Distributed Embedded Applications; Real-Time Systems Series; Springer Science+Business Media: LLC: Boston, MA, USA, 2011. [Google Scholar] [CrossRef]

- Spiegel, M.H. Linking Simulation and Automation Infrastructure—A Study Based on the FMI and IEC 61499. Master’s Thesis, Technische Universität Wien, Wien, Austria, 2018. [Google Scholar]

- Hindmarsh, A.C.; Brown, P.N.; Grant, K.E.; Lee, S.L.; Serban, R.; Shumaker, D.E.; Woodward, C.S. SUNDIALS: Suite of nonlinear and differential/algebraic equation solvers. ACM Trans. Math. Softw. (TOMS) 2005, 31, 363–396. [Google Scholar] [CrossRef]

- Strasser, T.; Rooker, M.; Ebenhofer, G.; Zoitl, A.; Sunder, C.; Valentini, A.; Martel, A. Framework for distributed industrial automation and control (4DIAC). In Proceedings of the INDIN 2008 6th IEEE International Conference on Industrial Informatics, Daejon, Korea, 13–16 July 2008; pp. 283–288. [Google Scholar]

| Experiment | Dist. Stage | Delay Metrics | |||

|---|---|---|---|---|---|

| Samples | Mean (s) | Variance () | Max. (s) | ||

| PLC Predictive | Begin | 282 | 0.0903 | 0.003331 | 0.187 |

| End | 282 | 0.0909 | 0.003335 | 0.187 | |

| PLC Periodic | Begin | 771 | 0.0262 | 2.176 × | 0.0336 |

| End | 771 | 0.0275 | 4.919 × | 0.0468 | |

| HW Predictive | Begin | 222 | 0.0219 | 0.001354 | 0.187 |

| End | 222 | 0.0224 | 0.001381 | 0.187 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spiegel, M.H.; Widl, E.; Heinzl, B.; Kastner, W.; Akroud, N. Model-Based Virtual Components in Event-Based Controls: Linking the FMI and IEC 61499. Appl. Sci. 2020, 10, 1611. https://doi.org/10.3390/app10051611

Spiegel MH, Widl E, Heinzl B, Kastner W, Akroud N. Model-Based Virtual Components in Event-Based Controls: Linking the FMI and IEC 61499. Applied Sciences. 2020; 10(5):1611. https://doi.org/10.3390/app10051611

Chicago/Turabian StyleSpiegel, Michael H., Edmund Widl, Bernhard Heinzl, Wolfgang Kastner, and Nabil Akroud. 2020. "Model-Based Virtual Components in Event-Based Controls: Linking the FMI and IEC 61499" Applied Sciences 10, no. 5: 1611. https://doi.org/10.3390/app10051611

APA StyleSpiegel, M. H., Widl, E., Heinzl, B., Kastner, W., & Akroud, N. (2020). Model-Based Virtual Components in Event-Based Controls: Linking the FMI and IEC 61499. Applied Sciences, 10(5), 1611. https://doi.org/10.3390/app10051611