Landfill Slope Stability Improvement Incorporating Reinforcements in Reclamation Process Applying Observational Method

Abstract

1. Introduction

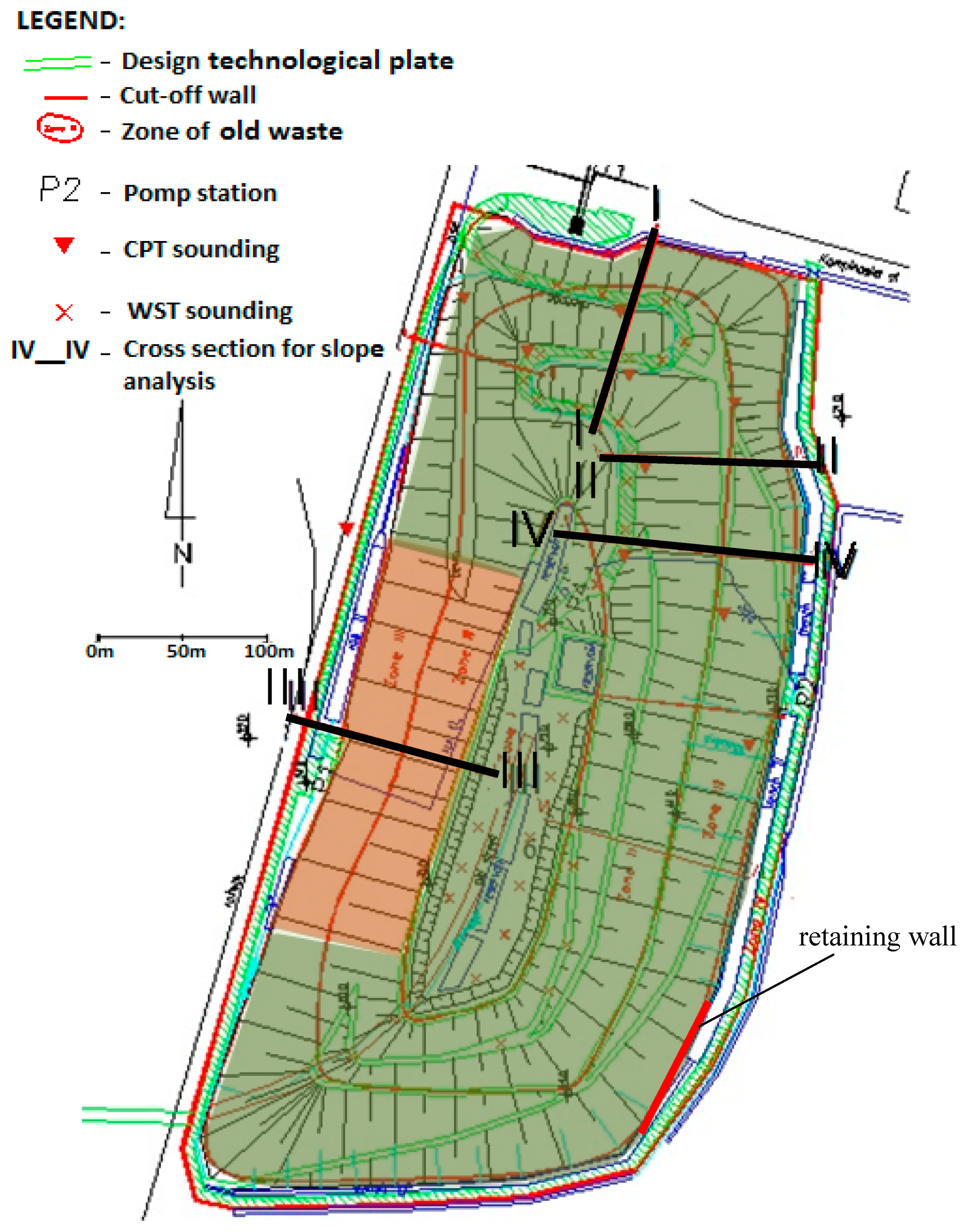

2. Materials and Methods

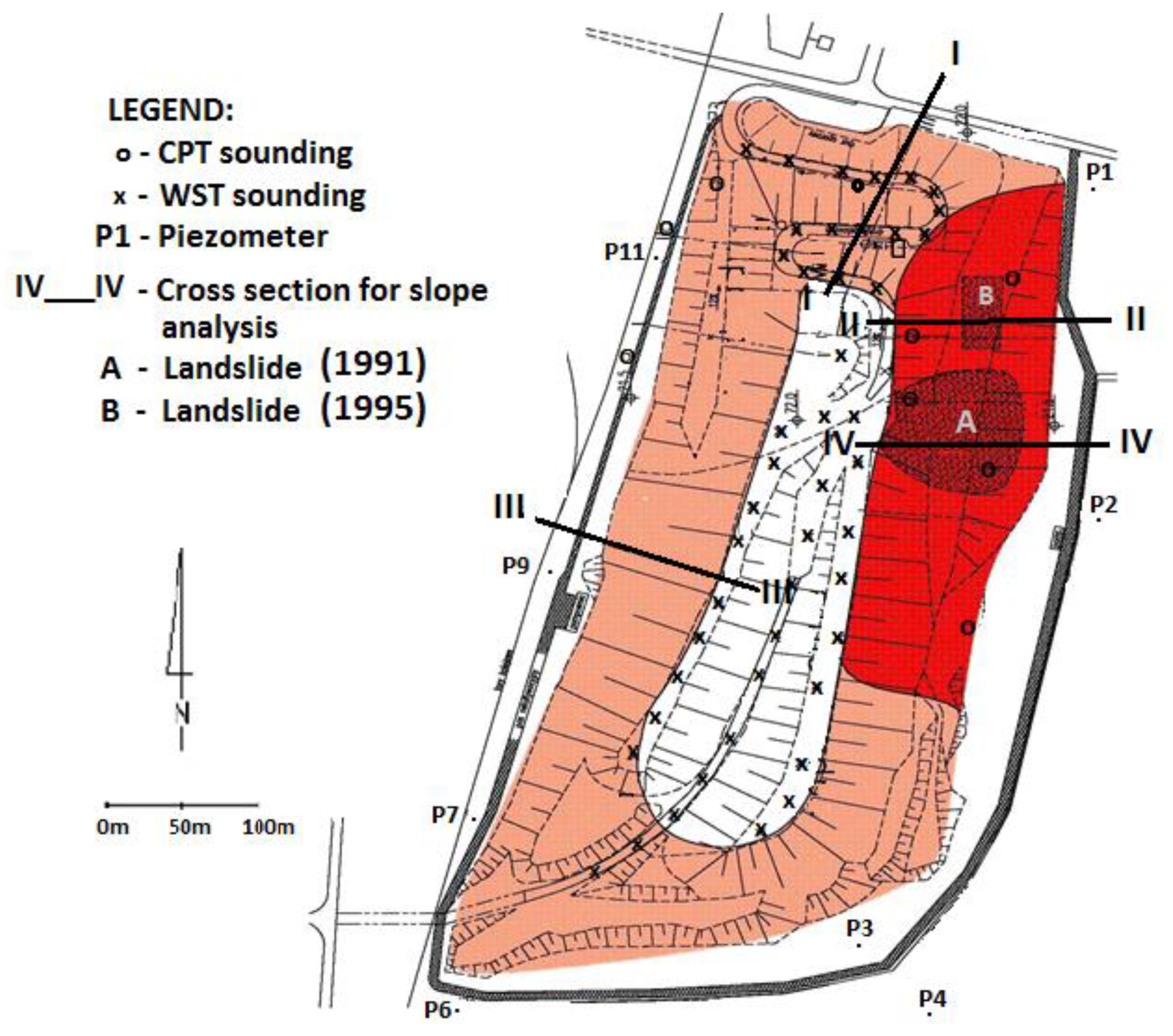

2.1. Site Investigation for Establishing Landfill Waste Properties

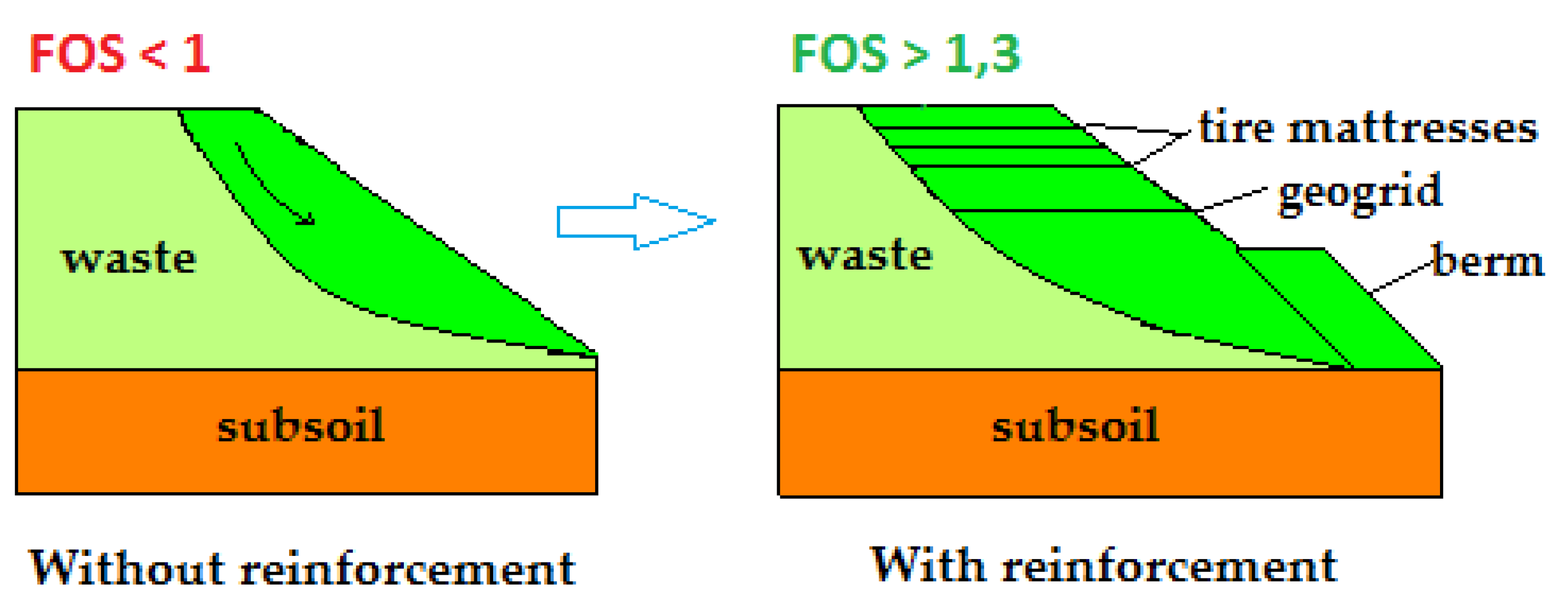

2.2. Geosynthetic Lateral Reinforcements

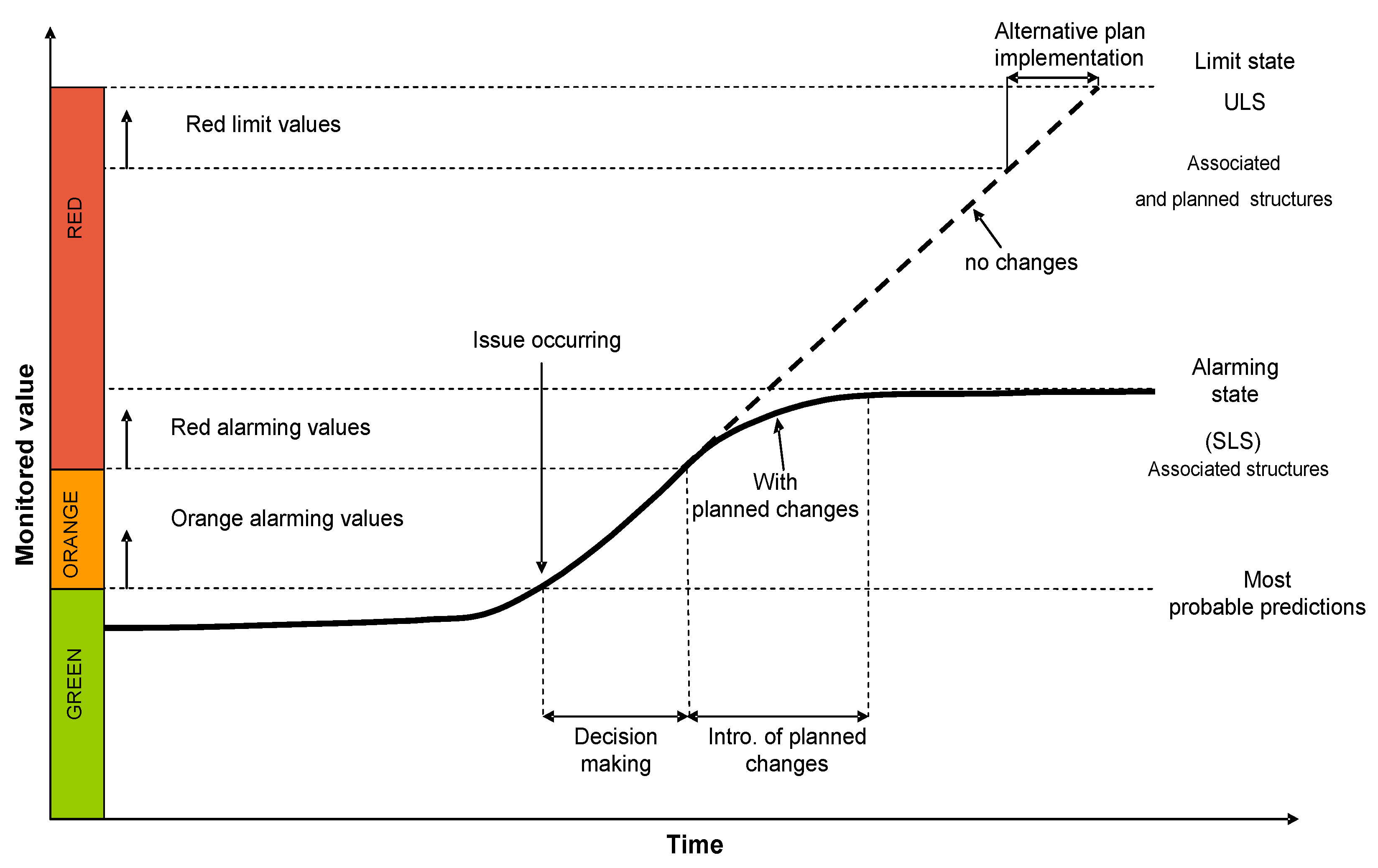

2.3. Observational Method Approach Adopted in the Present Study

- (1)

- Warning level, indicating the shifts in forecasted values, leaving space for introducing (or not) corrections in the design process,

- (2)

- Limit level, indicating the shift in forecasted values that requires immediate response and introducing an alternative solution.

- (1)

- Green; the measured values are lower than the alarming ones (orange); it is a safe stage (level 1),

- (2)

- Orange; the values exceed admissible levels, more data control is required here, and there is a little risk of failure (level 2),

- (3)

- Red; it is considered after the values exceeded alarming levels; to prevent serviceability limit states, immediate action needs to be taken (level 3).

3. Results and Discussion

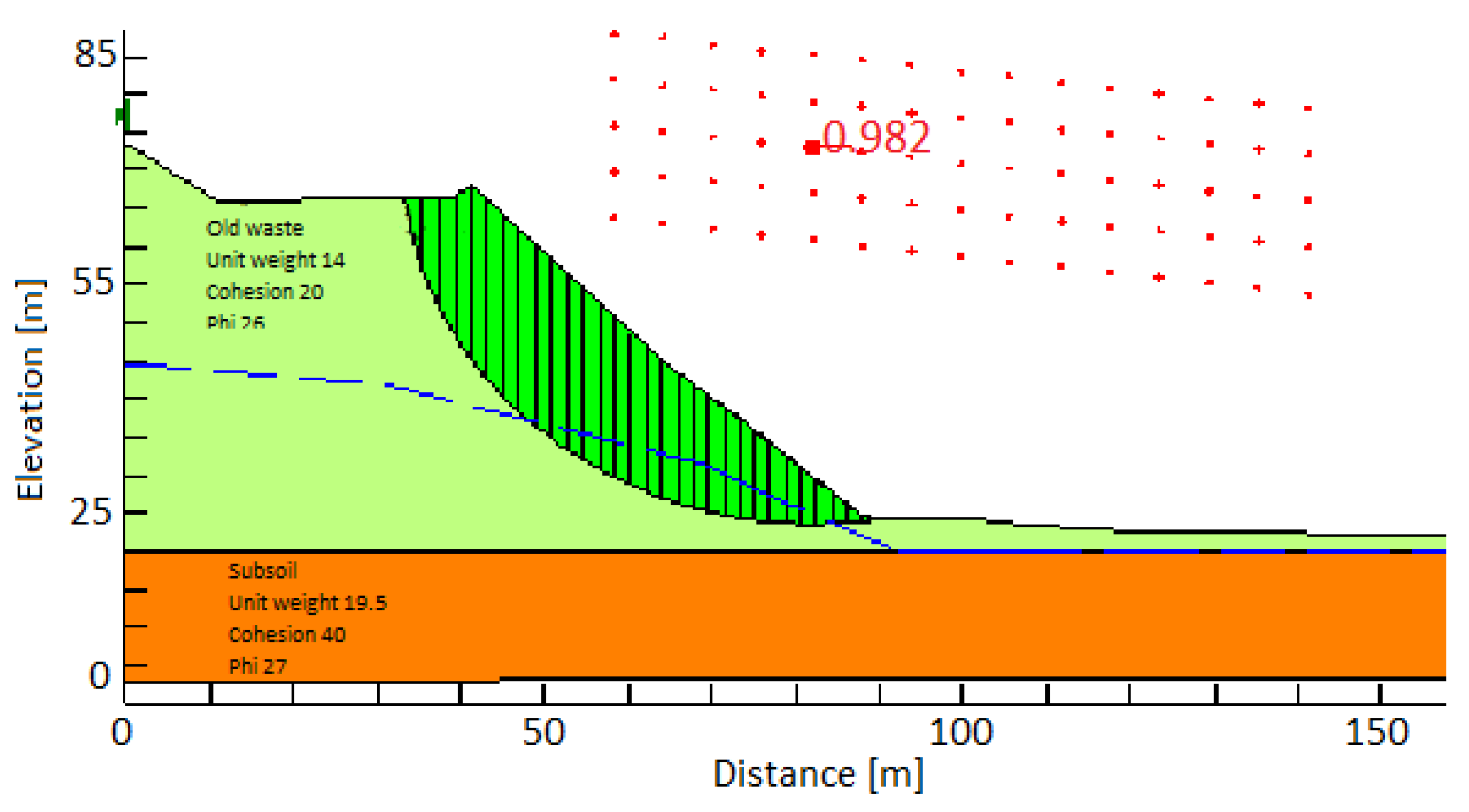

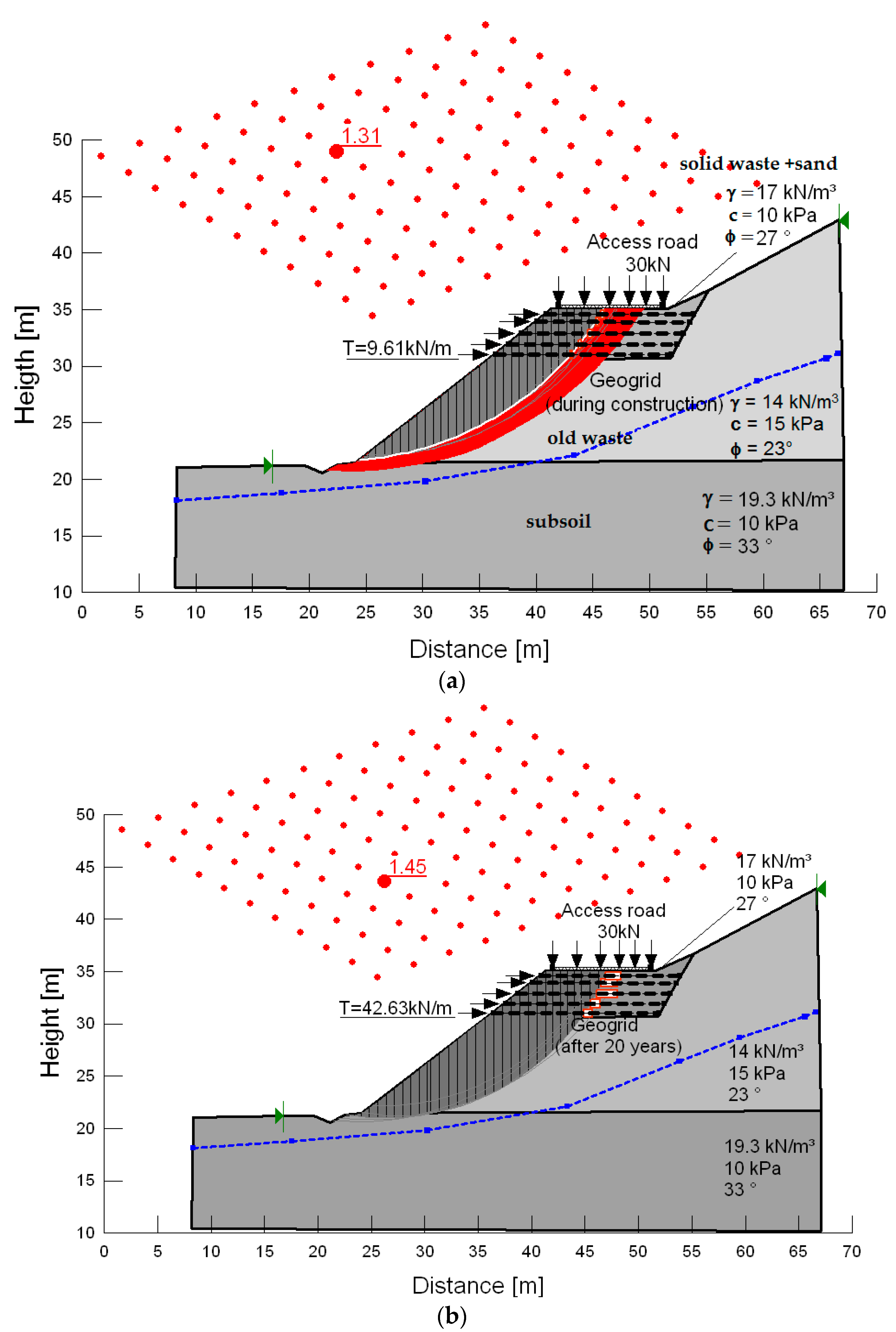

3.1. Slope Stability Analyses Incorporating Reinforcements

- (1)

- Green color - FOS > 1.3, the slope is safe (risk level 1), does not require further action (continuous monitoring and maintenance is required).

- (2)

- Orange color - FOS = 1.3–1.1, alarming condition (risk level 2), stability uncertain, extensive monitoring required, reinforcements application depending on results.

- (3)

- Red color - FOS < 1.1, possibility of exceeding ultimate limit state (risk level 3), it is necessary to adopt an alternative plan and immediate changes in the project.

3.2. Mechanical and Physical Parameters Analyses of Geogrids

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References and Notes

- Reddy, K.R.; Hettiarachchi, H.; Gangathulasi, J.; Bogner, J.E. Geotechnical properties of municipal solid waste at different phases of biodegradation. Waste Manag. 2011, 31, 2275–2286. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.J.; Gao, K.W.; Chen, Y.X.; Li, Y.; Zhang, L.M.; Chen, H.X. Geotechnical properties of municipal solid waste at Laogang Landfill, China. Waste Manag. 2017, 63, 354–365. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Kim, W.; Lee, J.; Baek, Y. Case Study on Slope Stability Changes Caused by Earthquakes—Focusing on Gyeongju 5.8 ML EQ. Sustainability 2018, 10, 3441. [Google Scholar] [CrossRef]

- Yang, R.; Zengguang, X.; Junrui, C.A. Review of characteristics of landfilled municipal solid waste in several countries: Physical composition, Unit Weight, and Permeability Coefficient. Pol. J. Environ. Stud. 2018, 27, 2425–2435. [Google Scholar] [CrossRef]

- Spross, J.; Johansson, F. When is the observational method in geotechnical engineering favourable? Str. Saf. 2017, 66, 17–26. [Google Scholar] [CrossRef]

- Nicholson, D.; Tse, C.M.; Penny, C.; O’Hana, S.; Hana, S.; Dimmock, R. The Observational Method in Ground Engineering: Principles and Applications; CIRIA Report No. 185; Construction Industry Research and Information Association: London, UK, 1999. [Google Scholar]

- Gunturi, V.R. (Ed.) Analysis and Modeling of Landfill Failure; Technical Report; Indian Institute of Technology: Dehli, India, 2018. [Google Scholar]

- Vaverkova, M. Impact assessment of the municipal solid landfill on environment: A case study. Acta Sci. Pol. 2019, 18, 11–20. [Google Scholar] [CrossRef]

- Koda, E. Stability conditions improvement of the old sanitary landfills. In Proceedings of the 3th Internatonal Congress on Environment Geotechnics, Lisboa, Portugal, 7–11 September 1998. [Google Scholar]

- Pancar, E.B.; Akpınar, M.V. Comparison of Effects of Using Geosynthetics and Lime Stabilization to Increase Bearing Capacity of Unpaved Road Subgrade. Adv. Mat. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Geosynthetics—Guidelines for the Assessment of Durability; ISO/TS 13434; International Organization for Standardization: Geneva, Switzerland, 2008.

- EBGEO. Recommendations for Design and Analysis of Earth Structures Using Geosynthetic Reinforcements; Ernst & Sohn Verlag: Berlin, Germany, 2011. [Google Scholar]

- Koda, E.; Szymanski, A.; Wolski, W. Behavior of geodrains in organic subsoil. In Proceedings of the Conference on Soil Mechanics and Foundation Engineering, Rio de Janeiro, Brazil, 13–18 August 1989; Volume 2, pp. 1377–1380. [Google Scholar]

- Koda, E.; Szymański, A.; Wolski, W. Field and laboratory experience with the use of strip drains in organic soils. Can. Geotech. J. 1993, 30, 308–318. [Google Scholar] [CrossRef]

- Hufenus, R.; Rüegger, R.; Flum, D.; Sterba, I.J. Strength reduction factors due to installation damage of reinforcing geosynthetics. Geotext. Geomembr. 2005, 23, 55–75. [Google Scholar] [CrossRef]

- Carneiro, J.R.; Almeida, P.J.; Lopes, M.L. Resistance of high-density polyethylene geonets against chemical ageing. In Proceedings of the 6th International Congress on Environmental Geotechnics, New Delhi, India, 7–12 November 2010. [Google Scholar]

- Rowe, K.; Islam, M.Z.; Hsuan, Y.G. Leachate chemical composition effects on OIT depletion in an HDPE geomembrane. Geosynth. Int. 2008, 15, 2. [Google Scholar] [CrossRef]

- Rowe, R.K.; Ewais, A.M.R. Ageing of exposed geomembranes at locations with different climatological conditions. Can. Geotech. J. 2015, 52, 326–343. [Google Scholar] [CrossRef]

- Kiersnowska, A.; Koda, E.; Fabianowski, W.; Kawalec, J. Effect of the Impact of Chemical and Environmental Factors on the Durability of the High Density Polyethylene (HDPE) Geogrid in a Sanitary Landfill. Appl. Sci. 2017, 7, 22. [Google Scholar] [CrossRef]

- Kay, D.; Blond, E.; Mlynarek, J. Geosynthetics Durability: A Polymer Chemistry Issue. In 57th Canadian Geotechnical Conference 5th Joint Cgs/Iah-Cnc Conference; Geological Survey of Canada: Quebec, QC, Canada, 2004; Volume 4, pp. 1–14. [Google Scholar]

- Patel, D.; Nicholson, D.; Huybrechts, N.; Maertens, J. The observational method in geotechnics. In Proceedings of the XIV European Conference on Soil Mechanics and Geotechnical Engineering, Madrid, Spain, 24–27 September 2007. [Google Scholar]

- Koda, E. Landfill Stability under Reclamation and Pollutant Transport Using the Observational Method; Treatises and Monographs. No 384; Warsaw University of Life Sciences Press: Warsaw, Poland, 2011. [Google Scholar]

- Koda, E.; Grzyb, M.; Osiński, P.; Vaverkova, M.D. Analysis of failure in landfill construction systems. Matec. Web Conf. 2019, 284, 03002. [Google Scholar] [CrossRef]

- Baiocchi, V.; Quintilio, N.; Martina, T.; Giampaolo, S.; Maria, A.; Domenica, C. UAV for monitoring the settlement of a landfill. Eur. J. Rem. Sens. 2019, 52, 41–52. [Google Scholar] [CrossRef]

- Cuartas, M.; López, A.; Pérez, F.; Lobo, A. Analysis of landfill design variables based on scientific computing. Waste Manag. 2018, 71, 287–300. [Google Scholar] [CrossRef]

- Gao, W.; Bian, X.C.; Xu, W.J.; Chen, Y.M. Storage capacity and slope stability analysis of municipal solid waste landfills. J. Perf. Constr. Fac. 2018, 32, 04018036. [Google Scholar] [CrossRef]

- CEN/TC 189 Geosynthetics (Committee), & ISO/TC 221 Geosynthetics (Committee). (2005). Geosynthetics—Test Method for the Determination of Mass Per Unit Area of Geotextiles and Geotextile-related Products. International Organization for Standardization.

- ISO. PN-EN ISO 9863-1: Geosynthetics—Determination of Thickness at Specified—1: Single Layers; CEN: Brussels, Belgium, 2005. [Google Scholar]

- PN-EN ISO 10319: ISO, E. (2008). Geosynthetics—Wide-width tensile test. PN-EN ISO, 10319.

- Bhowmik, R.; Datta, M.; Shahu, J.T. Pullout Behaviour of Geosynthetics—A Review of Laboratory Testing Techniques. In Ground Improvement Techniques and Geosynthetics; Springer: Singapore, 2019; pp. 219–227. [Google Scholar]

- Sun, Y.; Xu, H.; Gu, P.; Hu, W. Application of FBG sensing technology in stability analysis of geogrid-reinforced slope. Sensors 2017, 17, 597. [Google Scholar] [CrossRef] [PubMed]

- Pant, S. Stability Analysis of Geosynthetic Reinforced MSW Landfill. Management 2016, 31, 2275–2286. [Google Scholar]

- Mokhtari, M.; Rafsanjani, A.A.H.; Shariatmadari, N. The effect of aging on the compressibility behavior and the physical properties of municipal solid wastes: A case study of Kahrizak landfill, Tehran. Environ. E. Sci. 2019, 78, 519. [Google Scholar] [CrossRef]

- Salimi, K.; Ghazavi, M. Soil reinforcement and slope stabilisation using recycled waste plastic sheets. Geomech. Geoeng. 2019, 1, 1–12. [Google Scholar] [CrossRef]

- Tensar. The Long-Term Performance of Tensar Geogrids; Tensar/Nelton LTD: Blackburn, UK, 1990. [Google Scholar]

- Osiński, P.; Dobrzelewski, B.; Koda, E.; Król, P. Slope stability analyses incorporating soil improvement methods for valuable urban area. In Geotechnics for Sustainable Infrastructure Development; Springer: Singapore, 2020; pp. 803–808. [Google Scholar]

| Waste Material | Γ [kN/m3] | Φ [°] | C [kPa] | Testing Methods |

|---|---|---|---|---|

| Solid waste | 9.0 | 20 | 25 | trial loading, CPT, WST |

| Solid waste + sand | 12.0 | 25 | 23 | trial loading, CPT, WST |

| Old waste | 14.0 | 26 | 20 | back-analysis, CPT, WST |

| Mechanical Properties | |

|---|---|

| Tensile strength at 2% strain (kN/m) | 19.0 |

| Tensile strength at 5% strain (kN/m) | 33.5 |

| Peak tensile strength (kN/m) | 55 |

| Yield point elongation (%) | 11.2 |

| Slope Cross-Section | Reinforcement | FOS | |

|---|---|---|---|

| Bishop Method | |||

| Without Reinforcement | With Reinforcement | ||

| Northern -I | Inclination change (geogrid) | 1.04 | 1.36 |

| Western -II | Berm (tire mattress) | 1.14 | 1.27 |

| Eastern -III | Berm | 1.06 | 1.36 |

| Further Western -IV | Berm and retaining wall | 1.18 | 1.33 |

| Tests | Parameters | Specific Standard | New Sample 1 | Exhumed Samples | |

|---|---|---|---|---|---|

| Mean Value | Standard Deviation | ||||

| Physical | Mass per unit area (g/m2) | PN-EN ISO 9864 [27] | 500 | 532 | - |

| Aperture Size (mm) | - | 140 | 140.24 | 1.56 | |

| Rib Thickness (mm) | PN-EN ISO 9863-1 [28] | 0.95 | 0.97 | 0.0078 | |

| CMD Bar Thickness (mm) | 2.5 ÷ 2.7 | 2.70 | 0.0640 | ||

| Mechanical | Mean Tensile Strength (kN/m) | PN-EN ISO 10319 [29] | 55 | 48.92 | 4.20 |

| Mean Strain at Maximum Load (%) | 11.2 | 6.40 | 0.89 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koda, E.; Kiersnowska, A.; Kawalec, J.; Osiński, P. Landfill Slope Stability Improvement Incorporating Reinforcements in Reclamation Process Applying Observational Method. Appl. Sci. 2020, 10, 1572. https://doi.org/10.3390/app10051572

Koda E, Kiersnowska A, Kawalec J, Osiński P. Landfill Slope Stability Improvement Incorporating Reinforcements in Reclamation Process Applying Observational Method. Applied Sciences. 2020; 10(5):1572. https://doi.org/10.3390/app10051572

Chicago/Turabian StyleKoda, Eugeniusz, Agnieszka Kiersnowska, Jacek Kawalec, and Piotr Osiński. 2020. "Landfill Slope Stability Improvement Incorporating Reinforcements in Reclamation Process Applying Observational Method" Applied Sciences 10, no. 5: 1572. https://doi.org/10.3390/app10051572

APA StyleKoda, E., Kiersnowska, A., Kawalec, J., & Osiński, P. (2020). Landfill Slope Stability Improvement Incorporating Reinforcements in Reclamation Process Applying Observational Method. Applied Sciences, 10(5), 1572. https://doi.org/10.3390/app10051572