A Flux-Controllable NI HTS Flux-Switching Machine for Electric Vehicle Applications

Abstract

1. Introduction

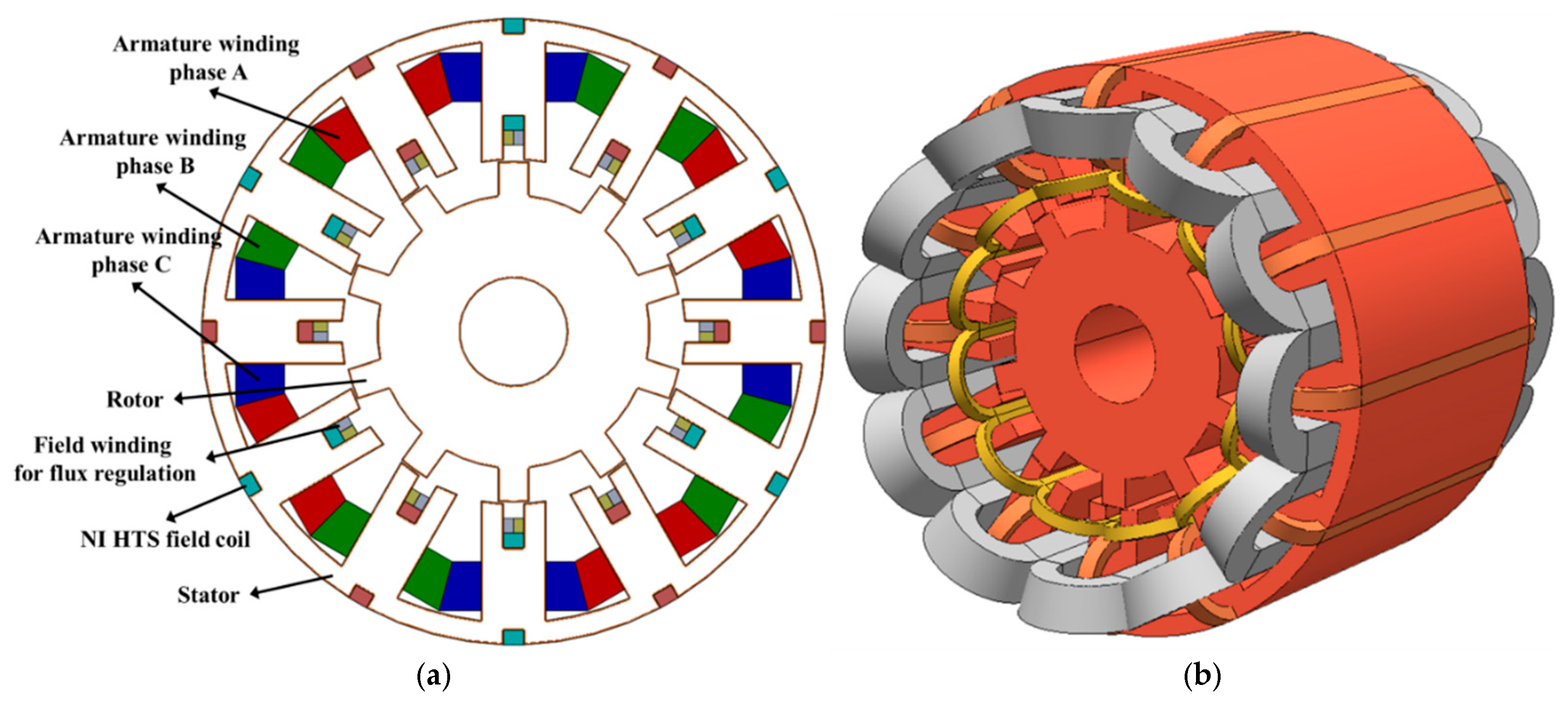

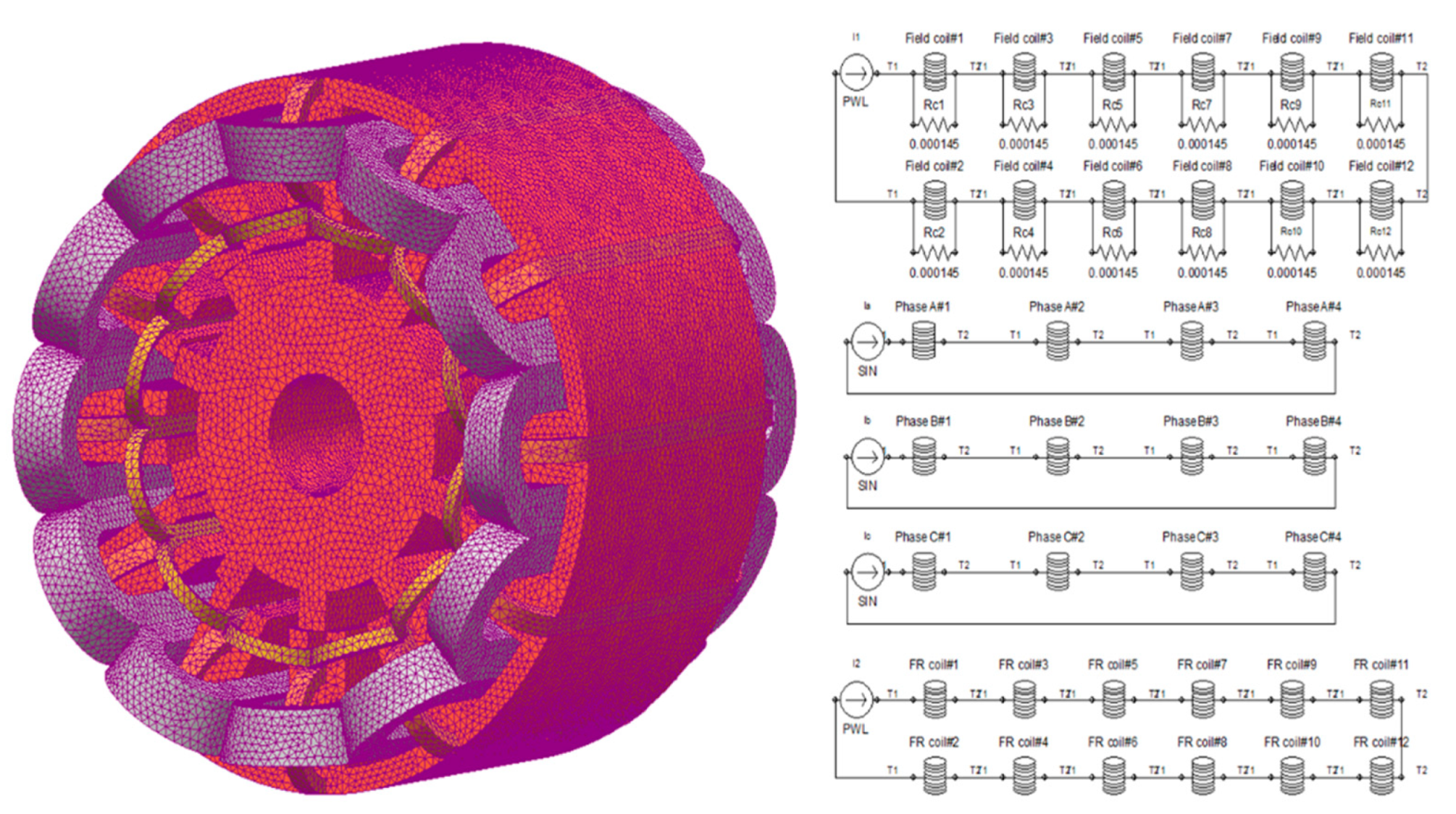

2. Machine Structure Operating Principle and Design of the Flux-Controllable NI HTS FSM

2.1. Machine Structure of the Flux-Controllable NI HTS FSM

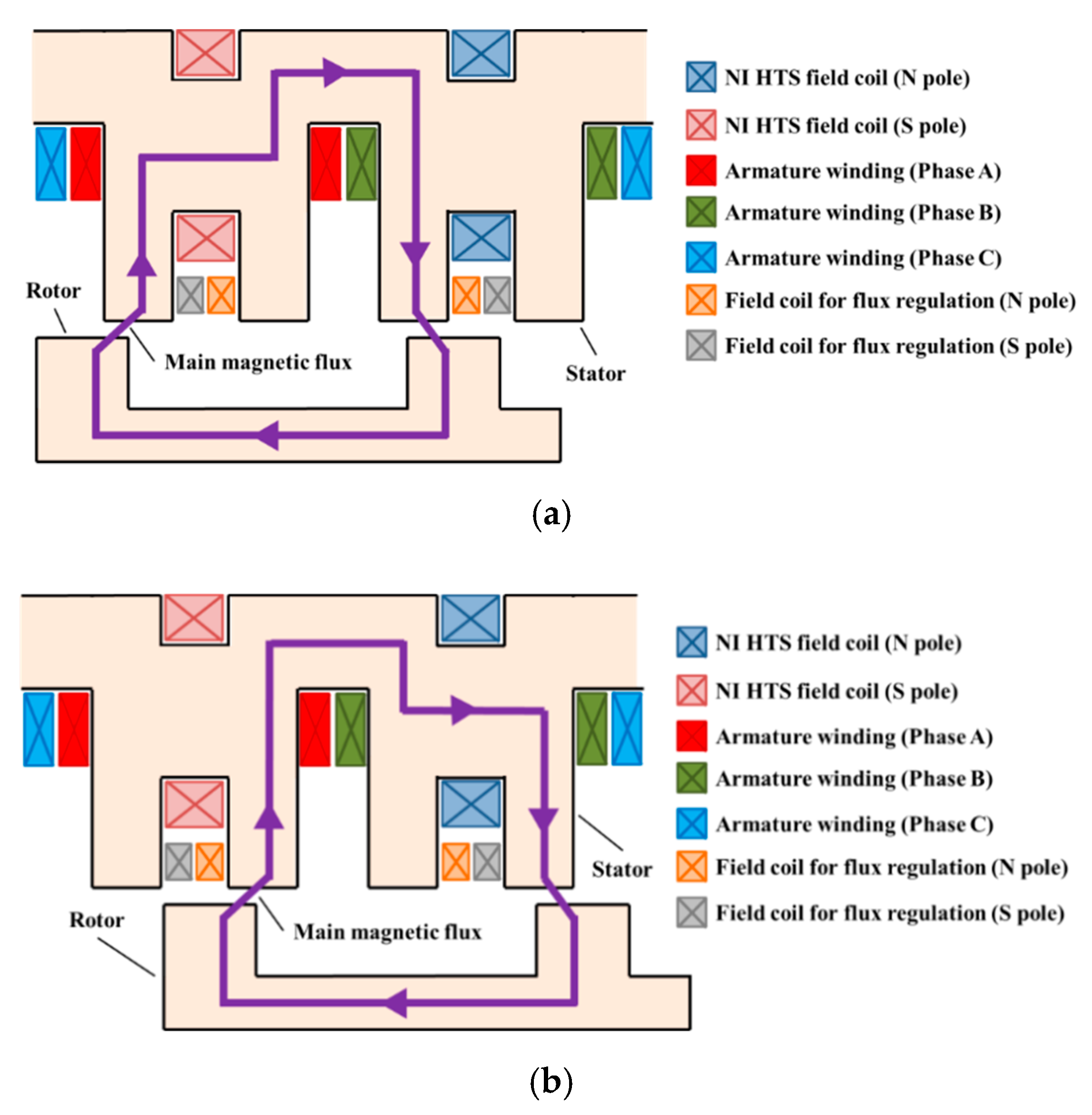

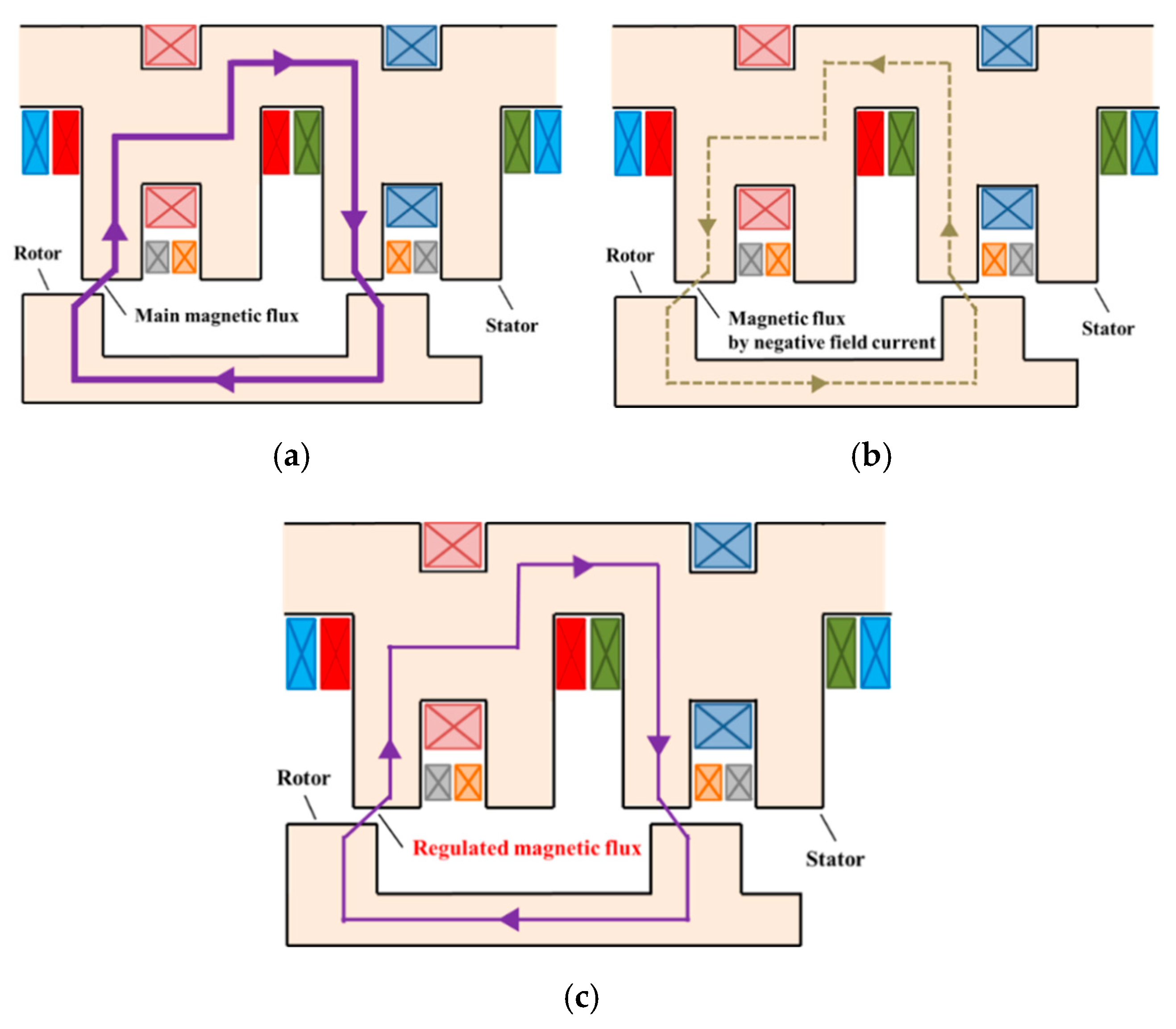

2.2. Operating Principle of the Flux-Controllable NI HTS FSM

2.3. Design of the Flux-Controllable FSM

- The design specifications of the NI HTS FSM, in this case the output power, flux regulation ratio and phase, are determined.

- The maximum radius rr,max and length lmax of the rotor are calculated considering rotor material’s mechanical properties, using Equations (1) and (2), respectively.

- The slot pitch is calculated based on the pole pitch and the numbers of slots. The number of conductors also are calculated using Equation (3).

- The dimensions of the armature conductor and the slot are determined by Equation (4).

- The tangential stress in the rotor is calculated using the rotor dimension and the torque via Equation (5).

- The required air-gap field density, B0, is then calculated by Equation (6).

- Based on the required flux regulation ratio and B0, the NI HTS field coil and the additional field winding are designed by means of FEM under a no-load condition.

- The cryostat for the NI HTS field coil is designed based on the HTS field coil and other thermal loads. The thermal loads of the cryostat are calculated by the equations below [39,40,41].Here, QCL, QK, and QR are the thermal loads from the conduction heat transfers by a pair of current leads, the leading-in tubes for the signal lines, and the radiation heat transfer.

- Characteristic analyses of the deigned machine are carried out in the form of a transient motion analysis, using a commercialized FEM software package.

3. Characteristic Analysis of the Flux-Controllable NI HTS FSM

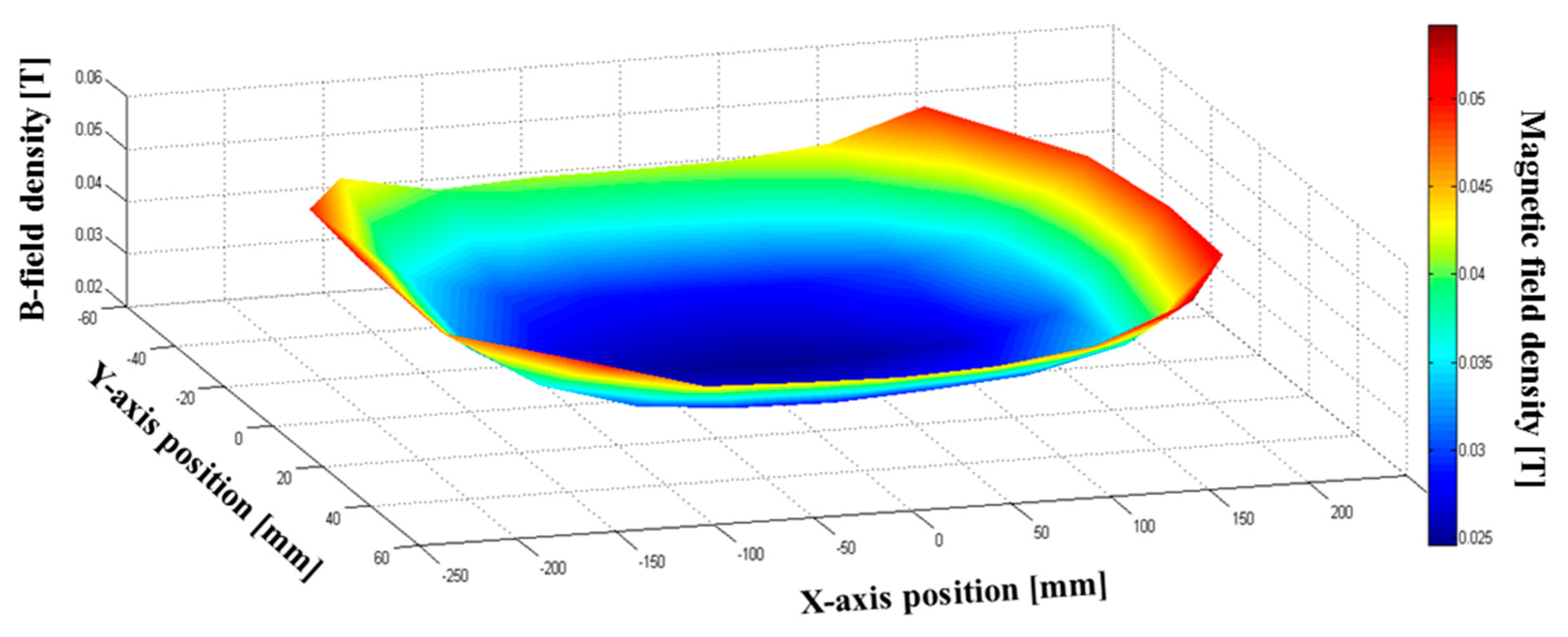

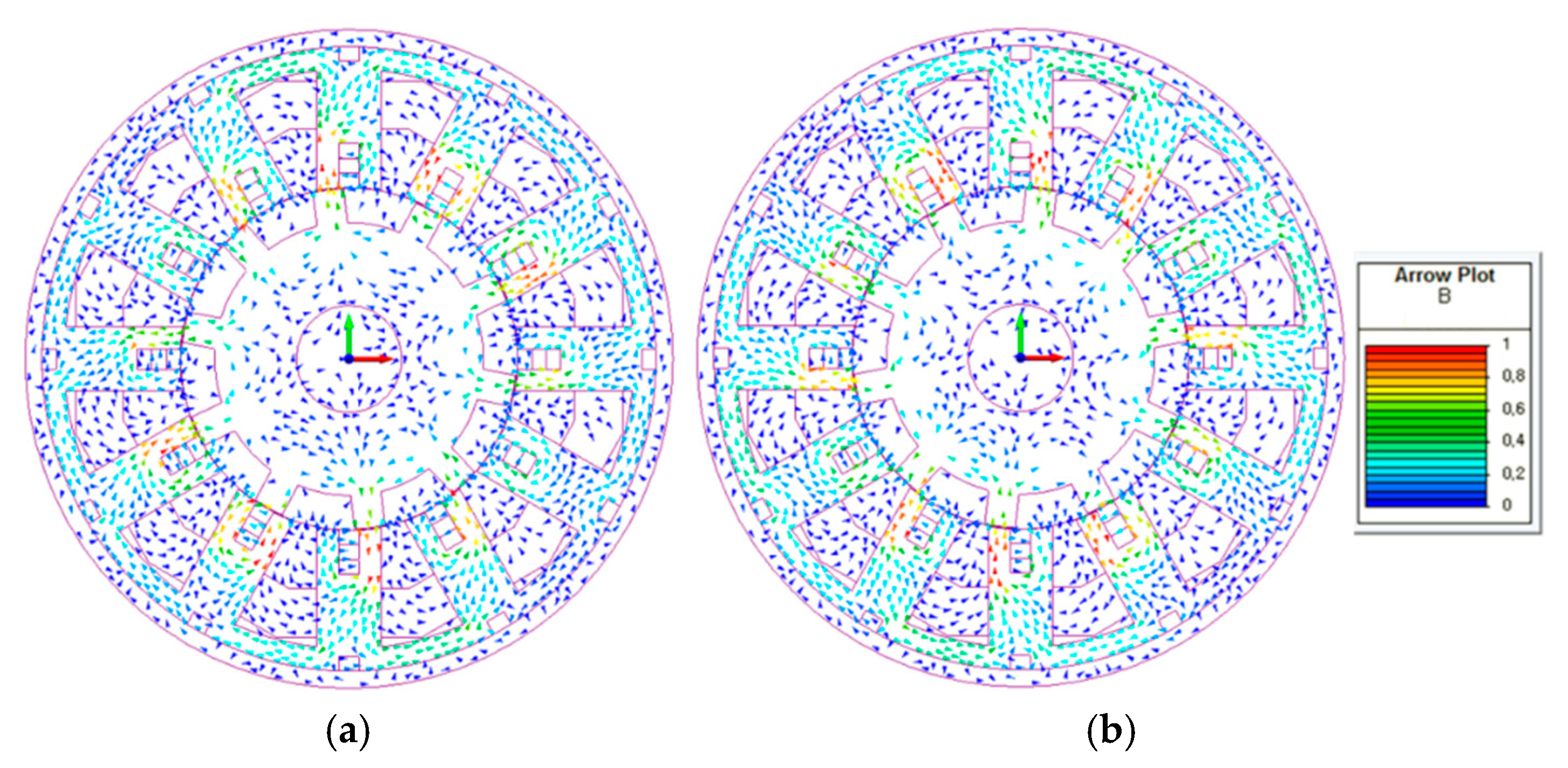

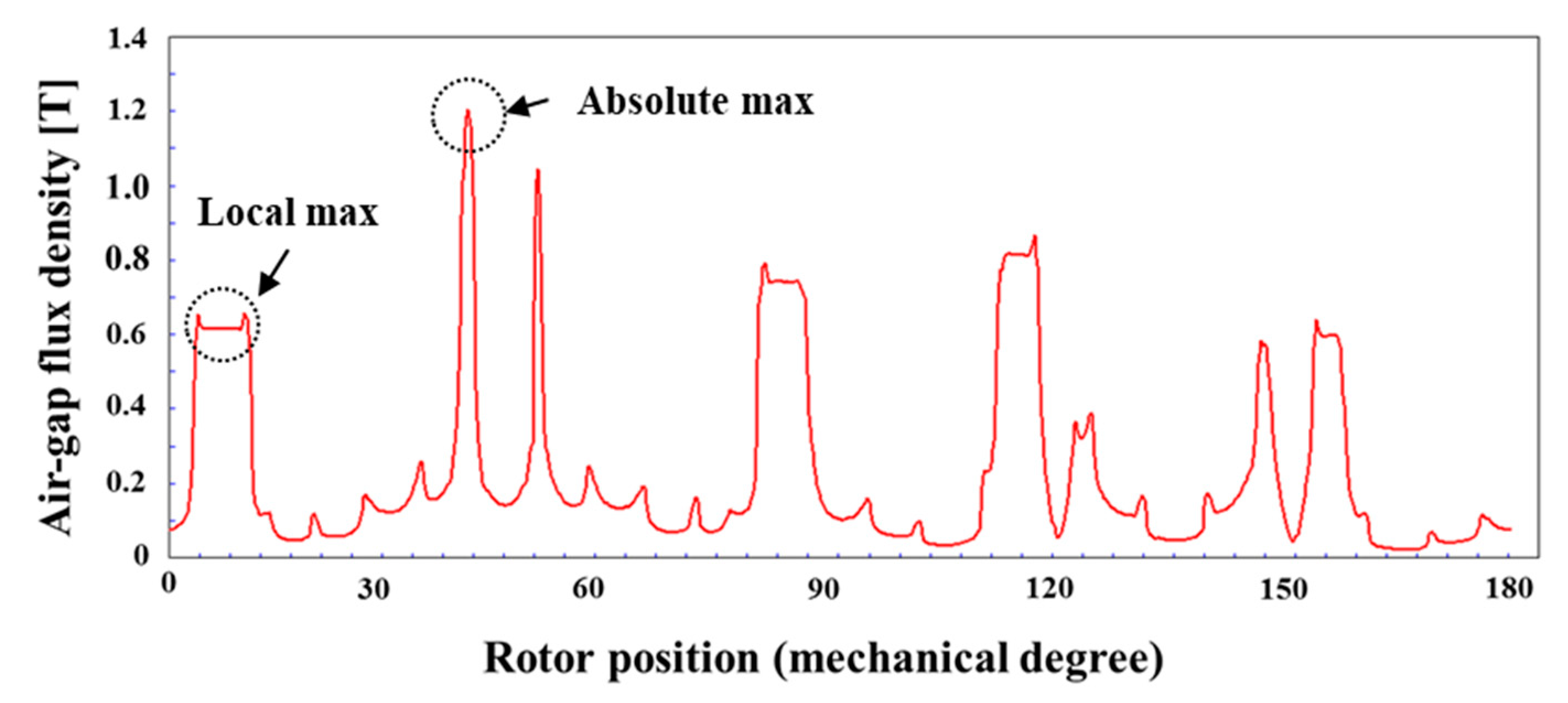

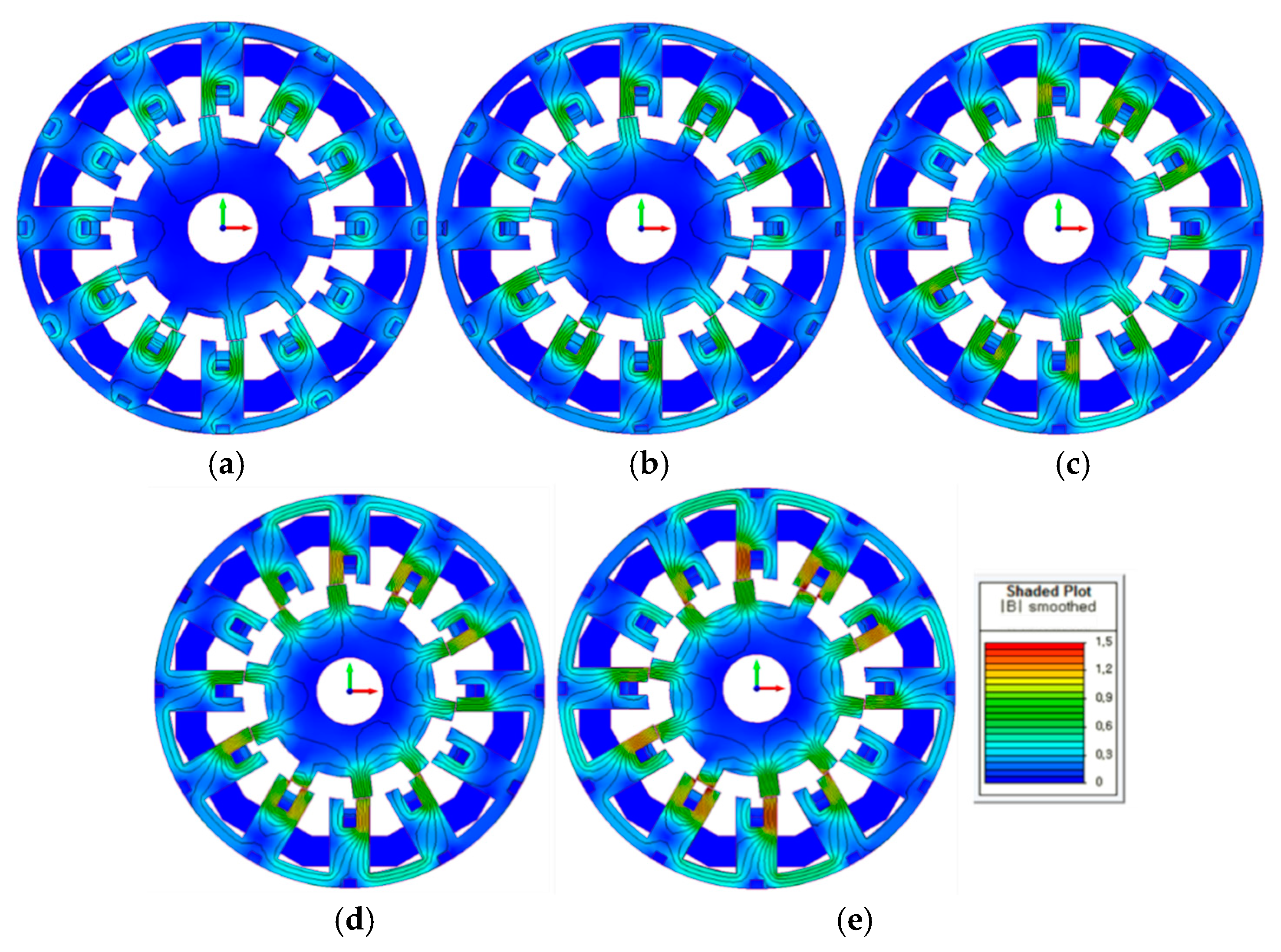

3.1. Field Distribution of the Proposed FSM

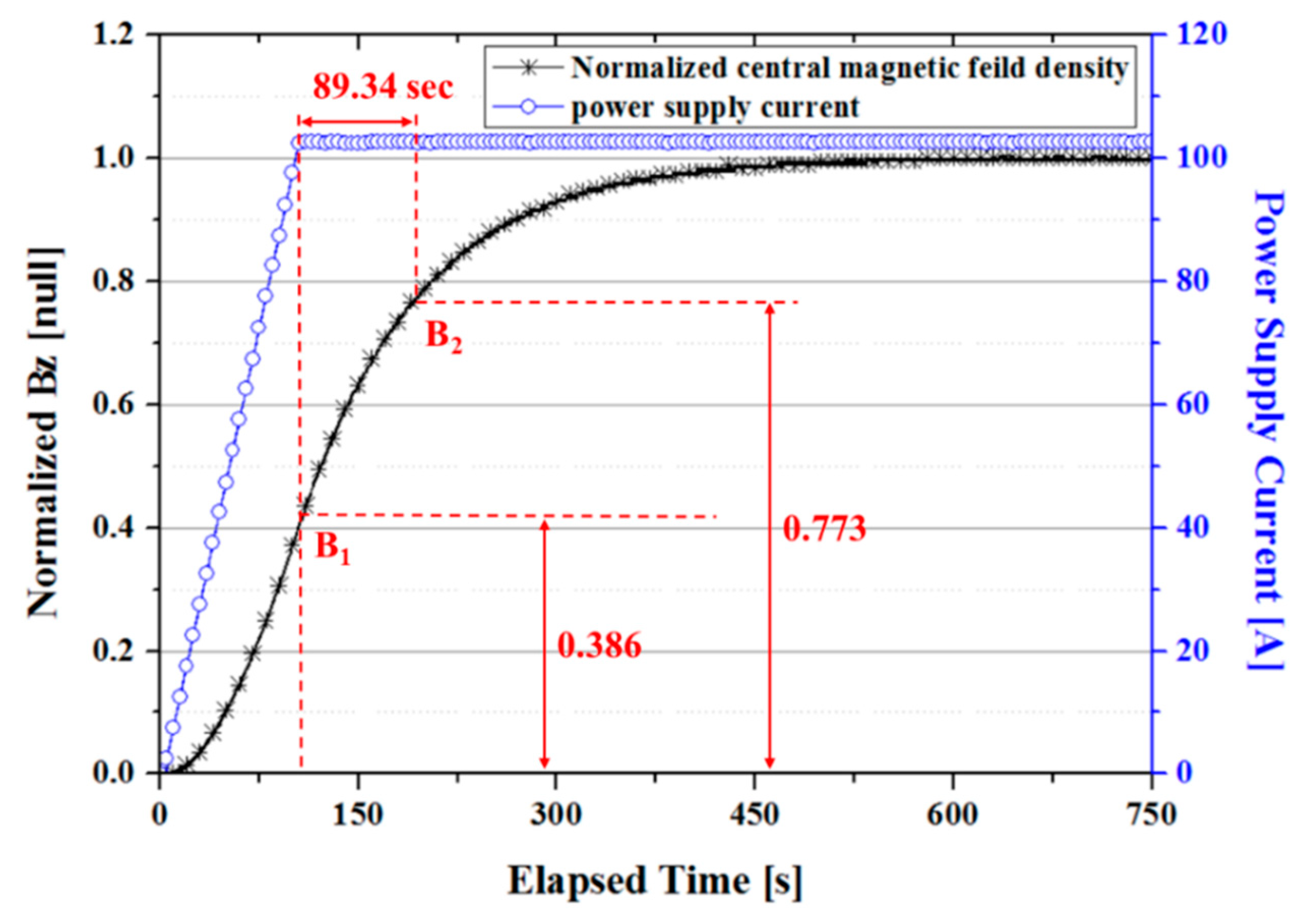

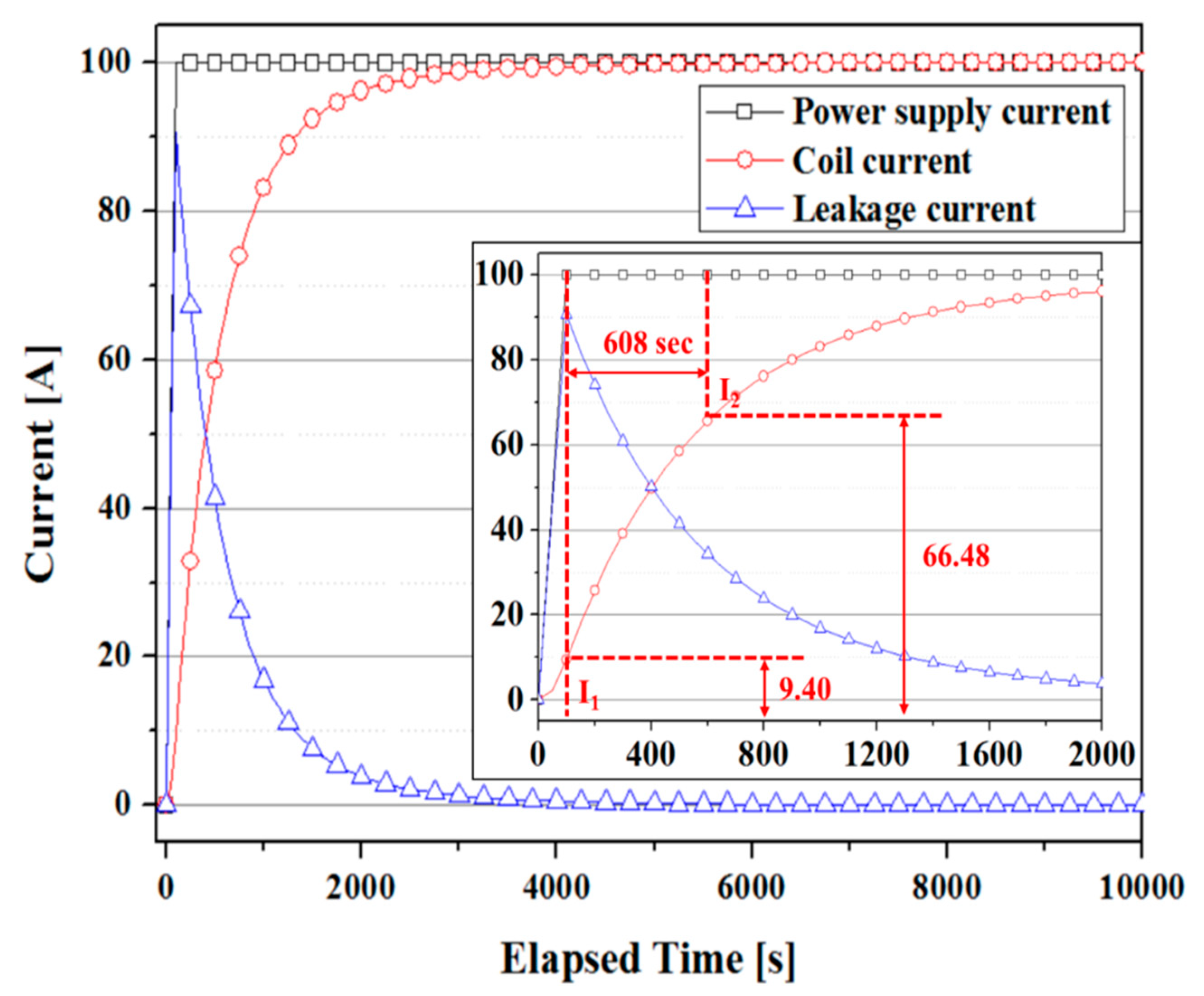

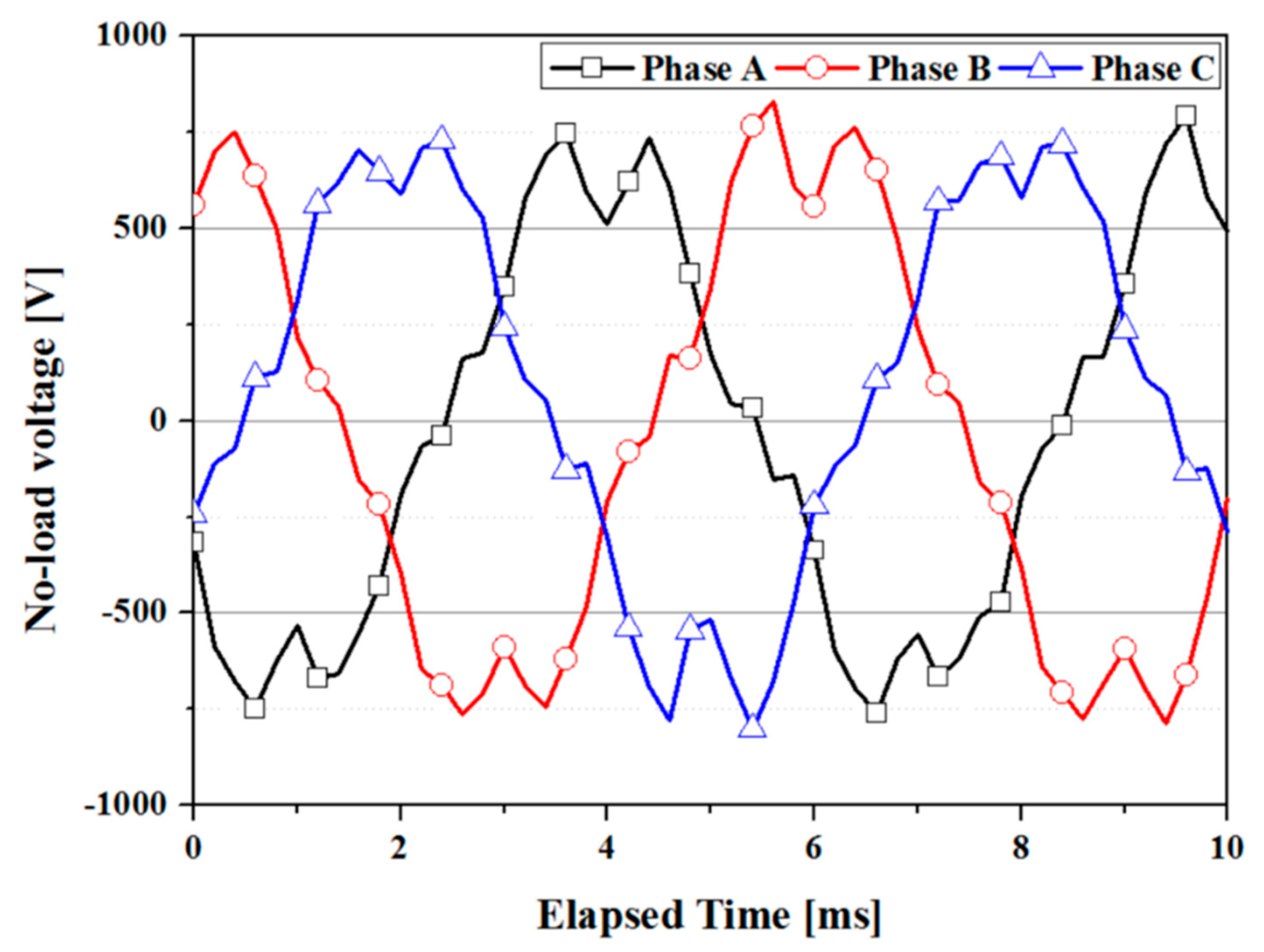

3.2. Operating Characteristics of the Proposed FSM Due Only to NI HTS Field Coil Excitation

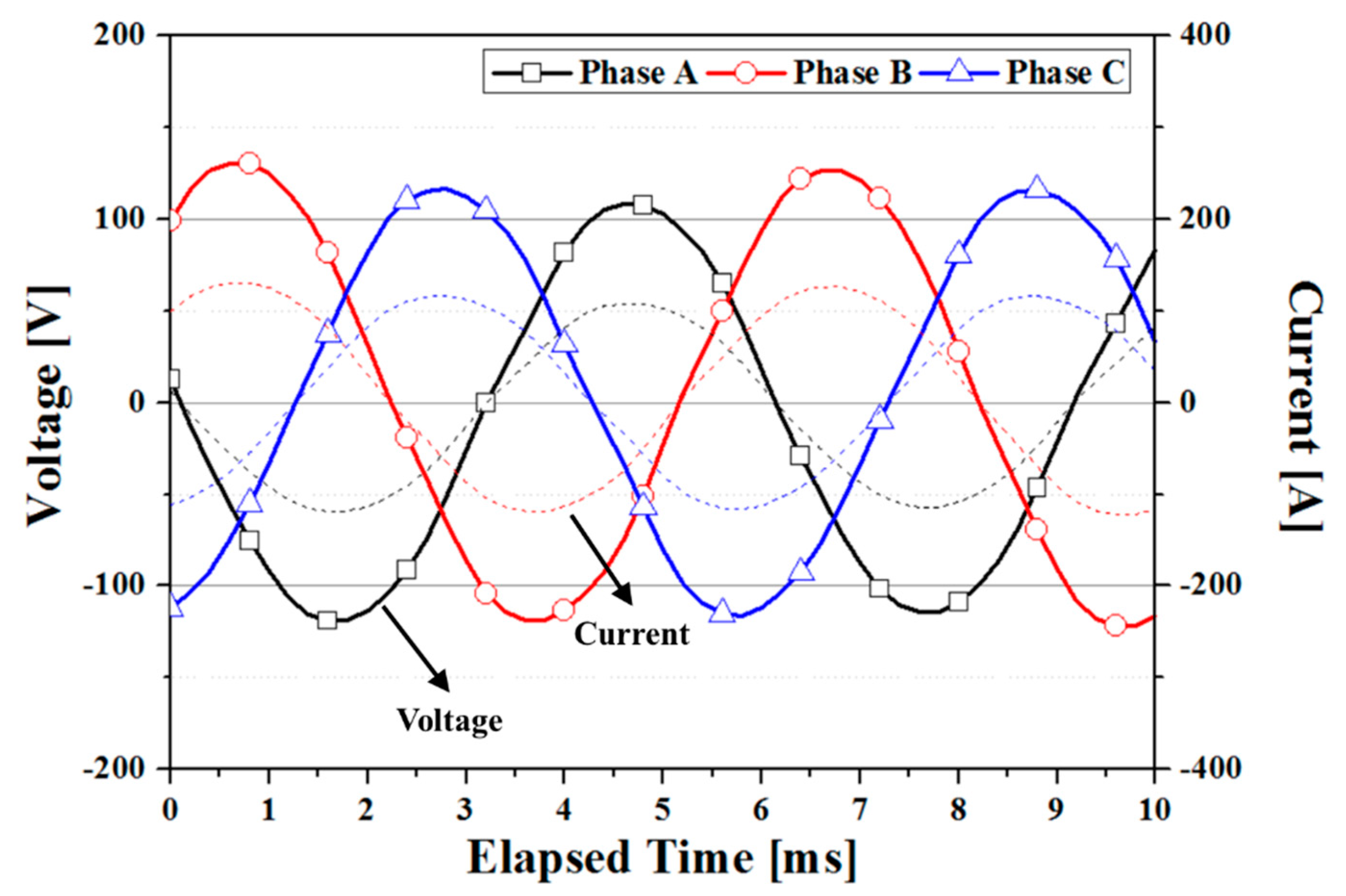

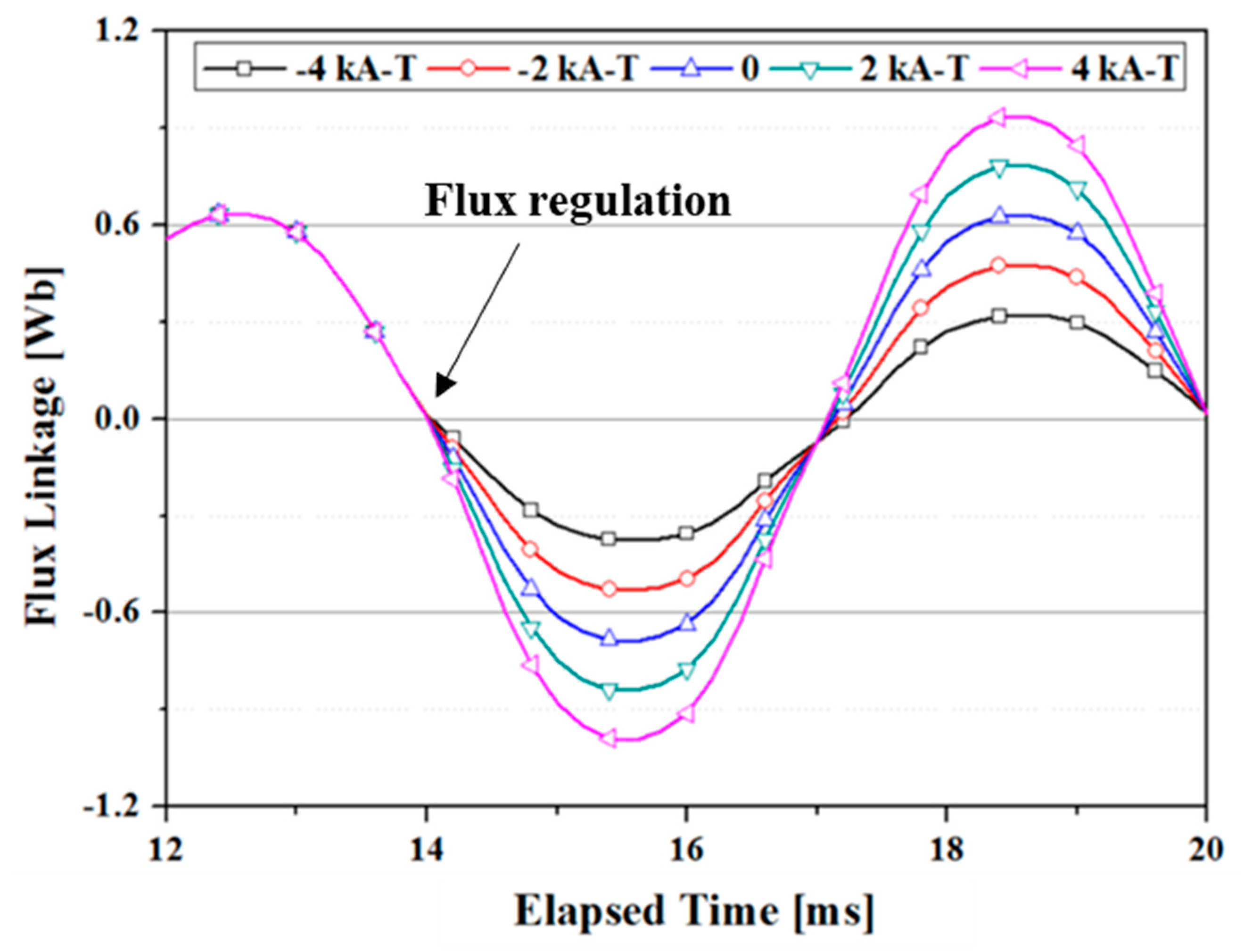

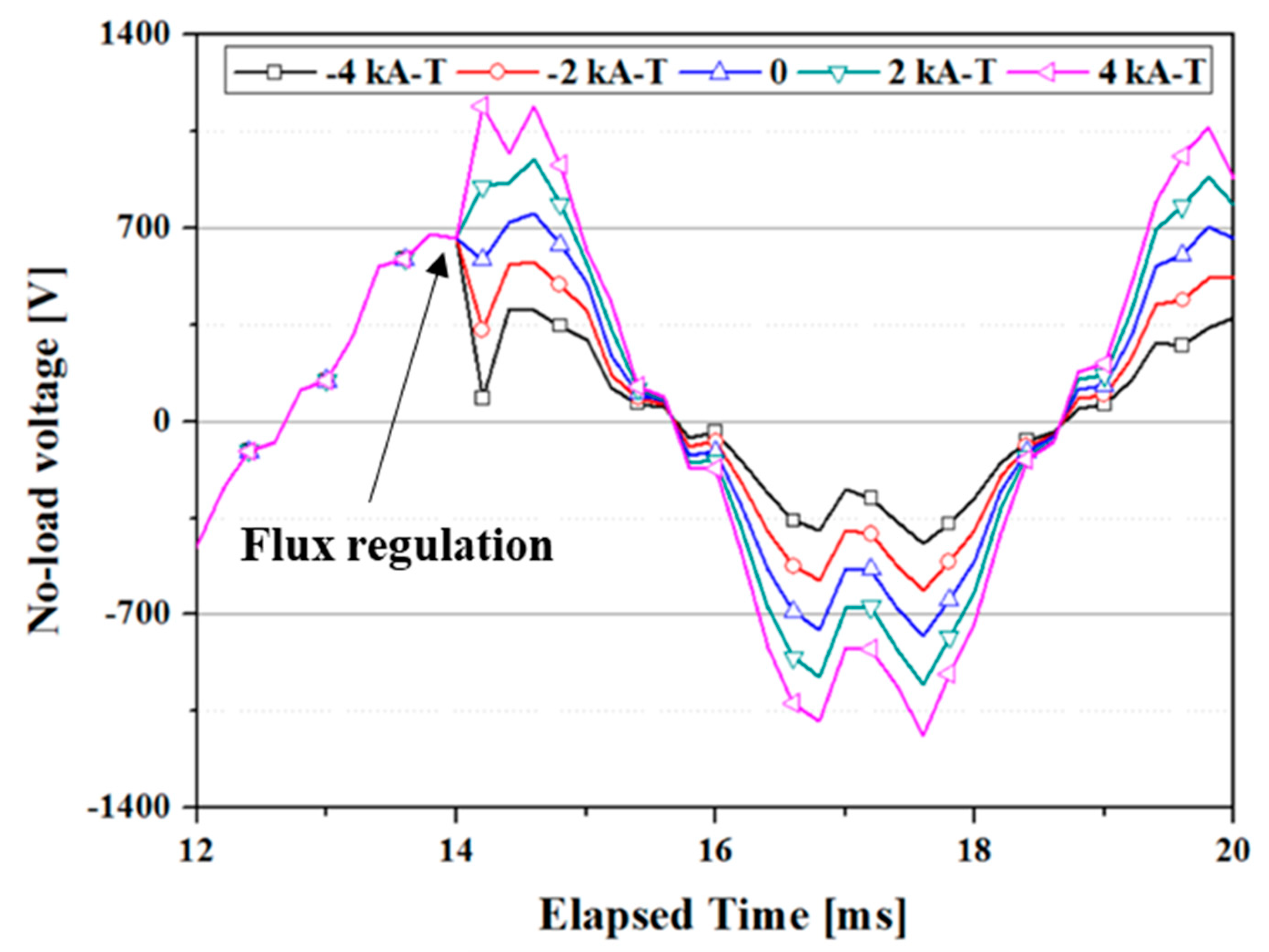

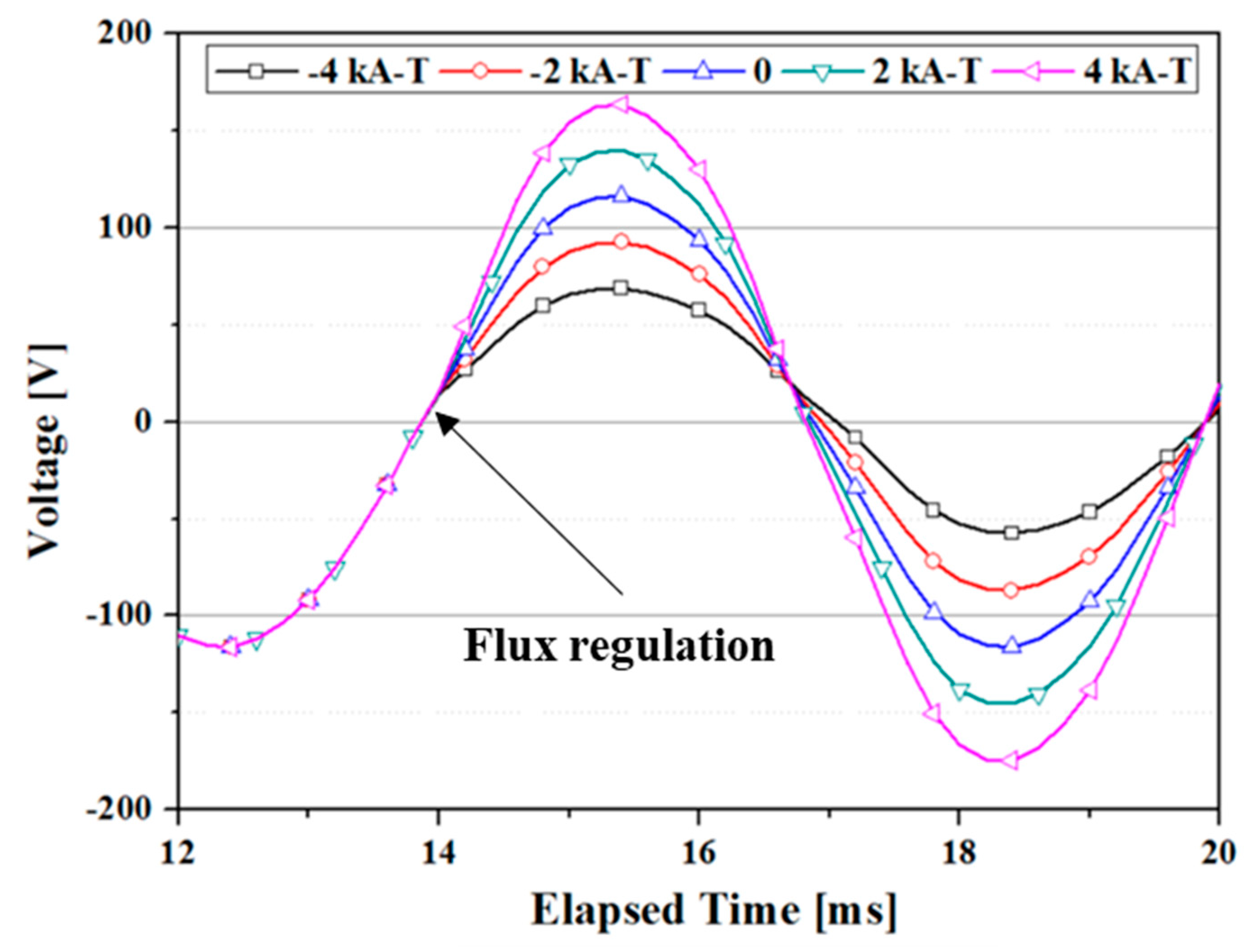

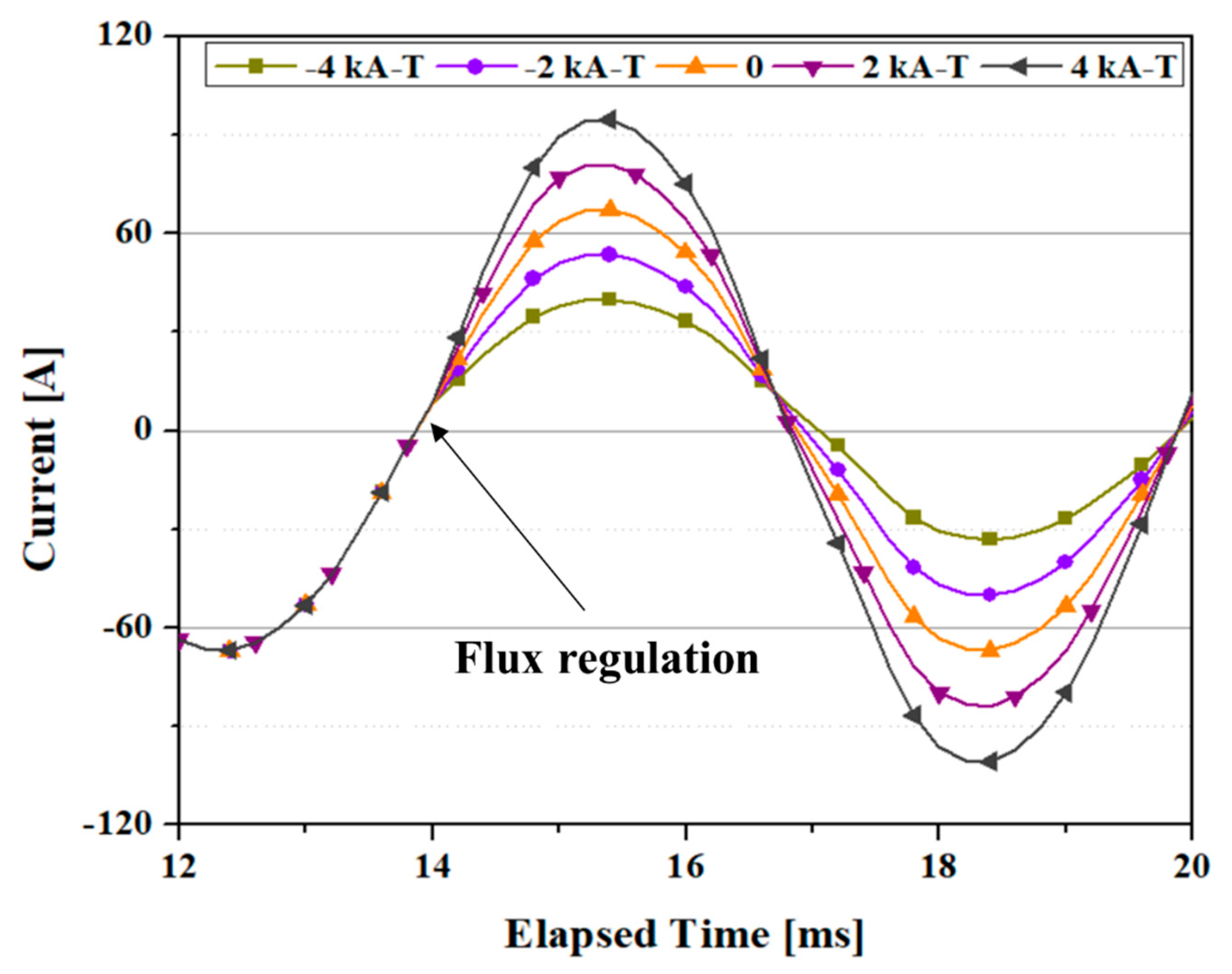

3.3. Flux-Regulation Characteristics of the Proposed FSM

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| yield strength | |

| v | Poisson’s ratio |

| ρ | density of the rotor material |

| n0 | number of armature conductors per slot |

| I0 | total current per slot |

| r | outer radius of the rotor |

| l | effective length of the rotor |

| mechanical angular speed | |

| E | Young’s modulus |

| k | safety factor |

| SCu | cross-sectional area of the armature conductor |

| JCu | the allowable current density of the armature conductor |

| dslot | slot height |

| wslot | slot width |

| dCu | armature conductor height |

| wCu | armature conductor width |

| β | packing factor |

| P | rated output power |

| σFtan | tangential stress of the rotor |

| T | torque of the rotor |

| IS | RMS value of the phase current |

| q | number of the slots |

| cos φ | power factor |

| ρcl | electrical resistivity of the current lead |

| lcl | length of the current lead |

| I | transport current through the current lead |

| Acl | cross-sectional area of the current lead |

| kcl | thermal conductivity of the current lead |

| TH | temperature at the high-temperature part |

| TL | temperature at the low-temperature part |

| Nl | no. of signal lines or leading-in tubes |

| Al | cross-sectional area of a signal line or a leading-in tube |

| kl | thermal conductivity of a signal line or a leading-in tube |

| Ll | length of a signal line or a leading-in tube |

| σ | Stefan–Boltzmann constant (5.67 × 10−8 W·m−2·K−4) |

| εH | emissivity of the vessel |

| εN | emissivity of MLI |

| N | no. of MLI layers |

| AH | surface area of the high-temperature part |

| AL | surface area of the low-temperature part |

References

- Ehsani, E.; Gao, Y.; Miller, J.M.; John, M.M. Hybrid electric vehicles: Architecture and motor drives. Proc. IEEE 2007, 4, 719–728. [Google Scholar] [CrossRef]

- Chan, C.C.; Chau, K.T. An overview of power electronics in electric vehicles. IEEE Trans. Ind. Electron. 1997, 44, 3–13. [Google Scholar] [CrossRef]

- Gao, D.W.; Mi, C.; Emadi, A. Modeling and simulation of electric and hybrid vehicles. Proc. IEEE 2007, 95, 729–745. [Google Scholar] [CrossRef]

- Chau, K.T.; Chan, C.C. Electric vehicle technology - a timely course for electrical engineering students. Int. J. Electr. Eng. Educ. 1998, 35, 212–220. [Google Scholar] [CrossRef]

- Okura, K. Development and future issues of high voltage systems for FCV. Proc. IEEE 2007, 95, 790–795. [Google Scholar] [CrossRef]

- Chau, K.T.; Wong, Y.S.; Chan, C.C. An overview of energy sources for electric vehicles. Energy Convers. Manag. 1999, 40, 1021–1039. [Google Scholar] [CrossRef]

- Chau, K.T.; Wu, K.C.; Chan, C.C.; Shen, W.X. A new battery capacity indicator for nickel-metal hydride battery powered electric vehicles using adaptive neuro-fuzzy inference system. Energy Convers. Manag. 2003, 44, 2059–2071. [Google Scholar] [CrossRef]

- Sekiguchi, D.; Nakamura, T.; Misawa, S.; Kitano, H.; Matsuo, T.; Amemiya, N.; Ito, Y.; Yoshikawa, M.; Tezarawa, T.; Osamura, K.; et al. Trial Test of Fully HTS Induction/Synchronous Machine for Next Generation Electric Vehicle. IEEE Trans. Appl. Supercond. 2012, 22, 5200904. [Google Scholar] [CrossRef]

- Shinzato, T.; Arakawa, S.; Oyama, H.; Saka, H.; Hayasaki, T. Development of High-Temperature Superconducting Motor for Automobiles. SEI Tech. Rev. 2012, 75, 62–65. [Google Scholar]

- Oyama, H.; Shinzato, T.; Kitajima, K.; Hayashi, K. Application of Superconductors for Automobiles. SEI Tech. Rev. 2008, 67, 22–26. [Google Scholar]

- Nakamura, T.; Itoh, Y.; Yoshikawa, M.; Nishimura, T.; Ogasa, T.; Amemiya, N.; Ohsashi, Y.; Fukui, S.; Furuse, M. Tremendous Enhancement of Torque Density in HTS Induction/Synchronous Machine for Transportation Equipments. IEEE Trans. Appl. Supercond. 2015, 25, 1–4. [Google Scholar] [CrossRef][Green Version]

- Masson, P.J.; Soban, D.S.; Upton, E.; Pienkos, J.E.; Luongo, C.A. HTS motors in Aircraft Propulsion: Design Considerations. IEEE Trans. Appl. Supercond. 2005, 15, 2218–2221. [Google Scholar] [CrossRef]

- Haran, K.S.; Kalsi, S.; Arndt, T.; Karmaker, H.; Badcock, R.; Buckley, B.; Haugan, T.; Izumi, M.; Loder, D.; Bray, J.W.; et al. High power density superconducting rotating machines–development status and technology roadmap. Supercond. Sci. Technol. 2017, 30, 123002. [Google Scholar] [CrossRef]

- Hata, R.; Isojima, S. The Road to Liquid Hydrogen Electric Vehicle Powered by High-Temperature Superconducting Motor. SEI Tech. Rev. 2009, 69, 25–35. [Google Scholar]

- Li, W.; Ching, T.W.; Chau, K.T.; Lee, C.H.T. A Superconducting Vernier Motor for Electric Ship Propulsion. IEEE Trans. Appl. Supercond. 2018, 28, 52010706. [Google Scholar] [CrossRef]

- Kim, Y.-G.; Hahn, S.; Km, K.L.; Kwon, O.J.; Lee, H. Investigation of HTS racetrack coil without turn-to-turn insulation for superconducting rotating machines. IEEE Trans. Appl. Supercond. 2011, 22, 5200604. [Google Scholar]

- Kim, H.-W.; Jo, Y.-S.; Kim, S.-W.; Kim, H.M.; Jeong, J.-S.; Hong, J.-P.; Hur, J. Determining the Operating Current of No-Insulation Field Coils in HTS Generators. IEEE Trans. Appl. Supercond. 2015, 51, 9000404. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Ahn, M.C.; Lee, T.S.; Lee, W.S.; Ko, T.K. Experimental study of the effects of alternating fields on HTS coils according to the winding insulation conditions. Supercond. Sci. Technol. 2013, 26, 085021. [Google Scholar] [CrossRef]

- Kim, K.L.; Choi, Y.H.; Yang, D.G.; Song, J.B.; Lee, H.G. Transient characteristics of a GdBCO racetrack pancake coil without turn-to-turn insulation. Supercond. Sci. Technol. 2014, 27, 015001. [Google Scholar] [CrossRef]

- Hahn, H.; Park, D.K.; Bascunan, J.; Iwasa, Y. HTS pancake coils without turn-turn insulation. IEEE Trans. Appl. Supercond. 2011, 21, 1592–1595. [Google Scholar] [CrossRef]

- Choi, S.; Jo, H.C.; Hwang, Y.J.; Hahn, S.; Ko, T.K. A Study on the no insulation winding method of the HTS coil. IEEE Trans. Appl. Supercond. 2012, 22, 4904004. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, W.K.; Schwartz, J. Self-protection mechanisms in no-insulation (RE)Ba2Cu3Ox high temperature superconductor pancake coils. Supercond. Sci. Technol. 2017, 29, 045007. [Google Scholar] [CrossRef]

- Zhang, Z.; Kim, C.H.; Kim, J.G.; Kvitkovic, J.; Pamidi, S.; Zhang, M.; Li, J.; Yuan, W. An Experimental Investigation of the Transient Response of HTS Non-insulation Coil. J. Supercond. Nov. Magn. 2017, 30, 387–393. [Google Scholar] [CrossRef]

- Choi, Y.H.; Song, J.B.; Yang, D.G.; Kim, Y.G.; Lee, H.G. A novel no-insulation winding technique of high temperature-superconducting racetrack coil for rotating applications: A progress report in Korea university. Rev. Sci. Instrum. 2016, 87, 104704. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xu, D.; Li, Z.Y.; Jin, Z.; Hong, Z.; Song, H. An equivalent circuit grid model for no-insulation HTS pancake coils. Supercond. Sci. Technol. 2015, 28, 045017. [Google Scholar] [CrossRef]

- Quddes, M.R.; Sekino, M.; Ohsaki, H.; Kashima, N.; Nagaya, S. Electromagnetic Design Study of Transverse Flux Enhanced Type Superconducting Wind Turbine Generators. IEEE Trans. Appl. Supercond. 2011, 21, 1101–1104. [Google Scholar] [CrossRef]

- Li, X.; Han, L.; Yang, X.; Zhang, D.; Zhang, J.; Xiao, L. Design and Model Test of the Racetrack Excitation Coil in a Novel High Temperature Superconducting Generator. IEEE Trans. Appl. Supercond. 2010, 20, 1081–1084. [Google Scholar]

- Fukui, S.; Ogawa, J.; Sato, T.; Tsukamoto, O.; Kashima, N.; Nagaya, S. Study of 10 MW-Class Wind Turbine Synchronous Generators With HTS Field Windings. IEEE Trans. Appl. Supercond. 2011, 21, 1151–1154. [Google Scholar] [CrossRef]

- Snitchler, G.; Gamble, B.; King, C.; Winn, P. 10 MW Class Superconductor Wind Turbine Generators. IEEE Trans. Appl. Supercond. 2011, 21, 1089–1092. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Choi, S.; Jang, J.Y.; Lee, J.; Yoon, Y.S.; Kim, H.M.; Chung, Y.D.; Jo, Y.-S.; Jang, M.H.; Al-Ammar, E.A.; et al. A Study on the Superconducting Synchronous Generator with the Fixed-Type Field Coil. IEEE Trans. Appl. Supercond. 2013, 23, 5200305. [Google Scholar] [CrossRef]

- Jeong, J.-S.; An, D.-K.; Hong, J.-P.; Kim, H.J.; Jo, Y.-S. Design of a 10-MW-Class HTS Homopolar Generator for Wind Turbines. IEEE Trans. Appl. Supercond. 2017, 27, 5202804. [Google Scholar] [CrossRef]

- Kim, J.M.; Jang, J.Y.; Lee, S.-G.; Hwang, Y.J. Characteristic Analysis of a HTS Flux-Switching Synchronous Generator with NI-Type HTS Field Coils. IEEE Trans. Appl. Supercond. 2018, 28, 5202705. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Ahn, M.C.; Lee, J.; Yoon, Y.S.; Kim, H.M.; Chung, Y.D.; Jo, Y.-S.; Kim, T.J.; Ko, T.K. Electromagnetic Design of a 15 MW-class HTS Flux Switching Synchronous Generator considering Mechanical Stress of the Rotor Core. IEEE Trans. Appl. Supercond. 2014, 24, 5202305. [Google Scholar]

- Wang, Y.; Wang, C.; Feng, Q.; Li, X.; Ching, T.W. Design and Experiment of an HTS Flux-Switching Machine with Stationary Seal. IEEE Trans. Appl. Supercond. 2017, 27, 5201405. [Google Scholar] [CrossRef]

- Zhao, J.; Zheng, Y.; Zhu, C.; Liu, X.; Li, B. A Novel Modular-Stator Outer-Rotor Flux-Switching Permanent-Magnet Motor. Energies 2017, 10, 937. [Google Scholar] [CrossRef]

- Ullah, N.; Basit, A.; Khan, F.; Ullah, W.; Shahzad, M.; Zahid, A. Enhancing Capabilities of Double Sided Linear Flux Switching Permanent Magnet Machines. Energies 2018, 11, 2781. [Google Scholar] [CrossRef]

- Kwon, J.-W.; Lee, J.-H.; Zhao, W.; Kwon, B.-I. Flux-Switching Permanent Magnet Machine with Phase-Group Concentrated-Coil Windings and Cogging Torque Reduction Technique. Energies 2018, 11, 2758. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, C.; Lee, C.H.T. Quantitative Comparisons of Six-Phase Outer-Rotor Permanent-Magnet Brushless Machines for Electric Vehicles. Energies 2018, 11, 2141. [Google Scholar] [CrossRef]

- Incropera, F.P. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- Kim, M.S.; Choi, Y.S.; Kim, D.L. Variable Temperature Cryostat for Cryogenic Temperature Sensor Calibration. Supercond. Cryog. 2012, 14, 46–49. [Google Scholar] [CrossRef]

- Kim, J.M.; Jang, J.Y.; Chung, J.; Hwang, Y.J. A New Outer-Rotor Hybrid Excited Flux-Switching Machine Employing the HTS Homopolar Topology. Energies 2019, 12, 2654. [Google Scholar] [CrossRef]

- Kim, K.L.; Choi, Y.H.; Yang, D.G.; Kang, D.H.; Kim, J.-H.; Kim, H.-M.; Lee, H.-G. Analytical and empirical studies on the characteristic resistances of no-insulation GdBCO racetrack pancake coil under various operating currents. Curr. Appl. Phys. 2015, 15, 8–13. [Google Scholar] [CrossRef]

- Zhang, G.; Hua, W.; Cheng, M.; Zhang, J.; Jinag, W. Investigation of an Improved Hybrid-Excitation Flux-Switching Brushless Machine for HEV/EV Applications. IEEE Trans. Ind. Appl. 2015, 51, 3791–3799. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| 2G HTS wire | 2G HTS wire manufactured by AMSC |

| Wire width | 12 mm |

| Winding structure | Racetrack and single pancake |

| Length of the straight coil part | 600 mm |

| Inner radius of the coil end part | 65 mm |

| Total winding turns | 40 |

| Insulation type | No-insulation |

| Inductance | 1.3 mH |

| Operating temperature | 77 K |

| Nominal operating current | 100 A |

| Item | Value |

|---|---|

| Maximum output power | 36 kW |

| Phases | 3 |

| Rotating speed | 1000 rpm |

| Stator inner diameter | 563 mm |

| Air-gap distance | 3 mm |

| Rotor inner diameter | 175 mm |

| Active stack length | 600 mm |

| No. of stator slots | 12 |

| No. of rotor poles | 10 |

| Stator tooth arc | 7.5° |

| Slot arc | 8.25° |

| Winding turns per armature coil | 12 |

| No. of field coils for flux regulation | 12 |

| Winding turns per field coil for flux regulation | 20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, Y.J.; Jang, J.Y.; Lee, S. A Flux-Controllable NI HTS Flux-Switching Machine for Electric Vehicle Applications. Appl. Sci. 2020, 10, 1564. https://doi.org/10.3390/app10051564

Hwang YJ, Jang JY, Lee S. A Flux-Controllable NI HTS Flux-Switching Machine for Electric Vehicle Applications. Applied Sciences. 2020; 10(5):1564. https://doi.org/10.3390/app10051564

Chicago/Turabian StyleHwang, Young Jin, Jae Young Jang, and SangGap Lee. 2020. "A Flux-Controllable NI HTS Flux-Switching Machine for Electric Vehicle Applications" Applied Sciences 10, no. 5: 1564. https://doi.org/10.3390/app10051564

APA StyleHwang, Y. J., Jang, J. Y., & Lee, S. (2020). A Flux-Controllable NI HTS Flux-Switching Machine for Electric Vehicle Applications. Applied Sciences, 10(5), 1564. https://doi.org/10.3390/app10051564