3.1. Fatigue Behavior of Three Typical Connections of the Rib-To-Deck

OSBD involves groove welding joints among bridge deck, longitudinal ribs and crossbeams. Due to the differences in the stiffness of the longitudinal rib and the crossbeam, fatigue cracks can occur at various locations and can have different propagation directions. Literature [

22] showed that fatigue cracks occurred mainly at the location of the connection of rib-to-deck (30.2%), rib-to-crossbeam (62.4%), and the arc-shaped zone of the crossbeam and other locations (7.6%). Single-sided weld seam is the traditional connection of the rib-to-deck and this type of connection was applied widely in OSBD. Some scholars [

12,

13] proposed new types of connections of the rib-to-deck, namely large-fillet weld seam and double-sided weld seam.

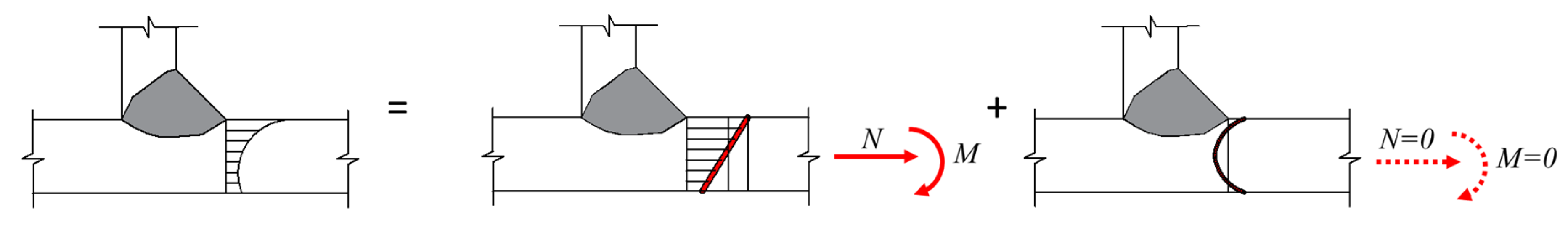

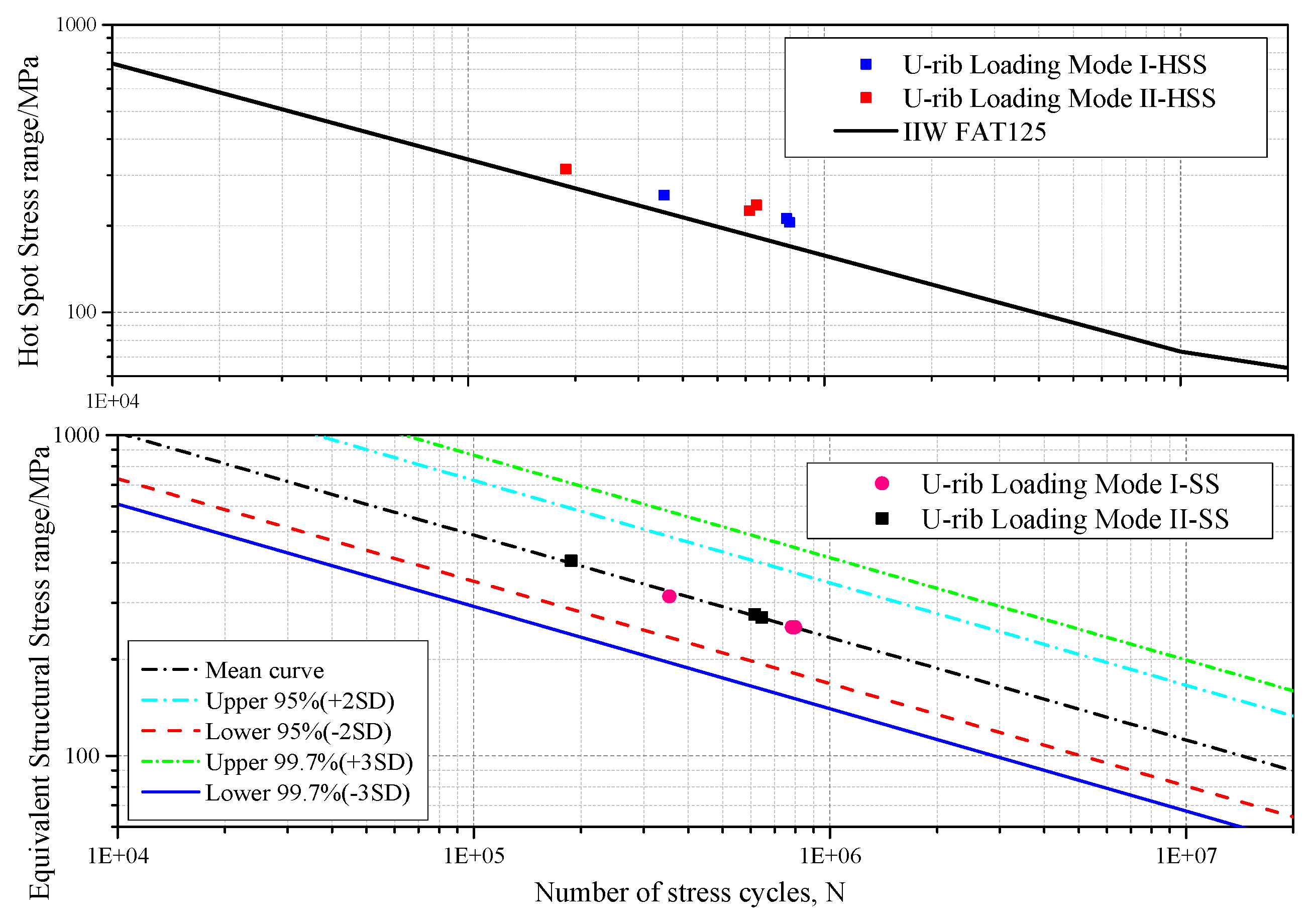

Traction structural stress method can be effectively used to study the differences in the fatigue behaviors of the traditional and new types of the rib-to-deck connections. The equivalent structural stress range under the fatigue load is considered as a control target in this study. Besides, the effect of the crossbeam on the fatigue performance of the rib-to-deck is considered for more accurate results.

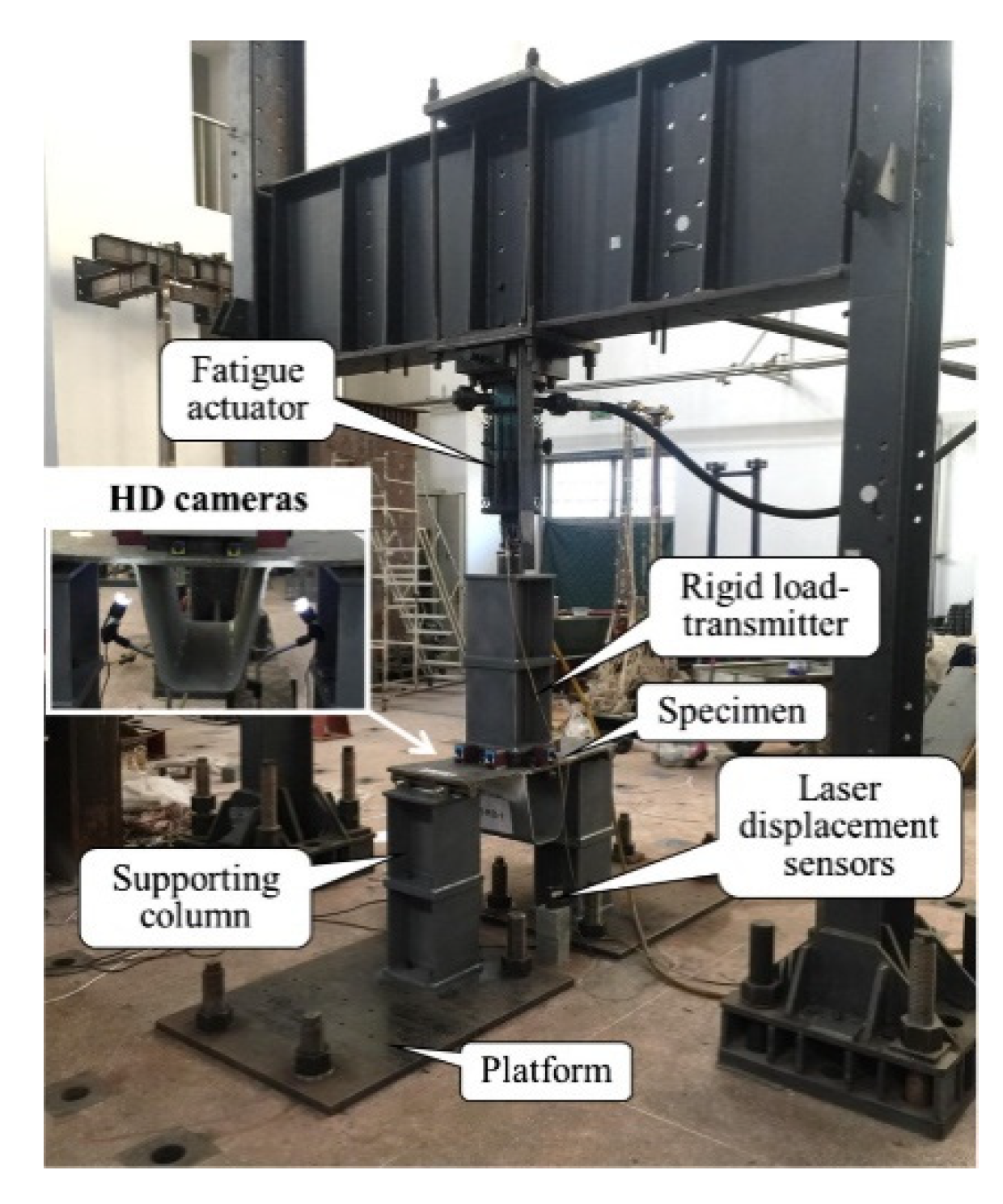

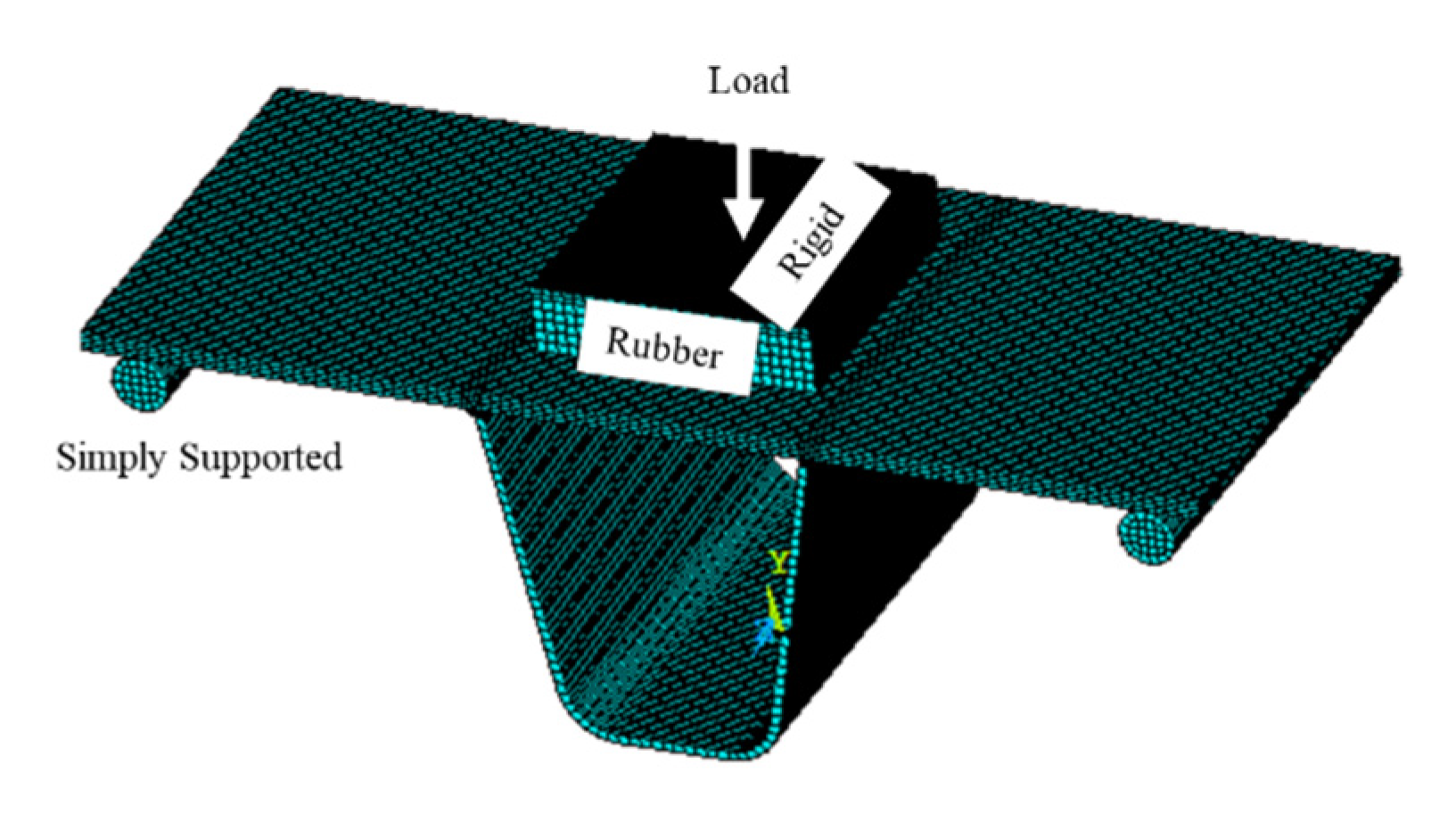

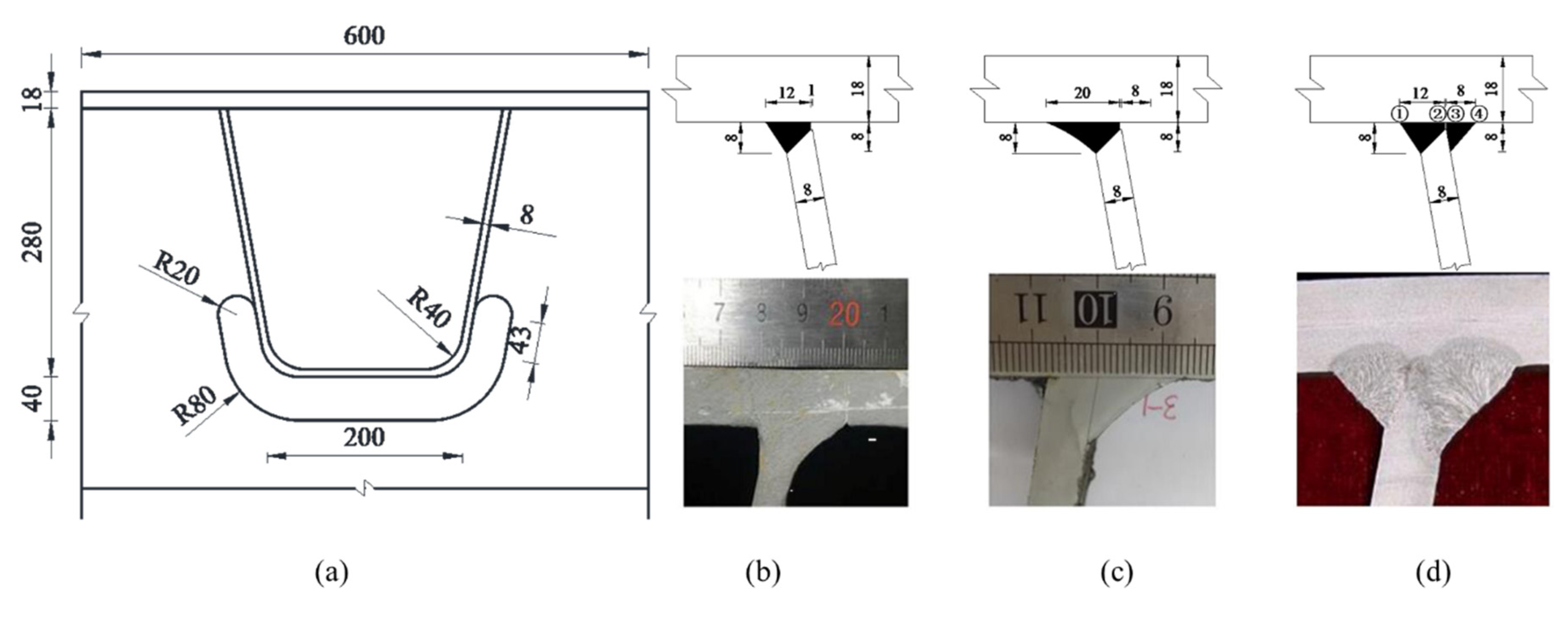

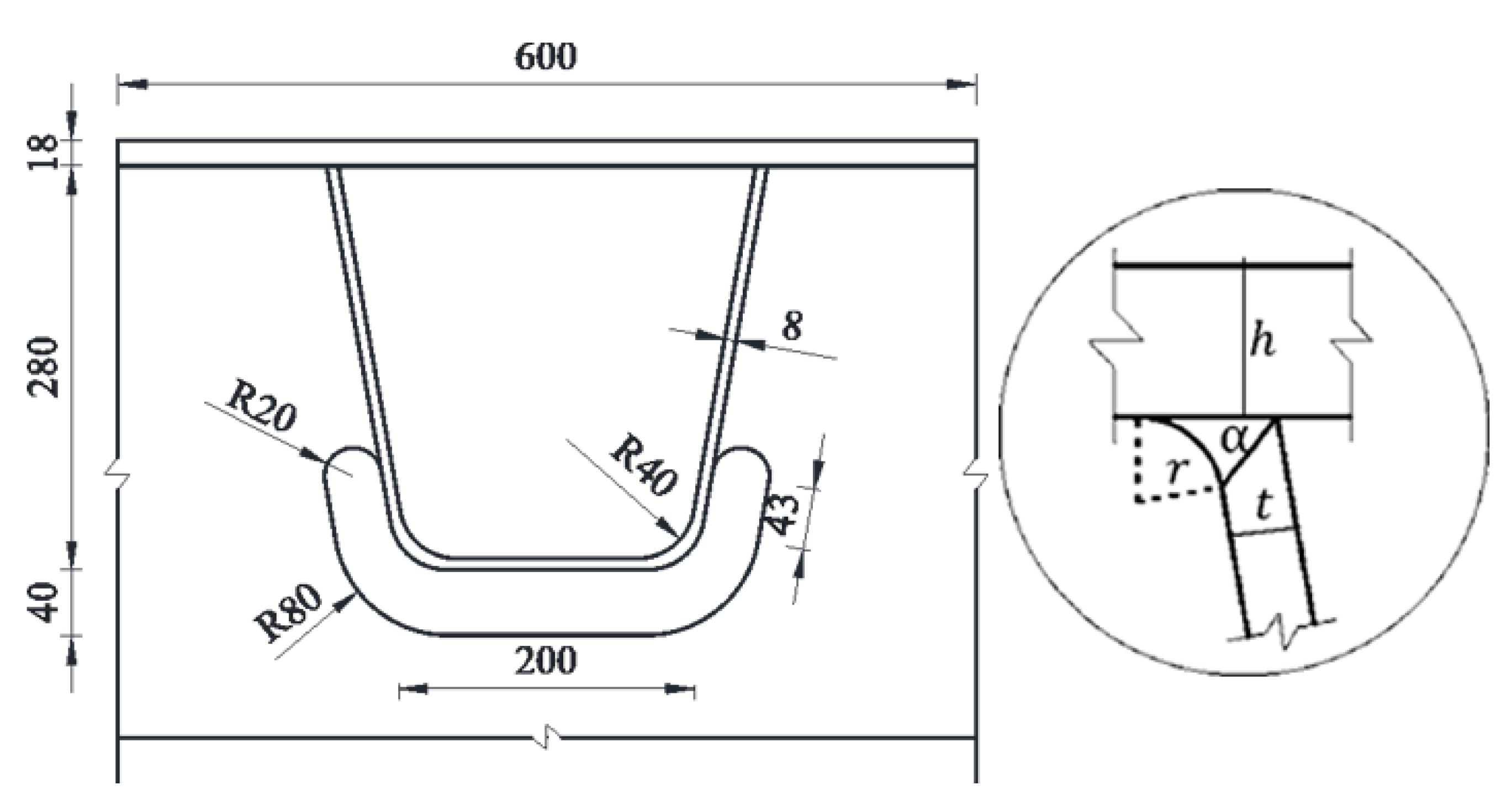

Figure 6 shows a local model of an OSBD constructed with a bridge deck, a U-rib and a crossbeam. The overall size of the local model was 600 mm (length) × 400 mm (height) × 200 mm (width) based on the size of an actual bridge. The sizes of the bridge deck, crossbeam and U-rib were 18 mm, 14 mm and 8 mm, respectively. The model of the OSBD and three typical weld seams of the connections between the bridge deck and U-rib are plotted in

Figure 6.

Furthermore, the size of the weld seams, including the size of the weld root and weld throat, are shown in the figure. The equivalent structural stress of the four typical weld seams, including the weld toe of the outer seam, weld root of the outer seam, weld root of the inner seam and weld toe of the inner seam, were identified as the evaluation target. Based on the traction structural stress method, the fatigue performance of the region with higher equivalent structural stress was more significant than other zones with lower stress.

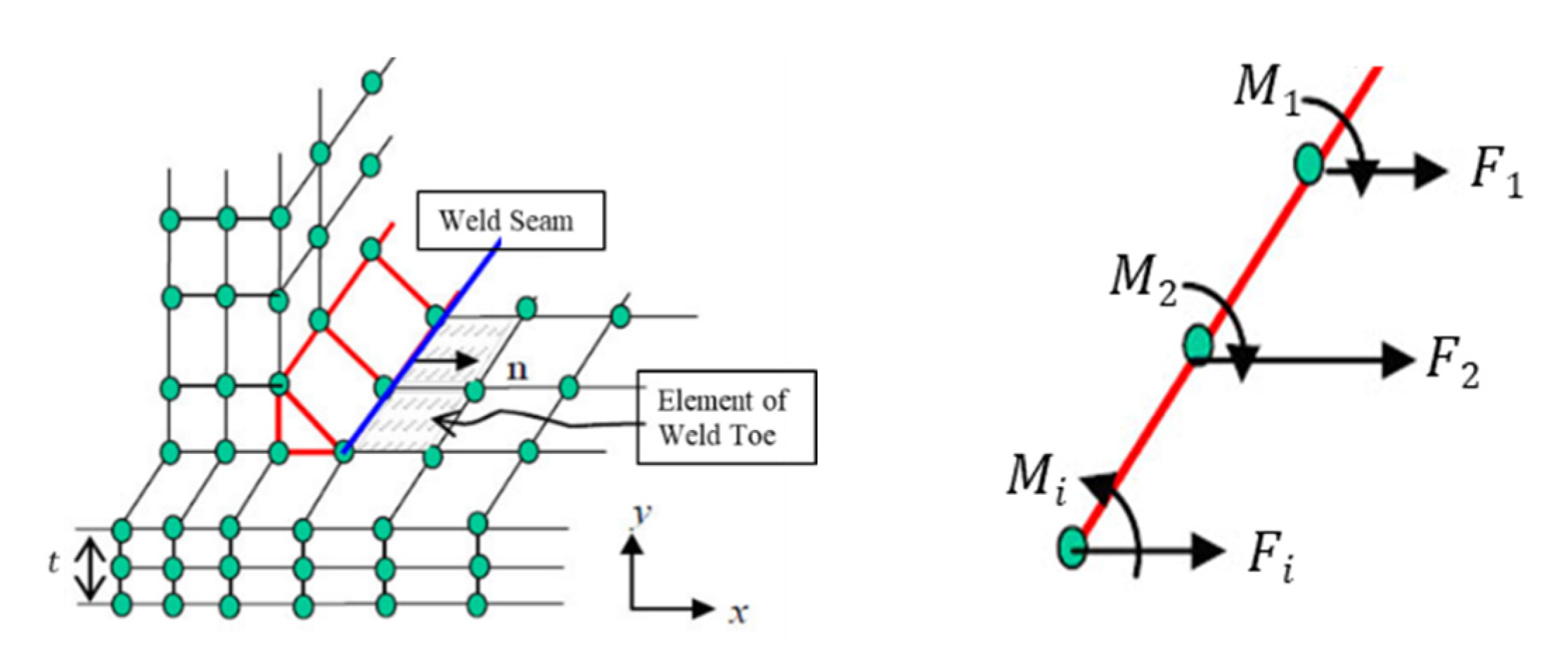

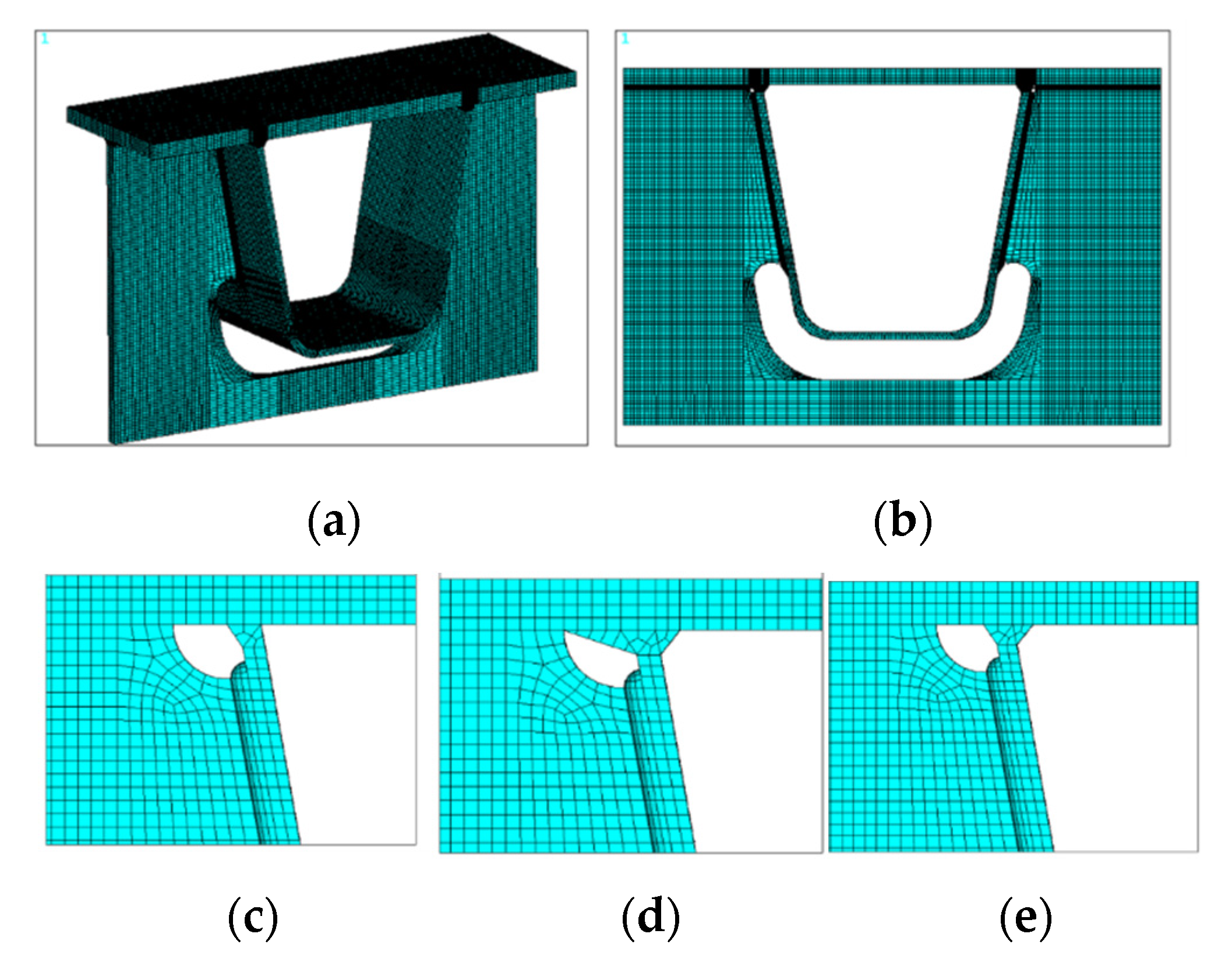

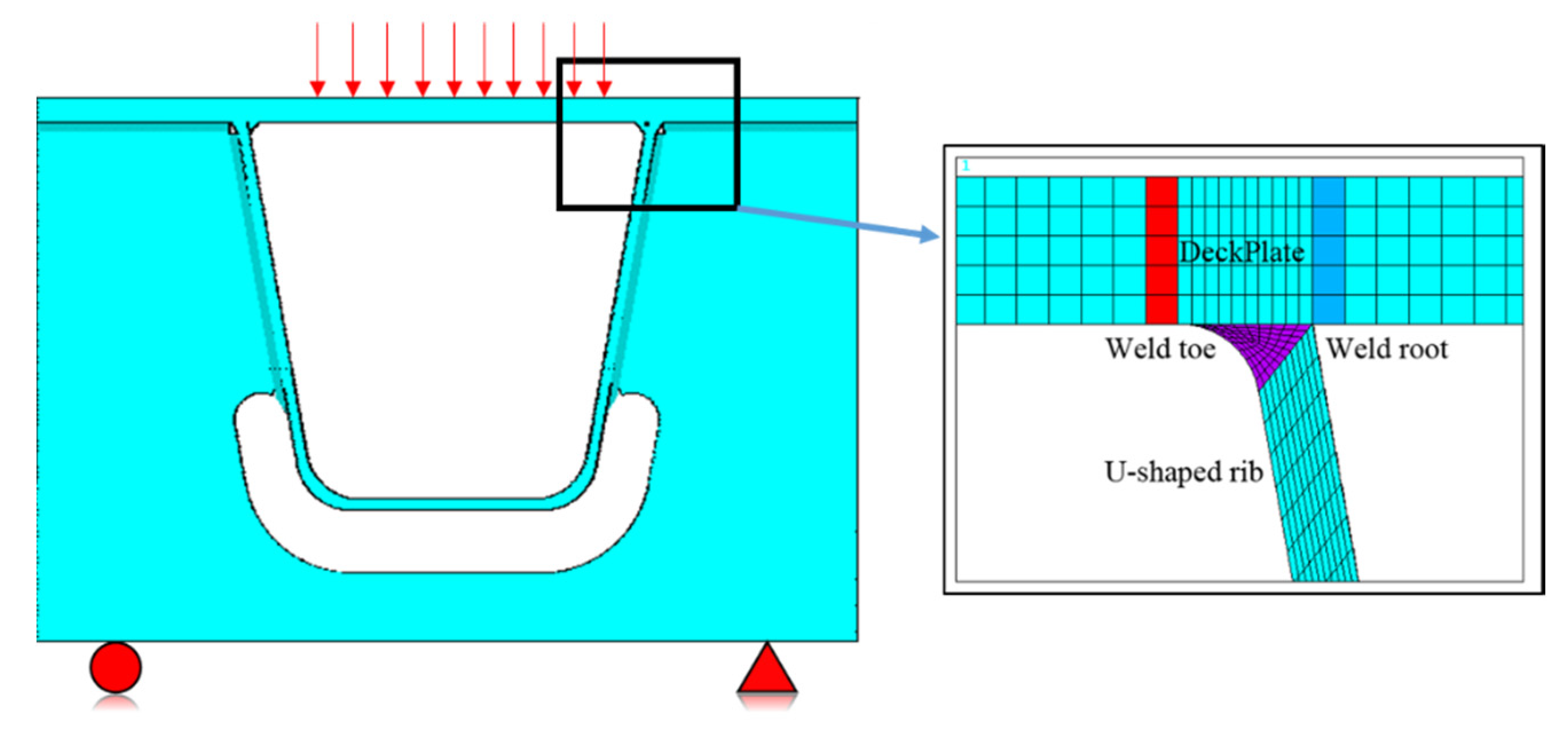

The finite element model of the local model was made of Q370qE steel, and the SOLID 185 element was used for higher accuracy, as shown in

Figure 7. The stress ratio of the fatigue load was −1. The size of the hexahedron element was 6 mm and the groove seam of the connection between the U-rib and bridge deck was 2 mm. The element grid layer of the rib-to-deck along the direction of thickness was six and that of the rib-to-crossbeam along the thickness direction was three, which satisfy the recommendations of the traction structural stress method [

17]. The view of the finite element model of the local connection between the bridge deck and U-rib are shown in

Figure 7.

In order to simulate the actual loading condition and the vertical constraint from the box girder, the local finite model was simply supported at the bottom of both sides of the crossbeam. Based on the orthotropic steel bridge specification, Eurocode 3, the fatigue load was applied to the middle of the top side of the bridge deck.

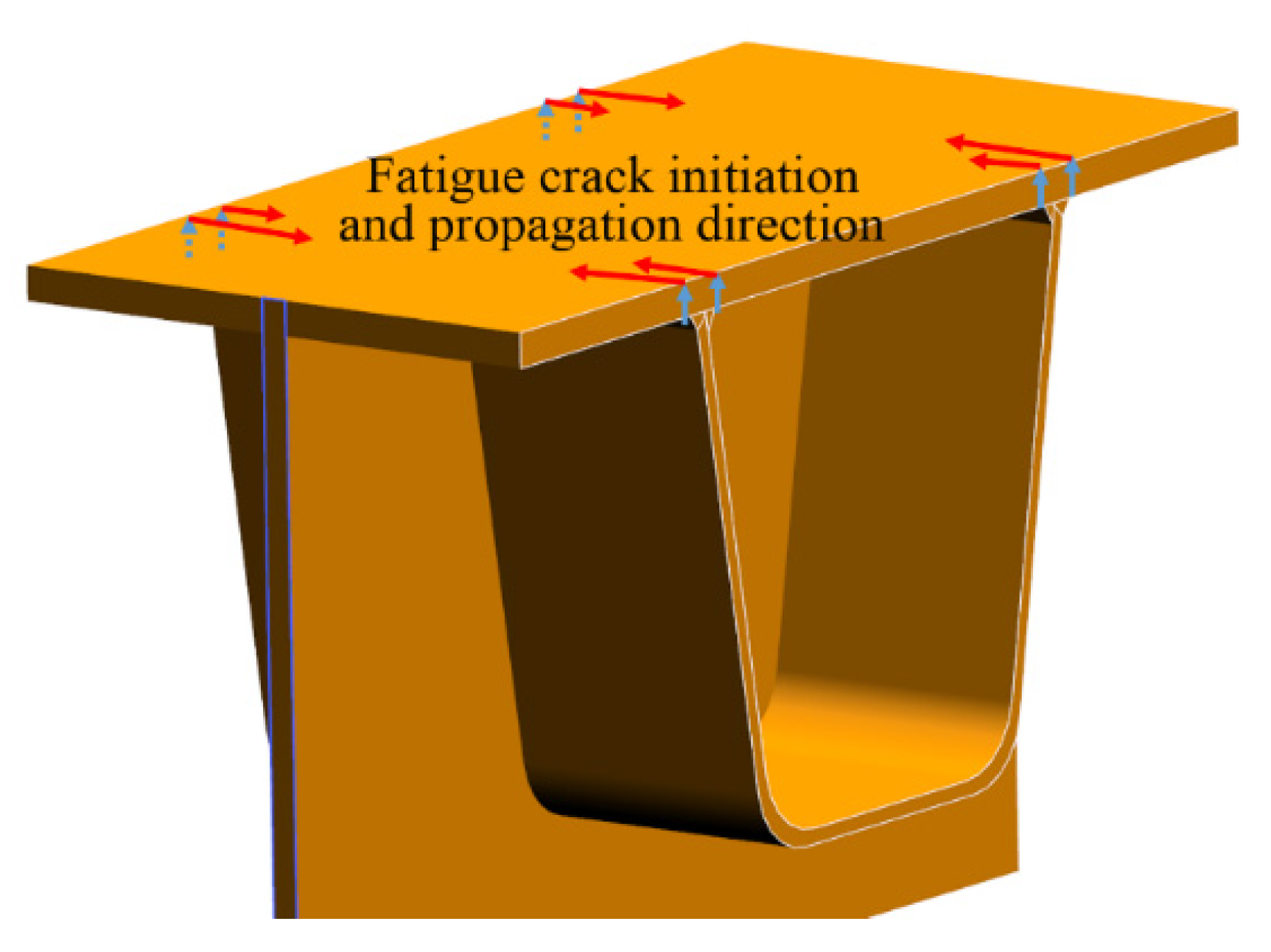

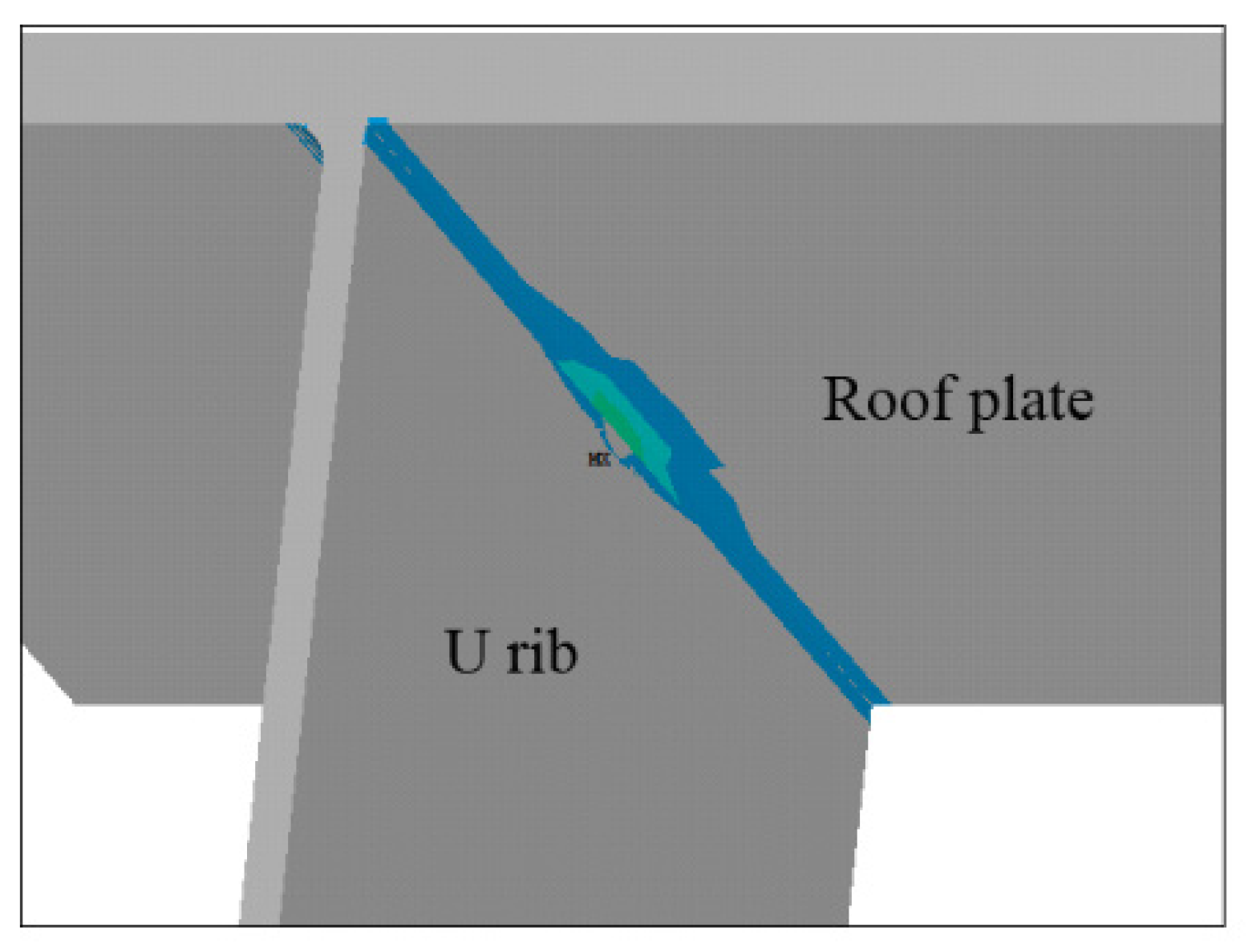

As mentioned above, fatigue cracks occurring at the connection of the bridge deck and U-rib account for 30.2% of all the observed cracks. In order to obtain the equivalent structural stress of the weld seam, the hypothetical fatigue crack initiation and propagation on the bridge deck were determined as shown in

Figure 8. The fatigue crack was initiated in the weld toe or weld root and propagated to the base [

20]. This crack continued to expand along the weld line until the specimen was failed.

Figure 8 shows the hypothetical positions of fatigue crack initiation and the propagation direction on the bridge deck.

3.2. Comparative Results of Three Typical Connections and Discussions

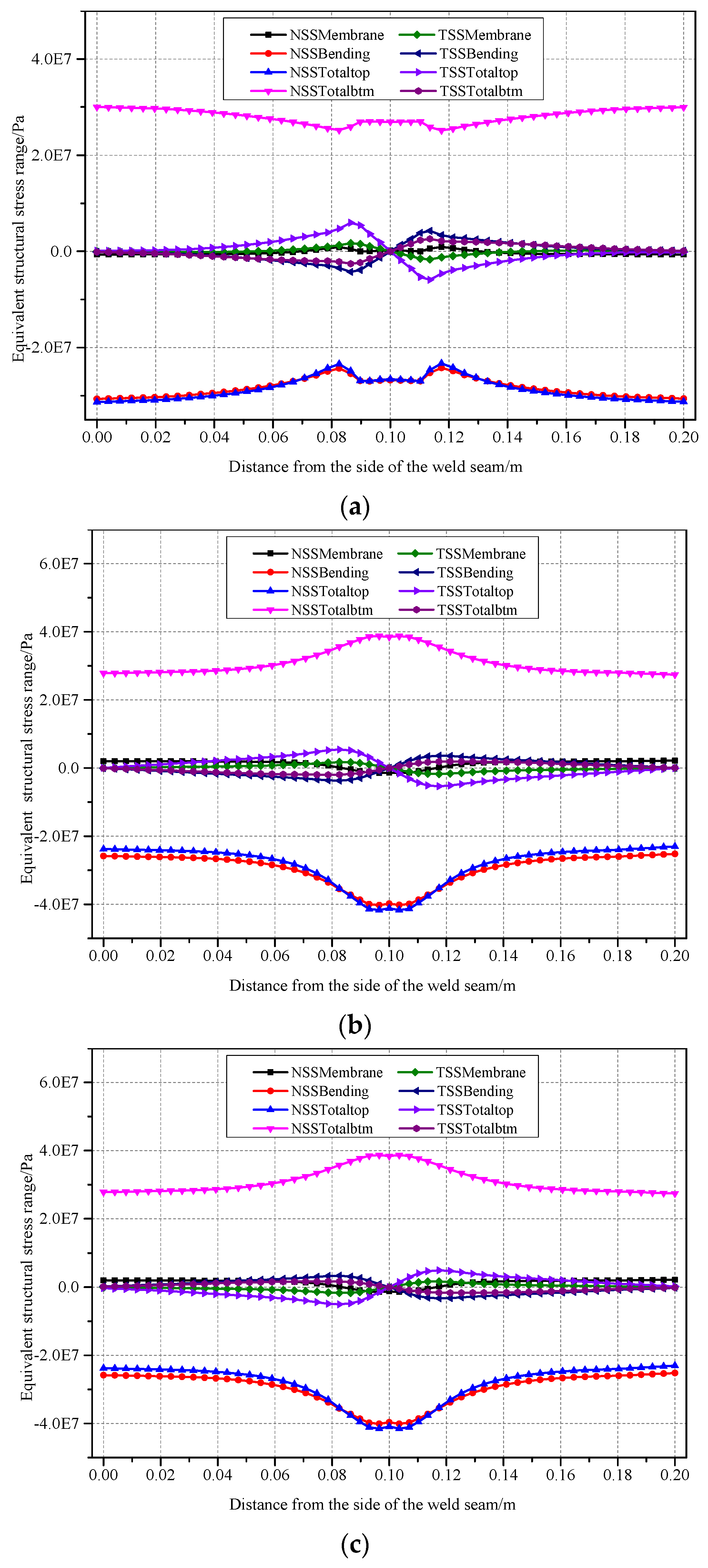

The Mises stress diagram of the connection of the bridge deck and U-rib under fatigue load was obtained with the finite element simulation method. The equivalent structural stress contained membrane stress and bending stress. The equivalent structural stress and the stress components of the bottom side of the bridge deck were obtained based on the traction structural stress method. The fatigue cyclic life was calculated using the master S-N curve and Equation (4). Furthermore, in the figure, the vertical axis represents the equivalent structural stress and the horizonal axis represents distance from the side of the weld toe or weld root. The NSS represents the normal structural stress and TSS represents the in-plane shear structural stress. “Membrane” stands for the membrane structural stress and “bending” represents the bending stress. “Total” means the sum of the membrane stress and bending stress. The equivalent structural stress of the bottom and the top side of the bridge deck were obtained similarly.

As shown in

Figure 5, the left weld seam (Trad-Weldline1) is a traditional single-sided weld seam of the weld toe and bridge deck. The right weld seam (Trad-Weldline2) is a traditional single-sided weld seam of the weld root and bridge deck.

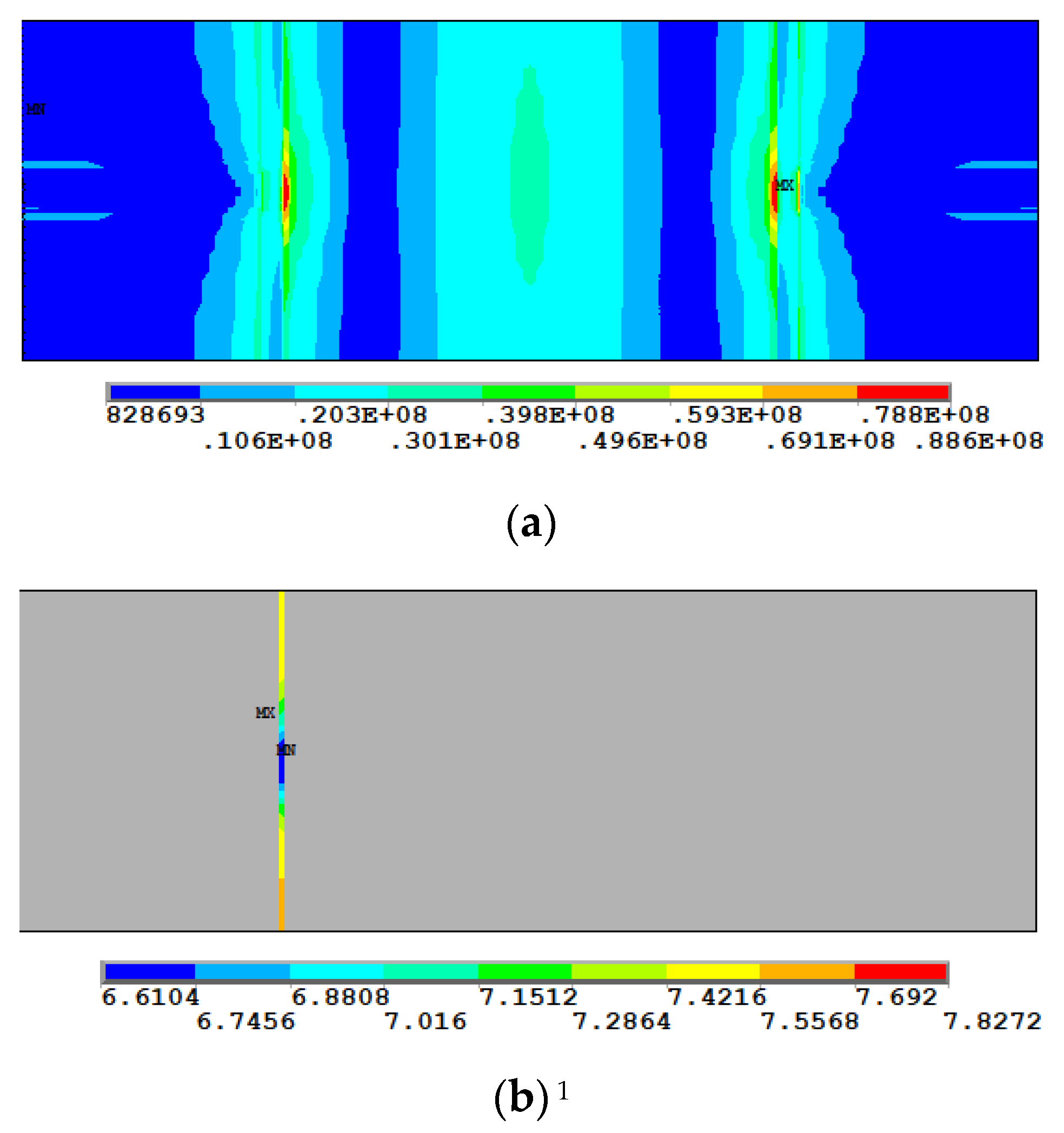

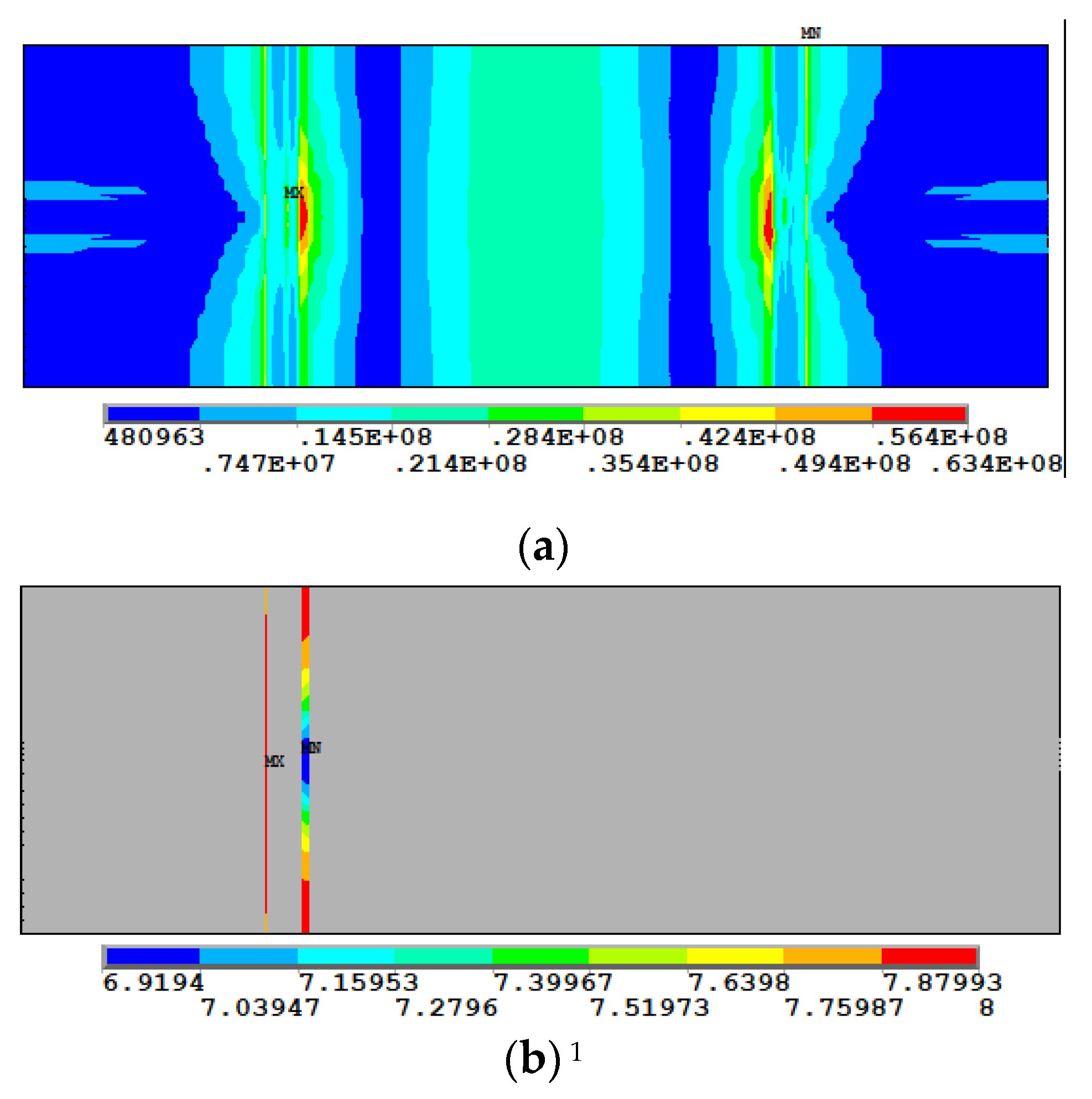

Figure 9 shows the Mises stress and fatigue cyclic life of the bottom side of the bridge deck of a traditional weld seam. It can be seen clearly that the maximum stress of the conventional single-sided weld seam occurred in the middle of the conventional weld seam between the bottom of the bridge deck and the groove weld seam.

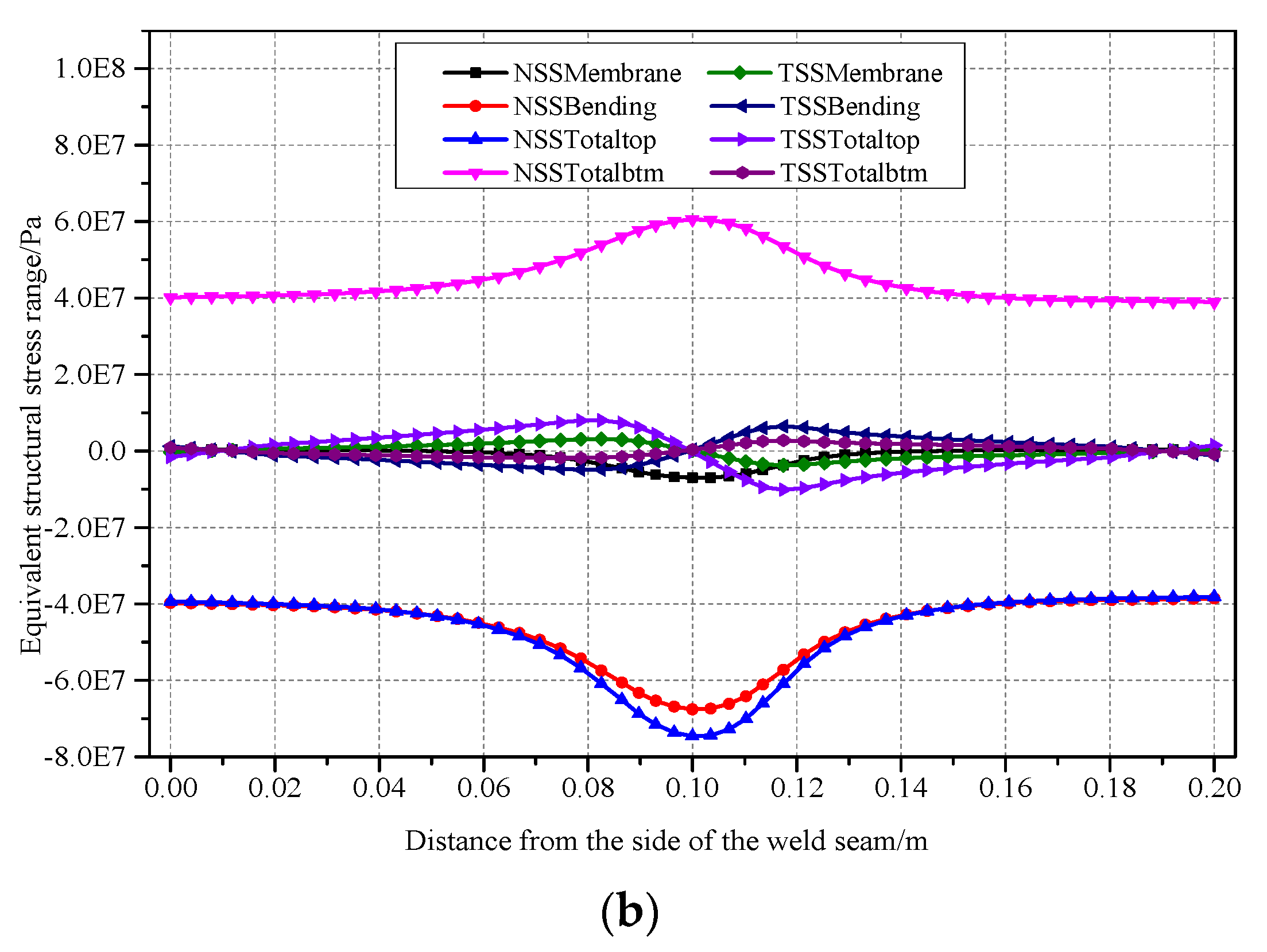

The equivalent structural stress and the stress components of the Trad-Weldline1 and Trad-Weldline2 are plotted in

Figure 10. The comparative results indicate that the structural stress changed sharply at the location of the rib-to-deck connection and the crossbeam. The bottom of the two weld seams were subjected to the normal tensile stress and the top of weld seams were subjected to the normal compressive stress. The major component of the equivalent structural stress was bending stress with little in-plane shear stress. The maximum tensile stress of Trad-Weldline1 was 39 MPa and that of Trad-Weldline2 was 62 MPa. The equivalent structural stress increased slowly from the side of the weld seam to the middle of the seam. The total structural stress in the middle of the bottom surface of the bridge deck was the most significant with the lowest fatigue cyclic life. As can be seen from the figure, the location of the minimum fatigue life corresponded to the middle of the connection between the weld seam and the bridge deck. The location was regarded as the location of initiation of the fatigue crack and the crack propagated along the weld seam.

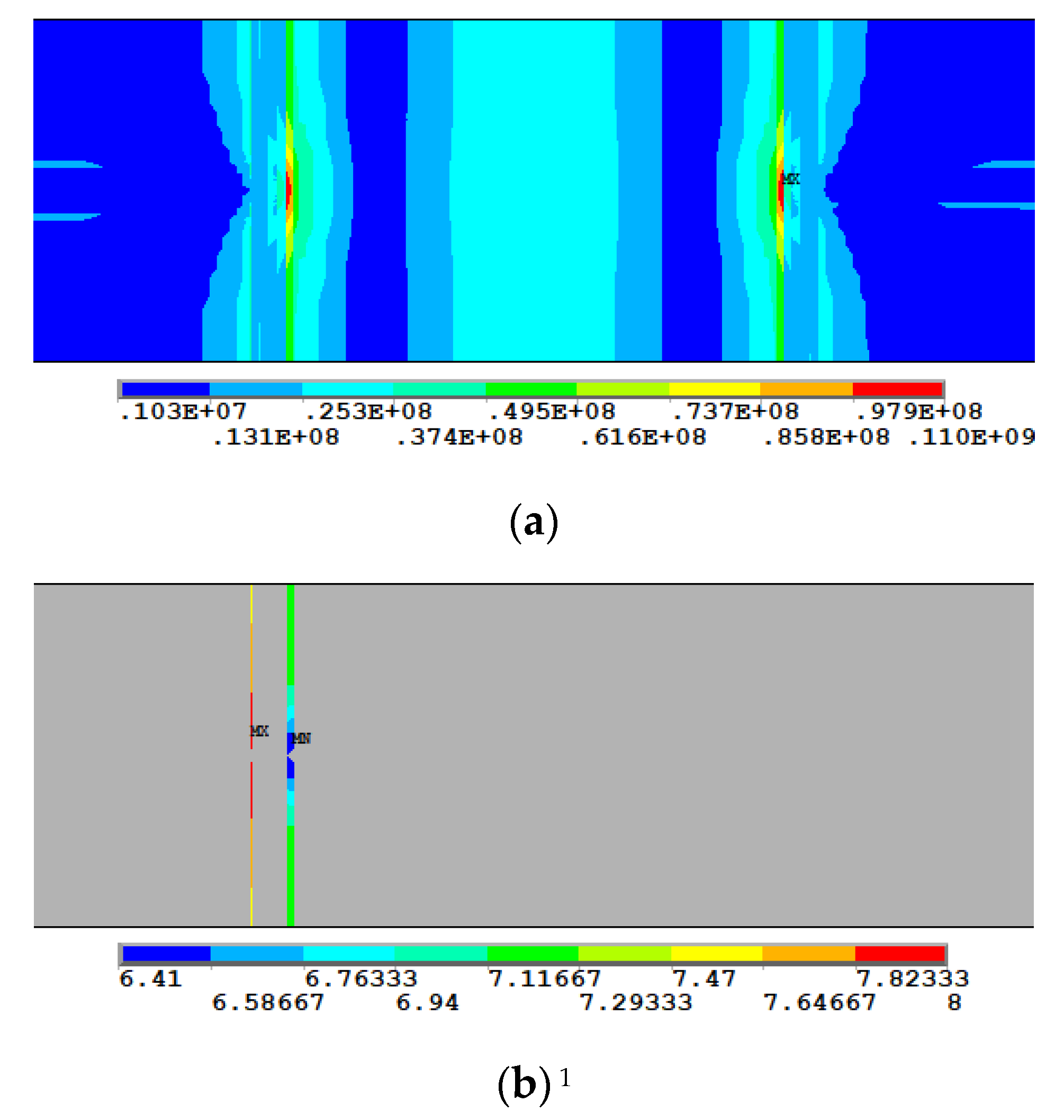

Figure 11 plots the Mises stress and fatigue cyclic life of the bottom side of the bridge deck of the weld seam of a large root. As shown in the figure, the left weld seam (Large-Weldline1) is the weld seam of the large root of the weld toe and bridge deck and the right weld seam (Large-Weldline2) is the weld seam of the large root of the weld root and bridge deck. Compared to the distribution contours of the traditional weld seam (

Figure 5), the distribution trend of the Mises stress contours and fatigue cyclic life were similar. Moreover, the location of the maximum stress was the same as in the traditional weld seam.

Figure 12 shows the equivalent structural stress of the weld toe for Large-Weldline1 and Large-Weldline2. The equivalent structural stress of Large-Weldline1 and Large-Weldline2 indicate that the top side of the bridge deck was mainly subjected to the normal compressive stress and the bottom of the bridge deck was subjected to the normal tensile stress. The bending structural stress was more significant than the in-plane shear structural stress. The normal tensile stress and compressive stress of Large-Weldline1 decreased from the side of the weld seam and the stress of the side was more significant than the stress of the middle of the weld seam. The trend of structural stress of the Large-Weldline2 was similar to the trend of the Trad-Weldline2. Compared to the structural stress of Large-Weldline2, the maximum bending stress of the Trad-Weldline2 increased by 16.4%. The normal compressive stress increased by 14.9% and the normal tensile stress increased by 16.7%.

The comparative results showed that the equivalent structural stress of the bridge deck with the weld seam of a large root was much more significant than that of the bridge deck with a traditional weld seam. The fatigue performance of the bridge deck with a traditional weld seam was better than that of the bridge deck with the weld seam of a large root. Therefore, it is not recommended to apply the weld seam of a large root with relatively larger seam area. Furthermore, the weld seam size should be controlled crucially for better fatigue resistance.

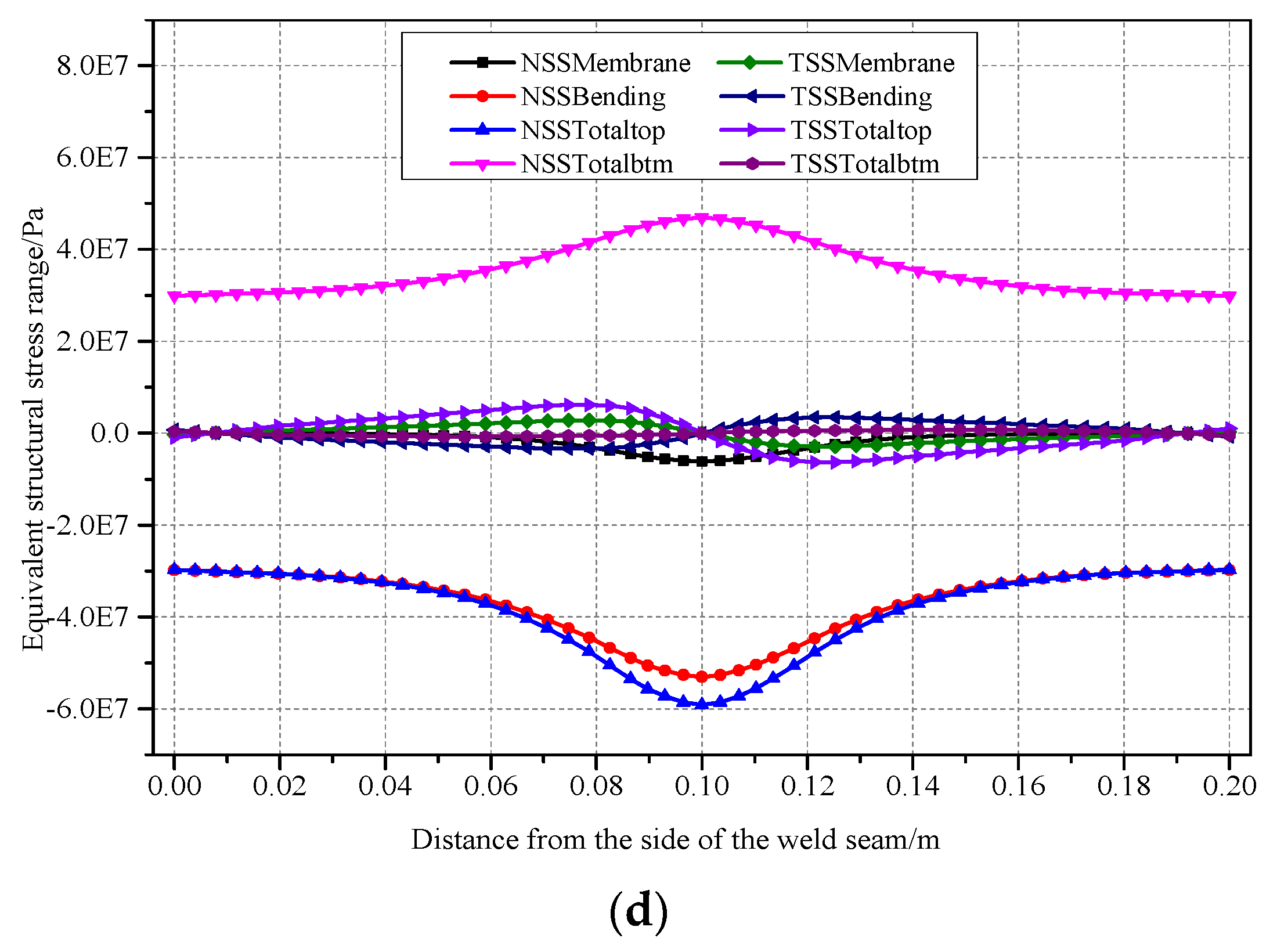

Four types of the weld lines of the double-sided weld seams of the bridge deck were considered. The weld seam called Double-Weldline1 is the weld seam of the outer weld toe and bridge deck. The weld seam called Double-Weldline2 is the weld seam of the weld root and bridge deck. The weld seam called Double-Weldline3 is the weld seam of the inner weld root and bridge deck. The weld seam called Double-Weldline4 is the weld seam of the inner weld toe and the bridge deck.

Compared to the bridge deck with the traditional weld seam and the weld seam of the large root, the location of the maximum Mises stress (

Figure 13) and the lowest fatigue cyclic life in the bottom of the bridge deck was shifted from the weld root of the outer weld seam to the weld toe of the inner weld seam. In addition, the location of the minimum cyclic life was shifted to the weld toe of the inner weld seam instead.

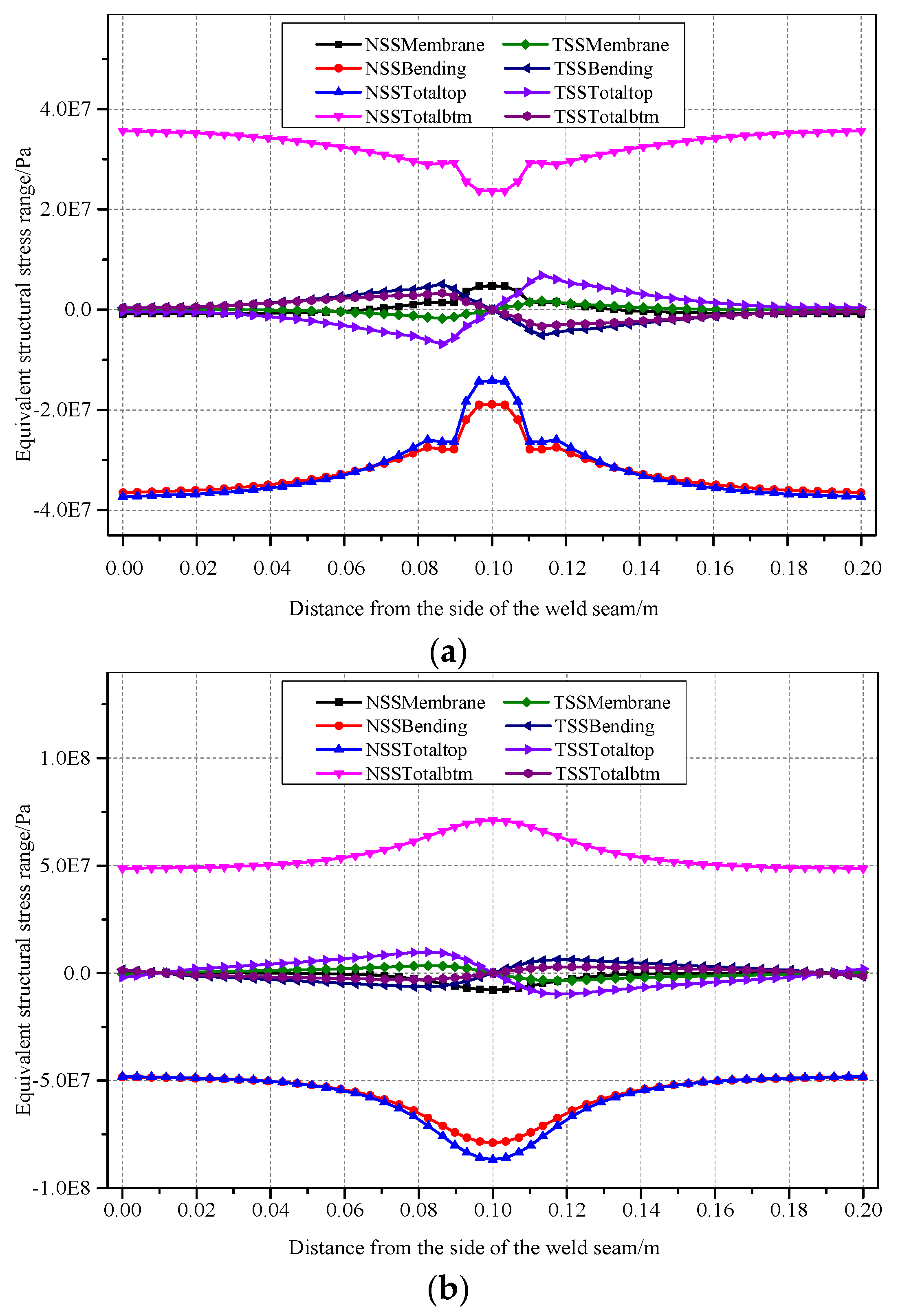

Figure 14 shows the equivalent structural stress for the four weld lines from Double-Weldline1 to Double-Weldline4. The stress trends of Double-Weldline1 to Double-Weldline4 were similar to the other weld seams. The bottom of the bridge deck was mainly subjected to normal tensile stress with little normal shear stress. The normal stress was mostly tensile stress with significant structural stress value.

Comparison of the in-plane shear structural stress showed that the effect of the shear structural stress could be ignored when considering the fatigue behavior of the connection of the rib-to-deck.

The maximum normal stress at both ends of the Double-Weldline1 was 30 MPa. The normal stress gradually decreased from the end to the middle of the weld seam and the minimum normal stress in the middle section was 25.21 MPa. However, the structural stress increased in the reverse direction in the connection between the weld toe and crossbeam when compared to the traditional seam. The stiffness of the bridge deck was changed due to the presence of the crossbeam. The stress distribution was non-uniform with the stress concentration at the connection of the rib-to-deck and crossbeam. The shear stress changed in the reverse direction at the middle position.

The minimum normal stress at both ends of the Double-Weldline2 was 27.8 MPa. The normal stress increased gradually from the side to the middle of the weld seam and the maximum stress in the middle section was 38.8 MPa. The direction of the shear stress of the weld seam was modified.

The trends of the equivalent structural stress and stress components of Double-Weldline3 and Double-Weldline4 were similar to that of Double-Weldline2. The maximum of the normal stress at the bottom side of the bridge deck decreased by 10.6% compared to the traditional weld seam. The normal stress at the top side of the bridge deck decreased by 29.0% and the normal stress at the bottom side of the bridge deck decreased by 17.5%.

The comparative results indicated that the equivalent structural stress of the bridge deck with traditional weld seam was more significant when compared to the bridge deck with double-sided weld seam. The fatigue performance of the bridge deck with double-sided seam was much better than that of the bridge deck with traditional weld seam.

It can be concluded that the bottom side of the bridge deck was mainly subjected to tensile stress with significant normal structural stress. The fatigue performance of the connection of the bridge deck and U-rib was influenced largely by the type of the weld seam.

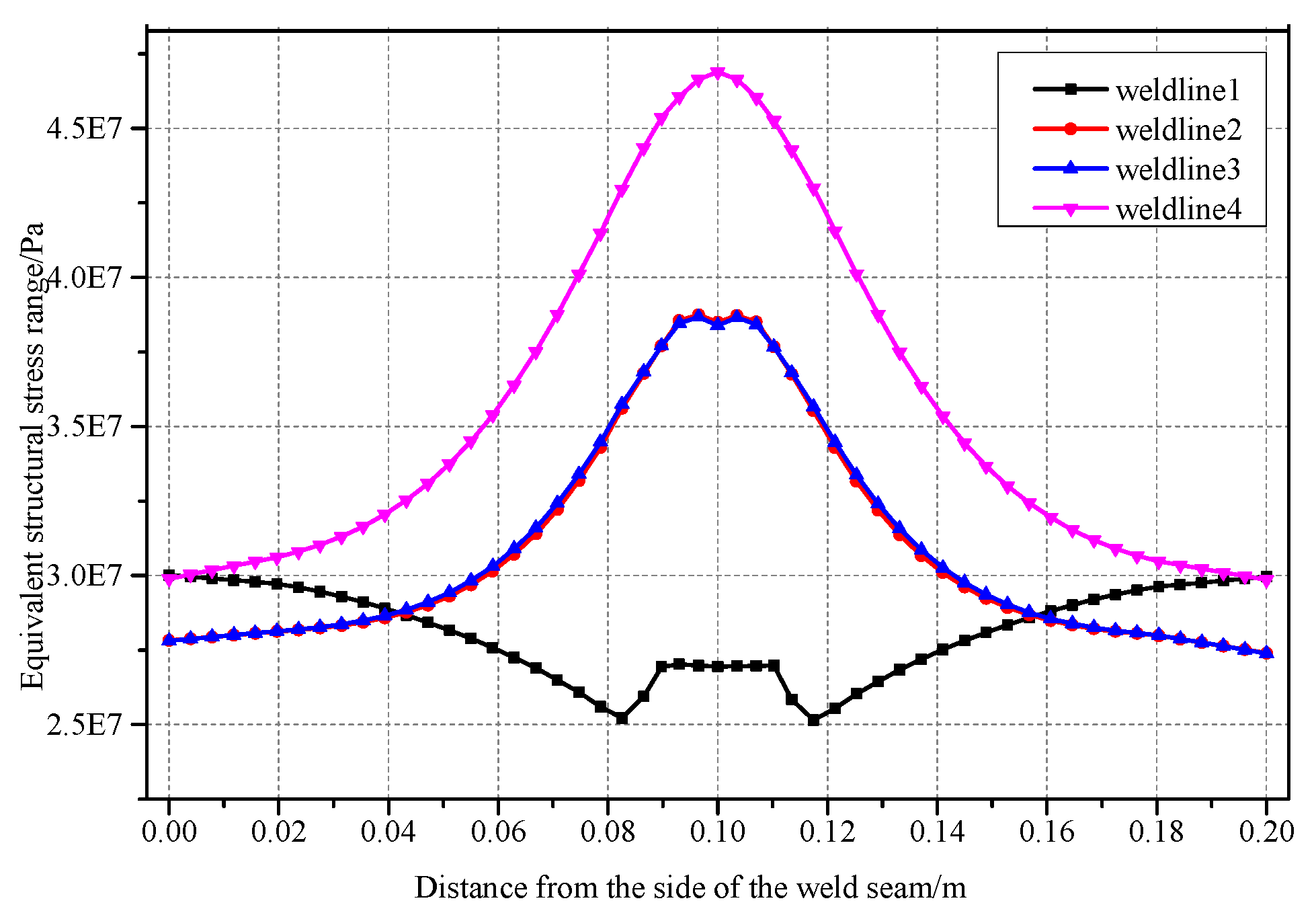

Figure 15 shows the equivalent structural stress of various weld seams of the bridge deck with double-sided weld seam. The trend of normal structural stress of Double-Weldline1 was opposite to that of the other three weld seams. The maximum normal stress at both sides of the Double-Weldline1 was 30 MPa and the stress gradually decreased to the middle of the weld seam. The minimum normal stress is 25.2 MPa. The normal stress increased reversely compared to the other three seams and remained uniform. The trends of the equivalent structural stress of Double-Weldline2 and Double-Weldline3 were similar and the normal stress values were close to each other. The normal stress increased gradually from the side of the weld seam to the middle section and the growth rate increased gradually. The maximum normal stress was 38.74 MPa and 38.68 MPa, respectively, for Double-Weldline2 and Double-Weldline3. The normal stress at the middle section decreased slightly.

Figure 16 shows the equivalent structural stress of various weld seams of the bridge deck with various weld seam. The increase of stress in the inner weld seam of the rib-to-deck connection optimizes the distribution of the equivalent structural stress. The fatigue failure location was shifted from the weld root of the outer weld seam to the weld toe of the inner weld seam demonstrating the effect of the crossbeam.

3.4. The Law of Traction Structural Stress of Geometric Parameters of the Rib-To-Deck

Figure 19 shows the Mises stress distribution of the connection of rib-to-deck, and

Figure 20 gives the von Mises stress distribution and fatigue cyclic lives distribution trend of the bottom side of the bridge deck. The Mises stress at the middle of the connection was more significant than that at other locations, and the stress decreased along the weld seam. The stress at the weld root was more significant than that at the weld toe, and the minimum cyclic life was obtained in the middle of weld root.

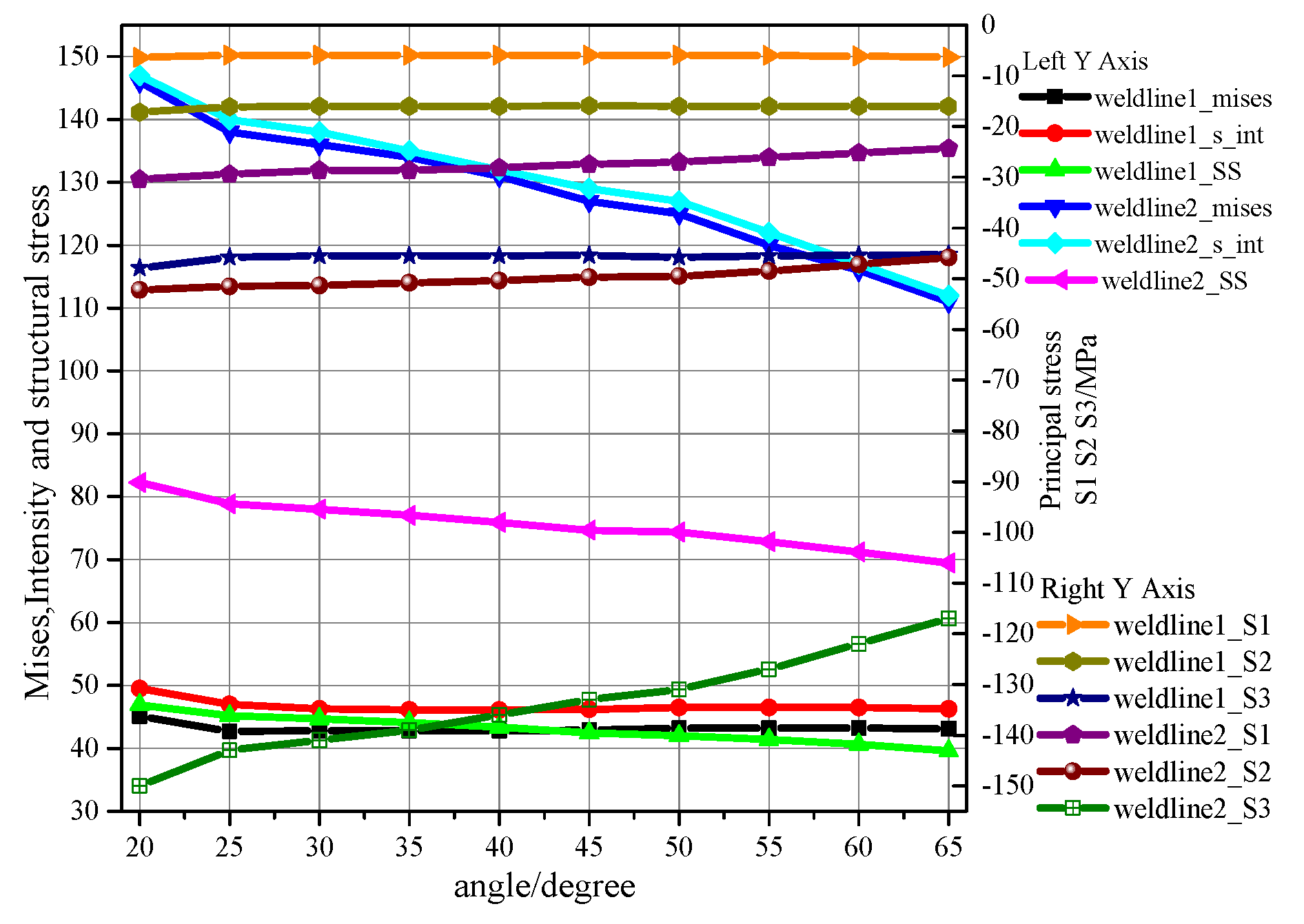

Various stresses, including the Mises stress (Mises), stress intensity (s_int), principal stresses (S1–3) and equivalent structural stress (SS), were determined as the evaluation indices. In the stress distribution contours shown in

Figure 21,

Figure 22,

Figure 23,

Figure 24, the left coordinate axis represents the value of the Mises stress (Mises), stress intensity (s_int) and equivalent structural stress (SS). The right coordinate axis stands for the value of the principal stresses (S1–3). Weldline1 represents the weld toe of the weld seam and Weldline2 stands for the weld root of the weld seam.

Figure 21 shows the trends of various stresses with the groove angle. The Mises stress, stress intensity, principle stress and the equivalent structural stress of Weldline1 and Weldline2 are calculated and plotted as the contours.

The comparative contours show that the Mises stress, stress intensity and equivalent structural stress of Weldline1 were small and decreased slightly with an increase in the groove angle. The trends of Mises stress and stress intensity of Weldline2 were similar. The Mises stress, equivalent structural stress and stress intensity of Weldline2 decreased with an increase in the angle. The principal stresses of Weldline2 remained constant with an increase in the groove angle.

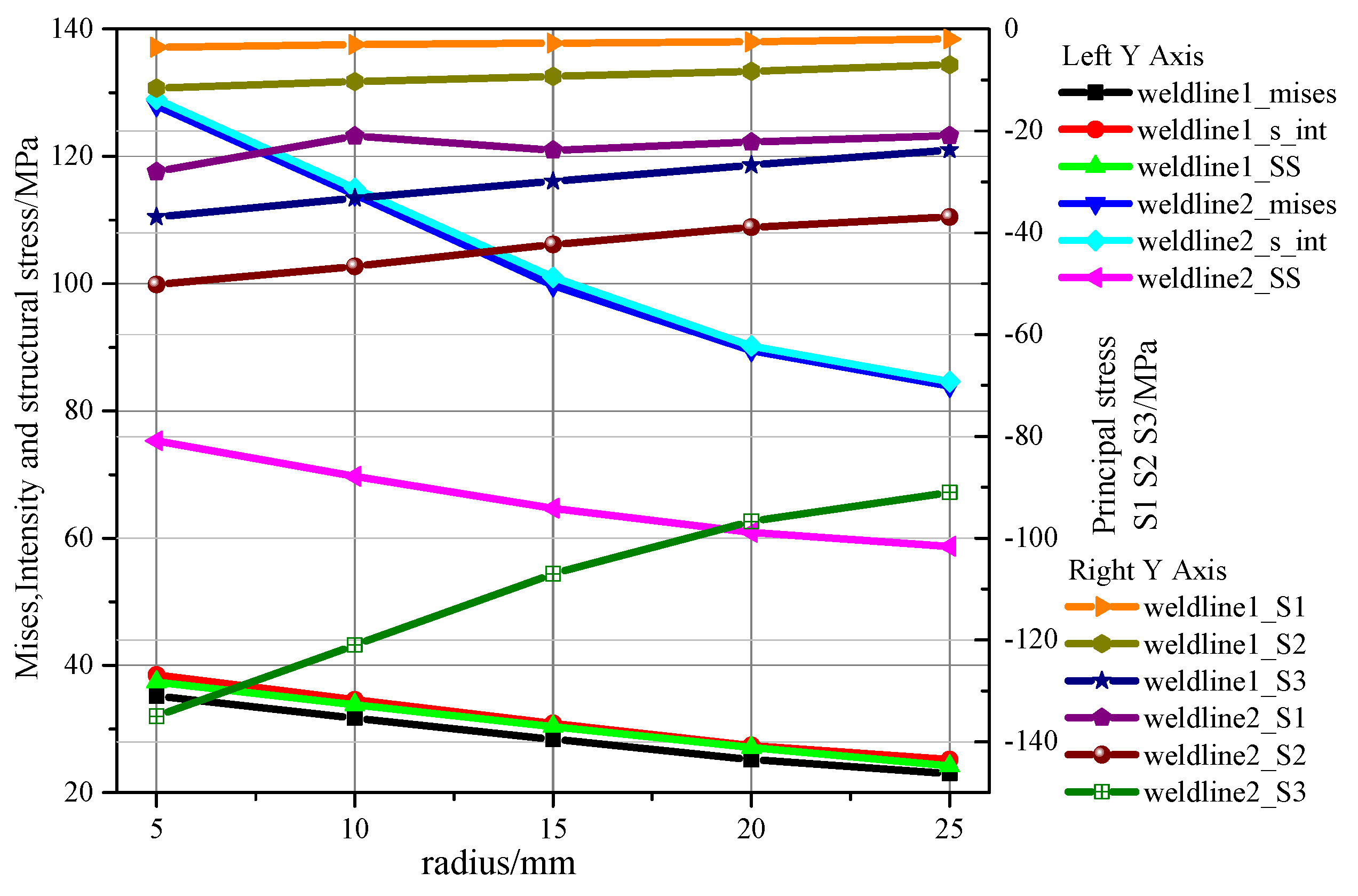

Figure 22 shows the trends of various stresses with the radius of the weld seam. The results indicate that the Mises stress, stress intensity and equivalent structural stress of Weldline1 were relatively small and decreased sharply with an increase in the radius. The trends of Mises stress and stress intensity were similar. The Mises stress, equivalent structural stress and stress intensity decreased with an increase in the radius. The principal stresses decreased with an increase in the radius. In addition, the third principal stress (S3) of Weldline2 decreased sharply by 32.6% with an increase in the radius from 5 mm to 25 mm.

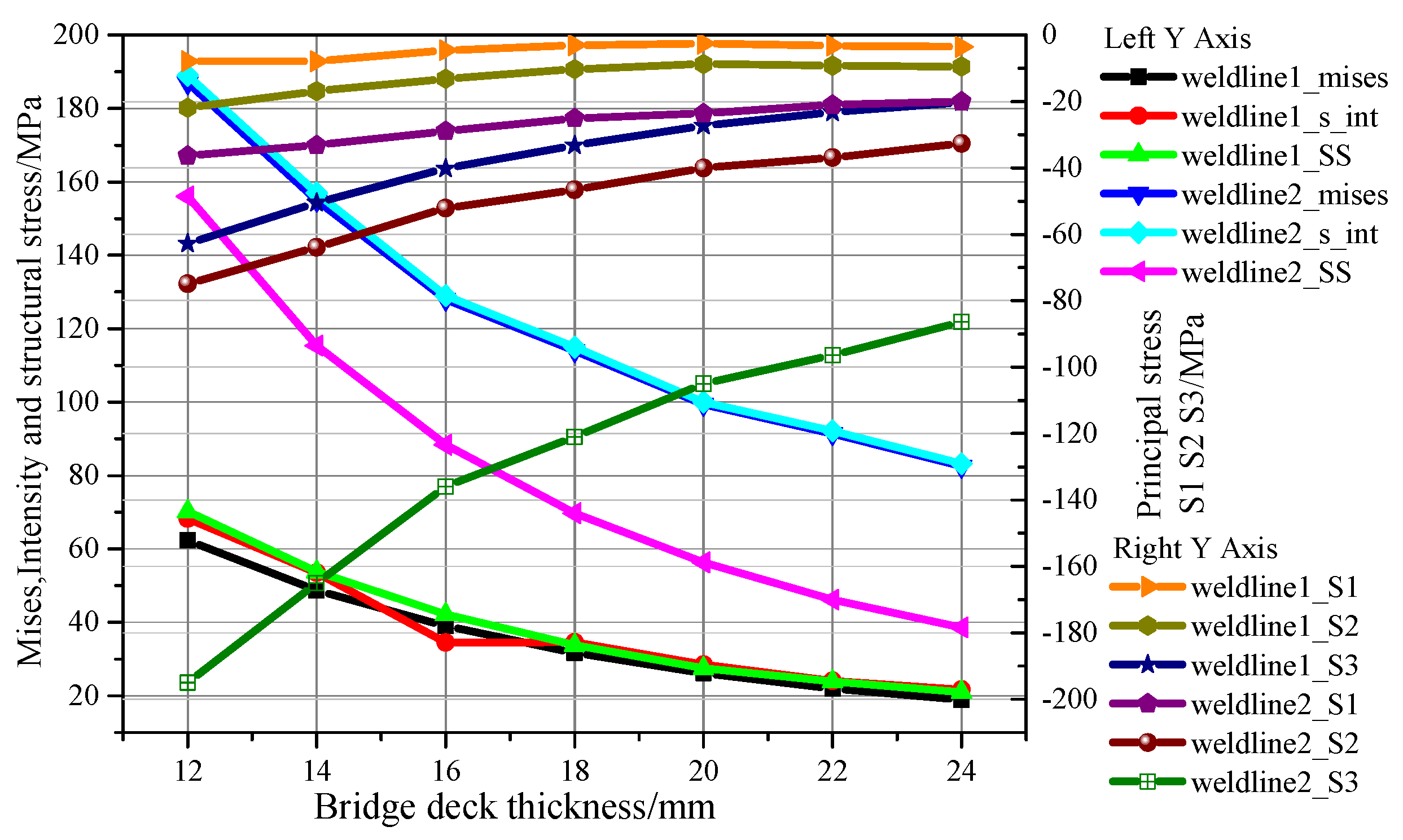

Figure 23 shows the trends of various stresses with the bridge deck thickness. The Mises stress, stress intensity and equivalent structural stress of Weldline1 decreased by up to 70% with an increase in the bridge deck thickness, respectively. The trends of Mises stress and stress intensity of Weldline2 were similar. The Mises stress, equivalent structural stress and stress intensity decreased by approximately 55% with an increase in the bridge deck thickness. The principal stresses of Weldline1 and Weldline2 decreased slightly with an increase in the bridge deck thickness.

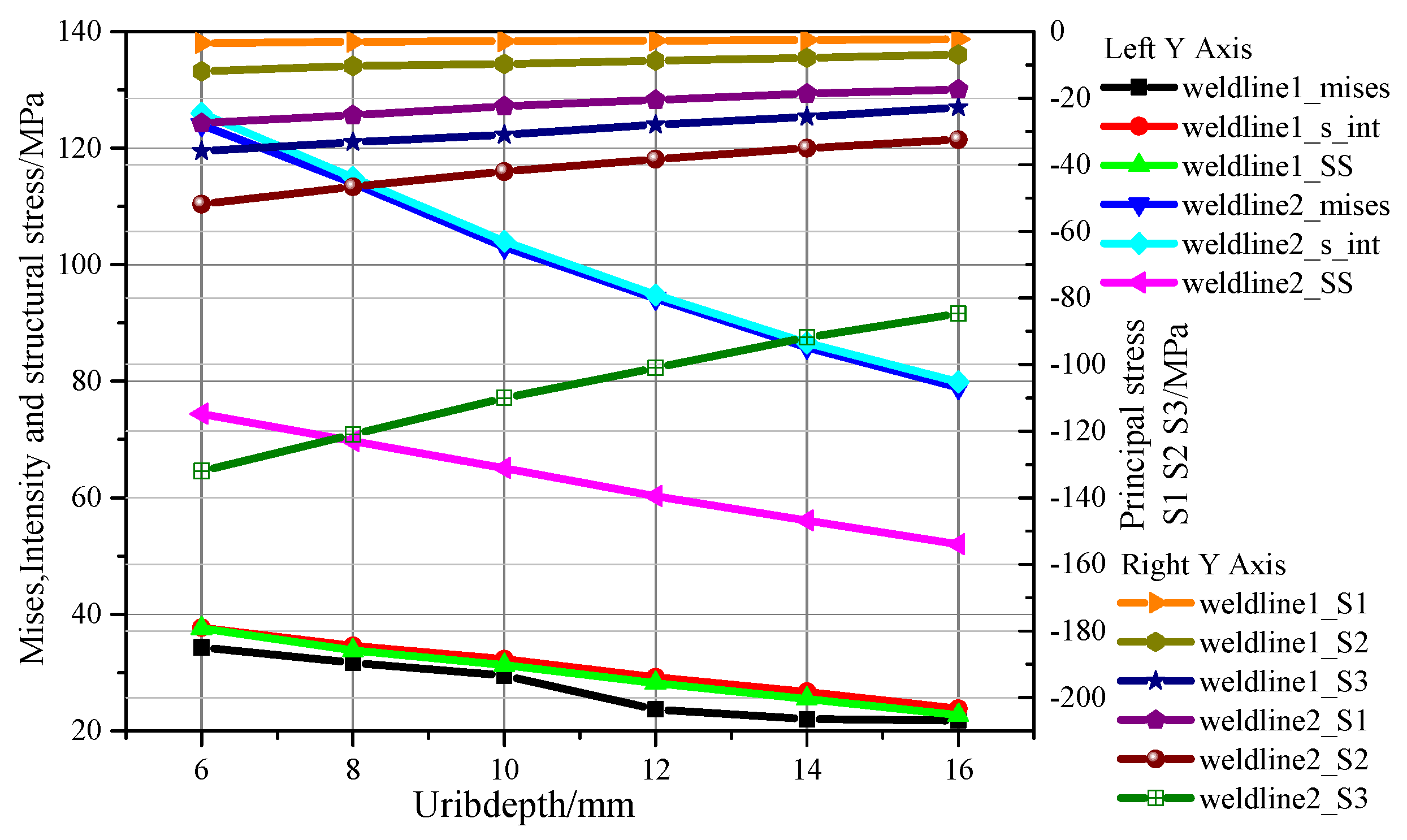

The trends of various stresses with the U-rib thickness are shown in

Figure 24. The comparative results demonstrate that the Mises stress, stress intensity and equivalent structural stress of Weldline1 decreased slightly with an increase in the U-rib thickness. The trends of Mises stress and stress intensity were similar. The Mises stress, equivalent structural stress and stress intensity of Weldline2 decreased by 44% with an increase in the U-rib thickness. The principal stresses of Weldline2 decreased slightly and the 3rd principal stress decreased by 34.5% with an increase in the U-rib thickness from 6 mm to 26 mm.

The comparative results indicated that the equivalent structural stress decreased by 13.4%, with the groove angle increasing from 20° to 60°. The connection of the rib-to-deck was strengthened with the increase in the angle. The equivalent structural stress reduced by 21.4%, with an increase in the radius from 5 mm to 25 mm. The equivalent structural stress at the middle of the bridge deck decreased by 24.6% with an increase in the U-rib from 8 mm to 16 mm. The equivalent structural stress at the middle of the bridge deck decreased significantly by 64.1% (from 156 MPa to 56 MPa), with an increase in the deck plate thickness from 12 mm to 24 mm. The bridge deck thickness influenced the equivalent structural stress and fatigue performance of the connection of the OSBD significantly and this observation substantiates why the equation of equivalent structural stress method includes the parameter of bridge deck thickness, t.

The comparative results from the analysis of geometric parameters of the rib-to-deck connection in OSBD will provide guidance for engineering fatigue design using the traction structural stress method. It is recommended that the variation in equivalent structural stress due to various geometric parameters should be added to the OSBD specification of Eurocode3.