Potential Applications in Relation to the Various Physicochemical Characteristics of Al-Hasa Oasis Clays in Saudi Arabia

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Clays Sampling

2.2. Samples Characterization

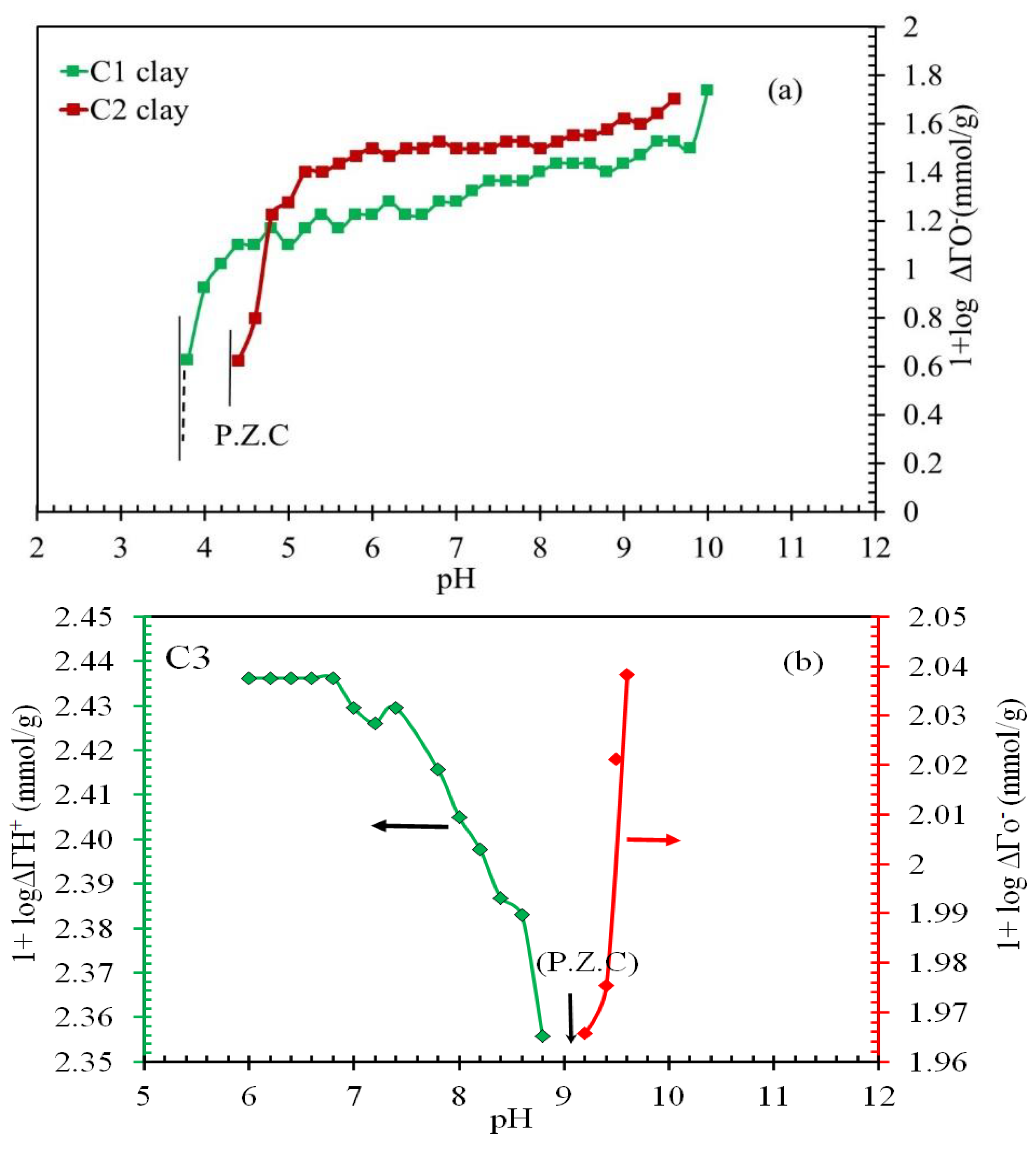

2.3. Measurement of Acid–Base Properties

2.4. Lead Adsorption Study

2.5. Catalytic Activity Study

3. Results and Discussion

3.1. XRD Analysis and Mineralogy Composition

3.2. Thermogravimetric Analysis

3.3. Textural and Morphological Characteristics

3.3.1. Pore Size Distribution (PSD) Models of Studied Clay Samples

3.3.2. SEM Investigation

3.4. Removal of Lead from Aqueous Solution

3.4.1. Effect of Contact Time

3.4.2. Effect of pH

3.4.3. Adsorption Isotherm

3.4.4. Adsorption Kinetics

3.5. Catalytic Conversion of Methanol

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Alandis, N.M.; Mekhamer, W.; Aldaye, O.; Hefne, J.A.A.; Ala, M. Adsorptive applications of montmorillonite clay for the removal of Ag(I) and Cu(II) from aqueous medium. J. Chem. 2019. [Google Scholar] [CrossRef]

- Al-Jlil, S.A.; Alsewailem, F.D. Saudi Arabian clays for lead removal in wastewater. Appl. Clay Sci. 2009, 42, 671–674. [Google Scholar] [CrossRef]

- Mohsen, Q.; El-Maghraby, A. Characterization and assessment of Saudi clays raw material at different area. Arabian J. Chem. 2012, 3, 271–277. [Google Scholar] [CrossRef]

- Shadfan, H.; Mashhady, A.; Eter, A.; Hussen, A.A. Mineral composition of selected soils in Saudi Arabia. J. Plant Nutr. Soil Sci. 1984, 147, 657–668. [Google Scholar] [CrossRef]

- Aba-Rusayn, M.M. Mineralogy of AL-Hasa desert soils (Saudi Arabia). Clay Clay Miner. 1977, 25, 138–147. [Google Scholar] [CrossRef]

- Lee, S.Y.; Dixon, J.B.; Aba-Husayn, M.M. Mineralogy of Saudi Arabian soils: Eastern Region. Soil Sci. Soc. Am. 1983, 47, 321–326. [Google Scholar] [CrossRef]

- Grim, R.E.; Guven, N. Bentonites: Geology, Mineralogy, Properties, and Use. Developments in Sedimentology; Elsevier: Amsterdam, The Netherlands, 1978; Volume 24. [Google Scholar]

- Murray, H.H. Traditional and new applications for kaolin, smectite, and palygorskite: A general overview. Appl. Clay Sci. 2000, 17, 207–221. [Google Scholar] [CrossRef]

- Bergaya, F.; Theng, B.K.G.; Lagaly, G. Clays in Industry. In Handbook of Clay Science, 1st ed.; Bergaya, F., Theng, B.K.G., Lagaly, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2006; Volume 1, pp. 823–850. [Google Scholar]

- Chang, C.D.; Lang, W.H.; Silvestri, A.J. Manufacture of Light Olefins. U.S. Patent 4,062,90, 13 December 1977. [Google Scholar]

- Chang, C.D. Methanol conversion to light olefins. Catal. Rev. Sci. Eng. 1984, 26, 323–345. [Google Scholar] [CrossRef]

- Dugkhuntod, P.; Wattanakit, C. A comprehensive review of the applications of hierarchical zeolite nanosheets and nanoparticle assemblies in light olefin production. Catalysts 2020, 10, 245. [Google Scholar] [CrossRef]

- Galn, E. Properties and applications of palygorskite-sepiolite clays. Clay Miner. 1996, 31, 443–453. [Google Scholar] [CrossRef]

- Bridley, G.W. Quantitative X-ray analysis of clays. In Crystal Structures of Clay Minerals and Their X-ray Identification; Brindley, G.W., Brown, G., Eds.; Mineralogical. Society Monograph N.5: London, UK, 1980. [Google Scholar]

- Reynolds, R.C. Principles and techniques of quantitative analysis of clay minerals by X-ray powder diffraction. In The Clay Mineral Society CMS Workshop Lectures; Pevear, D.R., Mumpton, F.A., Eds.; Clay Minerals Society: Evergreen, CO, USA, 1989; Volume 1, pp. 4–36. [Google Scholar]

- Kita, H.; Henmi, N.; Shimazu, K.; Hattori, H.; Tanabe, K. Measurement of acid–base properties on metal oxide surfaces in aqueous solution. Chem. Soc. Farady Trans. 1981, 1, 2451–2463. [Google Scholar] [CrossRef]

- Abendroth, R.P. Behavior of pyrogenic silica in simple electrolytes. J. Colloid Interface Sci. 1970, 34, 591–596. [Google Scholar] [CrossRef]

- Brady, P.V.; Walther, J.V. Surface chemistry and silicate dissolution at elevated temperatures. Am. J. Sci. 1992, 292, 639–658. [Google Scholar] [CrossRef]

- Huang, C.P.; Stumm, W. Specific adsorption of cations on hydrous-Al2O3. J. Colloid Interface Sci. 1973, 43, 409–420. [Google Scholar] [CrossRef]

- Avena, M.J.; De Pauli, C.P. Proton adsorption and electrokinetics of an Argentinean montmorillonite. J. Colloid Interface Sci. 1998, 202, 195–204. [Google Scholar] [CrossRef]

- Ward, D.B.; Brady, P.V. Effect of Al and organic acids on the surface chemistry of kaolinite. Clay Clay Miner. 1998, 46, 453–465. [Google Scholar] [CrossRef]

- Huertas, F.J.; Chou, L.; Wollast, R. Mechanism of kaolinite dissolution at room temperature and pressure: Part 1. Surface speciation. Geochim. Cosmochim. Acta. 1998, 62, 417–431. [Google Scholar] [CrossRef]

- AbdelDayem, H.M.; Al-Shihry, S.S.; Hassan, S.A. Impact of Titanium in Controlling Silver Particle Size on Enhancement of Catalytic Performance of AgMoO3/Ti-HMS for Direct Epoxidation of Propylene. ACS Omega 2020, 5, 4469–4481. [Google Scholar] [CrossRef]

- Zatta, L.; Ramos, L.P.; Wypych, F. Acid-activated montmorillonites as heterogeneous catalysts for the esterification of lauric acid with methanol. Appl. Clay Sci. 2013, 80–81, 236–244. [Google Scholar] [CrossRef]

- Hart, M.P.; Brown, D.R. Surface acidities and catalytic activities of acid-activated clays. J. Mol. Catal. A Chem. 2004, 212, 315–321. [Google Scholar] [CrossRef]

- Baran, B.; ErtÖuk, T.; Sarikaya, Y.; Alemdaroglu, T. Workability test method for metals applied to examine a work ability measure (plastic limit) for clays. Appl. Clay Sci. 2001, 20, 53–63. [Google Scholar] [CrossRef]

- Bayram, H.; Önal, M.; Üstünişik, G.; Sarikaya, Y. Some thermal characteristics of a mineral mixture of palygorskite, metahalloysite, magnesite and dolomite. J. Therm. Anal. Calorim. 2007, 89, 169–174. [Google Scholar] [CrossRef]

- Frost, R.L.; Ding, Z. Controlled rate thermal analysis and differential scanning calorimetry of sepiolites and palygorskites. Thermochim. Acta 2003, 397, 119–128. [Google Scholar] [CrossRef]

- Brigatti, M.F.; Laurora, A.; Malferrari, D.; Medici, L.; Poppi, L. Adsorption of [Al(Urea)6]3+ and [Cr(Urea)6]3+ complexes in the vermiculite interlayer. Appl. Clay Sci. 2005, 30, 21–32. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 6013–6019. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Barrett, E.; Joyner, P.; Halenda, P.P. The determination of pore volume and area distributions in porous substances: I. computations from nitrogen isotherms. J. Am. Chem. Soc. 1938, 73, 373–380. [Google Scholar] [CrossRef]

- Ledoux, R.L.; White, J.L. Infrared studies of the hydroxyl groups in intercalated kaolinite complexes. Clay Clay Miner. 1964, 13, 289–315. [Google Scholar] [CrossRef]

- Russell, J.D.; Frase, A.R. IR spectroscopic evidence for interaction between hydronium ions and lattice OH groups in montmorillonite. Clay Clay Miner. 1971, 19, 55–59. [Google Scholar] [CrossRef]

- Tyagi, B.; Chudasama, C.D.; Jasra, R.V. Determination of structural modification in acid activated montmorillonite clay by FT-IR spectroscopy. Spectrochim. Acta A 2006, 64, 273–278. [Google Scholar] [CrossRef]

- Douiri, H.; Louati, S.; Baklouti, S.; Arous, M.; Fakhfakh, Z. Structural and dielectric comparative studies of geopolymers prepared with metakaolin and Tunisian natural clay. Appl. Clay Sci. 2017, 139, 40–44. [Google Scholar] [CrossRef]

- Potgieter, J.P.; Potgieter-Vermaak, S.S.; Kalibantonga, P.D. Heavy metals removal from solution by palygorskite clay. Miner. Energy 2006, 19, 463–470. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Huo, W.G. Adsorption behavior of Pb (II) on montmorillonite. Colloid Surf. A Physico. Chem. Eng. Asp. 2008, 320, 92–97. [Google Scholar] [CrossRef]

- Godelitsas, A.; Astilleros, J.M.; Hallam, K.; Harissopoulos, S.; Putnis, A. Interaction of calcium carbonates with lead in aqueous solutions. Environ. Sci. Technol. 2003, 37, 3351–3360. [Google Scholar] [CrossRef] [PubMed]

- Fan, Q.; Li, Z.; Zhao, H.; Jia, Z.; Xu, J.; Wu, W. Adsorption of Pb (II) on palygorskite from aqueous solution: Effect of pH, ionic strength and temperature. Appl. Clay Sci. 2009, 45, 111–116. [Google Scholar] [CrossRef]

- Chen, H.; Wang, B. Kinetic and isothermal studies of lead ion adsorption onto palygorskite clay. J. Colloid Interface Sci. 2007, 307, 309–316. [Google Scholar] [CrossRef] [PubMed]

- Rangel-Porras, G.; García-Magno, J.B.; González-Muñoz, M.P. Lead and cadmium immobilization on calcitic limestone materials. Desalination 2010, 262, 1–10. [Google Scholar] [CrossRef]

- Chu, Y.; Khan, M.A.; Wang, F.; Xia, M.; Lei, W.; Zhu, S. Kinetics and equilibrium isotherms of adsorption of Pb (II) and Cu (II) onto raw and arginine-modified montmorillonite. Adv. Powder Technol. 2019, 30, 1067–1078. [Google Scholar] [CrossRef]

- Giles, C.H.; Smith, D. A general treatment and classification of the solute adsorption isotherm I. theoretical. J. Colloid Interface Sci. 1974, 47, 755–765. [Google Scholar] [CrossRef]

- Langmuir, I. The constitution and fundamental properties of solids and liquids. Part I. solids. J. Am. Chem. Soc. 1916, 38, 2221–2295. [Google Scholar] [CrossRef]

- Hall, K.R.; Eagleton, L.C.; Acrivos, A.; Vermeulen, T. Pore- and solid-diffusion kinetics in fixed-bed adsorption under constant-pattern conditions. Ind. Eng. Chem. Fundam. 1966, 5, 212–223. [Google Scholar] [CrossRef]

- Freundlich, H.M.F. Over the Adsorption in Solution. Z. Phys. Chem. 1906, 57, 385–471. [Google Scholar]

- Hutson, N.D.; Yang, R.T. Theoretical basis for the Dubinin-Radushkevitch (D-R) adsorption isotherm equation. Adsorption 2000, 3, 189–195. [Google Scholar] [CrossRef]

- Temkin, M.I.; Pyzhev, V. Kinetic of Ammonia Synthesis on Promoted Iron Catalyst. Acta Physicochim. Chem. URSS 1940, 12, 327–356. [Google Scholar]

- Mahamdi, C.; Nharingo, C. Utilization of water hyacinth weed (Eichhornia crassipes) for the removal of Pb(II), Cd(II) and Zn(II) from aquatic environments: An adsorption isotherm study. Environ. Technol. 2010, 31, 1221–1228. [Google Scholar] [CrossRef]

- Aharoni, C.; Ungarish, M. Kinetics of activated chemisorption. Part 2. Theoretical models. J. Chem. Soc. Faraday Trans. 1977, 73, 456–464. [Google Scholar] [CrossRef]

- Dubinin, M.M.; Radushevich, L.V. The equation of the characteristic curve of the activated charcoal. Proc. Acad. Sci. USSR Phys. Chem. Sect. 1947, 55, 331–337. [Google Scholar]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Rev. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Gunay, A.; Arslankaya, E.; Tosun, I. Lead removal from aqueous solution by natural and pretreated clinoptilolite: Adsorption equilibrium and kinetics. J. Hazard. Mater. 2007, 146, 362–371. [Google Scholar] [CrossRef]

- Dabrowski, A. Adsorption-from theory to practice. Adv. Colloid Interface Sci. 2001, 93, 135–224. [Google Scholar] [CrossRef]

- Dubinin, M.M. The potential theory of adsorption of gases and vapors for adsorbents with energetically non-uniform surface. Chem. Rev. 1960, 60, 235–266. [Google Scholar] [CrossRef]

- Hobson, J.P. Physical adsorption isotherms extending from ultra-high vacuum to vapor pressure. J. Phys. Chem. 1969, 73, 2720–2727. [Google Scholar] [CrossRef]

- Monika, J.; Garg, V.; Kadirvelu, K. Chromium (VI) removal from aqueous solution, using sunflower stem waste. J. Hazard. Mater. 2008, 162, 365–372. [Google Scholar]

- Lagergren, S. Zur theorie der sogenannten adsorption gelöster stoffe. K. Sven. Vetensk. Handl. 1898, 24, 1–39. [Google Scholar]

- Ho, Y.S.; McKay, G. Pseudo-second order model for sorption processes. Proc. Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Weber, W.J., Jr.; Morriss, J.C.; Sanitary, J. Kinetics of adsorption on carbon from solution. J. Eng. Div. Am. Soc. Civ. Eng. 1963, 89, 31–38. [Google Scholar]

- Baskaralingam, P.; Pulikesi, M.; Elango, D.; Ramamurthi, V.; Sivanesan, S. Adsorption of acid dye onto organobentonite. J. Hazard. Mater. 2006, 128, 138–144. [Google Scholar] [CrossRef]

- Guibal, E.; Milot, C.; Tobin, J.M. Metal anion sorption by chitosan beads: Equilibrium and kinetic studies. Ind. Eng. Chem. Res. 1998, 37, 1454–1463. [Google Scholar] [CrossRef]

- Gupta, S.S.; Bhattacharyya, K.G. Adsorption of Ni (II) on Clays. J. Colloid Interface Sci. 2006, 295, 21–32. [Google Scholar] [CrossRef]

- Derouane, E.D.; Chang, C.D. Confinement effects in the adsorption of simple bases by zeolites. Micropor. Mesopr. Mater. 2000, 35/36, 425–433. [Google Scholar] [CrossRef]

- Cheng, S.; Peng, G.Z.; Clearfield, A. Decomposition of alcohols over zirconium and titanium phosphates. Ind. Eng. Chem. Res. Dev. 1984, 23, 219–225. [Google Scholar] [CrossRef]

- Ravichandran, J.; Sivasankar, B. Properties and catalytic activity of acid-modified montmorillonite and vermiculite. Clay Clay Miner. 1997, 45, 854–858. [Google Scholar] [CrossRef]

| Clay | Montmorillonite (%) | Chlorite (%) | Palygorskite (%) | Kaolinite (%) | Illite (%) | Calcite (%) | Quartz (%) |

|---|---|---|---|---|---|---|---|

| C1 | 0 | 1 | 61 | 9 | 28 | 0 | 1 |

| C2 | 73 | 0 | 9 | 6 | 7 | 4 | 1 |

| C3 | 6 | 1 | 57 | 9 | 20 | 6 | 1 |

| C4 | 2 | 5 | 54 | 7 | 9 | 22 | 1 |

| C5 | 10 | 0 | 27 | 10 | 3 | 39 | 11 |

| Composition\Clay (%) | C1 Palygorskite | C2 Montmorillonite | C3 Palygorskite | C4 Palygorskite | C5 Palygorskite |

|---|---|---|---|---|---|

| SiO2 | 56.80 | 56.07 | 57.22 | 51.59 | 59.82 |

| Al2O3 | 13.04 | 24.44 | 13.29 | 9.75 | 12.93 |

| Fe2O3 | 5.05 | 3.38 | 5.28 | 7.47 | 5.6 |

| MgO | 4.59 | 1.88 | 5.06 | 6.37 | 4.99 |

| K2O | 0.24 | 0.24 | 0.26 | 0.34 | 0.28 |

| CaO | 0.08 | 0.10 | 0.05 | 0.10 | 0.10 |

| Cs2O | 3.77 | 13.2 | 1.79 | 1.32 | 2.89 |

| H2O | 13.60 | - | 16.80 | 23.00 | 13.95 |

| Clay | SBET (m2/g) | Vp (cm3/g) | r (nm) | Scum (m2/g) | Vcum (cm3/g) | P.Z.C |

|---|---|---|---|---|---|---|

| C1 | 93.74 | 0.177 | 3.78 | 51.06 | 0.152 | 4.4 |

| C2 | 42.75 | 0.085 | 3.97 | 49.62 | 0.009 | 3.8 |

| C3 | 75.01 | 0.131 | 3.50 | 34.72 | 0.107 | 9.0 |

| C4 | 90.8 | 0.270 | 5.94 | 71.75 | 0.260 | 7.6 |

| C5 | 63.91 | 0.096 | 2.99 | 86.10 | 0.106 | 7.1 |

| Adsorption-Model | Constants | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|---|

| Langmuir | qmax (mg/g) | 74.07 | 40.0 | 68.03 | 53.48 | 99.01 a |

| b (L mg−1) | 0.008 | 0.027 | 0.007 | 0.0060 | 0.001 a | |

| r2 | 0.997 | 0.999 | 0.996 | 0.993 | 0.607 | |

| Freundlich | Kf | 1.69 | 2.66 | 1.35 | 0.80 | 7.35 |

| n | 1.68 | 2.19 | 1.64 | 1.56 | 0.93 | |

| r2 | 0.946 | 0.892 | 0.9488 | 0.953 | 0.916 | |

| Temkin | B | 14.61 | 6.45 | 13.48 | 10.59 | 13.74 b |

| A (L/g) | 0.116 | 1.088 | 0.102 | 0.079 | 0.038 b | |

| L (J/mol) | 169.5 | 384.0 | 183.7 | 233.9 | 186.02 b | |

| r2 | 0.985 | 0.903 | 0.983 | 0.981 | 0.990 | |

| D-R | β (mol2/KJ2) | 0.00004 | 0.00001 | 0.00004 | 0.00007 | 0.0005 |

| E (KJ/mol) | 111.80 | 223.60 | 111.80 | 84.51 | 31.62 | |

| qs (mg/g) | 42.2 | 30.22 | 38.12 | 28.56 | 32.56 | |

| r2 | 0.758 | 0.769 | 0.756 | 0.753 | 0.908 |

| Kinetic Model | Constants | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|---|

| Pseudo-first order | qe (mg/g) | 53.36 | 21.62 | 35.50 | 26.27 | 3.56 |

| k1 (min−1) | 0.0124 | 0.0094 | 0.0061 | 0.0063 | 0.0094 | |

| r2 | 0.789 | 0.901 | 0.979 | 0.976 | 0.348 | |

| Pseudo-second order | qe (mg/g) | 53.76 | 40.32 | 50.0 | 36.90 | 32.47 |

| k2 (g/mg min) | 0.00034 | 0.00094 | 0.00027 | 0.00039 | 0.0028 | |

| r2 | 0.993 | 0.999 | 0.990 | 0.990 | 0.996 | |

| Intraparticle | ki (mg/g min0.5) | 1.68 | 1.02 | 1.57 | 1.16 | 0.57 |

| diffusion | C(mg/g) | 13.15 | 17.58 | 9.67 | 7.59 | 20.98 |

| r2 | 0.881 | 0.768 | 0.941 | 0.933 | 0.316 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Hawas, I.A.; Hassan, S.A.; AbdelDayem, H.M. Potential Applications in Relation to the Various Physicochemical Characteristics of Al-Hasa Oasis Clays in Saudi Arabia. Appl. Sci. 2020, 10, 9016. https://doi.org/10.3390/app10249016

Al-Hawas IA, Hassan SA, AbdelDayem HM. Potential Applications in Relation to the Various Physicochemical Characteristics of Al-Hasa Oasis Clays in Saudi Arabia. Applied Sciences. 2020; 10(24):9016. https://doi.org/10.3390/app10249016

Chicago/Turabian StyleAl-Hawas, Ibrahim A., Salah A. Hassan, and Hany M. AbdelDayem. 2020. "Potential Applications in Relation to the Various Physicochemical Characteristics of Al-Hasa Oasis Clays in Saudi Arabia" Applied Sciences 10, no. 24: 9016. https://doi.org/10.3390/app10249016

APA StyleAl-Hawas, I. A., Hassan, S. A., & AbdelDayem, H. M. (2020). Potential Applications in Relation to the Various Physicochemical Characteristics of Al-Hasa Oasis Clays in Saudi Arabia. Applied Sciences, 10(24), 9016. https://doi.org/10.3390/app10249016