Eco-Efficient Hybrid Cements: Pozzolanic, Mechanical and Abrasion Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mortar Preparation

- Ordinary Portland cement systems (CEM I): a type I 42.5R Portland cement was used and hydrated with water.

- Alkaline-activated materials: these were composed of a subindustrial waste (slag) and activated using alkaline solutions with basic pH (pH > 13). In this sense, two solutions were used: 4 M NaOH solution (AAS-N) and a commercial sodium silicate solution (waterglass) with a SiO2/Na2O ratio of 1.2 (AAS-WG).

- Hybrid materials: these mortars were composed of ordinary Portland cement (20 wt %) and industrial and ceramic wastes (fly ash, blast furnace slag and two ceramic wastes), of which the amount was 80 wt % Furthermore, in these hybrid systems, a percentage of Na2SO4 (at 3% and 5 wt %) was added to favor the hydration process of the materials. Water was used as the activating solution.

2.3. Tests Conducted

3. Results and Discussion

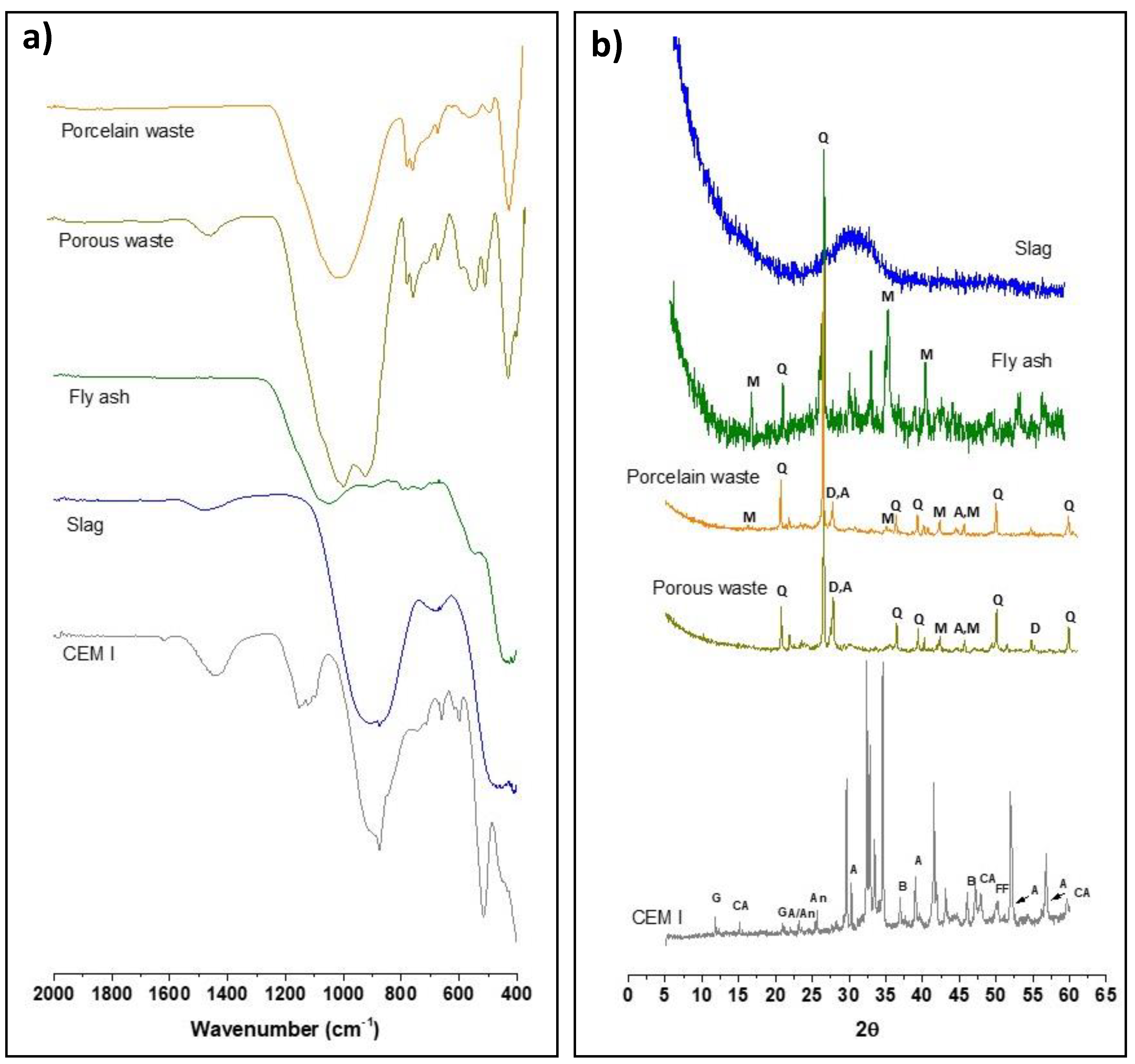

3.1. Mineralogical Characterization of Raw Materials

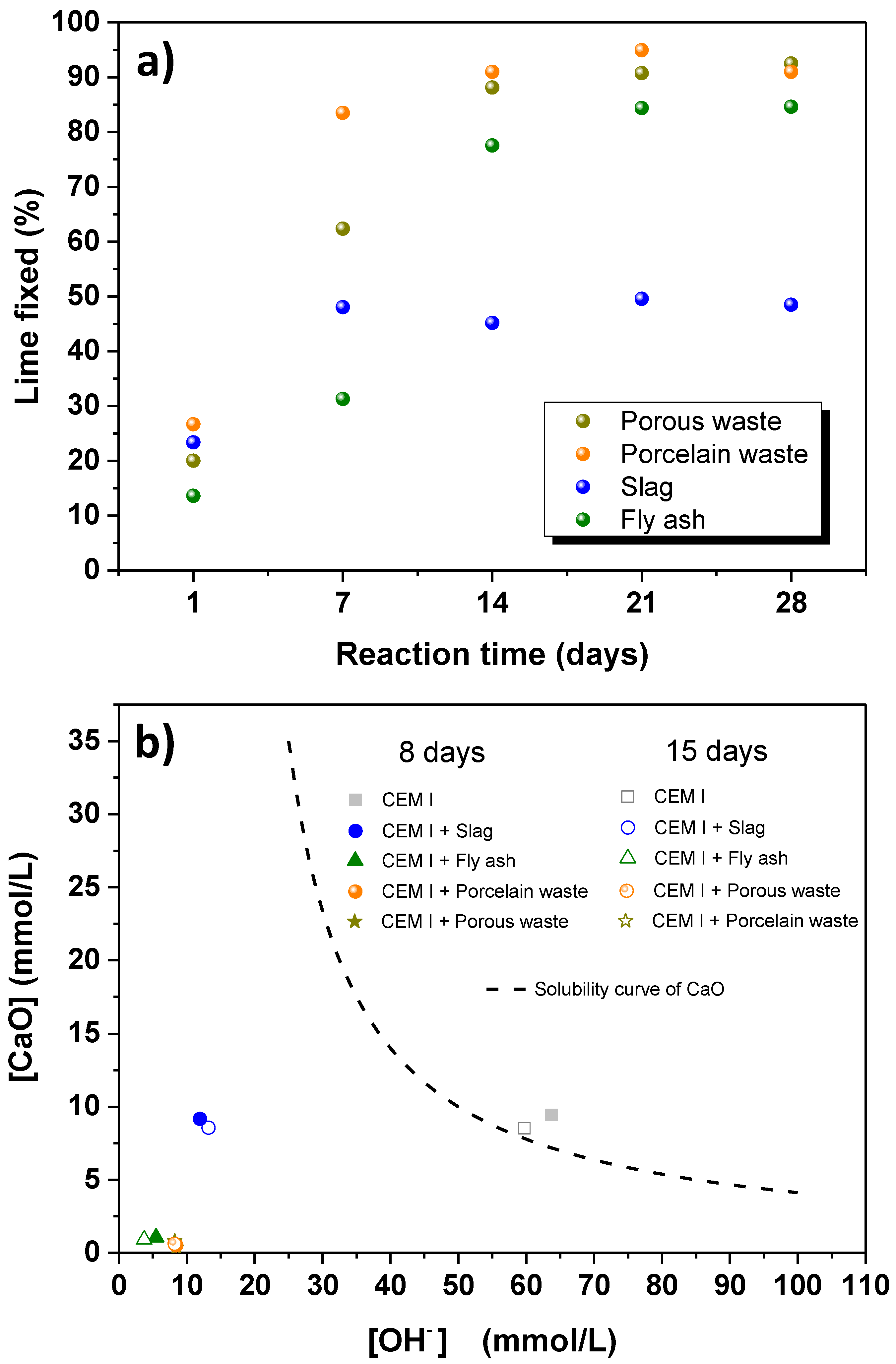

3.2. Pozzolanic Properties of Raw Materials

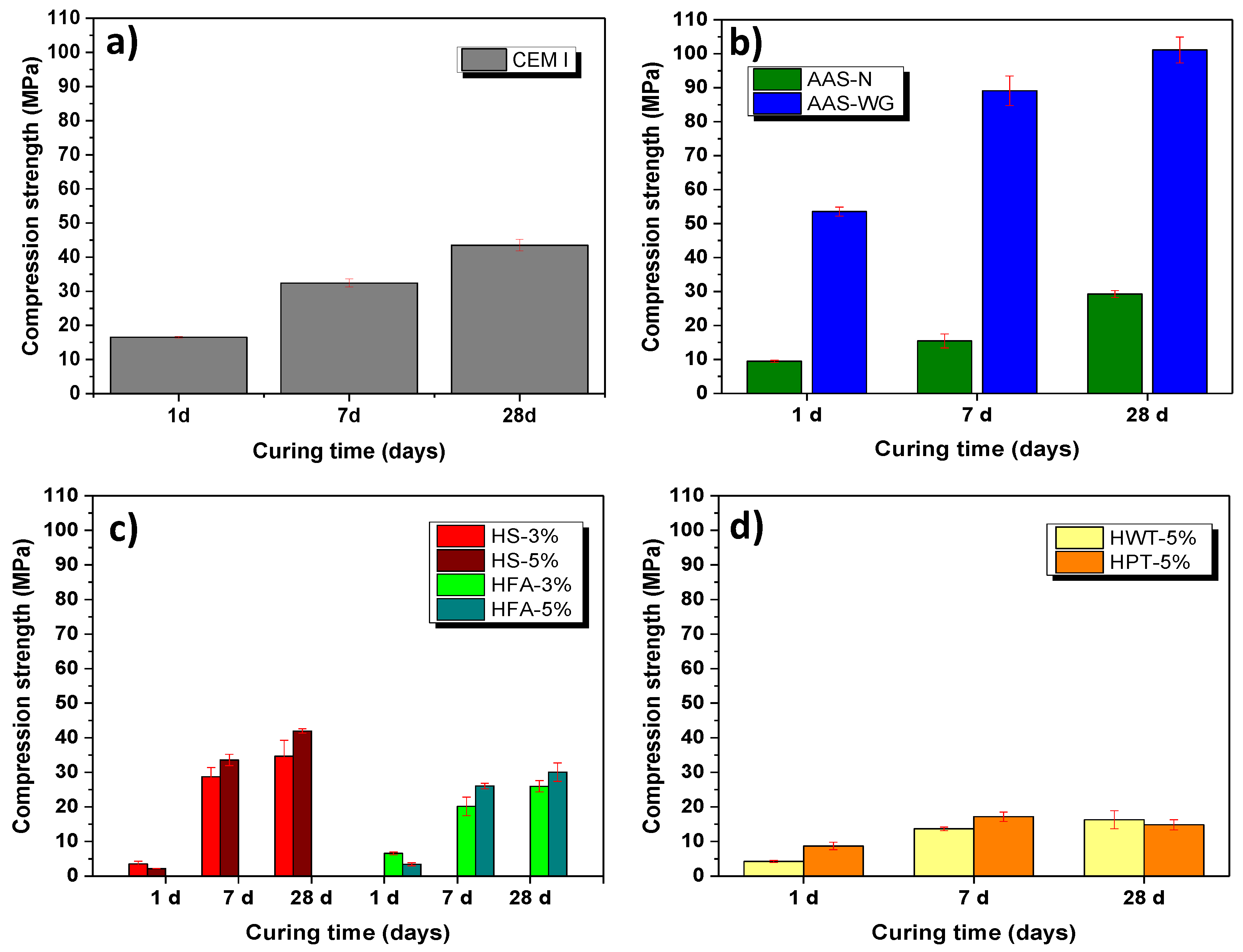

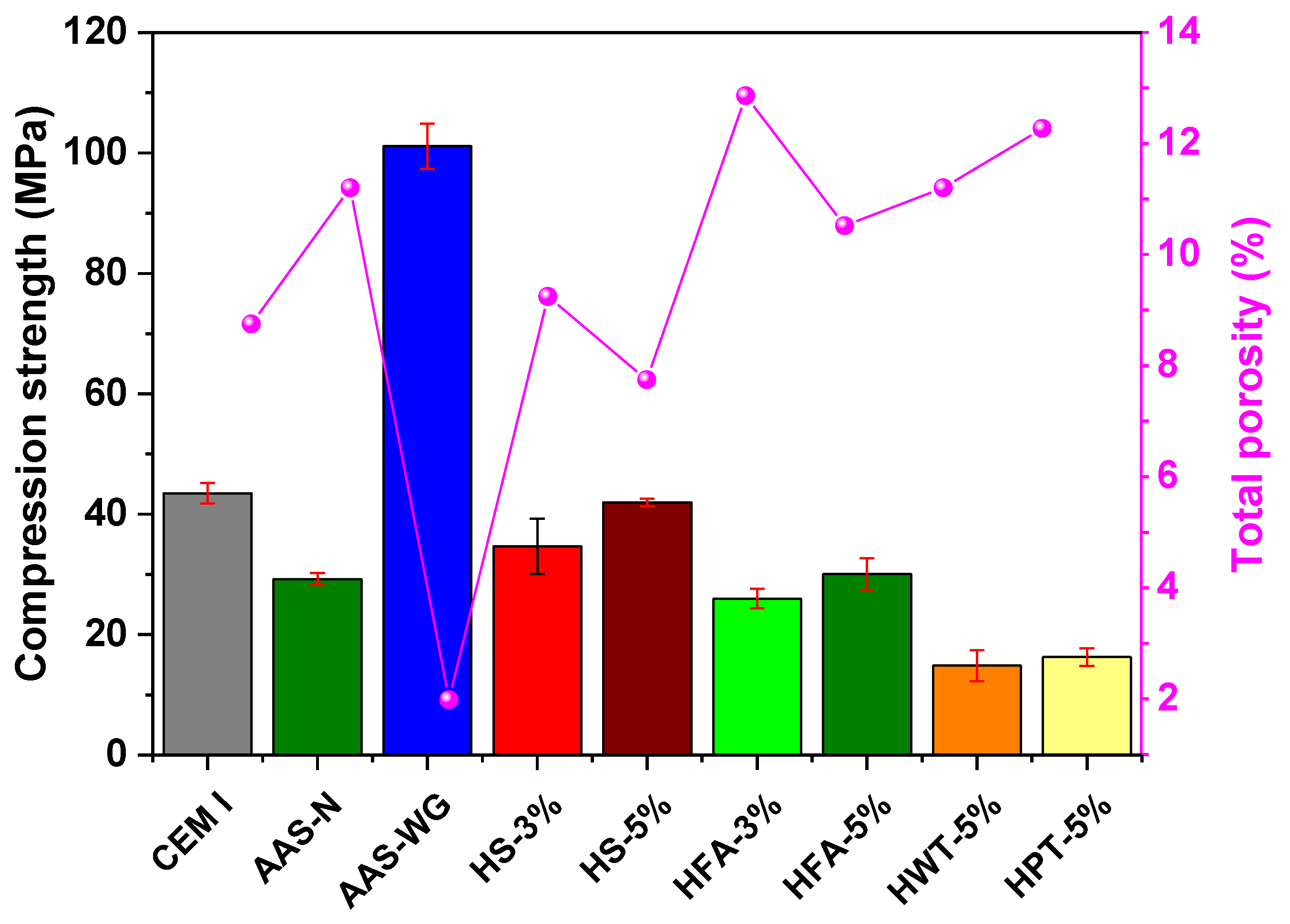

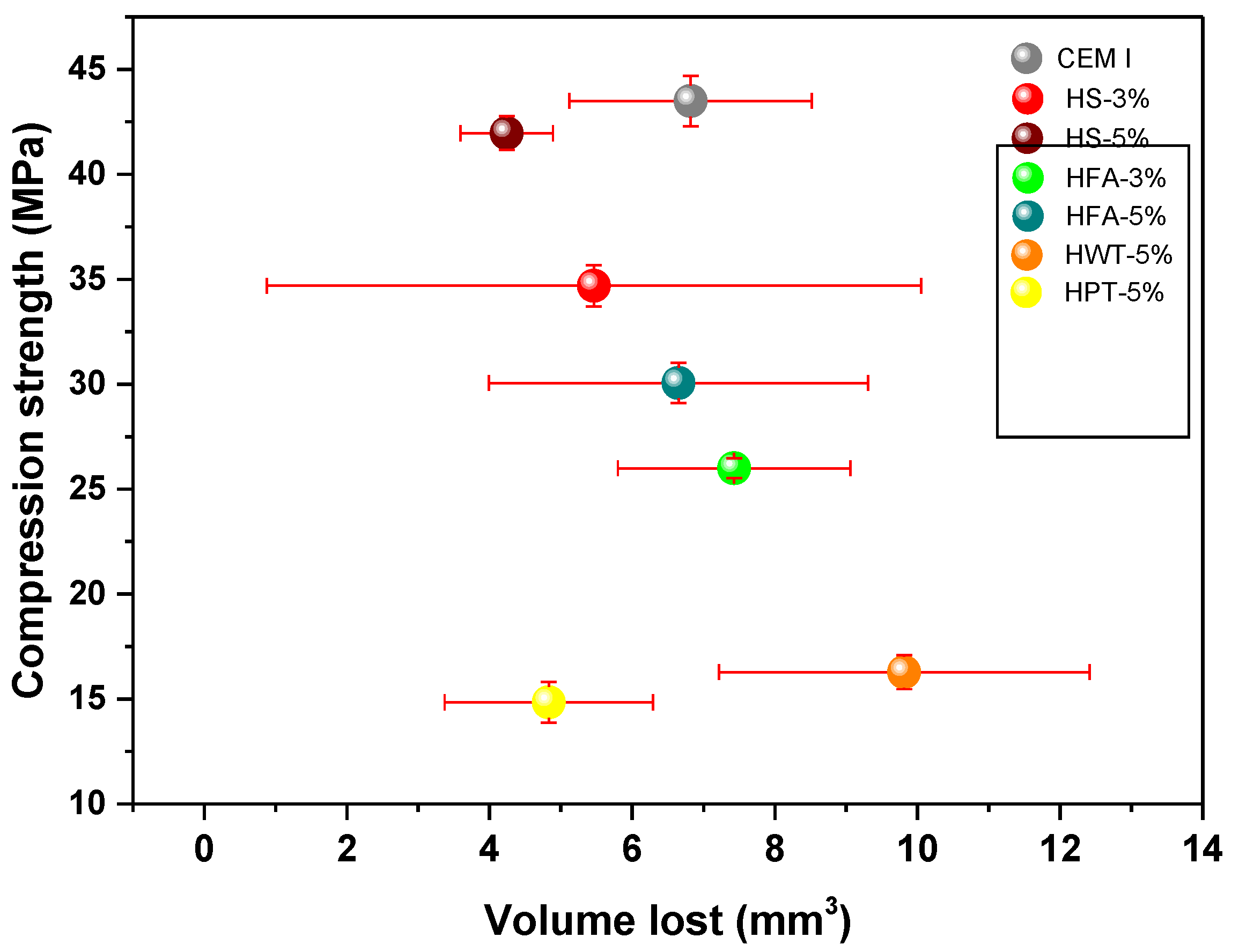

3.3. Mechanical Behavior and Total Porosity

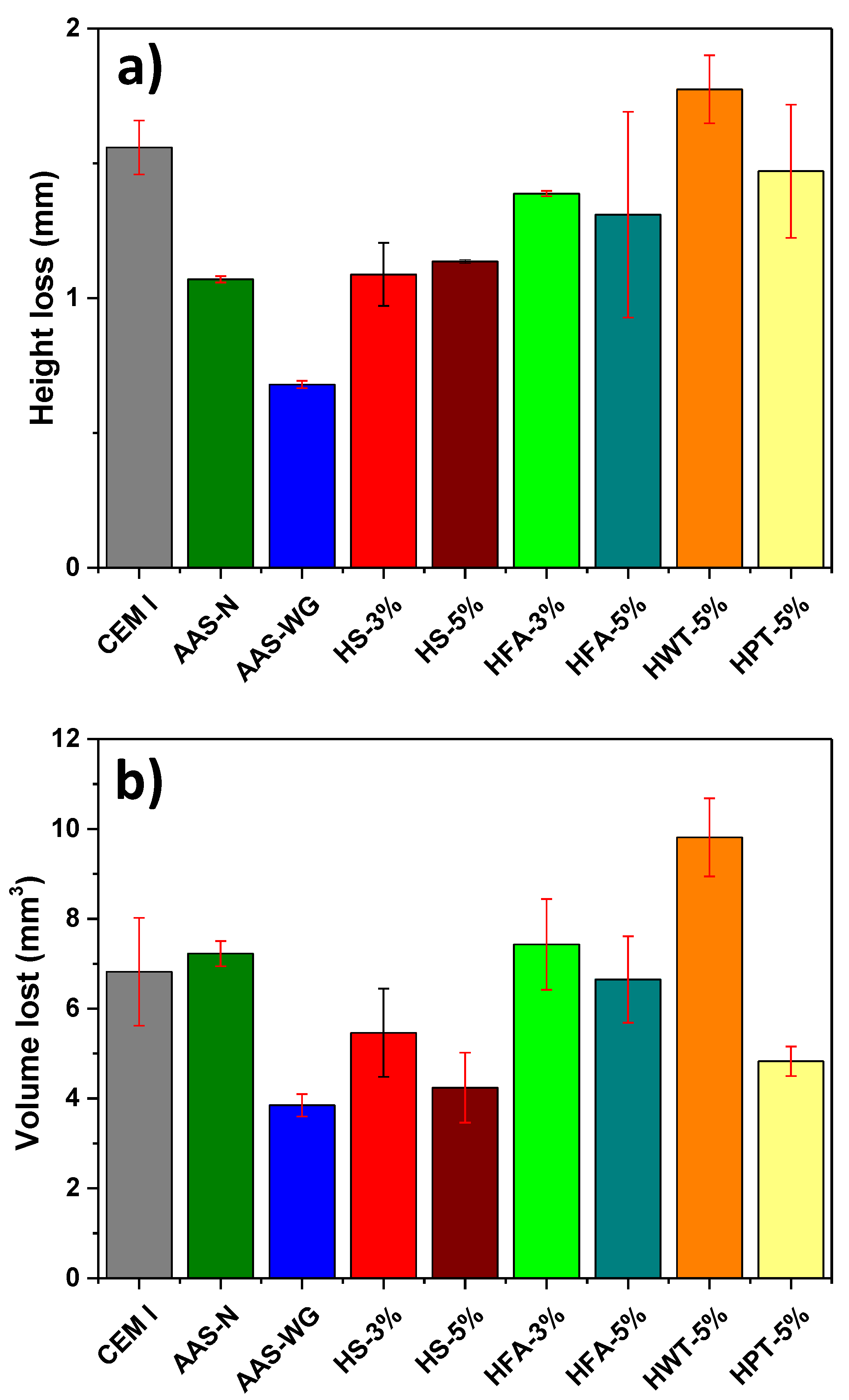

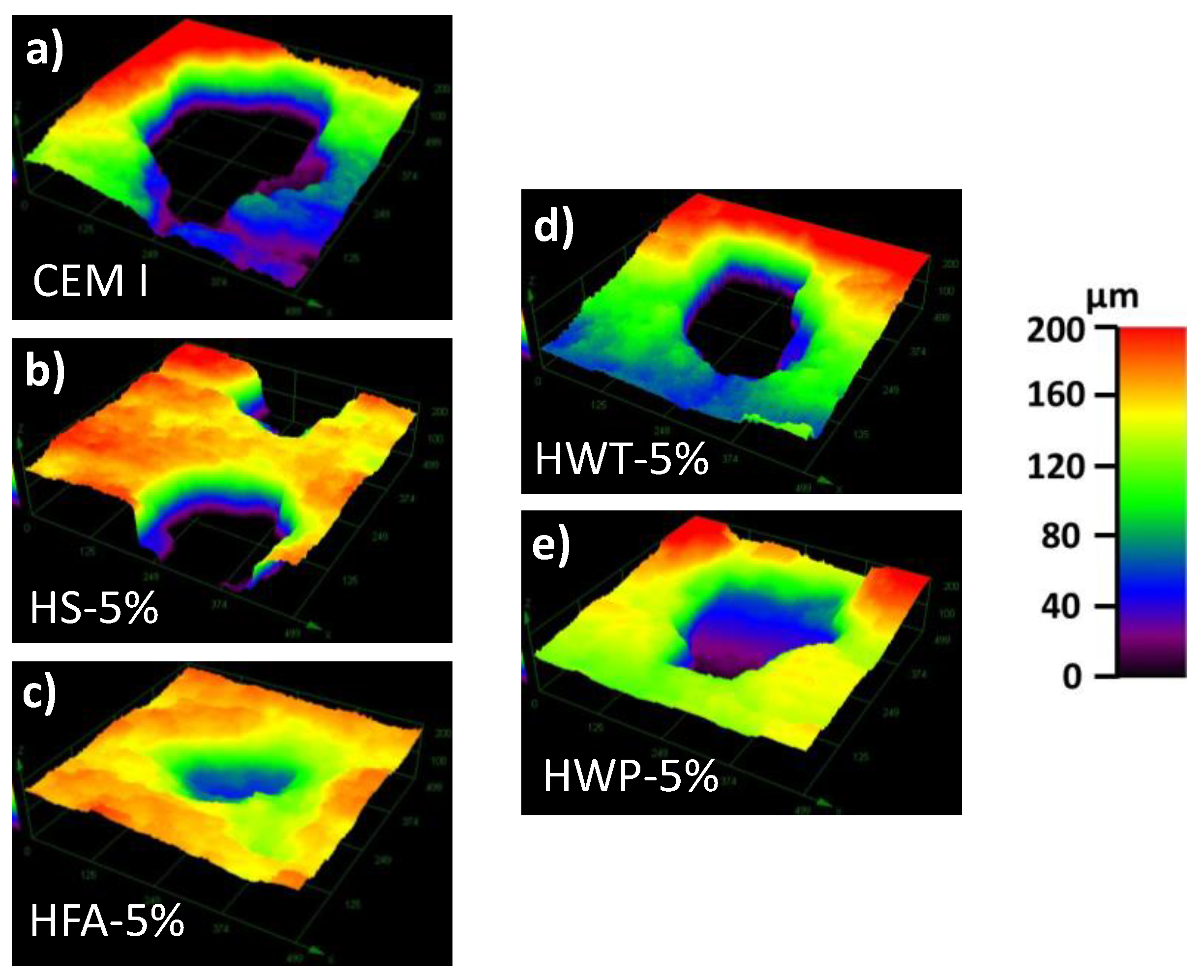

3.4. Durability to Wear: Böhme Test

4. Conclusions

- All the residues used in this work show pozzolanic behavior (SLS and Fratini tests) and have good capacities for the manufacturing of alternative cements. The residues from the ceramic industry are those with the greatest pozzolanic character.

- Silicate-activated slag systems (AAS-WG) present the best mechanical performance, but hybrid mortars present an important alternative, obtaining competitive results.

- Ceramic waste hybrid mortars show worse mechanical resistance results. It is necessary to increase the percentage of CEM I to improve the hydration process.

- Most of the alternative hybrid systems proposed showed an improvement in durability to abrasion compared to Portland cement (CEM I), highlighting the behavior of AAS-WG and HS-5%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2017, 1–52. [Google Scholar] [CrossRef]

- Bernal, E.; Edgar, D.; Burnes, B. Building Sustainability on Deep Values Through Mindfulness Nurturing. Ecol. Econ. 2018, 146, 645–657. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Wang, Y.S.; Dai, J.G. The effectiveness of different superplasticizers in ambient cured one-part alkali activated pastes. Cem. Concr. Compos. 2019, 97, 166–174. [Google Scholar] [CrossRef]

- Fořt, J.; Černý, R. Transition to circular economy in the construction industry: Environmental aspects of waste brick recycling scenarios. Waste Manag. 2020, 118, 510–520. [Google Scholar] [CrossRef] [PubMed]

- Açıkkalp, E.; Hepbasli, A.; Yucer, C.T.; Karakoc, T.H. Advanced life cycle integrated exergoeconomic analysis of building heating systems: An application and proposing new indices. J. Clean. Prod. 2018, 195, 851–860. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. La activación alcalina de diferentes aluminosilicatos como una alternativa al Cemento Portland: Cementos activados alcalinamente o geopolímeros. Rev. Ing. Constr. 2017, 32, 5–12. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Puertas, F.; Torres-Carrasco, M. Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterisation. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

- Mikhailova, O.; del Campo, A.; Rovnanik, P.; Fernández, J.F.; Torres-Carrasco, M. In situ characterization of main reaction products in alkali-activated slag materials by Confocal Raman Microscopy. Cem. Concr. Compos. 2019, 99, 32–39. [Google Scholar] [CrossRef]

- Nwankwo, C.O.; Bamigboye, G.O.; Davies, I.E.E.; Michaels, T.A. High volume Portland cement replacement: A review. Constr. Build. Mater. 2020, 260, 120445. [Google Scholar] [CrossRef]

- Pitarch, A.M.; Reig, L.; Tomás, A.E.; Forcada, G.; Soriano, L.; Borrachero, M.V.; Payá, J.; Monzó, J.M. Pozzolanic activity of tiles, bricks and ceramic sanitary-ware in eco-friendly Portland blended cements. J. Clean. Prod. 2021, 279. [Google Scholar] [CrossRef]

- Samadi, M.; Huseien, G.F.; Mohammadhosseini, H.; Lee, H.S.; Abdul Shukor Lim, N.H.; Tahir, M.M.; Alyousef, R. Waste ceramic as low cost and eco-friendly materials in the production of sustainable mortars. J. Clean. Prod. 2020, 266, 121825. [Google Scholar] [CrossRef]

- Enríquez, E.; Torres-Carrasco, M.; Cabrera, M.J.; Muñoz, D.; Fernández, J.F. Towards more sustainable building based on modified Portland cements through partial substitution by engineered feldspars. Constr. Build. Mater. 2020, 121334. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Enríquez, E.; Terrón-menoyo, L.; Cabrera, M.J.; Muñoz, D.; Fernández, J.F. Improvement of thermal efficiency in cement mortars by using synthetic feldspars. Constr. Build. Mater. 2020, 121279. [Google Scholar] [CrossRef]

- Bernal, S.A.; Mejía de Gutiérrez, R.; Ruiz, F.; Quiñones, H.; Provis, J.L. Desempeño a temperaturas altas de morteros y hormigones basados en mezclas de escoria/metacaolín activadas alcalinamente. Mater. Constr. 2012, 62, 471–488. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, L.; Yonggen, W. Freeze–thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Build. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Gifford, P.M.; Gillott, J.E. Freeze-thaw durability of activated blast furnace slag cement concrete. ACI Mater. J. 1996, 93, 242–245. [Google Scholar]

- Torres-Carrasco, M.; Tognonvi, M.; Tagnit-Hamou, A.; Puertas, F. Durability of Alkali-Activated Slag Concretes Prepared using waste glass as Alternative activator. ACI 2015, 112, 791–800. [Google Scholar]

- Shi, C.; Jiménez-Fernández, A.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Shagñay, S.; Velasco, F.; del Campo, A.; Torres-Carrasco, M. Wear behavior in pastes of alkali-activated materials: Influence of precursor and alkali solution. Tribol. Int. 2020, 147. [Google Scholar] [CrossRef]

- Lam, M.N.T.; Le, D.H.; Jaritngam, S. Compressive strength and durability properties of roller-compacted concrete pavement containing electric arc furnace slag aggregate and fly ash. Constr. Build. Mater. 2018, 191, 912–922. [Google Scholar] [CrossRef]

- Asociación Española de Normalización y Certificación, EN 196-5. Method of Testing Cement. Part 5: Pozzolanicity Test for Pozzolanic Cement; AENOR: Madrid, Spain, 2011. [Google Scholar]

- Asensio, E.; Medina, C.; Frías, M.; de Rojas, M.I.S. Characterization of Ceramic-Based Construction and Demolition Waste: Use as Pozzolan in Cements. J. Am. Ceram. Soc. 2016, 99, 4121–4127. [Google Scholar] [CrossRef]

- UNE-EN 196-5. Métodos de Ensayo de Cementos. Ensayo de Puzolanicidad Para Los Cementos Puzolánicos; AENOR: Madrid, Spain, 2011. [Google Scholar]

- En, N.E.; Une-en, N. Española; AENOR: Madrid, Spain, 2016. [Google Scholar]

- Torres-Carrasco, M.; Campo, A.; De Rubia, M.A.; Reyes, E.; Moragues, A.; Fernández, J.F. New insights in weathering analysis of anhydrous cements by using high spectral and spatial resolution Confocal Raman Microscopy. Cem. Concr. Res. 2017, 100, 119–128. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; del Campo, A.; de la Rubia, M.A.; Reyes, E.; Moragues, A.; Fernández, J.F. In situ full view of the Portland cement hydration by confocal Raman microscopy. J. Raman Spectrosc. 2019, 50, 720–730. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass as a precursor in alkaline activation: Chemical process and hydration products. Constr. Build. Mater. 2017, 139, 342–354. [Google Scholar] [CrossRef]

- Puertas, F.; Torres-Carrasco, M.; Alonso, M.M. Reuse of urban and industrial waste glass as novel activator for alkali-activated slag cement pastes: A case study. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Woodhead: Cambrige, UK, 2014; pp. 75–110. ISBN 9781782422884. [Google Scholar]

- Karahan, O.; Yakupoğlu, A. Resistance of alkali-activated slag mortar to abrasion and fire. Adv. Cem. Res. 2011, 23, 289–297. [Google Scholar] [CrossRef]

- Yetgin, S.; Çavdar, A. Abrasion Resistance of Cement Mortar with Different Pozzolanic Compositions and Matrices. J. Mater. Civ. Eng. 2011, 23, 5533. [Google Scholar] [CrossRef]

- Bilir, T.; Yüksel, I.; Topcu, I.B.; Gencel, O. Effects of bottom ash and granulated blast furnace slag as fine aggregate on abrasion resistance of concrete. Sci. Eng. Compos. Mater. 2017, 24, 261–269. [Google Scholar] [CrossRef]

- Sevinç, A.H.; Durgun, M.Y.; Eken, M. A Taguchi approach for investigating the engineering properties of concretes incorporating barite, colemanite, basaltic pumice and ground blast furnace slag. Constr. Build. Mater. 2017, 135, 343–351. [Google Scholar] [CrossRef]

| wt % | CaO | SiO2 | Al2O3 | MgO | Fe2O3 | SO3 | K2O | Na2O | LOI * |

|---|---|---|---|---|---|---|---|---|---|

| CEM I | 61.8 | 21.5 | 6.6 | <0.01 | 2.5 | 5.9 | 1.1 | <0.014 | 2.35 |

| Slag | 38.0 | 35.0 | 11.7 | 12.0 | 0.2 | 1.9 | 0.3 | <0.014 | 2.10 |

| Fly ash | 4.1 | 46.6 | 28.1 | 0.7 | 17.0 | 1.1 | 1.1 | <0.014 | 1.00 |

| Porcelain waste | 2.5 | 64.7 | 21.2 | 0.5 | 2.3 | 0.05 | 1.2 | 8.5 | 1.00 |

| Porous waste | 8.7 | 62.5 | 22.7 | 0.3 | 2.6 | 0.3 | 1.8 | <0.014 | 2.00 |

| CEM I | Slag | Fly Ash | Porous Waste | Porcelain Waste | |

|---|---|---|---|---|---|

| D10 (µm) | 2.9 | 3.8 | 0.1 | 0.6 | 2.5 |

| D50 (µm) | 19.6 | 13.2 | 6.5 | 10.7 | 11.5 |

| D90 (µm) | 65.3 | 34.9 | 35.4 | 78.9 | 95.8 |

| System | Name | Waste | wt % of CEM I | wt % of Waste | Activator | L/S |

|---|---|---|---|---|---|---|

| Portland cement | CEM I | - | 100 | 0 | H2O | 0.50 |

| Alkali-activated materials | AAS-N | Slag | 0 | 100 | 4M NaOH | 0.50 |

| AAS-WG | Slag | 0 | 100 | Waterglass | 0.50 | |

| Hybrid materials | HFA-3% | Fly ash | 20 | 80 | H2O + 3%Na2SO4 | 0.37 |

| HFA-5% | Fly ash | 20 | 80 | H2O + 5%Na2SO4 | 0.37 | |

| HS-3% | Slag | 20 | 80 | H2O + 3%Na2SO4 | 0.42 | |

| HS-5% | Slag | 20 | 80 | H2O + 5%Na2SO4 | 0.42 | |

| HWT-5% | Porous waste | 20 | 80 | H2O + 5%Na2SO4 | 0.42 | |

| HPT-5% | Porcelain waste | 20 | 80 | H2O + 5%Na2SO4 | 0.37 |

| System | Density (g/cm3) |

|---|---|

| CEM I | 2.51 ± 0.0066 |

| AAS-N | 2.49 ± 0.0021 |

| AAS-WG | 2.52 ± 0.0021 |

| HS-3% | 2.56 ± 0.0072 |

| HS-5% | 2.54 ± 0.0051 |

| HFA-3% | 2.64 ± 0.0025 |

| HFA-5% | 2.64 ± 0.0069 |

| HWT-5% | 2.56 ± 0.0075 |

| HPT-5% | 2.51 ± 0.0012 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shagñay, S.; Ramón, L.; Fernández-Álvarez, M.; Bautista, A.; Velasco, F.; Torres-Carrasco, M. Eco-Efficient Hybrid Cements: Pozzolanic, Mechanical and Abrasion Properties. Appl. Sci. 2020, 10, 8986. https://doi.org/10.3390/app10248986

Shagñay S, Ramón L, Fernández-Álvarez M, Bautista A, Velasco F, Torres-Carrasco M. Eco-Efficient Hybrid Cements: Pozzolanic, Mechanical and Abrasion Properties. Applied Sciences. 2020; 10(24):8986. https://doi.org/10.3390/app10248986

Chicago/Turabian StyleShagñay, Segundo, Leticia Ramón, María Fernández-Álvarez, Asunción Bautista, Francisco Velasco, and Manuel Torres-Carrasco. 2020. "Eco-Efficient Hybrid Cements: Pozzolanic, Mechanical and Abrasion Properties" Applied Sciences 10, no. 24: 8986. https://doi.org/10.3390/app10248986

APA StyleShagñay, S., Ramón, L., Fernández-Álvarez, M., Bautista, A., Velasco, F., & Torres-Carrasco, M. (2020). Eco-Efficient Hybrid Cements: Pozzolanic, Mechanical and Abrasion Properties. Applied Sciences, 10(24), 8986. https://doi.org/10.3390/app10248986