Dynamic Response of Drill Floor Considering Propagation of Blast Pressure Subsequent to Blowout

Abstract

Featured Application

Abstract

1. Introduction

2. Drill Floor Design and Risk Assessment for Gas Explosion

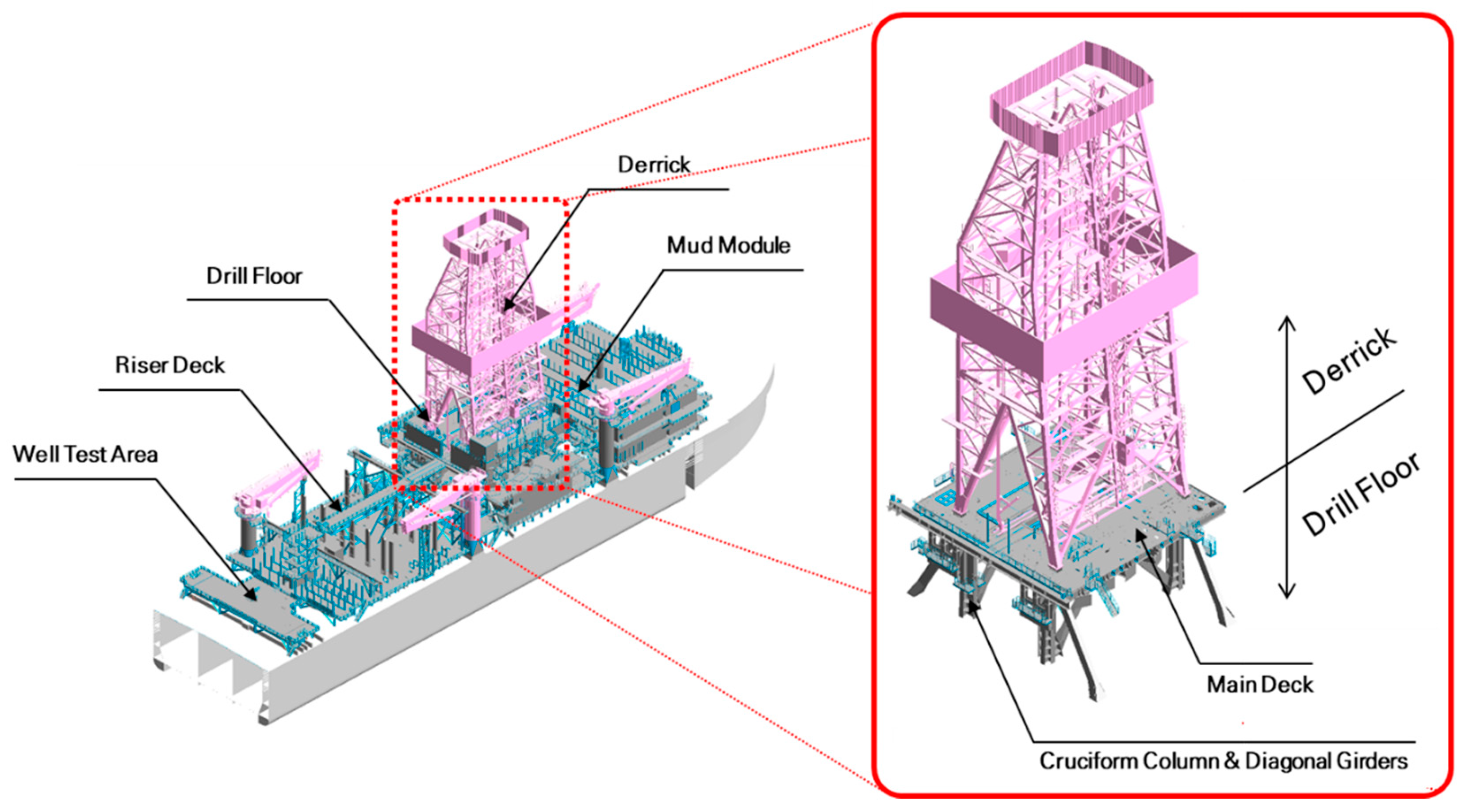

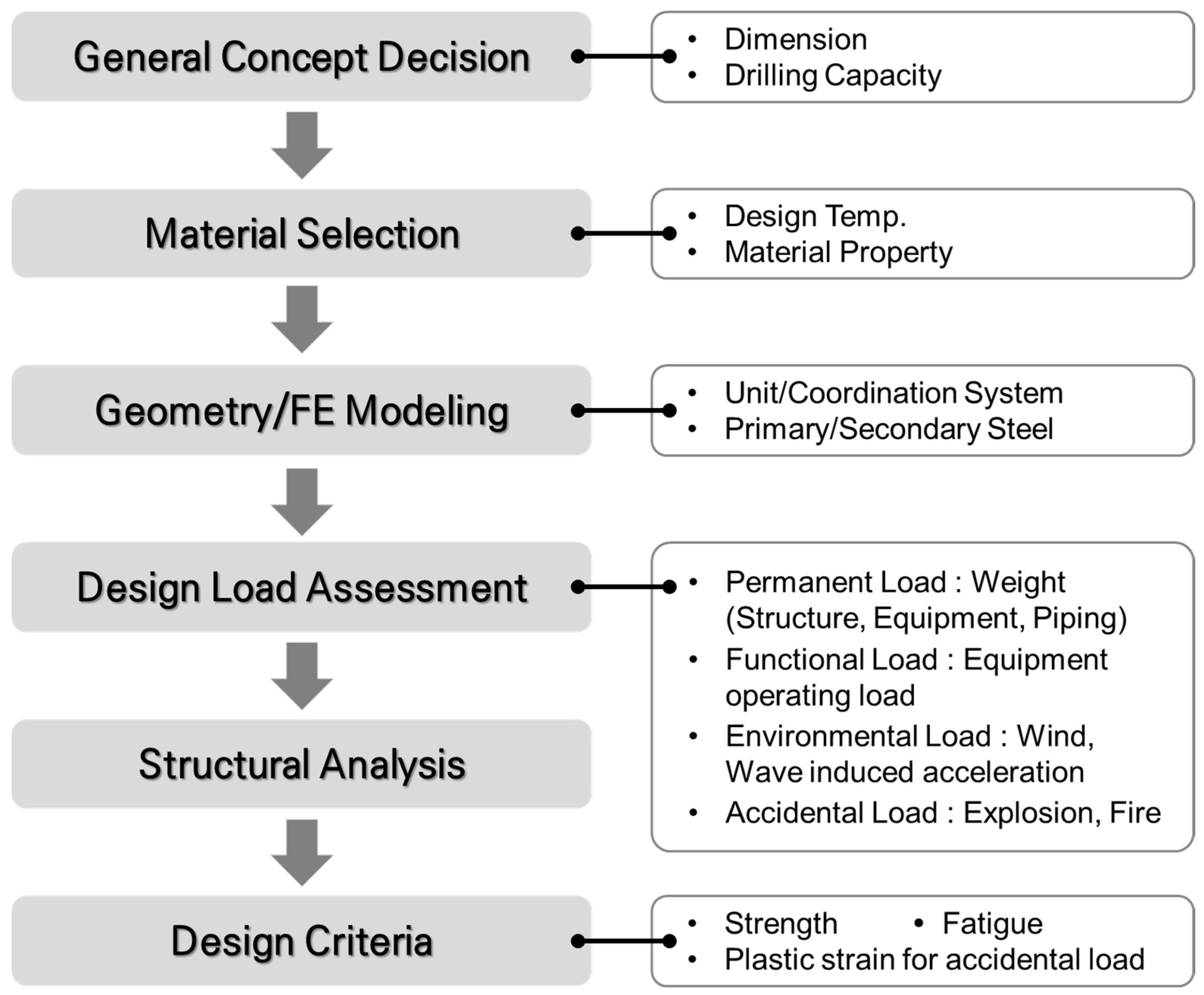

2.1. General Information and Design Procedure for Drill Floor

2.2. Gas Explosion Risk Assessment and Management

2.3. The Contribution of This Study to Drill Floor Design for Blast Load

3. Blowout Explosion Analysis

3.1. FLACS Program

- Mass;

- Momentum;

- Enthalpy;

- Mass fraction of fuel (or products);

- Mixture fraction;

- Turbulent kinetic energy;

- Dissipation rate of turbulent kinetic energy.

3.2. Major Assumptions for Simulation

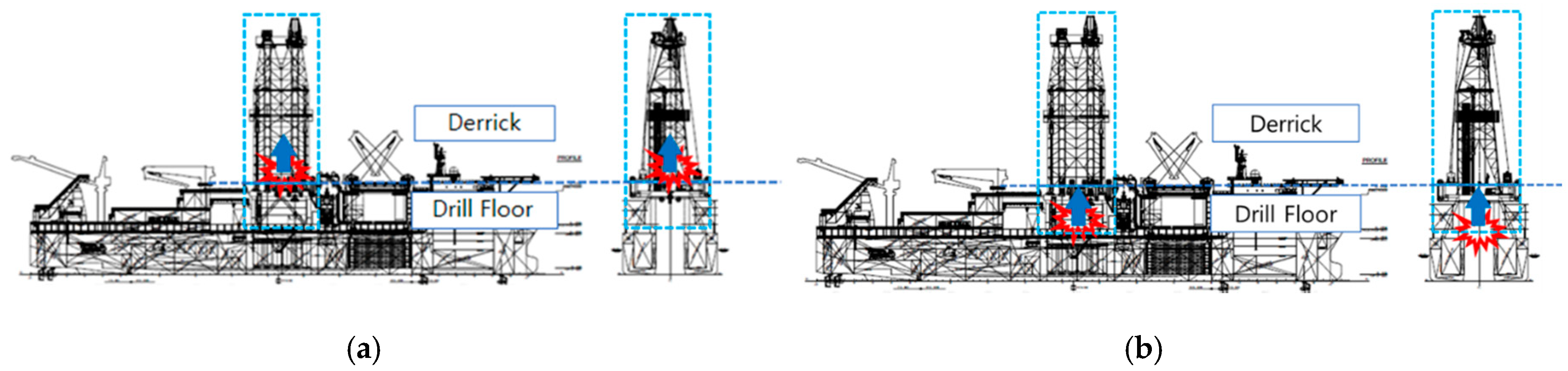

3.3. Explosion Cases According to Blowout Locations

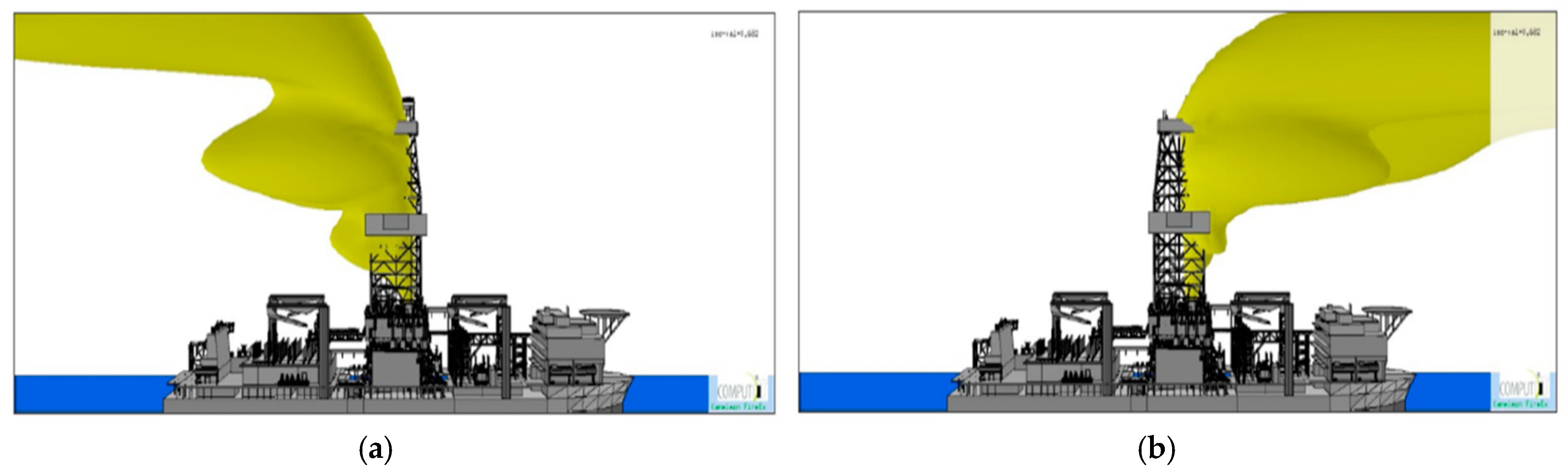

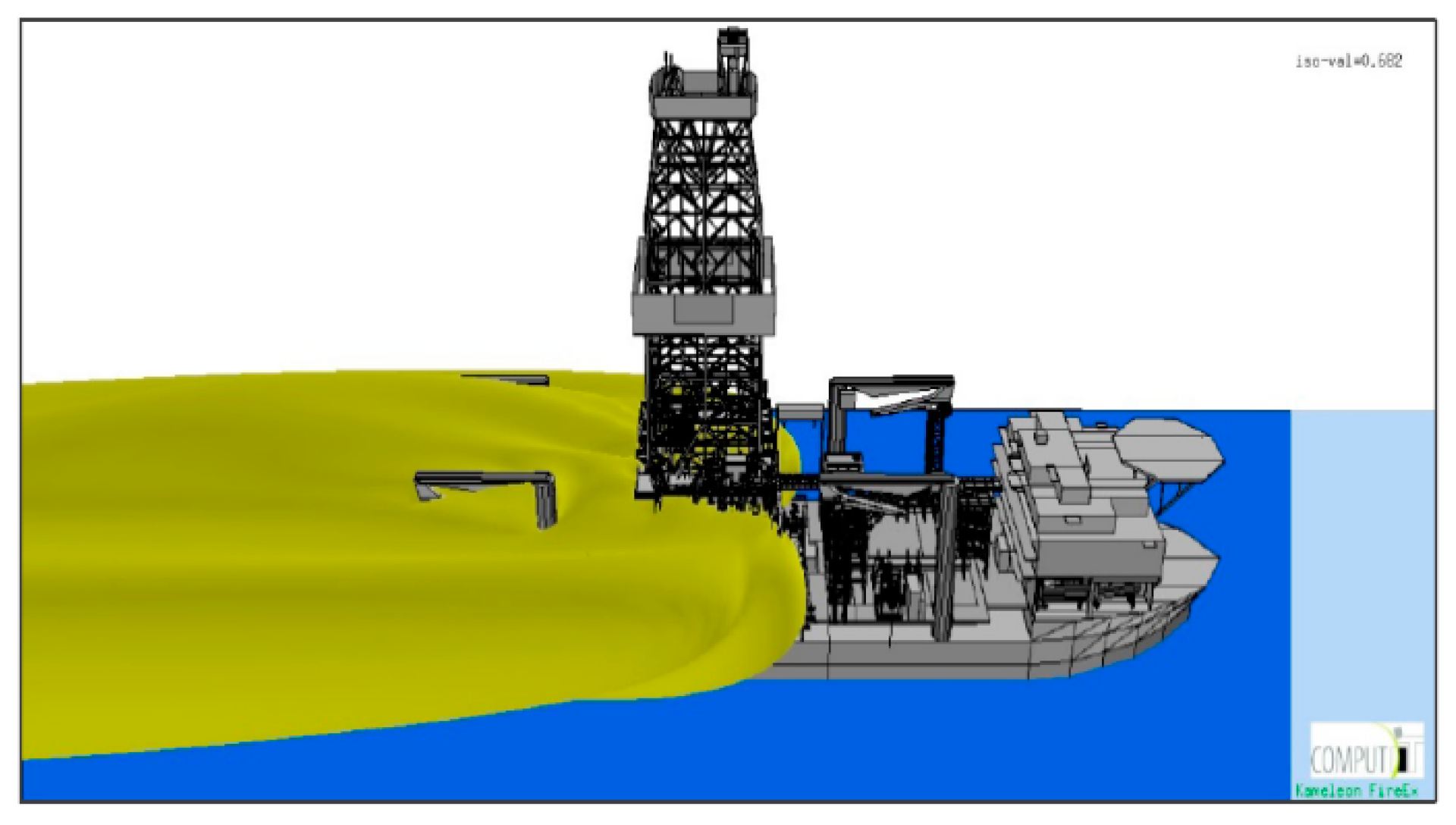

3.4. Dispersion and Gas Cloud after Blowout

4. Blast Pressure Selection from Explosion Analysis Results

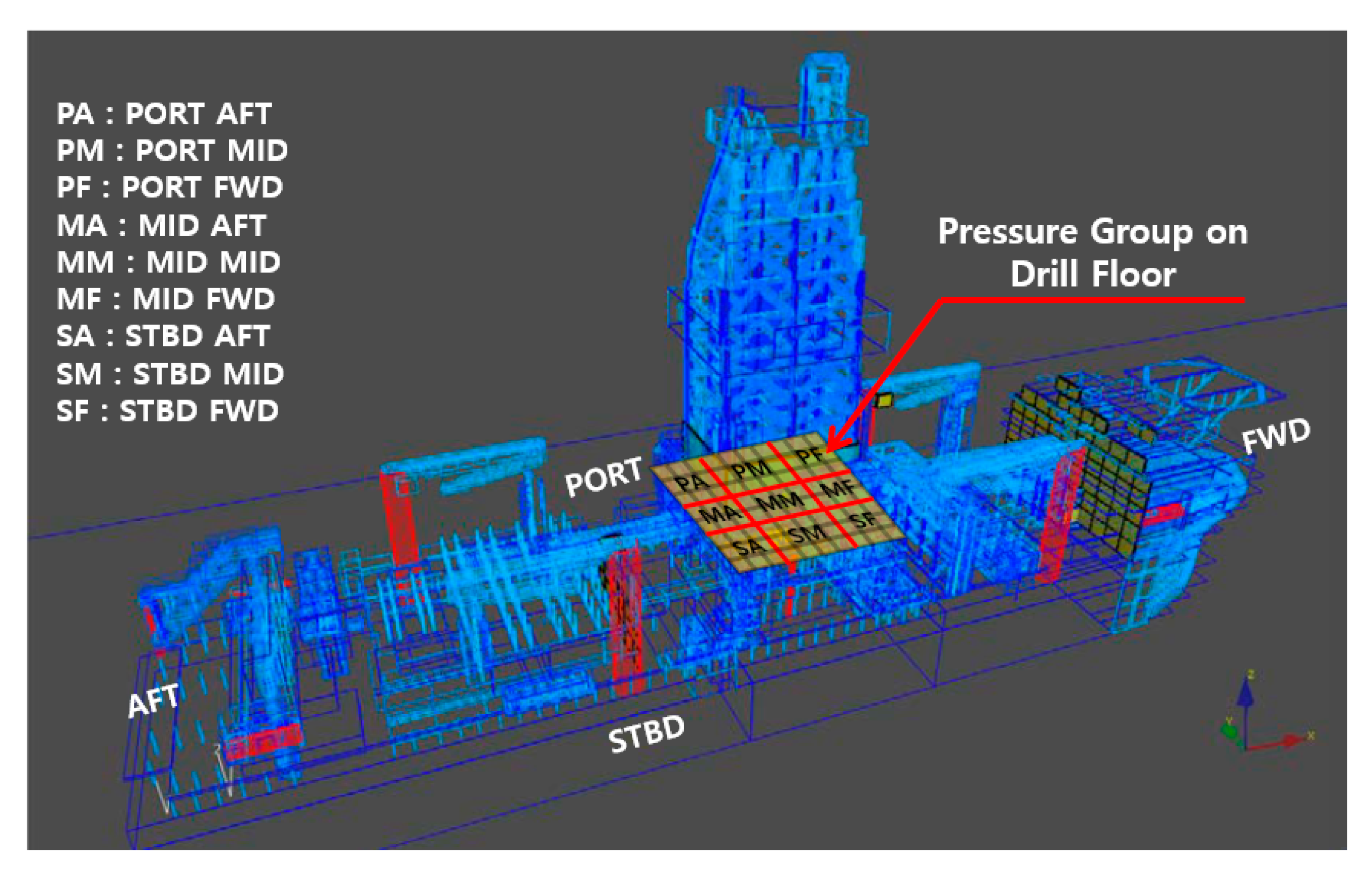

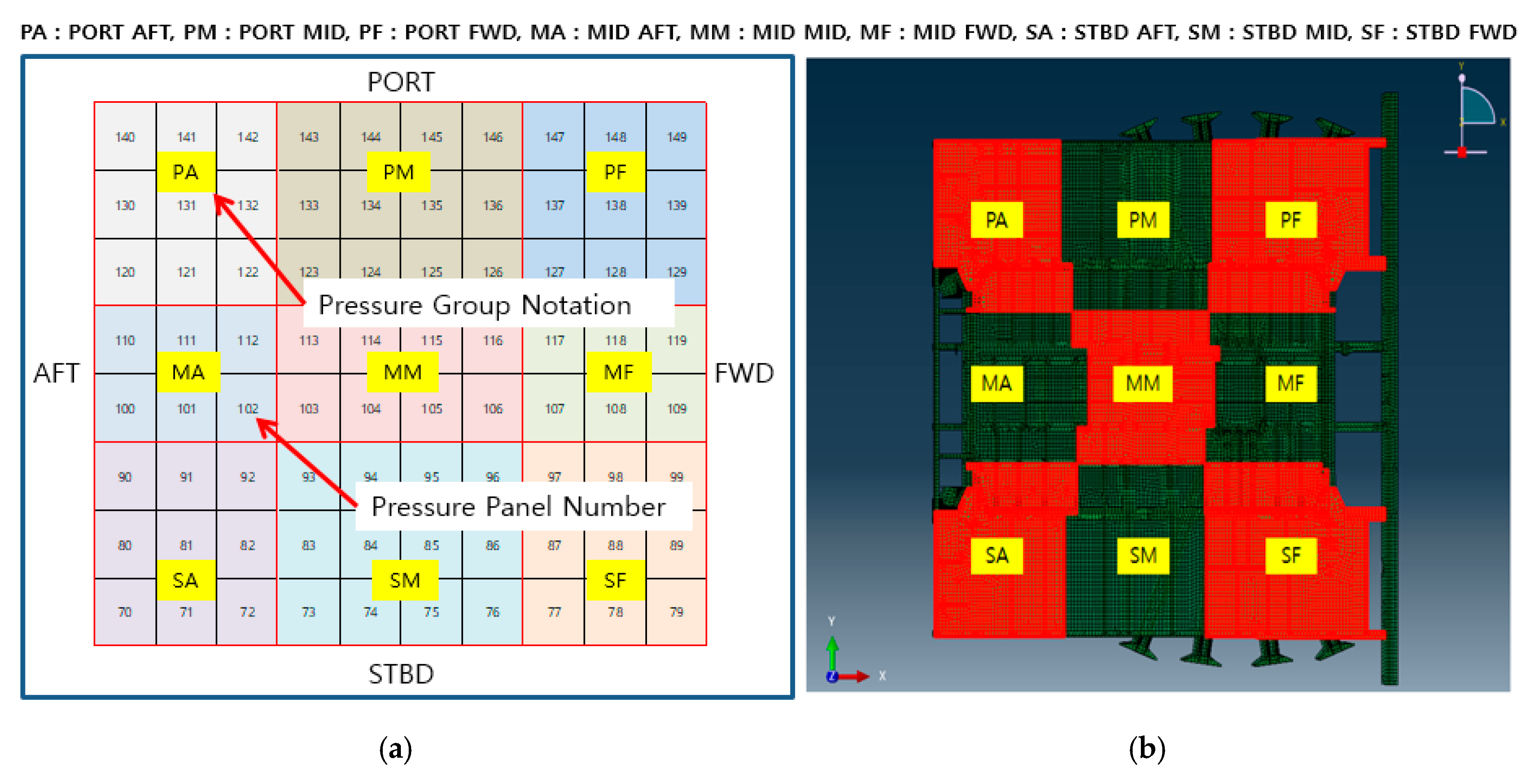

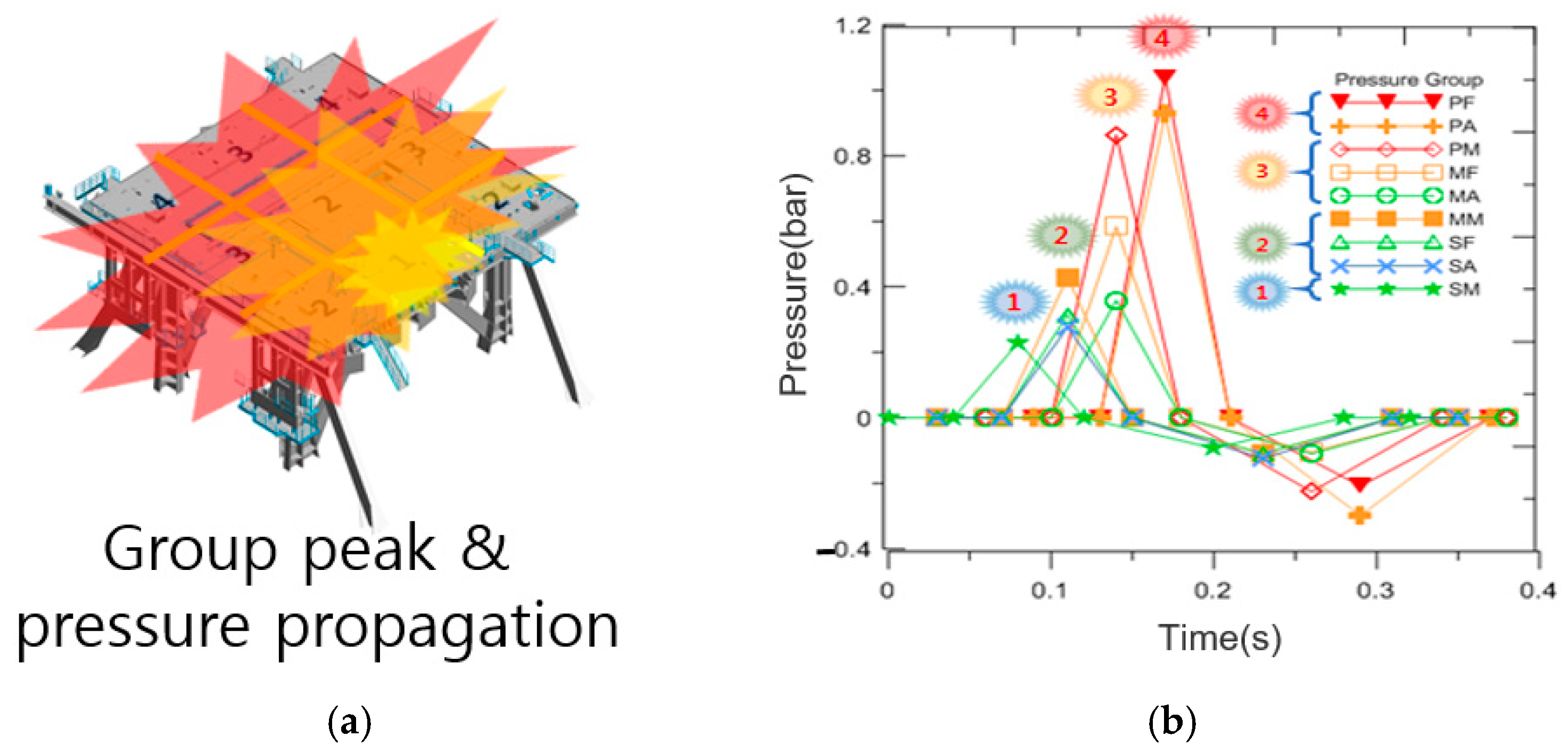

4.1. Explosion Model and Pressure Measurement and Grouping

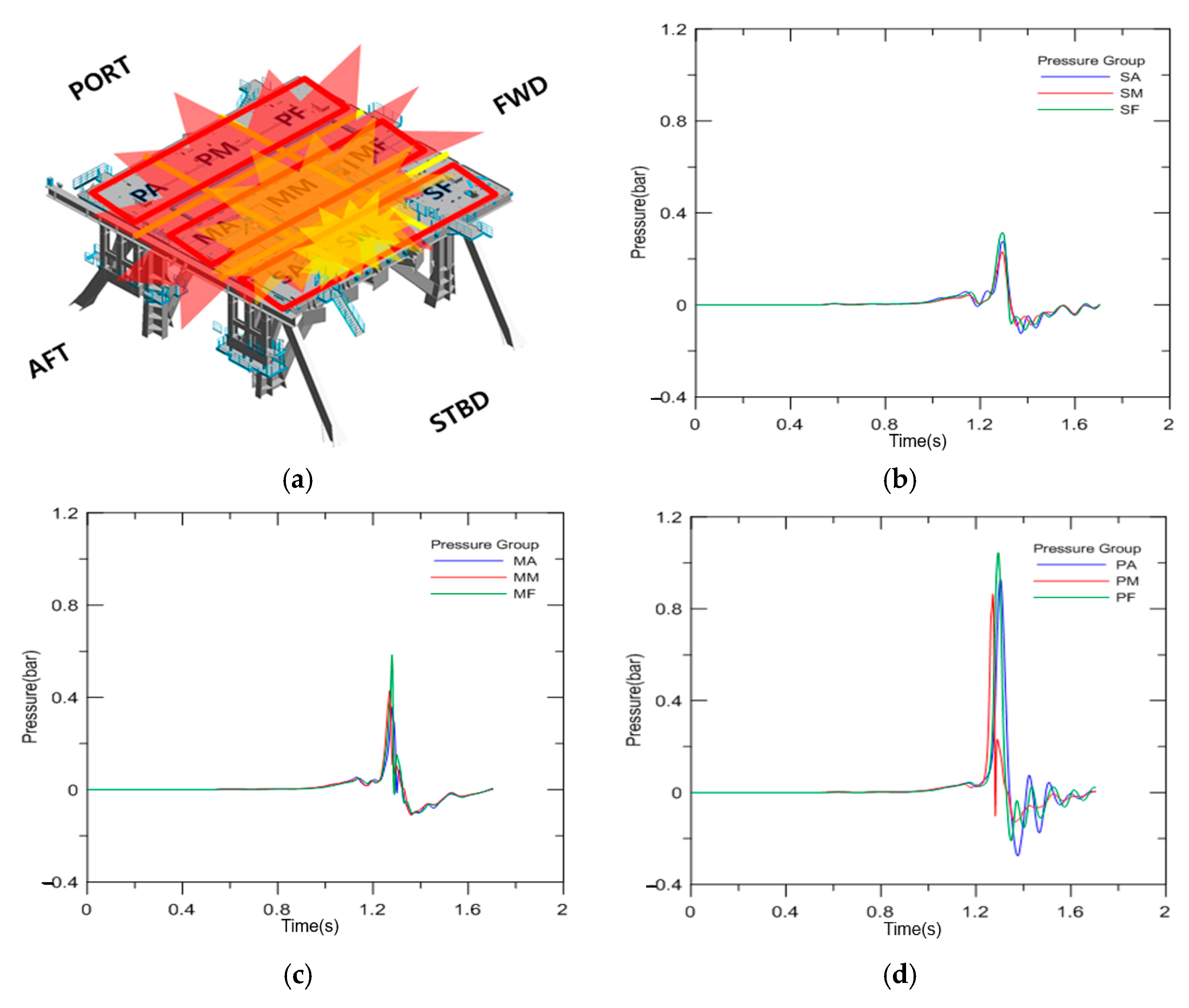

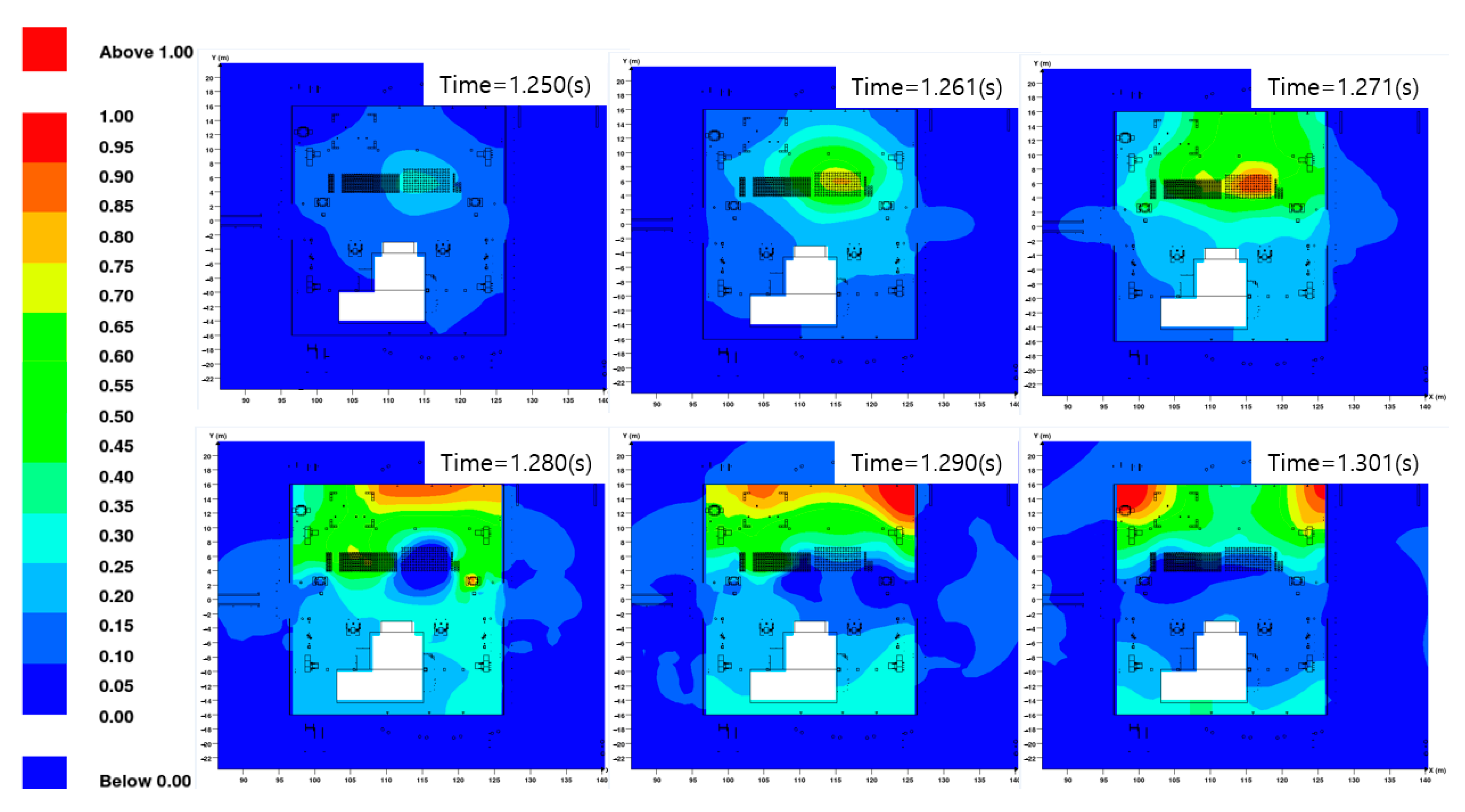

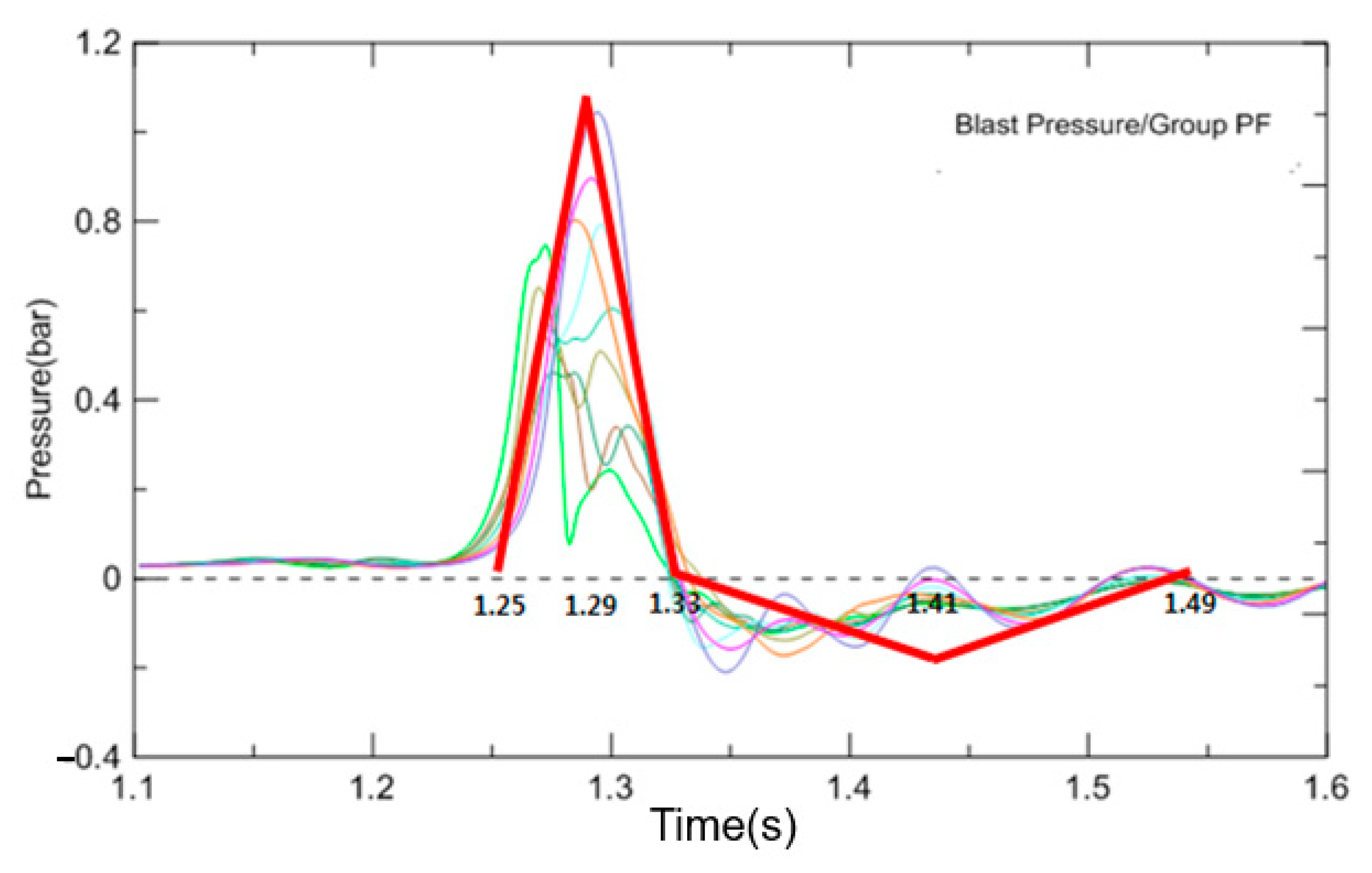

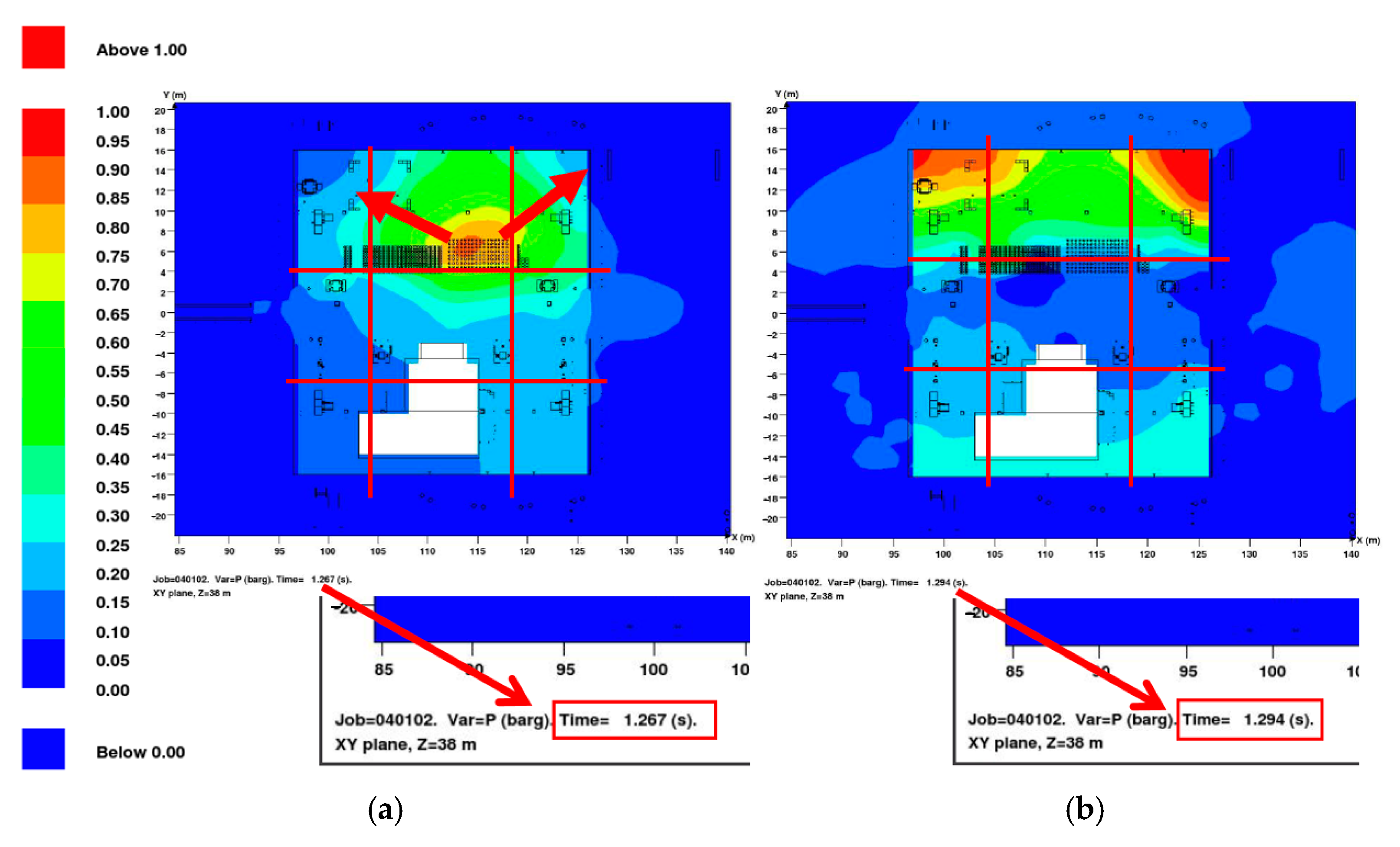

4.2. Blast Pressure Propagation Features

4.3. New Methodology for Blast Pressure Application

4.3.1. Idealization of Blast Pressure Profile

4.3.2. Assessment of Blast Pressure Propagation Time

4.3.3. Blast Pressure Application Considering Propagation Features

5. Structural Analysis

5.1. Implementation to Finite Element Analysis

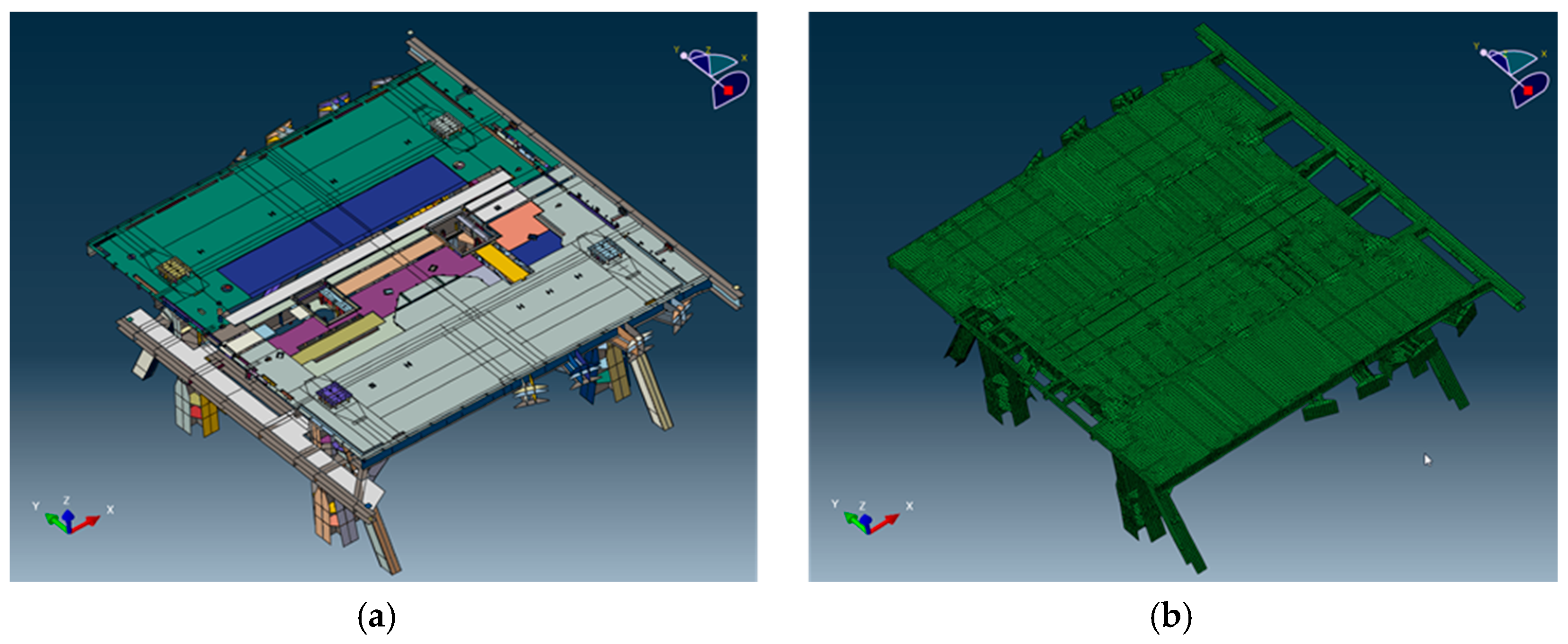

5.1.1. Finite Element Model

5.1.2. Material Properties and Behavior

5.1.3. Strain Rate Effect

5.1.4. Structural Design Criteria against Explosion

5.1.5. Load Cases According to Explosion Scenario

5.2. Simulation Results and Discussion

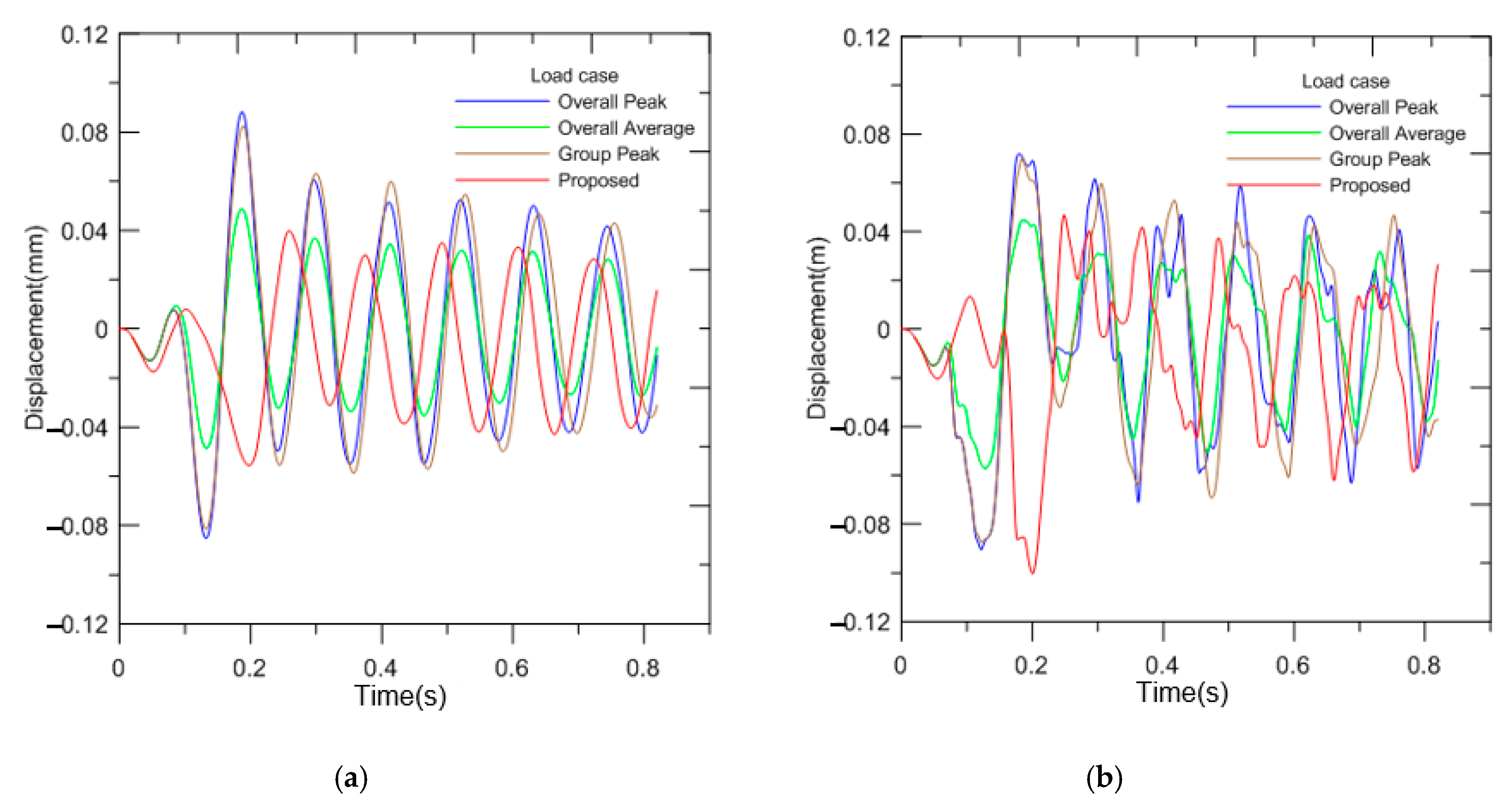

5.2.1. Displacement of Frame and Plate of Drill Floor

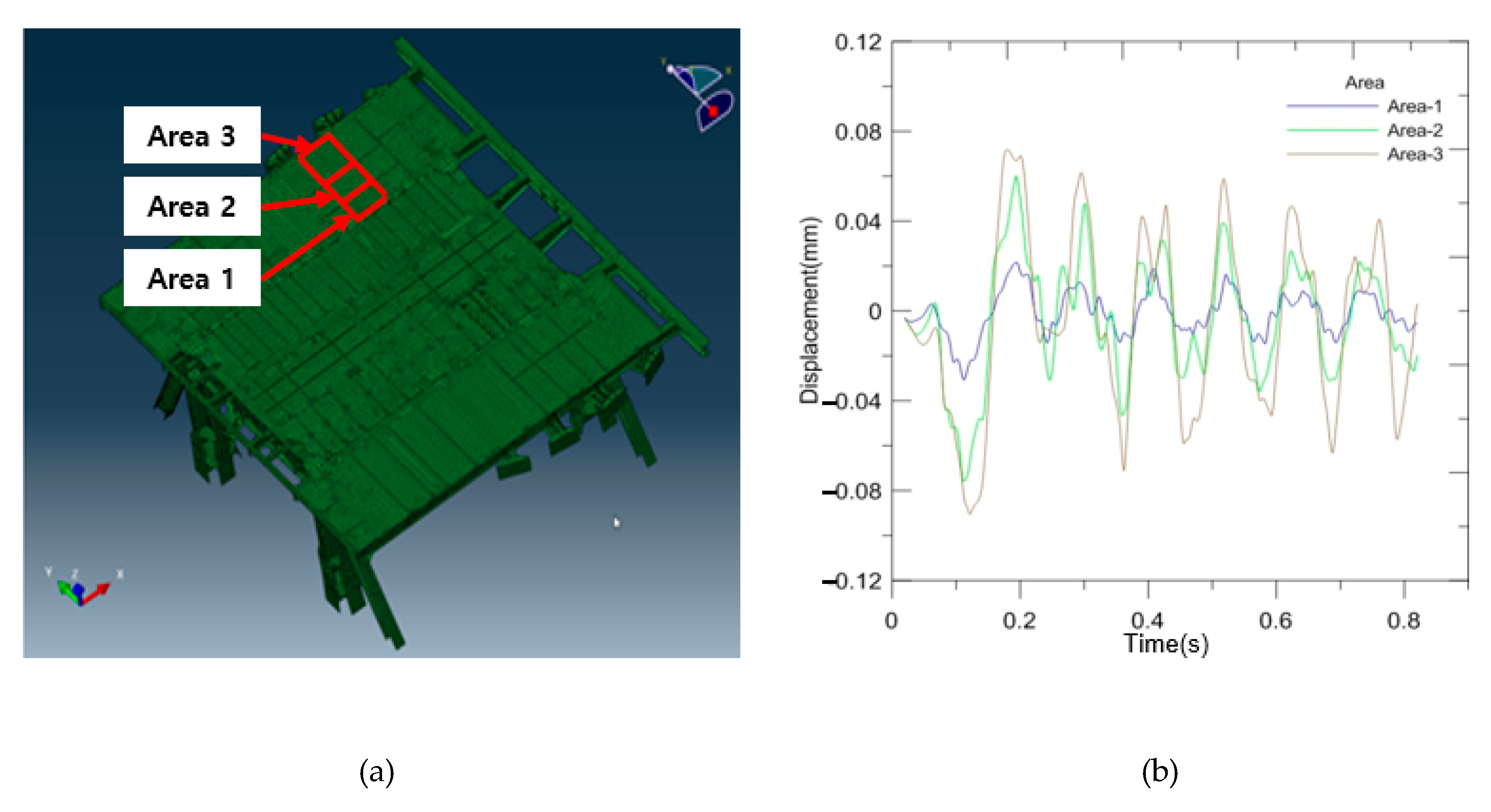

5.2.2. Displacement and Area of Plate

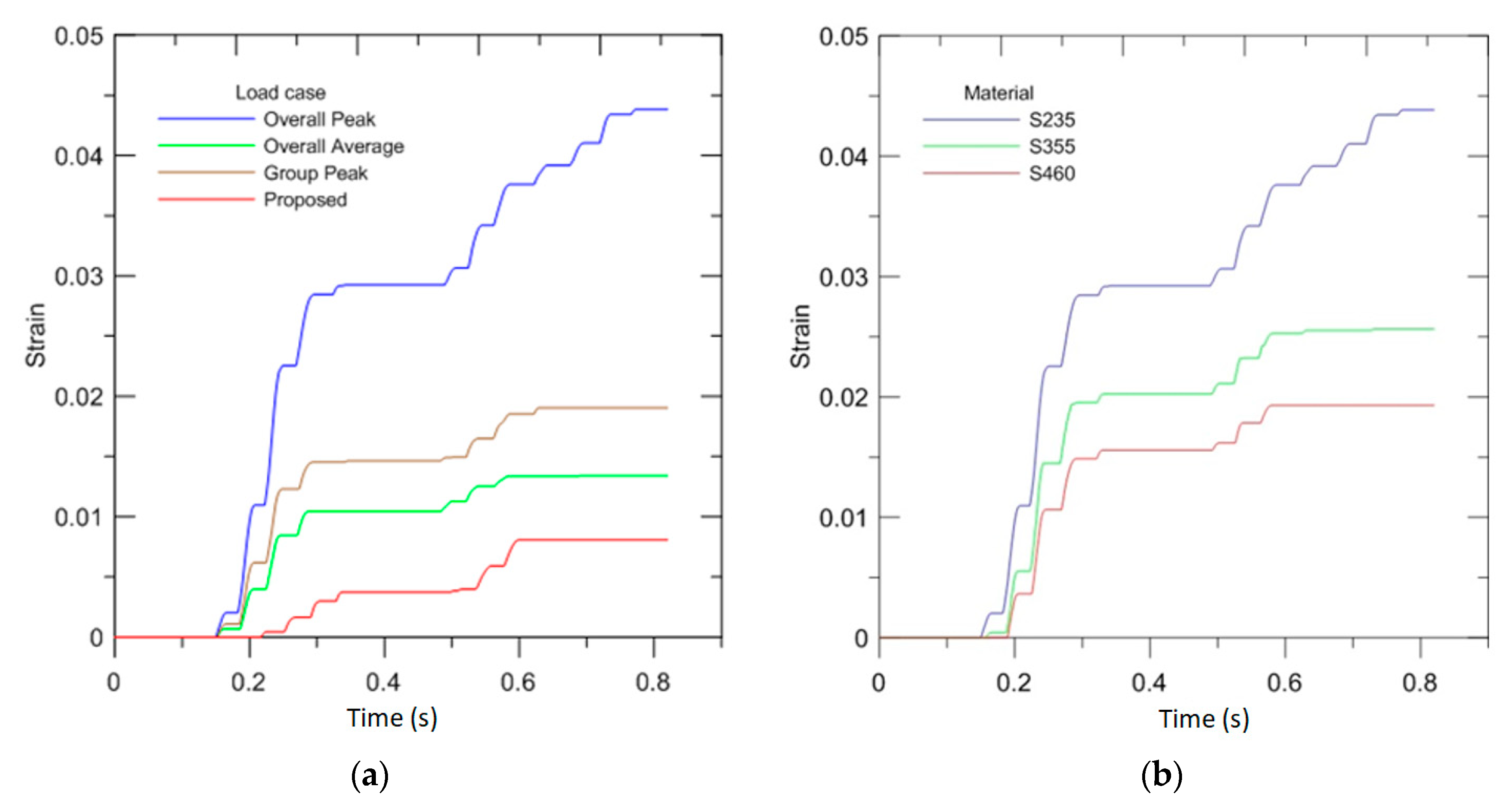

5.2.3. Strain of Drill Floor Frame for Applied Pressure

6. Conclusions

- The characteristics of blast pressure propagation after ignition in gas dispersion due to blowout are described. The blast pressure value increases as the explosion propagates the gas volume within the drill floor.

- This study proposed an improved grouped blast pressure reflecting propagation, which captures the phenomenon of explosion in a more realistic manner. The maximum single method is a very conservative approach and could result in a heavy structure. The total average method is non-conservative and could therefore fail to catch higher pressure than the average. A group method is developed to make up for the above two methods, but it does not fully reflect the nature of explosion. The method proposed in this study captures the nature of the explosion and estimates the blast pressure accurately, therefore contributes to a safer and lighter blast resistant design for offshore facility structures, which are very sensitive to weight due to buoyancy and payload.

- Different grades of steels generally used in offshore structures are introduced and compared in terms of exposure to blast pressure. As the material for blast resistance, a low tensile material is considered favorable since it has sufficient ductility than high tensile ones. However, this study shows that high tensile material, which is widely used in offshore facilities from the viewpoint of strength, has advantage in strain as well.

Author Contributions

Funding

Conflicts of Interest

References

- Dan, S.; Lee, C.J.; Park, J.; Shin, D.; Yoon, E.S. Quantitative risk analysis of fire and explosion on the top-side LNG-liquefaction process of LNG-FPSO. Process Saf. Environ. Prot. 2014, 92, 430–441. [Google Scholar] [CrossRef]

- Suardin, J.A.; McPhate, A.J.; Sipkema, A.; Childs, M.; Mannan, M.S. Fire and explosion assessment on oil and gas floating production storage offloading (FPSO): An effective screening and comparison tool. Process Saf. Environ. Prot. 2009, 87, 147–160. [Google Scholar] [CrossRef]

- Jin, Y.; Jang, B.-S. Probabilistic fire risk analysis and structural safety assessment of FPSO topside module. Ocean Eng. 2015, 104, 725–737. [Google Scholar] [CrossRef]

- Bai, Y.; Jin, W.-L. Explosion and Fire Response Analysis for FPSO. In Marine Structural Design; Bai, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 907–938. [Google Scholar] [CrossRef]

- Gupta, S.; Chan, S. A CFD based explosion risk analysis methodology using time varying release rates in dispersion simulations. J. Loss Prev. Process Ind. 2016, 39, 59–67. [Google Scholar] [CrossRef]

- Dadashzadeh, M.; Abbassi, R.; Khan, F.; Hawboldt, K. Explosion modeling and analysis of BP Deepwater Horizon accident. Saf. Sci. 2013, 57, 150–160. [Google Scholar] [CrossRef]

- Skogdalen, J.E.; Vinnem, J.E. Quantitative risk analysis of oil and gas drilling, using Deepwater Horizon as case study. Reliab. Eng. Syst. Saf. 2012, 100, 58–66. [Google Scholar] [CrossRef]

- Xue, L.; Fan, J.; Rausand, M.; Zhang, L. A safety barrier-based accident model for offshore drilling blowouts. J. Loss Prev. Process. Ind. 2013, 26, 164–171. [Google Scholar] [CrossRef]

- Sohaimi, A.S.M.; Risby, M.S.; Ishak, S.A.F.M.; Khalis, S.; Norazman, M.N.; Ariffin, I.; Yusof, M.A. Using Computational Fluid Dynamics (CFD) for Blast Wave Propagation under Structure. Procedia Comput. Sci. 2016, 80, 1202–1211. [Google Scholar] [CrossRef]

- Hansen, O.R.; Hinze, P.; Engel, D.; Davis, S. Using computational fluid dynamics (CFD) for blast wave predictions. J. Loss Prev. Process Ind. 2010, 23, 885–906. [Google Scholar] [CrossRef]

- Paris, L.; Dubois, A. Recent developments to evaluate global explosion loading on complex systems. J. Loss Prev. Process Ind. 2017, 46, 163–176. [Google Scholar] [CrossRef]

- Sohn, J.M.; Kim, S.J.; Kim, B.H.; Paik, J.K. Nonlinear structural consequence analysis of FPSO topside blastwalls. Ocean Eng. 2013, 60, 149–162. [Google Scholar] [CrossRef]

- Kim, S.J.; Kim, B.J.; Seo, J.K.; Paik, J.K. A New Method for Structural Assessment of Topside Structure Subjected to Hydrocarbon Explosions. Procedia Eng. 2017, 173, 479–486. [Google Scholar] [CrossRef]

- Kang, K.-Y.; Choi, K.-H.; Choi, J.W.; Ryu, Y.H.; Lee, J.-M. Explosion induced dynamic responses of blast wall on FPSO topside: Blast loading application methods. Int. J. Nav. Archit. Ocean Eng. 2017, 9, 135–148. [Google Scholar] [CrossRef]

- Urgessa, G.S.; Arciszewski, T. Blast response comparison of multiple steel frame connections. Finite Elem. Anal. Des. 2011, 47, 668–675. [Google Scholar] [CrossRef]

- Louca, L.A.; Mohamed Ali, R.M. Improving the ductile behaviour of offshore topside structures under extreme loads. Eng. Struct. 2008, 30, 506–521. [Google Scholar] [CrossRef]

- Ryu, Y.; Burgan, B.; Choi, J.; Lee, H.S. Structural Safety Analyses for Offshore Platforms under Explosion Loadings. J. Offshore Mech. Arct. Eng. 2019, 141, 041602. [Google Scholar] [CrossRef]

- Det Norske Veritas. Accident Statistics for Floating Offshore Units on the UK Continental Shelf 1980–2005; Health and Safety Executive: Derbyshire, UK, 2007.

- Li, J.; Ma, G.; Abdel-jawad, M.; Hao, H. Evaluation of Gas Explosion Overpressures at Configurations with Irregularly Arranged Obstacles. J. Perform. Constr. Facil. 2015, 29. [Google Scholar] [CrossRef]

- Vannucchi de Camargo, F. Survey on Experimental and Numerical Approaches to Model Underwater Explosion. J. Mar. Sci. Eng. 2019, 7, 15. [Google Scholar] [CrossRef]

- Arntzen, B.J. Modelling of Turbulence and Combustion for Simulation of Gas Explosions in Complex Geometries. Ph.D. Thesis, Norwegian University of Science and Technology, NTNU, Trondheim, Norway, 1998. [Google Scholar]

- GexconAS. FLACS v10.6 User’s Manual; Gexcon: Bergen, Norway, 2017. [Google Scholar]

- Wang, G.; Wang, Y.; Lu, W.; Zhou, W.; Chen, M.; Yan, P. On the determination of the mesh size for numerical simulations of shock wave propagation in near field underwater explosion. Appl. Ocean Res. 2016, 59, 1–9. [Google Scholar] [CrossRef]

- Hibbitt, K.S. Abaqus Explicit User’s Manual, version 6.1; Hibbitt, Karlsson & Sorenson: Providence, RI, USA, 2000. [Google Scholar]

- Boh, J.W.; Louca, L.A.; Choo, Y.S. Strain rate effects on the response of stainless steel corrugated firewalls subjected to hydrocarbon explosions. J. Constr. Steel Res. 2004, 60, 1–29. [Google Scholar] [CrossRef]

- Ling, Q.; He, Y.; He, Y.; Pang, C. Dynamic response of multibody structure subjected to blast loading. Eur. J. Mech. A. Solids 2017, 64, 46–57. [Google Scholar] [CrossRef]

- Moghimi, H.; Driver, R.G. Performance assessment of steel plate shear walls under accidental blast loads. J. Constr. Steel Res. 2015, 106, 44–56. [Google Scholar] [CrossRef]

- Abaqus Analysis User’s Guide, Abaqus 6.13; Dassault Systèmes: Velizy Villacoublay, France, 2013.

- Langdon, G.S.; Schleyer, G.K. Inelastic deformation and failure of profiled stainless steel blast wall panels. Part II: Analytical modelling considerations. Int. J. Impact Eng. 2005, 31, 371–399. [Google Scholar] [CrossRef]

- Langdon, G.S.; Schleyer, G.K. Deformation and failure of profiled stainless steel blast wall panels. Part III: Finite element simulations and overall summary. Int. J. Impact Eng. 2006, 32, 988–1012. [Google Scholar] [CrossRef]

| Discipline | Weight (ton) |

|---|---|

| Machinery | 1500 |

| Structure | 2000 |

| Steel outfitting | 150 |

| Outfitting machinery | 10 |

| Electrical | 70 |

| Architectural | 10 |

| HVAC * | 10 |

| Piping | 250 |

| Total | 4000 |

| No | Filling Ratio (%) | Gas Cloud Dimension (m) | Volume (m3) | ||

|---|---|---|---|---|---|

| X | Y | Z | |||

| 1 | 50 | 26 | 20 | 16.25 | 8450 |

| 2 | 40 | 26 | 20 | 13 | 6760 |

| 3 | 30 | 26 | 20 | 9.75 | 5070 |

| 4 | 20 | 26 | 13.34 | 9.75 | 3382 |

| No | Filling Ratio (%) | Gas Cloud Dimension (m) | Volume (m3) | ||

|---|---|---|---|---|---|

| X | Y | Z | |||

| 1 | 30 | 30 | 22.4 | 11.2 | 7553 |

| 2 | 20 | 30 | 22.4 | 7.5 | 5022 |

| 3 | 10 | 23.8 | 17.8 | 5.94 | 2516 |

| Ignition Points | Filling Ratio | Cloud Volumes |

|---|---|---|

| 1. Center of gas cloud (1 point) | 1. 50% | 8450 m3 |

| 2. Corner of gas cloud (8 points) | 2. 40% | 6760 m3 |

| 3. Center on surface of gas cloud (6 points) | 3. 30% | 5070 m3 |

| 4. 20% | 3382 m3 |

| Ignition Points | Filling Ratio | Cloud Volumes |

|---|---|---|

| 1. Center of gas cloud (1 point) | 1. 30% | 7553 m3 |

| 2. Corner of gas cloud (8 points) | 2. 20% | 5022 m3 |

| 3. Center on surface of gas cloud (6 points) | 3. 10% | 2516 m3 |

| Material | Elastic Modulus (GPa) | Poisson’s Ratio | Density (kg/m3) | Engineering | True | ||||

|---|---|---|---|---|---|---|---|---|---|

| Min. Yield Strength (MPa) | Min. Ultimate Strength (MPa) | Critical Strain | Min. Yield Strength (MPa) | Min. Ultimate Strength (MPa) | Critical Strain | ||||

| S235 | 205 | 0.3 | 7850 | 235 | 360 | 0.20 | 236.2 | 432.6 | 0.1817 |

| S355 | 205 | 0.3 | 7850 | 355 | 470 | 0.15 | 357.0 | 541.0 | 0.1391 |

| S460 | 205 | 0.3 | 7850 | 460 | 540 | 0.10 | 462.8 | 595.4 | 0.0948 |

| Explosion Location | Load Cases | Steel Grade | Deflection | Strain | |||

|---|---|---|---|---|---|---|---|

| No | Description | (MPa) | |||||

| On Drill Floor | Overall Peak Case-1 | Pressure | Peak Pressure | 235 | Frame Deck Plate | Frame Deck Plate | |

| Area | All Area | 355 | |||||

| Time | Same Time | 460 | |||||

| Overall Average Case-2 | Pressure | Average Pressure | 235 | Frame Deck Plate | Frame Deck Plate | ||

| Area | All Area | 355 | |||||

| Time | Same Time | 460 | |||||

| Group Peak Case-3 | Pressure | Peak Pressure | 235 | Frame Deck Plate | Frame Deck Plate | ||

| Area | Each Area | 355 | |||||

| Time | Same Time | 460 | |||||

| Proposed Case-4 | Pressure | Peak Pressure | 235 | Frame Deck Plate | Frame Deck Plate | ||

| Area | Each Area | 355 | |||||

| Time | Propagation | 460 | |||||

| Under Drill Floor | Overall Peak Case-5 | Pressure | Peak Pressure | 235 | Frame Deck Plate | Frame Deck Plate | |

| Area | All Area | 355 | |||||

| Time | Same Time | 460 | |||||

| Overall Average Case-6 | Pressure | Average Pressure | 235 | Frame Deck Plate | Frame Deck Plate | ||

| Area | All Area | 355 | |||||

| Time | Same Time | 460 | |||||

| Group Peak Case-7 | Pressure | Peak Pressure | 235 | Frame Deck Plate | Frame Deck Plate | ||

| Area | Each Area | 355 | |||||

| Time | Same Time | 460 | |||||

| Proposed Case-8 | Pressure | Peak Pressure | 235 | Frame Deck Plate | Frame Deck Plate | ||

| Area | Each Area | 355 | |||||

| Time | Propagation | 460 | |||||

| Load Case | Material | |||

|---|---|---|---|---|

| S235 | S355 | S460 | ||

| Overall Peak Case-1 | Min | −0.0852 | −0.0842 | −0.0842 |

| Max | 0.0882 | 0.0885 | 0.0887 | |

| Overall Average Case-2 | Min | −0.0485 | −0.0485 | −0.0485 |

| Max | 0.0487 | 0.0488 | 0.0488 | |

| Group Peak Case-3 | Min | −0.0814 | −0.0810 | −0.0809 |

| Max | 0.0824 | 0.0828 | 0.0831 | |

| Proposed Case-4 | Min | −0.0556 | −0.0554 | −0.0554 |

| Max | 0.0398 | 0.0403 | 0.0404 | |

| Load Case | Material | |||

|---|---|---|---|---|

| S235 | S355 | S460 | ||

| Overall Peak Case-1 | Min | −0.090 | −0.089 | −0.089 |

| Max | 0.072 | 0.073 | 0.073 | |

| Overall Average Case-2 | Min | −0.090 | −0.057 | −0.057 |

| Max | 0.072 | 0.045 | 0.045 | |

| Group Peak Case-3 | Min | −0.088 | −0.086 | −0.086 |

| Max | 0.070 | 0.069 | 0.069 | |

| Proposed Case-4 | Min | −0.100 | −0.099 | −0.099 |

| Max | 0.047 | 0.047 | 0.047 | |

| Areas | Material | Displacement Ratio | |||||

|---|---|---|---|---|---|---|---|

| Name | Dimension | Ratio | S235 | S355 | S460 | ||

| Area-1 | 2.375 m × 1.305 m | 1.00 | Min | −0.031 | −0.031 | −0.031 | 1.00 |

| 3.099 | Max | 0.022 | 0.022 | 0.022 | |||

| Area-2 | 2.375 m × 1.995 m | 1.53 | Min | −0.076 | −0.076 | −0.076 | 2.62 |

| 4.738 | Max | 0.060 | 0.061 | 0.061 | |||

| Area-3 | 2.375 m × 3.155 m | 2.42 | Min | −0.091 | −0.089 | −0.089 | 3.13 |

| 7.493 | Max | 0.072 | 0.073 | 0.073 | |||

| Load Case | Material | ||

|---|---|---|---|

| S235 | S355 | S460 | |

| Overall Peak Case-1 | 4.38% | 2.57% | 1.93% |

| Overall Average Case-2 | 1.34% | 0.36% | 0.15% |

| Group Peak Case-3 | 1.90% | 0.79% | 0.49% |

| Proposed Case-4 | 0.81% | 0.17% | 0.00% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.-K.; Kim, S.-K.; Lee, J.-M. Dynamic Response of Drill Floor Considering Propagation of Blast Pressure Subsequent to Blowout. Appl. Sci. 2020, 10, 8841. https://doi.org/10.3390/app10248841

Kim T-K, Kim S-K, Lee J-M. Dynamic Response of Drill Floor Considering Propagation of Blast Pressure Subsequent to Blowout. Applied Sciences. 2020; 10(24):8841. https://doi.org/10.3390/app10248841

Chicago/Turabian StyleKim, Teak-Keon, Seul-Kee Kim, and Jae-Myung Lee. 2020. "Dynamic Response of Drill Floor Considering Propagation of Blast Pressure Subsequent to Blowout" Applied Sciences 10, no. 24: 8841. https://doi.org/10.3390/app10248841

APA StyleKim, T.-K., Kim, S.-K., & Lee, J.-M. (2020). Dynamic Response of Drill Floor Considering Propagation of Blast Pressure Subsequent to Blowout. Applied Sciences, 10(24), 8841. https://doi.org/10.3390/app10248841