Comparative Study of Induction Motors of IE2, IE3 and IE4 Efficiency Classes in Pump Applications Taking into Account CO2 Emission Intensity

Abstract

Featured Application

Abstract

1. Introduction

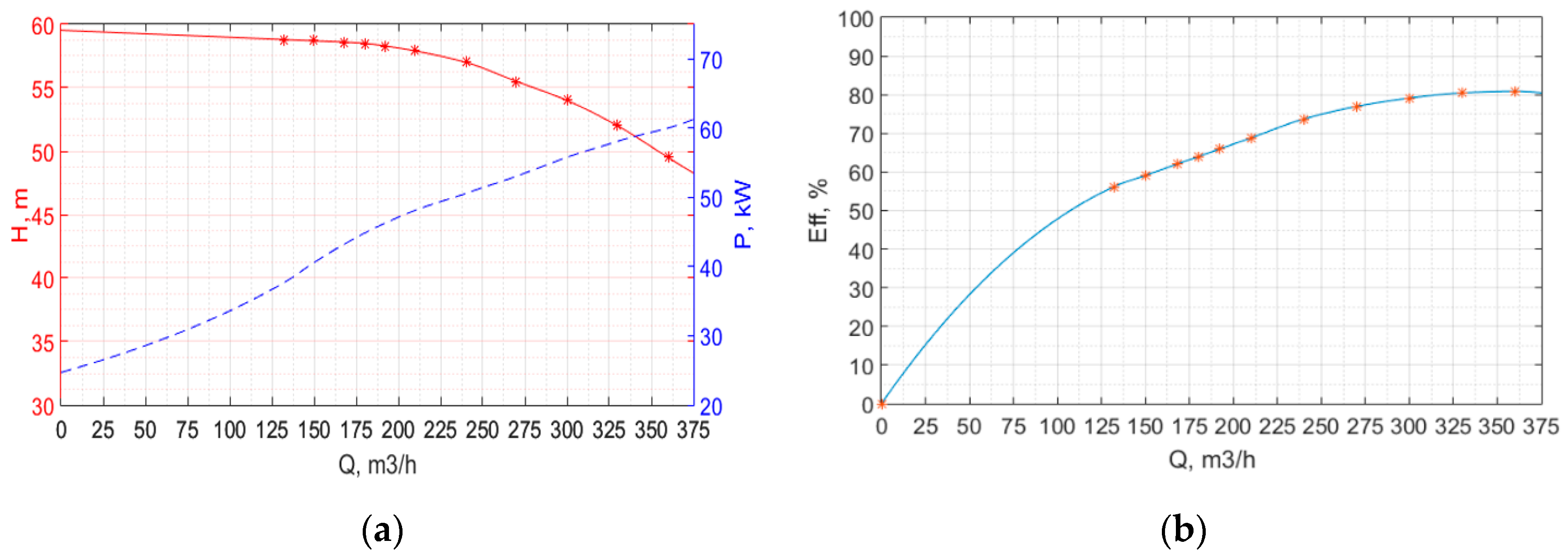

2. Characteristics of the Pump

3. Calculation Method for Assessment of the Energy Consumption of the Pump Unit

4. Calculation Method for Assessment of the CO2 Emission Intensity

5. Calculation Method for Assessment of the Lifecycle Costs and Cost Savings

6. Results and Discussions

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| IE | International efficiency |

| IEC | International Electrotechnical Commission |

| VSD | variable speed drive |

| CO2 | carbon dioxide |

| IM | induction motor |

| MEI | minimum efficiency index |

| LS-PMSM | line-start permanent magnet motors |

| BEP | best efficiency point |

| CDE | carbon dioxide emissions |

| EFE | CO2 emissions factor for electricity consumption |

| PEF | primary energy factor |

| NPV | net present value |

References

- European Commission. Study on Improving the Energy Efficiency of Pumps. 2001. Available online: http://www.jakob-albertsen.dk/komposit/Darmstadtrapport.pdf (accessed on 14 August 2020).

- Rotating Electrical Machines-Part 30–32: Efficiency Classes of Variable Speed AC Motors (IE-Code) IEC 60034-30-2/ IEC: 2016–2012. Available online: https://webstore.iec.ch/publication/30830 (accessed on 14 August 2020).

- Rotating Electrical Machines-Part 30–31: Efficiency Classes of Line Operated AC Motors (IE code). IEC 60034-30-1/ Ed. 1. Available online: https://webstore.iec.ch/publication/136 (accessed on 14 August 2020).

- European Commission Regulation (EC) No. 640/2009 Implementing Directive 2005/32/ EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Electric Motors, 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32014R0004 (accessed on 14 August 2020).

- Commission Regulation (EU) 2019/1781 of 1 October 2019 Laying Down Ecodesign Requirements for Electric Motors and Variable Speed Drives Pursuant to Directive 2009/125/EC of the European Parliament and of the Council, Amending Regulation (EC) No 641/2009 with Regard to Ecodesign Requirements for Glandless Standalone Circulators and Glandless Circulators Integrated in Products and Repealing Commission Regulation (EC). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019R1781&from=EN (accessed on 14 August 2020).

- Efficiency Regulations for Motors: International Norms. Available online: https://www.nord.com/cms/media/documents/bw/S4700_6069202_4019_Screen.pdf (accessed on 14 August 2020).

- Chodakowska, E.; Nazarko, J. Assessing the Performance of Sustainable Development Goals of EU Countries: Hard and Soft Data Integration. Energies 2020, 13, 3439. [Google Scholar] [CrossRef]

- Siksnelyte, I.; Zavadskas, E.K. Achievements of the European Union Countries in Seeking a Sustainable Electricity Sector. Energies 2019, 12, 2254. [Google Scholar] [CrossRef]

- Mathiesen, B.V.; Lund, H.; Karlsson, K. 100% Renewable energy systems, climate mitigation and economic growth. Appl. Energy 2011, 88, 488–501. [Google Scholar] [CrossRef]

- Phillips, R.; Tieben, R. Improvement of Electric Motor Systems in Industry (IEMSI). In Proceedings of the 10th International Conference on Energy Efficiency in Motor Driven Systems (EEMODS ‘17), Rome, Italy, 6–8 September 2017. [Google Scholar] [CrossRef]

- Arun Shankar, V.K.; Umashankar, S.; Paramasivam, S.; Hanigovszki, N. A comprehensive review on energy efficiency enhancement initiatives in centrifugal pumping system. Appl. Energy 2016, 181, 495–513. [Google Scholar] [CrossRef]

- Ahonen, T.; Orozco, S.M.; Ahola, J.; Tolvanen, J. Effect of electric motor efficiency and sizing on the energy efficiency in pumping systems. In Proceedings of the 18th European Conference on Power Electronics and Applications (EPE’16 ECCE Europe), Karlsruhe, Germany, 5–9 September 2016; pp. 1–9. [Google Scholar] [CrossRef]

- Van Rhyn, P.; Pretorius, J.H.C. Utilising high and premium efficiency three phase motors with VFDs in a public water supply system. In Proceedings of the IEEE 5th International Conference on Power Engineering, Energy and Electrical Drives (POWERENG), Riga, Latvia, 11–13 May 2015; pp. 497–502. [Google Scholar] [CrossRef]

- Brinner, T.R.; McCoy, R.H.; Kopecky, T. Induction Versus Permanent-Magnet Motors for Electric Submersible Pump Field and Laboratory Comparisons. IEEE Trans. Ind. Appl. 2014, 50, 174–181. [Google Scholar] [CrossRef]

- Kazakbaev, V.; Prakht, V.; Dmitrievskii, V.; Ibrahim, M.N.; Oshurbekov, S.; Sarapulov, S. Efficiency analysis of low electric power drives employing induction and synchronous reluctance motors in pump applications. Energies 2019, 12, 1144. [Google Scholar] [CrossRef]

- Commission Regulation (EC) July 22, 2009 implementing Directive 2005/32/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Glandless Standalone Circulators and Glandless Circulators Integrated in Products, Amended by Commission Regulation (EU). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02009R0641-20170109 (accessed on 14 August 2020).

- Europump. Extended Product Approach for Pumps. Available online: http://europump.net/uploads/Extended%20Product%20Approach%20for%20Pumps%20-%20A%20Europump%20guide%20(27OCT2014).pdf (accessed on 14 August 2020).

- Stoffel, B. Assessing the Energy Efficiency of Pumps and Pump Units. Background and Methodology; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Commission Regulation (EU) Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Water Pumps. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32012R0547 (accessed on 14 August 2020).

- Goman, V.; Oshurbekov, S.; Kazakbaev, V.; Prakht, V.; Dmitrievskii, V. Energy Efficiency Analysis of Fixed-Speed Pump Drives with Various Types of Motors. Appl. Sci. 2019, 9, 5295. [Google Scholar] [CrossRef]

- Oshurbekov, S.; Kazakbaev, V.; Prakht, V.; Dmitrievskii, V.; Alecksey Paramonov. Comparative Study of Energy Consumption of 15 kW Induction Motors of IE1 and IE2 Efficiency Classes in Pump Applications. In Proceedings of the XI International Conference on Electrical Power Drive Systems (ICEPDS), Saint-Petersburg, Russia, 4–7 October 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Technical Regulations of Eurasian Economic Union. O Trebovaniyah k Energeticheskoy Effectivnosti Energopotreblyaushih Ustroistv. Available online: https://www.garant.ru/products/ipo/prime/doc/73240518/ (accessed on 14 August 2020).

- W22 High Efficiency IE2 75 kW 4P 280S/M 3Ph 380-415/660//460 V 50 Hz IC411-TEFC-B3T. Product Details. Available online: https://www.weg.net/catalog/weg/CY/en/Electric-Motors/Low-Voltage-IEC-Motors/General-Purpose-ODP-TEFC/Cast-Iron-TEFC-General-Purpose/W22---Cast-Iron-TEFC-General-Purpose/W22-IE2/W22-IE2-75-kW-4P-280S-M-3Ph-380-415-660-460-V-50-Hz-IC411---TEFC---B3T/p/11130155 (accessed on 14 August 2020).

- W22 Premium Efficiency IE3 75 kW 4P 280S/M 3Ph 380-415/660//460 V 50 Hz IC411-TEFC- B3T. Product Details. Available online: https://www.weg.net/catalog/weg/CI/en/Electric-Motors/Low-Voltage-IEC-Motors/General-Purpose-ODP-TEFC/Cast-Iron-TEFC-General-Purpose/W22---Cast-Iron-TEFC-General-Purpose/W22-IE3/W22-IE3-75-kW-4P-280S-M-3Ph-380-415-660-460-V-50-Hz-IC411---TEFC---B3T/p/12864750 (accessed on 14 August 2020).

- W22 Super Premium Efficiency IE4 75 kW 4P 280S/M 3Ph 400/690//460 V 50 Hz IC411-TEFC-B3T. Product Details. Available online: https://www.weg.net/catalog/weg/CI/en/Electric-Motors/Low-Voltage-IEC-Motors/General-Purpose-ODP-TEFC/Cast-Iron-TEFC-General-Purpose/W22---Cast-Iron-TEFC-General-Purpose/W22-IE4/W22-IE4-75-kW-4P-280S-M-3Ph-400-690-460-V-50-Hz-IC411---TEFC---B3T/p/12774369 (accessed on 14 August 2020).

- NM, NMS, Close Coupled Centrifugal Pumps with Flanged Connections; Catalogue; Calpeda, 2018. Available online: https://www.calpeda.com/system/products/catalogue_50hzs/53/en/NM_NMS_EN2018.pdf?1549893188 (accessed on 14 August 2020).

- Ferreira, F.J.T.E.; de Almeida, A.T. Energy savings potential associated with stator winding connection mode change in induction motors. In Proceedings of the XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 2775–2783. [Google Scholar] [CrossRef]

- CO2 Intensity of Electricity Generation. European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/data/co2-intensity-of-electricity-generation (accessed on 14 August 2020).

- Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32012L0027 (accessed on 8 August 2020).

- Wilby, M.R.; González, A.B.R.; Díaz, J.J.V. Empirical and dynamic primary energy factors. Energy 2014, 73, 771–779. [Google Scholar] [CrossRef]

- Final Report. Evaluation of Primary Energy Factor Calculation Options for Electricity. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/final_report_pef_eed.pdf (accessed on 8 August 2020).

- Tucki, K.; Orynycz, O.; Mitoraj-Wojtanek, M. Perspectives for Mitigation of CO2 Emission due to Development of Electromobility in Several Countries. Energies 2020, 13, 4127. [Google Scholar] [CrossRef]

- Eurostat Data for the Industrial Consumers in Germany. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Electricity_price_statistics#Electricity_prices_for_industrial_consumers (accessed on 14 August 2020).

- Pump Life Cycle Costs: A Guide to LCC Analysis for Pumping Systems, Executive Summary. (2001) Hydraulic Institute (Parsippany, NJ); Europump (Brussels, Belgium); Office of Industrial Technologies Energy Efficiency and Renewable Energy U.S. Department of Energy (Washington, DC). Available online: https://searchworks.stanford.edu/view/4676735 (accessed on 14 August 2020).

- Waghmode, L.; Sahasrabudhe, A. A comparative study of life cycle cost analysis of pumps. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (ASME 2010), Montreal, QC, Canada, 15–18 August 2010; Volume 6, pp. 491–500. [Google Scholar]

- AC Electric Motor. Available online: https://www.acelectricmotor.co.uk/ (accessed on 14 August 2020).

| Parameter | Type | PRATE, W | nRATE, rpm | QBEP, m3/h | HBEP, m | Efficiency, % |

|---|---|---|---|---|---|---|

| Value | NMS4 150/400A/A | 75,000 | 1450 | 352 | 50.3 | 81 |

| No. of Loading Points (i) | 1 | 2 | 3 |

|---|---|---|---|

| Qi, % | 75 | 100 | 110 |

| Qi, m3/h | 264.0 | 352.0 | 387.2 |

| Hpump.i, m | 55.8 | 50.3 | 47.2 |

| ηpump.i, % | 76.22 | 81.00 | 79.85 |

| Pmech.i, W | 52,538 | 59,520 | 62,421 |

| Pmech.i, % | 70.05 | 79.36 | 83.23 |

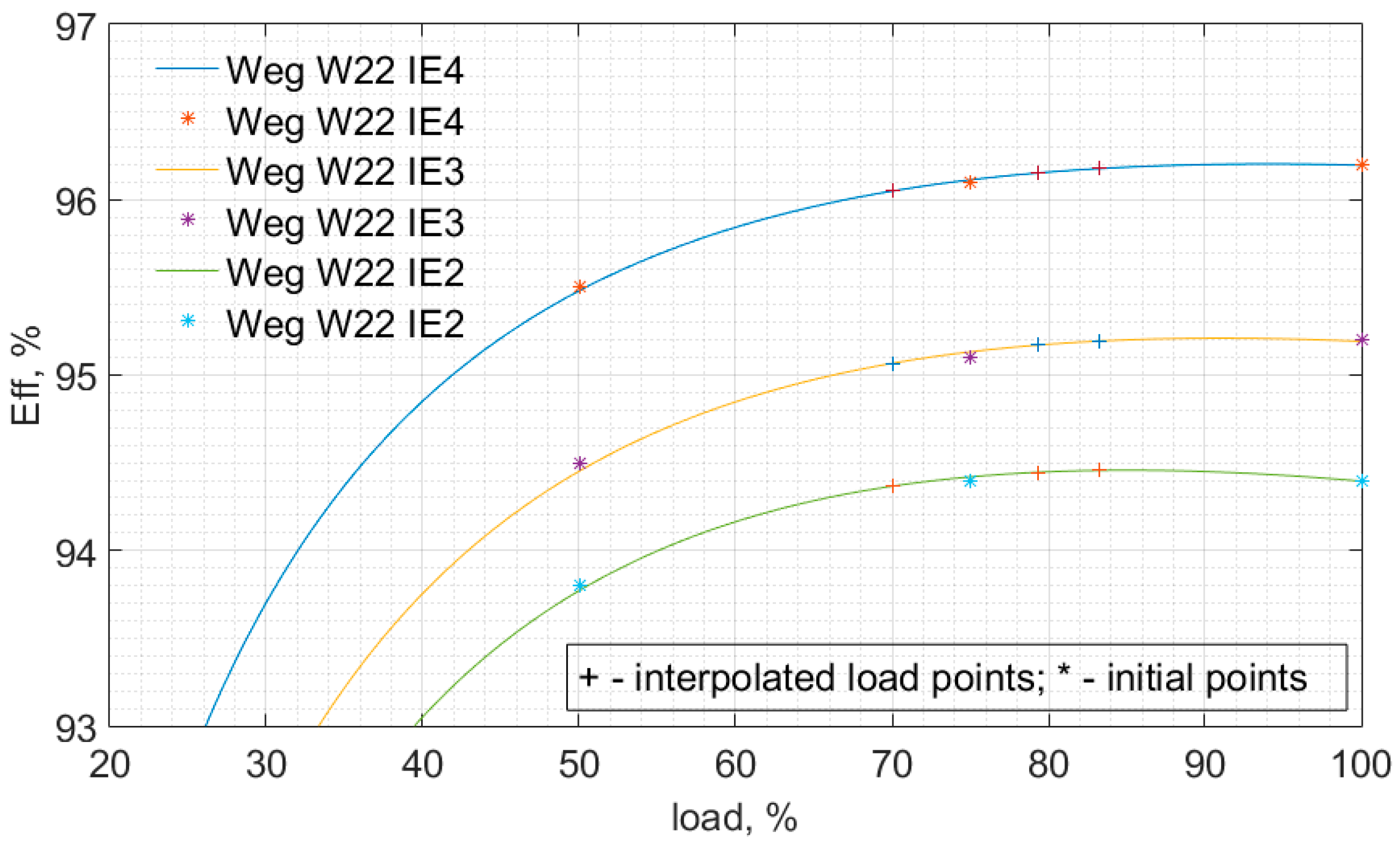

| m | Type of Motor, IE Class | Catalog Efficiency, % at the Loads | Interpolated Efficiency ηM.i.m, % in the Loading Points | ||||

|---|---|---|---|---|---|---|---|

| 50% | 75% | 100% | 1 | 2 | 3 | ||

| 1 | IM, IE4 | 95.5 | 96.1 | 96.2 | 96.05 | 96.15 | 96.18 |

| 2 | IM, IE3 | 94.5 | 95.1 | 95.2 | 95.07 | 95.17 | 95.19 |

| 3 | IM, IE2 | 93.8 | 94.4 | 94.4 | 94.37 | 94.40 | 94.40 |

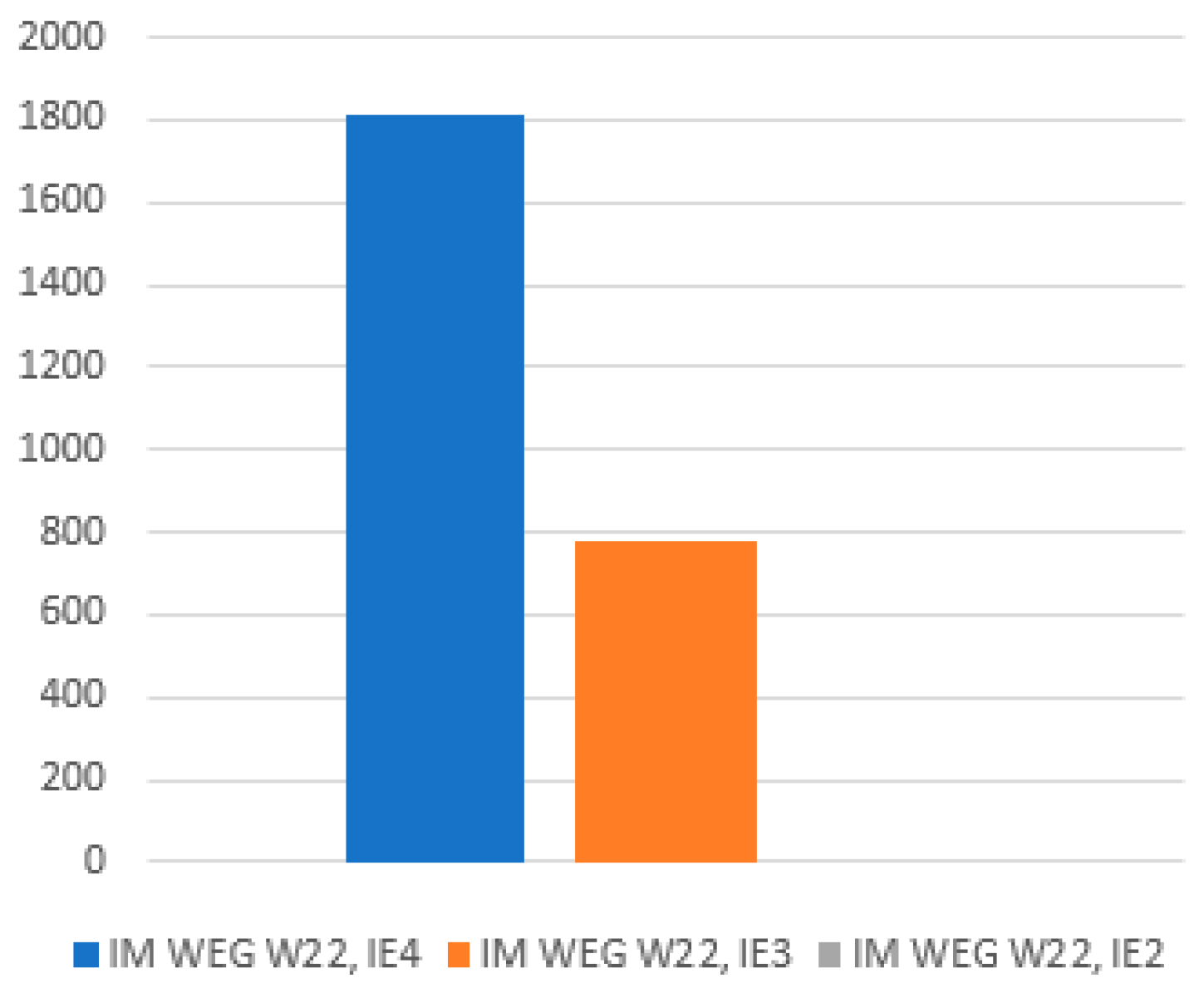

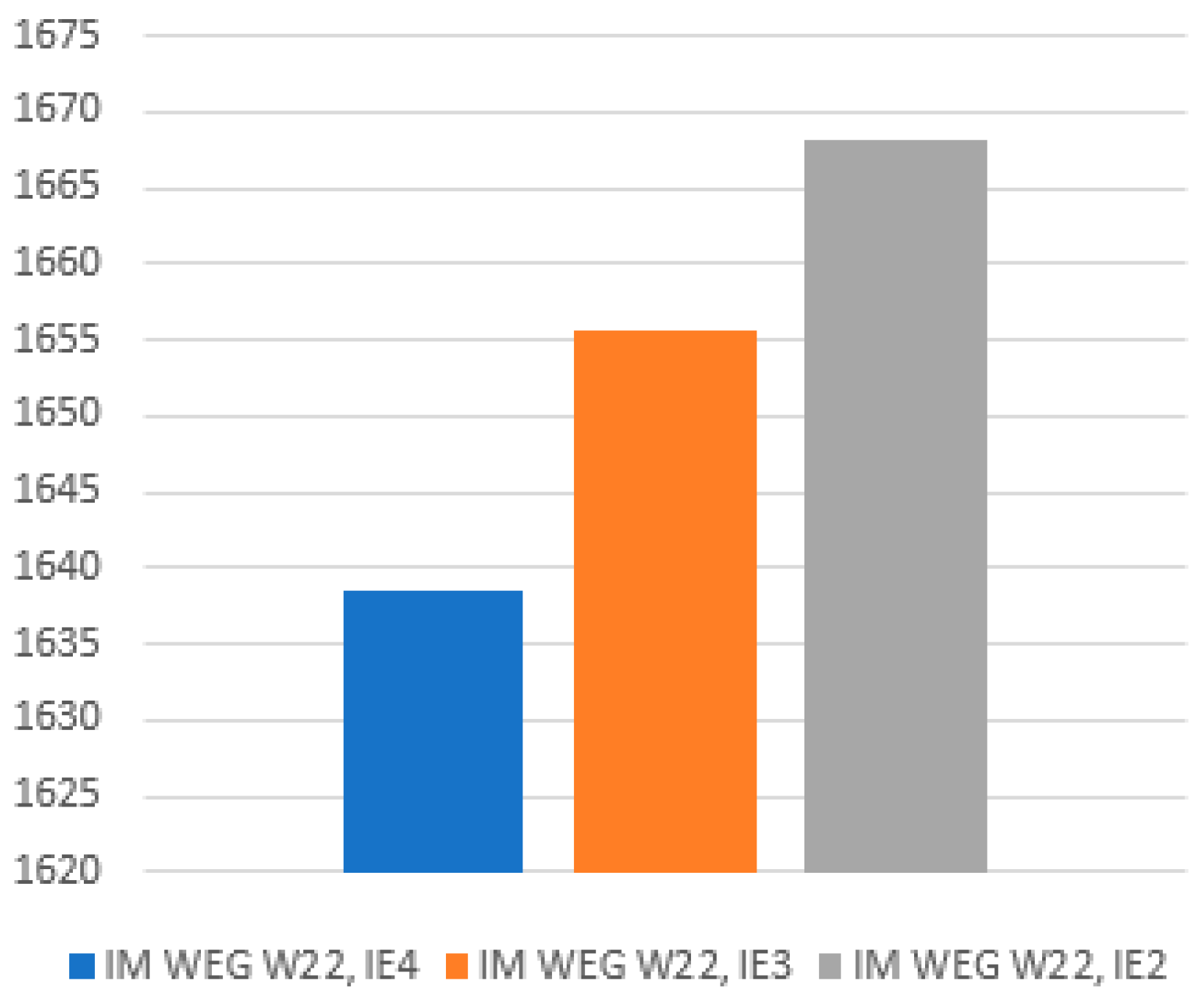

| m | Type of Motor, IE Class | Ey.m, MW·h | Cy.m, k€ | Sy.3m, € | CLCCen.m, k€ | ΔCLCCen.3m, k€ | Ciic.m, € | Tm, Years |

|---|---|---|---|---|---|---|---|---|

| 1 | IM WEG W22, IE4 | 533.05 | 100.21 | 1809.4 | 1638.58 | 29.59 | 5246 | 2.9 |

| 2 | IM WEG W22, IE3 | 538.56 | 101.25 | 775.0 | 1655.58 | 12.59 | 4035 | 5.2 |

| 3 | IM WEG W22, IE2 | 542.68 | 102.02 | - | 1668.17 | - | - | - |

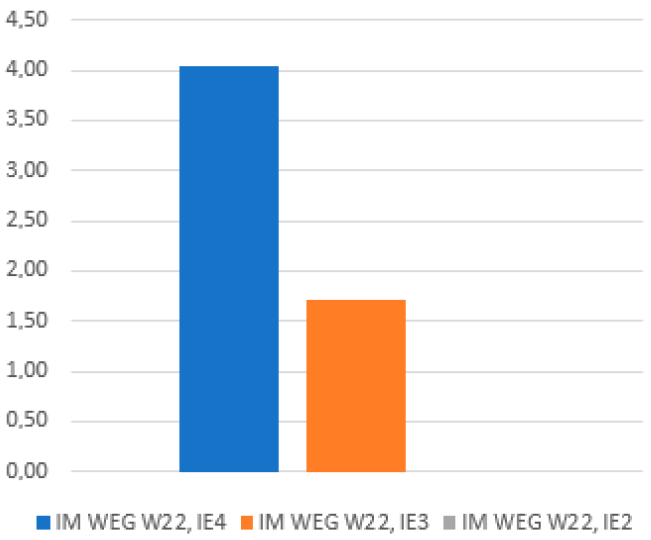

| m | Type of Motor, IE Class | Emissions Considering the Final Energy | Emissions Considering the Primary Energy | ||

|---|---|---|---|---|---|

| CDEy.m, Tons | ΔCDEy.3m, Tons | CDE*y.m, Tons | ΔCDE*y.3m, Tons | ||

| 1 | IM WEG W22, IE4 | 223.24 | 4.03 | 491.12 | 8.87 |

| 2 | IM WEG W22, IE3 | 225.55 | 1.72 | 496.21 | 3.78 |

| 3 | IM WEG W22, IE2 | 227.27 | - | 499.99 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goman, V.; Prakht, V.; Kazakbaev, V.; Dmitrievskii, V. Comparative Study of Induction Motors of IE2, IE3 and IE4 Efficiency Classes in Pump Applications Taking into Account CO2 Emission Intensity. Appl. Sci. 2020, 10, 8536. https://doi.org/10.3390/app10238536

Goman V, Prakht V, Kazakbaev V, Dmitrievskii V. Comparative Study of Induction Motors of IE2, IE3 and IE4 Efficiency Classes in Pump Applications Taking into Account CO2 Emission Intensity. Applied Sciences. 2020; 10(23):8536. https://doi.org/10.3390/app10238536

Chicago/Turabian StyleGoman, Victor, Vladimir Prakht, Vadim Kazakbaev, and Vladimir Dmitrievskii. 2020. "Comparative Study of Induction Motors of IE2, IE3 and IE4 Efficiency Classes in Pump Applications Taking into Account CO2 Emission Intensity" Applied Sciences 10, no. 23: 8536. https://doi.org/10.3390/app10238536

APA StyleGoman, V., Prakht, V., Kazakbaev, V., & Dmitrievskii, V. (2020). Comparative Study of Induction Motors of IE2, IE3 and IE4 Efficiency Classes in Pump Applications Taking into Account CO2 Emission Intensity. Applied Sciences, 10(23), 8536. https://doi.org/10.3390/app10238536