Multiscale Analytical Method and Its Parametric Study for Lining Joint Leakage of Shield Tunnel

Abstract

Featured Application

Abstract

1. Introduction

2. Leakage Model of Shield Joints Based on the Persson Model

2.1. Influencing Factors of Shield Joints

2.1.1. Configuration of Shield Joints

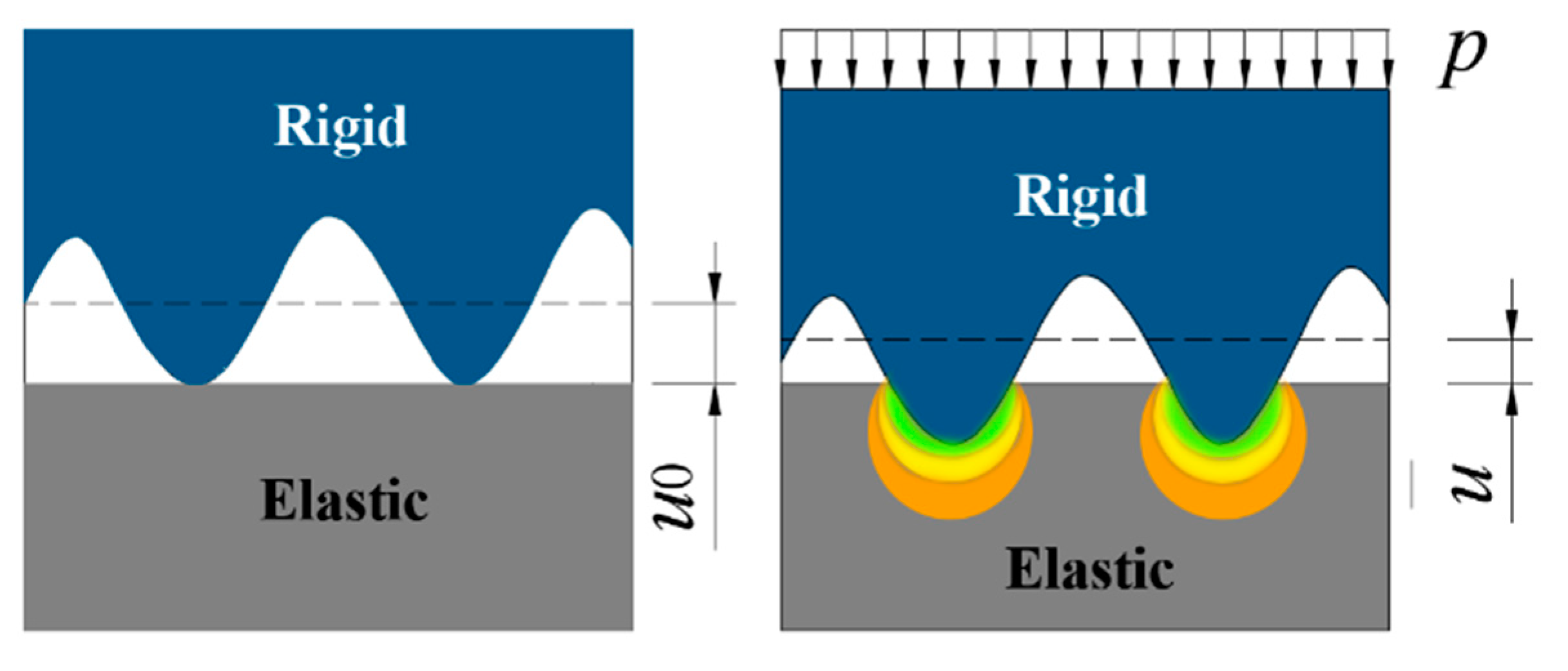

2.1.2. Sealing Principle and Influencing Factors of Shield Joint Leakage

2.2. Persson Model

2.2.1. Magnification and Actual Contact Area

2.2.2. The Equivalent Value of the Modulus

2.2.3. Characterization of Roughness

2.2.4. Average Interfacial Separation

2.3. Critical State of Leakage

2.3.1. Critical Percolation Channel

2.3.2. Critical Leakage Pressure and Self-Sealing Effect

- λ is the dynamic friction coefficient of the fluid, , and Re is the Reynolds number of fluids.

- is the length of the critical percolation channel;

- is the equivalent diameter of the critical percolation channel; and

- v is the average fluid velocity of water in the process of filing the percolation channel.

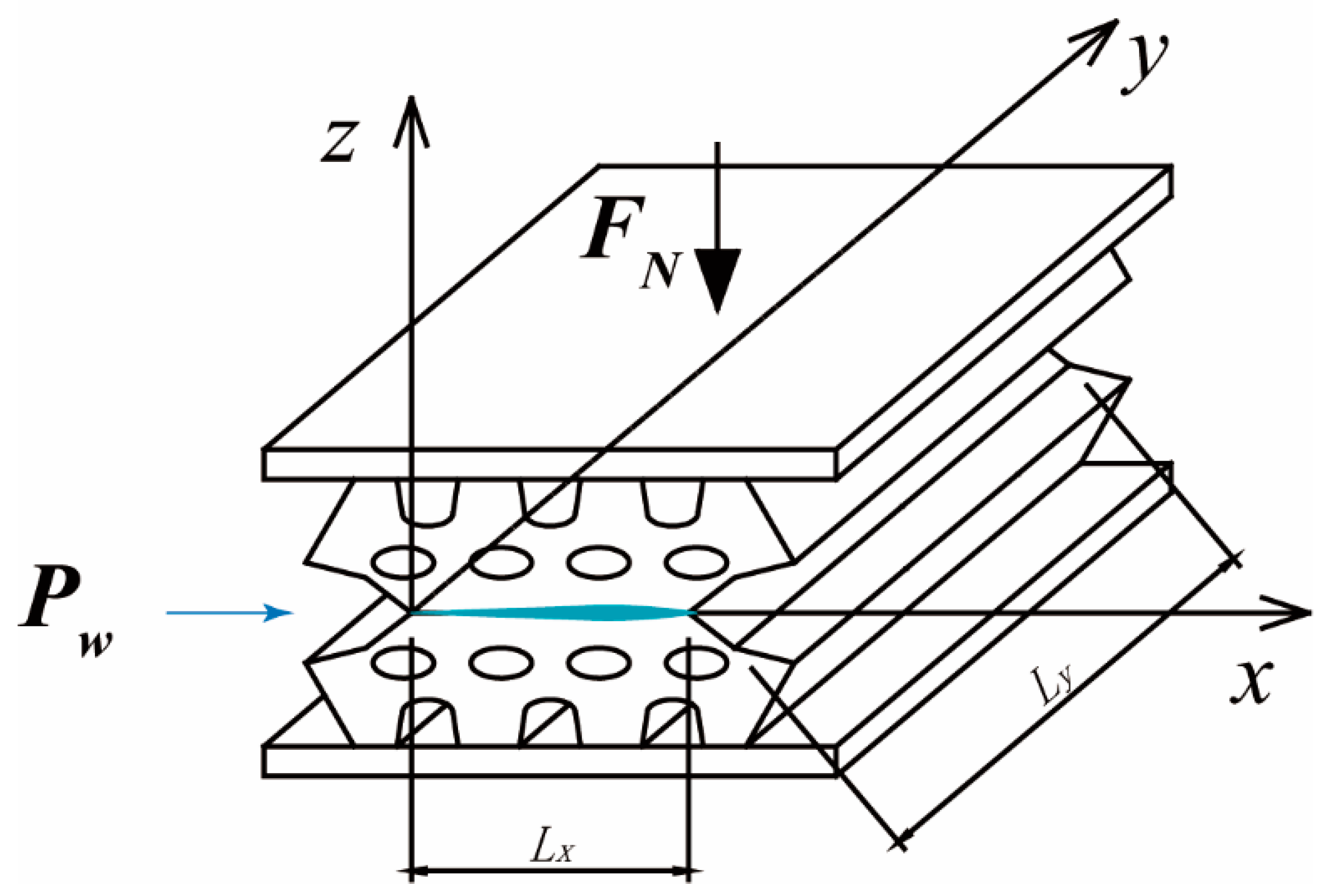

2.4. Calculation of Shield Lining Joint Leakage

3. Case Study and Parametric Analysis

3.1. Case Introduction and Calculation Parameters

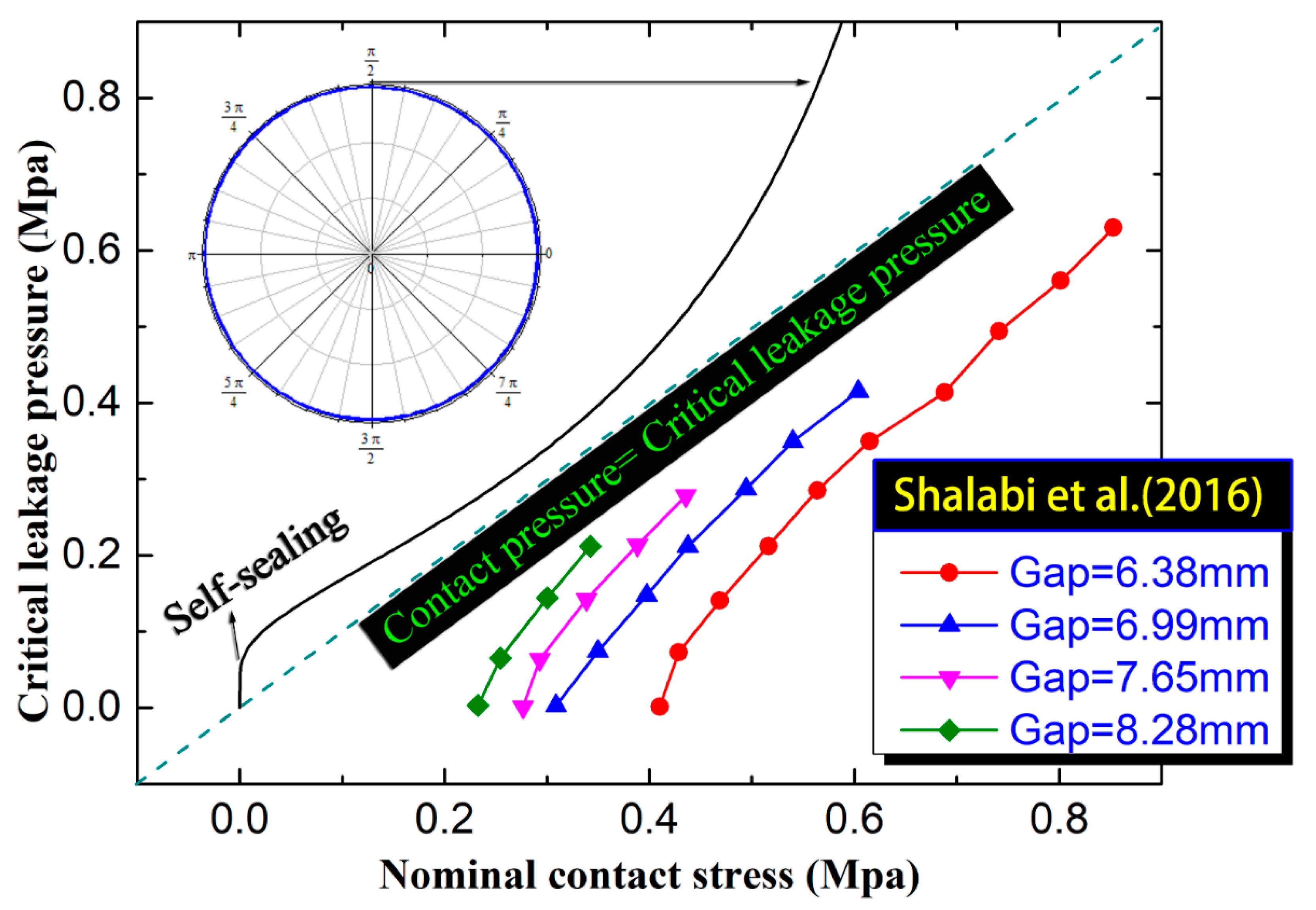

3.2. Calculation and Analysis of Critical State

3.2.1. Critical Magnification and Critical Percolation Channel Height

3.2.2. Critical Leakage Pressure and Self-Sealing Stress

3.3. Factors Influencing the Sealing Capacity of the EPDM Gasket

3.3.1. The Joint Gap of Lining Segments

3.3.2. The Joint Offset of Lining Segments

3.3.3. Service Time

3.3.4. Roughness of Sealing Surface

3.3.5. Groundwater Pressure

3.3.6. Sensitivity Analyses of Influencing Factors

4. Discussion

- (1)

- The measurement error of the contact surface height profile of the EPDM gasket is large, which has a great influence on the accuracy of the calculation results.

- (2)

- Consider that the groove is filled with a fully compressed gasket and it is bonded by the sealant, the model assumes that the leakage mainly occurs at the contact interface of the gaskets and ignores the effects of water pressure (lateral pressure) on the gasket to the gasket contact pressure.

- (3)

- When the groundwater pressure is large enough, the contact region will be split into several leakage channels, which is not reflected in the model. As a result, the calculation results may be relatively smaller than that in practice.

- (4)

- The model cannot consider the effects of water—swelling sealing materials.

- (5)

- The calculation results of self-sealing stress and leakage need more observed results and experiments for further verification.

5. Conclusions

- (1)

- Any sealing interface is permeable; they are mainly sealed by the interfacial fluid, which can form a plug, preventing further penetration. We called this phenomenon the self-sealing effect. The greater the squeezing pressure, the narrower the size of the critical percolation channel, which further provides stronger self-sealing stress.

- (2)

- The joint gap is often accompanied by joint offset. For the case where the joint offset is independent of the joint gap, the offset with considerable contact stress will enhance the joint waterproof performance, while, for the gap-dependent offset, the offset will increase the leakage. The leakage mainly depends on the increasing gap, and the effect of the offset change on leakage is slight.

- (3)

- The leakage increases with the aging of the sealing material. The aging model of Shi CH is utilized to calculate the leakage trend for one year, and the results show good agreement with the monitoring value of the second Dapu Road Tunnel.

- (4)

- The orthogonal array testing is designed with four factors including the joint gap, the surface roughness, the service time, and groundwater pressure in five levels. The range analysis showed that the roughness of the contact surface is the most influential, followed then by the service time, groundwater pressure and the joint gap.

- (5)

- The applicability of this model was verified by comparing the calculation results with experimental results in the literature. However, due to the differences between the hypothesis and the actual situation of engineering, this model aims to help more clearly understand the underlying processes of shield lining joint leakage and the influential laws of various factors rather than accurately predict it.

Author Contributions

Funding

Conflicts of Interest

Glossary

| Definitions are given here in the following sequence: Bold quantities denote vectors or tensors. | |

| ζ | magnification, |

| L | length of the nominal contact surface |

| λ | length of asperity wavelength |

| A(ζ) | actual contact area |

| nominal contact area (i.e., observed contact region is when ζ = 1) | |

| relative contact area fraction: | |

| E* | equivalent elastic modulus (MPa) |

| , | Young’s elastic module and respective Poisson’s ratios of the two contact faces |

| surface roughness power spectrum | |

| 〈〉 | mean of the square of the contact surface height profile (μm) |

| hrms | The root -mean -square roughness of the contact surface height profile (μm) |

| autocorrelation function of the surface height profiles (μm) | |

| Wavevector of asperity, q0, q1 represent the minimum and maximum surface fluctuation frequency, respectively | |

| Df | The fractal dimension of self-affine fractal surfaces, Df = 3 − H, where H is Hurst exponent |

| the pressure distribution at sealing interface with the average interfacial separation | |

| the elastic potential energy (J) | |

| relative area fraction of the contact surface with the compressive stress p and magnification | |

| critical observation scale | |

| uc | the average height of the critical percolation channel (μm) |

| W(q,p) | elastic energy |

| the average interfacial separation | |

| p1, p2, v1, v2 | the fluid pressure and the velocity on both sides of the sealing interface |

| z1, z2 | Head height on both sides of the seal interface |

| the energy loss | |

| Pw | Groundwater pressure (MPa) |

| critical leakage pressure (MPa) | |

| Pss | self-sealing stress (MPa) |

| Pc | site percolation threshold |

| r | the radius of the percolation path, r = /2 |

| vmax | the maximum flow rate of liquid in percolation path (m/s) |

| λ | Coefficient of head loss: |

| Re | Reynolds numbers, Re = 2ρvr/μ |

| v | the average fluid velocity of water (m/s) |

| q* | the wavenumber where the contact area percolate when increasing the magnification |

| hydrodynamic viscosity coefficient () | |

| the relative position of the leak point in the tunnel | |

| σ, | the conductivity of percolation channel |

| J | the fluid volume per unit time passing through the percolation channel |

| the pressure field distribution | |

| Lx, Ly | the geometrical dimension of sealing interface (m) |

| Q | total groundwater inflow (L/m2/day) |

References

- Girnau, G. Lining and waterproofing techniques in Germany. Tunn. Tunn. Int. 1978, 10. Available online: https://trid.trb.org/view/79297 (accessed on 25 November 2020).

- Nilsen, B. Characteristics of water ingress in Norwegian subsea tunnels. Rock Mech. Rock Eng. 2014, 47, 933–945. [Google Scholar] [CrossRef]

- Shin, J.H.; Addenbrooke, T.I.; Potts, D.M. A numerical study of the effect of groundwater movement on long-term tunnel behaviour. Géotechnique 2002, 52, 391–403. [Google Scholar] [CrossRef]

- Xu, C.; Chen, Q.; Luo, W.; Liang, L. Evaluation of permanent settlement in Hangzhou Qingchun road crossing-river tunnel under traffic loading. Int. J. Geomech. 2019, 19, 06018037. [Google Scholar] [CrossRef]

- Mair, R.J. Tunnelling and geotechnics: New horizons. Géotechnique 2008, 58, 695–736. [Google Scholar] [CrossRef]

- Wu, H.; Xu, Y.; Shen, S.-L.; Chai, J.-C. Long-term settlement behavior of ground around shield tunnel due to leakage of water in soft deposit of Shanghai. Front. Archit. Civ. Eng. China 2011, 5, 194–198. [Google Scholar] [CrossRef]

- Cividini, A.; Contini, A.; Locatelli, L.; Gioda, G. Investigation on the cause of damages of a deep tunnel. Int. J. Geomech. 2012, 12, 722–731. [Google Scholar] [CrossRef]

- Cividini, A.; Bonomi, S.; Vignati, G.C.; Gioda, G. Seepage-induced erosion in granular soil and consequent settlements. Int. J. Geomech. 2009, 9, 187–194. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Li, L.; Wang, J. Failure mechanism of tunnel lining joints and bolts with uneven longitudinal ground settlement. Tunn. Undergr. Space Technol. 2014, 40, 300–308. [Google Scholar] [CrossRef]

- Wu, H.-N.; Huang, R.-Q.; Sun, W.-J.; Shen, S.-L.; Xu, Y.-S.; Liu, Y.-B.; Du, S.-J. Leaking behavior of shield tunnels under the Huangpu River of Shanghai with induced hazards. Nat. Hazards 2014, 70, 1115–1132. [Google Scholar] [CrossRef]

- Shalabi, F.I. Behavior of Gasketed Segmental Concrete Tunnel Lining. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 2001. Available online: https://www.ideals.illinois.edu/handle/2142/83169 (accessed on 25 November 2020).

- Shalabi, F.I.; Cording, E.J.; Paul, S.L. Sealant behavior of gasketed segmental tunnel lining. In Proceedings of the Workshop of the International Tunneling and Underground Space Association, Underground Structures in Hot Climate Conditions, Riyadh, Saudi Arabia, 8–9 December 2016; pp. 8–9. [Google Scholar]

- Shalabi, F.I.; Cording, E.J.; Paul, S.L. Concrete segment tunnel lining sealant performance under earthquake loading. Tunn. Undergr. Space Technol. 2012, 31, 51–60. [Google Scholar] [CrossRef]

- Liu, J.G. The experimental research of the contact pressure of hydrophilic sealing gasket for shield tunnel segments. Chin. J. Undergr. Space Eng. 2009, 5, 1122–1125. (In Chinese) [Google Scholar] [CrossRef]

- Ming, Z.; Wenqi, D.; Yicheng, P.; Biwei, S.; Linsong, G.X.Y. Experimental study on the reliability of shield tunnel segment joints to remain watertight under high water pressure. Mod. Tunn. Technol. 2013, 50, 87–93. (In Chinese) [Google Scholar] [CrossRef]

- Ding, W.; Gong, C.; Mosalam, K.M.; Soga, K. Development and application of the integrated sealant test apparatus for sealing gaskets in tunnel segmental joints. Tunn. Undergr. Space Technol. 2017, 63, 54–68. [Google Scholar] [CrossRef]

- Gong, C.; Ding, W.; Soga, K.; Mosalam, K.M.; Tuo, Y. Sealant behavior of gasketed segmental joints in shield tunnels: An experimental and numerical study. Tunn. Undergr. Space Technol. 2018, 77, 127–141. [Google Scholar] [CrossRef]

- Gong, C.; Ding, W. A computational framework to predict the water-leakage pressure of segmental joints in underwater shield tunnels using an advanced finite element method. Int. J. Numer. Anal. Methods Geomech. 2018, 42, 1957–1975. [Google Scholar] [CrossRef]

- Zhou, N.; Yuan, Y. Correlation of cross-river shield tunnel between longitudinal deformation curvature and segment leakage. J. Tongji Univ. (Nat. Sci.) 2009, 37, 1446–1451. [Google Scholar]

- Zhang, D.M.; Ma, L.X.; Zhang, J.; Hicher, P.Y.; Juang, C.H. Ground and tunnel responses induced by partial leakage in saturated clay with anisotropic permeability. Eng. Geol. 2015, 189, 104–115. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for Construction and Acceptance of Shield Tunnelling Method; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2017.

- Persson, B.N. Theory of rubber friction and contact mechanics. J. Chem. Phys. 2001, 115, 3840–3861. [Google Scholar] [CrossRef]

- Persson, B.; Albohr, O.; Tartaglino, U.; Volokitin, A.; Tosatti, E. On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter 2004, 17, R1. Available online: https://iopscience.iop.org/article/10.1088/0953-8984/17/1/R01/meta (accessed on 25 November 2020). [CrossRef]

- Persson, B.N.J. Contact mechanics for randomly rough surfaces. Surf. Sci. Rep. 2006, 61, 201–227. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Yang, C. Theory of the leak-rate of seals. J. Phys. Condes. Matter 2008, 20, 11. [Google Scholar] [CrossRef]

- Persson, B.; Lorenz, B.; Shimizu, M.; Koishi, M. Multiscale contact mechanics with application to seals and rubber friction on dry and lubricated surfaces. In Designing of Elastomer Nanocomposites: From Theory to Applications; Springer: Berlin, Germany, 2016; pp. 103–156. [Google Scholar] [CrossRef]

- Tallian, T.; Chiu, Y.; Van Amerongen, E. Prediction of traction and microgeometry effects on rolling contact fatigue life. J. Lubr. Technol. 1978, 100, 156–165. [Google Scholar] [CrossRef]

- Nayak, P.R. Random process model of rough surfaces. J. Lubr. Technol. 1971, 93, 398–407. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A. Surface energy and the contact of elastic solids. R. Soc. Lond. Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar] [CrossRef]

- Johnson, K. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; Volume 95, p. 365. [Google Scholar]

- Yang, C.; Persson, B. Contact mechanics: Contact area and interfacial separation from small contact to full contact. J. Phys. Condens. Matter 2008, 20, 215214. Available online: https://iopscience.iop.org/article/10.1088/0953-8984/20/21/215214/meta (accessed on 25 November 2020). [CrossRef]

- Yadav, R.; Kumar, M.; Mittal, A.; Dwivedi, S.; Pandey, A.C. On the scaling law analysis of nanodimensional LiF thin film surfaces. Mater. Lett. 2014, 126, 123–125. [Google Scholar] [CrossRef]

- Stauffer, D.; Aharony, A. Introduction to Percolation Theory; Taylor & Francis: Abingdon, UK, 2018; ISBN 1482272377. [Google Scholar]

- Batchelor, C.K.; Batchelor, G. An Introduction to Fluid Dynamics; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Aspnes, D.E. Local-field effects and effective-medium theory—A microscopic perspective. Am. J. Phys. 1982, 50, 704–709. [Google Scholar] [CrossRef]

- Liu, S.; Wang, X.; Wang, J.; Chen, J. Numerical analysis of cut-and-cover excavation part of a cross-river tunnel. Chin. J. Geotech. Eng. 2013, 35, 330–334. Available online: http://d.wanfangdata.com.cn/conference/8211707 (accessed on 11 July 2020). (In Chinese).

- Bottiglione, F.; Carbone, G.; Mangialardi, L.; Mantriota, G. Leakage mechanism in flat seals. J. Appl. Phys. 2009, 106, 104902. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, P. Waterproof grade standard and detection of tunnel engineering. Constr. Technol. 2009, 38, 22–24, 45. Available online: http://d.wanfangdata.com.cn/periodical/sgjs200904006 (accessed on 25 November 2020). (In Chinese).

- Shalabi, F.I.; Cording, E.J.; Paul, S.L. Sealant behavior of gasketed segmental tunnel lining–Conceptual model. Geomech. Tunn. 2016, 9, 345–355. [Google Scholar] [CrossRef]

- Shi, C.; Cao, C.; Lei, M.; Peng, L.; Shen, J. Time-dependent performance and constitutive model of EPDM rubber gasket used for tunnel segment joints. Tunn. Undergr. Space Technol. 2015, 50, 490–498. [Google Scholar] [CrossRef]

| Joint Gap (mm) | Time (Year) | Roughness h (nm) | Groundwater Pressure (Mpa) | Leakage (L/m2/day) | |

|---|---|---|---|---|---|

| 1 | 1 (0) | 1 (0) | 1 (10) | 1 (0.4) | 0.000123 |

| 2 | 1 | 2 (25) | 2 (30) | 2 (0.6) | 0.011012 |

| 3 | 1 | 3 (50) | 3 (60) | 3 (0.8) | 0.073867 |

| 4 | 1 | 4 (75) | 4 (90) | 4 (1.0) | 0.288195 |

| 5 | 1 | 5 (100) | 5 (120) | 5 (1.2) | 0.838985 |

| 6 | 2 (2.5) | 1 | 2 | 3 | 0.003468 |

| 7 | 2 | 2 | 3 | 4 | 0.073565 |

| 8 | 2 | 3 | 4 | 5 | 0.312645 |

| 9 | 2 | 4 | 5 | 1 | 0.266312 |

| 10 | 2 | 5 | 1 | 2 | 0.008295 |

| 11 | 3 (5) | 1 | 3 | 5 | 0.030485 |

| 12 | 3 | 2 | 4 | 1 | 0.090373 |

| 13 | 3 | 3 | 5 | 2 | 0.382805 |

| 14 | 3 | 4 | 1 | 3 | 0.011040 |

| 15 | 3 | 5 | 2 | 4 | 0.078869 |

| 16 | 4 (7.5) | 1 | 4 | 2 | 0.064213 |

| 17 | 4 | 2 | 5 | 3 | 0.494333 |

| 18 | 4 | 3 | 1 | 4 | 0.014627 |

| 19 | 4 | 4 | 2 | 5 | 0.103503 |

| 20 | 4 | 5 | 3 | 1 | 0.118154 |

| 21 | 5 (10) | 1 | 5 | 4 | 0.177043 |

| 22 | 5 | 2 | 1 | 5 | 0.007473 |

| 23 | 5 | 3 | 2 | 1 | 0.045529 |

| 24 | 5 | 4 | 3 | 2 | 0.156215 |

| 25 | 5 | 5 | 4 | 3 | 0.399236 |

| A | B | C | D | ||

| 0.123722 | 0.233642 | 0.423584 | 0.154520 | ||

| Rank | 4 | 2 | 1 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yang, Y.; Su, F.; Wang, L. Multiscale Analytical Method and Its Parametric Study for Lining Joint Leakage of Shield Tunnel. Appl. Sci. 2020, 10, 8528. https://doi.org/10.3390/app10238528

Wang Y, Yang Y, Su F, Wang L. Multiscale Analytical Method and Its Parametric Study for Lining Joint Leakage of Shield Tunnel. Applied Sciences. 2020; 10(23):8528. https://doi.org/10.3390/app10238528

Chicago/Turabian StyleWang, Yajian, Yuyou Yang, Fei Su, and Linbing Wang. 2020. "Multiscale Analytical Method and Its Parametric Study for Lining Joint Leakage of Shield Tunnel" Applied Sciences 10, no. 23: 8528. https://doi.org/10.3390/app10238528

APA StyleWang, Y., Yang, Y., Su, F., & Wang, L. (2020). Multiscale Analytical Method and Its Parametric Study for Lining Joint Leakage of Shield Tunnel. Applied Sciences, 10(23), 8528. https://doi.org/10.3390/app10238528