1. Introduction

The process of vulcanisation of natural or synthetic rubber is applied to produce an elastic material, namely rubber, whose properties facilitate a vast spectrum of applications. Extremely high elongation with very low strength [

1] and high absorption and insulation properties of elastomer materials are suitable for a wide range of industrial applications, such as electric insulation, medical devices and transportation. Elastomer materials are exposed to extreme load conditions, such as complex mechanical loads, high temperatures, UV radiation, oxygen and humidity. Their mechanical and utility properties are therefore affected by particular operating conditions. Mechanical and utility properties of elastomers strongly depend on their loading history and exposure to chemical and physical ageing. These properties are directly affected by changes in the macromolecular mesh structure induced by a chemical reaction [

2]. Elastomers are widely used in various industries thanks to their remarkable dissipation properties: they endure high mechanical loads, i.e., high deformation velocities and large strains [

3].

Rubber represents an important component of a rubber composite, i.e., a conveyor belt. The conveyor belt is the basic structural component of a belt conveyor, which is very important in mining, transport and processing of bulk materials [

4] and in many other areas. The belt conveyor is one of the most commonly used conveyor types thanks to its high transportation efficiency and velocity, long-distance transport capacity, low energy consumption, operational safety and simple operation and maintenance [

5]. Conveyor belts, i.e., the carrying and tractive elements of conveyors, are used in practically all industries [

6]; they are also widely used in the transport of grainy materials [

7]. However, the costs of purchase, maintenance, repairs and renewal of the conveyor belt often exceed the costs of the remaining parts of the conveyance system, such as support systems and drives. It is therefore still a great priority to extend the belt service life, which may be achieved by reducing the conveyor belt wear.

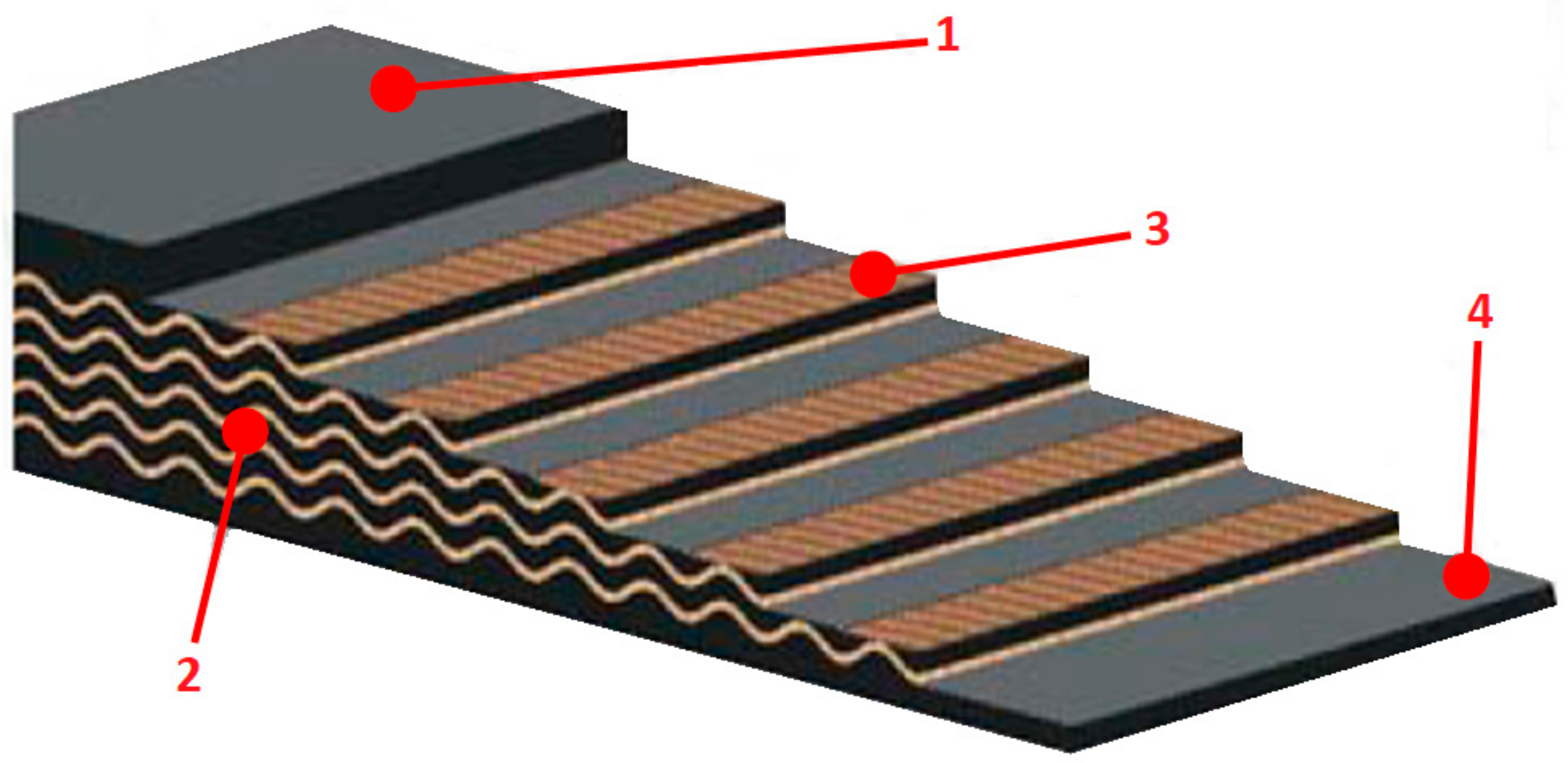

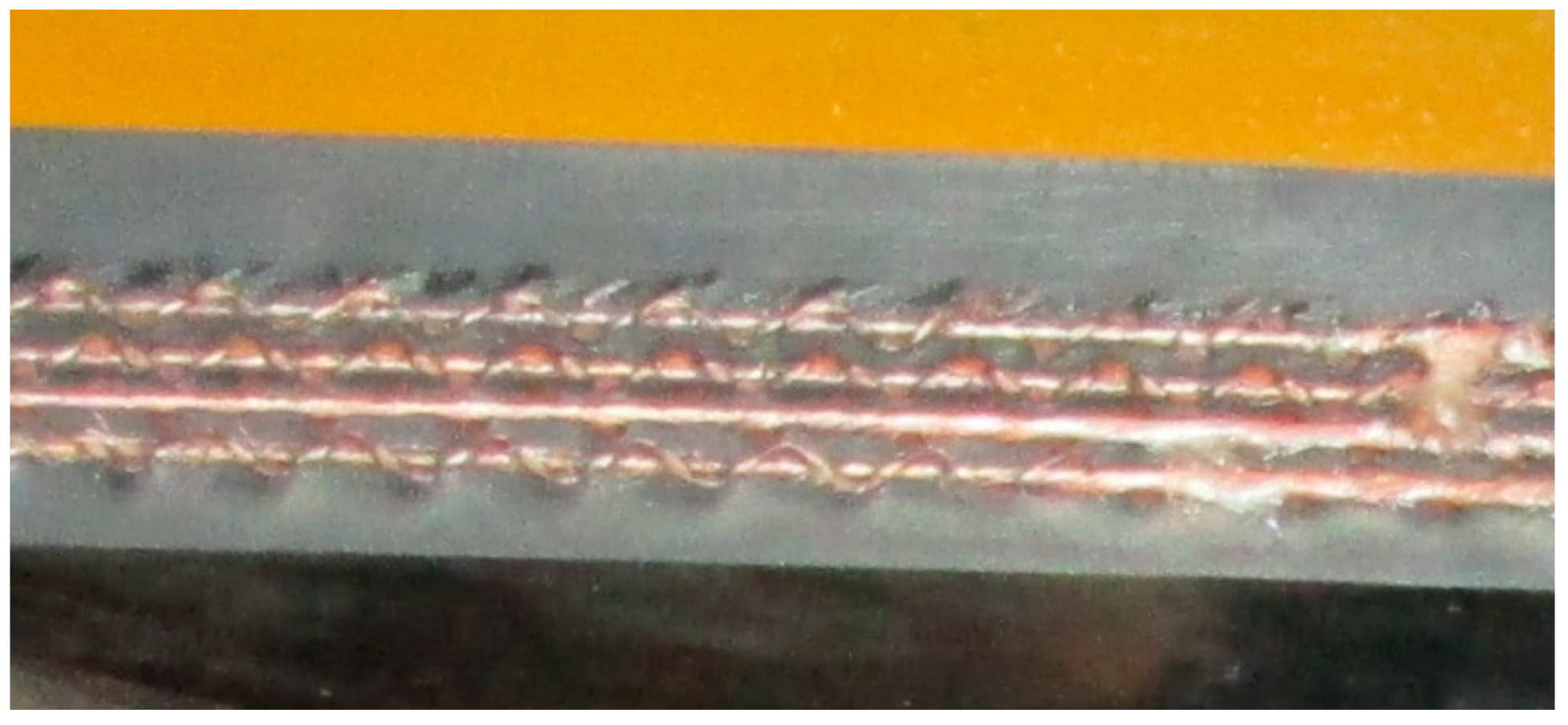

A conveyor belt is a composite consisting of different materials. The properties of its individual components significantly affect the final properties of the belt as such and determine its suitability for a particular function and application in real operations. From the structural point of view, both fabric and steel-cord conveyor belts have the same cover layer materials. Rubber cover layers protect the belt carcass and provide the required resistance to forces to which the conveyor belt is exposed. The top cover layer is in direct contact with the transported material, which damages it during the operation. Fabric conveyor belts, which are the ones most frequently used [

8], usually consist of a wear-resistant top cover layer, with the fabric carcass providing the tensile strength of the belt, the adhesive mixture between the rubber and the carcass, and the bottom rubber cover layer covering the carcass and providing sufficient friction on the driving pulley [

9]. The structure of different steel-cord conveyor belts is basically the same, and only the carcass material is different. In real operations, special attention is paid to the top cover layer as it is tribologically the most stressed belt part.

Conveyor belt wear is characterised by abrasion [

10]. It is very important to describe the wearing process in rubber products exposed to high stresses, for example, in belts transporting sharp-edged materials. Sharp edges and rough surfaces gradually abrade the rubber parts. Such wear significantly damages individual belt parts and eventually destroys the belt [

11].

The service life of conveyor belts used in quarries depends on operating conditions and may last a few years or even more than 10 years, while belts with steel cords have longer service lives [

12]. In underground mines, the service lives of conveyor belts are reduced to several years, and the average service life of fabric belts used in mines is approximately 3–4 years [

13].

The issues regarding the examination of belt conveyor properties and the monitoring of belt wear or damage have been discussed in many papers. Hardygora [

14] stated that basic experimental methods used to assess reliability and quality of conveyor belts made of rubber and fabric include the monitoring of puncture resistance, cut resistance, stress-strain testing and belt joints examination. Bocko et al. [

15] tested mechanical properties of rubber conveyor belts by exposing them to impact loading, and the resulting belt failures were assessed by computed tomography. Andrejiová and Grinčová [

16] categorised the types of impact damage that occur in fabric conveyor belts. In laboratory conditions, they tested various types of conveyor belts (unused, used and used ones with renovated top cover layers).

In order to evaluate belt properties and quality, it is necessary to determine conventional mechanical, physical and special properties that provide complex data on the behaviour of used belts in complicated loading conditions. The operational service life of a conveyor belt depends on multiple factors—transported material, operating conditions, conveyor belt quality and material properties [

17]. One of the material properties of conveyor belts is the tensile strength, which is determined primarily by the strength of fabric plies forming the carcass.

The belt’s cover layer material is rubber, and its elastic properties change as it ages. Ageing of polymers, such as rubber, may be caused by various chemical and mechanical processes, accelerated high loading and temperatures, or by the effects of ozone or sunlight. High temperatures in particular may accelerate oxidation and radical-activated processes of chain cleavage. These processes may be referred to as chemical degradation, which affects the properties of the material. As elastomers age, their efficiency is affected not only by chemical degradation (bond-breaking and bond-making processes) but also by molecular regrouping affecting entropic processes that are crucial for elasticity [

18]. The purpose of paper [

19] was the experimental testing of rubber hardness and identification of the impact of natural ageing on that particular mechanical property. The issues regarding conveyor belt ageing at higher temperatures and its impact on abrasive properties of rubber have been dealt with by Edgea et al. [

20], who investigated the oxidation stability of natural rubber at the temperature of 150 °C. It has been demonstrated that after the absorption of even 1% of oxygen, natural rubber completely loses its elasticity, and its abrasive resistance is hence impaired. This has also been confirmed in paper [

4], which discusses the experimental investigation of abrasive resistance and hardness of fabric belts. It was confirmed that oxygen reacting with sulphur transversally bound among rubber molecules reduces the rubber’s elastic properties. The fact that rubber in conveyor belts loses its tensile strength due to ageing was confirmed by Turnbull [

21]. This process may also cause the reduction of the polymerisation degree, and as a result, the chemical composition of the belt changes. In [

22], rubber hardness and abrasive resistance were identified, and the effects of natural ageing on rubber properties were investigated. The test results confirmed that even at the ambient temperature, the ageing of rubber increased its hardness and that this affected the functional properties of the rubber cover layer.

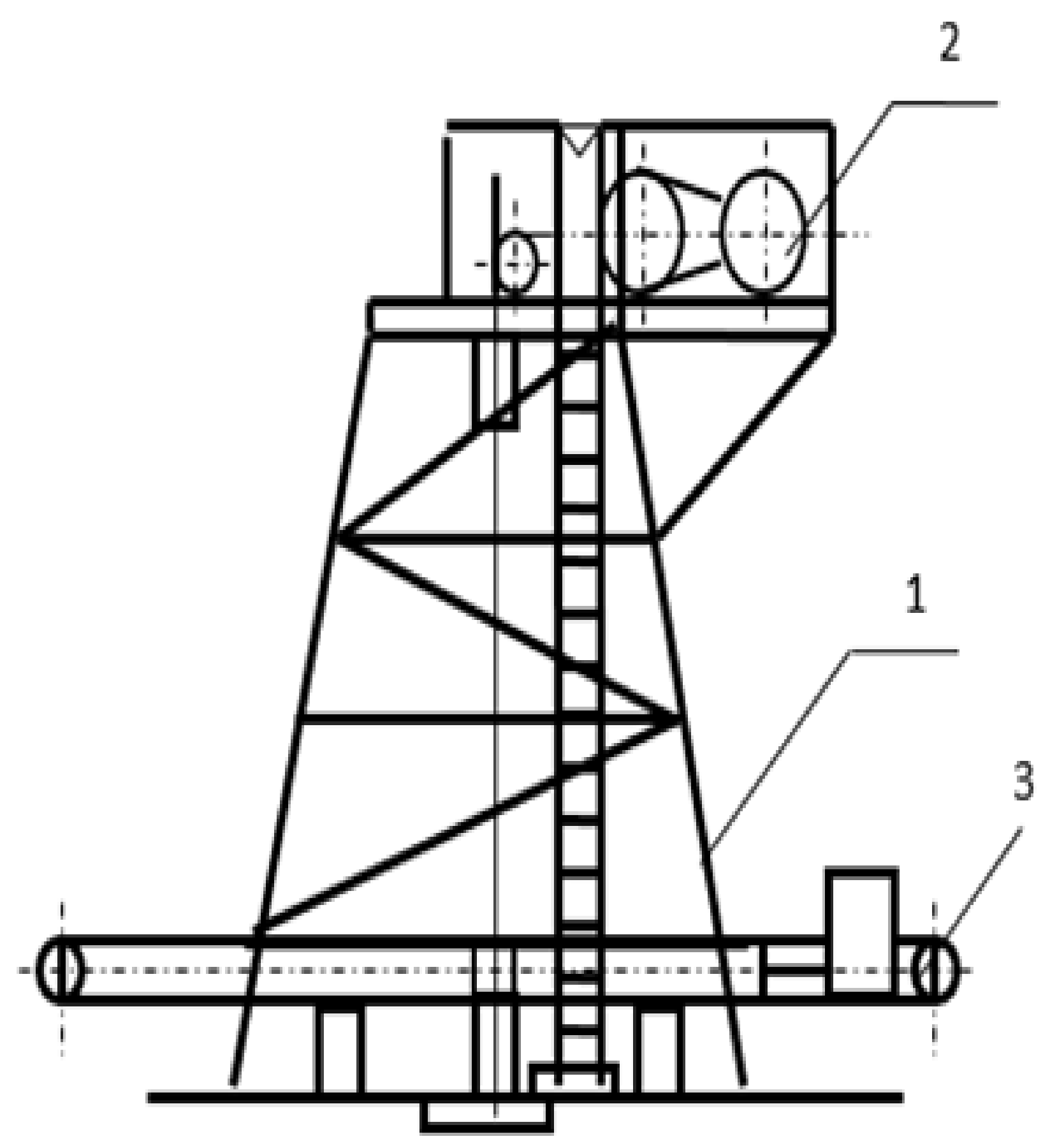

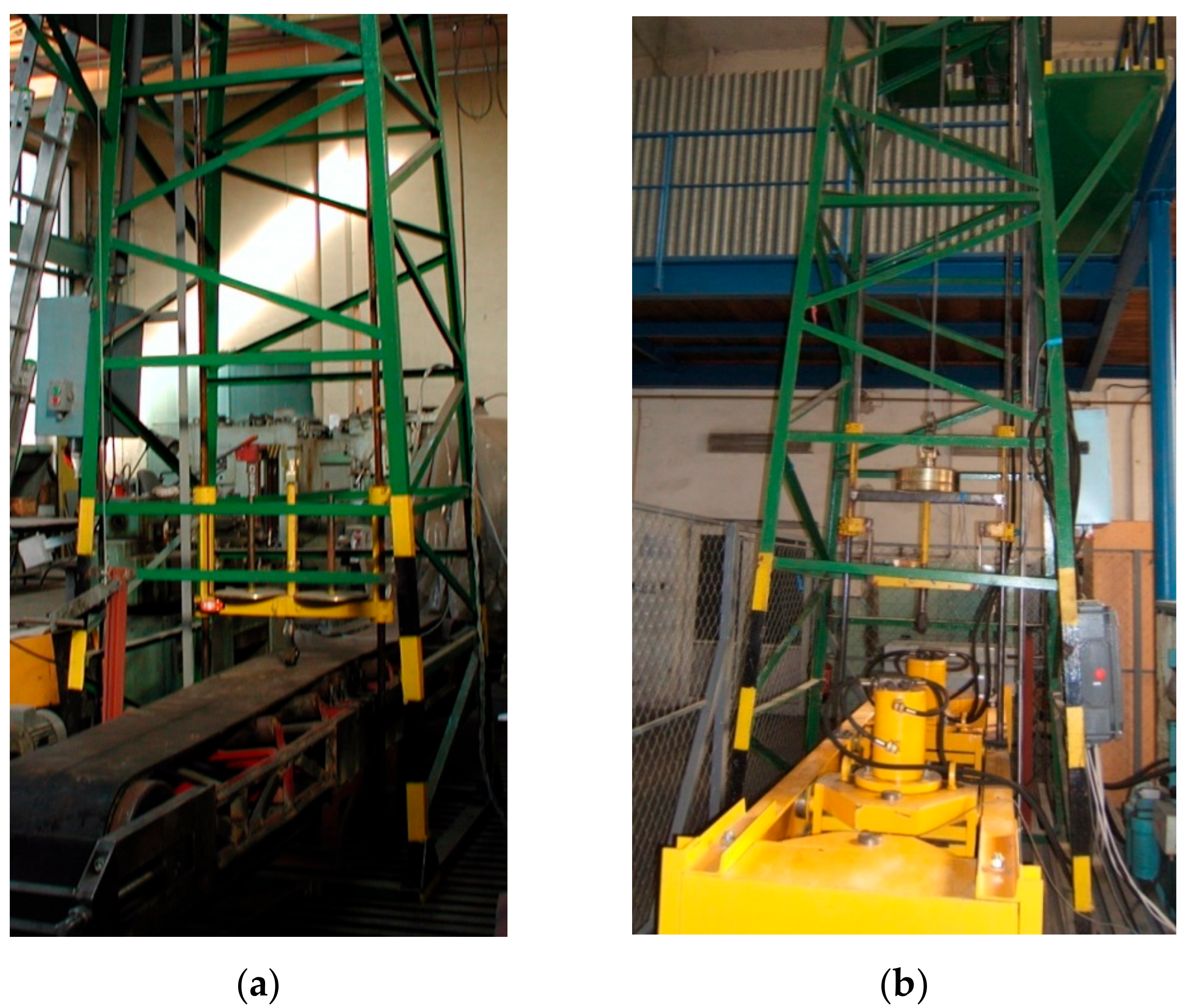

The present paper deals with the identification of the effects of the support system on the impact force and the identification of correlations between the impact force and the tensile force based on the measured data.

3. Results and Discussion

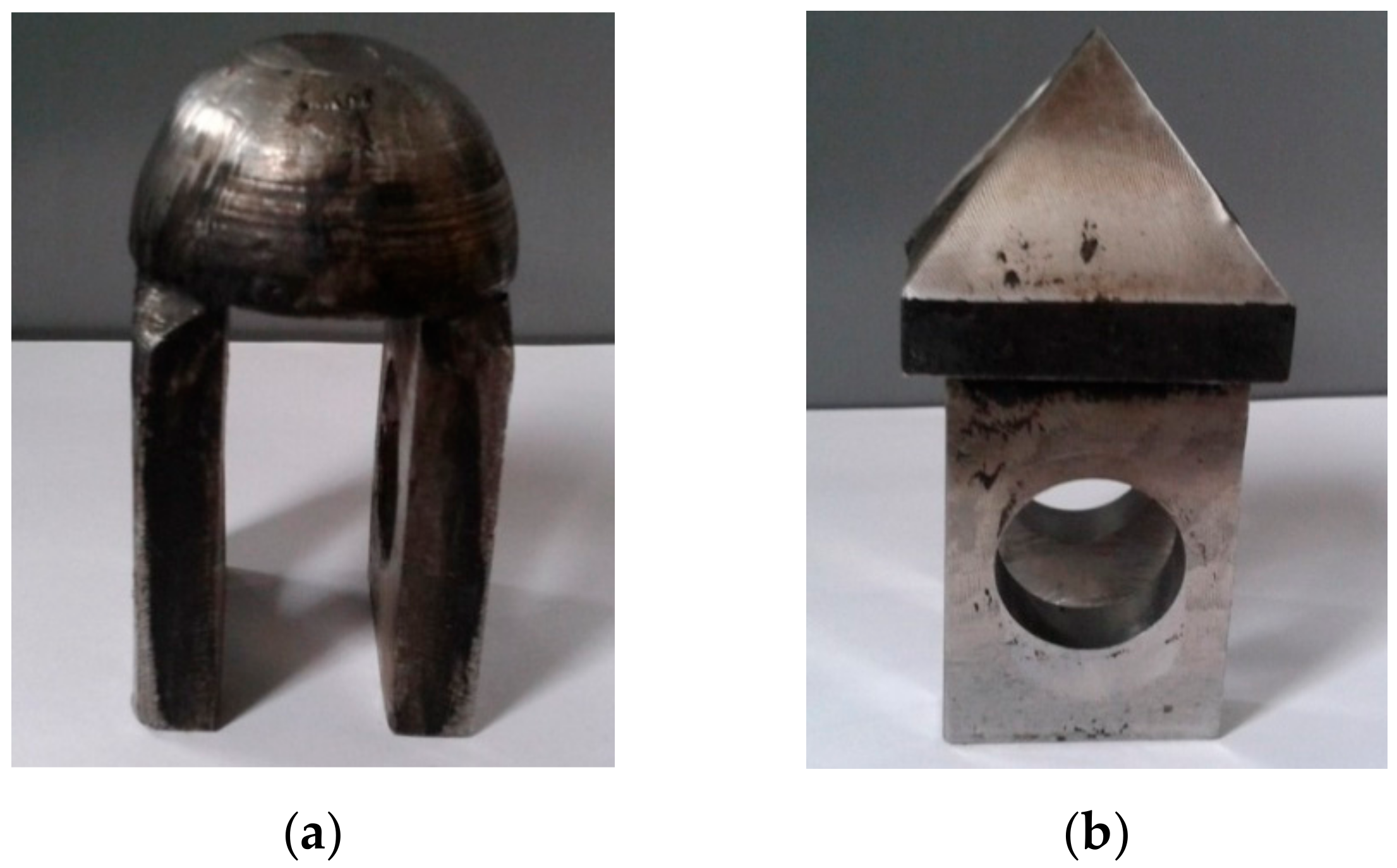

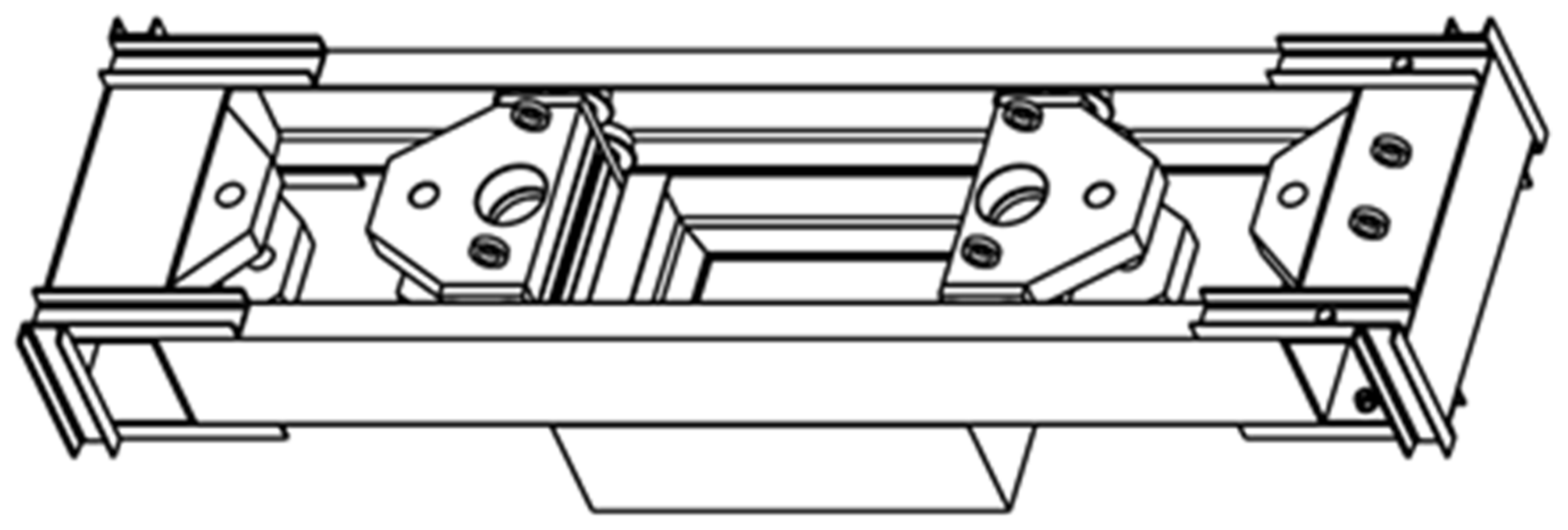

The tests were carried out with and without the support system and at drop hammer weights of 60, 80, 90 and 100 kg. The drop hammer was dropped onto the conveyor belt from the maximum height of 2.6 m. A puncture of the belt was observed when the drop hammer weighing 80 kg was dropped from the height of 1.8 m, when the drop hammer weighing 90 kg was dropped from the height of 1.6 m and when the drop hammer weighing 100 kg was dropped from the height of 1.6 m. In testing without the support system, the impact loading lasted longer than in testing with the support system. At the drop hammer weight of 90 kg, the impact loading without the support system lasted 0.98 s to 3.36 s. At the drop hammer weight of 100 kg, the impact loading without the support system lasted 0.9 s to 3.74 s. In testing without the support system, the puncture did not occur, not even at the maximum height of 2.6 m. When the idler set (support system) was used, at the drop hammer weight of 90 kg, the impact loading lasted 0.62 s to 1.82 s, and at the drop hammer weight of 100 kg, the times were similar, i.e., from 0.62 s to 1.92 s. In both cases of the impact loading of the conveyor belt using the support system, the puncture occurred at the drop height of 1.6 m. At the weight of 90 kg, the idler set reduced the impact process duration to 0.3 s to 1.54 s. At the weight of 100 kg, the idler set reduced the impact process duration to 0.16 s to 1.82 s.

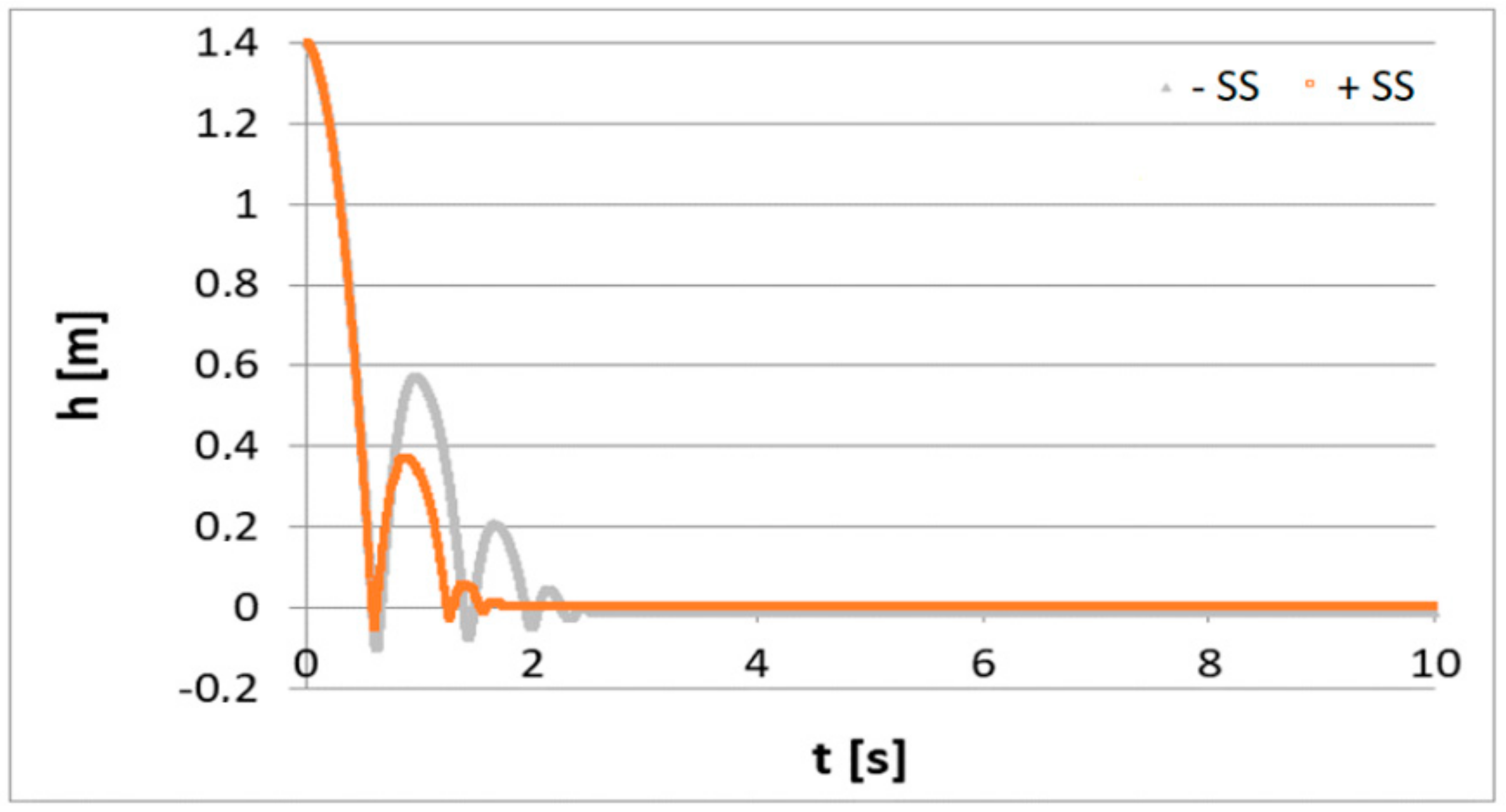

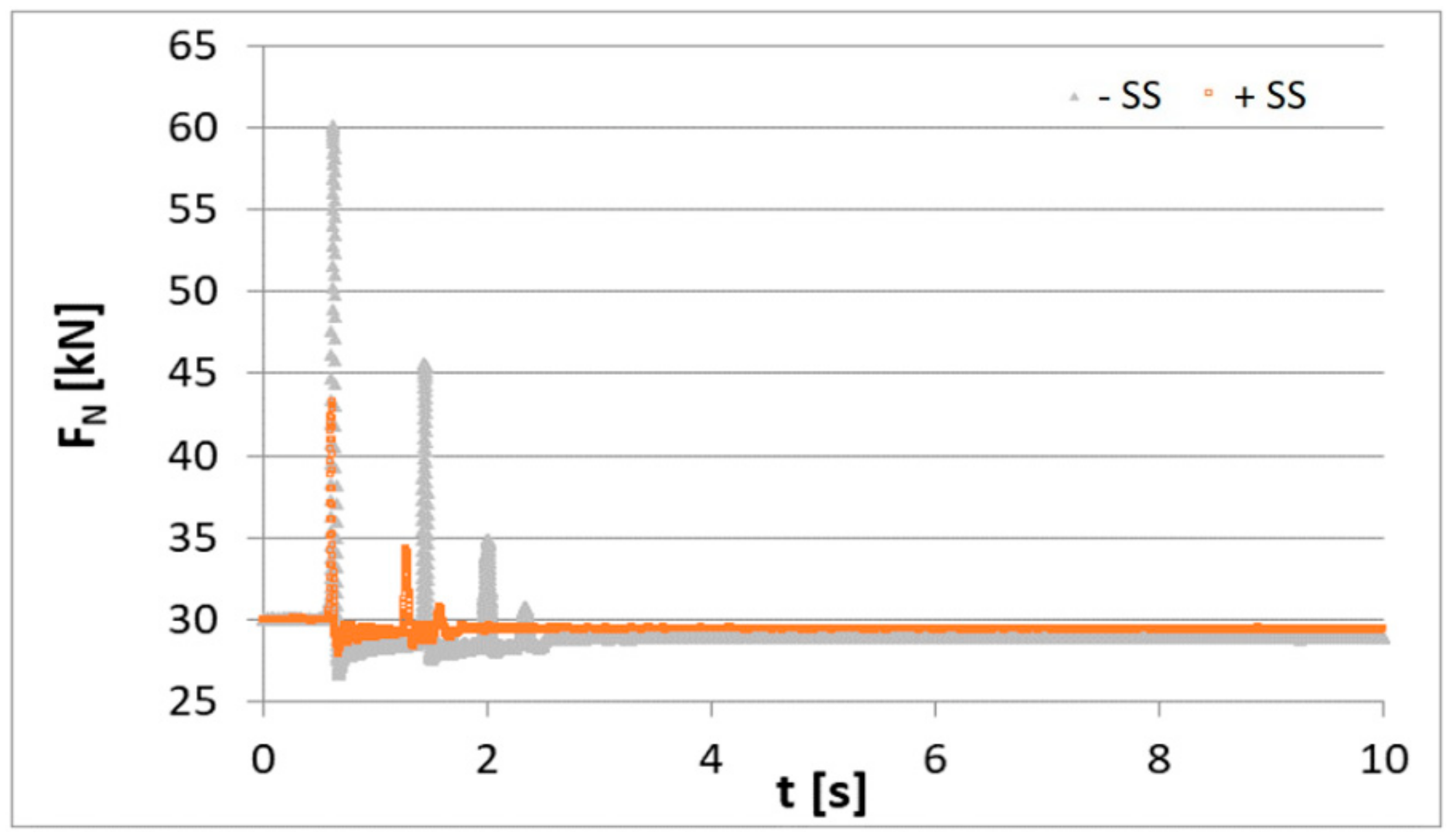

In both cases, the drop hammer weighing 90 kg was dropped onto the belt from the height of 1.4 m. The impact with the use of the support system lasted less time than without the support system. With the support system, it lasted approximately 1.8 s, and without the support system, it lasted more than 2 s. The drop hammer weight was identical in both cases. At the impact loading with the idler set, the puncture of the belt occurred when the drop hammer was dropped from the height of 1.6 m, and without the idler set, the puncture did not occur at all.

Figure 7 shows the comparison of the impact duration without and with the support system when the drop hammer was dropped from the drop height of 1.4 m and with a weight of 90 kg. The comparison indicates that the support system reduced the impact duration, as the idler set prevented the conveyor belt specimen from bending and hence absorbed the impact energy. Without the support system, the belt specimen was free to bend, and due to different bumping effects, the impact lasted longer.

The first contact between the drop hammer and the tested specimen and the subsequent decay of the impact process are shown in

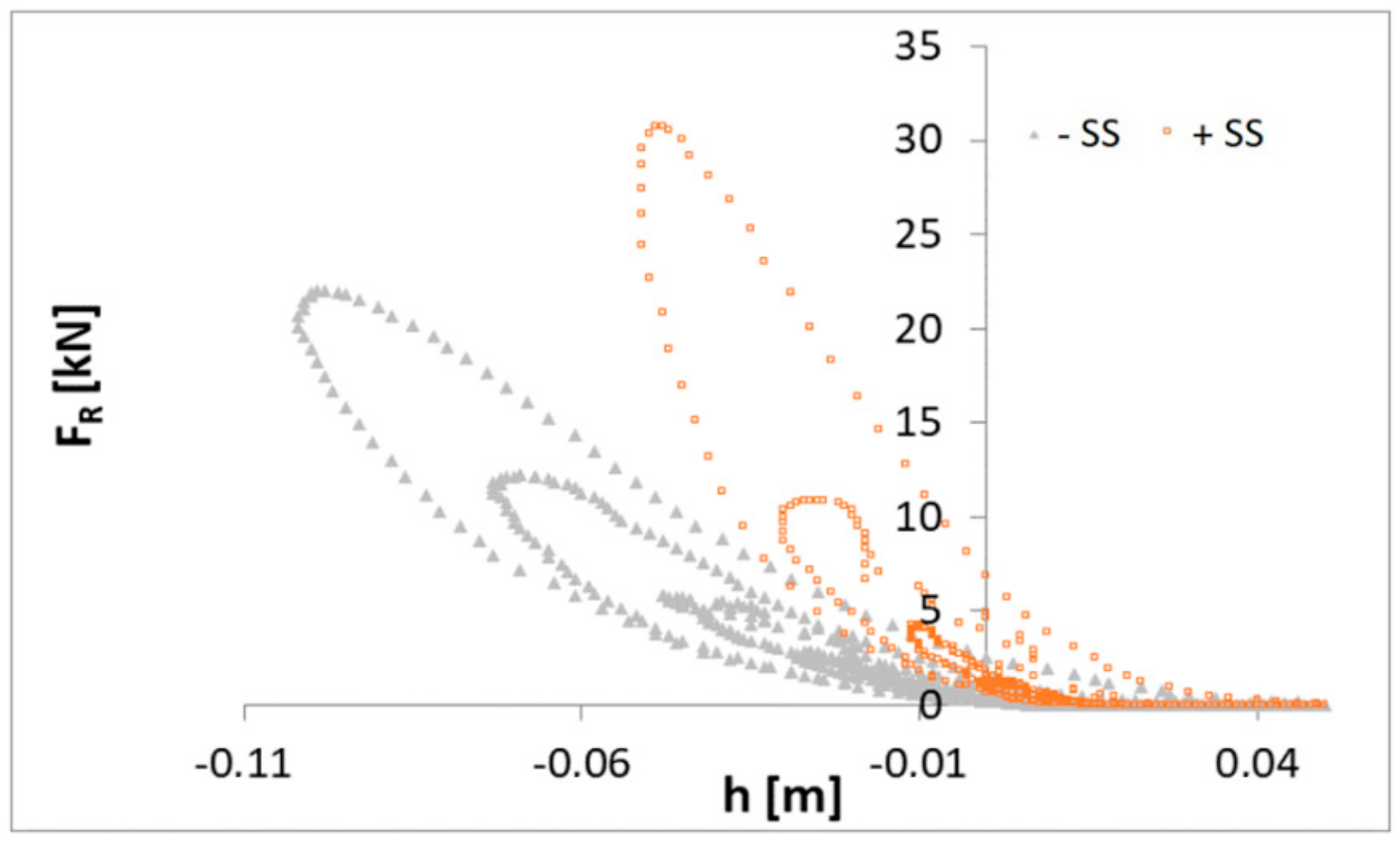

Figure 8. At the impact loading with the support system, at the first contact between the drop hammer and the belt specimen, the impact force was higher than without the support system, as the idler set absorbed the effects of the impact. Without the support system, the decay of the impact force lasted longer than in the testing carried out with the support system.

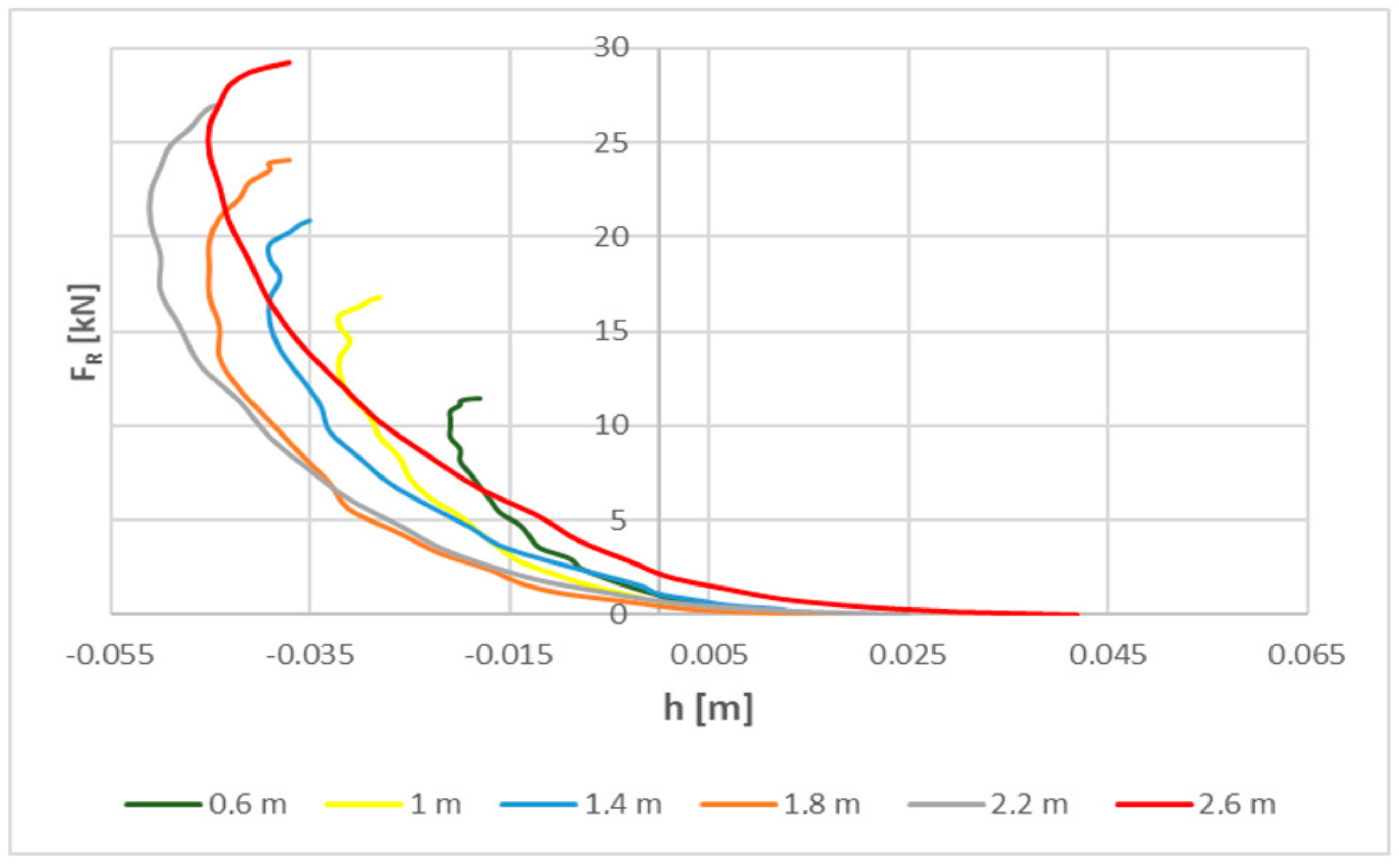

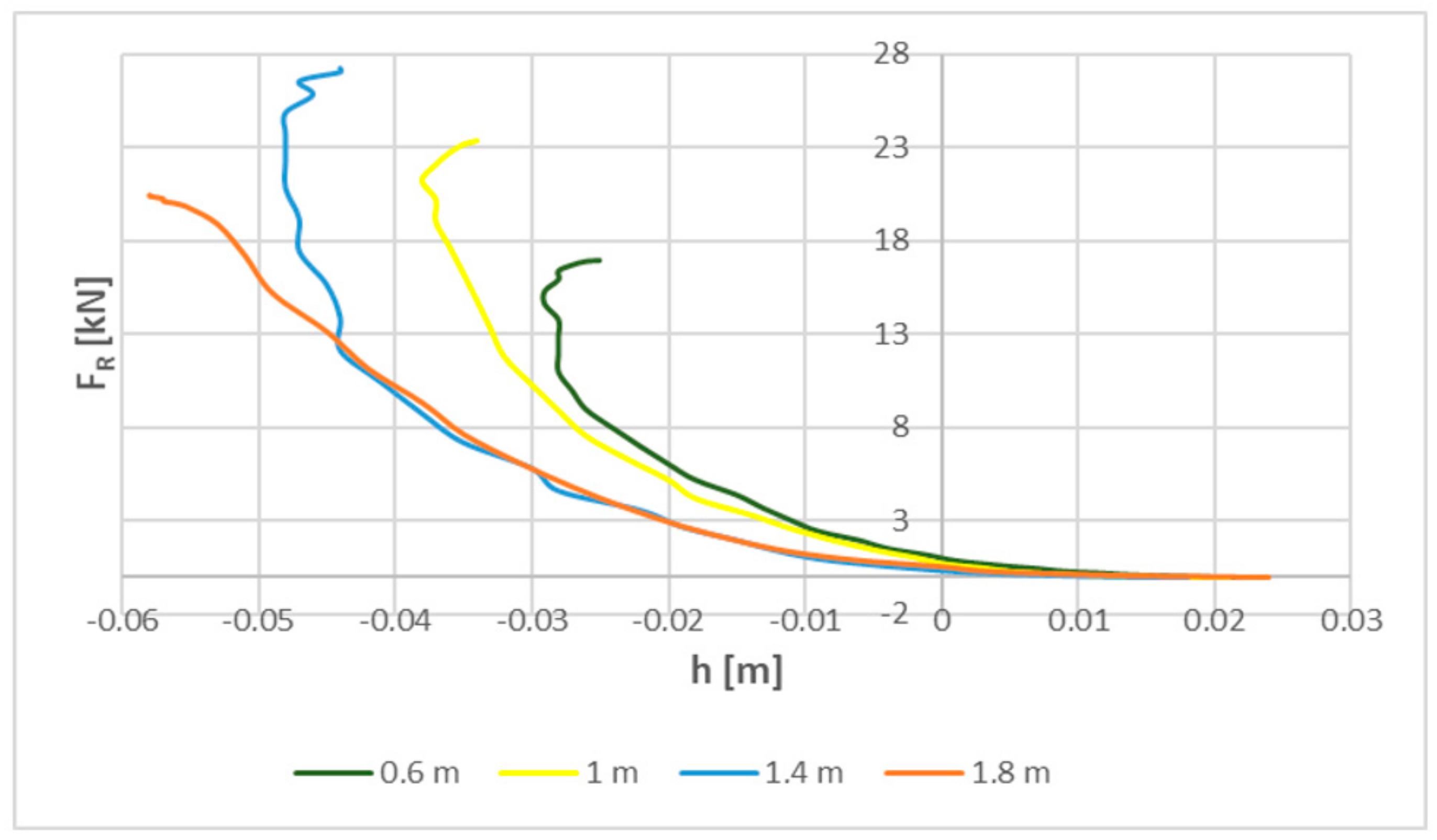

Figure 9 shows the correlation between the impact force and the height; at the impact loading without the support system, there are larger height variations than in cases when the support system was used, because the tested belt was not supported. The figure shows the changes in the impact force and the height when the drop hammer contacted the tested specimen. The impact force and height increased, reached their peaks and then decreased.

Figure 10 shows the influence of the support system on the correlation between the tensile force and the time. When the support system was used, the tensile force was lower, and its decay lasted less time than under the impact loading without using the support system; in the latter case, at the first contact between the drop hammer and the specimen, the tensile force was the highest and reached its peak and subsequently decreased.

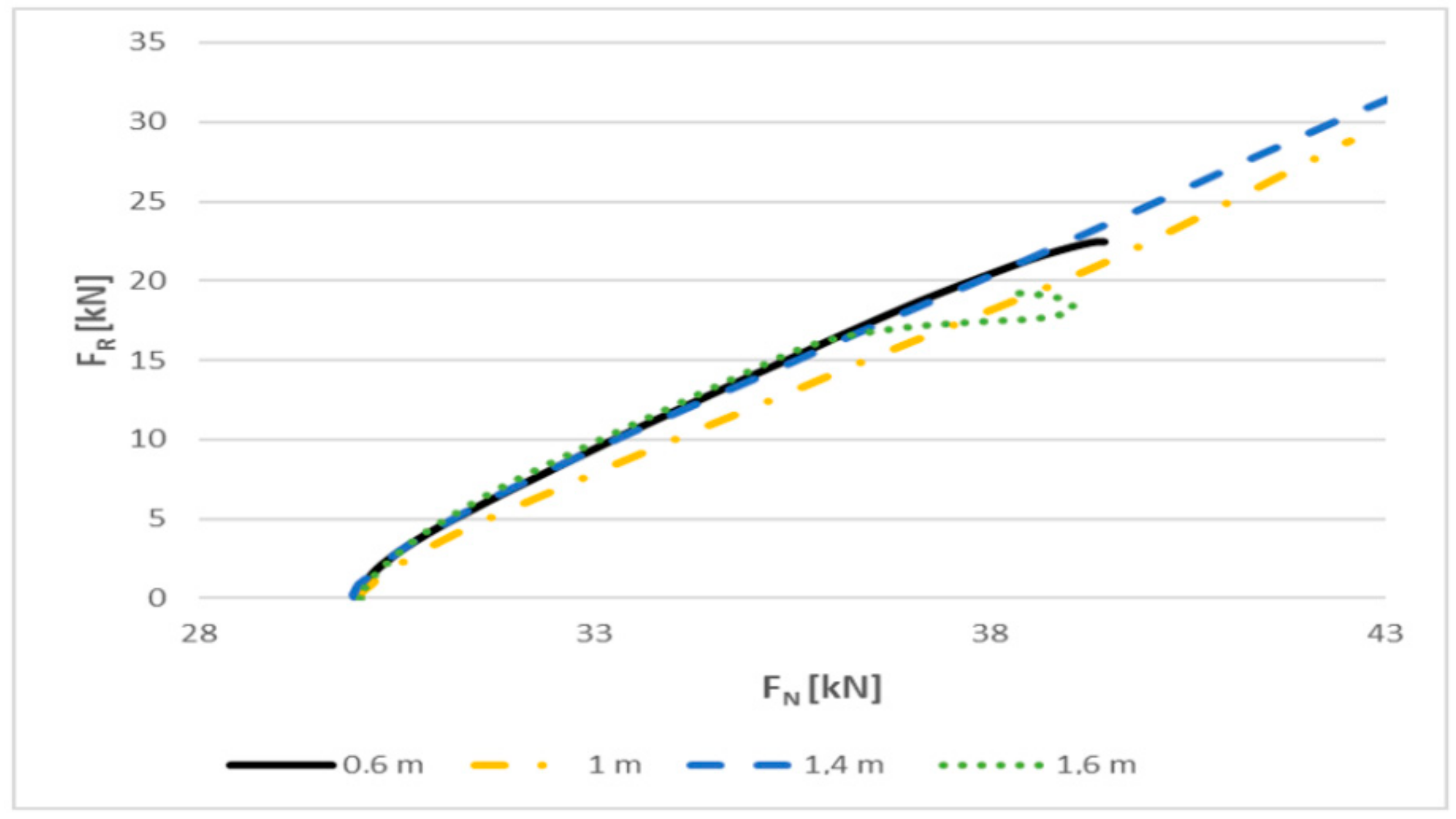

Figure 11 shows the correlation between the impact force and the tensile force and indicates that as the impact force increased, the tensile force increased as well. When the support system was used, the impact force was higher and the tensile force was lower, and in the absence of the support system, the opposite was the case. The correlation between the impact force and the tensile force when the support system was used exhibits a steeper slope than without the support system.

3.1. Correlation between the Impact Force and the Drop Height

To identify the correlation between the impact force and the drop height, the experimentally measured data were evaluated with the method of mathematical regression. In the analysis of conveyor belt damage caused by the falling material described in paper [

31], polynomials were used as the most appropriate ones for the impact process. The correlations were described by applying the functions selected based on the value of the coefficient of determination. The data were evaluated and processed, and specific parameters of the tested puncture resistance were selected for the relevant documentation.

With regard to the correlation between the impact force and the height at the drop hammer weight of 100 kg and the drop height of 1.6 m (

Figure 12), under the impact loading with the support system, the puncture of the belt occurred (orange data series in

Figure 12). In this case, the correlation was described using a 4th-degree polynomial on the basis of the elevated value of the coefficient of determination R

2. In the absence of the support system and with identical test parameters, the puncture did not occur, and such correlation was described using the exponential function on the basis of the elevated value of the coefficient of determination R

2.

The correlations between the impact force and the height at the drop hammer weight of 100 kg and the drop height of 1.4 m (

Figure 13) are described using more appropriate exponential functions, while the coefficient of determination R

2 achieved higher values than for the correlations with the 4th-degree polynomial.

3.1.1. Use of the Support System

The curves of the impact process for the correlation between the impact force and the height at the drop hammer weight of 60 kg and with the use of the support system (

Figure 14) indicate that as the drop height increased, the impact force increased too. An increase in the impact force with an increasing height in the monitored correlations exhibited similar behaviour.

The regression equations obtained from the evaluated correlations, including the coefficient of determination R

2, are listed in

Table 1.

The curves of the impact process for the correlation between the impact force and the height at the drop hammer weight of 80 kg with the use of the support system (

Figure 15) indicate that both the drop height and the impact force increased. In the event of a puncture, the curve takes a smoother shape than at lower heights, and at the end of the curve, there is a sharp increase in the impact force. Similar curves were observed with drop hammer weights of 90 kg and 100 kg.

The regression equations obtained from the evaluated correlations, including the coefficient of determination R

2, are listed in

Table 2,

Table 3 and

Table 4.

3.1.2. Absent Support System

It was confirmed that even when the support system was absent, the correlation between the impact force and the drop height for the drop hammer weights of 90 and 100 kg (

Table 5 and

Table 6) shows that the impact force increased, but its value was lower than when the support system was used; as a result, a puncture did not occur.

3.1.3. Correlation between the Impact Force and the Tensile Force with the Use of the Support System

The curve of the impact process for the correlation between the impact force and the tensile force at drop hammer weights of 60, 80, 90 and 100 kg with the use of the support system indicates that as the drop height increased, the impact force, as well as the tension force, also increased. At the drop height of 1.8 m (weight of 80 kg), the tensile force peak occurred sooner than the puncture, i.e., the maximum impact force. When the carcass was damaged, the tensile force decreased because the carrying puncture of the tested specimen was weaker. The same was also confirmed at the drop height of 1.6 m at drop hammer weights of 90 and 100 kg (

Figure 16). The regression equations obtained from the evaluated correlations for drop hammer weights of 60, 80, 90 and 100 kg, including the coefficient of determination R

2, are listed in

Table 7,

Table 8,

Table 9 and

Table 10. When the support system was used, the correlation between the impact force and the tensile force was described using the 4th-degree polynomial on the basis of higher values of the coefficient of determination than for the exponential function.

3.1.4. Correlation between the Impact Force and the Tensile Force without the Support System

During the impact process in which the support system was absent, the impact force was correlated with the tensile force at the drop hammer weight of 100 kg (

Figure 17), no puncture of the tested belt occurred, and the same result was observed with the drop hammer weighing 90 kg. Experiments confirmed that as the drop height increased, both the impact force and the tensile force increased too. Regression equations with the coefficient of determination R

2 of the evaluated correlations are listed in

Table 11 and

Table 12.

4. Conclusions

The tests with impact loading were carried out with and without the support system (the idler set). The experimental investigation confirmed that the support system reduces the duration of the impact; in particular, this means that tests without the support system lasted longer. During the testing of the rubber composite (conveyor belt) without the support system, no puncture occurred, not even at the maximum drop height of 2.6 m. When the support system was used, the puncture occurred at the drop hammer weight of 80 kg at the drop height of 1.8 m, and at the drop hammer weights of 90 and 100 kg at the drop height of 1.6 m. At the first contact between the drop hammer and the belt, the impact force was higher when the support system was used than when it was absent, but the decay of the impact lasted longer than when the support system was absent. For the correlation between the impact force and the height without the support system, there were more significant height variations than with the use of the support system. When the support system was used, the tensile force was lower, and its decay was shorter than in tests without the support system. At the first contact between the drop hammer and the belt specimen, the tensile force reached its peak and then decreased. When the idler set was used, the impact force was higher and the tensile force was lower, but in the absence of the idler set, the opposite was the case.

The correlation between the impact force and the tensile force when the support system was used exhibits a steeper slope than when it was absent. The correlation between the impact force and the height for the tested belts, determined by the regression analysis, is described using the 4th-degree polynomial, and the belts were punctured under the impact loading (80 kg/1.8 m; 90 kg/1.6 m; and 100 kg/1.6 m). In all the remaining evaluated tests in which the belt was not punctured, the correlation between the impact force and the height was described using the exponential function, because the coefficients of determination reached higher values than when the 4th-degree polynomial was applied. The regression analysis of the correlation between the impact force and the tensile force confirmed that the best alternative was the 4th-degree polynomial for all the evaluated cases, i.e., conveyor belt specimens with or without punctures, which were tested with and without using the support system.