Hydrotalcites in Construction Materials

Abstract

Featured Application

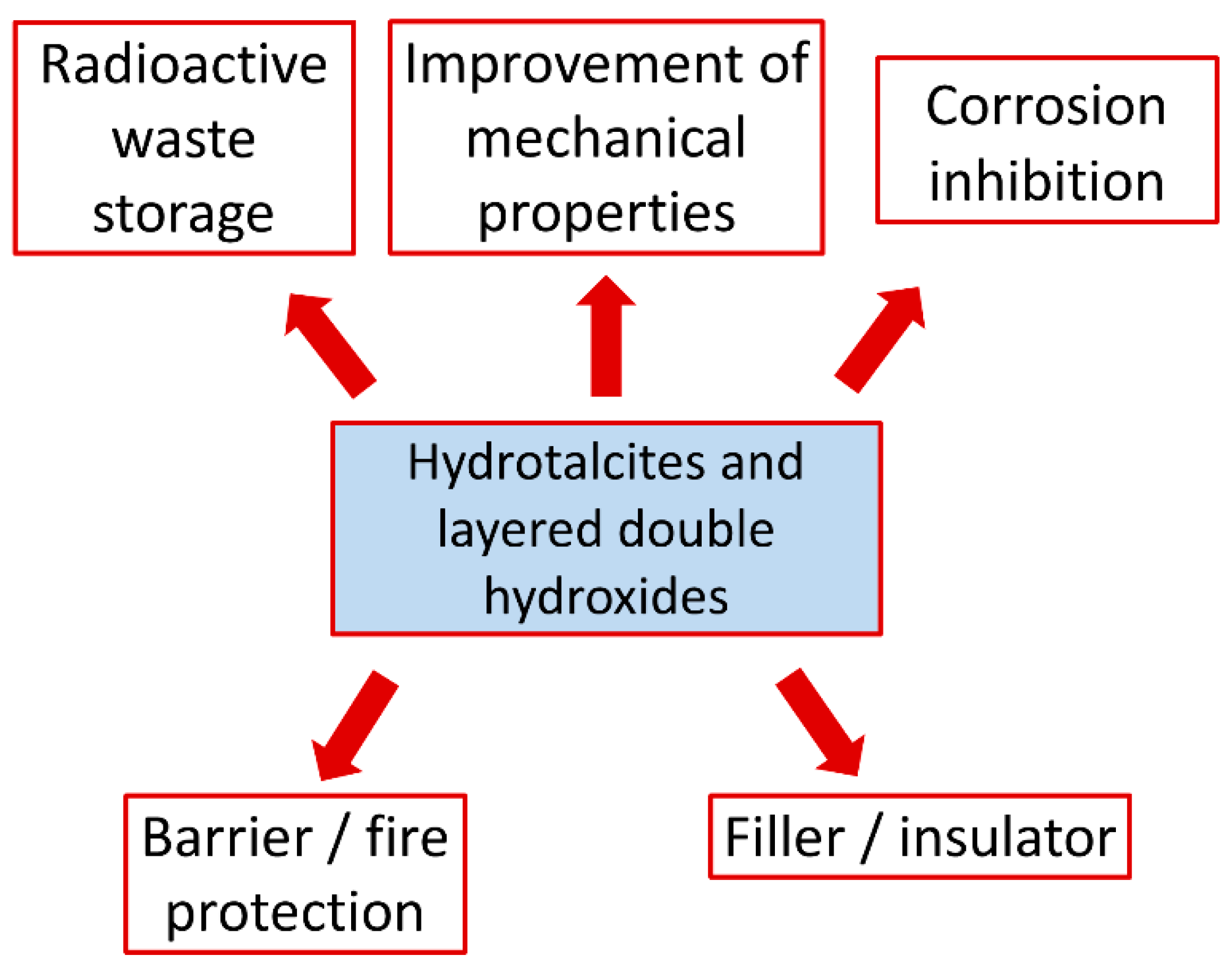

Abstract

1. Introduction

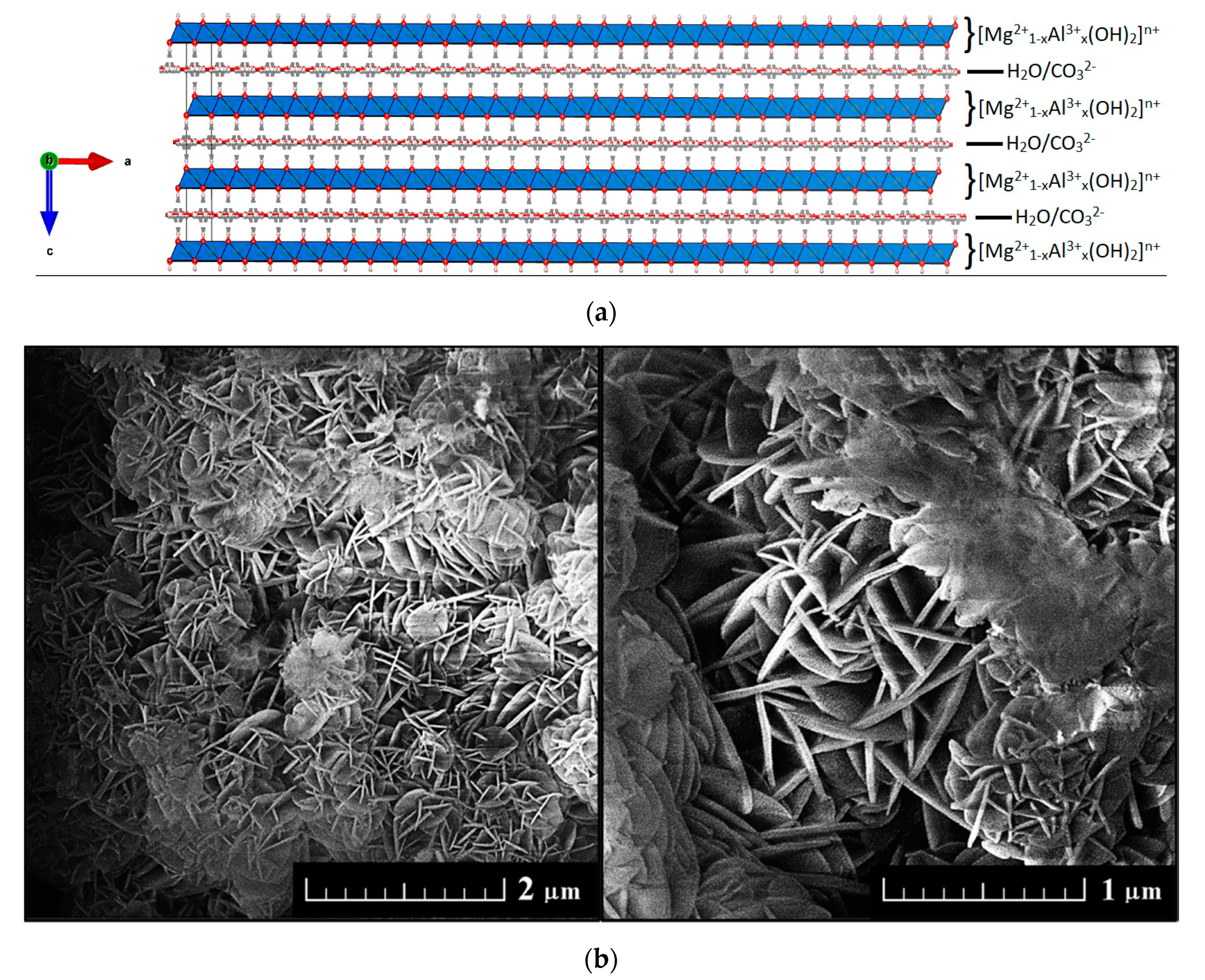

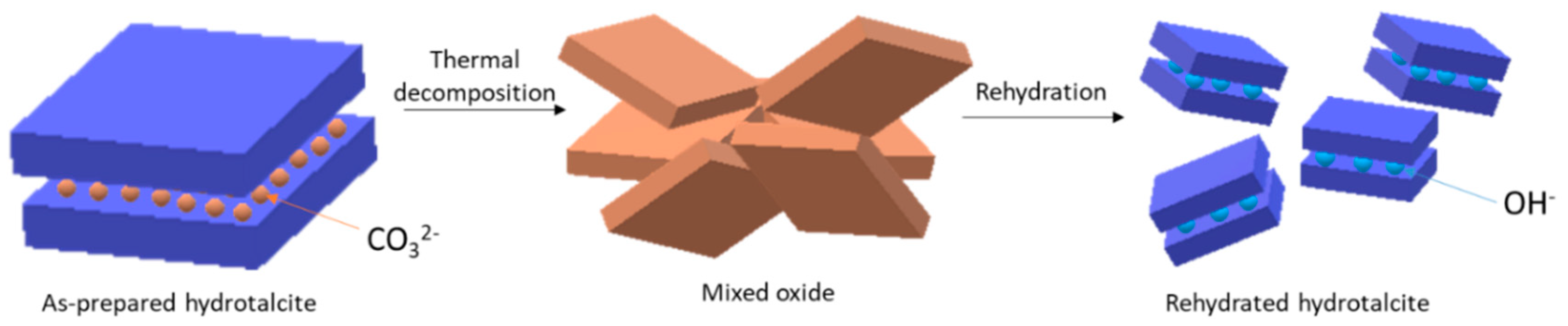

2. Synthesis of Hydrotalcites

3. General Application of the Hydrotalcites

4. Hydrotalcites as a Part of the Building Materials

4.1. Application in Radioactive Waste Repository

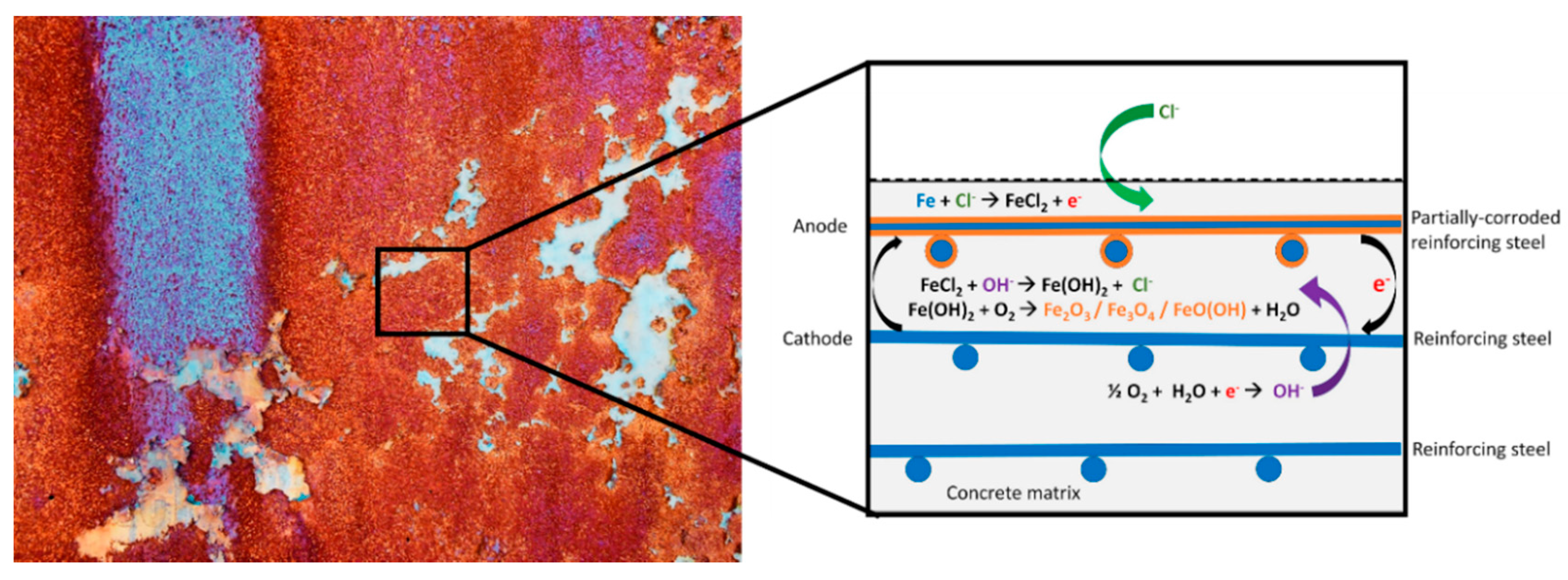

4.2. Hydrotalcites in Reinforced Concrete as Corrosion Inhibitive Addition

4.3. Hydrotalcites in Cements and Mortars

4.4. Hydrotalcites in Polymer Composites

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Manasse, E. Atti soc Toscana sc Nat. Proc. Verb. 1915, 24, 92. [Google Scholar]

- Jakubikova, B.; Kovanda, F. Utilization of layered double hydroxides in medical applications. Chem. Listy 2010, 104, 906–912. [Google Scholar]

- Gupta, S.; Agarwal, D.D.; Banerjee, S. Thermal stabilization of poly(vinyl chloride) by hydrotalcites, zeolites, and conventional stabilizers. J. Vinyl Addit. Technol. 2009, 15, 164–170. [Google Scholar] [CrossRef]

- Gupta, S.; Agarwal, D.D.; Banerjee, S. Role of hydrotalcites cations in thermal stabilization of poly (vinyl chloride). Int. J. Polym. Mater. 2012, 61, 124–135. [Google Scholar] [CrossRef]

- Hitt, D.J.; Haworth, B.; Thomas, N.L.; Algahtani, M.A. Melt compounding of rigid pvc formulations with hydrotalcites. Plast. Rubber Compos. 2008, 37, 445–452. [Google Scholar] [CrossRef]

- Bookin, A.S.; Drits, V.A. Polytype diversity of the hydrotalcite-like minerals i. Possible polytypes and their diffraction features. Clays Clay Miner. 1993, 41, 551–557. [Google Scholar] [CrossRef]

- Zhitova, E.; Yakovenchuk, V.; Krivovichev, S.; Zolotarev, A.; Pakhomovsky, Y.A.; Ivanyuk, G.Y. Crystal chemistry of natural layered double hydroxides. 3. The crystal structure of mg, al-disordered quintinite-2h. Miner. Mag. 2010, 74, 841–848. [Google Scholar] [CrossRef]

- Mills, S.J.; Christy, A.G.; Génin, J.M.R.; Kameda, T.; Colombo, F. Nomenclature of the hydrotalcite supergroup: Natural layered double hydroxides. Miner. Mag. 2012, 76, 1289–1336. [Google Scholar] [CrossRef]

- Dunn, P.J.; Peacor, D.R.; Palmer, T.D. Desautelsite, a new mineral of the pyroaurite group. Am. Miner. 1979, 64, 127–130. [Google Scholar]

- Chukanov, N.V.; Pekov, I.V.; Levitskaya, L.A.; Zadov, A.E. Droninoite, Ni3Fe3+Cl(OH)8 2H2O, a new hydrotalcite-group mineral species from the weathered dronino meteorite. Geol. Ore Deposits 2009, 51, 767–773. [Google Scholar] [CrossRef]

- Braithwaite, R.S.W.; Dunn, P.J.; Pritchard, R.G.; Paar, W.H. Iowaite, a re-investigation. Miner. Magaz. 1994, 58, 79–85. [Google Scholar] [CrossRef]

- Kohls, D.W.; Rodda, J.L. Iowaite, a new hydrous magnesium hydroxide-ferric oxychloride from the precambrian of iowa. Am. Miner. 1967, 52, 1261–1271. [Google Scholar]

- Koritnig, S.; Süsse, P. Meixnerit, mg6al2(oh)18·4h2o, ein neues magnesium-aluminium-hydroxid-mineral. Tsch. Miner. Petrograph. Mitt. 1975, 22, 79–87. [Google Scholar] [CrossRef]

- Ingram, L.; Taylor, H.F.W. The crystal structures of sjögrenite and pyroaurite. Miner. Magaz. J. Miner. Soc. 1967, 36, 465–479. [Google Scholar] [CrossRef]

- Frondel, C. Constitution and polymorphism of the pyroaurite and sjogrenite groups. Am. Miner. 1941, 26, 295–315. [Google Scholar]

- Song, Y.; Moon, H.S. Additional data on reevesite and its co-analogue, as a new member of the hydrotalcite group. Clay Miner. 1998, 33, 285–296. [Google Scholar] [CrossRef]

- Taylor, H. Crystal structures of some double hydroxide minerals. Miner. Magaz. 1973, 39, 377–389. [Google Scholar] [CrossRef]

- Mills, S.; Whitfield, P.; Wilson, S.; Woodhouse, J.N.; Dipple, G.; Raudsepp, M.; Francis, C. The crystal structure of stichtite, re-examination of barbertonite, and the nature of polytypism in mgcr hydrotalcites. Am. Miner. 2011, 96, 179–187. [Google Scholar] [CrossRef]

- Ashwal, L.D.; Cairncross, B. Mineralogy and origin of stichtite in chromite-bearing serpentinites. Contrib. Miner. Petrol. 1997, 127, 75–86. [Google Scholar] [CrossRef]

- Bish, D.L.; Brindley, G.W. A reinvestigation of takovite, a nickel aluminum hydroxy-carbonate of the pyroaurite group. Am. Miner. 1977, 62, 458–464. [Google Scholar]

- Maksimović, Z. Takovite, hydrous nickel aluminate, a new mineral. Zapisnici Srpskog Geoloskog Drustva. Compte Rendu Séances Soc. Serb. Géol. 1957, 1955, 219–224. [Google Scholar]

- Smith, D.G.W.; Nickel, E.H. A system of codification for unnamed minerals: Report of the subcommittee for unnamed minerals of the ima commission on new minerals, nomenclature and classification. Can. Miner. 2007, 45, 983–990. [Google Scholar] [CrossRef]

- Maksimović, Z.; Pantó, G.; Nagy, G. Iron-rich reevesitefrom the ni-fe ores of mt. Radočelo, serbia, a possible new member of the hydrotalcite subgroup. Acta Geol. Hung. 2002, 45, 373–383. [Google Scholar] [CrossRef]

- Mills, S.; Whitfield, P.; Kampf, A.; Wilson, S.; Dipple, G.; Raudsepp, M.; Favreau, G. Contribution to the crystallography of hydrotalcites: The crystal structures of woodallite and takovite. J. Geosci. 2012, 57. [Google Scholar] [CrossRef]

- Jambor, J.L. Muskoxite, a new hydrous magnesium-ferric iron oxide from the muskox intrusion, northwest territories, canada. Am. Miner. 1969, 54, 684–696. [Google Scholar]

- Lozano, R.P.; Rossi, C.; La Iglesia, A.; Matesanz, E. Zaccagnaite-3r, a new zn-al hydrotalcite polytype from el soplao cave (cantabria, spain). Am. Miner. 2012, 97, 513–523. [Google Scholar] [CrossRef]

- Jing, F.L.; Zhang, Y.Y.; Luo, S.Z.; Chu, W.; Qian, W.Z. Nano-size mznal (m = cu, co, ni) metal oxides obtained by combining hydrothermal synthesis with urea homogeneous precipitation procedures. Appl. Clay Sci. 2010, 48, 203–207. [Google Scholar] [CrossRef]

- Kloprogge, J.T.; Hickey, L.; Frost, R.L. The effects of synthesis ph and hydrothermal treatment on the formation of zinc aluminum hydrotalcites. J. Solid State Chem. 2004, 177, 4047–4057. [Google Scholar] [CrossRef]

- Othman, M.R.; Helwani, Z.; Martunus; Fernando, W.J.N. Synthetic hydrotalcites from different routes and their application as catalysts and gas adsorbents: A review. Appl. Organomet. Chem. 2009, 23, 335–346. [Google Scholar] [CrossRef]

- Pan, G.X.; Xia, X.H.; Luo, J.S.; Cao, F.; Yang, Z.H.; Fan, H.J. Preparation of coal layered double hydroxide nanoflake arrays and their high supercapacitance performance. Appl. Clay Sci. 2014, 102, 28–32. [Google Scholar]

- Yang, Z.Y.; Zhou, H.W.; Zhang, J.C.; Cao, W.L. Relationship between al/mg ratio and the stability of single-layer hydrotalcite. Acta Phys. Chim. Sin. 2007, 23, 795–800. [Google Scholar] [CrossRef]

- Cavani, F.; Trifiro, F.; Vaccari, A. Hydrotalcite-type anionic clays: Preparation, properties and applications. Catal. Today 1991, 11, 173–301. [Google Scholar] [CrossRef]

- Rao, M.M.; Reddy, B.R.; Jayalakshmi, M.; Jaya, V.S.; Sridhar, B. Hydrothermal synthesis of mg-al hydrotalcites by urea hydrolysis. Mater. Res. Bull. 2005, 40, 347–359. [Google Scholar] [CrossRef]

- Aramendia, M.A.; Borau, V.; Jimenez, U.; Marinas, J.M.; Ruiz, J.R.; Urbano, F.J. Comparative study of mg/m(iii) (m = al, ga, in) layered double hydroxides obtained by coprecipitation and the sol-gel method. J. Solid State Chem. 2002, 168, 156–161. [Google Scholar] [CrossRef]

- Prinetto, F.; Ghiotti, G.; Graffin, P.; Tichit, D. Synthesis and characterization of sol-gel mg/al and ni/al layered double hydroxides and comparison with co-precipitated samples. Microporous Mesoporous Mater. 2000, 39, 229–247. [Google Scholar] [CrossRef]

- Zhang, W.H.; Guo, X.D.; He, J.; Qian, Z.Y. Preparation of ni(ii)/ti(iv) layered double hydroxide at high supersaturation. J. Eur. Ceram. Soc. 2008, 28, 1623–1629. [Google Scholar] [CrossRef]

- Patil, K.C.; Aruna, S.T.; Mimani, T. Combustion synthesis: An update. Curr. Opin. Solid State Mater. Sci. 2002, 6, 507–512. [Google Scholar] [CrossRef]

- Patil, K.C.; Aruna, S.T.; Ekambaram, S. Combustion synthesis. Curr. Opin. Solid State Mater. Sci. 1997, 2, 158–165. [Google Scholar] [CrossRef]

- Davila, V.; Lima, E.; Bulbulian, S.; Bosch, P. Mixed mg(al)o oxides synthesized by the combustion method and their recrystallization to hydrotalcites. Microporous Mesoporous Mater. 2008, 107, 240–246. [Google Scholar] [CrossRef]

- Chen, C.R.; Zeng, H.Y.; Xu, S.; Liu, X.J.; Xiao, H.M.; Duan, H.Z. Microwave-assisted preparation of so42- intercalated hydrotalcites for ammonia-nitrogen removal. RSC Adv. 2016, 6, 12753–12760. [Google Scholar] [CrossRef]

- Muriithi, G.N.; Petrik, L.F.; Gitari, W.M.; Doucet, F.J. Synthesis and characterization of hydrotalcite from south african coal fly ash. Powder Technol. 2017, 312, 299–309. [Google Scholar] [CrossRef]

- Frias, M.; Rodriguez Largo, O.; Garcia Jimenez, R.; Vegas, I. Influence of activation temperature on reaction kinetics in recycled clay waste-calcium hydroxide systems. J. Am. Ceram. Soc. 2008, 91, 4044–4051. [Google Scholar] [CrossRef]

- Ferreiro, S.; Blasco, T.; de Rojas, M.I.S.; Frias, M. Influence of activated art paper sludge-lime ratio on hydration kinetics and mechanical behavior in mixtures cured at 20 degrees c. J. Am. Ceram. Soc. 2009, 92, 3014–3021. [Google Scholar] [CrossRef]

- Tichit, D.; Coq, B. Catalysis by hydrotalcites and related materials. Cattech 2003, 7, 206–217. [Google Scholar] [CrossRef]

- Debecker, D.P.; Gaigneaux, E.M.; Busca, G. Exploring, tuning, and exploiting the basicity of hydrotalcites for applications in heterogeneous catalysis. Chem. Eur. J. 2009, 15, 3920–3935. [Google Scholar] [CrossRef]

- Abello, S.; Medina, F.; Tichit, D.; Perez-Ramirez, J.; Groen, J.C.; Sueiras, J.E.; Salagre, P.; Cesteros, Y. Aldol condensations over reconstructed mg-al hydrotalcites: Structure-activity relationships related to the rehydration method. Chem. Eur. J. 2005, 11, 728–739. [Google Scholar] [CrossRef]

- Tichit, D.; Bennani, M.N.; Figueras, F.; Tessier, R.; Kervennal, J. Aldol condensation of acetone over layered double hydroxides of the meixnerite type. Appl. Clay Sci. 1998, 13, 401–415. [Google Scholar] [CrossRef]

- Climent, M.J.; Corma, A.; Fornes, V.; Guil-Lopez, R.; Iborra, S. Aldol condensations on solid catalysts: A cooperative effect between weak acid and base sites. Adv. Synth. Catal. 2002, 344, 1090–1096. [Google Scholar] [CrossRef]

- Guida, A.; Lhouty, M.H.; Tichit, D.; Figueras, F.; Geneste, P. Hydrotalcites as base catalysts. Kinetics of claisen-schmidt condensation, intramolecular condensation of acetonylacetone and synthesis of chalcone. Appl. Catal. A Gen. 1997, 164, 251–264. [Google Scholar] [CrossRef]

- Kikhtyanin, O.; Tisler, Z.; Velvarska, R.; Kubicka, D. Reconstructed mg-al hydrotalcites prepared by using different rehydration and drying time: Physico-chemical properties and catalytic performance in aldol condensation. Appl. Catal. A Gen. 2017, 536, 85–96. [Google Scholar] [CrossRef]

- Tisler, Z.; Vrbkova, E.; Kocik, J.; Kadlec, D.; Vyskocilova, E.; Cerveny, L. Aldol condensation of benzaldehyde and heptanal over zinc modified mixed mg/al oxides. Catal. Lett. 2018, 148, 2042–2057. [Google Scholar] [CrossRef]

- Choudary, B.M.; Kantam, M.L.; Reddy, C.R.V.; Rao, K.K.; Figueras, F. The first example of michael addition catalysed by modified mg-al hydrotalcite. J. Mol. Catal. A Chem. 1999, 146, 279–284. [Google Scholar] [CrossRef]

- Kaneda, K.; Ueno, S.; Imanaka, T. Heterogeneous baeyer-villiger oxidation of ketones using an oxidant consisting of molecular-oxygen and aldehydes in the presence of hydrotalcite catalysts. J. Chem. Soc. Chem. Commun. 1994, 797–798. [Google Scholar] [CrossRef]

- Pillai, U.R.; Sahle-Demessie, E. Sn-exchanged hydrotalcites as catalysts for clean and selective baeyer-villiger oxidation of ketones using hydrogen peroxide. J. Mol. Catal. A Chem. 2003, 191, 93–100. [Google Scholar] [CrossRef]

- Climent, M.J.; Corma, A.; Iborra, S. Heterogeneous catalysts for the one-pot synthesis of chemicals and fine chemicals. Chem. Rev. 2011, 111, 1072–1133. [Google Scholar] [CrossRef]

- Tichit, D.; Ortiz, M.D.M.; Francova, D.; Gerardin, C.; Coq, B.; Durand, R.; Prinetto, F.; Ghiotti, G. Design of nanostructured multifunctional pd-based catalysts from layered double hydroxides precursors. Appl. Catal. A Gen. 2007, 318, 170–177. [Google Scholar] [CrossRef]

- Climent, M.J.; Corma, A.; Iborra, S.; Mifsud, M.; Velty, A. New one-pot multistep process with multifunctional catalysts: Decreasing the e factor in the synthesis of fine chemicals. Green Chem. 2010, 12, 99–107. [Google Scholar] [CrossRef]

- Colmenares, M.C.; Mare, E. Removal of chloride ions from de wastewater using hydrotalcites as adsorbent materials. Ing. UC 2017, 24, 204–217. [Google Scholar]

- Jawad, A.; Peng, L.; Liao, Z.W.; Zhou, Z.H.; Shahzad, A.; Ifthikar, J.; Zhao, M.M.; Chen, Z.L.; Chen, Z.Q. Selective removal of heavy metals by hydrotalcites as adsorbents in diverse wastewater: Different intercalated anions with different mechanisms. J. Clean Prod. 2019, 211, 1112–1126. [Google Scholar] [CrossRef]

- Rosset, M.; Sfreddo, L.W.; Hidalgo, G.E.N.; Perez-Lopez, O.W.; Feris, L.A. Adsorbents derived from hydrotalcites for the removal of diclofenac in wastewater. Appl. Clay Sci. 2019, 175, 150–158. [Google Scholar] [CrossRef]

- Tiwari, E.; Singh, N.; Khandelwal, N.; Monikh, F.A.; Darbha, G.K. Application of zn/al layered double hydroxides for the removal of nanoscale plastic debris from aqueous systems. J. Hazard. Mater. 2020, 397, 9. [Google Scholar] [CrossRef] [PubMed]

- Linares, C.F.; Solano, S.; Infante, G. The influence of hydrotalcite and cancrinite-type zeolite in acidic aspirin solutions. Microporous Mesoporous Mater. 2004, 74, 105–110. [Google Scholar] [CrossRef]

- Leon-Vallejo, A.M.; Fetter, G.; Sampieri, A.; Rubio-Rosas, E. Synthesis of cotton fibers impregnated with bactericidal hydrotalcites to be used in medical textile supplies. MRS Adv. 2017, 2, 3787–3795. [Google Scholar] [CrossRef]

- Rives, V.; Perez-Bernal, M.E.; Ruano-Casero, R.J.; Nebot-Diaz, I. Development of a black ceramic pigment from non stoichiometric hydrotalcites. J. Eur. Ceram. Soc. 2012, 32, 975–987. [Google Scholar] [CrossRef]

- Terry, P. Characterization of cr ion exchange with hydrotalcite. Chemosphere 2004, 57, 541–546. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.R.; Lim, H.M.; Lee, S.H.; Kim, K.J. Layered double hydroxide and its anion exchange capacity. Adv. Technol. Mater. Mater. Process. J. 2004, 6, 218–223. [Google Scholar]

- Shin, H.-S.; Kim, M.-J.; Nam, S.-Y.; Moon, H.-C. Phosphorus removal by hydrotalcite-like compounds (htlcs). Water Sci. Technol. 1996, 34, 161–168. [Google Scholar]

- Palin, L.; Milanesio, M.; van beek, W.; Conterosito, E. Understanding the ion exchange process in ldh nanomaterials by fast in situ xrpd and pca-assisted kinetic analysis. J. Nanomater. 2019, 2019, 1–9. [Google Scholar] [CrossRef]

- Bontchev, R.P.; Liu, S.; Krumhansl, J.L.; Voigt, J.; Nenoff, T.M. Synthesis, characterization, and ion exchange properties of hydrotalcite mg6al2(oh)16(a)x(a‘)2-x·4h2o (a, a‘ = cl-, br-, i-, and no3-, 2 ≥ x ≥ 0) derivatives. Chem. Mater. 2003, 15, 3669–3675. [Google Scholar] [CrossRef]

- Miyata, S. Anion-exchange properties of hydrotalcite-like compounds. Clays Clay Miner. 1983, 31, 305–311. [Google Scholar] [CrossRef]

- Coenen, K.; Gallucci, F.; Cobden, P.; van Dijk, E.; Hensen, E.J.M.; Annaland, M.v.S. Chemisorption of h2o and CO2 on hydrotalcites for sorption-enhanced water-gas-shift processes. Energy Proc. 2017, 114, 2228–2242. [Google Scholar] [CrossRef]

- Bhatta, L.K.G.; Subramanyam, S.; Chengala, M.D.; Bhatta, U.M.; Venkatesh, K. Enhancement in CO2 adsorption on hydrotalcite-based material by novel carbon support combined with K2CO3 impregnation. Ind. Eng. Chem. Res. 2015, 54, 10876–10884. [Google Scholar] [CrossRef]

- Ding, Y.; Alpay, E. Equilibria and kinetics of CO2 adsorption on hydrotalcite adsorbent. Chem. Eng. Sci. 2000, 55, 3461–3474. [Google Scholar] [CrossRef]

- Hufton, J.R.; Mayorga, S.; Sircar, S. Sorption-enhanced reaction process for hydrogen production. AIChE J. 1999, 45, 248–256. [Google Scholar] [CrossRef]

- Yang, J.-I.; Kim, J.-N. Hydrotalcites for adsorption of CO2 at high temperature. Korean J. Chem. Eng. 2006, 23, 77–80. [Google Scholar] [CrossRef]

- Yong, Z.; Mata; Rodrigues, A.E. Adsorption of carbon dioxide onto hydrotalcite-like compounds (htlcs) at high temperatures. Ind. Eng. Chem. Res. 2001, 40, 204–209. [Google Scholar] [CrossRef]

- Moreira, R.F.P.M.; Soares, J.L.; Casarin, G.L.; Rodrigues, A.E. Adsorption of CO2 on hydrotalcite-like compounds in a fixed bed. Sep. Sci. Technol. 2006, 41, 341–357. [Google Scholar] [CrossRef]

- Machner, A.; Zajac, M.; Ben Haha, M.; Kjellsen, K.O.; Geiker, M.R.; De Weerdt, K. Chloride-binding capacity of hydrotalcite in cement pastes containing dolomite and metakaolin. Cem. Concr. Res. 2018, 107, 163–181. [Google Scholar] [CrossRef]

- Poonoosamy, J.; Brandt, F.; Stekiel, M.; Kegler, P.; Klinkenberg, M.; Winkler, B.; Vinograd, V.; Bosbach, D.; Deissmann, G. Zr-containing layered double hydroxides: Synthesis, characterization, and evaluation of thermodynamic properties. Appl. Clay Sci. 2018, 151, 54–65. [Google Scholar] [CrossRef]

- Król, B.; Pielichowska, K.; Król, P.; Kędzierski, M. Polyurethane cationomer films as ecological membranes for building industry. Prog. Org. Coatings 2019, 130, 83–92. [Google Scholar] [CrossRef]

- Nishimura, S.; Takagaki, A.; Ebitani, K. Characterization, synthesis and catalysis of hydrotalcite-related materials for highly efficient materials transformations. Green Chem. 2013, 15, 2026–2042. [Google Scholar] [CrossRef]

- Olguin, M.T.; Bosch, P.; Acosta, D.; Bulbulian, S. I-131(-) sorption by thermally treated hydrotalcites. Clay Clay Min. 1998, 46, 567–573. [Google Scholar] [CrossRef]

- Balsley, S.D.; Brady, P.V.; Krumhansl, J.L.; Anderson, H.L. Anion scavengers for low-level radioactive waste repository backfills. J. Soil Contam. 1998, 7, 125–141. [Google Scholar] [CrossRef]

- James, A.; Bazarchi, E.; Chiniforush, A.A.; Aghdam, P.P.; Hosseini, M.R.; Akbarnezhad, A.; Martek, I.; Ghodoosi, F. Rebar corrosion detection, protection, and rehabilitation of reinforced concrete structures in coastal environments: A review. Constr. Build. Mater. 2019, 224, 1026–1039. [Google Scholar] [CrossRef]

- Song, H.W.; Saraswathy, V. Corrosion monitoring of reinforced concrete structures-a review. Int. J. Electrochem. Sci. 2007, 2, 1–28. [Google Scholar]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Monitoring corrosion of steel bars in reinforced concrete structures. Sci. World J. 2014. [Google Scholar] [CrossRef]

- Shi, X.; Fay, L.; Yang, Z.; Nguyen, T.A.; Liu, Y. Corrosion of deicers to metals in transportation infrastructure: Introduction and recentdevelopments. Corros. Rev. 2009, 27, 23. [Google Scholar] [CrossRef]

- Rodrigues, M.P.M.C.; Costa, M.R.N.; Mendes, A.M.; Eusébio Marques, M.I. Effectiveness of surface coatings to protect reinforced concrete in marine environments. Mater. Struct. 2000, 33, 618–626. [Google Scholar] [CrossRef]

- Raupach, M.; Wolff, L. Long-term durability of hydrophobic treatment on concrete. Surf. Coatings Int. Part B Coatings Trans. 2005, 88, 127–133. [Google Scholar] [CrossRef]

- Medeiros, M.; Helene, P. Efficacy of surface hydrophobic agents in reducing water and chloride ion penetration in concrete. Mater. Struct. 2008, 41, 59–71. [Google Scholar] [CrossRef]

- Chung, D.D.L. Use of polymers for cement-based structural materials. J. Mater. Sci. 2004, 39, 2973–2978. [Google Scholar] [CrossRef]

- Montemor, M.F.; Simões, A.M.P.; Salta, M.M. Effect of fly ash on concrete reinforcement corrosion studied by eis. Cem. Concr. Compos. 2000, 22, 175–185. [Google Scholar] [CrossRef]

- Arya, C.; Xu, Y. Effect of cement type on chloride binding and corrosion of steel in concrete. Cem. Concr. Res. 1995, 25, 893–902. [Google Scholar] [CrossRef]

- Yang, Z.; Fischer, H.; Polder, R. Modified hydrotalcites as a new emerging class of smart additive of reinforced concrete for anticorrosion applications: A literature review. Mater. Corros. 2013, 64, 1066–1074. [Google Scholar] [CrossRef]

- Yang, Z.; Fischer, H.; Cerezo, J.; Mol, J.M.C.; Polder, R. Modified hydrotalcites for improved corrosion protection of reinforcing steel in concrete—Preparation, characterization, and assessment in alkaline chloride solution. Mater. Corros. 2016, 67, 721–738. [Google Scholar] [CrossRef]

- Yang, Z.X.; Fischer, H.; Cerezo, J.; Mol, J.M.C.; Polder, R. Aminobenzoate modified mg-al hydrotalcites as a novel smart additive of reinforced concrete for anticorrosion applications. Constr. Build. Mater. 2013, 47, 1436–1443. [Google Scholar] [CrossRef]

- Yang, Z.; Fischer, H.; Polder, R. The Application of Modified Hydrotalcites as Chloride Scavengers and Inhibitor Release Agents in Cem. Mortars; Crc Press—Taylor & Francis Group: Boca Raton, FL, USA, 2014; pp. 461–469. [Google Scholar]

- Pan, C.; Chen, N.; He, J.; Liu, S.; Chen, K.; Wang, P.; Xu, P. Effects of corrosion inhibitor and functional components on the electrochemical and mechanical properties of concrete subject to chloride environment. Constr. Build. Mater. 2020, 260, 119724. [Google Scholar] [CrossRef]

- Yang, Z.X.; Polder, R.; Mol, J.M.C.; Andrade, C. The effect of two types of modified mg-al hydrotalcites on reinforcement corrosion in cement mortar. Cem. Concr. Res. 2017, 100, 186–202. [Google Scholar] [CrossRef]

- Cao, Y.H.; Zheng, D.J.; Dong, S.G.; Zhang, F.; Lin, J.Y.; Wang, C.; Lin, C.J. A composite corrosion inhibitor of mgal layered double hydroxides co-intercalated with hydroxide and organic anions for carbon steel in simulated carbonated concrete pore solutions. J. Electrochem. Soc. 2019, 166, C3106–C3113. [Google Scholar] [CrossRef]

- Lozano-Lunar, A.; Ledesma, E.F.; Esquinas, A.R.; Romero, J.R.J.; Rodriguez, J.M.F. A double barrier technique with hydrotalcites for pb immobilisation from electric arc furnace dust. Materials 2019, 12, 16. [Google Scholar] [CrossRef]

- Machner, A.; Zajac, M.; Ben Haha, M.; Kjellsen, K.O.; Geiker, M.R.; De Weerdt, K. Limitations of the hydrotalcite formation in portland composite cement pastes containing dolomite and metakaolin. Cem. Concr. Res. 2018, 105, 1–17. [Google Scholar] [CrossRef]

- Szybilski, M.; Nocuń-Wczelik, W. The effect of dolomite additive on cement hydration. Proc. Eng. 2015, 108, 193–198. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. Controlling cement hydration with nanoparticles. Cem. Concr. Compos. 2015, 57, 64–67. [Google Scholar] [CrossRef]

- Bräu, M.; Ma-Hock, L.; Hesse, C.; Nicoleau, L.; Strauss, V.; Treumann, S.; Wiench, K.; Landsiedel, R.; Wohlleben, W. Nanostructured calcium silicate hydrate seeds accelerate concrete hardening: A combined assessment of benefits and risks. Arch. Toxicol. 2012, 86, 1077–1087. [Google Scholar] [CrossRef]

- Xu, J.; Lu, D.; Zhang, S.; Ling, K.; Xu, Z. Pore structures of mortars with dolomite and limestone powders cured at various temperatures. J. Chin. Ceram. Soc. 2017, 45, 268–273. [Google Scholar]

- Li, H.; Guan, X.; Yang, L.; Liu, S.; Zhang, J.; Guo, Y. Effects of lial-layered double hydroxides on early hydration of calcium sulphoaluminate cement paste. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2017, 32, 1101–1107. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, R.; Wang, X.; Chen, J.; Shui, Z. Evaluation and optimization of ultra-high performance concrete (uhpc) subjected to harsh ocean environment: Towards an application of layered double hydroxides (ldhs). Constr. Build. Mater. 2018, 177, 51–62. [Google Scholar] [CrossRef]

- Zou, D.; Wang, K.; Li, H.; Guan, X. Effect of lial-layered double hydroxides on hydration of calcium sulfoaluminate cement at low temperature. Constr. Build. Mater. 2019, 223, 910–917. [Google Scholar] [CrossRef]

- Yang, Z.; Fischer, H.; Polder, R. Laboratory investigation of the influence of two types of modified hydrotalcites on chloride ingress into cement mortar. Cem. Concr. Compos. 2015, 58, 105–113. [Google Scholar] [CrossRef]

- Mir, Z.M.; Bastos, A.; Höche, D.; Zheludkevich, M.L. Recent advances on the application of layered double hydroxides in concrete-a review. Materials 2020, 13, 1426. [Google Scholar] [CrossRef]

- Qu, Z.Y.; Yu, Q.L.; Brouwers, H.J.H. Relationship between the particle size and dosage of ldhs and concrete resistance against chloride ingress. Cem. Concr. Res. 2018, 105, 81–90. [Google Scholar] [CrossRef]

- Ke, X.; Bernal, S.A.; Provis, J.L. Controlling the reaction kinetics of sodium carbonate-activated slag cements using calcined layered double hydroxides. Cem. Concr. Res. 2016, 81, 24–37. [Google Scholar] [CrossRef]

- Khan, M.S.H.; Kayali, O.; Troitzsch, U. Chloride binding capacity of hydrotalcite and the competition with carbonates in ground granulated blast furnace slag concrete. Mater. Struct. 2016, 49, 4609–4619. [Google Scholar] [CrossRef]

- Raki, L.; Beaudoin, J.J.; Mitchell, L. Layered double hydroxide-like materials: Nanocomposites for use in concrete. Cem. Concr. Res. 2004, 34, 1717–1724. [Google Scholar] [CrossRef]

- Kim, M.S.; Jun, Y.; Lee, C.; Oh, J.E. Use of cao as an activator for producing a price-competitive non-cement structural binder using ground granulated blast furnace slag. Cem. Concr. Res. 2013, 54, 208–214. [Google Scholar] [CrossRef]

- Peng, H.-K.; Wang, X.X.; Li, T.-T.; Huang, S.-Y.; Lin, Q.; Shiu, B.-C.; Lou, C.-W.; Lin, J.-H. Effects of hydrotalcite on rigid polyurethane foam composites containing a fire retarding agent: Compressive stress, combustion resistance, sound absorption, and electromagnetic shielding effectiveness. RSC Adv. 2018, 8, 33542–33550. [Google Scholar] [CrossRef]

- Gómez-Fernández, S.; Ugarte, L.; Peña-Rodriguez, C.; Zubitur, M.; Corcuera, M.Á.; Eceiza, A. Flexible polyurethane foam nanocomposites with modified layered double hydroxides. Appl. Clay Sci. 2016, 123, 109–120. [Google Scholar] [CrossRef]

- Gómez-Fernández, S.; Ugarte, L.; Peña-Rodriguez, C.; Corcuera, M.Á.; Eceiza, A. The effect of phosphorus containing polyol and layered double hydroxides on the properties of a castor oil based flexible polyurethane foam. Polym. Degrad. Stab. 2016, 132, 41–51. [Google Scholar] [CrossRef]

- Sun, G.; Liu, L.; Wang, J.; Wang, H.; Wang, W.; Han, S. Effects of hydrotalcites and tris (1-chloro-2-propyl) phosphate on thermal stability, cellular structure and fire resistance of isocyanate-based polyimide foams. Polym. Degrad. Stab. 2015, 115, 1–15. [Google Scholar] [CrossRef]

- Evans, D.G.; Duan, X. Preparation of layered double hydroxides and their applications as additives in polymers, as precursors to magnetic materials and in biology and medicine. Chem. Commun. 2006, 485–496. [Google Scholar] [CrossRef]

| Type of Hydrotalcite | Cations | Space Group | Reference |

|---|---|---|---|

| Hydrotalcite-2H | Mg2+, Al3+ | P63/mmc | Bookin, A.S. et al. [6], Zhitova, E.S. et al. [7] |

| Hydrotalcite-3R | Mg2+, Al3+ | Rm | Mills, S. et al. [8], Zhitova, E.S. et al. [7] |

| Desautelsite | Mg2+, Mn3+ | Rm | Dunn, P.J. et al. [9] |

| Droninoite | Ni2+, Fe2+ | Rm | Chukanov, N.V. et al. [10] |

| Iowaite | Mg2+, Fe2+ | Rm | Braithwaite, R.S.W. et al. [11], Kohls, D.W. et al. [12] |

| Meixnerite | Mg2+, Al3+ | Rm | Mills, S. et al. [8], Koritnig, S. et al. [13] |

| Pyroaurite-2H | Mg2+, Fe3+ | P63/mmc | Ingram, L. et al. [14], Frondel, C. [15] |

| Pyroaurite-3R | Mg2+, Fe3+ | Rm | Ingram, L. et al. [14] |

| Reevesite | Ni2+, Fe3+ | Rm | Song, Y. et al. [16], Taylor, H. F. W. [17] |

| Stichtite-2H | Mg2+, Cr3+ | P63/mmc | Mills, S. et al. [18], Ashwal, L.D. et al. [19] |

| Stichtite-3R | Mg2+, Cr3+ | Rm | Mills, S. et al. [18], Ashwal, L.D. et al. [19] |

| Takovite | Ni2+, Al3+ | Rm | Bish, D. L. [20], Mills, S. et al. [8], Maksimović, Z. [21] |

| UM1998-10-CO:CoHNi | Ni2+, Co3+ | Rm | Song, Y. et al. [16] |

| UM2002-02-COH:FeNi | Ni2+, Fe3+, Fe2+ | Rm | Smith, D.G.W. et al. [22], Maksimović, Z. et al. [23] |

| Woodallite | Mg2+, Cr3+ | Rm | Mills, S. et al. [24] |

| Muskoxite | Mg2+, Fe3+ | Rm | Jambor, J.L. [25] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lauermannová, A.-M.; Paterová, I.; Patera, J.; Skrbek, K.; Jankovský, O.; Bartůněk, V. Hydrotalcites in Construction Materials. Appl. Sci. 2020, 10, 7989. https://doi.org/10.3390/app10227989

Lauermannová A-M, Paterová I, Patera J, Skrbek K, Jankovský O, Bartůněk V. Hydrotalcites in Construction Materials. Applied Sciences. 2020; 10(22):7989. https://doi.org/10.3390/app10227989

Chicago/Turabian StyleLauermannová, Anna-Marie, Iva Paterová, Jan Patera, Kryštof Skrbek, Ondřej Jankovský, and Vilém Bartůněk. 2020. "Hydrotalcites in Construction Materials" Applied Sciences 10, no. 22: 7989. https://doi.org/10.3390/app10227989

APA StyleLauermannová, A.-M., Paterová, I., Patera, J., Skrbek, K., Jankovský, O., & Bartůněk, V. (2020). Hydrotalcites in Construction Materials. Applied Sciences, 10(22), 7989. https://doi.org/10.3390/app10227989