A Crack Characterization Method for Reinforced Concrete Beams Using an Acoustic Emission Technique

Abstract

1. Introduction

- Previously conducted researches have used different AE features for the detection and classification of the fractures in concrete beams. It is quite hard to sort out which features have a higher sensitivity to crack growth. Certain features may have sensitivity to the incipient cracks that occur in the time history, whereas some may show sensitivity to crack severity (fractures) during the final failure period. Apart from the classification and detection of the cracks, it is also of paramount importance to assess the degradation in concrete structures over their full lifetime so that drastic and catastrophic failures can be avoided. Existing works have not focused on this perspective of crack evaluation in concrete structures.

- Machine learning-based classification algorithms in many cases would require failure data for training in order to build a condition monitoring system for concrete structures. Such data related to concrete failure are very hard to collect in real-life scenarios, which may eventually lead to an inefficacious crack assessment indicator.

- In many cases, the existing works have failed to precisely determine the time period of early crack occurrence, since used AE features have displayed discrete fluctuations, making it very problematic to sort out the time period. Additionally, nonmonotonic curves of these features even after the severity of cracks has increased can be observed as well. It may lead to false maintenance alerts resulting in a waste of resources.

- The existing methods do not focus on the classification of crack types, even though machine learning-based classification methods can be effective measures to detect cracks. Very few methods that have adopted classification approaches fail to distinguish the micro-cracks from the macro ones.

- A reliable CAI presenting the time history of crack formation in the concrete beam is proposed. From the proposed CAI, we can observe the initial crack formation until the complete failure (fracture) of the beam. The CAI encompasses different crucial AE features reflecting the change in the concrete condition over time due to the conducted three-point bending test. Furthermore, the proposed CAI does not necessitate any previous knowledge of the crack/fracture data for measuring the CAI.

- A NRS-based on the CUMSUM method is proposed to deal with the scattered points of MD so that we can obtain a monotonic and smooth CAI that increases with the crack growth, leading to fractures and severe degradation.

- The proposed method outsmarts the existing method by achieving a 99.61% average classification accuracy, which is 17.61% higher than the previous method.

2. Related Works

3. Technical Background

3.1. AE Monitoring of Reinforced Concrete (RC) Structures

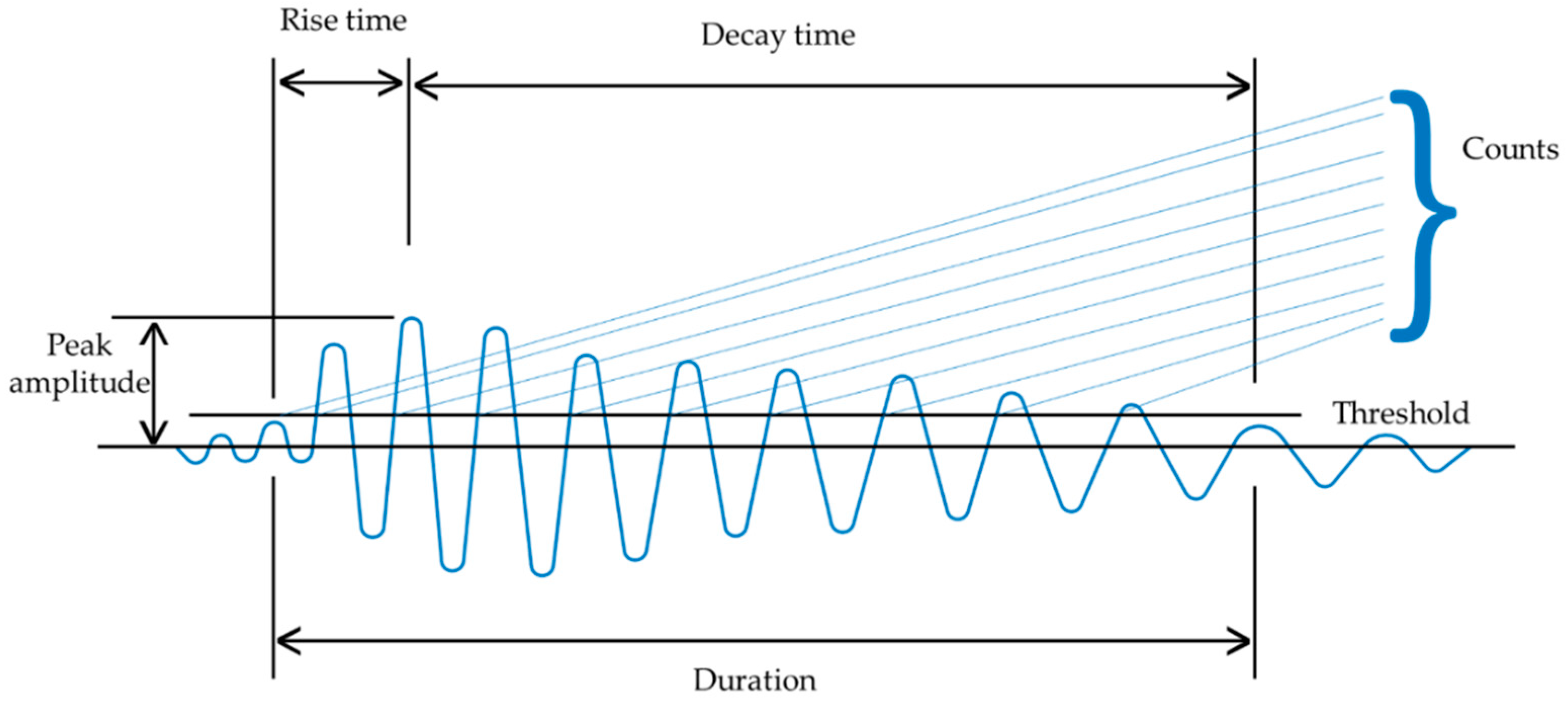

3.2. Acoustic Emission Burst Features

3.3. Boruta-Mahalanobis System

- First, we have to expand our information system by adding copies of all the variables. The system must be expanded by at least five shadow attributes.

- It is next required to shuffle the attributes that are newly added to get rid of their correlations with the response.

- The random forest classifier is invoked at this step on the expanded information system. The Z scores are computed and stored.

- From the shadow attributes, we must find out the maximum Z score. This score is referred to as MZSA. If any attribute scores better than the MZSA, we are supposed to assign a hit for that.

- If there is any attribute with an undetermined importance, we have to perform a two-tailed test of equality with the MZSA.

- There will be attributes in the system that have a significantly lower importance than MZSA. Those attributes are regarded as unimportant and must be wiped out from the information system. We must deem attributes as “important” if they have an importance significantly higher than the MZSA.

- Finally, we must remove all the shadow attributes and repeat the whole process unless the importance is assigned for all the attributes or the algorithm reaches a prior limit of the number of random forest runs.

3.4. The CUMSUM Algorithm

- (a)

- Under the no-change hypothesis (H0), the PDF of MD (w) is

- (b)

- Under one change hypothesis (H1), the PDF is as follows:

| Algorithm 1 CUMSUM Algorithm |

| Initialization |

| set the detection threshold |

| end |

| whilethe algorithm is not stoppeddo |

| measure the current sample MD [k] |

| if > h then |

| stop or reset the algorithm |

| end |

| End |

3.5. k-Nearest Neighbor Algorithm

4. Methodology

4.1. Experimental Test Setup and Data Acquisition

4.2. Proposed Methodology for CAI Development and Crack Classification

- AE signals are collected from the testbed that involves conducting three-point bending tests on RC beams.

- Some AEB features were described in Section 3.1. They are extracted from the collected raw signals.

- Features representing the condition of the RC beams when there are no cracks are defined first. Next, we collect data of all the features denoting this normal condition. After that, the MDs of the normal condition are calculated.

- The MDs of the abnormal groups: micro-cracks and macro cracks/fractures are calculated at this step using the MS. These two groups consist of feature points related to micro-crack and macro-crack/fracture formation in the RC beam. To normalize the features of these two abnormal groups, the standard deviation and mean of the corresponding features from the normal group are used. Lastly, the correlation matrix associated with the normal group is adopted to find out the MDs of the two conditions that are abnormal, corresponding to the micro and macro-cracks, respectively.

- As stated in Section 3.3, the Boruta feature selection algorithm is used in this step to sustain the crucial features.

- The MD corresponding to the CAI that fuses the crucial features selected using the Boruta algorithm is denoised using Algorithm 1, presented in Section 3.4. Algorithm 1 works perfectly as a NRS and provides us with a monotonic CAI curve.

- The CAI consists of 872 data points. The first 300 points represent the normal condition with no crack formation in the concrete beam. The next 300 and 272 points represent the micro-cracks and macro-cracks/fractures, respectively. This CAI plot was fed to a k-NN classifier as an input for classification.

| Algorithm 2 Algorithm of the proposed method |

| Step 1: Feature extraction |

| Step 2: Feature selection using Boruta |

| Input: Given an information set: I; |

| Output: Relevant features: F; |

| Initialization |

| Shadow information set, |

| end |

| for, ; where, |

| Global system, |

| while < the prior limit of the random forest runs, do |

| For two-tailed test of equality, |

| update H and |

| end |

| return F |

| end |

| Step 2: MD calculation |

| Input: Feature set F, ; a = number of healthy observations |

| Output: MD of all the features |

| while calculation of MD is underway, do |

| = uth observation of the vth reference, g = Total observations, h = total features |

| for 1: (g × h) |

| calculate the mean, variance, and normalized feature using equations 3, 4, and 2 |

| calculate the covariance matrix, C for the normalized features |

| update with normalized features |

| calculate the MD using Equation (5) |

| compute until u |

| end |

| return MD |

| Step 3: Algorithm 1 for noise removal from the MD |

| Step 4: Classification using the k-NN algorithm |

5. Results Analysis

5.1. Feature Extraction and CAI Development

5.2. Classification Using k-NN

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hou, T.C.; Lynch, J.P. Electrical impedance tomographic methods for sensing strain fields and crack damage in cementitious structures. J. Intell. Mater. Syst. Struct. 2009, 20, 1363–1379. [Google Scholar] [CrossRef]

- Li, V.C.; Herbert, E. Robust self-healing concrete for sustainable infrastructure. J. Adv. Concr. Technol. 2012, 10, 207–218. [Google Scholar] [CrossRef]

- Aldahdooh, M.; Bunnori, N.M. Crack classification in reinforced concrete beams with varying thicknesses by mean of acoustic emission signal features. Constr. Build. Mater. 2013, 45, 282–288. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Soulioti, D.V.; Sapouridis, N.; Barkoula, N.M.; Paipetis, A.S.; Matikas, T.E. Acoustic emission characterization of the fracture process in fibre reinforced concrete. Constr. Build. Mater. 2011, 25, 4126–4131. [Google Scholar] [CrossRef]

- Nair, A.; Cai, C.S. Acoustic emission monitoring of bridges: Review and case studies. Eng. Struct. 2010, 32, 1704–1714. [Google Scholar] [CrossRef]

- Otsuka, K.; Date, H. Otsuka2000.Pdf. Eng. Fract. Mech. 2000, 65, 1–13. [Google Scholar]

- Habib, M.A.; Rai, A.; Kim, J.M. Performance degradation assessment of concrete beams based on acoustic emission burst features and Mahalanobis—Taguchi system. Sensors 2020, 20, 3402. [Google Scholar] [CrossRef]

- Yu, X.; Bentahar, M.; Mechri, C.; Montrésor, S. Passive monitoring of nonlinear relaxation of cracked polymer concrete samples using acoustic emission. J. Acoust. Soc. Am. 2019, 146, EL323–EL328. [Google Scholar] [CrossRef]

- Das, A.K.; Suthar, D.; Leung, C.K.Y. Machine learning based crack mode classification from unlabeled acoustic emission waveform features. Cem. Concr. Res. 2019, 121, 42–57. [Google Scholar] [CrossRef]

- Aggelis, D.G.; De Sutter, S.; Verbruggen, S.; Tsangouri, E.; Tysmans, T. Acoustic emission characterization of damage sources of lightweight hybrid concrete beams. Eng. Fract. Mech. 2019, 210, 181–188. [Google Scholar] [CrossRef]

- Aggelis, D.G. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 2011, 38, 153–157. [Google Scholar] [CrossRef]

- Banjara, N.K.; Sasmal, S.; Srinivas, V. Investigations on acoustic emission parameters during damage progression in shear deficient and GFRP strengthened reinforced concrete components. Measurement 2019, 137, 501–514. [Google Scholar] [CrossRef]

- Tsangouri, E.; Remy, O.; Boulpaep, F.; Verbruggen, S.; Livitsanos, G.; Aggelis, D.G. Structural health assessment of prefabricated concrete elements using Acoustic Emission: Towards an optimized damage sensing tool. Constr. Build. Mater. 2019, 206, 261–269. [Google Scholar] [CrossRef]

- Yue, J.G.; Kunnath, S.K.; Xiao, Y. Uniaxial concrete tension damage evolution using acoustic emission monitoring. Constr. Build. Mater. 2020, 232, 117281. [Google Scholar] [CrossRef]

- Chen, C.; Fan, X.; Chen, X. Experimental investigation of concrete fracture behavior with different loading rates based on acoustic emission. Constr. Build. Mater. 2020, 237, 117472. [Google Scholar] [CrossRef]

- Pantazopoulou, S.J.; Zanganeh, M. Assessing damage in corroded reinforced concrete using acoustic emission. J. Mater. Civ. Eng. 2001, 13, 340–348. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Paggi, M. Acoustic emission monitoring and numerical modeling of FRP delamination in RC beams with non-rectangular cross-section. Mater. Struct. Constr. 2007, 40, 553–566. [Google Scholar] [CrossRef]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Review of nondestructive testing methods for condition monitoring of concrete structures. J. Constr. Eng. 2013, 1–11. [Google Scholar] [CrossRef]

- Holford, K.M.; Davies, A.W.; Pullin, R.; Carter, D.C. Damage location in steel bridges by acoustic emission. J. Intell. Mater. Syst. Struct. 2001. [Google Scholar] [CrossRef]

- ElBatanouny, M.K.; Larosche, A.; Mazzoleni, P.; Ziehl, P.H.; Matta, F.; Zappa, E. Identification of cracking mechanisms in scaled FRP reinforced concrete beams using acoustic emission. Exp. Mech. 2014, 54, 69–82. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Jasinge, D.; Song, J.Y.; Choi, S.K. A study of the effect of displacement rate and moisture content on the mechanical properties of concrete: Use of acoustic emission. Mech. Mater. 2008, 40, 453–469. [Google Scholar] [CrossRef]

- Ohno, K.; Ohtsu, M. Crack Classification in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- Yun, H.D.; Choi, W.C.; Seo, S.Y. Acoustic emission activities and damage evaluation of reinforced concrete beams strengthened with CFRP sheets. NDT E Int. 2010, 43, 615–628. [Google Scholar] [CrossRef]

- Sagar, R.V.; Prasad, B.K.R.; Sharma, R. Evaluation of damage in reinforced concrete bridge beams using acoustic emission technique. Nondestruct. Test. Eval. 2012, 27, 95–108. [Google Scholar] [CrossRef]

- Huang, S.F.; Li, M.M.; Xu, D.Y.; Zhou, M.J.; Xie, S.H.; Cheng, X. Investigation on a kind of embedded ae sensor for concrete health monitoring. Res. Nondestruct. Eval. 2013, 24, 202–210. [Google Scholar] [CrossRef]

- Mahalanobis, P.C. Reprint of: Mahalanobis, P.C. (1936) “On the generalised distance in statistics.”. Sankhya A 2018, 80, 1–7. [Google Scholar] [CrossRef]

- Kursa, M.B.; Jankowski, A.; Rudnicki, W.R. Boruta—A system for feature selection. Fundam. Inform. 2010. [Google Scholar] [CrossRef]

- Morales-Esteban, A.; Martínez-Álvarez, F.; Scitovski, S.; Scitovski, R. A fast partitioning algorithm using adaptive Mahalanobis clustering with application to seismic zoning. Comput. Geosci. 2014. [Google Scholar] [CrossRef]

- Shang, J.; Chen, M.; Zhang, H. Fault detection based on augmented kernel Mahalanobis distance for nonlinear dynamic processes. Comput. Chem. Eng. 2018. [Google Scholar] [CrossRef]

- Ruiz de la Hermosa González-Carrato, R. Wind farm monitoring using Mahalanobis distance and fuzzy clustering. Renew. Energy 2018. [Google Scholar] [CrossRef]

- Jin, X.; Ma, E.W.M.; Cheng, L.L.; Pecht, M. Health monitoring of cooling fans based on mahalanobis distance with mRMR feature selection. IEEE Trans. Instrum. Meas. 2012. [Google Scholar] [CrossRef]

- Lin, J.; Chen, Q. Fault diagnosis of rolling bearings based on multifractal detrended fluctuation analysis and Mahalanobis distance criterion. Mech. Syst. Signal Process. 2013. [Google Scholar] [CrossRef]

- MacGregor, J.F.; Kourti, T. Statistical process control of multivariate processes. Control Eng. Pract. 1995. [Google Scholar] [CrossRef]

- Tra, V.; Kim, J.-Y.; Jeong, I.; Kim, J.-M. An acoustic emission technique for crack modes classification in concrete structures. Sustainability 2020, 12, 6724. [Google Scholar] [CrossRef]

- Noorsuhada, M.N. An overview on fatigue damage assessment of reinforced concrete structures with the aid of acoustic emission technique. Constr. Build. Mater. 2016, 112, 424–439. [Google Scholar] [CrossRef]

- Ali, S.M.; Hui, K.H.; Hee, L.M.; Leong, M.S.; Abdelrhman, A.M.; Al-Obaidi, M.A. Observations of changes in acoustic emission parameters for varying corrosion defect in reciprocating compressor valves. Ain Shams Eng. J. 2019, 10, 253–265. [Google Scholar] [CrossRef]

- Hasan, M.J.; Uddin, J.; Pinku, S.N. A Novel Modified SFTA Approach for Feature Extraction. In Proceedings of the 3rd International Conference on Electrical Engineering and Information Communication Technology (ICEEICT), Dhaka, Bangladesh, 22–24 September 2016; pp. 1–5. [Google Scholar]

- Breiman, L. Random forests. Mach. Learn. 2001. [Google Scholar] [CrossRef]

- Hasan, M.J.; Kim, J.; Kim, C.H.; Kim, J.M. Health state classification of a spherical tank using a hybrid bag of features and K-Nearest neighbor. Appl. Sci. 2020, 10, 2525. [Google Scholar] [CrossRef]

- Hasan, M.J.; Kim, J.M. A hybrid feature pool-based emotional stress state detection algorithm using EEG signals. Brain Sci. 2019, 9, 376. [Google Scholar] [CrossRef] [PubMed]

- Page, E.S. Cumulative sum charts. Technometrics 1961. [Google Scholar] [CrossRef]

- Peterson, L. K-nearest neighbor. Scholarpedia 2009. [Google Scholar] [CrossRef]

- ASTM International—Standards Worldwide. Available online: https://www.astm.org/ (accessed on 6 April 2020).

- R15I-AST Sensor. Available online: http://www.pacndt.com/downloads/Sensors/IntegralPreamp/R15I-AST.pdf (accessed on 29 May 2020).

- WD—100-900 KHZ Wideband Differential AE Sensor. Available online: https://www.physicalacoustics.com/by-product/sensors/WD-100-900-kHz-Wideband-Differential-AE-Sensor (accessed on 29 May 2020).

- ASTM. ASTM E976-10, Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response; ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

| Specification | Value |

|---|---|

| Number of sensors per experiment | 8 |

| Sensor type | WD and R15I AE sensors |

| Sensor elected after pencil lead fracture test | R15I |

| Number of RC beams | 6 |

| Data acquisition period | Around 15 min |

| Concrete type | 24 MPa |

| Reinforcement | Korean Standard Reinforced Steel Bar, D16 (SD400) |

| Load | 1.03 kN (initial) and 107.6 kN (final) |

| Load velocity | 2 mm/s |

| Displacement type | In-plane |

| Displacement measurement location | Mid-span |

| Methods | Accuracy (%) | F1-Score |

|---|---|---|

| k-NN and CAI plot | 99.6 | 0.988 |

| k-NN and selected AE features | 74 | 0.738 |

| k-NN and CFAR | 82.46 | 0.819 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habib, M.A.; Kim, C.H.; Kim, J.-M. A Crack Characterization Method for Reinforced Concrete Beams Using an Acoustic Emission Technique. Appl. Sci. 2020, 10, 7918. https://doi.org/10.3390/app10217918

Habib MA, Kim CH, Kim J-M. A Crack Characterization Method for Reinforced Concrete Beams Using an Acoustic Emission Technique. Applied Sciences. 2020; 10(21):7918. https://doi.org/10.3390/app10217918

Chicago/Turabian StyleHabib, Md Arafat, Cheol Hong Kim, and Jong-Myon Kim. 2020. "A Crack Characterization Method for Reinforced Concrete Beams Using an Acoustic Emission Technique" Applied Sciences 10, no. 21: 7918. https://doi.org/10.3390/app10217918

APA StyleHabib, M. A., Kim, C. H., & Kim, J.-M. (2020). A Crack Characterization Method for Reinforced Concrete Beams Using an Acoustic Emission Technique. Applied Sciences, 10(21), 7918. https://doi.org/10.3390/app10217918