1. Introduction

There are many phenomena in different fields of science and engineering where the physical response of a variable involves not only the value at time

but also the effects that occur in an earlier state

. Thus, delay systems appear in many engineering problems, such as in the shimmy effect (wheel vibration) [

1], vehicle traffic models [

2], feedback stabilization problems [

3] and in the regenerative vibration of machine-tools better known as chatter [

4]. In cases where the net force depends on the current values and some past values (history) such as position and speed, the system dynamic behavior can be modeled using a differential delay equation (DDE).

It is well-known that during a milling process, unstable vibrations also known as self-excited vibration or chatter may occur. Chatter reduces the machining efficiency due to low material removal rate by reducing the workload and affects surface quality, shortens tool life and accelerates tool wear. Researchers are studying several ways to overcome this limitation. Kuljanic et al. [

5] studied the incorporation of a chatter detection system based on multiple sensors to milling operations for industrial conditions, Zhuo et al. [

6] used a method based on fractal dimension for the flank milling of a thin-walled blade, which can reflect the chatter severity level through the morphological change in signal. Paul and Morales [

7], to mitigate chatter, presented an active controller based on the technique of discrete time sliding mode control (DSMC) blended with the type-2 fuzzy logic system. Moreover, Peng et al. [

8] presented a method based on a dynamic cutting force simulation model and a machine learning approach based on statistical learning theory to predict and avoid the cutting chatter. In addition, to control and suppress chatter vibrations, the use of piezoelectric actuators embedded in the tool holder [

9], electromagnetic actuators integrated into the spindle system [

10] and tunable clamping table [

11] has been analyzed. In the milling process, the use of variable pitch cutters has demonstrated to improve productivity [

12]. Different from the uniform pitch cutter, when a variable pitch cutter is used the dynamics model of cutting vibration changes from DDEs with a single delay to DDEs with multiple delays [

13]. A common technique offline to predict unstable vibrations is the so-called stability lobes of the DDE based on Floquet theory [

14], in which a curve describes the limit of stable vibration under feasible range values of cutting parameters.

The stability analysis of the milling process with multiple delays has been studied through different methods. Among all these methods, those with variable pitch tools play a critically important role [

15]. Slavicek [

16] was the one who first demonstrated the effectiveness of variable pitch cutters in suppressing vibrations in the milling process, he assumed a rectilinear tool motion for cutting teeth, and applied the theory of orthogonal stability to the irregular pitch of the tooth, by assuming an alternating step variation then, he obtained an expression of the stability limit as a function of the step angle variation. Budak [

17,

18] proposed an analytical method for nonconstant pitch milling cutters from a design point of view, showing for some applications how this variable effect helps to reduce self-excited vibrations, so he found that chatter stability can be improved significantly even at slow cutting speeds by properly designing the pitch angles. Altintas et al. [

19] used the frequency domain method to analyze the milling stability of the variable pitch cutter and introduced a method to select the optimal pitch angles. Olgac and Sipahi proposed a mathematical approach, the cluster treatment of characteristic roots (CTCR), which optimizes the design of variable pitch cutters [

20]. Jin et al. [

21] presented an improved semi-discretization algorithm to predict the stability lobes for variable pitch cutters, which were verified and compared with previous works such as the Altintas analytical method (zero-order method) [

19]. Comak and Budak [

22] showed the optimal design of a tool for milling operations with variable geometry to widen the stability zones using the semi-discretization method, validating it experimentally. They also used a design methodology to determine the optimal pitch angle geometry for a given cutting condition, allowing increased stability.

Zatarain et al. [

23] extended the multifrequency solution proposed by Budak and Altintas [

24] to include the helix effect, they pointed out that the variation of the helix angle plays an important role in stability graphs due to repetitive vibrations driven by impact (flip), they found that the flip lobes became closed curves that are separated by horizontal lines where the depth of cut is equal to a multiple of the helix pitch. A similar phenomenon was confirmed using the semi-discretization method (SDM) in [

25], meanwhile, B.R. Patel et al. [

26] considered the influence of the helix angle of the tool to obtain an analytical force model, they found that isolated islands of instability can occur in the milling processes, which are induced by the helix angle of the tool and lead to separate regions of period-doubling and quasi-period behavior. Sims et al. [

27] by using an adapted and time-averaged version of the SDM analyzed both the influence on the variation of the helix angle and the pitch angle of the tool to improve the prediction of vibrations and estimate predictions of surface errors. They used the semi-discretization method, the time-averaged semi-discretization method and the temporal finite element method to predict vibration stability for variable helix and variable pitch milling tools. Turner et al. [

28] modeled and compared stability for variable pitch and helix angle cutters, demonstrating that variable helix angle tools can have higher stability and productivity.

Yusoff and Sims in [

29] combined SDM with differential evolution to optimize variable helix milling tools to minimize vibration, their analysis predicted total vibration mitigation using the optimized variable helix milling tool at low radial immersion. Furthermore, Dombovari and Stepan [

30] introduced a general mechanical model based on SDM to predict the linear stability of specialty cutters with optional continuous variation of the helix angle. Using an extended second-order SDM, Zhan et al. [

15] predicted the stability lobe diagrams for tools with variable pitch angles. Meanwhile, Huang et al. [

31] conducted a stability analysis for milling operations with variable pitch mills at variable speed, while Cai et al. [

32] proposed an integrated process machine model based on the computer graphics method to simulate the milling process of a variable pitch cutter.

On the other hand, Olvera and Elías-Zuñiga in [

33] led to the development of the enhanced multistage homotopy perturbation method (EMHPM) to solve differential delay equations (DDEs) with constant and variable coefficients and then this EMHPM was applied to predict the stability of a multivariate milling tool in which they consider the helix angle and the pitch angle variation of the cutting edges [

34]. Based on the Laplace formulation, Sims [

35] studied the stability of milling operations with a variable helix angle. Using the multi-frequency solution, Otto et al. [

36] derived a dynamic process model where the non-linear shear force and the runout effect are included for milling with non-uniform pitch and variable helix tools. Niu et al. [

37] found that runout can significantly increase the stability limits regardless of spindle speed ranges, while Olvera et al. [

38] in a study for a thin-walled workpiece demonstrated that by considering the effects of the runout, the helix angle and characterization dependent on the cutting speed, more precise stability boundaries are achieved.

To demonstrate that one of the effective ways to suppress vibration in milling operations is to use tools with variable pitch and helix angle, Wang et al. [

12] proposed an improved semi-discretization method based on Floquet′s theory. Since the delay between each cutting edge varies along with the axial depth of the tool in milling, they discretized the cutting tool in some axial layers to simplify the calculation. Iglesias et al. [

39] presented a method to find the optimal angles between the inserts, and the stability diagrams were obtained through the iterative brute force (BF) method, which consists of an iterative maximization of stability through the semi-discretization method. They conclude that, if an optimal selection of the angle between the inserts is possible then, the material removal rate can be improved up to three times. Gou et al. [

40] proposed an effective optimization method for the variable helical cutter introducing an index called “suppression factor” to measure stability quantitatively.

Therefore, in the present work, the EMHPM developed in [

33] and extended for analysis of multivariable tools in [

34], is now expanded to solve the dynamics of the machining process in milling in which the approximation to the delay is performed with polynomials of degree two and three. In order to study the proposed method performance in terms of convergency and computational cost, a multivariable milling tool with a variable pitch cutter and helix angle is used to determine milling process in stability domains.

This paper is summarized as follows.

Section 2 focuses on the development of second- and third-order EMHPM for stability analysis of DDE.

Section 3 studies the application of the second- and third-order EMHPM on the milling equation to demonstrate its improvement in the convergence rate.

Section 4 is focused on the use of the third-order EMHPM to compute the stability analysis in milling for multivariable tools, and theoretical predictions with time-domain simulations are performed. Finally, some conclusions are drawn.

4. Stability Analysis of Multivariable Milling Tools

The EMHPM can be generalized for stability analysis of DDEs having multiple delays. A multivariable tool contains some of the following characteristics: uneven pitch between teeth, and/or at least one helix angle with a different value from the others. This analysis was developed by Compeán et al., in [

34] by using the first-order EMHPM, where the methodology for the characterization of the cutting coefficients for a multivariable tool was discussed, and the dynamic behavior was studied from the productivity point of view. Since the angular spacing at the beginning of the edge is different between teeth (pitch) and the different values of helix angles of the edges between adjacent teeth, the angular spacing between teeth at a specific height changes continuously, which produces an infinite number of delays. A common approach to deal with the DDE with an infinite number of delay is to discretize the tool by cutting disks in the axial direction with a thickness

to induce a DDE with a finite number of delays. A single disk still has the same number of flutes (discrete flutes) and considering that the maximum delay in the process is the period of rotation of the tool or the spindle rotation period

, then, it can be discretized in

intervals.

The angular position between two adjacent teeth in each cutting disk changes according to the axial position of the referred disk and is related to the expression

, where

. Here

is the diameter of the tool and

represents the cutting-edge offset angle due to the helix angle. A certain interval can be associated with a discrete time delay of each tooth

and disk

using the following formulation

where

is the angular pitch between consecutive teeth for each disk, the round function converts the argument to the nearest integer. In Equation (27)

, is a table (matrix) of dimension

iz ×

l. Since this procedure could generate several delayed terms and some of them with the same value of discrete time delay due to the discretization scheme, it is required to collect all the different (non-repeated) discrete time delays

from

.

Thus, without loss of generality, the DDE with multiple delays can be written as

where

x is the vector of states,

,

and

is the period of rotation of the spindle. Following the EMHPM procedure, Equation (28) can be written equivalently by intervals as:

being

the solution by intervals of order m for Equation (28) in the

interval that satisfies the initial condition

, the matrices

and

represent the values of the matrices

and

evaluated at time

respectively.

4.1. Third-Order EMHPM for Multivariable Milling Tool

To approximate the term associated with the delayed terms

of Equation (29), the interval of the period

is discretized in

intervals that can be equal size. For simplicity, intervals of equal size

are chosen. Then it is assumed that the function

, which is defined in the interval

for the third-order EMHPM has the representation of the form:

Defining

to simplify the notation, and substituting Equation (30) in Equation (29), the following equation is obtained:

where

here,

is the specific cutting force in the

y-direction due to flexibility in

y-direction, which is used for thin wall machining. This force was calculated depending on the position of the tool via the following equation:

Then, solving Equation (31) yields

Notice that Equation (34) can be written recursively as

where

and

the solution of order

for Equation (31) was obtained by adding each of the approximations

of Equation (35). Similar to Equation (15), to obtain the stability graphs the solution of Equation (35) is rewritten by grouping the discrete states, which results in:

where

The approximate solution obtained from Equation (37) was used to define a discrete map:

where

is a vector represented by Equation (20) and

is a coefficient matrix given by

The transition matrix

over the period

was determined by coupling each solution

through the discrete map

,

. However, the computational cost can be reduced by computing only the transition matrix up to the maximum delayed term without losing precision in the calculation of the eigenvalues:

Thus, the stability graphs of Equation (28) were determined by computing the eigenvalues of the transition matrix of Equation (41). The results obtained from the EMHPM were corroborated with the stability lobes in the study of multivariate tools [

27].

4.2. Experimental Characterization of One Degree of Freedom Milling Equation and Cutting Force Model

4.2.1. Experimental Modal Analysis

An experimental workpiece was assembled with a 7075T6 aluminum block of 101 mm × 172 mm supported by two thin plates (walls) with a thickness of 4.5 mm. This assembly mimics a DOF as described in Equation (23). The workpiece assembly was rigidly fixed to the workbench of a Makino F3 machining center. For modal analysis, tap testing was performed using a 352C68 PCB Piezotronics accelerometer and an impact hammer model 9722A500. The signals were acquired with a Polytec VIB-E-220 data acquisition card and processed with VibSoft signal analyzer software as shown in

Figure 5a. Using the CutPro 8 software, the modal parameters were fitted resulting the values

,

kg,

= 132 Hz and

rad/s.

4.2.2. Experimental Determination of Cutting Coefficients

The force model in Equation (33) was used to predict the cutting force magnitude for a given depth of cut. It is based on a mechanistic approach that assumes a relationship between forces and the uncut chip thickness by means of the cutting coefficients. The cutting force model was established by introducing cutting (shearing) and edge coefficients for the tangential and normal directions of the milling tool. The characterization procedure assumed the linear relationship between the averaged experimental cutting forces

and the feed rate

fz in

x- and

y- directions. This relationship is established as follows:

Here,

and

are the cutting shear and edge components, respectively. The experimental forces at each feed rate are measured, and the cutting-edge components

and

were evaluated

A multivariable cutter provided by a local toolmaker was characterized by using Equation (43) and the experimental setup shown in

Figure 5b.

Table 2 summarizes the main geometric characteristics of the multivariable tool. A total of five cuttings were performed for full radial immersion in aluminum 7075T6 during dry machining. The forces were recorded by using a dynamometer 9257B Kistler and the spindle speed was set at 3000 rpm based on the dynamometer’s natural frequency to avoid the amplification of milling forces. The force signals were acquired using a VibSoft-20 acquisition card at a sample rate of 48 kHz and processed in a custom-made MATLAB app to remove drift and noise. Cutting forces data were collected for the axial depth of cut of 2 mm and four values of feed per tooth 0.05, 0.10, 0.015 and 0.20, so the resulting cutting coefficients

for the tooth 1, 2, 3 and 4 were

1

and

N/

respectively, while that the coefficients

for the tooth 1, 2, 3 and 4 resulted

,

and

N/

respectively.

4.3. Stability Analysis of 1 DOF Milling with a Multivariable Tool

The stability lobes computed for the multivariable tool using the third-order EMHPM with a mesh of

(

) are shown in

Figure 6 together with stability lobes for a regular tool (angles of 90° and helix angles of 30° for all flutes). An approximation of order

was used with

N = 241 and

mm. Notice from

Figure 6 that the stable zone obtained for the multivariable tool was significantly larger, meaning that the critical depth of cut was higher in most spindle speeds, which allowed having more global productivity. It is also observed in the range of spindle speed between 2000 and 3000 rpm, a stable peninsula formed with axial depth ranging from 11 to 20 mm or higher values of critical depth of cut. For instance, for the multivariable cutter at 2500 rpm, the critical depth of cut

was 2.17 mm, however it became stable again as shown in

Figure 6 for the interval values between 11 and 20 mm. To validate this unexpected behavior, we performed several time-domain simulations using the third-order EMHPM solution described by Equation (37).

Furthermore, the simulated vibrations for the chosen cutting conditions were analyzed using the continuous wavelet transform (CWT), the power spectral density (PSD) and Poincaré maps (PM). The CWT is a time-frequency representation of a signal that offers the capability to observe how frequencies evolve in time. The scalograms display the absolute value of CWT of the simulated vibration and therefore, they were used to detect chatter phenomena that appeared when milling with a multivariable tool. The PSD is based on the Fourier transform that provides the transformation from the time-domain to the frequency-domain. Additionally, PSD is defined as the squared value of the signal and describes the power of a signal or time series distributed over different frequencies [

46]. Moreover, a PM represents points in phase space, which are sampled every spindle rotation [

47]. The frequencies

of the CWT and PM were normalized

according to the spindle frequency

. When milling with a regular milling tool the excitation frequency

is equal to

times frequencies of the spindle speed

but in a multivariable tool, there are several excitation frequencies since the angular spacing between teeth change as a function of the axial depth of cut.

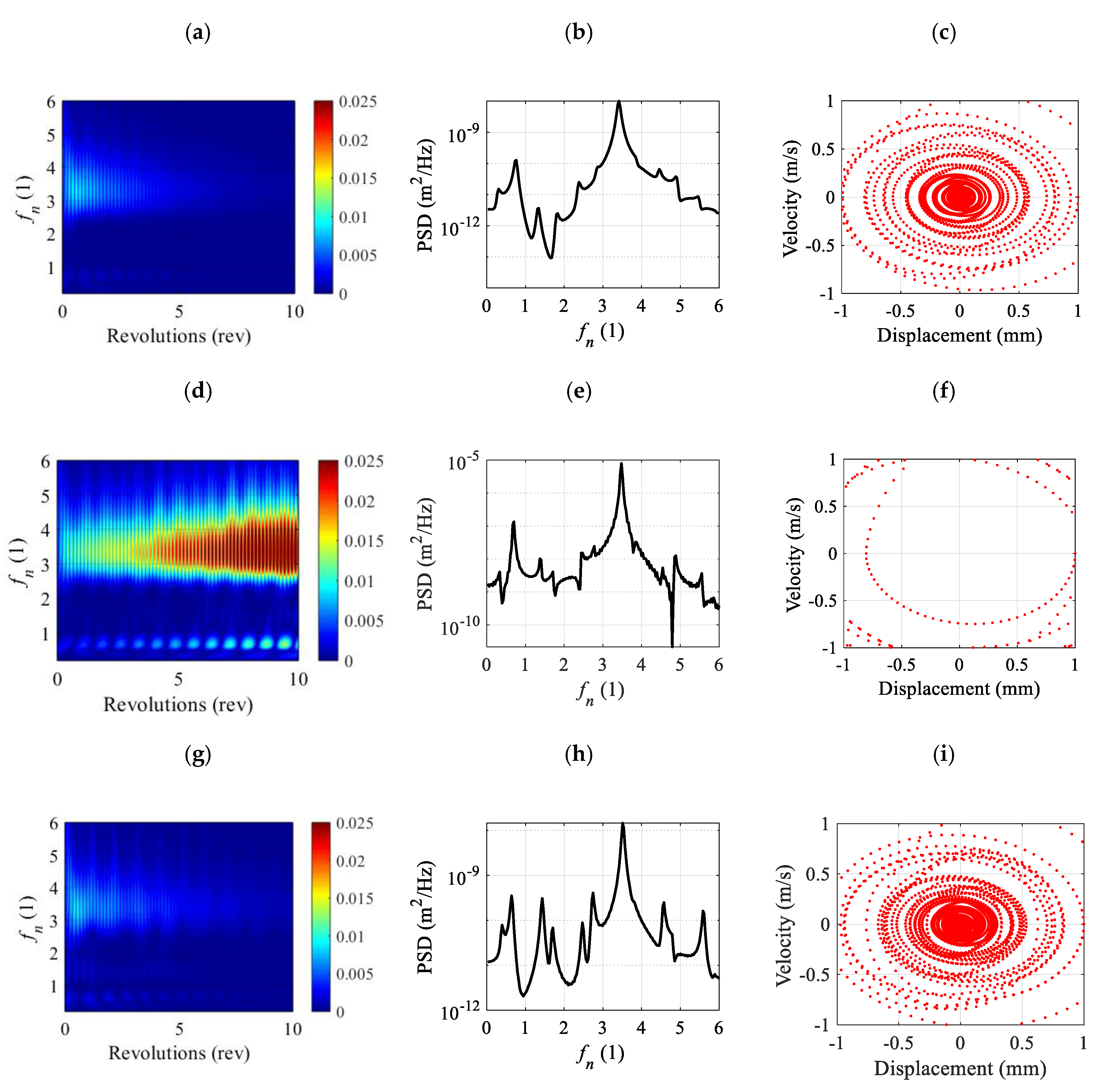

Figure 7 illustrates the CWT, PSD and PM for simulated vibrations using the multivariable tool with different axial depths denoted as cutting conditions A, B and C for the axial depths of cut of 1.0, 1.7 and 1.7 mm respectively.

Figure 7a–c refers to the vibrations of the cutting conditions A marked in

Figure 6, using a regular tool. The scalogram in

Figure 7a identifies point A as a stable cutting since normalized cutting frequencies present a dominant value of

= 3.2, which corresponds to the natural frequency

Hz. This is also confirmed by the PSD analysis shown in

Figure 7b. The PM illustrated in

Figure 7c shows a vibration that decreased with time and sampled data concentrated in the center confirmed a typical stable case. When the axial depth of cut was increased to 1.7 mm, the stability diagram predicted unstable cutting conditions according to the stability lobes for the regular tool. This case is denoted with cutting conditions B and the corresponding scalogram (shown in

Figure 7d) illustrated how the intensity of the dominant frequency increased with time even when the excitation frequency was the same as the case in A.

The PM diagram shown in

Figure 7f exhibited a vibration far from zero. In fact, the PM diagram shows that the vibration amplitude grows exponentially because our equation of motion did not consider nonlinear effects such as those that appeared when the tool lost contact with the workpiece. Both cutting conditions A and B agreed with the stability boundaries in

Figure 6. Now, the cutting conditions B were used but with a multivariable tool, which was referred to as cutting conditions C. The CWT plotted in

Figure 7g described completely different results since there were no single dominant frequencies in comparison with cutting conditions A, but appeared several frequencies around

= 3.2 and close to

= 1 that reduced in intensity with time, suggesting a stable cutting.

Figure 7i illustrates how the vibration amplitude approached to zero when using a multivariable tool in contrast to the PM obtained for the regular tool and exhibited in

Figure 7f. This can be explained by observing that there were several excitation frequencies due to the irregular pitch and helix angles that break a single excitation frequency avoiding regenerative chatter phenomena.

Figure 8 illustrates the CWT, PSD and PM for simulated vibrations using the multivariable tool with different axial depths denoted as cutting conditions D, E, F and G for the axial depths of cut of 2.3, 3.0, 8.55 and 18 mm respectively. Notice that a stable case C was already validated when the axial depth was 1.7 mm in

Figure 7g–i that corresponded to cutting conditions under the stability boundaries shown in

Figure 6. For case D, a transient cutting condition was chosen very close to the critical axial depth of the cut. It is interesting to point out that transition cutting conditions in the CWT scalogram shown in

Figure 8a not only shows frequencies with higher intensity in comparison with the stable case B, but also presents shifted frequencies that varied in intensity every single revolution. This shifting suggests a marginally stable cutting condition that was confirmed by the PM illustrated in

Figure 8c, where circular trajectories were described close to the center point.

Unstable vibrations that appeared for case E were because of the intensity of frequencies increased exponentially with time, see

Figure 8d. Notice that other frequencies arose with time close to the values of

= 0.5 and

= 1.5. These frenquencies also occurred for cutting conditions D, which is an indication of the appearance of chatter phenomena. In contrast to

Figure 7i for a stable case,

Figure 8f exhibited few trajectories because the vibration amplitude was out of the range selected (±1 mm). The qualitative and quantitative dynamic behaviour due to cutting conditions F, and illustrated in

Figure 8g-i, were classified as transition cutting behaviour. Here, a more severe shifting in frequencies was observed in the scalogram (

Figure 8g). From

Figure 8g, it is seen that drastic shifting occurred in the time domain in the range of normalized frequencies from 3.5 to 6. It was also evident in the PM showed in

Figure 8i, that the amplitude of vibration remained below 1 mm during several revolutions of the tool but the amplitude of vibration never aproached to the center point, in contrast to the stable cutting condition C shown in

Figure 7i in which the oscillation aplitudes aproached the center.

An interesting dynamic behaviour was observed in the milling cutting process when the cutting conditions were selected in the middle of the stable peninsula, above unstable cutting conditions such as E cutting conditions. The axial depth of the cut was increased from the unstable axial depth of cut of 3–18 mm, 6 times higher of the stable cutting condition C and 2 times higher than the unstable condition E. Since the vibration quickly decreased in a few revolutions no dominant frequencies appeared in the CWT and PSD failed to clearly identify a dominant frequency since the vibration amplitude decreased to zero after few revolutions, as confirmed by the PM shown in

Figure 8l.

Figure 9 shows the normalized excitation frequencies that the multivariable tool produced for a fixed spindle speed of 2500 rpm. The total number of disks of 50 μm of thickness was grouped in sets of each millimeter in the axial direction. The waterfall plot in

Figure 9 explains that a stable peninsula was formed above 11 mm because the workpiece was excited with several frequencies simultaneously. For instance, for a milling operation with the axial depth of cut of 1 mm (stable cutting), 80 discrete disks were cut with four normalized excitation frequencies values (3.3, 3.6, 4.5 and 5.1). On the other hand, when milling at 18 mm (stable cutting), there were 14 normalized excitation frequencies (3.30, 3.35, 3.39, 3.44, 3.49, 3.54, 3.60, 4.55, 4.64, 4.73, 4.82, 4.92, 5.02 and 5.13), most of them with at least 115 discrete disks.

5. Conclusions

In this work, quadratic and cubic polynomials were used to approximate the delayed terms of delay differential equations. Numerical simulations showed that using second- and third-order EMHPM improved the convergence rate and required less computational time when compared to the first-order EMHPM, and to semi-discretization and full-discretization methods, since fewer approximations or less discrete intervals were needed to reduce the computation time.

To further assess the applicability of the proposed method, the third-order EMHPM was used for determining the stability bounds in one-degree-of-freedom milling operation with a multivariable tool, demonstrating that the stability zone improved in comparison with a regular tool. For instance, at 2500 rpm the critical axial depth of the cut was 1.3 mm using the regular milling tool. However, using the multivariable tool, the critical axial depth of the cut was increased until 2.17 mm but more interesting, a stable zone appeared above 8.55 mm.

The CWT scalograms, PSD charts and PM were employed to validate the stability lobes found by using the third-order EMHPM for the multivariable tool. Numerical solutions confirmed the system dynamics behavior predicted by the third-order EMHPM.

Based on the above results, this paper provided evidence the third-order EMHPM could be used to study dynamic phenomena that appeared at higher axial depths of cut due to the multivariable design of the tool, which broke the excitation frequencies at a lower depth of cut.