PetriNet Editor + PetriNet Engine: New Software Tool For Modelling and Control of Discrete Event Systems Using Petri Nets and Code Generation

Abstract

1. Introduction

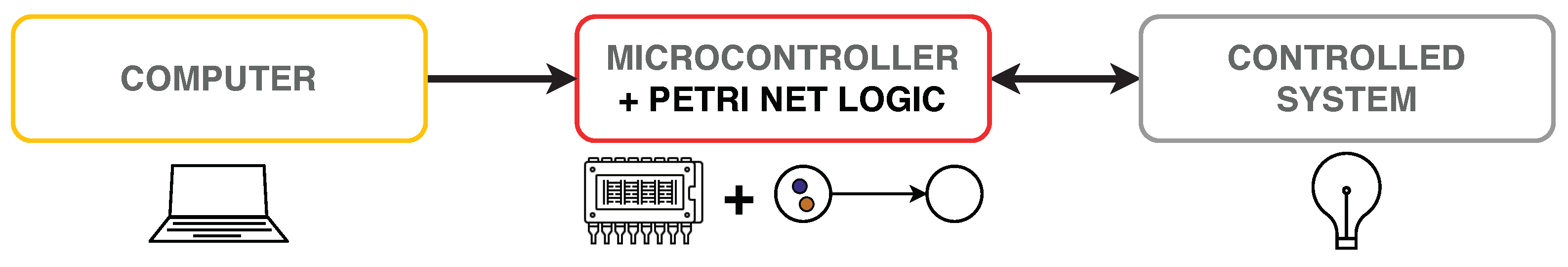

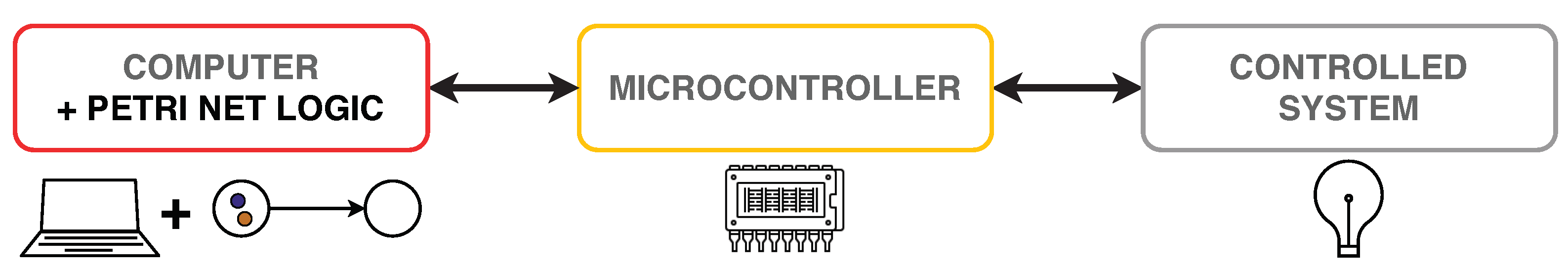

2. Materials & Methods

3. Results

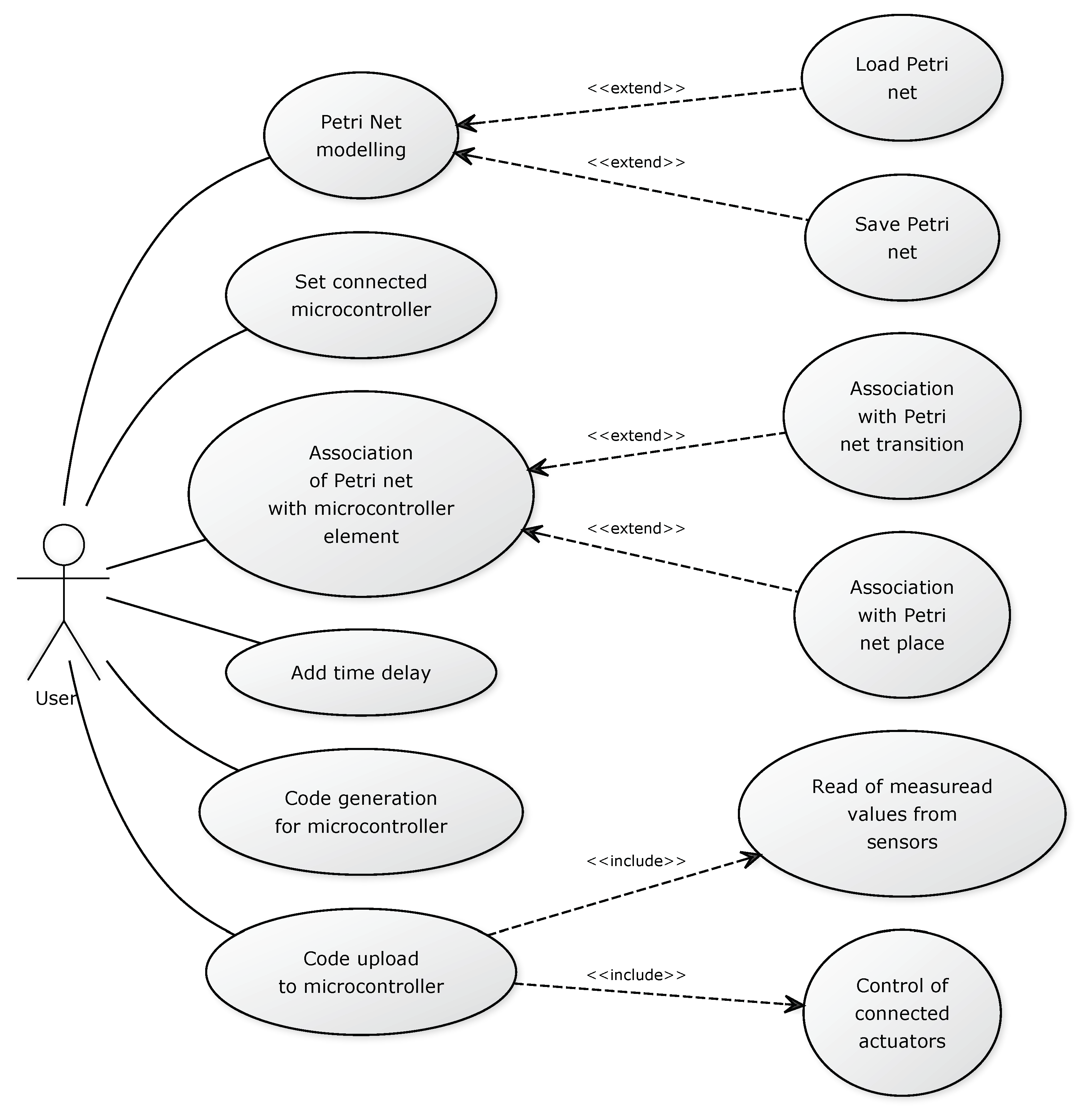

3.1. Description of Developed Software Tool: “PetriNet editor + PetriNet engine”

- After launching the application, the user is given the opportunity to directly create and model a Petri net, which is a model of a particular selected event system, which the user has chosen to analyse and/or control.

- Petri net modeling must meet at least the basic required mathematical formalisms, ideally this solution concept will be extended by other specific properties of Petri nets, which were the subject of the previous analysis.

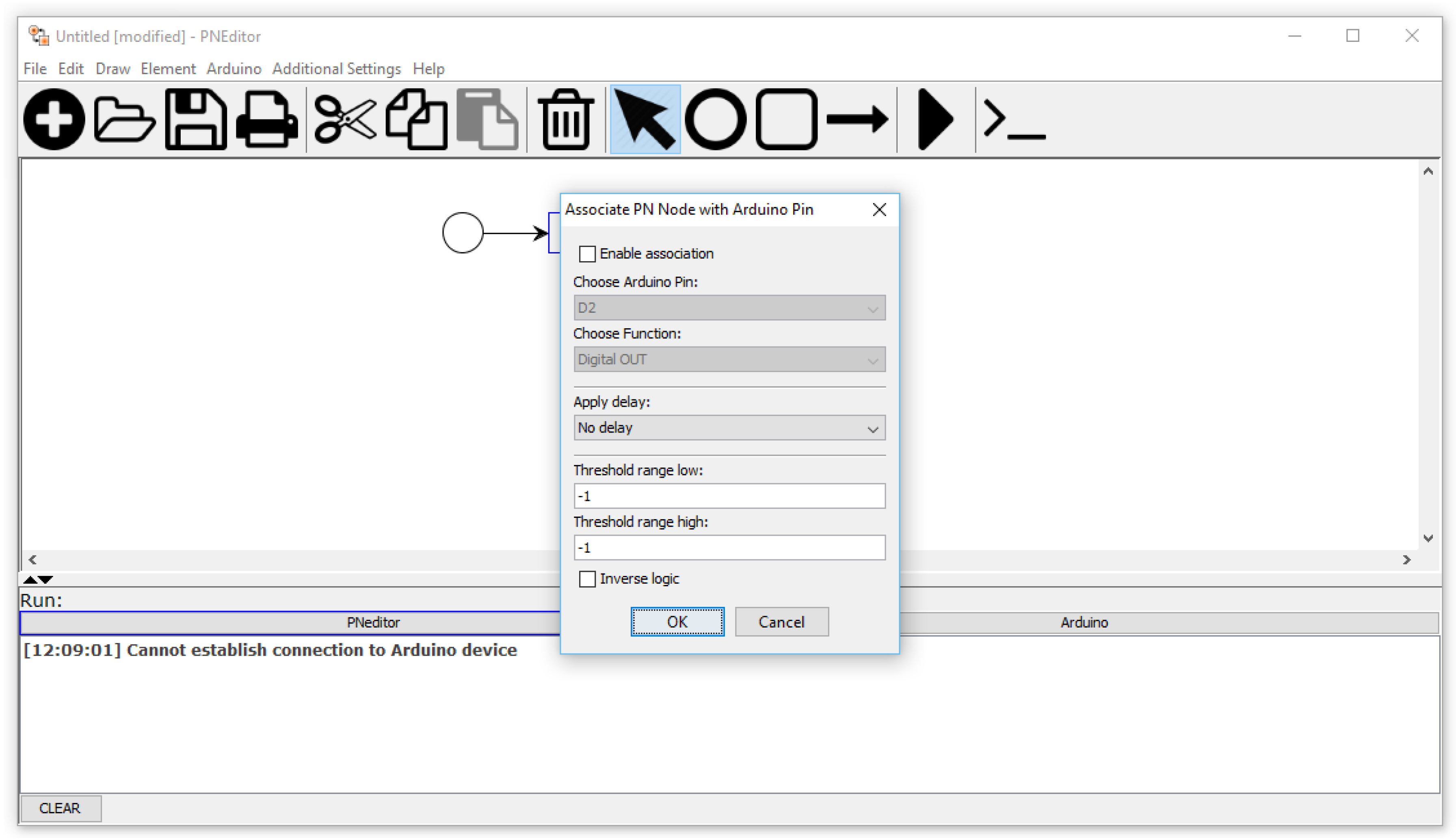

- In case the user decides that the created model is final, he/she must be able to clearly associate the individual components of the Petri net with the control modules of the selected microcontroller.

- The application must be able to process the choice of these dependencies and automatically adjust them to avoid possible collisions when defining different actions on one component.

- The necessary functionality of the system must be the possibility of setting of specific values needed for proper communication with the microcontroller.

- The system must be able to communicate with the selected microcontroller based on the selected parameters.

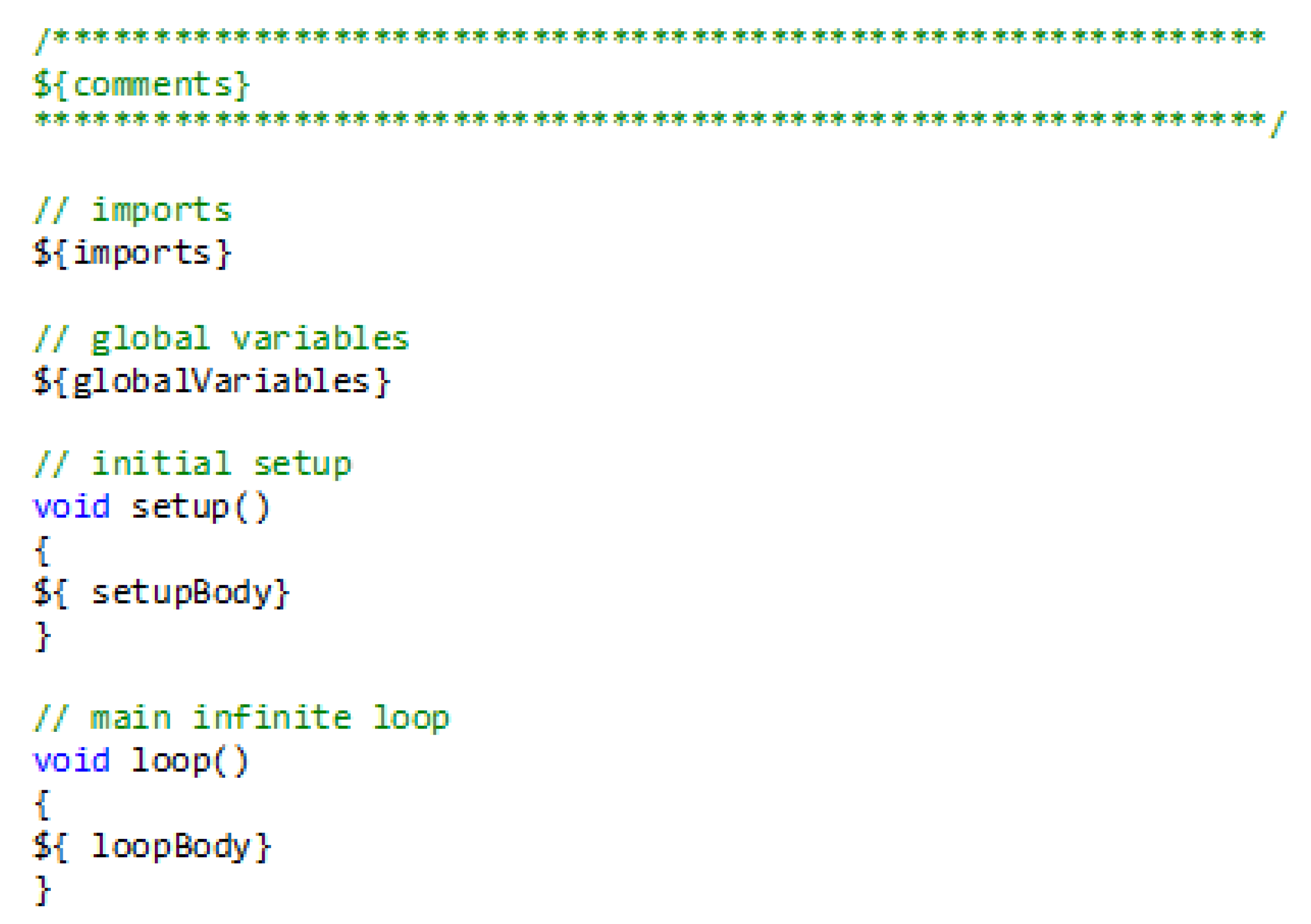

- One of the essential functions is the creation of such an option in the system, by which the user can automatically generate a control logic algorithm based on the specific properties of the selected microcontroller and modelled Petri net.

- It must be possible to upload the generated algorithm (program code) to the microcontroller.

- The system will inform the user through the visualisation of text messages about the current ongoing activity and the result of the system status itself, in order to provide the user with an overview of whether the action was successful, or for what reason and in which step failed.

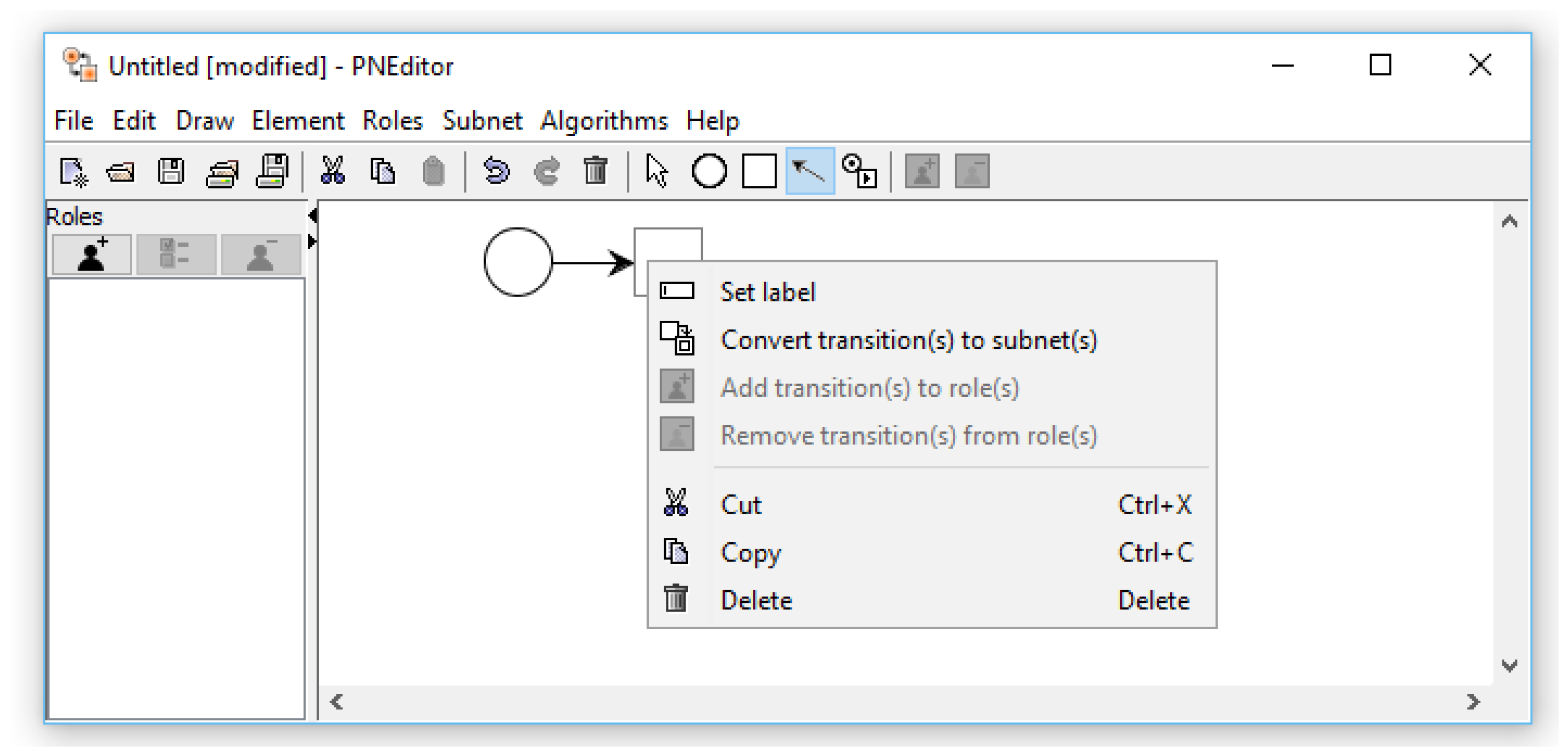

3.1.1. Presentation Layer—PetriNet Editor

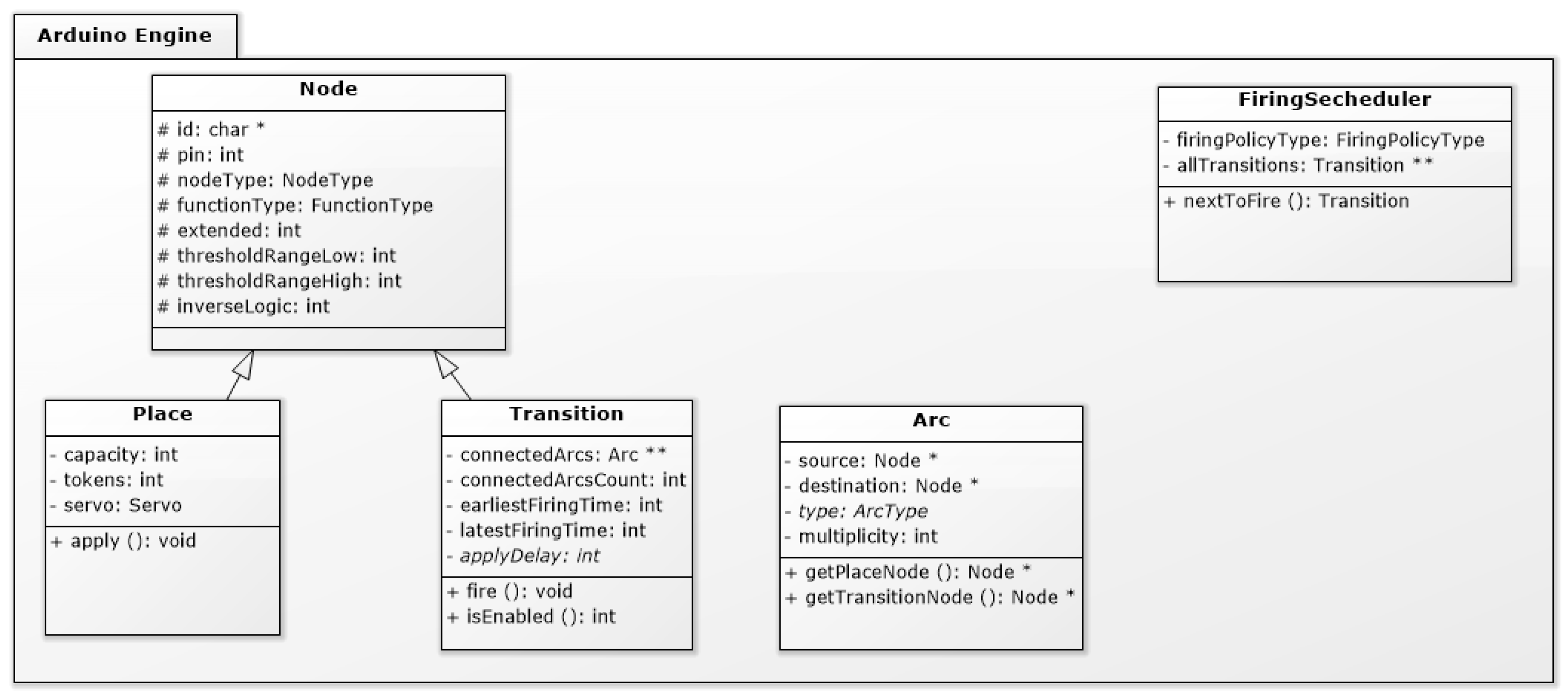

3.1.2. Application Layer—PetriNet Engine

- mapping of a formal Petri net model into an object language,

- definition of an appropriate transition firing mechanism to ensure consistency and parallelism throughout the start-up period of the net,

- conflict resolution in several possible executable transitions,

- emulation of non-determinism of Petri nets,

- support for timed Petri nets.

3.1.3. Transition Firing Strategy

- In the order the individual transitions were created in the editor—Each crawl of executable transitions starts from the first transition. As a result, for example, if the first transition is still executable, it will also be executed and no other transition will ever be selected to start.

- By priority—Each transition carries information about the priority. The priority is any number in the range 0–32,767. The range is limited by the supported size of the int data type on Arduino boards with ATMega microcontroller. A transition with a higher number has a higher priority. In case of equality of priorities, the first strategy is taken into account.

- In the order that takes into account the last running transition—Internally, the last running transition is stored and the transition with the following index is selected from the set of executable transitions. The difference from the first rule is that all executable transitions have the ability to be run.

- Random—The next transition is selected randomly from the set of currently executable transitions.

3.1.4. Memory Optimisation

3.1.5. Time Policy

- Before the actual start of the transition—before the first phase—In this way, it is ensured that the new marking is applied to the input places only after a delay.

- Between the first and second phase—In this case, the tokens are taken from the input places, a delay is applied, and only then the markings at the output places change.

- After starting the transition—The time delay of the transition is applied only after a complete change of Petri net marking, but before selecting the next transition to start.

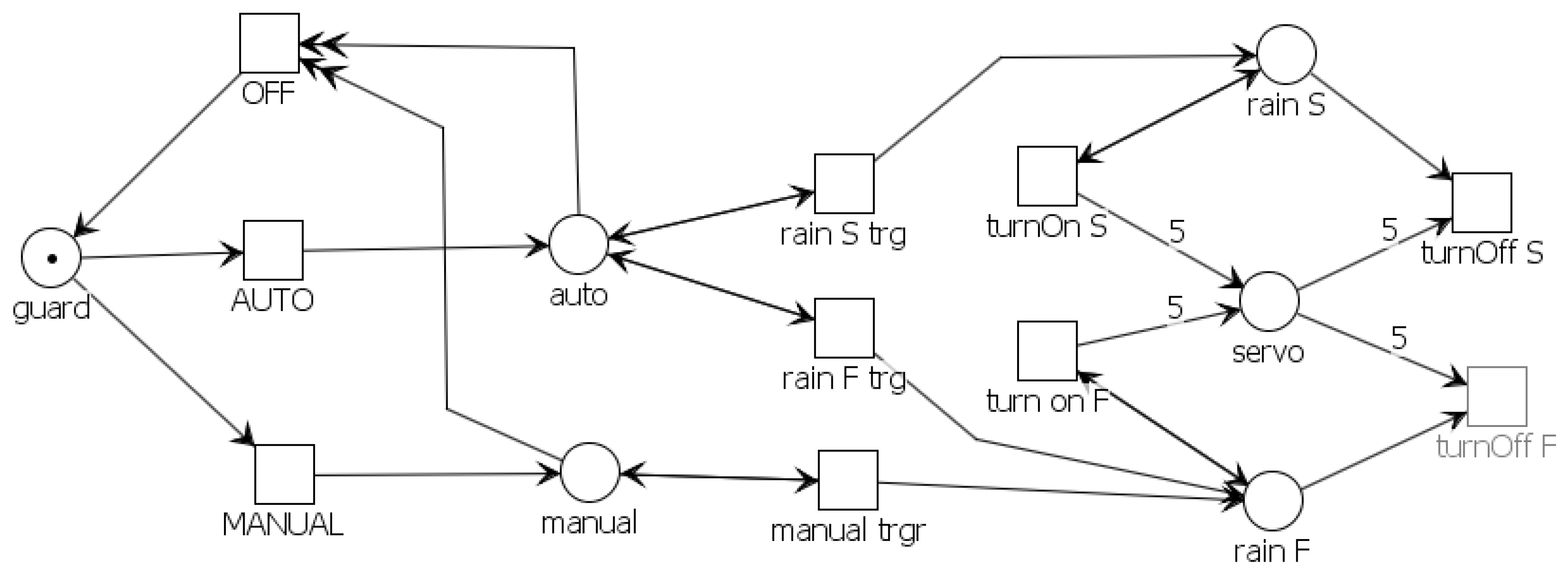

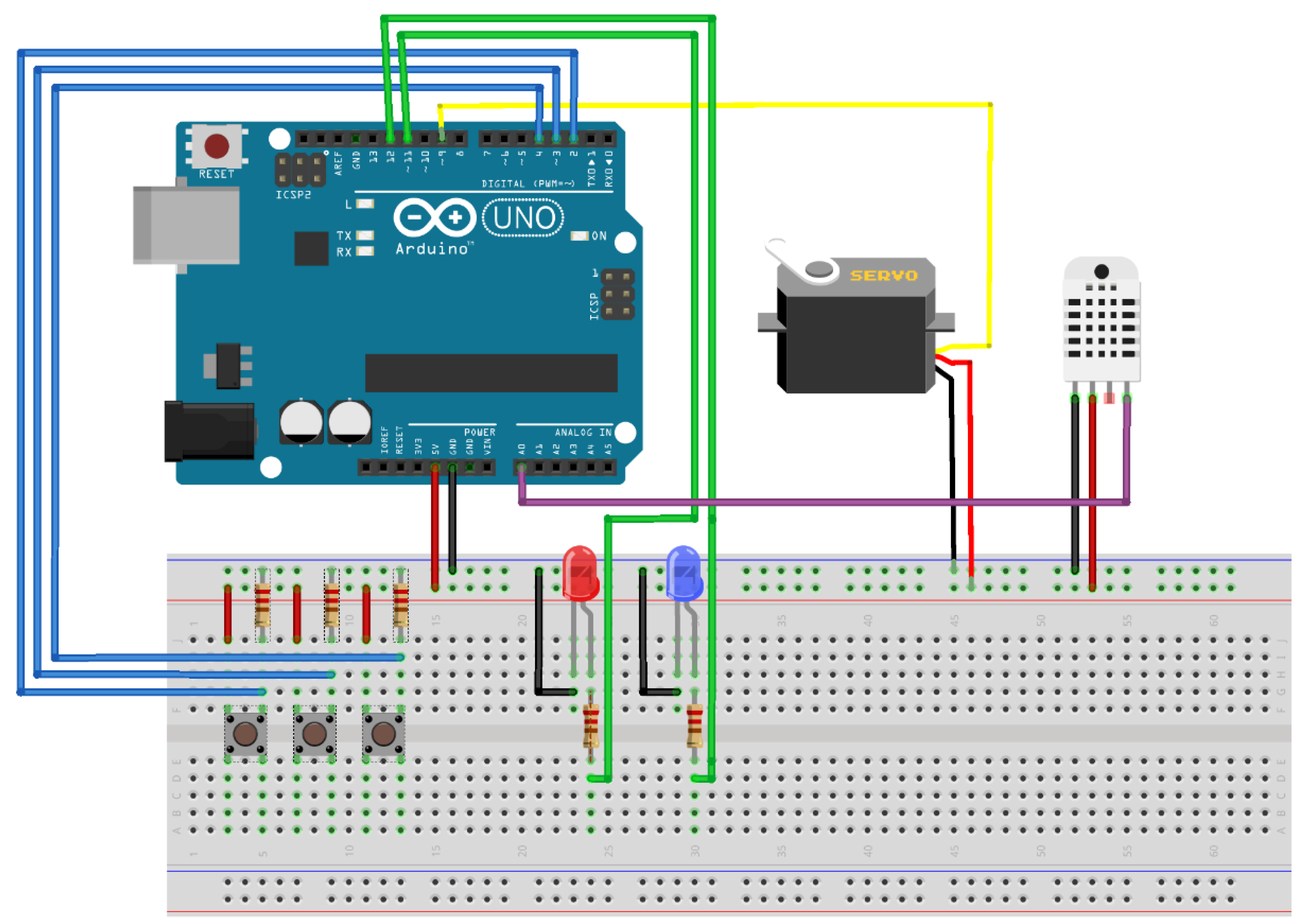

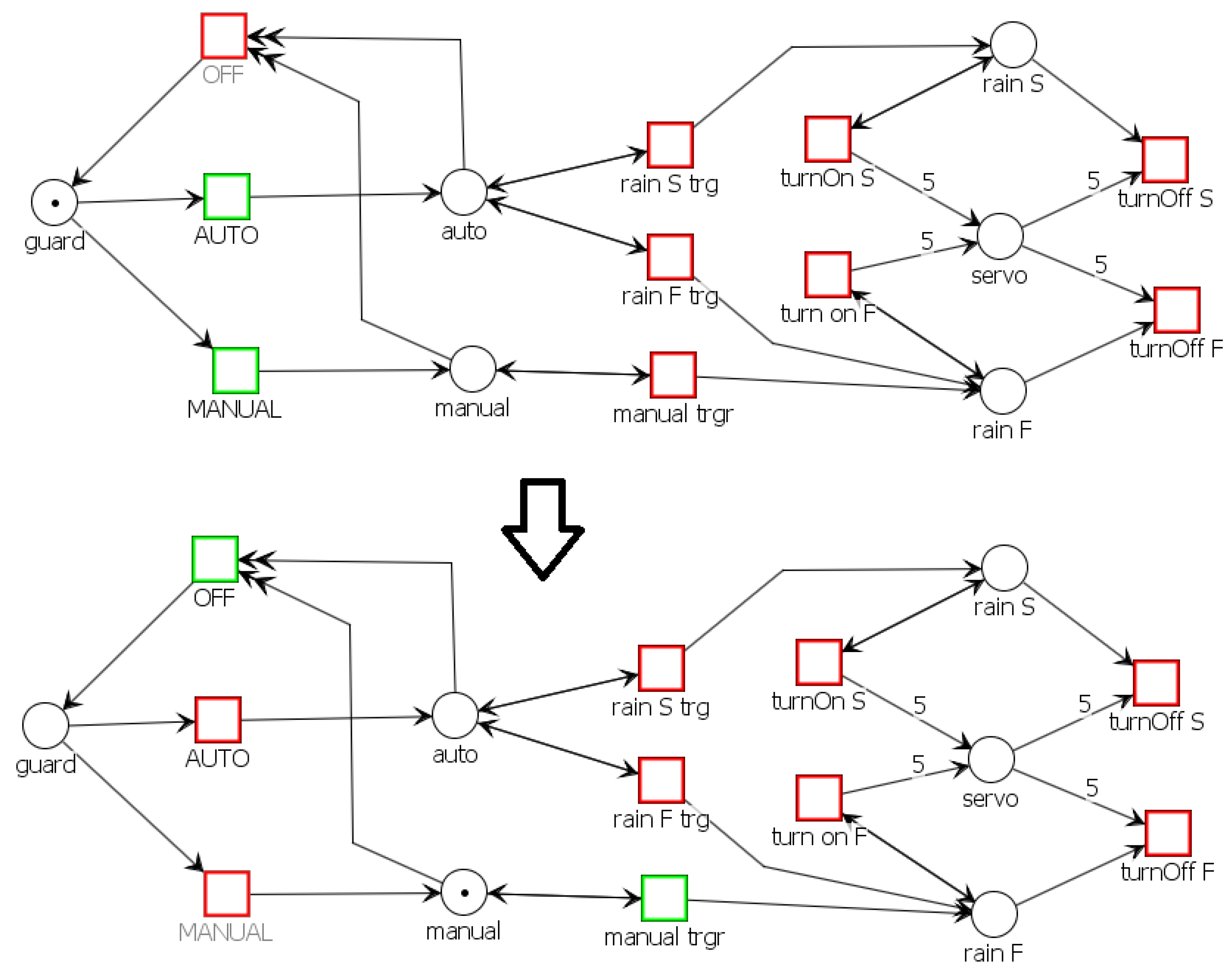

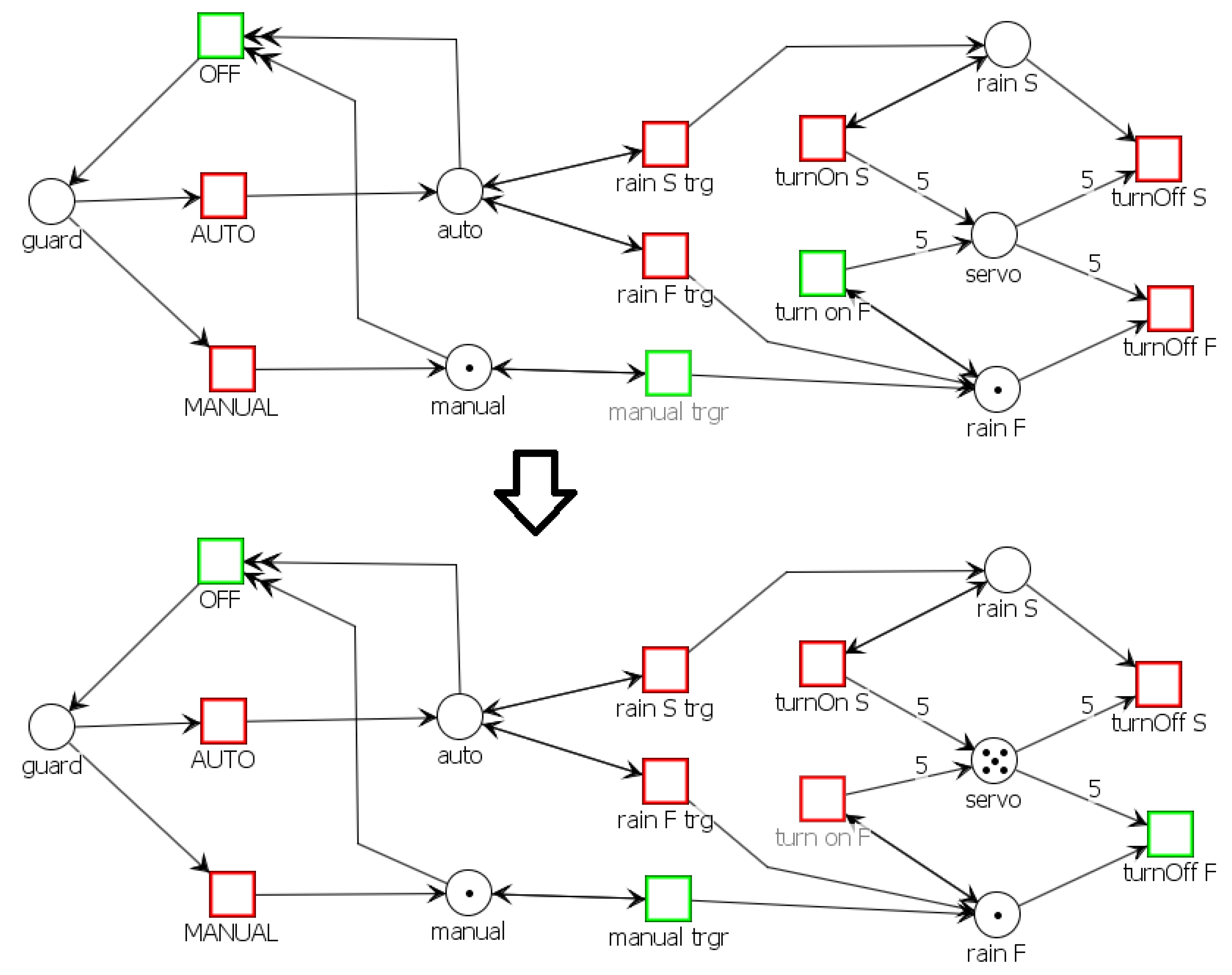

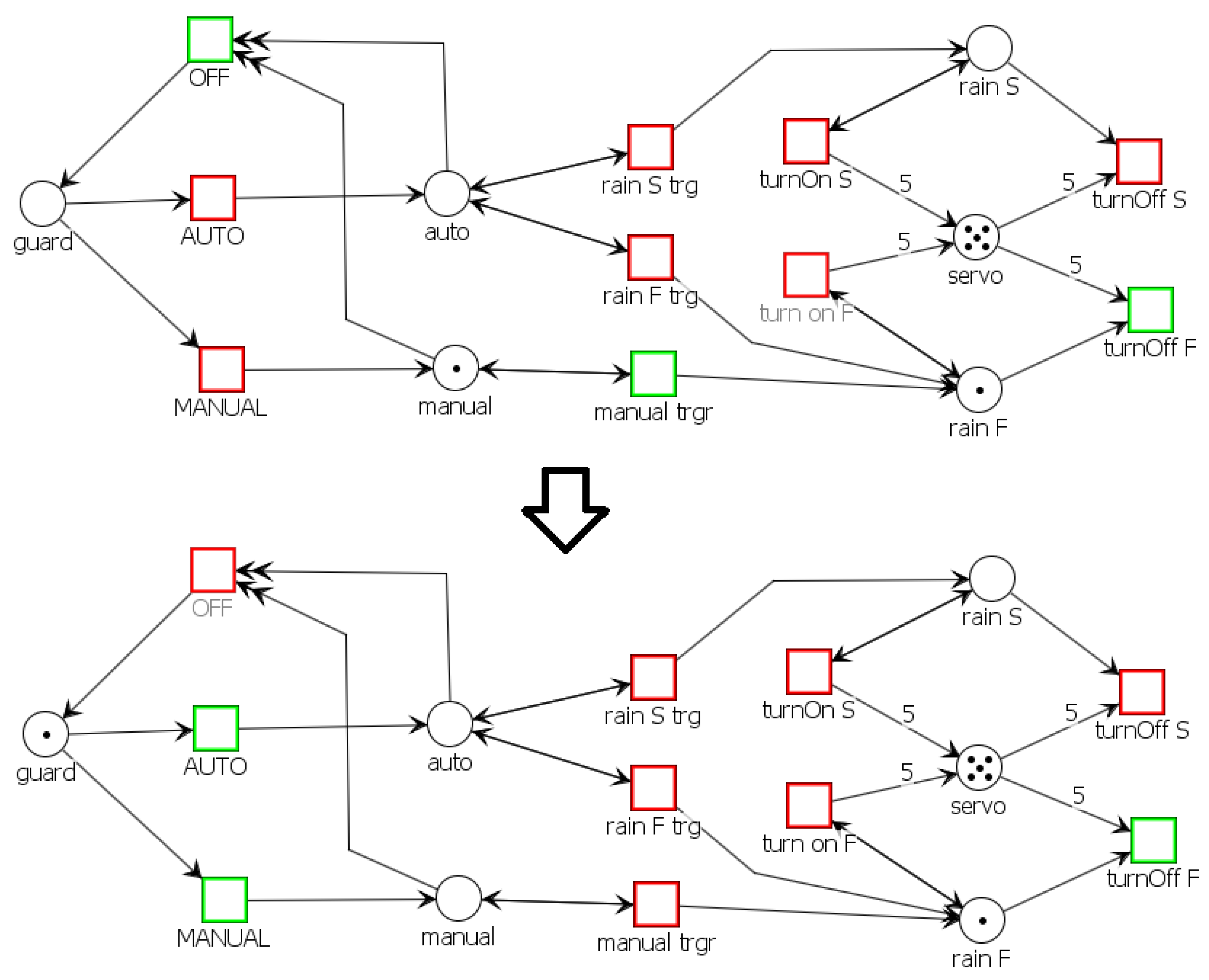

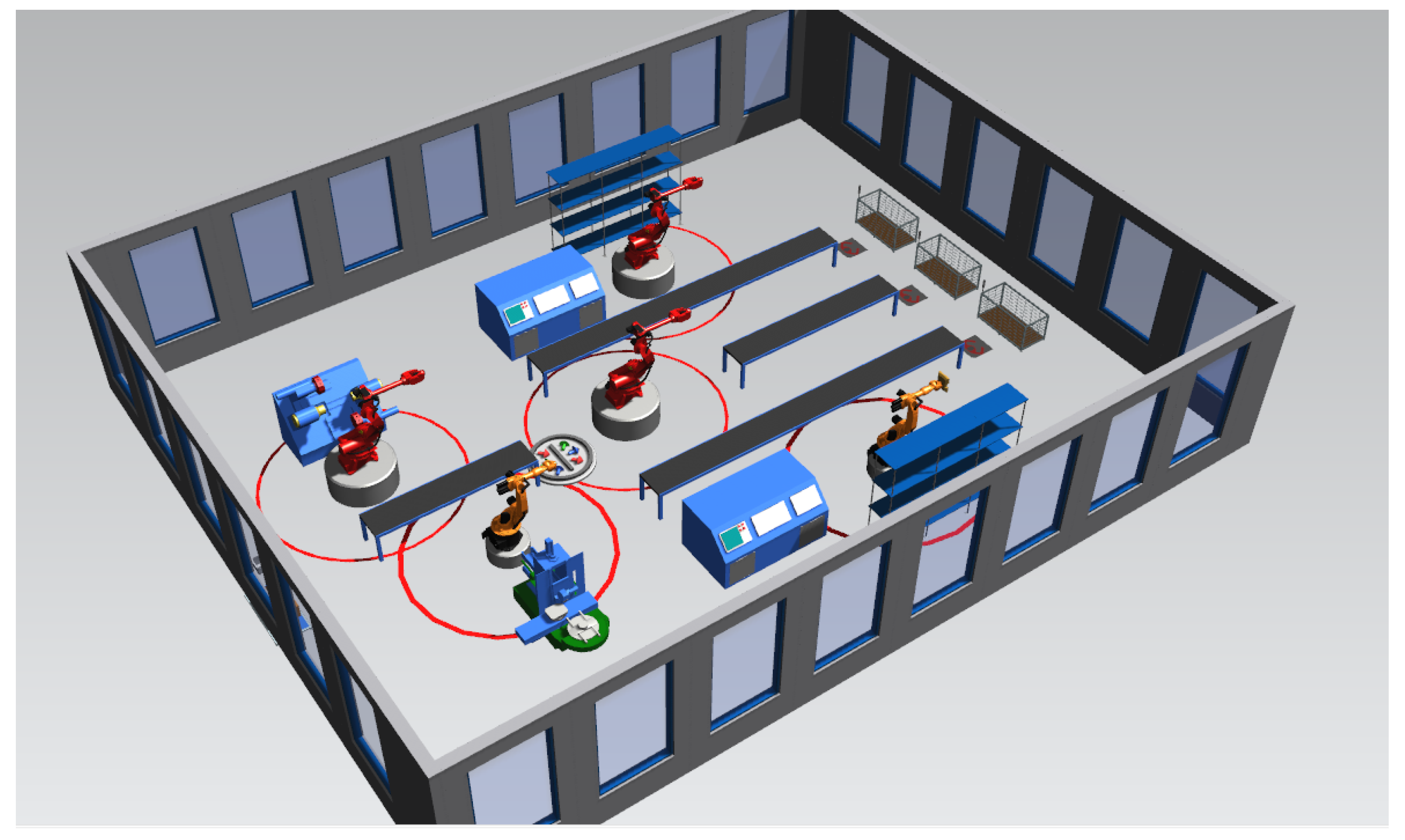

3.2. Case Study: Control of Laboratory Discrete Event System

- guard - 1

- auto - 2

- manual - 2

- rain S - 2

- servo - 6

- rain F - 2

- OFF - 4

- AUTO - 0

- MANUAL - 0

- rain S trg - 1

- rain F trg - 1

- manual trgr - 1

- turnOn S - 2

- turn on F - 2

- turnOff S - 3

- turnOff F - 3

4. Conclusions

- Development of the software application “PetriNet editor + PetriNet engine” supporting modelling and control of discrete event systemsA new software application called “PetriNet Editor + PetriNet Engine”, based on the open-source Petri Net editor PNEditor, has been created for the support of modeling of systems using timed interpreted Petri Nets. As a result, it enables to implement control algorithms on Arduino-type microcontrollers and other compatible microcontrollers as well.

- Verification of the developed software system on a laboratory plantTo verify the developed application “PetriNet editor + PetriNet engine”, and demonstrate its capabilities to control discrete event systems a laboratory car wiper system was proposed based on Arduino Uno microcontroller. The respective Petri net was modelled in the developed “PetriNet editor + PetriNet engine”, and the designed control was demonstrated on the real-world discrete event system.

- Verification of the developed original control methodology based on timed interpreted Petri netsObtained results have proved that the “PetriNet editor + PetriNet engine” can be successfully used to control real plants; though the provided case study is just a basic example, the proposed procedure can be generalised for more complex applications and even more complicated scenarios. Hybrid systems for Industry 4.0 manufacturing processes are a combination of time-driven and event-driven dynamics. Compared with conventional (PID) control, the hybrid control based on discrete event control methods considerably improves controlled system performance and robustness because using hybrid dynamics is unavoidable to reflect the interplay between digital and analog components of a complex manufacturing system.

5. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Planke, L.J.; Lim, Y.; Gardi, A.; Sabatini, R.; Kistan, T.; Ezer, N. A Cyber-Physical-Human System for One-to-Many UAS Operations: Cognitive Load Analysis. Sensors 2020, 20, 5467. [Google Scholar] [CrossRef] [PubMed]

- Blume, C.; Blume, S.; Thiede, S.; Herrmann, C. Data-Driven Digital Twins for Technical Building Services Operation in Factories: A Cooling Tower Case Study. J. Manuf. Mater. Process. 2020, 4, 97. [Google Scholar] [CrossRef]

- Kaid, H.; Al-Ahmari, A.; Li, Z.; Davidrajuh, R. Intelligent Colored Token Petri Nets for Modeling, Control, and Validation of Dynamic Changes in Reconfigurable Manufacturing Systems. Processes 2020, 8, 358. [Google Scholar] [CrossRef]

- Pombo, I.; Godino, L.; Sánchez, J.A.; Lizarralde, R. Expectations and limitations of Cyber-Physical Systems (CPS) for Advanced Manufacturing: A View from the Grinding Industry. Future Internet 2020, 12, 159. [Google Scholar] [CrossRef]

- Dotoli, N.; Fanti, M.; Meloni, C. Coordination and real time optimization of signal timing plans for urban traffic control. In Proceedings of the IEEE International Conference on Networking, Sensing and Control, Taipei, Taiwan, 21–23 March 2004; Volome 2, pp. 1069–1074. [Google Scholar] [CrossRef]

- Boschian, V.; Dotoli, M.; Fanti, M.; Iacobellis, G.; Ukovich, W. A Metamodeling Approach to the Management of Intermodal Transportation Networks. IEEE Trans. Autom. Sci. Eng. 2011, 8, 457–469. [Google Scholar] [CrossRef]

- Cong, X.; Fanti, M.; Mangini, A.M.; Li, Z. Decentralized Diagnosis by Petri Nets and Integer Linear Programming. IEEE Trans. Syst. Man Cybern. Syst. 2018, 48, 1689–1700. [Google Scholar] [CrossRef]

- Fanti, M.; Mangini, A.M.; Roccotelli, M.; Ukovich, W. A District Energy Management Based on Thermal Comfort Satisfaction and Real-Time Power Balancing. IEEE Trans. Autom. Sci. Eng. 2015, 12, 1271–1284. [Google Scholar] [CrossRef]

- Heiner, M.; Herajy, M.; Liu, F.; Rohr, C.; Schwarick, M. Snoopy—A unifying Petri net tool. In Proceedings of the International Conference on Application and Theory of Petri Nets and Concurrency, Hamburg, Germany, 25–29 June 2012; pp. 398–407. [Google Scholar]

- Drath, R. Description of hybrid systems by modified petri nets. In Modelling, Analysis, and Design of Hybrid Systems; Springer: Berlin/Heidelberg, Germany, 2002; pp. 15–36. [Google Scholar]

- Chouikha, M.; Decknatel, G.; Drath, R.; Frey, G.; Müller, C.; Simon, C.; Wolter, K. Petri net-based descriptions for discrete-continuous systems. Automatisierungstechnik Methoden und Anwendungen der Steuerungs- Regelungs-und Informationstechnik 2000, 48, 415. [Google Scholar] [CrossRef]

- Drighiciu, M.A.; Cismaru, D.C. Modeling a Water Bottling Line Using Petri Nets; Annals of the University of Craiova, Electrical Engineering Series; Universitaria Craiova: Romania, Romania, 2011. [Google Scholar]

- Kučera, E.; Hrúz, B. Modelling of AS/RS using hierarchical and timed coloured Petri nets. In Proceedings of the 23rd International Conference on Robotics in Alpe-Adria-Danube Region (RAAD), Smolenice, Slovakia, 3–5 September 2014; pp. 1–8. [Google Scholar] [CrossRef]

- Kučera, E. Modelling of storage/manufacturing systems using coloured petri nets. In Proceedings of the 17th Conference of Doctoral Students, Bratislava, Slovak Republic, 25 May 2015; Volume 25. [Google Scholar]

- Giua, A.; Seatzu, C.; Sessego, F. Simulation and analysis of hybrid Petri nets using the Matlab tool HYPENS. In Proceedings of the 2008 IEEE International Conference on Systems, Man and Cybernetics, Singapore, 12–15 October 2008; pp. 1922–1928. [Google Scholar]

- Davidrajuh, R. Modeling Discrete-Event Systems with Gpensim: An Introduction; Springer International Publishing: New York, NY, USA, 2018. [Google Scholar]

- Liu, B. Simulation of Network Intrusion Detection System with GPenSim. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2011. [Google Scholar]

- Davidrajuh, R.; Skolud, B.; Krenczyk, D. Gpensim for performance evaluation of event graphs. In Advances in Manufacturing; Springer: Cham, Switzerland, 2018; pp. 289–299. [Google Scholar]

- Bonet, P.; Lladó, C.M.; Puijaner, R.; Knottenbelt, W.J. PIPE v2. 5: A Petri net tool for performance modelling. In Proceedings of the 23rd Latin American Conference on Informatics (CLEI 2007), San Jose, Costa Rica, 9–12 October 2007. [Google Scholar]

- Mostermany, P.J.; Ottery, M.; Elmqvistz, H. Modeling Petri Nets as Local Constraint Equations for Hybrid Systems Using Modelica. 1998. Available online: http://citeseer.ist.psu.edu/359408.html (accessed on 1 August 2020).

- Fabricius, S.; Badreddin, E. Modelica library for hybrid simulation of mass flow in process plants. In Proceedings of the 2nd International Modelica Conference, Oberpfaffenhofen, Germany, 18–19 March 2002; pp. 225–234. [Google Scholar]

- Pross, S.; Bachmann, B.; Stadtholz, A. A petri net library for modeling hybrid systems in openmodelica. In Proceedings of the Modelica Conference, Como, Italy, 20–22 September 2009. [Google Scholar]

- Pross, S.; Bachmann, B. Pnlib-an advanced petri net library for hybrid process modeling. In Proceedings of the Modelica Conference, Munich, Germany, 3–5 September 2012. [Google Scholar]

- Markiewicz, M.; Gniewek, L. A Program Model of Fuzzy Interpreted Petri Net to Control Discrete Event Systems. Appl. Sci. 2017, 7, 422. [Google Scholar] [CrossRef]

- Mazári, J.; Juhás, G.; Mladoniczky, M. Petriflow in actions: Events call actions call events. Algorithms Tools Petri Nets 2018, 2, 21–26. [Google Scholar]

- Kučera, E.; Haffner, O.; Drahoš, P.; Cigánek, J.; Leskovský, R.; Štefanovič, J. New Software Tool for Modeling and Control of Discrete-Event and Hybrid Systems Using Timed Interpreted Petri Nets. Appl. Sci. 2020, 10, 5027. [Google Scholar] [CrossRef]

- Steiner, H.C. Firmata: Towards making microcontrollers act like extensions of the computer. In Proceedings of the NIME, Pittsburgh, ON, Canada, 3–6 June 2009; pp. 125–130. [Google Scholar]

- MIDI Association: (2016) Summary of Midi Messages. Available online: https://www.midi.org/specifications/item/table-1-summary-of-midi-message (accessed on 1 August 2020).

- Hrúz, B.; Zhou, M. Modeling and Control of Discrete-Event Dynamic Systems: With Petri Nets and Other Tools; Springer Science & Business Media: New York, NY, USA, 2007. [Google Scholar]

- Kos, T.; Huba, M.; Vrančić, D. Parametric and Nonparametric PI Controller Tuning Method for Integrating Processes Based on Magnitude Optimum. Appl. Sci. 2020, 10, 1443. [Google Scholar] [CrossRef]

| Petri net Logic in PC | Petri Net Logic in Microcontroller |

|---|---|

| limited capability of real-time control | real-time control |

| much more computation and memory resources available | limited computation and memory resources |

| code in microcontroller does not need recompiling | during development repeated compiling is needed |

| PC must be still online | independence of control unit |

| Number of Places | Number of Transitions | Use of Memory without Optimisation | Use of Memory with Optimisation | ||

|---|---|---|---|---|---|

| FLASH | SRAM | FLASH | SRAM | ||

| 1 | 0 | 12 308 B (38 %) | 1 812 B (88 %) | 13 328 B (41 %) | 444 B (21 %) |

| 0 | 1 | 12 178 B (37 %) | 1 832 B (89 %) | 13 622 B (42 %) | 444 B (21 %) |

| 1 | 1 | 12 822 B (39 %) | 1 842 B (89 %) | 14 240 B (44 %) | 452 B (22 %) |

| 2 | 2 | 13 204 B (40 %) | 1 856 B (90 %) | 14 672 B (45 %) | 468 B (22 %) |

| 3 | 3 | 13 528 B (41 %) | 1 872 B (91 %) | 15 100 B (46 %) | 484 B (23 %) |

| 5 | 5 | 14 248 B (44 %) | 1 904 B (92 %) | 15 958 B (49 %) | 518 B (25 %) |

| 8 | 8 | 15 286 B (47 %) | 1 954 B (95 %) | 17 314 B (53 %) | 574 B (28 %) |

| 10 | 10 | 16 166 B (49 %) | 2 040 B (99 %) | 18 042 B (55 %) | 606 B (29 %) |

| 15 | 15 | 17 748 B (55 %) | 2 068 B (100 %) | 19 994 B (61 %) | 690 B (33 %) |

| 20 | 20 | 19 500 B (60 %) | 2 152 B (105 %) | 22 226 B (68 %) | 782 B (38 %) |

| 40 | 40 | 26 688 B (82 %) | 2 508 B (122 %) | 29 730 B (92 %) | 1 182 B (57 %) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kučera, E.; Haffner, O.; Drahoš, P.; Leskovský, R.; Cigánek, J. PetriNet Editor + PetriNet Engine: New Software Tool For Modelling and Control of Discrete Event Systems Using Petri Nets and Code Generation. Appl. Sci. 2020, 10, 7662. https://doi.org/10.3390/app10217662

Kučera E, Haffner O, Drahoš P, Leskovský R, Cigánek J. PetriNet Editor + PetriNet Engine: New Software Tool For Modelling and Control of Discrete Event Systems Using Petri Nets and Code Generation. Applied Sciences. 2020; 10(21):7662. https://doi.org/10.3390/app10217662

Chicago/Turabian StyleKučera, Erik, Oto Haffner, Peter Drahoš, Roman Leskovský, and Ján Cigánek. 2020. "PetriNet Editor + PetriNet Engine: New Software Tool For Modelling and Control of Discrete Event Systems Using Petri Nets and Code Generation" Applied Sciences 10, no. 21: 7662. https://doi.org/10.3390/app10217662

APA StyleKučera, E., Haffner, O., Drahoš, P., Leskovský, R., & Cigánek, J. (2020). PetriNet Editor + PetriNet Engine: New Software Tool For Modelling and Control of Discrete Event Systems Using Petri Nets and Code Generation. Applied Sciences, 10(21), 7662. https://doi.org/10.3390/app10217662