Safe and Sustainable Design of Composite Smart Poles for Wireless Technologies

Abstract

1. Introduction

1.1. Wireless Outdoor Platforms

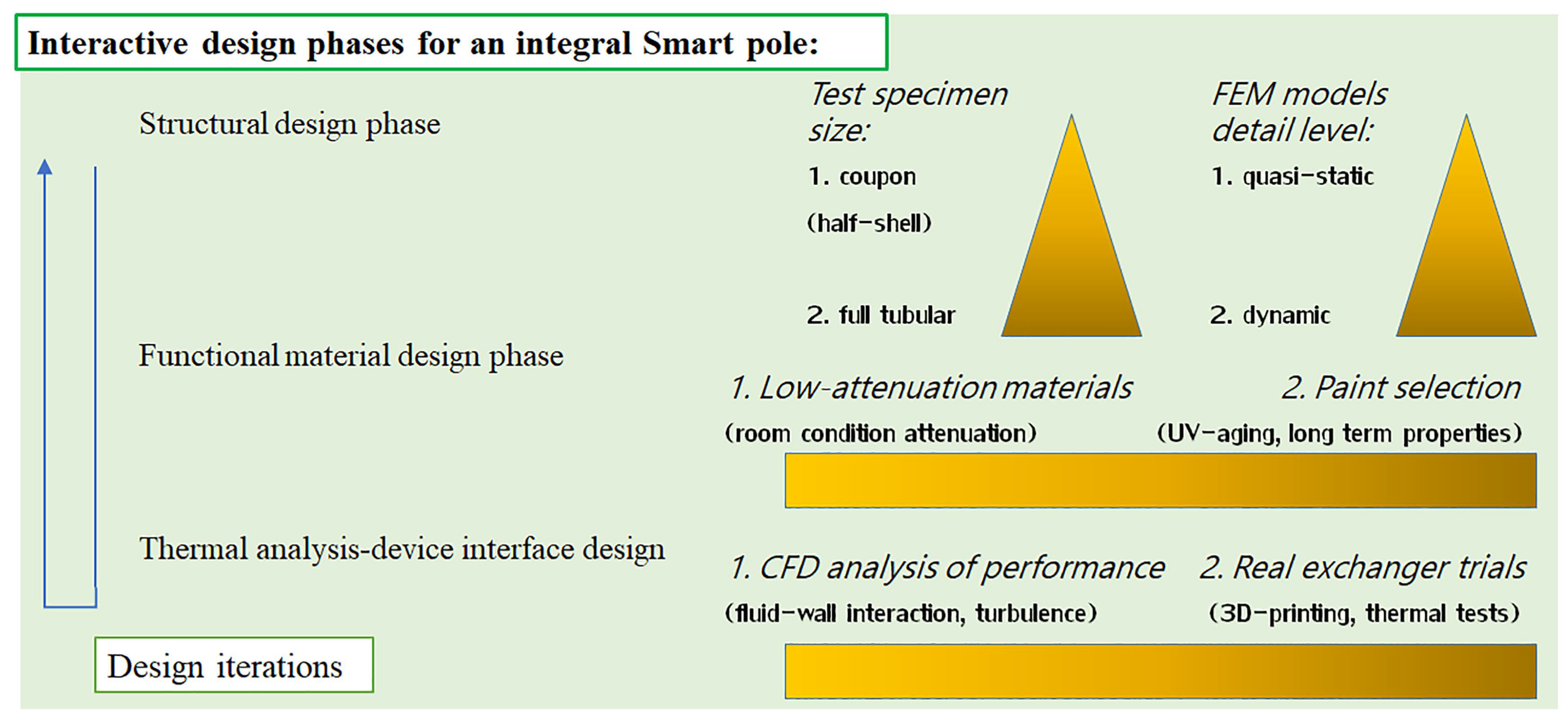

1.2. Design Drivers for a Smart Pole Structure

1.3. The Advantages and Sustainability of Composite Materials

2. Materials and Methods

2.1. Pole Structure

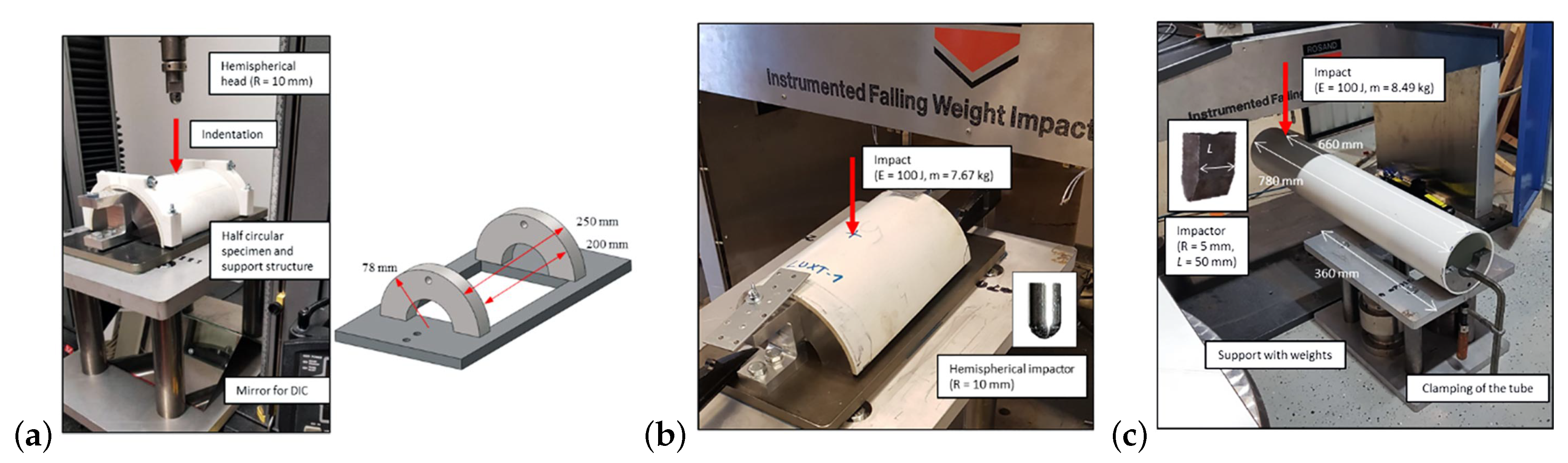

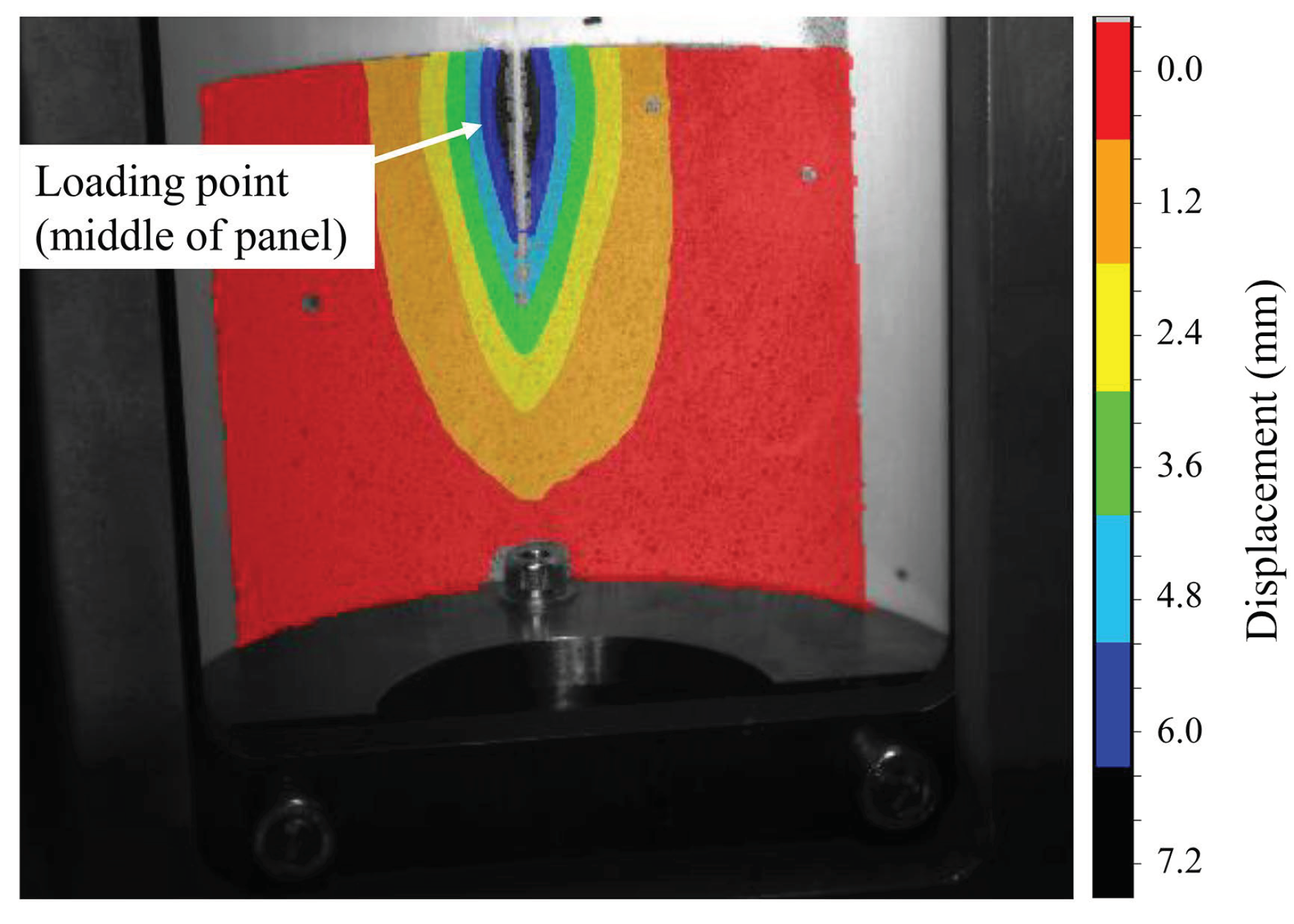

2.2. Impact Dynamics of the Shaft GFRP

2.3. Finite Element Modelling and Mechanical Analysis

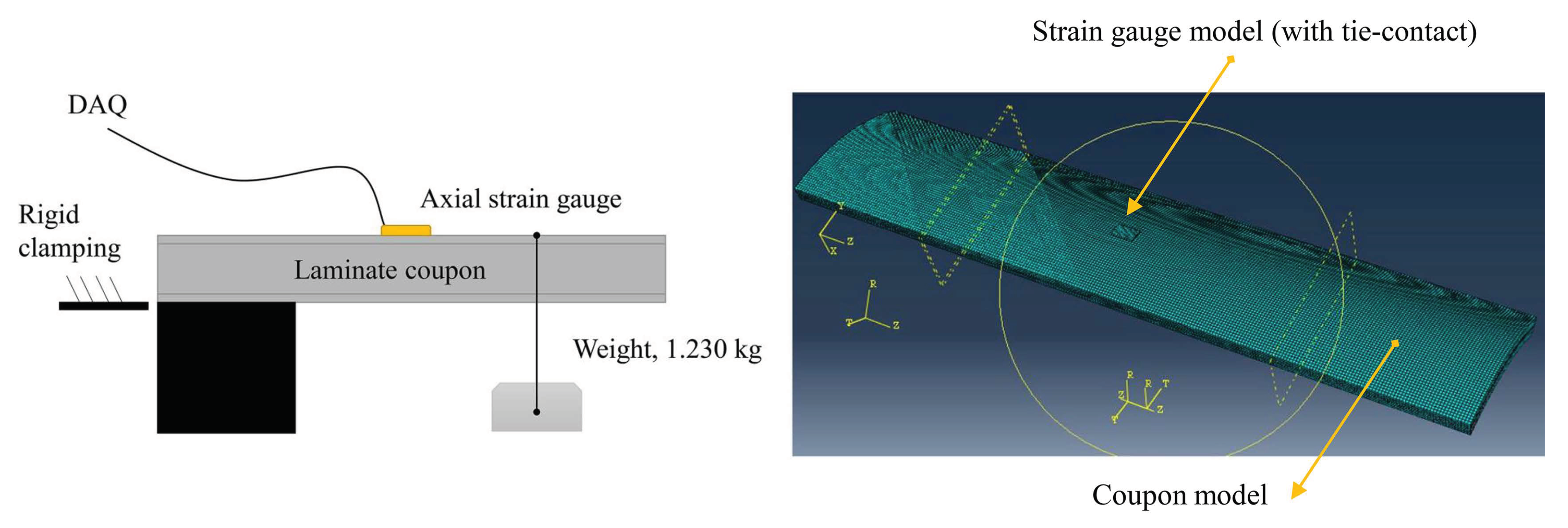

2.4. Experimental-Numerical CTE Determination

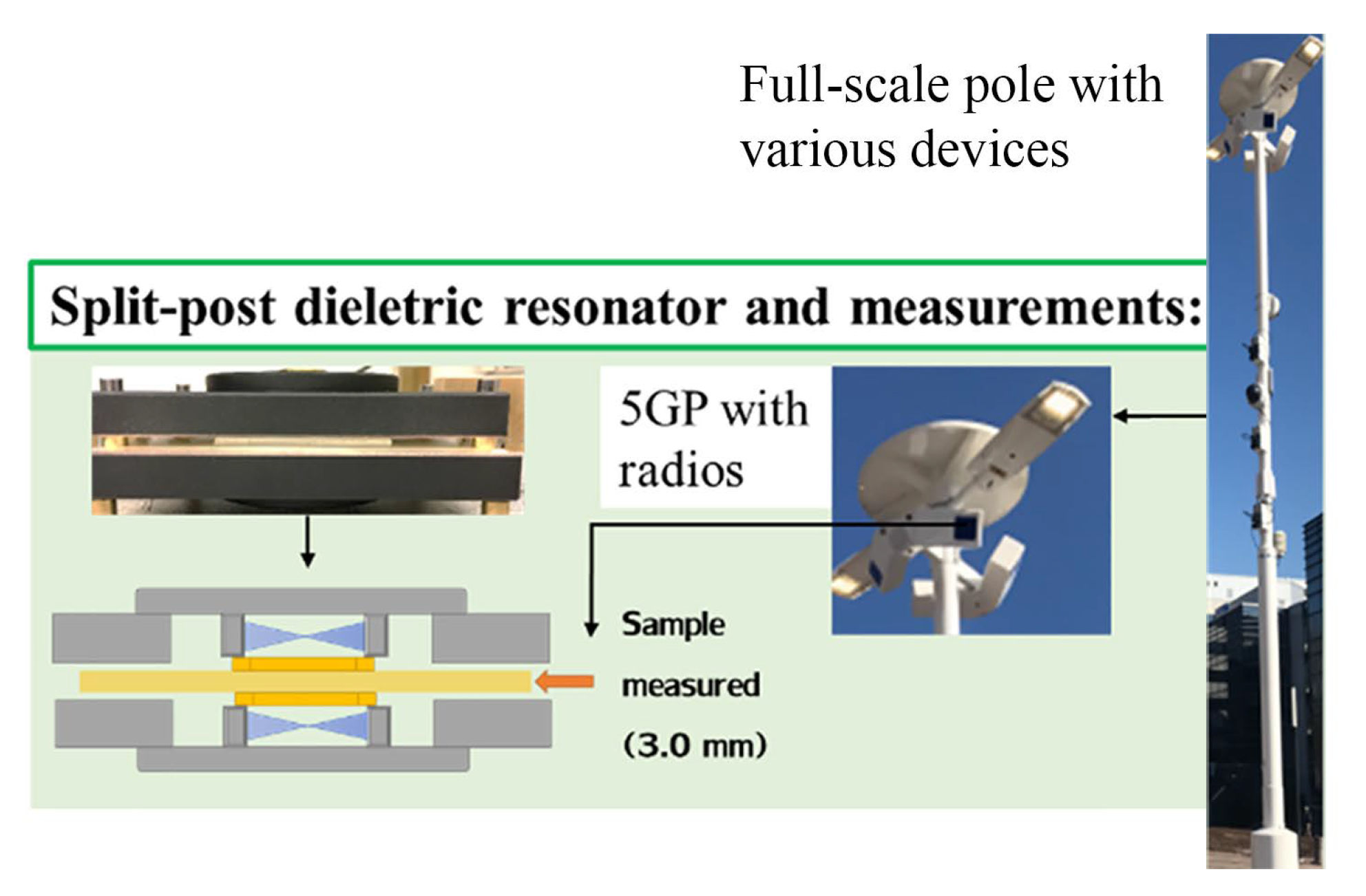

2.5. Signal Attenuation

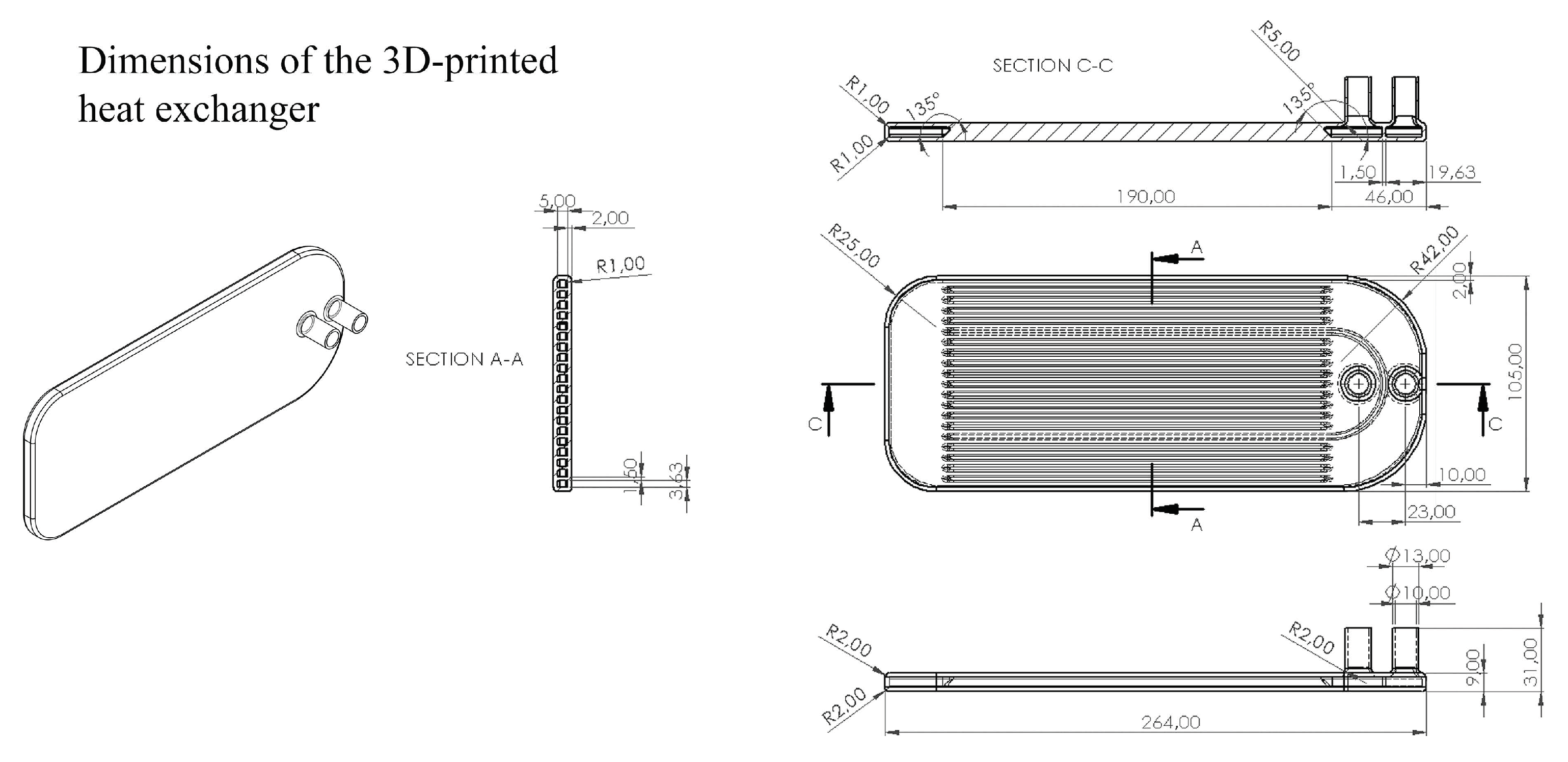

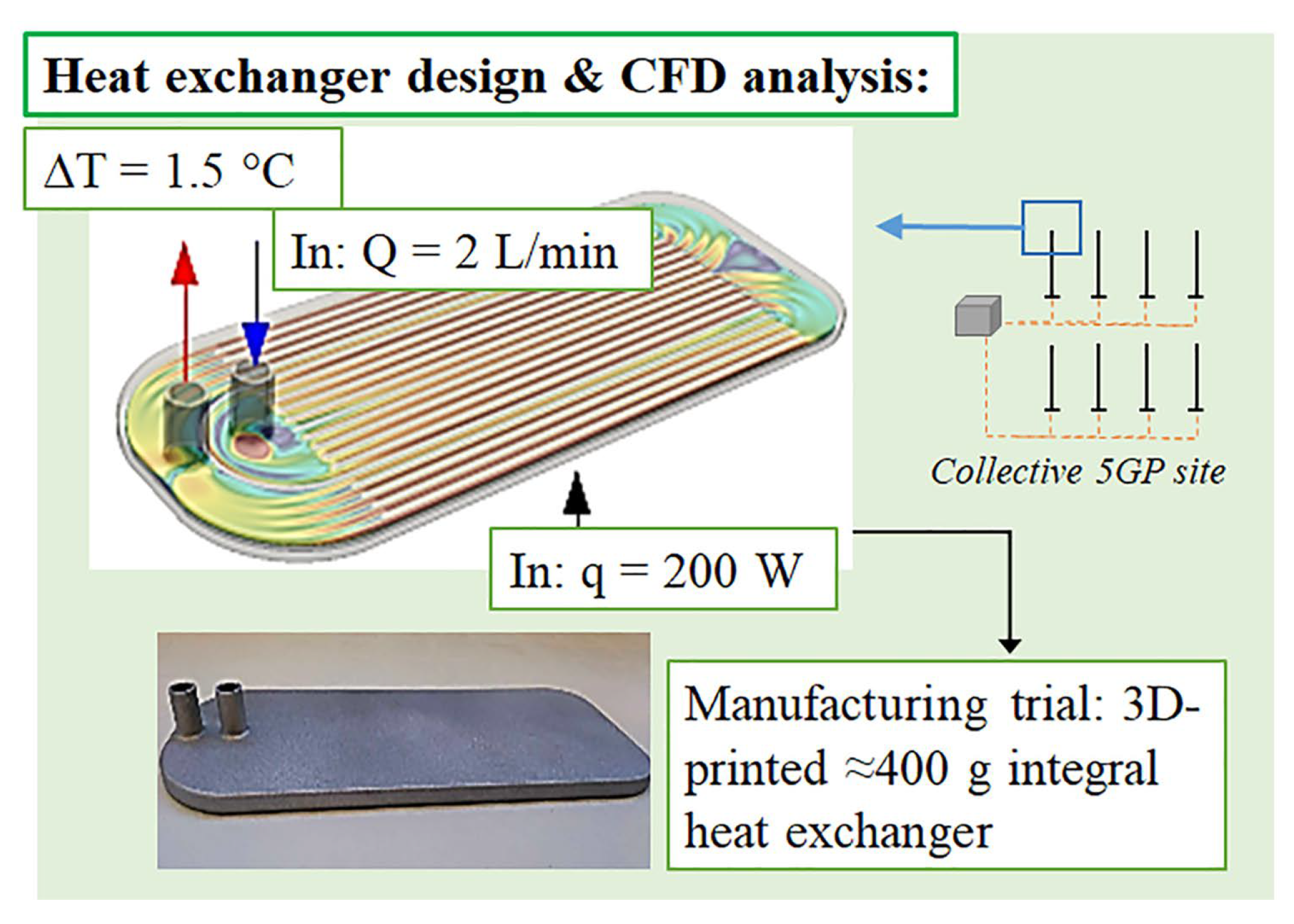

2.6. Heat Exchangers

2.7. Computational Fluid Dynamics

3. Results

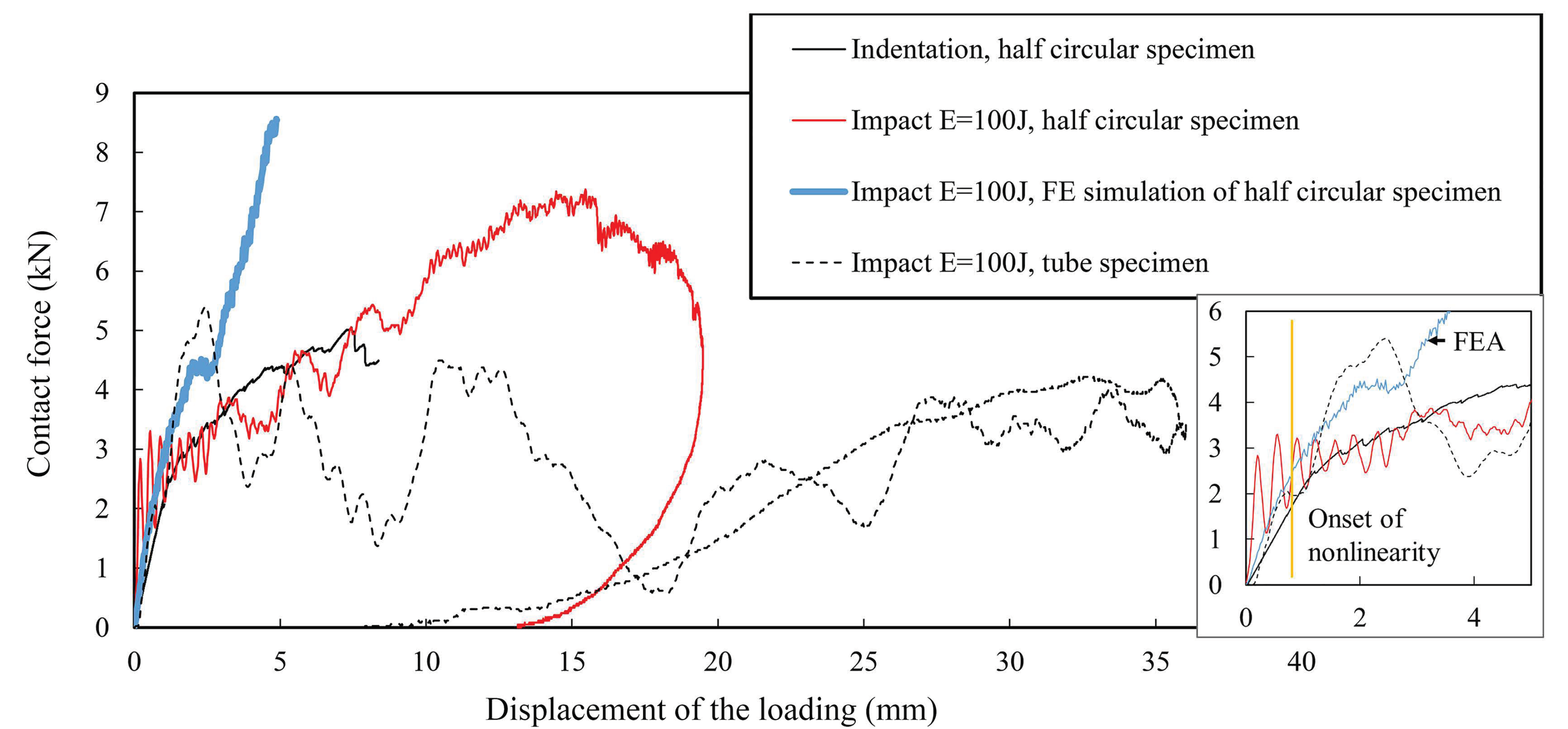

3.1. Impact Dynamics of the Selected GFRP Shaft

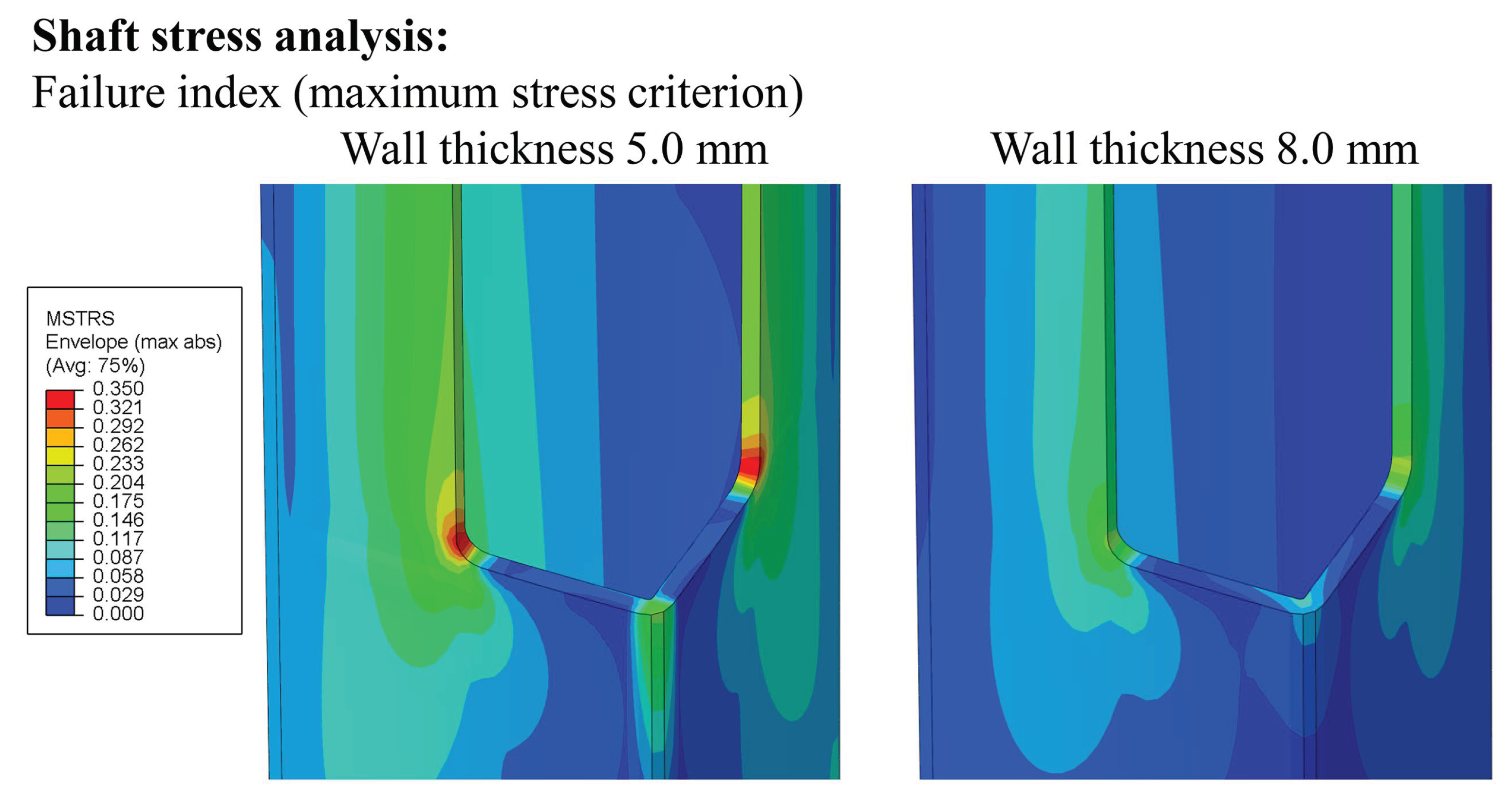

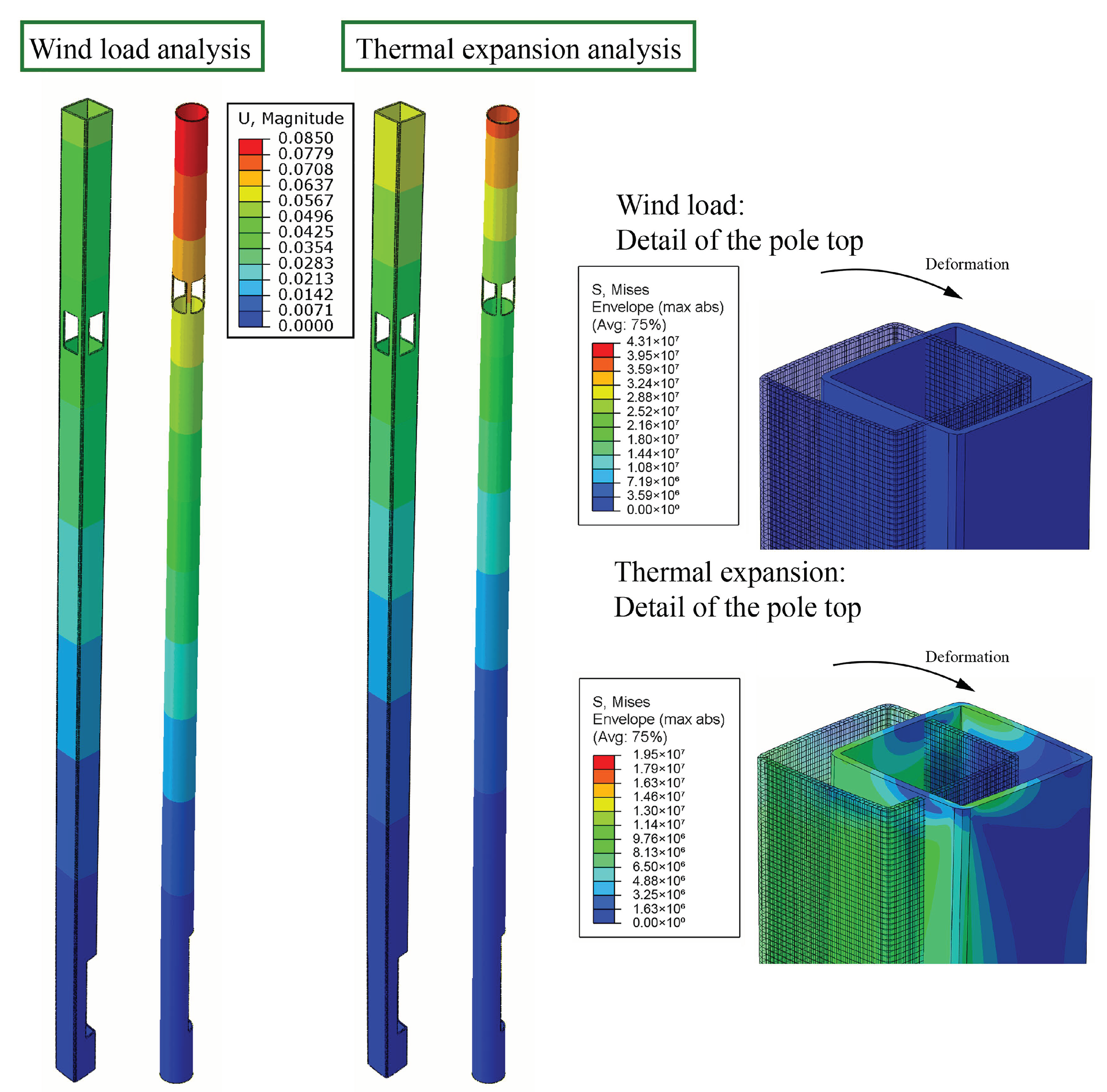

3.2. Finite Element Analysis

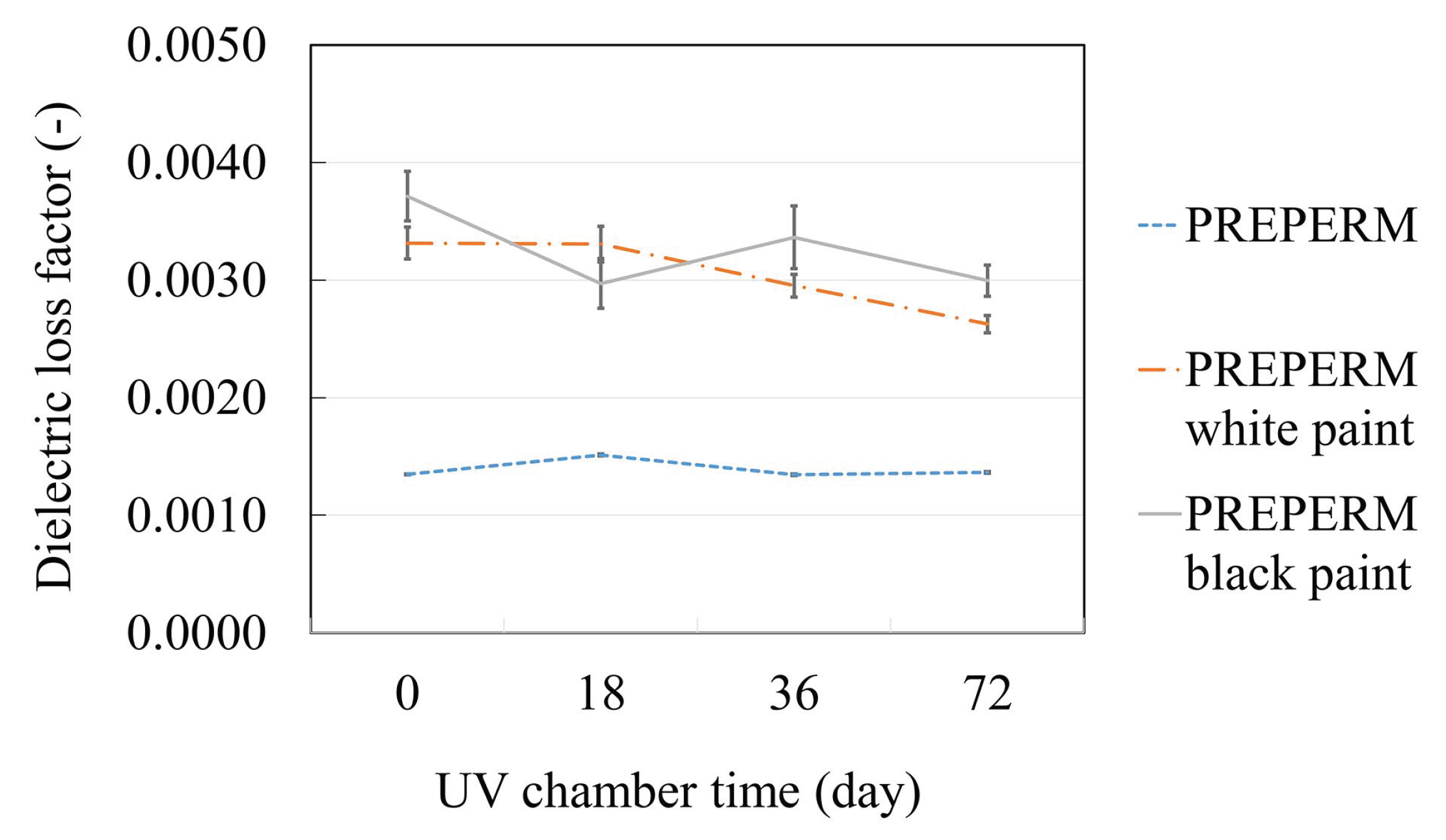

3.3. Signal Attenuation at the GHz-Regime

3.4. Thermal Management and Multiple Radio Analysis

4. Discussion

4.1. Design Process and Interconnections of Results

4.2. Assembly and Future Applications

5. Conclusions

- A full-composite glass fibre reinforced 5G pole was FE-modelled and analysed against standard wind and thermal load. The findings showed that a mechanically safe and functional (stiff) GFRP shaft results in significant weight savings (37–80%) compared to traditional steel shafts;

- RF signal attenuation at a GHz-regime (2.45 GHz) was found to increase significantly (90–175%) due to any paint layer while long-term UV degradation in the polymer structure led only to a nominal decrease of attenuation in terms of dielectric loss;

- Entirely integral one-piece heat exchangers were designed with CFD analysis of the fluid-solid interaction for heat transfer, and printed. It was found that a parallel liquid cooling of four radio units is rather insensitive to the flow rate (range 2…6 L/min) and as high as ≈60 °C inlet temperature can be allowed to keep the device surfaces at or below a critical 65 °C.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Thermal Expansion of the GFRP Composite

Appendix B. Heat Exchanger Design

References

- Henry, S.; Alsohaily, A.; Sousa, E. 5G is Real: Evaluating the Compliance of the 3GPP 5G New Radio System with the ITU IMT-2020 Requirements. IEEE Access 2020, 8, 42828–42840. [Google Scholar] [CrossRef]

- Munoz, R.; Mangues-Bafalluy, J.; Vilalta, R.; Verikoukis, C.; Alonso-Zarate, J.; Bartzoudis, N.; Georgiadis, A.; Payaro, M.; Perez-Neira, A.; Casellas, R.; et al. The CTTC 5G end-to-end experimental platform: Integrating heterogeneous wireless/optical networks, distributed cloud, and IoT devices. IEEE Veh. Technol. Mag. 2016, 11, 50–63. [Google Scholar] [CrossRef]

- Bangerter, B.; Talwar, S.; Arefi, R.; Stewart, K. Networks and devices for the 5G era. IEEE Commun. 2014, 52, 90–96. [Google Scholar] [CrossRef]

- Landertshamer, O.; Benseny, J.; Hämmäinen, H.; Wainio, P. Cost model for a 5G smart light pole network. In Proceedings of the CTTE-FITCE, Ghent, Belgium, 25–27 September 2019; Volume 1. [Google Scholar]

- Benseny, J.; Walia, J.; Hämmäinen, H.; Salmelin, J. City strategies for a 5G small cell network on light poles. In Proceedings of the CTTE-FITCE, Ghent, Belgium, 25–27 September 2019; Volume 1. [Google Scholar]

- International Commission on Non-Ionizing Radiation Protection. Guidelines for limiting exposure to electromagnetic fields (100 kHz to 300 GHz). Health Phys. 2020, 118, 483–524. [Google Scholar] [CrossRef] [PubMed]

- Seligar, G. Sustainability in Manufacturing: Recovery of Resources in Product and Material Cycles; Springer: Berlin, Germany, 2007. [Google Scholar]

- Francesco, F.; Smierzchalski, M.; Ettorre, M.; Aurinsalo, J.; Kautio, K.; Lahti, M.; Lamminen, A.; Säily, J.; Sauleau, R. An LTCC beam-switching antenna with high beam overlap for 60-GHz mobile access points. In Proceedings of the 2017 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, San Diego, CA, USA, 9–14 July 2017. [Google Scholar]

- Peltonen, P.; Saari, K.; Kukko, K.; Vuorinen, V.; Partanen, J. Large-Eddy Simulation of local heat transfer in plate and pin fin heat exchangers confined in a pipe flow. Int. J. Heat Mass Transf. 2019, 134, 641–655. [Google Scholar] [CrossRef]

- Kanerva, M.; Lassila, M.; Gustafsson, R.; O’shea, G.; Aarikka-Stenroos, L.; Hemilä, J. Emerging 5G Technologies Affecting Markets of Composite Materials, 2018. White Paper, Exel Composites Plc. Available online: https://www.luxturrim5g.com/publications (accessed on 15 August 2020).

- Gubran, H. Dynamics of hybrid shafts. Mech. Res. Commun. 2005, 32, 368–374. [Google Scholar] [CrossRef]

- James Prasad Rao, B.; Srikanth, D.; Suresh Kumar, T.; Sreenivasa Rao, L. Design and analysis of automotive composite propeller shaft using FEA. Mater. Today Proc. 2016, 3, 3673–3679. [Google Scholar] [CrossRef]

- Reyes, V.G.; Cantwell, W. The mechanical properties of fibre-metal laminates based on glass fibre reinforced polypropylene. Compos. Sci. Technol. 2000, 60, 1085–1094. [Google Scholar] [CrossRef]

- Kanerva, M.; Sarlin, E.; Hoikkanen, M.; Rämö, K.; Saarela, O.; Vuorinen, J. Interface modification of glass fibre-polyester composite-composite joints using peel plies. Int. J. Adhes. Adhes. 2015, 59, 40–52. [Google Scholar] [CrossRef]

- Manuele, G.; Bringiotti, M.; Lagana, G.; Nicastro, D. Fiber Glass and ‘Green’ Special Composite Materials as Structural Reinforcement and Systems; Use and Applications from Milan Metro, Brenner Tunnel up to High Speed Train Milan–Genoa; CRC Press: Boca Raton, FL, USA, 2019; pp. 2625–2634. [Google Scholar]

- Pandey, J.; Ahn, S.; Lee, C.; Mohanty, A.; Misra, M. Recent advances in the application of natural fiber based composites. Macromol. Mater. Eng. 2010, 295, 975–989. [Google Scholar] [CrossRef]

- Khalili, P.; Liu, X.; Zhao, Z.; Blinzler, B. Fully biodegradable composites: Thermal, flammability, moisture absorption and mechanical properties of natural fibre-reinforced composites with nano-hydroxyapatite. Materials 2019, 12, 1145. [Google Scholar] [CrossRef] [PubMed]

- Crawford, B.; Pakpour, S.; Kazemian, N.; Klironomos, J.; Stoeffler, K.; Rho, D.; Denault, J.; Milani, A. Effect of fungal deterioration on physical and mechanical properties of hemp and flax natural fiber composites. Materials 2017, 10, 1252. [Google Scholar] [CrossRef]

- Brøndsted, P.; Lilholt, H.; Lystrup, A. Composite materials for wind power turbine blades. Annu. Rev. Mater. Res. 2005, 35, 505–538. [Google Scholar] [CrossRef]

- Bélan, F.; Bellenger, V.; Mortaigne, B. Hydrolytic stability of unsaturated polyester networks with controlled chain ends. Polym. Degrad. Stab. 1997, 56, 93–102. [Google Scholar] [CrossRef]

- Partini, M.; Pantani, R. FTIR analysis of hydrolysis in aliphatic polyesters. Polym. Degrad. Stab. 2007, 92, 1491–1497. [Google Scholar] [CrossRef]

- Atxaga, G.; Marcos, J.; Jurado, M.; Carapelle, A.; Orava, R. Radiation shielding of composite space enclosures. In Proceedings of the International Astronautical Congress, Naples, Italy, 1–5 October 2012. [Google Scholar]

- Kanerva, M.; Koerselman, J.; Revitzer, H.; Johansson, L.; Sarlin, E.; Rautiainen, A.; Brander, T.; Saarela, O. Structural assessment of tungsten-epoxy bonding in spacecraft composite enclosures with enhanced radiation protection. In Proceedings of the European Conference on Spacecraft Structures, Materials and Mechanical Testing, Braunschweig, Germany, 1–4 April 2014. ESA SP-727. [Google Scholar]

- Gaier, J.; Hardebeck, W.; Bunch, J.; Davidson, M.; Beery, D. Effect of intercalation in graphite epoxy composites on the shielding of high energy radiation. J. Mater. Res. 1998, 13, 2297–2301. [Google Scholar] [CrossRef]

- Jarvelainen, J.; Karttunen, A.; Aurinsalo, J.; Huhtinen, I.; Hujanen, A. Characterization of mmWave radomes for base stations and automotive radars. In Proceedings of the 13th European Conference on Antennas and Propagation, Krakow, Poland, 31 March–5 April 2019; EuCAP: Krakow, Poland, 2019; Volume 1. [Google Scholar]

- Karttunen, A.; Le Hong Nguyen, S.; Koivumäki, P.; Haneda, K.; Hentilä, T.; Asp, A.; Hujanen, A.; Huhtinen, I.; Somersalo, M.; Horsmanheimo, S.; et al. Window and wall penetration loss on-site measurements with three methods. In Proceedings of the 12th European Conference on Antennas and Propagation, London, UK, 9–13 April 2018; Institution of Engineering and Technology IET: London, UK, 2018; Volume CP741. [Google Scholar]

- Rodera Garcia, O. Damage Onset Modelling of Curved Composite Laminates. Master’s Thesis, Tampere University, Tampere, Finland, 2018. Available online: http://urn.fi/URN:NBN:fi:tty-201810032382 (accessed on 4 September 2020).

- Pournoori, N.; Guilherme, C.; Orell, O.; Palola, S.; Hokka, M.; Kanerva, M. Adiabatic heating and damage onset in a pultruded glass fiber reinforced composite under compressive loading at different strain rates. Int. J. Impact Eng. 2021, 147, 103728. [Google Scholar] [CrossRef]

- Lanza di Scalea, F. Measurement of thermal expansion coefficients of composites using strain gages. Exp. Mech. 1998, 38, 233–241. [Google Scholar] [CrossRef]

- Devendra, K.; Rangaswamy, T. Thermal conductivity and thermal expansion coefficient of GFRP composite laminates with fillers. Mech. Confab 2013, 2, 39–44. [Google Scholar]

- SFS. Standard SFS-EN 40-7 CEN/TC 50 Lighting Columns and Spigots; Finnish Transport Infrastructure Agency (FTIA): Helsinki, Finland, 2003; refers to EN 12767:2019. [Google Scholar]

- He, W.; Goudeau, P.; Le Bourhis, E.; Renault, P.O.; Dupre, J.; Doumalin, P.; Wang, S. Study on Young’s modulus of thin films on Kapton by microtensile testing combined with dual DIC system. Surf. Coat. Technol. 2016, 308, 273–279. [Google Scholar] [CrossRef]

- Laitinen, A.; Saari, K.; Kukko, K.; Peltonen, P.; Laurila, E.; Partanen, J.; Vuorinen, V. A computational fluid dynamics study by conjugate heat transfer in OpenFOAM: A liquid cooling concept for high power electronics. Int. J. Heat Fluid Flow 2020, 85, 108654. [Google Scholar] [CrossRef]

- Di Vito, D.; Pärnänen, T.; Jokinen, J.; Orell, O.; Kanerva, M. Lateral indentation and impact analyses on curved composite shells. In Proceedings of the 7th International Conference on Fracture Fatigue and Wear, Ghent, Belgium, 9–10 July 2018; Lecture Notes in Mechanical Engineering. Wahab, M., Ed.; Springer: Singapore, 2018; pp. 171–183. [Google Scholar] [CrossRef]

- Heino, M.; Salmelin, J.; Wainio, P. LuxTurrim5G—Building the Digital Backbone for a Smart City. White Paper, 2020. Available online: https://www.luxturrim5g.com/publications (accessed on 15 September 2020).

- Kanerva, M.; Antunes, P.; Sarlin, E.; Orell, O.; Jokinen, J.; Wallin, M.; Brander, T.; Vuorinen, J. Direct measurement of residual strains in CFRP-tungsten hybrids using embedded strain gauges. Mater. Des. 2017, 127, 352–363. [Google Scholar] [CrossRef]

- Sousa, J.; Correia, J.; Firmo, J.; Cabral-Fonseca, S.; Gonilha, J. Effects of thermal cycles on adhesively bonded joints between pultruded GFRP adherends. Compos. Struct. 2018, 202, 518–529. [Google Scholar] [CrossRef]

- Ran, Z.; Yan, Y.; Li, J.; Qi, Z.; Yang, L. Determination of thermal expansion coeffcients for unidirectional fiber-reinforced composites. Chin. J. Aeronaut. 2014, 27, 1180–1187. [Google Scholar] [CrossRef]

| Constant | Parameter | Value (Units) |

|---|---|---|

| Axial Young’s modulus | 35 GPa | |

| Transverse Young’s modulus | 7.0 GPa | |

| Out-of-plane Young’s modulus | 4.5 GPa | |

| Poisson’s ratios | 0.3 | |

| Poisson’s ratio | 0.05 | |

| Shear modulus | 3.6 GPa | |

| Shear modulus | 3.6 GPa | |

| Shear modulus | 2.0 GPa |

| Fluid Domain | Solid Domain |

|---|---|

| Turbulence model used: k- SST | |

| Inlet: | Heated surface: |

| Velocity 0.4 m/s | Fixed temperature gradient |

| Turbulent intensity 4.00% | Zero pressure gradient |

| k = 0.00038 m2/s2, ω = 51.57 1/s | Fluid-solid walls: |

| Temperature 300 K | Temperature calculated |

| Pressure with zero gradient | Zero pressure gradient |

| Walls: | Outer surfaces: |

| Velocity—no slip | Zero temperature gradient (adiabatic) |

| Turbulent variables—wall functions | Zero pressure gradient |

| Zero pressure gradient | |

| Temperature calculated | |

| Outlet: | |

| Zero velocity gradient | |

| Zero gradient of turbulent variables | |

| Fixed pressure (atm pressure) | |

| Zero temperature gradient |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Vito, D.; Kanerva, M.; Järveläinen, J.; Laitinen, A.; Pärnänen, T.; Saari, K.; Kukko, K.; Hämmäinen, H.; Vuorinen, V. Safe and Sustainable Design of Composite Smart Poles for Wireless Technologies. Appl. Sci. 2020, 10, 7594. https://doi.org/10.3390/app10217594

Di Vito D, Kanerva M, Järveläinen J, Laitinen A, Pärnänen T, Saari K, Kukko K, Hämmäinen H, Vuorinen V. Safe and Sustainable Design of Composite Smart Poles for Wireless Technologies. Applied Sciences. 2020; 10(21):7594. https://doi.org/10.3390/app10217594

Chicago/Turabian StyleDi Vito, Donato, Mikko Kanerva, Jan Järveläinen, Alpo Laitinen, Tuomas Pärnänen, Kari Saari, Kirsi Kukko, Heikki Hämmäinen, and Ville Vuorinen. 2020. "Safe and Sustainable Design of Composite Smart Poles for Wireless Technologies" Applied Sciences 10, no. 21: 7594. https://doi.org/10.3390/app10217594

APA StyleDi Vito, D., Kanerva, M., Järveläinen, J., Laitinen, A., Pärnänen, T., Saari, K., Kukko, K., Hämmäinen, H., & Vuorinen, V. (2020). Safe and Sustainable Design of Composite Smart Poles for Wireless Technologies. Applied Sciences, 10(21), 7594. https://doi.org/10.3390/app10217594